Analysis of the Influence of Different Plasticizing Systems in a Single-Screw Extruder on the Extrusion-Cooking Process and on Selected Physical Properties of Snack Pellets Enriched with Selected Oilseed Pomace

Abstract

1. Introduction

2. Materials and Methods

2.1. Extrudates Formulation and Production Using Extrusion-Cooking Process

2.2. Efficiency of the Extrusion-Cooking Process

2.3. Energy Consumption of the Extrusion-Cooking Process

2.4. Bulk Density of Snack Pellets

2.5. Water Absorption Index (WAI)

2.6. Water Solubility Index (WSI)

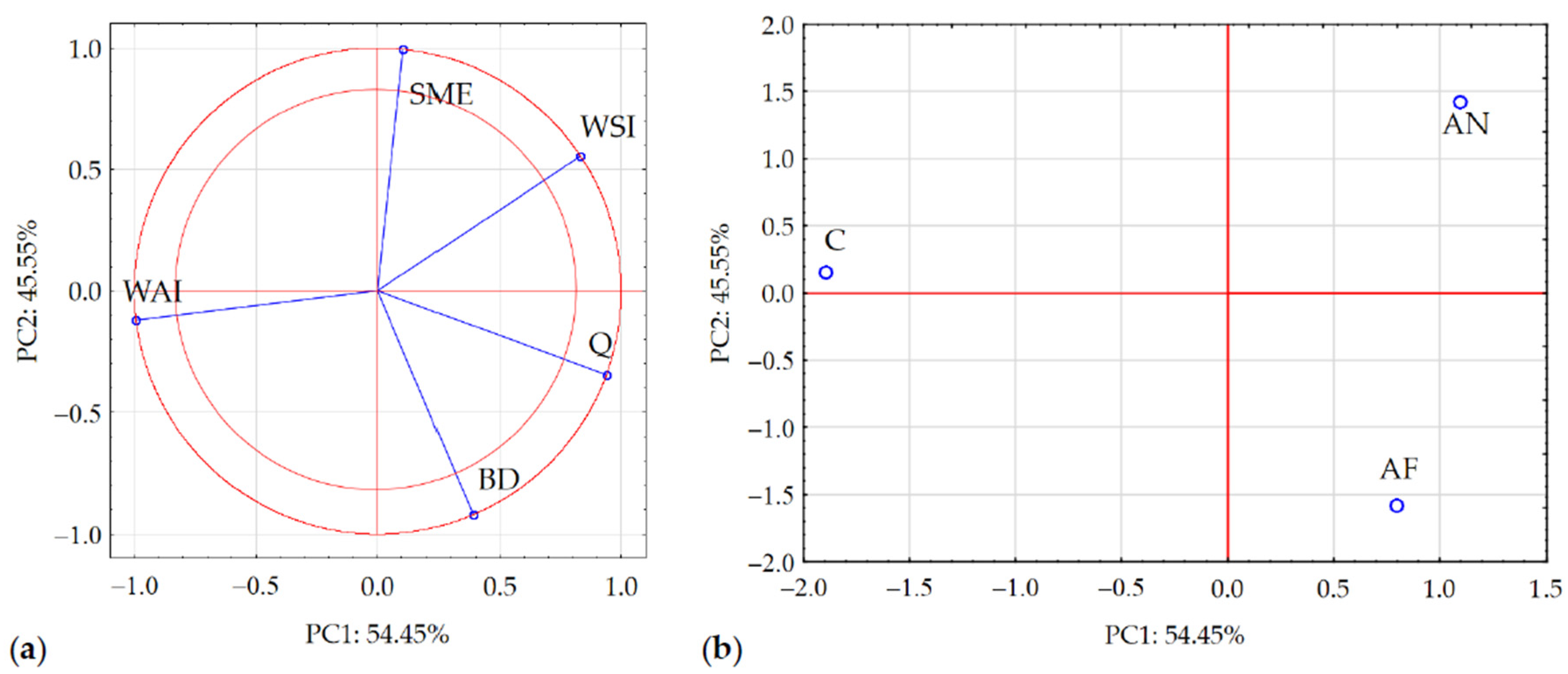

2.7. Principal Component Analysis (PCA)

3. Results and Discussion

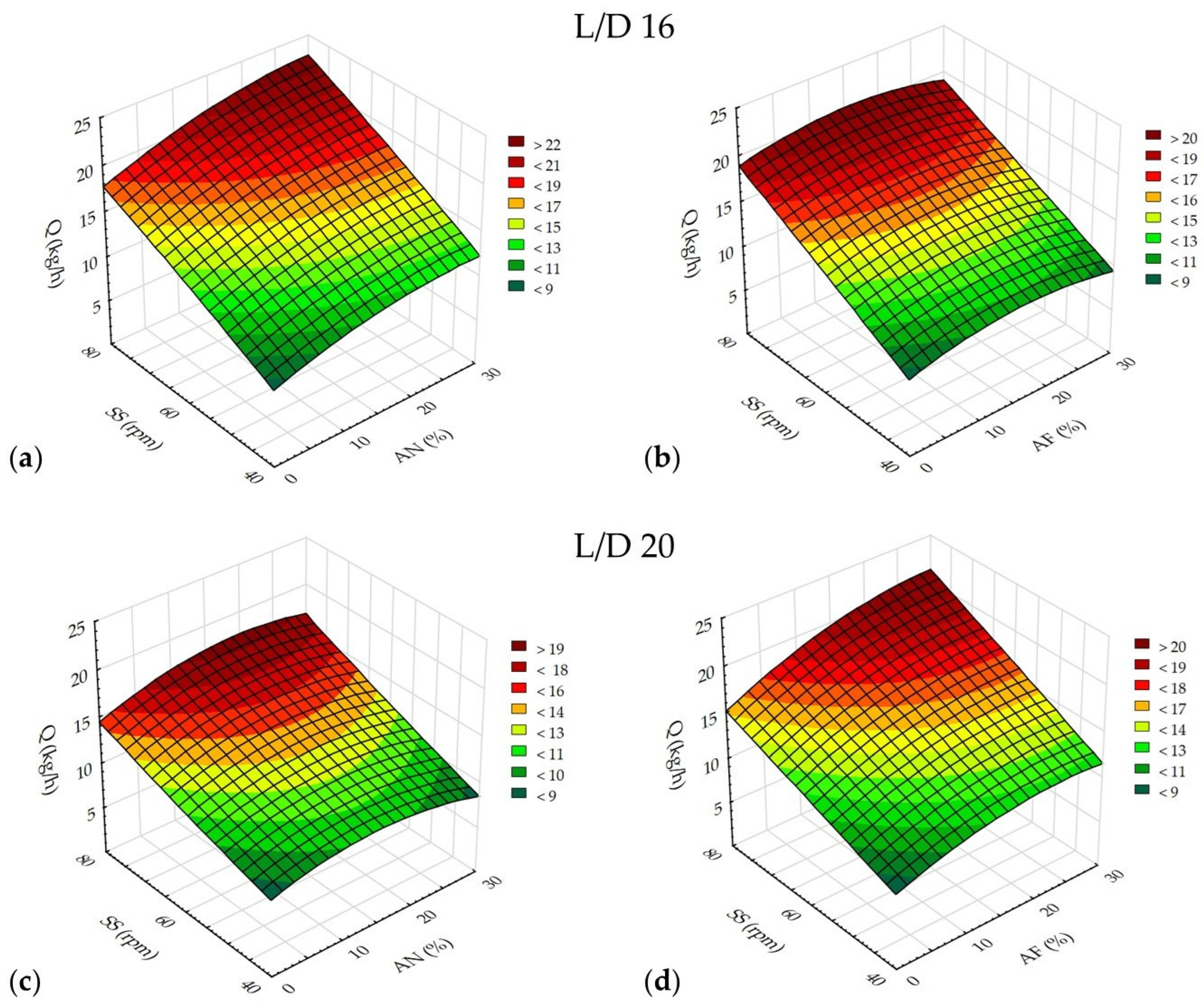

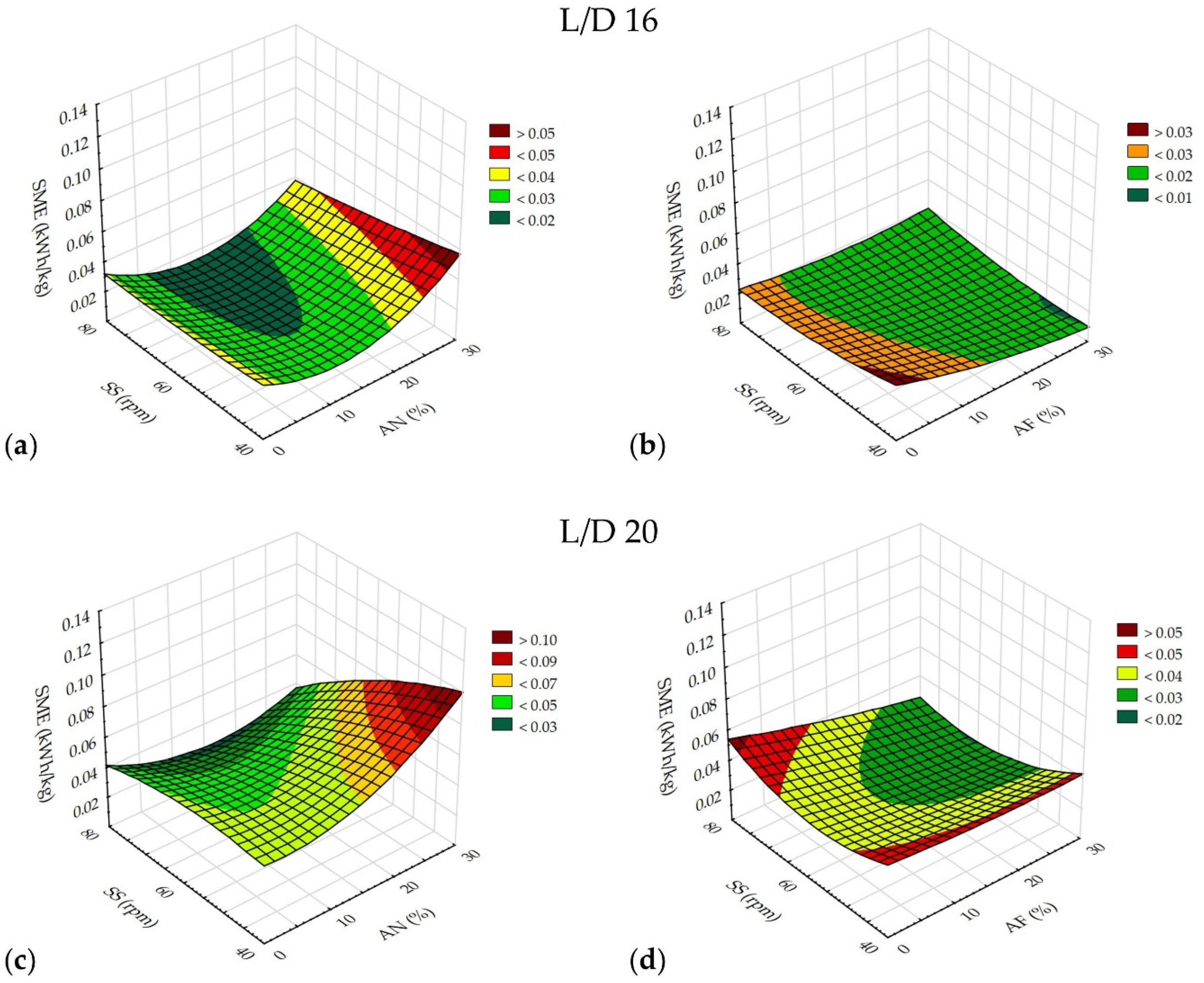

3.1. Results of Extrusion-Cooking Efficiency and Energy Consumption

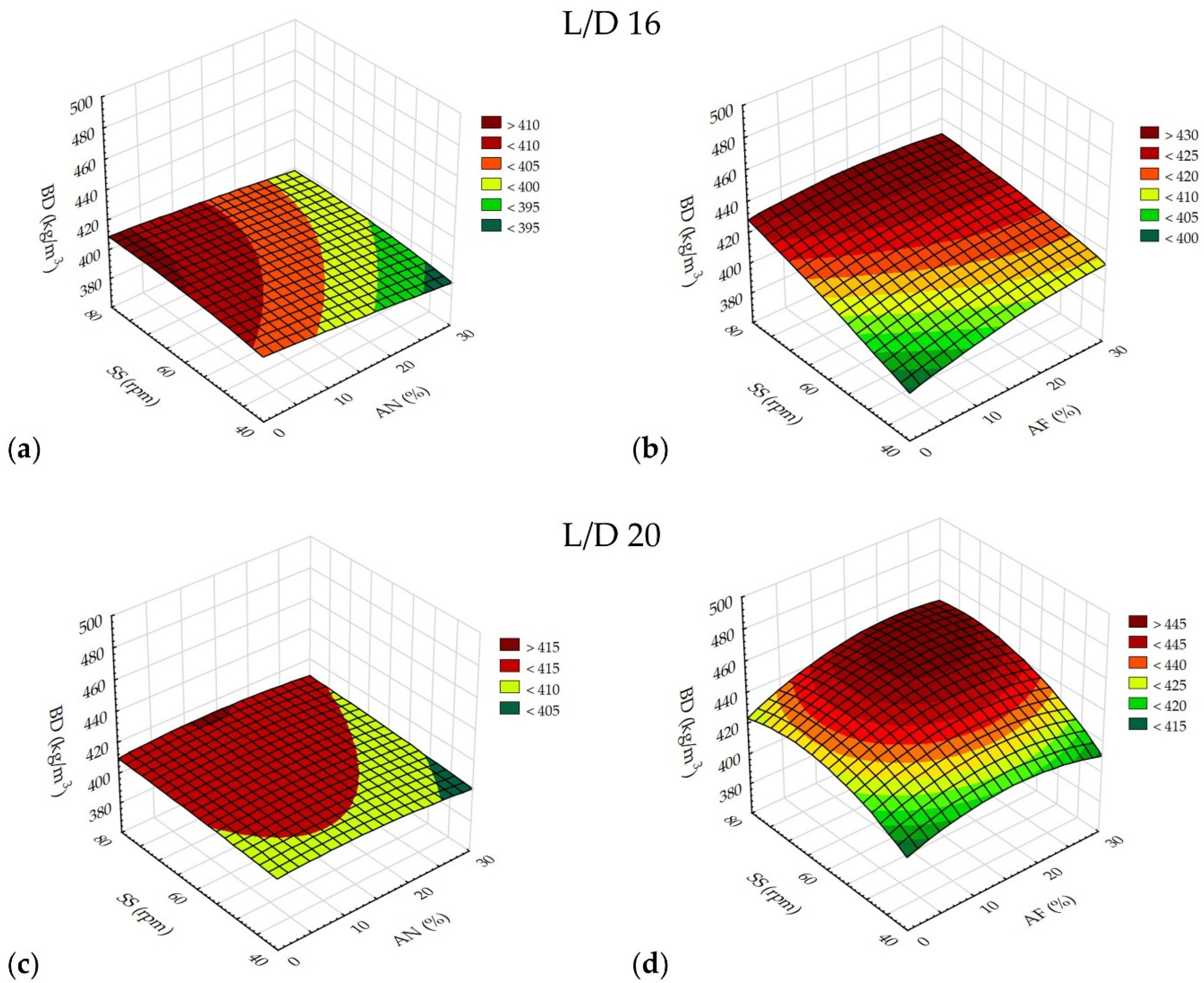

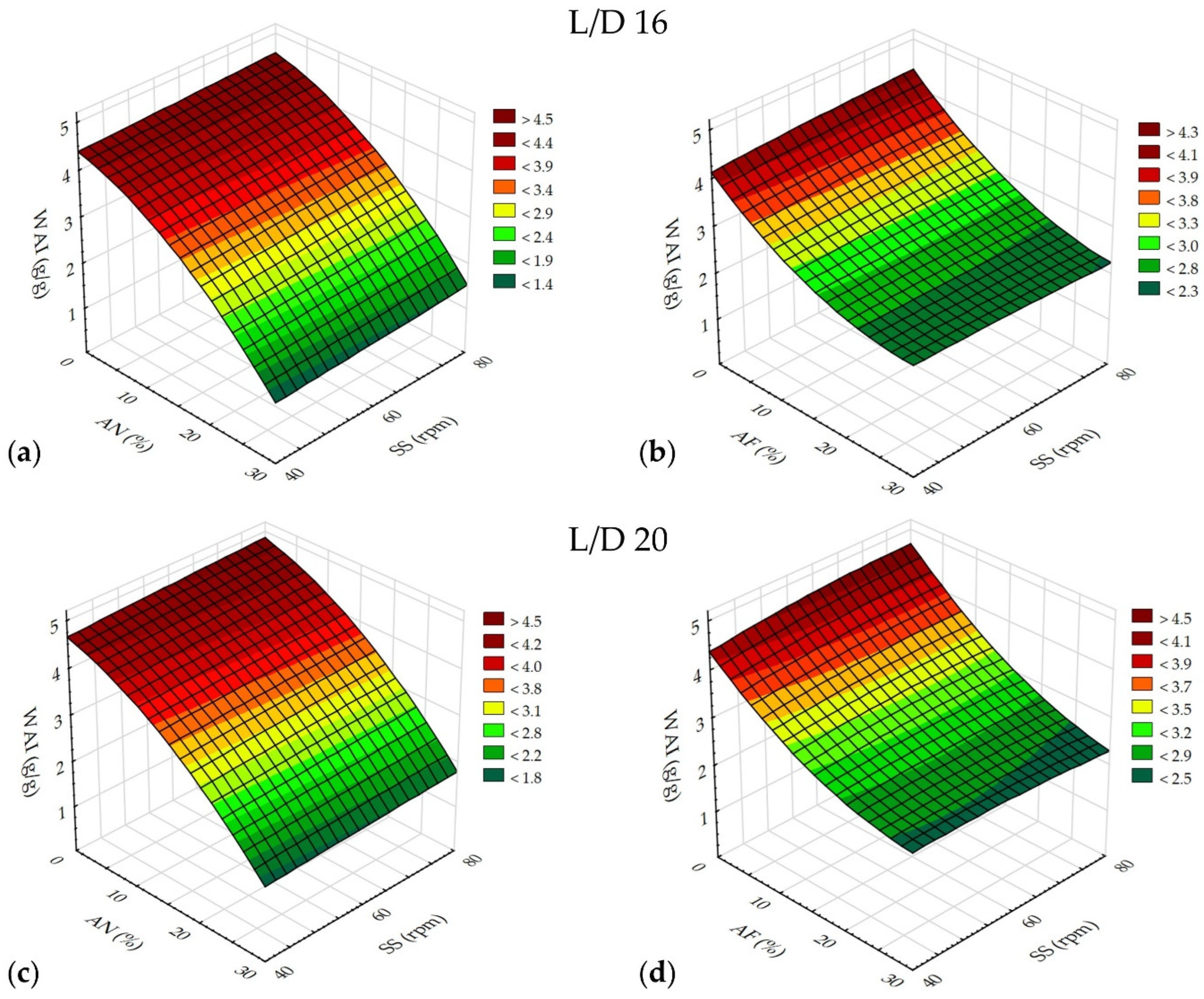

