Research Progress on Flue Gas Desulfurization and Denitrification by Activated Carbon Method

Abstract

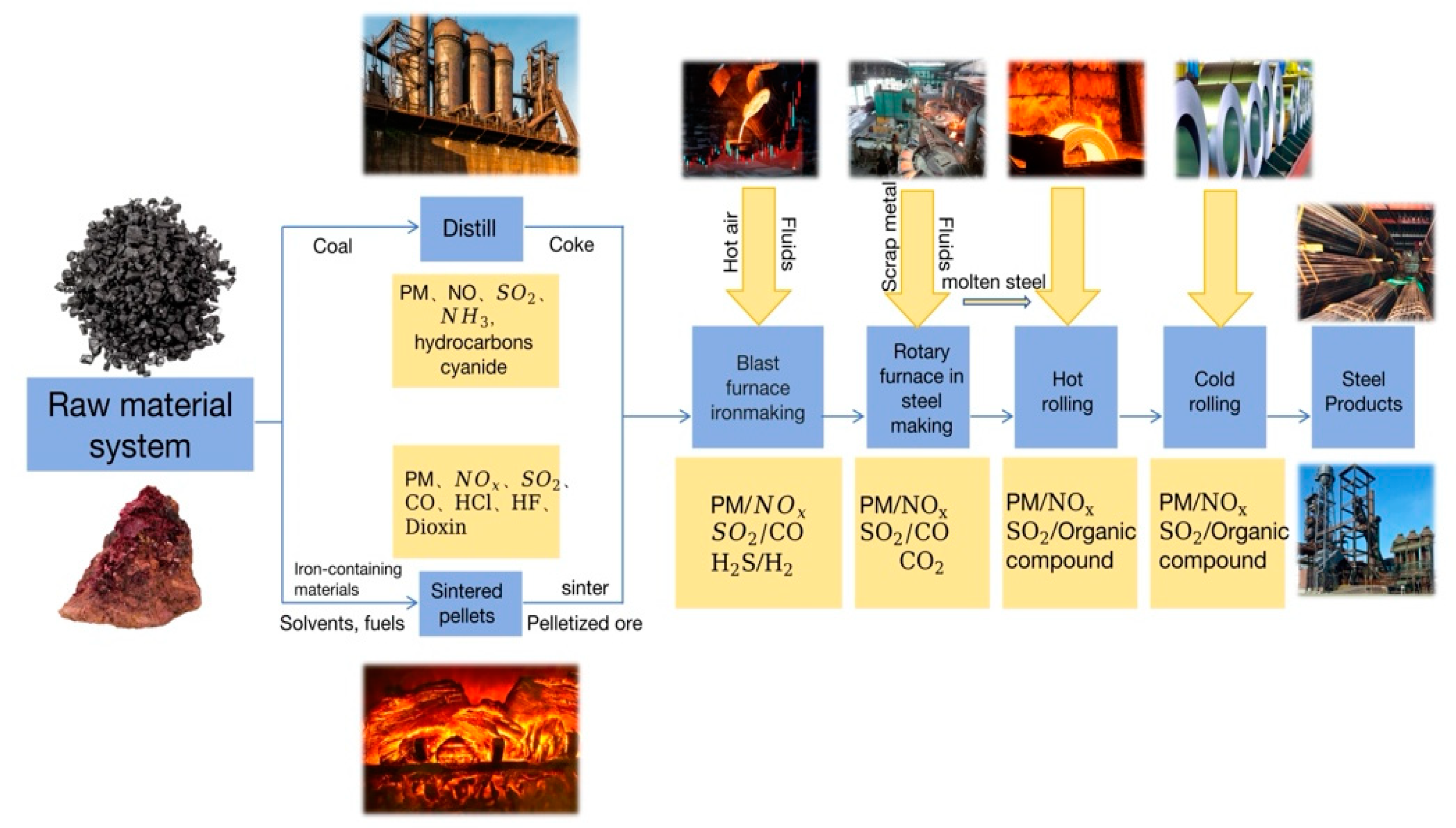

1. Introduction

2. Reaction Mechanism of Activated Carbon and Flue Gas Sulfur Nitrate

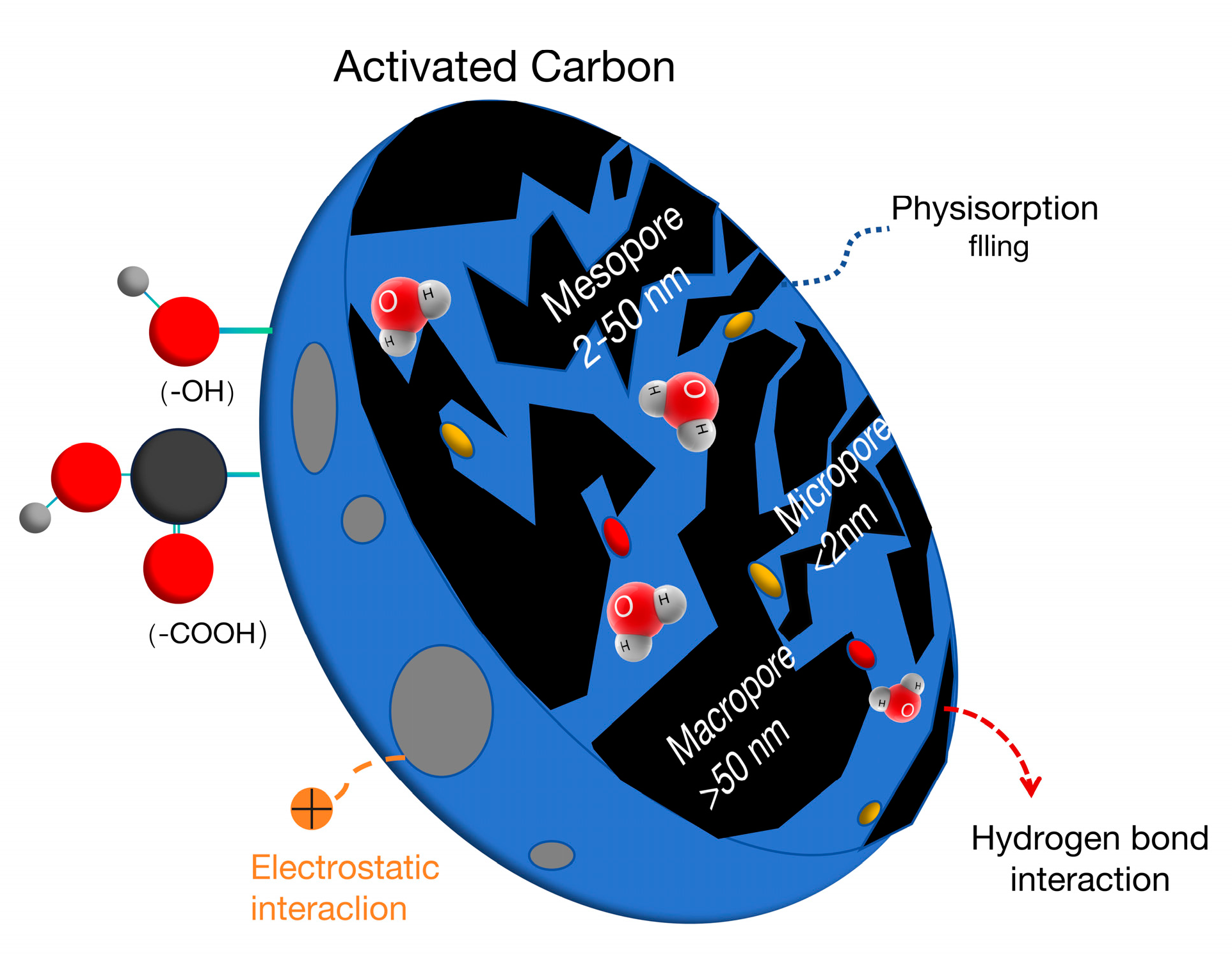

2.1. Activated Carbon and Its Characteristics

2.2. Adsorption Function and Principle of Activated Carbon

2.3. Activated Carbon Flue Gas Desulfurization and Denitrification Technology

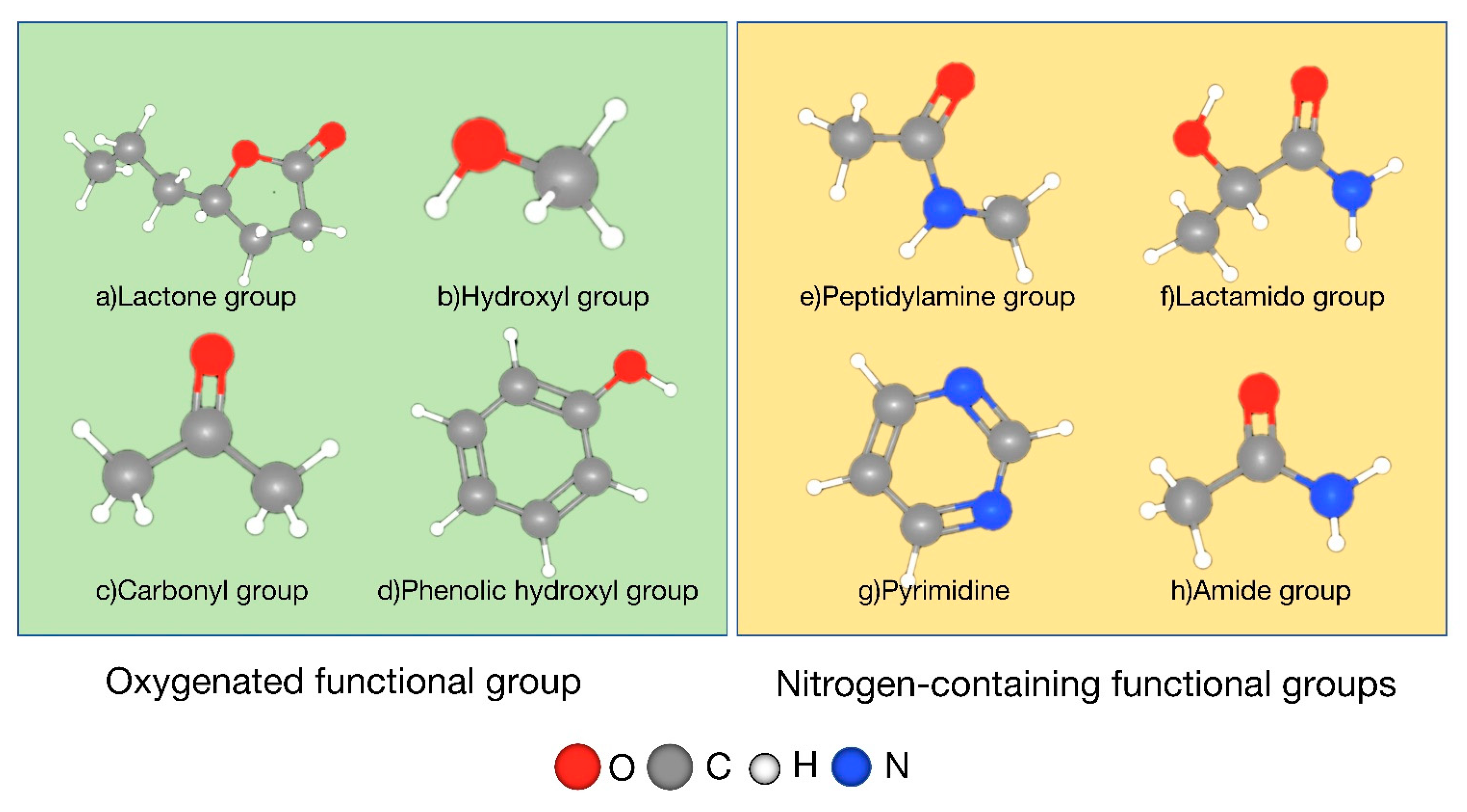

3. Different Modification Methods of Activated Carbon and Its Removal Effect on Sulfur and Nitrate in Flue Gas

3.1. Common Modification Methods of Activated Carbon

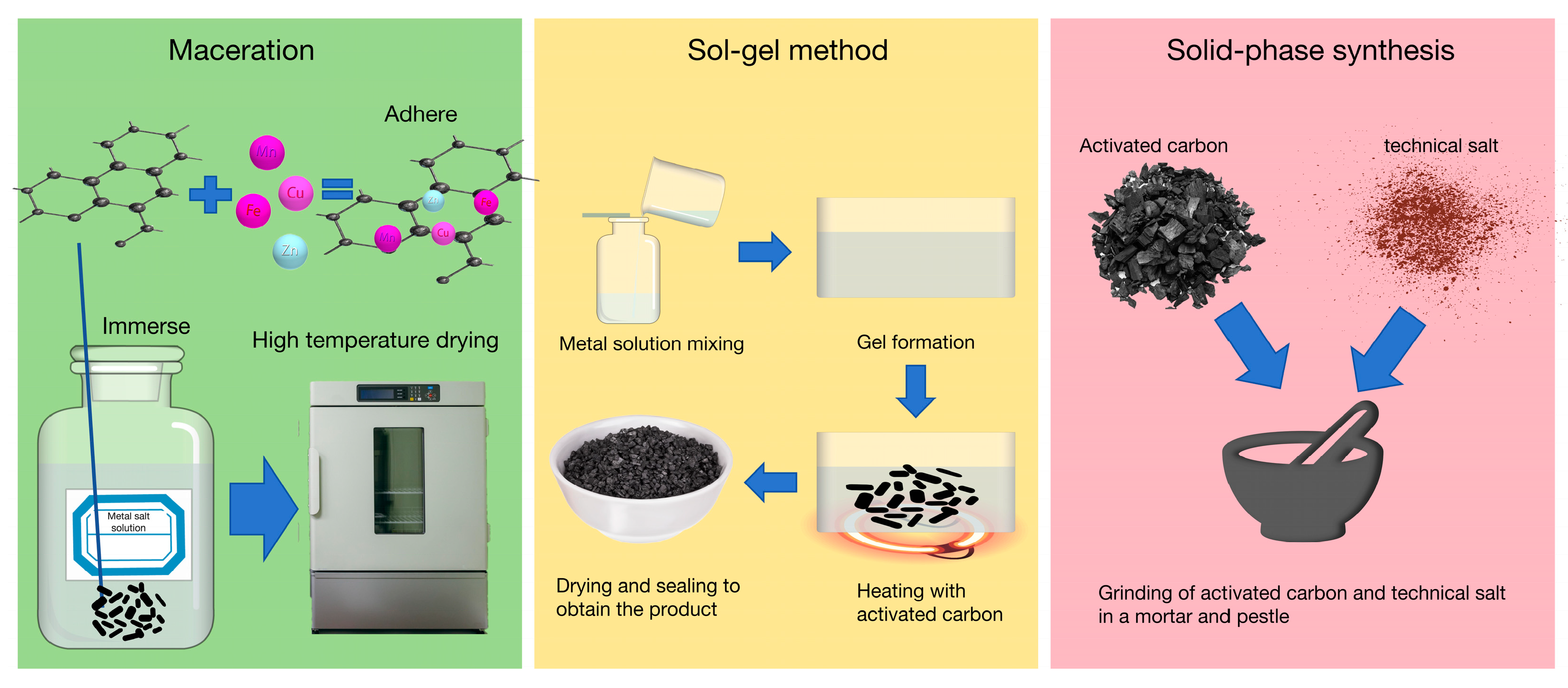

3.2. Modification of Metal-Loaded Activated Carbon

3.3. Loading Non-Noble Metal Oxide Activated Carbon Desulfurization and Denitrification

4. Loaded Non-Noble Metal Oxide Activated Carbon Microwave Flue Gas Desulfurization and Denitrification

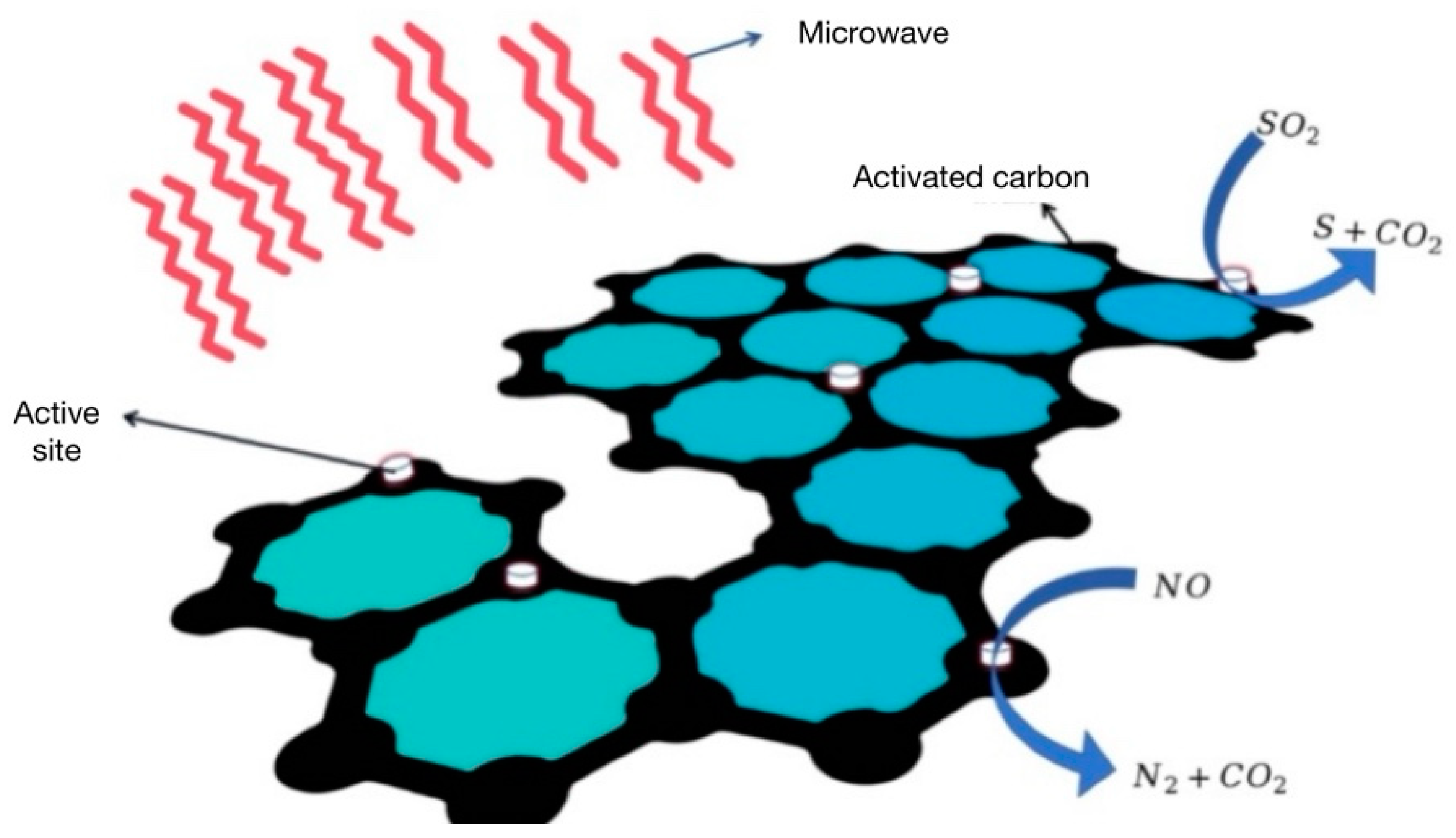

4.1. Activated Carbon Microwave Desulfurization and Denitrification

4.2. Loaded Non-Noble Metal Oxide Activated Carbon Microwave Desulfurization and Denitrification

- (1)

- The removal efficiency of sulfur and nitrate in the flue gas is improved. First of all, the traditional activated carbon microwave flue gas desulfurization and denitrification technology mainly depends on the adsorption of activated carbon. After the activated carbon is loaded with non-noble metal oxides, the original activated carbon becomes a catalyst or catalyst carrier under the action of microwaves. While exerting the adsorption effect, it can also effectively promote the reaction of desulfurization and denitrification. Secondly, after the non-metallic oxide is loaded on the surface