A New Method for Assessing the Performance of Photovoltaic Module Enhancing Techniques Based on the Lifespan and Power Effectiveness Factor

Abstract

1. Introduction

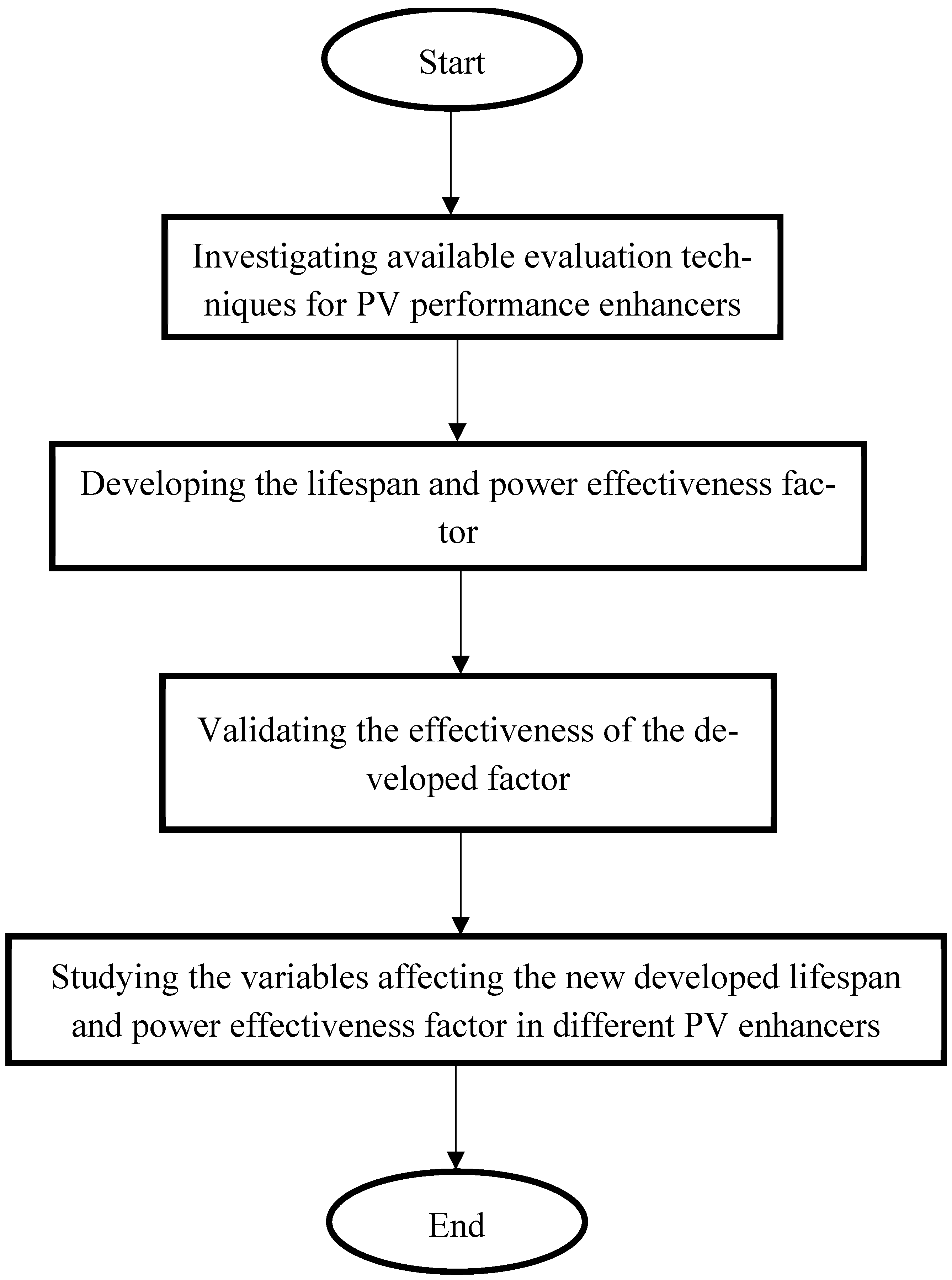

- This study introduces a novel method that links the lifespan and power of both PV modules and their coolers to improve the accuracy of PV enhancer performance evaluations.

- Validation of the method was conducted using data from prior experimental studies, demonstrating its applicability in real-world scenarios.