3.2. Results of the Analysis of Selected Physical Properties

4. Conclusions

- An increase in screw speed to 60 and 80 rpm led to a higher extrusion-cooking efficiency for both L/D 16 and L/D 20 configurations, particularly at higher pomace concentrations. However, L/D 16 exhibited rising efficiency compared to L/D 20, especially at a higher screw speed (60 and 80 rpm). At higher pomace concentrations, a decline in efficiency was observed, likely due to flow difficulties caused by the increased amount of added material. Therefore, the extrusion-cooking process was more efficient at lower pomace concentrations and higher screw speeds. These variations may result from the interaction between fiber-rich pomace particles and the starch structure, which affects the rheological behavior and flow resistance during processing.

- SME values increased with a higher screw speed at 60 and 80 rpm, indicating greater energy consumption at higher rotational speeds, particularly at higher pomace concentrations. For L/D 16, SME was generally lower compared to L/D 20, especially at higher speed, suggesting that L/D 16 may be more energy-efficient in certain conditions. The addition of nigella seed pomace and flaxseed pomace contributed to higher SME values, particularly at lower screw speeds, highlighting differences in energy efficiency depending on the type of pomace used. At higher pomace concentrations (20% and 30%), SME showed greater variability, with a tendency to increase at 40 rpm and decrease at 80 rpm. This suggests that higher pomace levels alter the energy demand of the extrusion-cooking process, potentially due to changes in material flow and processing resistance. This can be explained by differences in the composition of the pomace, especially fat and fiber content, which influence friction, torque, and energy transfer during extrusion-cooking process.

