The Effects of Leuconostoc mesenteroides RSG7 Exopolysaccharide on the Physicochemical Properties and Flavor Compounds of Set Yoghurt

Abstract

1. Introduction

2. Materials and Methods

2.1. Preparation of RE

2.2. Preparation of Set Yoghurt

2.3. Determination of pH and WHC

2.4. Texture Profile Analysis

2.5. Rheological Properties Analysis

2.6. Microstructure Analysis

2.7. Flavour Analysis with E-Nose and E-Tongue

2.8. Volatile Compound Analysis

2.9. Statistical Analysis

3. Results and Discussion

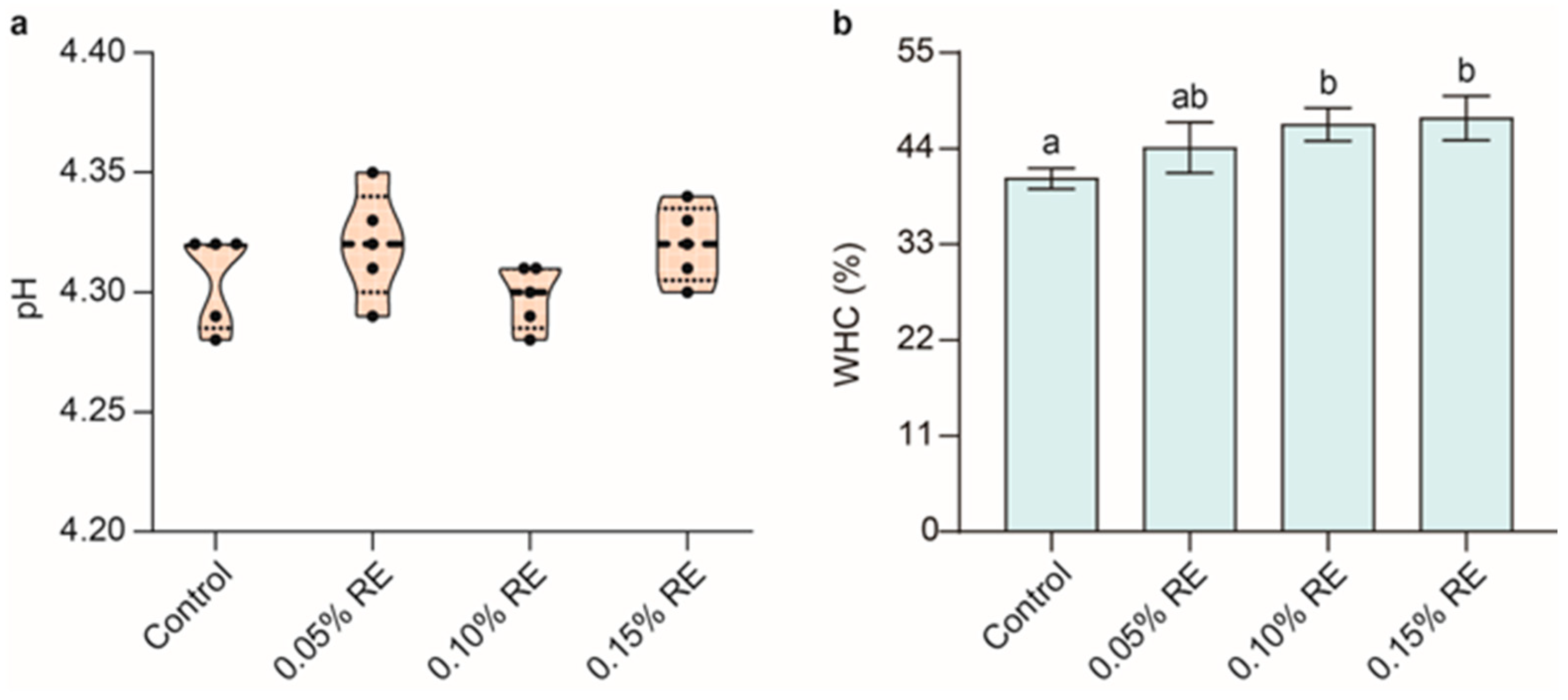

3.1. pH and WHC of Set Yoghurt

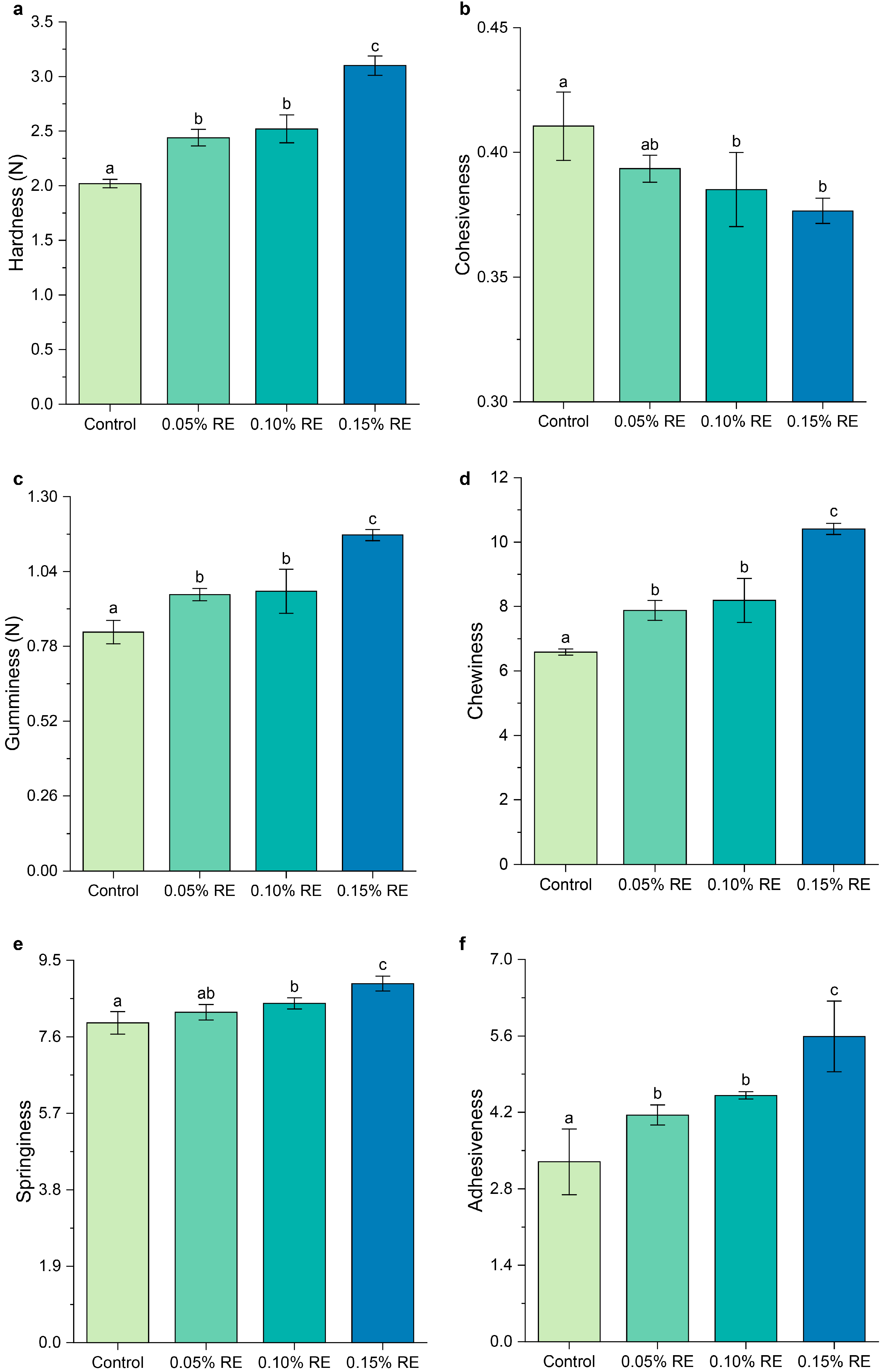

3.2. Texture Profile Analysis of Set Yoghurt

3.3. Rheological Properties Analysis of Set Yoghurt

3.4. Microstructure Analysis of Set Yoghurt

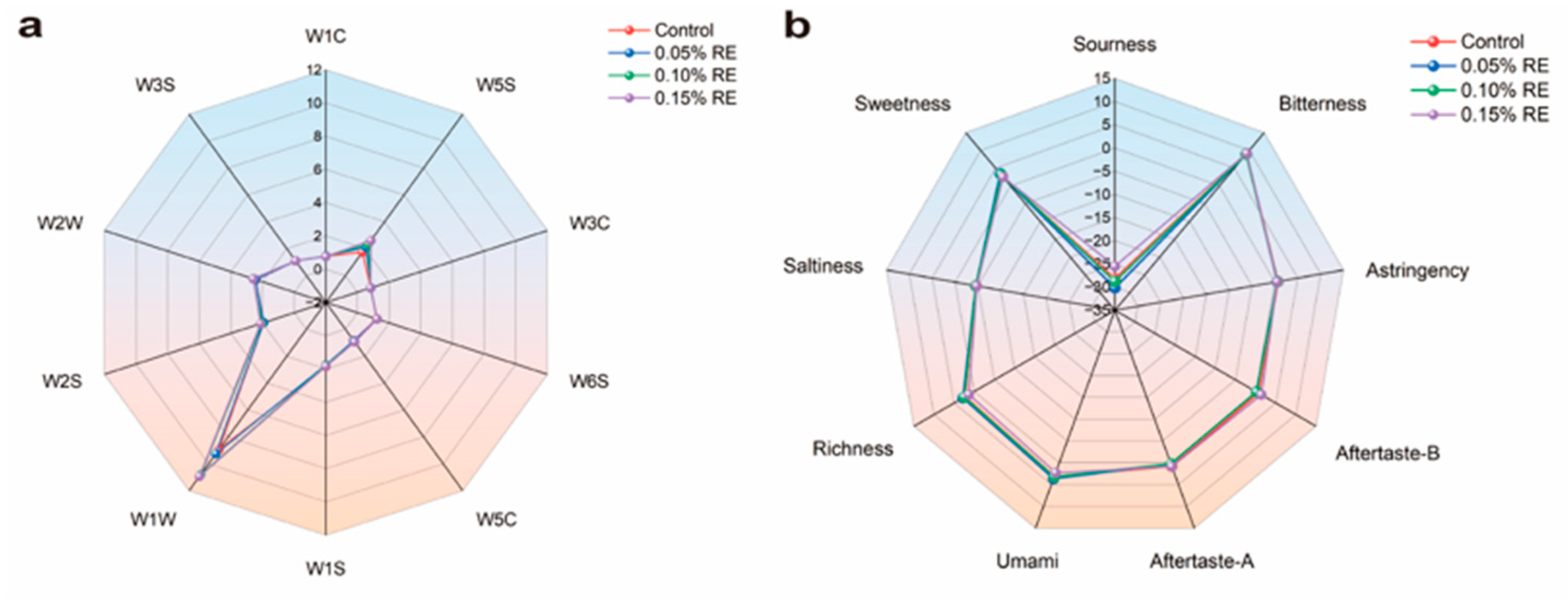