of the activated carbon, it will provide more active sites for the activated carbon under the action of microwaves. The abundant active sites provide more adsorption space for SO2 and NOx, which effectively alleviates the competitive adsorption of SO2 and NOx. Thirdly, the loading of non-noble metal oxides enhances the microwave absorption performance of activated carbon, which is beneficial to the rapid heating of activated carbon, forming a high temperature gradient and increasing the reaction rate.

- (2)

- Reduced energy consumption and operating costs. Firstly, activated carbon loaded with non-precious metal oxides is not easily saturated by sulfur oxides and nitrogen oxides in the process of flue gas desulfurization and denitrification, which prolongs the service life of activated carbon. Secondly, there is no need for tedious and accurate technical control in the whole technical link, which reduces the cost of human resources and other material costs. Thirdly, due to the lack of some cumbersome technology to control the environment, the cost of equipment in construction is relatively reduced.

- (3)

- It reduces the by-products such as CO, sulfate, and nitrate and reduces the secondary pollution to the environment. Firstly, microwave radiation loading of non-noble metal oxides will cause electrons inside the activated carbon to transition, resulting in a thermal effect. This thermal effect can promote non-noble metal oxides becoming better dispersed on the surface of activated carbon and prevent their agglomeration. Secondly, the microwave field can also induce the formation of a local electromagnetic field between the metal and the activated carbon. This affects the conductivity of the activated carbon, and the electron transfer