- Bulk density analysis showed that the control sample maintained stable values with a slight increase as screw speed became larger. In the case of nigella seed pomace, the changes were irregular—at 10% concentration, bulk density increased, while at 20% a decrease was observed, followed by another increase at 30%. On the other hand, flaxseed pomace demonstrated a more consistent trend, with bulk density gradually increasing along with higher concentrations and screw speed, indicating better compressibility during the extrusion-cooking process. A comparison to different plasticizing system revealed higher bulk density values for L/D 20, which suggests improved material compression in the longer screw system. Irregular changes in bulk density, especially for nigella seed pomace, may stem from variable hydration behavior and structural interference caused by the heterogeneous nature of the pomace components.

- The analysis of water absorption capacity (water absorption index) showed that the control sample exhibited a gradual increase in WAI with higher screw speeds, likely due to more intense starch gelatinization caused by the higher temperatures generated during extrusion. At a low concentration (10%), the addition of nigella seed pomace led to an increase in WAI, while at higher concentrations (20% and 30%), a significant decrease was observed. This suggests that a greater amount of this additive limits water absorption capacity. For flaxseed pomace, WAI values decreased progressively with increasing concentrations, which may be attributed to the greater presence of fats and fiber, reducing water retention. A comparison between L/D 16 and L/D 20 revealed higher WAI values for L/D 20, indicating that a longer screw zone enhances the moisture absorption capacity of the samples, possibly due to the extended contact time with water during extrusion-cooking process. The decreasing trend in WAI at higher pomace levels may be attributed to the presence of non-starch polysaccharides and lipids, which can limit water penetration and reduce starch gelatinization.

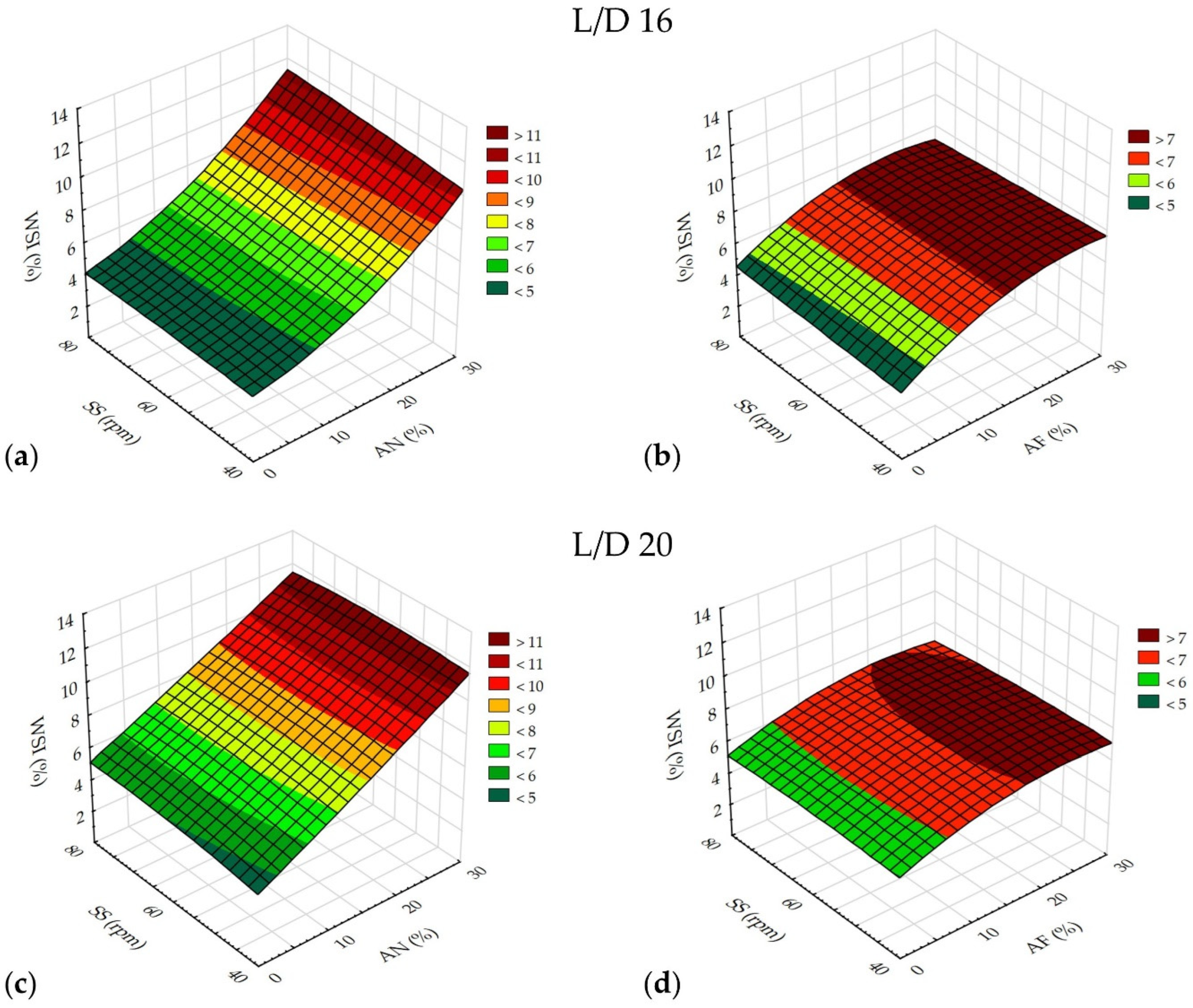

- The analysis of the water solubility index showed that the control sample had moderate values, with a minor increase as screw speed increased. For nigella seed pomace, a significant rise in WSI was observed at higher concentrations (20% and 30%), indicating more intense starch degradation and an increase in water-soluble components. For flaxseed pomace, WSI values increased at 10% and 20% concentrations, but at 30% a decline was noted. This may be due to the higher presence of insoluble components, such as fiber and fats, which reduce solubility. A comparison of WSI values between L/D 16 and L/D 20 showed that WSI was generally higher for L/D 20, suggesting that a longer screw zone promoted more intense starch degradation, leading to an increased number of water-soluble components. The observed fluctuations in WSI likely reflect complex interactions between starch degradation, lipid binding, and insoluble fiber content, which together influence the solubilization of extrudate components.

- Based on the findings, it can be recommended that the L/D 16 configuration, in combination with a higher screw speed (60–80 rpm) and moderate pomace concentrations (10–20%), provides a favorable balance between energy consumption and product quality. For applications requiring higher water absorption (e.g., instant foods), L/D 20 may offer advantages due to extended processing time. Additionally, flaxseed pomace demonstrated more predictable behavior than nigella pomace, making it a potentially more reliable additive in extrusion applications.

- Future research could investigate the effect of varying moisture content on the processing behavior of blends containing oilseed pomace, as moisture is a critical factor influencing extrusion-cooking dynamics and final product quality. Additionally, sensory acceptability of snacks obtained from the expansion of the produced extruded pellets should be evaluated to assess consumer preferences. This analysis would provide valuable insights into the commercial potential and market readiness of these products. These directions would help bridge the gap between technological development and real-world application.