- The proposed method is expected to benefit researchers, manufacturers, and designers working in PV enhancement technologies.

2. Methodology

2.1. The New PV Enhancer Lifespan and Power Effectiveness Factor,

2.2. Significance of the Value of the

- If or in terms of percentage, the PV enhancer has reached its optimal (maximum) performance in improving the PV system.

- If , the PV enhancer has reached its lowest effectiveness in improving the PV system.

- The lifespan and power factor of the PV enhancers should fall in the range of between and 1. In equation form,

3. Results and Discussion

3.1. The Use of the and in a Real-World Scenario

3.2. Further Analysis on the

3.2.1. The Effect of the on Different PV Enhancers

3.2.2. The Effect of Changing the Lifespan of the PV Enhancer on the

3.2.3. The Effect of Changing the Lifespan of the PV on the

3.2.4. The Effect of Changing the PV Enhancer Net Produced Power on the

3.2.5. The Effect of Changing the Produced Power from a PV Without an Enhancer on the

3.2.6. The Effect of Changing the Maximum Power Under PV Standard Test Conditions on the

3.3. Summary of the Existing and New Assessment Methods for PV Enhancers

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| β | Fractional decrease in photovoltaic efficiency per unit temperature increase (K−1) |

| F | Factor, dimensionless |

| P | Power (W) |

| PV | Photovoltaic module |

| PVC | Photovoltaic module with an enhancer |

| PVT | Photovoltaic thermal collector |

| T | Temperature, °C |

| Subscript | |

| LSE | Lifespan effectiveness factor |

| LS | Lifespan (years) |

| LSPE | Lifespan and power effectiveness |

| max | Maximum output power |

| MPP | Maximum power point |

| oc | Open circuit |

| ref | Reference |

| sc | Short circuit |

| STCs | Standard test conditions |

References

- Sultan, S.M.; Abdullah, M.Z. A new method for assessing photovoltaic module cooler based on lifespan effectiveness factor. Case Stud. Therm. Eng. 2022, 35, 102126. [Google Scholar] [CrossRef]

- Sultan, S.M.; Tso, C.P.; Ervina, E.M.N. A new production cost effectiveness factor for assessing photovoltaic module cooling techniques. Int. J. Energy Res. 2019, 44, 574–583. [Google Scholar] [CrossRef]

- Available online: https://www.iea.org/reports/solar-pv (accessed on 11 April 2025).

- Sultan, S.M.; Tso, C.P.; Ervina, E.M.N. Comments on “Performance evaluation of photovoltaic thermal solar air collector for composite climate of India”. Sol. Energy Mater. Sol. Cells 2019, 198, 63–64. [Google Scholar] [CrossRef]

- Sultan, S.M.; Ervina, E.M.N. Review on recent Photovoltaic/Thermal (PV/T) technology advances and applications. Sol. Energy 2018, 173, 939–954. [Google Scholar] [CrossRef]

- Fuentesa, M.; Vivar, M.; Casa, J.; Aguilera, J. An experimental comparison between commercial hybrid PV-T and simple PV systems intended for BIPV. Renew. Sustain. Energy Rev. 2018, 93, 110–120. [Google Scholar] [CrossRef]

- Ruobing, L.; Qiangguang, P.; Peng, W.; Jili, Z. Experiment research of solar PV/T cogeneration system on the building façade driven by a refrigerant pump. Energy 2018, 161, 744–752. [Google Scholar]

- Tiwari, G.N.; Fischer, O.; Mishra, R.K.; Al-Helal, I.M. Performance evaluation of N-photovoltaic thermal (PVT) water collectors partially covered by photovoltaic module connected in series: An experimental study. Sol. Energy 2016, 134, 302–313. [Google Scholar]

- Hossein, A.; Roghayeh, G.; Mohammad, B.S.; Mohammad, H.A.; Wei-Mon, Y.; Mohammad, A.N. Numerical simulation of PV cooling by using single turn pulsating heat pipe. Int. J. Heat Mass Transf. 2018, 127, 203–208. [Google Scholar]

- Nahar, A.; Hasanuzzaman, M.; Rahim, N.A. Numerical and experimental investigation on the performance of a photovoltaic thermal collector with parallel plate flow channel under different operating conditions in Malaysia. Sol. Energy 2017, 144, 517–528. [Google Scholar] [CrossRef]