becomes easier between the activated carbon and the non-noble metal. The change changes the electron cloud density around the non-noble metal, which affects the adsorption and activation ability of the reactant molecules. Thirdly, microwave loading of non-noble metal activated carbon will also cause changes in the functional groups on the surface of activated carbon. These changed functional groups interact with non-precious metals to form a special catalytic environment conducive to complete oxidation, making the reaction more inclined to generate carbon dioxide and reducing the generation of carbon monoxide.

4.3. Dilemma Analysis of Microwave Desulfurization and Denitrification of Loaded Non-Noble Metal Oxide Activated Carbon

- (1)

- Strive to make the flue gas composition and flue gas environment, through a significant amount of research, more similar to actual industrial emissions. In the current research process, scholars do not fully consider the flue gas environment. In most cases, only the flue gas components that have a direct impact on the experimental results are retained. Although there are studies on other factors such as heavy metal harmful substances, oxygen content, humidity, temperature, acidity, and alkalinity in flue gas, they remain at the basic level of separate research on single index parameters. In the existing literature, there is a lack of research on the microwave desulfurization and denitrification efficiency of non-noble metal oxide activated carbon in real flue gas environments. The amount of flue gas is far from the actual industrial production unit time or standard capacity of flue gas emission standards. Therefore, this technology not only has huge research space but also great research potential.