3.5. Flavour Characteristic Analysis of Set Yoghurt with E-Nose and E-Tongue

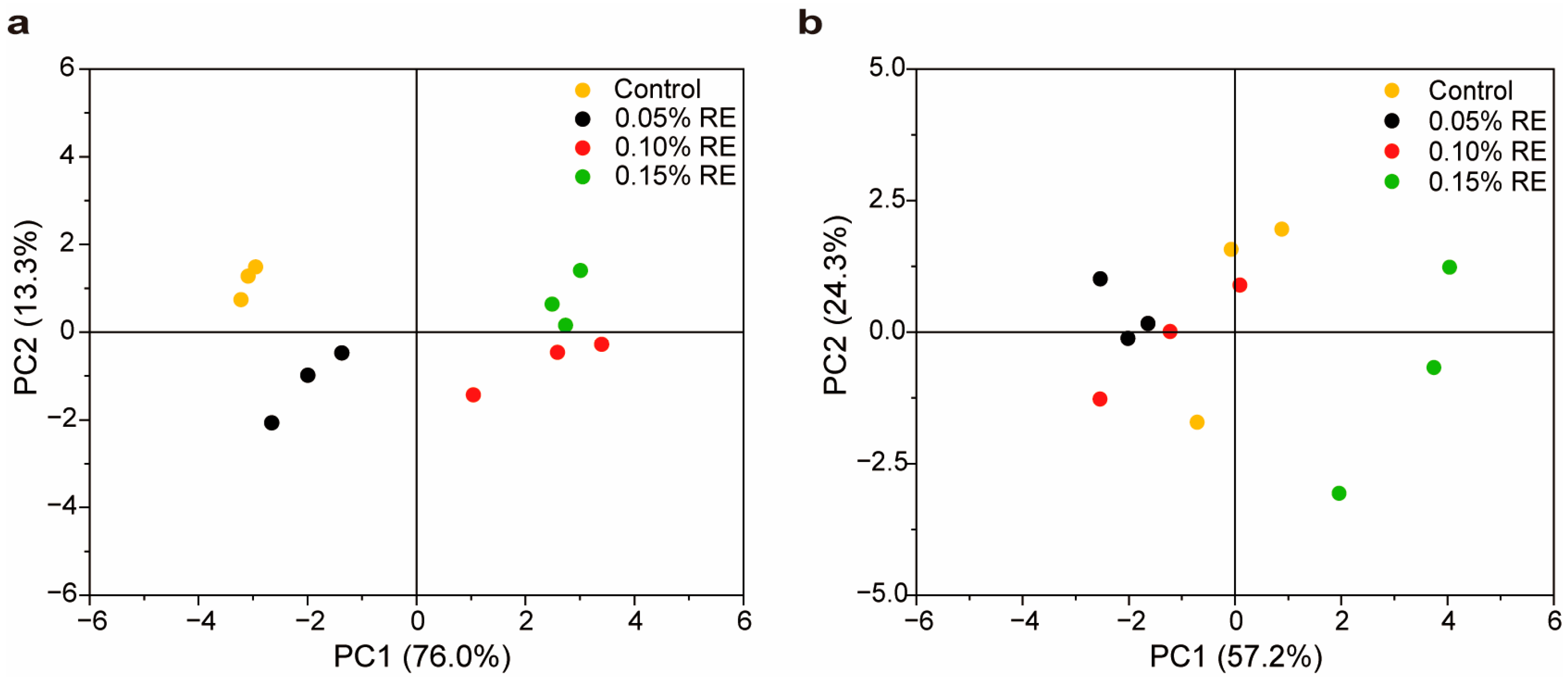

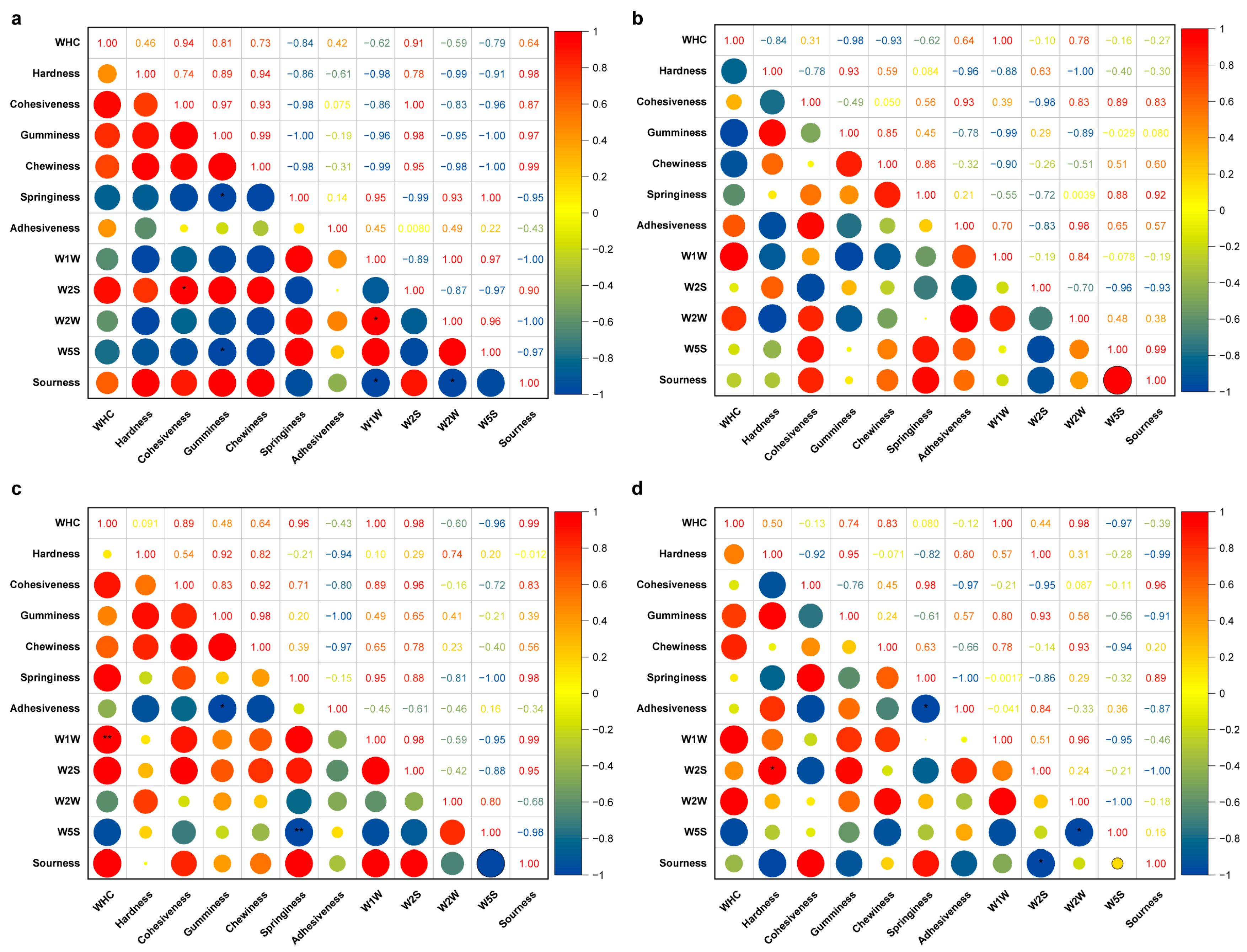

3.6. Correlation Analysis of Physicochemical Properties with Significant Differences

3.7. Volatile Compounds Analysis of Set Yoghurt

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhang, K.; Tang, H.; Farid, M.S.; Xiang, F.; Li, B. Effect of Lactobacillus helveticus exopolysaccharides molecular weight on yogurt gel properties and its internal mechanism. Int. J. Biol. Macromol. 2024, 262, 130006. [Google Scholar] [CrossRef]

- Vieira, P.; Pinto, C.A.; James Goodfellow, B.; Gomes, A.M.; Sousa, S.; Machado, M.; Delgadillo, I.; Saraiva, J.A. A chemical study of yoghurt produced under isostatic pressure during storage. Food Chem. 2023, 425, 136434. [Google Scholar] [CrossRef]