- The results of this study highlight the potential for utilizing oilseed pomace as a functional ingredient in the production of sustainable snack pellets. The incorporation of by-products such as flaxseed and nigella pomace into starch-based mixtures offers opportunities to enhance the nutritional profile of extruded products while supporting waste valorization strategies. Tested process configurations demonstrate that, with proper optimization of screw speed, L/D ratio and pomace concentration, it is possible to balance energy efficiency with desirable product attributes. These findings may serve as a foundation for industrial-scale implementation, particularly in the development of high-fiber, clean-label, or upcycled snack products that align with current consumer and sustainability trends.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Varzakas, T.; Smaoui, S. Global Food Security and Sustainability Issues: The Road to 2030 from Nutrition and Sustainable Healthy Diets to Food Systems Change. Foods 2024, 13, 306. [Google Scholar] [CrossRef] [PubMed]

- Cole, M.B.; Augustin, M.A.; Robertson, M.J.; Manners, J.M. The science of food security. npj Sci. Food 2018, 2, 14. [Google Scholar] [CrossRef]

- Rațu, R.N.; Veleșcu, I.D.; Stoica, F.; Usturoi, A.; Arsenoaia, V.N.; Crivei, I.C.; Postolache, A.N.; Lipșa, F.D.; Filipov, F.; Florea, A.M.; et al. Application of Agri-Food By-Products in the Food Industry. Agriculture 2023, 13, 1559. [Google Scholar] [CrossRef]

- Bhatia, L.; Jha, H.; Sarkar, T.; Sarangi, P.K. Food Waste Utilization for Reducing Carbon Footprints towards Sustainable and Cleaner Environment: A Review. Int. J. Environ. Res. Public Health 2023, 20, 2318. [Google Scholar] [CrossRef] [PubMed]

- Mangiapelo, L.; Pinna, N.; Blasi, F.; Ianni, F.; Verducci, G.; Cossignani, L. Harnessing Grape Pomace, a Multifunctional By-Product from the Wine Industry for High-Value Salad Dressings. Molecules 2025, 30, 693. [Google Scholar] [CrossRef] [PubMed]

- Aït-Kaddour, A.; Hassoun, A.; Tarchi, I.; Loudiyi, M.; Boukria, O.; Cahyana, Y.; Ozogul, F.; Khwaldia, K. Transforming plant-based waste and by-products into valuable products using various “Food Industry 4.0” enabling technologies: A literature review. Sci. Total Environ. 2024, 955, 176872. [Google Scholar] [CrossRef]

- Pathania, S.; Kaur, N. Utilization of fruits and vegetable by-products for isolation of dietary fibres and its potential application as functional ingredients. Bioact. Carbohydr. Diet. Fibre 2022, 27, 100295. [Google Scholar] [CrossRef]

- Comunian, T.A.; Silva, M.P.; Souza, C.J.F. The Use of Food By-Products as a Novel for Functional Foods: Their Use as Ingredients and for the Encapsulation Process. Trends Food Sci. Technol. 2021, 108, 269–280. [Google Scholar] [CrossRef]

- Berenguer, C.V.; Andrade, C.; Pereira, J.A.M.; Perestrelo, R.; Câmara, J.S. Current Challenges in the Sustainable Valorisation of Agri-Food Wastes: A Review. Processes 2023, 11, 20. [Google Scholar] [CrossRef]

- Mateus, A.R.S.; Pena, A.; Sanches-Silva, A. Unveiling the potential of bioactive compounds in vegetable and fruit by-products: Exploring phytochemical properties, health benefits, and industrial. Curr. Opin. Green Sustain. Chem. 2024, 48, 100938. [Google Scholar] [CrossRef]

- Râpă, M.; Darie-Niță, R.N.; Coman, G. Valorization of Fruit and Vegetable Waste into Sustainable and Value-Added Materials. Waste 2024, 2, 258–278. [Google Scholar] [CrossRef]

- Ueda, J.M.; Pedrosa, M.C.; Heleno, S.A.; Carocho, M.; Ferreira, I.C.F.R.; Barros, L. Food Additives from Fruit and Vegetable By-Products and Bio-Residues: A Comprehensive Review Focused on Sustainability. Sustainability 2022, 14, 5212. [Google Scholar] [CrossRef]

- García-Lomillo, J.; González-SanJosé, M.L. Applications of Wine Pomace in the Food Industry: Approaches and Functions. Compr. Rev. Food Sci. Food Saf. 2017, 16, 3–22. [Google Scholar] [CrossRef] [PubMed]

- Cassani, L.; Gomez-Zavaglia, A. Sustainable Food Systems in Fruits and Vegetables Food Supply Chains. Front. Nutr. 2022, 9, 829061. [Google Scholar] [CrossRef] [PubMed]

- Singh, J.P.; Kaur, A.; Singh, B.; Singh, N.; Singh, B. Physicochemical evaluation of corn extrudates containing varying buckwheat flour levels prepared at various extrusion temperatures. J. Food Sci. Technol. 2019, 56, 2205–2212. [Google Scholar] [CrossRef]

- Mironeasa, S.; Coţovanu, I.; Mironeasa, C.; Ungureanu-Iuga, M. A Review of the Changes Produced by Extrusion Cooking on the Bioactive Compounds from Vegetal Sources. Antioxidants 2023, 12, 1453. [Google Scholar] [CrossRef]

- Offiah, V.; Kontogiorgos, V.; Falade, K.O. Extrusion processing of raw food materials and by-products: A review. Crit. Rev. Food Sci. Nutr. 2019, 59, 2979–2998. [Google Scholar] [CrossRef]

- Ali, I.M.; Forsido, S.F.; Kuyu, C.G.; Ahmed, E.H.; Andersa, K.N.; Chane, K.T.; Regasa, T.K. Effects of extrusion process conditions on nutritional, anti-nutritional, physical, functional, and sensory properties of extruded snack: A review. Food Sci. Nutr. 2024, 12, 8755–8761. [Google Scholar] [CrossRef]

- Luo, S.; Chan, E.; Masatcioglu, M.T.; Erkinbaev, C.; Paliwal, J.; Koksel, F. Effects of extrusion conditions and nitrogen injection on physical, mechanical, and microstructural properties of red lentil puffed snacks. Food Bioprod. Process. 2020, 121, 143–153. [Google Scholar] [CrossRef]

- Pardhi, S.D.; Singh, B.; Nayik, G.A.; Dar, B.N. Evaluation of functional properties of extruded snacks developed from brown rice grits by using response surface methodology. J. Saudi Soc. Agric. Sci. 2019, 18, 7–16. [Google Scholar] [CrossRef]

- Raczkowska, E.; Serek, P. Health-promoting properties and the use of fruit pomace in the food industry—A Review. Nutrients 2024, 16, 2757. [Google Scholar] [CrossRef] [PubMed]