- Rahman, M.M.; Hasanuzzaman, M.; Rahim, N.A. Effects of operational conditions on the energy efficiency of photovoltaic modules operating in Malaysia. J. Clean. Prod. 2017, 143, 912–924. [Google Scholar] [CrossRef]

- Fayaz, H.; Nasrin, R.; Rahim, N.A.; Hasanuzzaman, M. Energy and exergy analysis of the PVT system: Effect of nanofluid flow rate. Sol. Energy 2018, 169, 217–230. [Google Scholar] [CrossRef]

- Fadhel, M.I.; Sultan, S.M.; Alkaff, S.A. Theoretical study of new configuration of PVT system design. J. Adv. Mater. Res. 2013, 772, 681–687. [Google Scholar] [CrossRef]

- Sultan, S.M.; Fadhel, M.I.; Alkaff, S.A. Performance analysis of the photovoltaic/thermal solar collector for different Malaysian climatic condition. J. Appl. Mech. Mater. 2014, 467, 522–527. [Google Scholar] [CrossRef]

- Nahar, A.; Hasanuzzaman, M.; Rahim, N.A.; Parvin, S. Numerical investigation on the effect of different parameters in enhancing heat transfer performance of photovoltaic thermal systems. Renew. Energy 2019, 132, 284–295. [Google Scholar] [CrossRef]

- Sakellariou, E.; Axaopoulos, P. Simulation and experimental performance analysis of a modified PV panel to a PVT collector. Sol. Energy 2017, 155, 715–726. [Google Scholar] [CrossRef]

- Bilbao, J.I.; Sproul, A.B. Detailed PVT-water model for transient analysis using RC networks. Sol. Energy 2015, 115, 680–693. [Google Scholar] [CrossRef]

- Grubišić-Čabo, F.; Nižetić, S.; Duje, C.; Ivo, M.K.; Agis, P. Experimental investigation of the passive cooled free-standing photovoltaic panel with fixed aluminum fins on the backside surface. J. Clean. Prod. 2018, 176, 119–129. [Google Scholar] [CrossRef]

- Grubišić-Čabo, F.; Nižetić, S.; Marinić, K.I.; Čoko, D. Further progress in the research of fin-based passive cooling technique for the free-standing silicon photovoltaic panels. Int. J. Energy Res. 2019, 43, 3475–3495. [Google Scholar] [CrossRef]

- Anand, V.P.; Khan, A.E.; Amuthan, V.; Pesala, B. Performance improvement of solar module system using flat plate reflectors. In Proceedings of the International Conference on Advanced Electrical Engineering (ICAEE), Vellore, India, 9–11 January 2014; pp. 1–4. [Google Scholar]

- Palaskar, V.N.; Deshmukh, S.P. Design and performance analysis of reflectors attached to commercial PV module. Int. J. Renew. Energy Res. 2014, 4, 240–245. [Google Scholar]

- Bahaidarah, H.M.; Tanweer; Gandhidasan, B.; Rehman, S. A combined optical, thermal and electrical performance study of a V-trough PV system experimental and analytical investigations. Energies 2015, 8, 2803–2827. [Google Scholar] [CrossRef]

- Naseer, K.K.; Ahmed, F.A.; Fadhil, M.E. Improve the performance of solar modules by reflectors. Sixth Sci. Conf. Renew. Energy Its Appl. 2018, 1032, 012031. [Google Scholar]

- Moon, K.K.; Khalid, O.A.; Liu, J.; Joon-Ho, C.; Wen, H. Optimal design strategy of a solar reflector combining photovoltaic panels to improve electricity output: A case study in Calgary, Canada. Sustainability 2021, 13, 6115. [Google Scholar] [CrossRef]

- Jin, S.; Choi, B.G.; Choi, J.H.; Kim, S.R.; Chun, R.T.; Yun-Su, K. New curved reflectors for significantly enhanced solar power generation in four seasons. Energies 2019, 12, 4602. [Google Scholar] [CrossRef]

- Amanlou, Y.; Hashjin, T.T.; Ghobadian, B.; Najafi, G. Air cooling low concentrated photovoltaic/thermal (LCPV/T) solar collector to approach uniform temperature distribution on the PV plate. Appl. Therm. Eng. 2018, 141, 413–421. [Google Scholar] [CrossRef]