- Hasegawa, Y.; Bolling, B.W. Yogurt consumption for improving immune health. Curr. Opin. Food Sci. 2023, 51, 101017. [Google Scholar] [CrossRef]

- Wang, X.; Kong, X.; Zhang, C.; Hua, Y.; Chen, Y.; Li, X. Comparison of physicochemical properties and volatile flavor compounds of plant-based yoghurt and dairy yoghurt. Food Res. Int. 2023, 164, 112375. [Google Scholar] [CrossRef]

- Wei, G.; Dai, X.; Zhao, B.; Li, Z.; Tao, J.; Wang, T.; Huang, A. Structure-activity relationship of exopolysaccharides produced by Limosilactobacillus fermentum A51 and the mechanism contributing to the textural properties of yogurt. Food Hydrocolloid. 2023, 144, 108993. [Google Scholar] [CrossRef]

- Nguyen, H.T.H.; Ong, L.; Kentish, S.E.; Gras, S.L. The effect of fermentation temperature on the microstructure, physicochemical and rheological properties of probiotic buffalo yoghurt. Food Bioprocess Technol. 2014, 7, 2538–2548. [Google Scholar] [CrossRef]

- Ahmad, I.; Hao, M.; Li, Y.; Zhang, J.; Ding, Y.; Lyu, F. Fortification of yogurt with bioactive functional foods and ingredients and associated challenges—A review. Trends Food Sci. Technol. 2022, 129, 558–580. [Google Scholar] [CrossRef]

- Wang, B.; Sun, X.; Xu, M.; Wang, F.; Liu, W.; Wu, B. Structural characterization and partial properties of dextran produced by Leuconostoc mesenteroides RSG7 from pepino. Front. Microbiol. 2023, 14, 1108120. [Google Scholar] [CrossRef]

- Zhang, K.; Liu, S.; Liang, S.; Xiang, F.; Wang, X.; Lian, H.; Li, B.; Liu, F. Exopolysaccharides of lactic acid bacteria: Structure, biological activity, structure-activity relationship, and application in the food industry: A review. Int. J. Biol. Macromol. 2024, 257, 128733. [Google Scholar] [CrossRef]

- Wu, J.S.; Han, X.P.; Ye, M.Z.; Li, Y.; Wang, X.; Zhong, Q.P. Exopolysaccharides synthesized by lactic acid bacteria: Biosynthesis pathway, structure-function relationship, structural modification and applicability. Crit. Rev. Food Sci. 2023, 63, 7043–7064. [Google Scholar] [CrossRef]

- Nobuhara, T.; Matsumiya, K.; Nambu, Y.; Nakamura, A.; Fujii, N.; Matsumura, Y. Stabilization of milk protein dispersion by soybean soluble polysaccharide under acidic pH conditions. Food Hydrocolloid. 2014, 34, 39–45. [Google Scholar] [CrossRef]

- Ramos, I.M.; Seseña, S.; Poveda, J.M.; Palop, M.L. Screening of lactic acid bacteria strains to improve the properties of non-fat set yogurt by in situ EPS production. Food Bioprocess Technol. 2023, 16, 2541–2558. [Google Scholar] [CrossRef]

- Wang, L.; Gu, Y.; Lv, Z. Processing properties of yogurt as affected by the EPS produced by Leuconostoc mesenteroides XR1. Int. J. Food Sci. Technol. 2022, 57, 4076–4085. [Google Scholar] [CrossRef]

- Wang, L.; Tian, H.; Liu, W.; Zheng, H.; Wu, H.; Guan, Y.; Lu, Q.; Lv, Z. Effects of EPS-producing Leuconostoc mesenteroides XR1 on texture, rheological properties, microstructure and volatile flavor of fermented milk. Food Biosci. 2023, 56, 103371. [Google Scholar] [CrossRef]

- Madhubasani, G.B.L.; Prasanna, P.H.P.; Chandrasekara, A.; Gunasekara, D.C.S.; Senadeera, P.; Chandramali, D.V.P.; Vidanarachchi, J.K. Exopolysaccharide producing starter cultures positively influence on microbiological, physicochemical, and sensory properties of probiotic goats’ milk set-yoghurt. J. Food Process Pres. 2020, 44, e14361. [Google Scholar] [CrossRef]

- Ge, Z.; Bao, X.; Feng, X.; Yin, X.; Chen, X.; Dong, M. In situ exopolysaccharides from Lactobacillus helveticus MB2-1 in Sayram ketteki yoghurt: Set yoghurts properties and interactions with sodium caseinate. Int. J. Biol. Macromol. 2022, 216, 871–881. [Google Scholar] [CrossRef]

- Wang, B.; Zuo, K.; Zeng, Z.; Guo, Y.; Pan, L.; Wu, B. Simulated digestion and fermentation characteristics of exopolysaccharide from Leuconostoc mesenteroides RSG7 and its effect on the human gut microbiota. Food Biosci. 2025, 63, 105683. [Google Scholar] [CrossRef]