- Sergheeva, E.; Netreba, N. Oil crop pomace as a potential source of protein and dietary fiber. J. Eng. Sci. 2024, 31, 196–215. [Google Scholar] [CrossRef] [PubMed]

- Ruiz-Gutiérrez, M.G.; Amaya-Guerra, C.A.; Quintero-Ramos, A.; Pérez-Carrillo, E.; Ruiz-Anchondo, T.D.J.; Báez-González, J.G.; Meléndez-Pizarro, C.O. Effect of Extrusion Cooking on Bioactive Compounds in Encapsulated Red Cactus Pear Powder. Molecules 2015, 20, 8875–8892. [Google Scholar] [CrossRef]

- Borah, A.; Lata Mahanta, C.; Kalita, D. Optimization of process parameters for extrusion cooking of low amylose rice flour blended with seeded banana and carambola pomace for development of minerals and fiber rich breakfast cereal. J. Food Sci. Technol. 2016, 53, 221–232. [Google Scholar] [CrossRef]

- Kebede Ali, M.; Abera, S.; Neme Tolesa, G. Optimization of extrusion cooking process parameters to develop teff (Eragrostis (Zucc) Trotter)-based products: Physical properties, functional properties, and sensory quality. Cogent Food Agric. 2023, 9, 2279705. [Google Scholar] [CrossRef]

- Ek, P.; Ganjyal, G.M. Basics of extrusion processing. In Extrusion Cooking; Elsevier: Amsterdam, The Netherlands, 2020; pp. 1–28. [Google Scholar] [CrossRef]

- Dey, D.; Richter, J.K.; Ek, P.; Gu, B.-J.; Ganjyal, G.M. Utilization of Food Processing By-products in Extrusion Processing: A Review. Front. Sustain. Food Syst. 2021, 4, 2020. [Google Scholar] [CrossRef]

- Soja, J.; Combrzyński, M.; Oniszczuk, T.; Gancarz, M.; Oniszczuk, A. Extrusion-Cooking Aspects and Physical Characteristics of Snacks Pellets with Addition of Selected Plant Pomace. Appl. Sci. 2024, 14, 8754. [Google Scholar] [CrossRef]

- Matysiak, A.; Wójtowicz, A.; Oniszczuk, T. Process efficiency and energy consumption during the extrusion of potato and multigram formulations. Agric. Eng. 2018, 22, 49–57. [Google Scholar] [CrossRef]

- Kręcisz, M. Energy Consumption during Produciton of Corn Extrudates in Relation to the Process Parameters. Agric. Eng. 2016, 20, 125–131. [Google Scholar] [CrossRef]

- Wójtowicz, A.; Kolasa, A.; Mościcki, L. Influence of Buckwheat Addition on Physical Properties, Texture and Sensory Characteristics of Extruded Corn Snacks. Pol. J. Food Nutr. Sci. 2013, 63, 239–244. [Google Scholar] [CrossRef]

- Bouasla, A.; Wójtowicz, A.; Zidoune, M.N. Gluten-free precooked rice pasta enriched with legumes flours: Physical properties, texture, sensory attributes and microstructure. LWT-Food Sci. Technol. 2017, 75, 569–577. [Google Scholar] [CrossRef]

- Lewko, P.; Wójtowicz, A.; Różańska-Boczula, M. Effect of Extruder Configuration and Extrusion Cooking Processing Parameters on Selected Characteristics of Non-Starch Polysaccharide-Rich Wheat Flour as Hybrid Treatment with Xylanase Addition. Processes 2024, 12, 1159. [Google Scholar] [CrossRef]

- Lisiecka, K.; Wójtowicz, A. Possibility to Save Water and Energy by Application of Fresh Vegetables to Produce Supplemented Potato-Based Snack Pellets. Processes 2020, 8, 153. [Google Scholar] [CrossRef]

- Kantrong, H.; Charunuch, C.; Limsangouan, N.; Pengpinit, W. Influence of process parameters on physical properties and specific mechanical energy of healthy mushroom-rice snacks and optimization of extrusion process parameters using response surface methodology. J. Food Sci. Technol. 2018, 55, 3462–3472. [Google Scholar] [CrossRef]

- Soja, J.; Oniszczuk, T.; Vaskina, I.; Combrzyński, M.; Wójtowicz, A. Integration of Plant Pomace into Extruded Products: Analysis of Process Conditions, Post-Production Waste Properties and Biogas Potential. Energies 2024, 17, 6476. [Google Scholar] [CrossRef]

- Drożdż, W.; Boruczkowska, H.; Boruczkowski, T.; Tomaszewska-Ciosk, E.; Zdybel, E. Use of blackcurrant and chokeberry press residue in snack products. Pol. J. Chem. Technol. 2019, 21, 13–19. [Google Scholar] [CrossRef]

- Wójtowicz, A.; Combrzyński, M.; Biernacka, B.; Różyło, R.; Bąkowski, M.; Wojtunik-Kulesza, K.; Mołdoch, J.; Kowalska, I. Fresh Chokeberry (Aronia melanocarpa) Fruits as Valuable Additive in Extruded Snack Pellets: Selected Nutritional and Physiochemical Properties. Plants 2023, 12, 3276. [Google Scholar] [CrossRef]

- Lisiecka, K.; Wójtowicz, A. Effect of fresh beetroot application and processing conditions on some quality features of new type of potato-based snacks. LWT-Food Sci. Technol. 2021, 141, 110919. [Google Scholar] [CrossRef]

- Combrzyński, M.; Wójtowicz, A.; Biernacka, B.; Oniszczuk, T.; Mitrus, M.; Soja, J.; Różyło, R.; Wojtunik-Kulesza, K.; Kasprzak-Drozd, K.; Oniszczuk, A. Possibility of water saving in processing of snack pellets by the application of fresh lucerne sprouts: Selected aspects and nutritional characteristics. J. Ecol. Eng. 2023, 24, 130–142. [Google Scholar] [CrossRef]

- Chang, Y.H.; Ng, P.K.W. Effects of extrusion process variables on quality properties of wheat-ginseng extrudates. Int. J. Food Prop. 2011, 14, 914–925. [Google Scholar] [CrossRef]

| Raw Materials | Control Sample | 10% Pomace | 20% Pomace | 30% Pomace |

|---|---|---|---|---|

| Nigella seed, flaxseed pomace (%) | 0 | 10 | 20 | 30 |

| Potato starch (%) | 82 | 72 | 62 | 52 |

| Potato flakes (%) | 15 | 15 | 15 | 15 |

| Vegetable oil (%) | 1 | 1 | 1 | 1 |

| Sugar (%) | 1 | 1 | 1 | 1 |

| Salt (%) | 1 | 1 | 1 | 1 |

| Type of Plant Pomace | Content of the Additive [%] | Screw Speed [RPM] | Type of Plasticizion System [L/D] | Temperature of Section I [°C] | Temperature of Section II [°C] | Temperature of Section III [°C] | Temperature of Section IV [°C] | Temperature of Section V [°C] |