- (2)

- Strive to explore the microwave irradiation time and the actual ratio and dosage of non-noble metal oxide loaded activated carbon more specifically in the study. In the existing research, in order to reduce the carbon loss of activated carbon, the use of microwave irradiation to load non-noble metal oxides in the research process is relatively short. In the actual production process, as long as the production line does not stop, flue gas emissions will not stop. How to rationally use microwave irradiation in the production practice to maximize the adsorption and catalytic effects of activated carbon loaded with non-noble metal oxides in order to achieve the ideal desulfurization and denitrification efficiency is another subject. The subject must be overcome in the application field of this technology. According to the different application fields and flue gas compositions, exploring the ratio of non-precious metal oxides and activated carbon and finally scientifically controlling the amount of activated carbon are effective ways to control costs.

- (3)

- Strive to design and manufacture the equipment from the perspective of specific practical applications in the research and calculate and control the operating costs. In the current research process, scholars use microwave tube furnaces as microwave generating devices and corundum furnace tubes as activated carbon loading devices. In the production practice, how to design and install the microwave-generating device and how to arrange the activated carbon to achieve the ideal desulfurization and denitrification effect of flue gas are key to the application of this technology. Some scholars have estimated the construction and operation costs of this technology. However, with the change of the times and the upgrading of production capacity, the economics of microwave desulfurization and denitrification technology of non-precious metal oxide activated carbon under the existing production environment have yet to be further verified by scholars.

Conclusions and Prospects

- (1)

- The advantages and disadvantages of the existing activated carbon flue gas desulfurization and denitrification process coexist. The advantage is that it can remove a variety of harmful substances in flue gas at the same time, and the activated carbon itself is cheap; the disadvantage is that the process is old and that the process is too long, resulting in high loss of activated carbon. Improper operation may also produce by-products such as CO and CO2, resulting in secondary pollution. Therefore, the process does not occupy a dominant position in flue gas desulfurization and denitrification in the field of iron and steel production.

- (2)

- The modification of activated carbon can not only improve the removal efficiency of flue gas sulfur and nitrate by activated carbon but also improve the regeneration ability of activated carbon. The special physical and chemical properties of activated carbon provide it with good adsorption, catalysis, and reduction properties, and it also has good wave absorption properties. Under the action of microwave, activated carbon can improve its activity and accelerate the reaction rate with sulfur and nitrate in flue gas. The modified activated carbon loaded with non-noble metal oxides (mainly loaded with Fe2O3, CuO, ZnO, Mn2O3) can also reduce the production of CO at the reaction terminal under the synergistic effect of microwave and improve the microwave absorption performance of activated carbon. It can also increase the active sites on activated carbon and improve the removal efficiency of sulfur and nitrate as a whole, so as to achieve the requirements of low cost, high efficiency, strong stability, and no pollution.

- (3)

- Activated carbon flue gas desulfurization and denitrification technology has great development potential and broad research space. Future research should focus on the optimization of the activated carbon modified load and the development of composite carbon-based materials. The regeneration of activated carbon, the batch loading process, and the multiple influencing factors of activated carbon desulfurization and denitrification under the synergistic effect of microwave irradiation should also be paid attention to. In addition, the advantages and disadvantages of the existing process technology should be summarized in close connection with the actual needs of production. In view of the good removal effect of load non-metallic oxides and microwave irradiation, the equipment should be continuously optimized and upgraded, so as to make greater contributions to flue gas desulfurization and denitrification in the iron and steel industry.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Garin, F.O. Mechanism of NOx decomposition. Appl. Catal. A Gen. 2001, 222, 183–219. [Google Scholar] [CrossRef]

- Fritz, A.; Pitchon, V. The current state of research on automotive lean NOx catalysis. Appl. Catal. B Environ. 1997, 13, 1–25. [Google Scholar] [CrossRef]

- Mauzerall, D.; Sultan, B.; Kim, N.; Bradford, D. NOx emissions from large point sources: Variability in ozone production, resulting health damages and economic costs. Atmos. Environ. 2005, 39, 2851–2866. [Google Scholar] [CrossRef]

- Rigby, D.; Batts, B. The isotopic composition of nitrogen in Australian coals and oil shales. Chem. Geol. Isot. Geosci. Sect. 1986, 58, 273–282. [Google Scholar] [CrossRef]

- Burchill, P.; Welch, L. Variation of nitrogen content and functionality with rank for some UK bituminous coals. Fuel 1989, 68, 100–104. [Google Scholar] [CrossRef]

- Snyder, L. Petroleum nitrogen compounds and oxygen compounds. Acc. Chem. Res. 1970, 3, 290–299. [Google Scholar] [CrossRef]

- Zhuang, J. Discussion on Desulfurization and Denitrification Technology of Sintering Flue Gas. Steel Manag. 2021, 7, 47–48. (In Chinese) [Google Scholar]

- Ma, S.; Ma, J.; Jin, X.; Yao, J. Experimental study on simultaneous removal of SO2 and NOx by microwave irradiation activated carbon bed. J. Eng. Thermophys. 2013, 34, 26–29. (In Chinese) [Google Scholar]

- Kwon, D.; Park, K.; Hong, S. Enhancement of SCR activity and SO2 resistance on VOx/TiO2 catalyst by addition of molybdenum. Chem. Eng. J. 2016, 284, 315–324. [Google Scholar] [CrossRef]

- Zhao, Y.; Hao, R.; Yuan, B.; Jiang, J. Simultaneous removal of SO2, NO and H2O through an integrative process utilizing a cost-effective complex oxidant. J. Hazard. Mater. 2016, 301, 74–83. [Google Scholar] [CrossRef]

- Debarr, J.; Lizzio, A. Adsorption of SO2 on Bituminous Coal and Activated Carbon Fiber. Energy Fuel 1997, 11, 267–271. [Google Scholar] [CrossRef]

- Gao, J.; Wang, T.; Shu, Q.; Nawaz, Z.; Wen, Q.; Wang, D.; Wang, J. An Adsorption Kinetic Model for Sulfur Dioxide Adsorption by ZL50 Activated Carbon. Chin. J. Chem. Eng. 2010, 18, 223–230. [Google Scholar] [CrossRef]

- Papangelakis, P.; Miao, R.; Lu, R.; Liu, H.; Wang, X.; Ozden, A.; Liu, S.; Sun, N.; O’Brien, C.; Hu, Y.; et al. Improving the SO2 tolerance of CO2 reduction electrocatalysts using a polymer/catalyst/ionomer heterojunction Design. Nat. Energy 2024, 9, 1011–1020. [Google Scholar] [CrossRef]

- Han, J.; Yan, Z.; Shao, J. Characteristics and Application of Countercurrent Activated Carbon Flue Gas Desulfurization and Denitrification Technology. Sinter. Pelletizing 2018, 43, 13–18. (In Chinese) [Google Scholar]

- Wang, J. Application of activated carbon flue gas countercurrent integrated purification (CCMB) technology in coke oven of Anyang Steel. Wide Heavy Plate 2023, 29, 43–45+48. (In Chinese) [Google Scholar]

- Zhang, P.; Helmut, W.; Joachim, U. Adsorption of SO2 on activated carbon for low gas concentrations. Chem. Eng. Technol. 2007, 30, 635. [Google Scholar] [CrossRef]

- Montagnaro, F.; Silvestre-Albero, A.; Silvestre-Albero, J.; Rodríguez-Reinoso, F.; Erto, A.; Lancia, A.; Balsamo, M. Post-combustion CO`adsorption on activated carbons with different textural properties. Microporous Mesoporous Mater. 2015, 209, 157–164. [Google Scholar] [CrossRef]

- Hao, L. (Ed.) Food Additives; Agricultural University Press: Beijing, China, 2016; Volume 7, p. 260. (In Chinese) [Google Scholar]

- The ‘Concise Chemical Reagent Manual’ was compiled. In Concise Handbook of Chemical Reagents; Shanghai Science and Technology Press: Shanghai, China, 1991; Volume 1, p. 338. (In Chinese)