- Mende, S.; Rohm, H.; Jaros, D. Influence of exopolysaccharides on the structure, texture, stability and sensory properties of yoghurt and related products. Int. Dairy J. 2016, 52, 57–71. [Google Scholar] [CrossRef]

- Zeng, Z.; Wang, L.; Zhang, Z.; Zhang, Y.; Zheng, B.; Yang, J.; Pan, L. Dictyophora indusiata polysaccharide improved 3D network structure and flavor benefits of set yoghurt. Food Biosci. 2024, 60, 104401. [Google Scholar] [CrossRef]

- Xu, K.; Guo, M.; Du, J.; Zhang, Z. Okra polysaccharide: Effect on the texture and microstructure of set yoghurt as a new natural stabilizer. Int. J. Biol. Macromol. 2019, 133, 117–126. [Google Scholar] [CrossRef] [PubMed]

- Pan, L.; Wang, Q.; Qu, L.; Liang, L.; Han, Y.; Wang, X.; Zhou, Z. Pilot-scale production of exopolysaccharide from Leuconostoc pseudomesenteroides XG5 and its application in set yogurt. J. Dairy Sci. 2022, 105, 1072–1083. [Google Scholar] [CrossRef]

- Wang, L.; Zhang, F.; Zheng, B.; Zhang, Y.; Pan, L. Stability and flavor of set yogurt fortified with Tremella fuciformis polysaccharide during cold storage. Curr. Res. Food Sci. 2023, 7, 100536. [Google Scholar] [CrossRef]

- Ma, W.; Zhang, C.; Kong, X.; Li, X.; Chen, Y.; Hua, Y. Effect of pea milk preparation on the quality of non-dairy yoghurts. Food Biosci. 2021, 44, 101416. [Google Scholar] [CrossRef]

- Akalın, A.S.; Fenderya, S.; Akbulut, N. Viability and activity of bifidobacteria in yoghurt containing fructooligosaccharide during refrigerated storage. Int. J. Food Sci. Technol. 2004, 39, 613–621. [Google Scholar] [CrossRef]

- Srisuvor, N.; Chinprahast, N.; Prakitchaiwattana, C.; Subhimaros, S. Effects of inulin and polydextrose on physicochemical and sensory properties of low-fat set yoghurt with probiotic-cultured banana purée. LWT-Food Sci. Technol. 2013, 51, 30–36. [Google Scholar] [CrossRef]

- Gyawali, R.; Ibrahim, S.A. Effects of hydrocolloids and processing conditions on acid whey production with reference to Greek yogurt. Trends Food Sci. Technol. 2016, 56, 61–76. [Google Scholar] [CrossRef]

- Delikanli, B.; Ozcan, T. Improving the textural properties of yogurt fortified with milk proteins. J. Food Process. Pres. 2017, 41, e13101. [Google Scholar] [CrossRef]

- Mousavi, M.; Heshmati, A.; Daraei Garmakhany, A.; Vahidinia, A.; Taheri, M. Texture and sensory characterization of functional yogurt supplemented with flaxseed during cold storage. Food Sci. Nutr. 2019, 7, 907–917. [Google Scholar] [CrossRef]

- Feng, C.; Wang, B.; Zhao, A.; Wei, L.; Shao, Y.; Wang, Y.; Cao, B.; Zhang, F. Quality characteristics and antioxidant activities of goat milk yogurt with added jujube pulp. Food Chem. 2019, 277, 238–245. [Google Scholar] [CrossRef]

- Radzki, W.; Skrzypczak, K.; Sołowiej, B.; Jabłońska-Ryś, E.; Gustaw, W. Properties of yogurts enriched with crude polysaccharides extracted from Pleurotus ostreatus cultivated mushroom. Foods 2023, 12, 4033. [Google Scholar] [CrossRef]

- Delikanli, B.; Ozcan, T. Effects of various whey proteins on the physicochemical and textural properties of set type nonfat yoghurt. Int. J. Dairy Technol. 2014, 67, 495–503. [Google Scholar] [CrossRef]

- Kumar, P.; Mishra, H.N. Effect of mango pulp and soymilk fortification on the texture profile of set yoghurt made from buffalo milk. J. Texture Stud. 2003, 34, 249–269. [Google Scholar] [CrossRef]

- Wang, J.; Liu, B.; Qi, Y.; Wu, D.; Liu, X.; Liu, C.; Gao, Y.; Shi, J.; Fang, L.; Min, W. Impact of Auricularia cornea var. Li polysaccharides on the physicochemical, textual, flavor, and antioxidant properties of set yogurt. Int. J. Biol. Macromol. 2022, 206, 148–158. [Google Scholar] [CrossRef]

- Mohsin, A.Z.; Marzlan, A.A.; Muhialdin, B.J.; Wai, L.K.; Mohammed, N.K.; Meor Hussin, A.S. Physicochemical characteristics, GABA content, antimicrobial and antioxidant capacities of yogurt from Murrah buffalo milk with different fat contents. Food Biosci. 2022, 49, 101949. [Google Scholar] [CrossRef]