- Monika, A.; Priyank, C.; Amartya, C. Performance analysis of photovoltaic module with reflector: Optimizing orientation with different tilt scenarios. Renew. Energy 2022, 186, 10–25. [Google Scholar]

- Wang, G.; Ge, Z.; Lin, J. Design and performance analysis of a novel solar photovoltaic/thermal system using compact linear Fresnel reflector and nanofluids beam splitting device. Case Stud. Therm. Eng. 2022, 35, 102167. [Google Scholar] [CrossRef]

- Baccoli, R.; Kumar, A.; Frattolillo, A.; Mastino, C.; Ghiani, E.; Gatto, G. Enhancing energy production in a PV collector—Reflector system supervised by an optimization model: Experimental analysis and validation. Energy Convers. Manag. 2021, 229, 113774. [Google Scholar] [CrossRef]

- Kumar, S.; Agyekum, E.B.; Kumar, A.; Velkin, V.I. Performance evaluation with low-cost aluminum reflectors and phase change material integrated to solar PV modules using natural air convection: An experimental investigation. Energy 2023, 266, 126415. [Google Scholar]

- Almadhhachi, M.; Seres, I.; Farkas, I. Electrical power harvesting enhancement of PV module by a novel hemispherical configuration. Int. J. Thermofluids 2023, 20, 100460. [Google Scholar] [CrossRef]

- Michael, L. Durability and climate change: Changing climatic loads as may affect the durability of building materials, components and assemblies. In Proceedings of the CIB/NRC Symposium, Ottawa, ON, Canada, 21 September 2018. [Google Scholar]

- Sultan, S.; Abdullah, Z.; Tso, C.; Abllah, N.; Zakaria, N.; Raheem, K.; Sobayel, K. An economic feasibility assessment of implementing photovoltaic module reflectors under Malaysian meteorological conditions. Sci. Rep. 2024, 14, 3349. [Google Scholar] [CrossRef]

- Sakhr, M.; Tso, C.; Ervina, E.; Abdullah, M. A cost effective and economic method for assessing the performance of photovoltaic module enhancing techniques: Analytical and experimental study. Sol. Energy 2023, 254, 27–41. [Google Scholar]

| Reference | PV Enhancer Description | Study Method | Absolute PV Efficiency with Enhancer (%) | Additional Insights |

|---|---|---|---|---|

| [6] | The operational performance of a commercial PVT system was assessed over a full day. | Experimental | 18.20% * | Active cooling integration. |

| [7] | A refrigerant pump was utilized for forced circulation cooling of the PVT system. | Experimental | 16.00% * | Feasibility demonstrated; COP ~3.1. |

| [8] | The electrical efficiency of a series-connected PVT water collector was analyzed. | Numerical analysis and experiment | 13.50%* | Validated theoretical model. |

| [9] | A copper fin integrated with a pulsating heat pipe (PHP) was simulated to compare PHP efficiency against a solid copper structure. | Numerical | 12.80% * | Enhanced heat dissipation. |

| [10,11] | A novel PVT system design was proposed. | Numerical analysis and experiment | 12.69% * | Tested under Malaysian climate. |

| [12] | An aluminum-based collector was introduced to improve heat transfer efficiency. | Numerical analysis and experiment | 12.25% * | Rectangular tube absorber design. |

| [13,14] | A new PVT system design was developed and assessed theoretically. | Numerical | 12.13% * | Used aluminum for better conduction. |

| [15] | A thermal collector was designed and evaluated using a mathematical model. | Numerical | 11.90% * | Used for dynamic condition simulations. |

| [16] | A modified PVT collector was constructed and installed alongside a PV module. | Numerical analysis and experiment | 10.72% * | Better airflow and temperature reduction. |

| [17] | A detailed transient model for PVT–water collectors was introduced. | Numerical analysis and experiment | 9.80% * | Increased incident irradiance. |

| [18] | Experimental studies were carried out to analyze the efficiency of PVT-PCM. | Experiment | 8.16% * | Boosted power output. |

| [18] | Experiments were performed to assess PVT system efficiency. | Experimental | 6.98% * | Enhanced optical and thermal performance. |

| [19] | Aluminum fins were affixed to the PV module’s backside using thermally conductive epoxy glue. | Experimental | 2% ** increase | Simple reflectors improved efficiency. |