- Chen, K. Treatment and Disposal of Agricultural Solid Waste; Guo, C., Xue, Z., Eds.; Henan Science and Technology Press: Zhengzhou, China, 2016; Volume 11, pp. 144–145. (In Chinese) [Google Scholar]

- Gu, J. (Ed.) Antibiotics; Shanghai Science and Technology Press: Shanghai, China, 2001; Volume 9, p. 144. (In Chinese) [Google Scholar]

- Ma, W. Solid-Water Interface Chemistry and Adsorption Technology; Metallurgical Industry Press: Beijing, China, 2011; Volume 10, pp. 65–66. (In Chinese) [Google Scholar]

- Wang, H.; Xu, Z.; Kohandehghan, A.; Li, Z.; Cui, K.; Tan, X.; Stephenson, T.; King’ondu, C.; Holt, C.; Olsen, B.; et al. Interconnected Carbon Nanosheets Derivedfrom Hemp for Ultrafast Supercapacitors with High Energy. ACS Nano 2013, 6, 5131–5141. [Google Scholar] [CrossRef]

- Nguyen, T.; Hur, J.; Kim, I.; Bui, V.; Lee, Y.-C. Development of Antimicrobial CuO/(3-aminopropyl)Triethoxysilane Activated Carbon Fiber. J. Nanosci. Nanotechnol. 2021, 21, 4519–4523. [Google Scholar] [CrossRef]

- Dubinin, M.M.; Serpinsky, V.V. Isotherm Equationfor Water Vapor Adsorption by Microporous Carbonaceous Adsorbents. Carbon 1981, 19, 402–403. [Google Scholar] [CrossRef]

- Bansal, R.C.; Goyal, M. Activated Carbon Adsorption; CRC press: Boca Raton, FL, USA, 2005. [Google Scholar]

- Wang, Y. Coal Chemical Technology; Zhou, G., Wang, L., Liu, S., Xu, D., Eds.; China University of Mining and Technology Press: Xuzhou, China, 2014; Volume 9, p. 384. (In Chinese) [Google Scholar]

- Shirra, G.; Ilan, K.; Carlos, G.D. Removal of dissolved organic matter by granular-activated carbonadsorption as a pretreatment to reverse osmosis of membrane bioreactor effluents. Water Res. 2008, 42, 6–7. [Google Scholar]

- Chiang, Y.; Chiang, P.; Huang, C. Effects of pore structure and temperature on VOC adsorption on activated carbon. Carbon 2001, 39, 523–534. [Google Scholar] [CrossRef]

- Li, H. Preparation of high-efficiency radon-absorbing material by water immersion-freeze-thaw cycle and multi-process coupling modified activated carbon. J. Radioanal. Nucl. Chem. 2022, 331, 3125–3133. (In Chinese) [Google Scholar] [CrossRef]

- Durigon, A.M.M.; da Silveira, G.D.; Sokal, F.R.; Pires, R.A.C.V.; Dias, D. Food dyes screeningusing electrochemistry approach in solid state: The case of sunset yellow dyeelectrochemical behavior. J. Solid State Electrochem. 2020, 24, 2907–2921. [Google Scholar] [CrossRef]

- Xu, M.; Zhang, Y.Z. Study of rejuvenators dynamic diffusion behavior into aged asphalt and its effects. Constr. Build. Mater. 2020, 261, 120673. [Google Scholar] [CrossRef]

- Zhou, Q.; Ju, W.; Su, X.; Yong, Y.; Li, X. Adsorption behavior of SO2 on Vacancy-defected graphene: A DFT Study. J. Phys. Chem. Solids 2017, 109, 40–45. [Google Scholar] [CrossRef]

- Greenwood, T.; Koehler, S.P.K. Molecular Dynamics Simulations of Nitric Oxide Scattering Off Graphene. ChemPhysChem 2022, 23, e202200216. [Google Scholar] [CrossRef]

- Wang, J.; Wang, Y.; She, X.; Wang, J.; Xue, Q. Numerical study on the distribution of flue gas residence time in the desulfurization and denitrification system by the optimization of the Model. Int. J. Chem. React. Eng. 2022, 20, 1095–1105. [Google Scholar] [CrossRef]

- Lin, Y.; Li, Y.; Xu, Z.; Xiong, J.; Zhu, T. Transformation of functional groups in the reduction of NO with NH3 over nitrogen-enriched activated carbons. Fuel 2018, 223, 312–323. [Google Scholar] [CrossRef]

- Zhou, H.; Chen, Y. Effect of acidic surface functional groups on Cr(VI) removal by activated carbon from aqueous Solution. Rare Met. 2010, 29, 333–338. [Google Scholar] [CrossRef]

- Zhao, X.; Cai, G.; Wang, Z.; Wang, Q.; Yang, Y.; Luo, J. Influences of surface functional groups on catalytic activity over activated carbon catalysts for sulfur dioxide removal from flue Gases. Appl. Catal. B Environ. 1994, 3, 229–238. [Google Scholar] [CrossRef]

- Fu, Y.; Zhang, Y.; Li, G.; Zhang, J.; Guo, Y. NO removal activity and surface characterization of activated carbon with oxidation Modification. J. Energy Inst. 2017, 90, 813–823. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, S.; Xu, S.; Cao, F.; Ren, X.; Sun, Q.; Yang, L.; Wennersten, R.; Mei, N. Simulation of the VOC Adsorption Mechanism on Activated Carbon Surface by Nitrogen-Containing Functional Groups. Appl. Sci. 2024, 14, 1793. [Google Scholar] [CrossRef]

- Jin, C.; Zhao, T. Engineering application of activated carbon desulfurization and denitrification integrated technology. CFHI Technol. 2017, 4, 45–47. (In Chinese) [Google Scholar]

- Li, F.; Zhang, J.; Qi, Y.; Gu, Q. Activated carbon combined desulfurization and denitrification process. Chem. Enterp. Manag. 2020, 4, 189–190. (In Chinese) [Google Scholar]

- Rubio, B.; Izquierdo, M.T.; Mastral, A.M. Influence of low-rank coal char properties on their SO2 removal capactity from flue gases.2. Activated chars. Carbon 1998, 36, 263–268. [Google Scholar] [CrossRef]

- Lisovskii, A.; Semiat, R.; Aharoni, C. Adsorption of sulfur dioxide by active carbon treated by nitric acid: I. Effect of the treatment on adsorption of SO2 and extractability of the acid formed. Carbon 1997, 35, 1639–1643. [Google Scholar] [CrossRef]

- Schröder, E.; Thomauske, K.; Weber, C.; Hornung, A.; Tumiatti, V. Experiments on the generation of activated carbon from biomass. J. Anal. Appl. Pyrolysis 2007, 79, 106–111. [Google Scholar] [CrossRef]

- Lin, W.; Johnsson, J.E.; Dam-Johansen, K.; van den Bleek, C.M. Interaction between emissions of sulfur dioxide and nitrogen oxides in fluidizedbed combustion. Fuel 1994, 73, 1202–1208. [Google Scholar] [CrossRef]

- Koebel, M.; Madia, G.; Elsener, M. Selective catalytic reduc-tion of NO and NO2 at low temperatures. Catal. Today 2002, 73, 239–247. [Google Scholar] [CrossRef]

- Yan, Z.; Liu, L.; Zhang, Y.; Liang, J.; Wang, J.; Zhang, Z.; Wang, X. Activated semi-coke in SO2 removal from flue gas:selection of activation methodology and desulfurization mechanism study. Energy Fuels 2013, 27, 3080–3089. [Google Scholar] [CrossRef]

- Tang, Q. Experimental Study on Competitive Adsorption of SO2 and NOx Mixed Gas; Xi’an Jiaotong University: Xi’an, China, 2003. (In Chinese) [Google Scholar]