- Kaur, R.; Riar, C.S. Sensory, rheological and chemical characteristics during storage of set type full fat yoghurt fortified with barley β-glucan. J. Food Sci. Technol. 2020, 57, 41–51. [Google Scholar] [CrossRef]

- Zhang, W.; Al-Wraikata, M.; Shu, Q.; Hu, J.; Li, L.; Liu, Y. Enhancement effect of kale fiber on physicochemical, rheological and digestive properties of goat yogurt. LWT 2024, 207, 116649. [Google Scholar] [CrossRef]

- Mudgil, D.; Barak, S.; Khatkar, B.S. Texture profile analysis of yogurt as influenced by partially hydrolyzed guar gum and process variables. J. Food Sci. Technol. 2017, 54, 3810–3817. [Google Scholar] [CrossRef]

- Cui, B.; Lu, Y.M.; Tan, C.P.; Wang, G.Q.; Li, G.H. Effect of cross-linked acetylated starch content on the structure and stability of set yoghurt. Food Hydrocolloid. 2014, 35, 576–582. [Google Scholar] [CrossRef]

- Li, G.; Guo, Q.; Chen, Q.; Ouyang, K.; Xie, H.; Xiong, H.; Du, Y.; Zhao, Q. Valorizing Arthrospira cell residues into polysaccharides: Characterization and application in yogurt. Food Chem. 2024, 461, 140902. [Google Scholar] [CrossRef]

- Zhang, K.; Liu, S.; Tang, H.; Evivie, S.E.; Guo, Z.; Li, B. Effect of exopolysaccharides yield and addition concentration of Lactobacillus helveticus on the processing characteristics of fermented milk and its mechanism. Int. J. Biol. Macromol. 2024, 260, 129480. [Google Scholar] [CrossRef]

- Lin, Y.; Xu, Q.; Li, X.; Shao, P. Tremella fuciformis polysaccharides as a fat substitute on the rheological, texture and sensory attributes of low-fat yogurt. Curr. Res. Food Sci. 2022, 5, 1061–1070. [Google Scholar] [CrossRef]

- Lee, Y.; Chang, Y.H. Influence of guar gum addition on physicochemical, microbial, rheological and sensory properties of stirred yoghurt. Int. J. Dairy Technol. 2016, 69, 356–363. [Google Scholar] [CrossRef]

- Ayyash, M.; Abdalla, A.; Abu-Jdayil, B.; Huppertz, T.; Bhaskaracharya, R.; Al-Mardeai, S.; Mairpady, A.; Ranasinghe, A.; Al-Nabulsi, A. Rheological properties of fermented milk from heated and high pressure-treated camel milk and bovine milk. LWT 2022, 156, 113029. [Google Scholar] [CrossRef]

- Brüls, M.; Foroutanparsa, S.; Maljaars, C.E.P.; Olsthoorn, M.; Tas, R.P.; Voets, I.K. Investigating the impact of exopolysaccharides on yogurt network mechanics and syneresis through quantitative microstructural analysis. Food Hydrocolloid. 2024, 150, 109629. [Google Scholar] [CrossRef]

- Yang, J.; Sun, J.; Yan, J.; Zhang, X.; Ma, Y.; Liu, C.; Du, P.; Li, A. Impact of Potentilla anserine polysaccharide on storage properties of probiotic yak yoghurt. Int. Dairy J. 2023, 141, 105585. [Google Scholar] [CrossRef]

- Ge, Z.; Bao, X.; Li, Z.; Chen, X.; Li, W.; Rui, X.; Wu, J.; Zhang, Q.; Dong, M. In situ exopolysaccharides produced by Lactobacillus helveticus MB2-1 and its effect on gel properties of Sayram ketteki yoghurt. Int. J. Biol. Macromol. 2022, 208, 314–323. [Google Scholar] [CrossRef]

- Yousefi, M.; Jafari, S.M. Recent advances in application of different hydrocolloids in dairy products to improve their techno-functional properties. Trends Food Sci. Technol. 2019, 88, 468–483. [Google Scholar] [CrossRef]

- Huang, T.; Tu, Z.; Shangguan, X.; Wang, H.; Zhang, L.; Bansal, N. Characteristics of fish gelatin-anionic polysaccharide complexes and their applications in yoghurt: Rheology and tribology. Food Chem. 2021, 343, 128413. [Google Scholar] [CrossRef]

- Nemati, V.; Mozafarpour, R. Exopolysaccharides isolated from fermented milk-associated lactic acid bacteria and applied to produce functional value-added probiotic yogurt. LWT 2024, 199, 116116. [Google Scholar] [CrossRef]

- Trygg, J.; Holmes, E.; Lundstedt, T. Chemometrics in metabonomics. J. Proteome Res. 2007, 6, 469–479. [Google Scholar] [CrossRef]