| [20] | The effect of reflector parameters on PV efficiency was analyzed through experimental testing. | Experimental | 60% ** increment | Combined cooling and reflection. |

| [21] | A PV system with an aluminum sheet reflector was examined using both numerical and experimental approaches. | Numerical analysis and experiment | 15% ** increment | Improved annual energy yield. |

| [22] | A predictive model was developed to estimate the output power of a V-trough concentrator. | Numerical analysis | 31.20% ** increment | Good performance in all seasons. |

| [23] | Outdoor experimental evaluation was conducted on a PV system integrated with a V-trough concentrator. | Experimental | 48% ** increment | Uniform PV temperature. |

| [24] | An analytical study assessed the performance of a PV system using an aluminum sheet as a reflector. | Numerical analysis | 19% ** increment | Higher thermal/electrical output. |

| [25] | A newly designed curved reflector for PV applications was proposed and examined. | Numerical analysis and experiment | 61% ** increment | Systematic energy enhancement. |

| [26] | A PV system with a flat reflector and cooling system was analyzed through theoretical and experimental studies. | Numerical analysis and experiment | 36% ** increment | Stable module temperature. |

| [27] | A method for enhancing PV efficiency using a commercial flat stainless-steel reflector was identified. | Experimental | 34.16% ** increment | Improved solar capture. |

| [28] | Performance evaluation of an innovative PVT system utilizing a compact linear Fresnel reflector and nanofluid-based beam splitting device was conducted. | Numerical analysis | 34.16% ** increment | Cost-effective evaluation framework. |

| [29] | A flat booster bottom reflector integrated with a collector was introduced and assessed. | Numerical analysis and experiment | Up to 17.8% ** increment | Integrated design enhanced PV-T performance. |

| [30] | A cost-effective aluminum reflector combined with phase change material and natural air convection was studied for PV performance enhancement. | Numerical analysis and experiment | 18.16% ** increment | Improved lower-side irradiance. |

| [31] | A novel hemispherical curved PV design was developed and tested. | Experimental | 19% * | Passive thermal regulation. |

| [32] | The impact of a double mirror reflector on PV efficiency was studied. | Experimental | 58.3% ** increment | Substantial gain in output with mirrors. |

| PV Cooler Type | Lifespan of the PV, Year | Lifespan of the PV Cooler, Year | Output Power, W | |