- Caglar, A.; Kaya, S.; Saka, C.; Yildiz, D.; Kivrak, H. Investigation of electrooxidation and methanolysis of sodium borohydride on activated carbon supported Co catalysts from poplar sawdust. Int. J. Hydron-Gen Energy 2024, 75, 171–178. [Google Scholar] [CrossRef]

- Yuan, Y.; Zhang, H.; Yang, F.; Zhang, N.; Cao, X. Inorganic composite sorbents for water vapor sorption: A research progress. Renew. Sustain. Energy Rev. 2016, 54, 761–776. [Google Scholar] [CrossRef]

- Kumar, N.; Pandey, A.; Sharma, Y.C. A review on sustainable mesoporous activated carbon as adsorbent for efficientremoval of hazardous dyes from industrial wastewater. J. Water Process Eng. 2023, 54, 104054. [Google Scholar] [CrossRef]

- Liu, W.; Xie, H.; Zhang, J.; Zhang, C. Sorption removal of cephalexin by HNO3 and H2O2 oxidized activated carbons. Sci. China Chem. 2012, 55, 1959–1967. [Google Scholar] [CrossRef]

- Blazewicz, S.; Swiatkouski, A.; Trznadel, B.J. The influence of heat treatment on activated carbon structure anporosity. Carbon 1999, 37, 693–700. [Google Scholar] [CrossRef]

- Qiu, W.; Dou, K.; Zhou, Y.; Huang, H.; Chen, Y.; Lu, H. Hierarchical pore structure of activated carbon fabricated by CO2/microwave for volatile organic compounds adsorption. Chin. J. Chem. Eng. 2018, 26, 81–88. [Google Scholar] [CrossRef]

- Haydar, S.; Ferro-Garcıa, M.A.; Rivera-Utrilla, J.; Joly, J.P. Adsorption of p-nitrophenol on an activated carbon with different oxidation. Carbon 2003, 41, 387–395. [Google Scholar] [CrossRef]

- Boudou, J.P.; Chehimi, M.; Broniek, E.; Siemieniewska, T.; Bimer, J. Adsorption of H2S or SO2 on an activated carbon cloth modified by ammonia treatment. Carbon 2003, 41, 1999–2007. [Google Scholar] [CrossRef]

- Ma, X.; Zhang, Z.; Wu, H.; Li, J.; Yang, L. Adsorption of volatile organic compounds at medium-high temperature conditions by activated carbons. Energy Fuels 2019, 34, 3679–3690. [Google Scholar] [CrossRef]

- Teresa, B.; Camille, P. On the reactive adsorption of ammonia on activated carbons modified by impregnation with inorganic compounds. J. Colloid Interface Sci. 2009, 338, 329–345. [Google Scholar]

- Zhang, J.; Duan, Y.; Zhou, Q.; Zhu, C.; She, M.; Ding, W. Adsorptive removal of gas-phase mercury by oxygen non-thermalplasma modified activated carbon. Chem. Eng. J. 2016, 294, 281–289. [Google Scholar] [CrossRef]

- Hawke. Effect of Activated Carbon Loading on Microwave Desulfurization and Denitrification of Sintering Flue Gas; North China University of Science and Technology: Tangshan, China, 2023. (In Chinese) [Google Scholar]

- Bhatnagar, A.; Hogland, W.; Marques, M.; Sillanpää, M. An overview of the modification methods of activated carbon for its water treatment applications. Chem. Eng. J. 2013, 219, 499–511. [Google Scholar] [CrossRef]

- Ning, P.; Yu, L.; Yi, H.; Tang, X.; Li, H.; Wang, H.; Yang, L. Effect of Fe/Cu/Ce loading on the coal-based activated carbons for hydrolysis of carbonyl sulfide. J. Rare Earths 2010, 28, 205–210. [Google Scholar] [CrossRef]

- Chukov, D.I.; Stepashkin, A.A.; Maksimkin, A.V.; Tcherdyntsev, V.V.; Kaloshkin, S.D.; Kuskov, K.V.; Bugakov, V.I. Investigation of structure, mechanical and tribological properties of short carbon fiber reinforced UHMWPE-matrix composites. Compos. Part B Eng. 2015, 76, 79–88. [Google Scholar] [CrossRef]

- Yang, Z.; Chen, Z.; Gong, H.; Wang, X. Copper oxide modified activated carbon for enhanced adsorption performance of siloxane: An experimental and DFT Study. Appl. Surf. Sci. 2022, 601, 154200. [Google Scholar] [CrossRef]

- Natrayan, L.; Arul Kumar, P.V.; Dhanraj, J.A.; Kaliappan, S.; Sivakumar, N.S.; Patil, P.P.; Sekar, S.; Paramasivam, P. Synthesis and Analysis of Impregnation on Activated Carbon in Multiwalled Carbon Nanotube for Cu Adsorption from Wastewater. Bioinorg. Chem. Appl. 2022, 2022, 7470263. [Google Scholar] [CrossRef]

- Antonopoulou, M.; Karagianni, P.; Giannakas, A.; Makrigianni, V.; Mouzourakis, E.; Deligiannakis, Y.; Konstantinou, I.; Giannakas, A. Photocatalytic degradation of phenol by char/N-TiO2 and char/N-F-TiO2 composite Photocatalysts. Catal. Today 2017, 280, 114–121. [Google Scholar] [CrossRef]

- Zhang, J.; Li, X.; Xie, W.; Hao, Q.; Chen, H.; Ma, X. Handy synthesis of robust Ni/carbon catalysts for methane decomposition by selective gasification of pine Sawdust. Int. J. Hydrogen Energy 2018, 43, 19414–19419. [Google Scholar] [CrossRef]

- Wang, L.; Wang, F. Design Strategy, Synthesis, and Mechanism of Ni Catalysts for Methane Dry Reforming Reaction: Recent Advances and Future Perspectives. Energy Fuels 2022, 36, 5594–5621. [Google Scholar] [CrossRef]

- Wang, J.; Bai, Z. Fe-based catalysts for heterogeneous catalytic ozonation of emerging contaminants in water and wastewater. Chem. Eng. J. 2017, 312, 79–98. [Google Scholar] [CrossRef]

- Sumathi, S.; Bhatia, S.; Lee, K.T.; Mohamed, A.R. Selection of best impregnatedpalm shell activated carbon(PSAC) for simultaneous removal of SO2 and NOx. J. Hazard. Mater. 2010, 176, 1093–1096. [Google Scholar] [CrossRef] [PubMed]

- Quan, W. Study on the Performance of Activated Carbon Supported Metal Oxide HC-SCR Denitration Catalyst; China University of Mining and Technology: Xuzhou, China, 2019. (In Chinese) [Google Scholar]

- Li, Y.; Yi, H.; Tang, X.; Liu, X.; Wang, Y.; Cui, B. Study on simultaneous desulfurization and denitrification performance of Ni-Cu metal oxide modified activated carbon. Ind. Saf. Environ. Prot. 2017, 43, 4–8. (In Chinese) [Google Scholar]

- Sun, D. Preparation of Modified Activated Carbon Adsorbent and Its Desulfurization Performance for Natural Gas; Northeast Petroleum University: Daqing, China, 2018. (In Chinese) [Google Scholar]

- Xue, L.; Jin, Y.; Liu, L.; Wei, L.; Liu, Z.; Zhao, K. Preparation and characterization of iron oxide modified activated carbon. Carbon 2017, 1, 16–19. (In Chinese) [Google Scholar]

- Yin, S.; Zhu, B.; Sun, Y.; Cao, Z.; Chen, G.; Jiang, R.; Xu, T.; Liu, F. Low temperature selective catalytic reduction denitrification performance of Fe2O3/AC catalysts. Chin. J. Process Eng. 2018, 18, 330–336. (In Chinese) [Google Scholar]