- Qiu, L.; Zhang, M.; Mujumdar, A.S.; Chang, L. Effect of edible rose (Rosa rugosa cv. Plena) flower extract addition on the physicochemical, rheological, functional and sensory properties of set-type yogurt. Food Biosci. 2021, 43, 101249. [Google Scholar] [CrossRef]

- Sfakianakis, P.; Tzia, C. Flavour profiling by gas chromatography-mass spectrometry and sensory analysis of yoghurt derived from ultrasonicated and homogenised milk. Int. Dairy J. 2017, 75, 120–128. [Google Scholar] [CrossRef]

- Zhang, L.; Mi, S.; Liu, R.B.; Sang, Y.X.; Wang, X.H. Evaluation of volatile compounds during the fermentation process of yogurts by Streptococcus thermophilus based on odor activity value and heat map analysis. Int. J. Anal. Chem. 2020, 2020, 3242854. [Google Scholar] [CrossRef]

- Xu, J.; Xu, X.; Yuan, Z.; Hua, D.; Yan, Y.; Bai, M.; Song, H.; Yang, L.; Zhu, D.; Liu, J.; et al. Effect of hemp protein on the physicochemical properties and flavor components of plant-based yogurt. LWT 2022, 172, 114145. [Google Scholar] [CrossRef]

- Jiang, J.; Jiang, Y.; Li, H.; Zhu, D.; He, Y.; Yang, L.; Wang, S.; Liu, J.; Zhang, Y.; Liu, H. Application of soybean isolate protein (SPI) and soy hull polysaccharide (SHP) complex in fermentation products. Int. J. Biol. Macromol. 2024, 258, 128806. [Google Scholar] [CrossRef]

| Kinds | Compounds | Control | Content (μg/kg) | ||

|---|---|---|---|---|---|

| 0.05% RE | 0.10% RE | 0.15% RE | |||

| Ketone | Acetoin | 0.026 ± 0.004 | 0.023 ± 0.001 | 0.020 ± 0.004 | 0.024 ± 0.010 |

| Acids | Butanoic acid | 0.008 ± 0.001 ab | 0.005 ± 0.001 a | 0.010 ± 0.001 b | 0.021 ± 0.004 c |

| Hexanoic acid | 0.025 ± 0.001 a | 0.025 ± 0.004 a | 0.035 ± 0.003 b | 0.053 ± 0.003 c | |

| n-Decanoic acid | N | N | 0.009 ± 0.001 | 0.008 ± 0.005 | |

| Octanoic acid | 0.011 ± 0.000 a | 0.014 ± 0.001 a | 0.023 ± 0.002 b | 0.022 ± 0.003 b | |

| Alkanes | Decamethyl cyclopentasiloxane | 0.012 ± 0.001 ab | 0.006 ± 0.002 a | 0.018 ± 0.004 b | 0.027 ± 0.006 c |

| Dodecamethyl cyclohexasiloxane | 0.026 ± 0.002 a | 0.026 ± 0.005 a | 0.046 ± 0.003 b | 0.052 ± 0.008 b | |

| Hexadecamethyl cyclooctasiloxane | 0.003 ± 0.002 | 0.004 ± 0.001 | 0.006 ± 0.002 | 0.004 ± 0.001 | |

| Octadecamethyl cyclononasiloxane | 0.007 ± 0.001 | N | N | N | |

| Tetradecamethyl Cycloheptasiloxane | 0.010 ± 0.002 a | 0.010 ± 0.001 a | 0.016 ± 0.004 b | 0.015 ± 0.001 b | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, B.; Guo, Y.; Hao, L.; Zuo, K.; Du, Y.; An, R.; Wang, B. The Effects of Leuconostoc mesenteroides RSG7 Exopolysaccharide on the Physicochemical Properties and Flavor Compounds of Set Yoghurt. Processes 2025, 13, 1442. https://doi.org/10.3390/pr13051442

Wu B, Guo Y, Hao L, Zuo K, Du Y, An R, Wang B. The Effects of Leuconostoc mesenteroides RSG7 Exopolysaccharide on the Physicochemical Properties and Flavor Compounds of Set Yoghurt. Processes. 2025; 13(5):1442. https://doi.org/10.3390/pr13051442

Chicago/Turabian StyleWu, Baomei, Yanru Guo, Linlin Hao, Kaiyue Zuo, Yufei Du, Ruixin An, and Binbin Wang. 2025. "The Effects of Leuconostoc mesenteroides RSG7 Exopolysaccharide on the Physicochemical Properties and Flavor Compounds of Set Yoghurt" Processes 13, no. 5: 1442. https://doi.org/10.3390/pr13051442

APA StyleWu, B., Guo, Y., Hao, L., Zuo, K., Du, Y., An, R., & Wang, B. (2025). The Effects of Leuconostoc mesenteroides RSG7 Exopolysaccharide on the Physicochemical Properties and Flavor Compounds of Set Yoghurt. Processes, 13(5), 1442. https://doi.org/10.3390/pr13051442