|---|---|---|---|---|

| Type A | 15 | 7 | 12 | 0.466 |

| Type B | 15 | 15 | 5.60 | 1 |

| Type C | 15 | 23 * | 4 | 1 |

| Method. | , Year | , Year | , W | , W | , W | Value | Value in % |

|---|---|---|---|---|---|---|---|

| (existing study from Ref. [1]) | 10 | 25 | * N/A | N/A | N/A | 0.40 | 40 |

(current study) | 10 | 25 | 16.16 | 110.86 | 525 | 0.22 | 22 |

| Reflector Type | , Year | , Year | , W | , W | , W | in % | |

|---|---|---|---|---|---|---|---|

| A single reflector | 10 | 25 | 0.205 | 0.374 | 1.25 | 0.36 | 36 |

| A double reflector | 10 | 25 | 0.218 | 0.374 | 1.25 | 0.37 | 37 |

| PV Cooler Type | , Year | , Year | , W | , W | , W | in % | |

|---|---|---|---|---|---|---|---|

| Type A | 7 | 15 | 12 | 100 | 120 | 0.88 | 88 |

| Type B | 15 | 15 | 5.60 | 100 | 120 | 0.88 | 88 |

| Type C | 23 * | 15 | 4 | 100 | 120 | 0.87 | 87 |

| PV Cooler Type | , Year | , Year | , W | , W | , W | in % | |

|---|---|---|---|---|---|---|---|

| Type A | 5 | 15 | 12 | 100 | 120 | 0.87 | 87 |

| Type B | 6 | 15 | 5.60 | 100 | 120 | 0.85 | 85 |

| Type C | 15 | 15 | 4 | 100 | 120 | 0.87 | 87 |

| PV Cooler Type | , Year | , Year | , W | , W | , W | in % | |

|---|---|---|---|---|---|---|---|

| Type A | 7 | 25 | 12 | 100 | 120 | 0.861 | 86.1 |

| Type B | 15 | 25 | 5.60 | 100 | 120 | 0.861 | 86.1 |

| Type C | 23 | 25 | 4 | 100 | 120 | 0.864 | 86.4 |

| PV Cooler Type | , Year | , Year | , W | , W | , W | in % | |

|---|---|---|---|---|---|---|---|

| Type A | 7 * | 5 | 12 | 100 | 120 | 0.93 | 93 |

| Type B | 15 * | 5 | 5.60 | 100 | 120 | 0.88 | 88 |

| Type C | 23 * | 5 | 4 | 100 | 120 | 0.87 | 87 |

| PV Cooler Type | , Year | , Year | , W | , W | , W | in % | |

|---|---|---|---|---|---|---|---|

| Type A | 7 | 15 | 10 | 100 | 120 | 0.87 | 87 |

| Type B | 15 | 15 | 15 | 100 | 120 | 0.96 | 96 |

| Type C | 23 * | 15 | 20 | 100 | 120 | 1.00 | 100 |

| PV Cooler Type | , Year | , Year | , W | , W | , W | in % | |

|---|---|---|---|---|---|---|---|

| Type A | 7 | 15 | 3 | 100 | 120 | 0.85 | 85 |

| Type B | 15 | 15 | 6 | 100 | 120 | 0.88 | 88 |

| Type C | 23 * | 15 | 10 | 100 | 120 | 0.92 | 92 |

| PV Cooler Type | , Year | , Year | , W | , W | , W | in % | |

|---|---|---|---|---|---|---|---|

| Type | 7 | 15 | 12 | 70 | 120 | 0.63 | 63 |

| Type B | 15 | 15 | 5.60 | 70 | 120 | 0.63 | 63 |

| Type C | 23 * | 15 | 4 | 70 | 120 | 0.62 | 62 |

| PV Cooler Type | , Year | , Year | , W | , W | , W | in % | |

|---|---|---|---|---|---|---|---|

| Type A | 7 | 15 | 12 | 80 | 120 | 0.71 | 71 |

| Type B | 15 | 15 | 5.60 | 80 | 120 | 0.71 | 71 |

| Type C | 23 * | 15 | 4 | 80 | 120 | 0.70 | 70 |

| PV Cooler Type | , Year | , Year | , W | , W | , W | in % | |

|---|---|---|---|---|---|---|---|

| Type A | 7 | 15 | 12 | 100 | 150 | 0.70 | 70 |

| Type B | 15 | 15 | 5.60 | 100 | 150 | 0.70 | 70 |

| Type C | 23 * | 15 | 4 | 100 | 150 | 0.69 | 69 |

| PV Cooler Type | , year | , year | , W | , W | , W | in % | |

|---|---|---|---|---|---|---|---|

| Type A | 7 | 15 | 12 | 100 | 130 | 0.81 | 81 |

| Type B | 15 | 15 | 5.60 | 100 | 130 | 0.81 | 81 |

| Type C | 23 * | 15 | 4 | 100 | 130 | 0.80 | 80 |

| Method | Equation | Parameters | Is the Power Included in the Analysis? |

|---|---|---|---|

| Existing method [1] | and | No | |

| New method | , , , and | Yes |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sultan, S.M.; Tso, C.P.; Abdullah, M.Z.; Sopian, K. A New Method for Assessing the Performance of Photovoltaic Module Enhancing Techniques Based on the Lifespan and Power Effectiveness Factor. Processes 2025, 13, 1311. https://doi.org/10.3390/pr13051311

Sultan SM, Tso CP, Abdullah MZ, Sopian K. A New Method for Assessing the Performance of Photovoltaic Module Enhancing Techniques Based on the Lifespan and Power Effectiveness Factor. Processes. 2025; 13(5):1311. https://doi.org/10.3390/pr13051311

Chicago/Turabian StyleSultan, Sakhr M., C. P. Tso, M. Z. Abdullah, and K. Sopian. 2025. "A New Method for Assessing the Performance of Photovoltaic Module Enhancing Techniques Based on the Lifespan and Power Effectiveness Factor" Processes 13, no. 5: 1311. https://doi.org/10.3390/pr13051311

APA StyleSultan, S. M., Tso, C. P., Abdullah, M. Z., & Sopian, K. (2025). A New Method for Assessing the Performance of Photovoltaic Module Enhancing Techniques Based on the Lifespan and Power Effectiveness Factor. Processes, 13(5), 1311. https://doi.org/10.3390/pr13051311