- Adachi, M.; Nakagawa, T.; Fujioka, T.; Mori, M.; Kubota, K.; Oda, G.; Kikkawa, T. Feasibility of portable microwave imaging device for breastcancer detection. Diagnostics 2021, 12, 27. [Google Scholar] [CrossRef]

- Koppel, T.; Shishkin, A.; Haldre, H.; Toropovs, N.; Vilcane, I.; Tint, P. Reflection and transmission properties of common construction materials at 2.4 GHz frequency. Energy Procedia 2017, 113, 158–165. [Google Scholar] [CrossRef]

- Kor-Bicakci, G.; Eskicioglu, C. Recent developments on thermal municipal sludge pretreatment technologies for enhanced anaerobic digestion. Renew. Sustain. Energy Rev. 2019, 110, 423–443. [Google Scholar] [CrossRef]

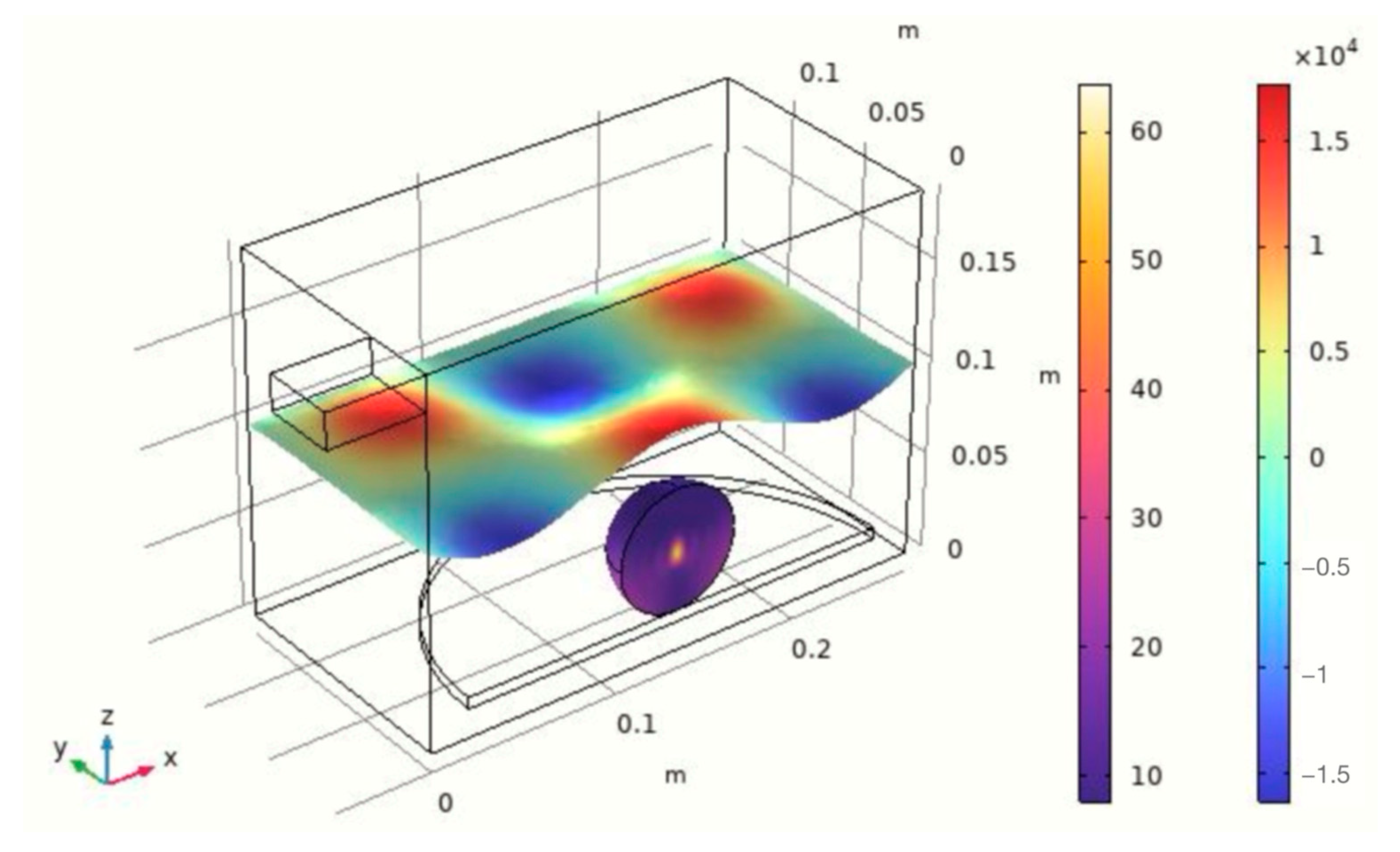

- Xue, L.; Gao, R.; Shen, L.; Zheng, X.; Gao, M. Dependence of degradation of anthocyanins on non-uniformity of microwave heating in blueberry puree. Food Bioprod. Process. 2023, 139, 129–143. [Google Scholar] [CrossRef]

- Zhang, X.; Rajagopalan, K.; Lei, H.; Ruan, R.; Sharma, B.K. An overview of a novel concept in biomass pyrolysis: Microwave irradiation. Sustain. Energy Fuels 2017, 1, 1664–1699. [Google Scholar] [CrossRef]

- Wei, Z.; Zeng, G.; Xie, Z.; Sun, J. Simultaneous Desulfurization and Denitrification by Microwave Catalytic over FeCoCu/Zeolite 5A Catalyst. J. Environ. Eng. 2010, 136, 1403–1408. [Google Scholar] [CrossRef]

- DeGroot, W.F.; Osterheld, T.H.; Richards, G.N. Chemisorption of oxygen and of nitricoxide on cellulosic chars. Carbon 1991, 29, 185–189. [Google Scholar] [CrossRef]

- Kong, Y.; Chang, Y. NOx Abatement with Carbon Adsorbents and Microwave Energy. Fuel Energy Abstr. 1995, 9, 971–975. [Google Scholar] [CrossRef]

- Cha, C. Microwave-induced reactions of SO2 and NOx decom-position in the char-bed. Res. Chem. Inter-Mediat. 1994, 20, 13–28. [Google Scholar] [CrossRef]

- Ma, S.; Li, Z.; Ma, J.; Chai, F.; Zhu, S. Influence study of oxygen in the flue gas on physical and chemical properties of activated carbon under microwave irradiation. J. Environ. Chem. Eng. 2015, 3, 1312–1319. [Google Scholar] [CrossRef]

- Ma, S.; Gao, L.; Ma, J.; Jin, X.; Yao, J.; Zhao, Y. Advances on simultaneous desulfurization and denitrification using activated carbon irradiated by microwaves. Environ. Technol. 2012, 33, 1225–1230. [Google Scholar] [CrossRef] [PubMed]

- Kappe, C.; Stadler, A.; Dallinger, D. Microwaves in Organic and Medicinal Chemistry; Wiley VCH: Weinheim, Germany, 2005. [Google Scholar]

- Kim, T.; Lee, J.; Lee, K.-H. Microwave heating of carbon-based solid materials. Carbon Lett. 2014, 15, 15–24. [Google Scholar] [CrossRef]

- Wang, N.; Zou, W.; Li, X.; Liang, Y.; Wang, P. Study and application status of the nonthermal effects of microwaves in chemistry and materials science-a brief review. RSC Adv. 2022, 12, 17158–17181. [Google Scholar] [CrossRef] [PubMed]

- Wang, B. Experimental and Simulation Study of Hot Spot Effect in Microwave Heating Process; Shandong University: Jinan, China, 2017. (In Chinese) [Google Scholar]