|---|---|---|---|---|---|---|---|---|

| Control sample | 0% | 40 | 16 | 31.40 ± 0.00 | 60.33 ± 0.67 | 75.63 ± 0.50 | N/A | 81.80 ± 1.91 |

| 20 | 30.50 ± 0.00 | 60.03 ± 0.15 | 64.90 ± 0.10 | 71.57 ± 0.06 | 72.67 ± 0.06 | |||

| Control sample | 0% | 60 | 16 | 31.80 ± 0.20 | 61.80 ± 0.26 | 77.77 ± 0.31 | N/A | 80.40 ± 0.20 |

| 20 | 30.70 ± 0.00 | 59.93 ± 0.25 | 64.90 ± 0.20 | 71.67 ± 0.06 | 72.97 ± 0.06 | |||

| Control sample | 0% | 80 | 16 | 32.37 ± 0.12 | 59.60 ± 1.01 | 76.93 ± 1.34 | N/A | 79.37 ± 0.71 |

| 20 | 30.97 ± 0.12 | 59.83 ± 0.55 | 64.90 ± 0.17 | 70.47 ± 0.31 | 69.67 ± 0.31 | |||

| Nigella seed pomace | 10% | 40 | 16 | 37.10 ± 0.36 | 60.00 ± 0.46 | 68.03 ± 1.33 | N/A | 70.17 ± 0.06 |

| 20 | 31.80 ± 0.10 | 31.67 ± 0.29 | 67.27 ± 0.15 | 71.57 ± 0.06 | 72.93 ± 0.12 | |||

| Nigella seed pomace | 10% | 60 | 16 | 35.03 ± 0.51 | 60.07 ± 1.08 | 69.77 ± 0.38 | N/A | 70.13 ± 0.06 |

| 20 | 31.50 ± 0.00 | 60.37 ± 1.69 | 66.57 ± 0.59 | 71.57 ± 0.15 | 72.67 ± 0.23 | |||

| Nigella seed pomace | 10% | 80 | 16 | 33.33 ± 0.23 | 61.73 ± 0.25 | 69.87 ± 0.29 | N/A | 71.70 ± 1.47 |

| 20 | 31.30 ± 0.00 | 58.73 ± 1.34 | 67.80 ± 0.75 | 70,60 ± 0.46 | 70.60 ± 1.05 | |||

| Nigella seed pomace | 20% | 40 | 16 | 38.27 ± 0.06 | 60.03 ± 0.06 | 68.53 ± 0.12 | N/A | 70.07 ± 0.06 |

| 20 | 32.13 ± 0.12 | 60.90 ± 1.21 | 65.30 ± 1.15 | 71.83 ± 0.06 | 72.90 ± 0.00 | |||

| Nigella seed pomace | 20% | 60 | 16 | 35.50 ± 0.00 | 60.00 ± 0.75 | 71.73 ± 0.12 | N/A | 74.40 ± 0.17 |

| 20 | 32.40 ± 0.00 | 59.47 ± 0.21 | 68.07 ± 0.06 | 75.73 ± 0.12 | 76.77 ± 0.06 | |||

| Nigella seed pomace | 20% | 80 | 16 | 35.03 ± 0.06 | 60.80 ± 1.10 | 72.67 ± 0.40 | N/A | 74.47 ± 0.15 |

| 20 | 32.40 ± 0.00 | 59.47 ± 0.21 | 68.07 ± 0.06 | 75.73 ± 0.12 | 76.77 ± 0.06 | |||

| Nigella seed pomace | 30% | 40 | 16 | 34.07 ± 0.06 | 60.20 ± 0.10 | 70.07 ± 0.38 | N/A | 78.70 ± 0.10 |

| 20 | 32.70 ± 0.26 | 69.00 ± 1.39 | 74.30 ± 1.08 | 75.57 ± 0.32 | 76.33 ± 0.23 | |||

| Nigella seed pomace | 30% | 60 | 16 | 34.20 ± 0.00 | 60.20 ± 0.00 | 70.90 ± 0.17 | N/A | 74.33 ± 0.49 |

| 20 | 32.20 ± 0.00 | 61.33 ± 1.72 | 69.37 ± 1.93 | 75.10 ± 0.10 | 76.07 ± 0.15 | |||

| Nigella seed pomace | 30% | 80 | 16 | 34.53 ± 0.15 | 59.63 ± 0.06 | 69.27 ± 3.06 | N/A | 74.43 ± 0.15 |

| 20 | 32.20 ± 0.00 | 60.03 ± 0.12 | 67.97 ± 0.15 | 75.00 ± 0.00 | 75.73 ± 0.06 | |||

| Flaxseed pomace | 10% | 40 | 16 | 36.57 ± 0.06 | 60.20 ± 0.70 | 67.97 ± 0.25 | N/A | 73.30 ± 0.10 |

| 20 | 33.47 ± 0.06 | 69.33 ± 0.40 | 76.50 ± 0.10 | 75.80 ± 0.00 | 77.43 ± 0.12 | |||

| Flaxseed pomace | 10% | 60 | 16 | 36.27 ± 0.06 | 59.50 ± 1.08 | 68.07 ± 0.29 | N/A | 73.27 ± 0.12 |

| 20 | 33.53 ± 0.06 | 69.67 ± 0.23 | 75.67 ± 0.06 | 75.93 ± 0.06 | 77.37 ± 0.06 | |||

| Flaxseed pomace | 10% | 80 | 16 | 35.60 ± 0.10 | 59.77 ± 0.67 | 68.37 ± 0.21 | N/A | 73.43 ± 0.15 |

| 20 | 33.40 ± 0.00 | 69.70 ± 0.66 | 76.50 ± 0.26 | 76.23 ± 0.06 | 77.63 ± 0.06 | |||

| Flaxseed pomace | 20% | 40 | 16 | 36.70 ± 0.00 | 60.73 ± 0.32 | 67.80 ± 0.36 | N/A | 73.50 ± 0.10 |

| 20 | 33.57 ± 0.06 | 71.00 ± 1.35 | 75.13 ± 0.12 | 76.03 ± 0.06 | 77.30 ± 0.00 | |||

| Flaxseed pomace | 20% | 60 | 16 | 36.90 ± 0.00 | 60.03 ± 0.15 | 68.17 ± 0.21 | N/A | 73.63 ± 0.06 |

| 20 | 33.43 ± 0.06 | 69.43 ± 1.05 | 76.73 ± 0.46 | 76.10 ± 0.00 | 77.57 ± 0.06 | |||

| Flaxseed pomace | 20% | 80 | 16 | 37.33 ± 0.06 | 59.77 ± 0.31 | 68.60 ± 0.10 | N/A | 73.70 ± 0.00 |

| 20 | 33.40 ± 0.00 | 70.80 ± 0.60 | 76.37 ± 0.58 | 76.13 ± 0.06 | 77.70 ± 0.00 | |||

| Flaxseed pomace | 30% | 40 | 16 | 39.80 ± 0.00 | 60.40 ± 0.17 | 68.03 ± 0.21 | N/A | 73.70 ± 0.00 |