- Ma, S.; Gao, L.; Jin, X.; Yao, J.; Zhao, Y. Research progress of microwave irradiation activated carbon desulfurization and denitrification technology. Environ. Sci. Technol. 2011, 34, 70–74. (In Chinese) [Google Scholar]

- Wang, X.; Wang, A.; Wang, X.; Zhang, T. Microwave plasma enhanced reduction of SO2 to sulfur with carbon. Energy Fuels 2007, 21, 867–869. (In Chinese) [Google Scholar] [CrossRef]

- Jiang, W.J.; Jin, Y.; Zhu, X.F.; Zhong, B.H.; Jiang, X. Activation and modification of activated carbon materials. Environ. Pollut. Control. Technol. Equip. 2002, 3, 25. (In Chinese) [Google Scholar]

- Ye, P. Effect of Microwave Heating on the Surface Properties of Activated Carbon. Carbon Tech. 2004, 23, 5–9. (In Chinese) [Google Scholar]

- Wang, X.; Wang, P.; Liu, Y.; Ren, J. Study on the desulfurization and denitrification performance of activated carbon based on microwave. Resour. Econ. Environ. Prot. 2015, 5, 15–16+20. (In Chinese) [Google Scholar]

- Jin, X. Experimental Study on Simultaneous Desulfurization and Denitrification of Activated Carbon Bed by Microwave Irradiation; North China Electric Power University: Beijing, China, 2011. (In Chinese) [Google Scholar]

- Li, H. Mn2O3/AC Microwave Catalysts for Microwave Selective Catalytic Reduction of Nitrogen Oxides; Xiangtan University: Xiangtan, China, 2013. (In Chinese) [Google Scholar]

- Liu, B. Research on Coal-Based Carbon Microwave Flue Gas Denitrification; Wuhan University of Science and Technology: Wuhan, Chian, 2016. (In Chinese) [Google Scholar]

| Technical Steps | Technical Process | Reactive Mode | Reaction Product |

|---|---|---|---|

| Adsorb | Activated carbon adsorbs sulfur dioxide, oxygen, and water by physical adsorption and produces sulfuric acid by chemical reaction. Sulfuric acid is adsorbed on activated carbon and then reacts with water adsorbed on activated carbon to produce sulfuric acid with n crystal water. Ammonia is injected into the flue gas after desulfurization (as a reducing agent, the effect is to reduce nitrogen oxides, namely, nitric oxide and nitrogen dioxide, to nitrogen). | N2 | |

| Desorption | The activated carbon after adsorption is heated to 400 °C in the regeneration tower. At this time, the carbon reacts with sulfuric acid to produce sulfur dioxide. | ||

| Sulphur recovery | 1. Preparation of sulfuric acid Method 1: Sulfur dioxide is catalytically oxidized to sulfur trioxide, which reacts with water to form sulfuric acid. Method 2: Sulfur dioxide is introduced into potassium permanganate solution or hydrogen peroxide solution and oxidized by potassium permanganate or hydrogen peroxide. 2. Preparation of ammonium sulfate Ammonium sulfate is prepared by introducing oxygen and ammonia into sulfur dioxide. | Sulfuricacid Method 1: Method 2: Preparation of ammonium sulfate |

| Method | Modification Medium | Characteristics After Modification | Merit | Defect | Temperature | Type |

|---|---|---|---|---|---|---|

| High temperature | Inert gas (N2/Ar) In oxidizing or oxidizing atmospheres (CO2/water vapor) | The specific surface area becomes larger, and the internal micropore volume expands. | The chemical properties are stable, and the adsorption capacity is stronger. | Pore contraction. | 500–900 °C | Physical modification |

| Microwave | Physical microwave field | New pores are generated, and the pore structure and surface functional groups are changed. | Fast heating, high efficiency, low energy consumption, easy to control. | The carbon skeleton and pore size shrinkage become smaller. | 300–800 °C | Physical modification |

| Oxidation | Gas phase oxidation (O3) liquid phase oxidation (HNO3, H2O2, KMnO4) | With the increase in oxygen-containing functional groups, the specific surface area increases. | The adsorption capacity of polar substances is enhanced. | The adsorption capacity of non-polar substances is weakened. | Gas phase oxidation at room temperature 300 °C Liquid phase oxidation at room temperature to 90 °C | Chemical modification |

| Reduction | Gas phase reduction (H2, NH3, N2) and liquid phase reduction (N2H4) | The number of basic functional groups is increased, the specific surface area is increased, the number of pores is increased, and the number of hydroxyl groups is increased. | The adsorption capacity of non-polar substances is increased. | The adsorption capacity of polar substances is weakened. | Gas phase reduction 30–1000 °C Liquid phase reduction at room temperature to 100 °C | Chemical modification |

| Acid base | Acidic (HCL, H2SO4, H3PO4) alkaline (NaOH, KOH, NH3) | The number and type of chemical functional groups is changed. | A special activated carbon for the adsorption of a substance can be obtained. | The specific surface area decreases, and the adsorption capacity decreases. | Acidic at room temperature to 90 °C Alkaline at room temperature to 120 °C | Chemical modification |

| Supported metal | Metal salts (Fe (NO3), CuCl2, AgNO3) metal oxides (ZnO, CuO, TiO2) | The pore structure changes, and the types of chemical functional groups change. | Produce new active sites, improve selectivity, and prolong the service life of activated carbon. | Adsorption of different substances requires loading different metal ions, atoms, or compounds. | Impregnated at room temperature to 80 °C Burning activation 200–950 °C | Chemical modification |

| Plasma | Oxidizing gases (O2/air) Reductive gas (H2/HNO3) Inert gas (N2, Ar) Composite gas (O2/Ar, N2/H2) | The number and type of functional groups is changed, and the specific surface area and micropore melting are increased. | High efficiency, fast speed, energy saving. | The operation cost is high, and the technology is difficult. | Heat treatment temperature from room temperature to 200 °C Drying temperature 80–120 °C Calcined at 200–600 °C | Chemical modification |

| Loading Method | Loading Process | Technological Superiority | Technical Bug |

|---|---|---|---|

| Immersion method | The activated carbon is soaked in metal salt solution. After a period of time, the activated carbon is dried by high-temperature calcination. | Low cost, easy to operate. | A long time will form metal particles. |

| Sol-gel method | The metal salt solution reserve solution is made into metal salt sol by mixing, stirring, and other processes; then activated carbon is added, and then it is evaporated, dried, cooled, and sealed. | The reaction temperature is low, it is easy to carry out, and the reactants are uniformly mixed. The prepared activated carbon has a large specific surface area and high metal activity. | Long production cycle, will produce harmful substances. |

| Solid-phase synthesis method | Activated carbon and technical salts are ground in a mortar or ball mill. | High selectivity, high yield, simple process. | Slow diffusion, slow reaction, load effect is not easy to control. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Meng, L.; Li, W.; Wang, J.; Shi, Y.; Hu, C. Research Progress on Flue Gas Desulfurization and Denitrification by Activated Carbon Method. Processes 2025, 13, 1396. https://doi.org/10.3390/pr13051396

Meng L, Li W, Wang J, Shi Y, Hu C. Research Progress on Flue Gas Desulfurization and Denitrification by Activated Carbon Method. Processes. 2025; 13(5):1396. https://doi.org/10.3390/pr13051396

Chicago/Turabian StyleMeng, Lingyi, Wenqi Li, Jianxiong Wang, Yan Shi, and Changqing Hu. 2025. "Research Progress on Flue Gas Desulfurization and Denitrification by Activated Carbon Method" Processes 13, no. 5: 1396. https://doi.org/10.3390/pr13051396

APA StyleMeng, L., Li, W., Wang, J., Shi, Y., & Hu, C. (2025). Research Progress on Flue Gas Desulfurization and Denitrification by Activated Carbon Method. Processes, 13(5), 1396. https://doi.org/10.3390/pr13051396