| 20 | 34.33 ± 0.06 | 69.83 ± 0.06 | 74.80 ± 0.17 | 76.10 ± 0.00 | 77.27 ± 0.06 | |||

| Flaxseed pomace | 30% | 60 | 16 | 38.87 ± 0.15 | 60.00 ± 0.78 | 68.46 ± 0.40 | N/A | 73.60 ± 0.10 |

| 20 | 34.73 ± 0.06 | 70.30 ± 0.17 | 75.50 ± 0.10 | 76.03 ± 0.06 | 77.37 ± 0.06 | |||

| Flaxseed pomace | 30% | 80 | 16 | 38.87 ± 0.15 | 60.00 ± 0.78 | 68.46 ± 0.40 | N/A | 73.73 ± 0.06 |

| 20 | 34.97 ± 0.06 | 70.67 ± 0.15 | 75.83 ± 0.31 | 76.30 ± 0.10 | 77.60 ± 0.10 |

| L/D | Additive | Property | Model Equation | R2 |

|---|---|---|---|---|

| 16 | Nigella seed pomace | Q (kg/h) | −2.653 + 0.214 × AN + 0.302 × SS − 0.005 × AN2 + 0.001 × AN × SS − 0.001 × SS2 | 0.958 |

| SME (kWh/kg) | 0.047 − 0.002 × AN − 0.0004 × SS + 9.251 × 10−5 × AN2 − 1.336 × 10−5 × AN × SS + 2.939 × 10−6 × SS2 | 0.706 | ||

| Flaxseed pomace | Q (kg/h) | −2.317 + 0.256 × AF + 0.274 × SS − 0.007 × AF2 − 0.001 × AF × SS − 0.0001 × SS2 | 0.954 | |

| SME (kWh/kg) | 0.078 − 0.002 × AF − 0.001 × SS + 1.706 × 10−5 × AF2 + 1.937 × 10−5 × AF × SS + 9.177 × 10−6 × SS2 | 0.729 | ||

| 20 | Nigella seed pomace | Q (kg/h) | 4.063 + 0.1686 × AN + 0.084 × SS − 0.008 × AN2 + 0.002 × AN × SS + 0.001 × SS2 | 0.940 |

| SME (kWh/kg) | 0.009 + 0.002 × AN + 0.002 × SS + 6.618 × 10−5 × AN2 − 4.552 × 10−5 × AN × SS − 1.561 × 10−5 × SS2 | 0.951 | ||

| Flaxseed pomace | Q (kg/h) | 0.818 + 0.199 × AF + 0.189 × SS − 0.006AF2 + 0.002 × AF × SS − 0.0001 × SS2 | 0.983 | |

| SME (kWh/kg) | 0.143 + 0.001 × AF − 0.004 × SS + 8.592 × 10−6 × AF2 − 2.089 × 10−5 × AF × SS + 3.229 × 10−5 × SS2 | 0.930 |

| L/D | Additive | Property | Model Equation | R2 |

|---|---|---|---|---|

| 16 | Nigella seed pomace | BD (kg/m3) | 379.897 − 0.458 × AN + 0.801 × SS − 0.003 × AN2 + 0.002 × AN × SS − 0.006 × SS2 | 0.992 |

| WAI (g/g) | 4.232 − 0.036 × AN + 0.004 × SS − 0.002 × AN2 + 1.25 × 10−5 × AN × SS + 7.292 × 10−6 × SS2 | 0.999 | ||

| WSI (%) | 3.308 + 0.041 × AN + 0.025 × SS + 0.005 × AN2 + 0.001 × AN × SS − 0.0002 × SS2 | 0.997 | ||

| Flaxseed pomace | BD (kg/m3) | 337.811 + 1.834 × AF + 1.514 × SS − 0.018 × AF2 − 0.016 × AF × SS − 0.005 × SS2 | 0.999 | |

| WAI (g/g) | 3.685 − 0.104 × AF + 0.014 × SS + 0.002 × AF2 − 0.0003 × AF × SS − 6.771 × 10−5 × SS2 | 0.999 | ||

| WSI (%) | 3.786 + 0.304 × AF + 0.008 × SS − 0.005 × AF2 − 0.001 × AF × SS + 2.396 × 10−5 × SS2 | 0.998 | ||

| 20 | Nigella seed pomace | BD (kg/m3) | 397.729 + 0.152 × AN + 0.261 × SS − 0.014 × AN2 + 0.003 × AN × SS − 0.001 × SS2 | 0.993 |

| WAI (g/g) | 4.369 − 0.039 × AN + 0.008 × SS − 0.002 × AN2 − 4.5 × 10−5 × AN × SS − 2.292 × 10−5 × SS2 | 0.999 | ||

| WSI (%) | 1.922 + 0.253 × AN + 0.084 × SS + 0.001 × AN2 − 0.001 × AN × SS − 0.01 × SS2 | 0.999 | ||

| Flaxseed pomace | BD (kg/m3) | 284.776 + 0.921 × AF + 4.383 × SS − 0.049 × AF2 + 0.017 × AF × SS − 0.033 × SS2 | 0.999 | |

| WAI (g/g) | 3.479 − 0.101 × AF + 0.029 × SS + 0.002 × AF2 − 0.0004 × AF × SS − 0.0002 × SS2 | 0.999 | ||

| WSI (%) | 3.65 + 0.193 × AF + 0.048 × SS − 0.004 × AF2 − 0.0003 × AF × SS − 0.0004 × SS2 | 0.993 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Soja, J.; Combrzyński, M.; Oniszczuk, T.; Gancarz, M.; Różyło, R. Analysis of the Influence of Different Plasticizing Systems in a Single-Screw Extruder on the Extrusion-Cooking Process and on Selected Physical Properties of Snack Pellets Enriched with Selected Oilseed Pomace. Processes 2025, 13, 1247. https://doi.org/10.3390/pr13041247

Soja J, Combrzyński M, Oniszczuk T, Gancarz M, Różyło R. Analysis of the Influence of Different Plasticizing Systems in a Single-Screw Extruder on the Extrusion-Cooking Process and on Selected Physical Properties of Snack Pellets Enriched with Selected Oilseed Pomace. Processes. 2025; 13(4):1247. https://doi.org/10.3390/pr13041247

Chicago/Turabian StyleSoja, Jakub, Maciej Combrzyński, Tomasz Oniszczuk, Marek Gancarz, and Renata Różyło. 2025. "Analysis of the Influence of Different Plasticizing Systems in a Single-Screw Extruder on the Extrusion-Cooking Process and on Selected Physical Properties of Snack Pellets Enriched with Selected Oilseed Pomace" Processes 13, no. 4: 1247. https://doi.org/10.3390/pr13041247

APA StyleSoja, J., Combrzyński, M., Oniszczuk, T., Gancarz, M., & Różyło, R. (2025). Analysis of the Influence of Different Plasticizing Systems in a Single-Screw Extruder on the Extrusion-Cooking Process and on Selected Physical Properties of Snack Pellets Enriched with Selected Oilseed Pomace. Processes, 13(4), 1247. https://doi.org/10.3390/pr13041247