Dynamic Scheduling for Multi-Objective Flexible Job Shops with Machine Breakdown by Deep Reinforcement Learning

Abstract

1. Introduction

- Problem Characteristics: Machine breakdown is a common occurrence in a wide range of discrete machining and manufacturing environments, such as the processing and manufacturing of aviation, aerospace, ships, and parts. In this paper, DFJSP with random machine breakdown is considered. The optimization objectives are set as the total tardiness of jobs and machine offset, which are most susceptible to machine breakdown in natural production.

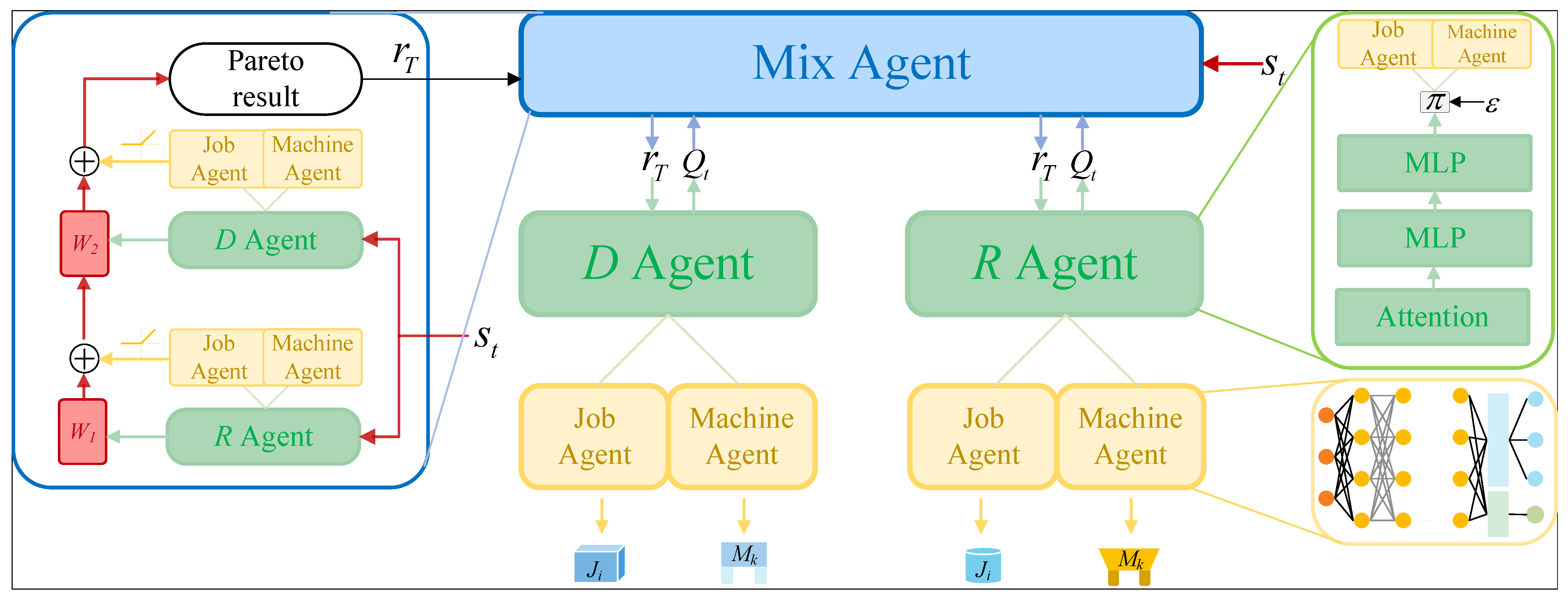

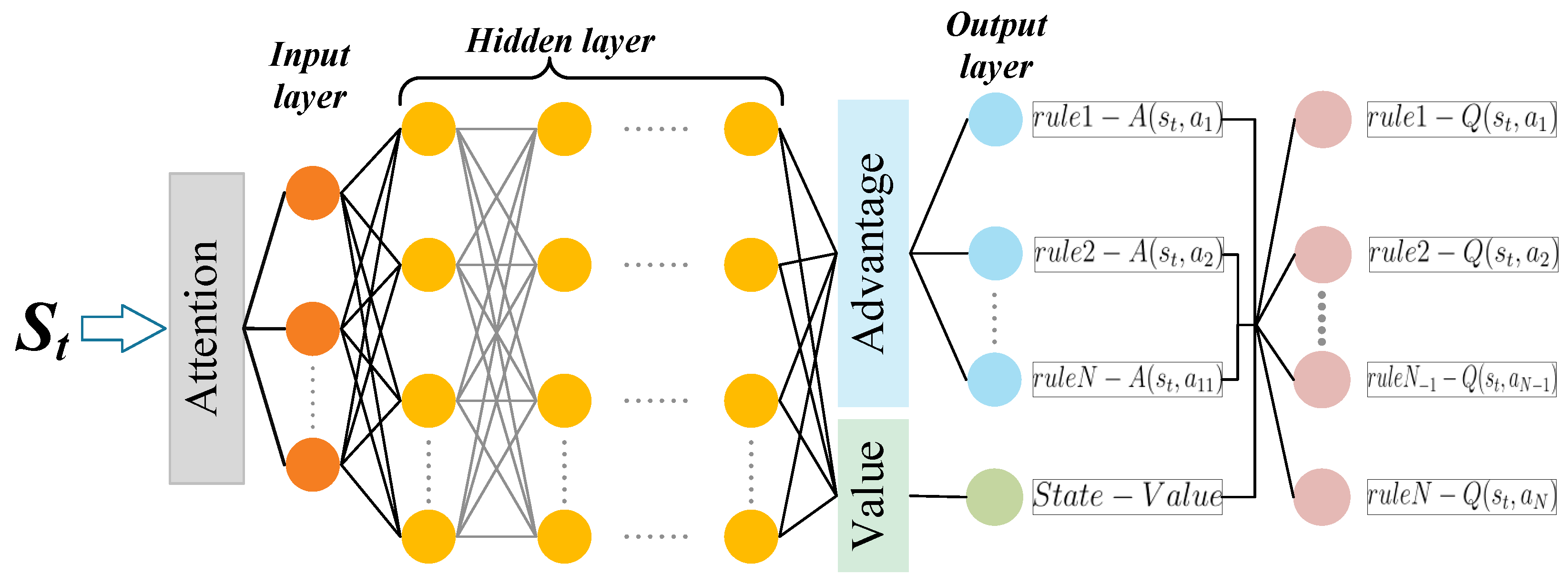

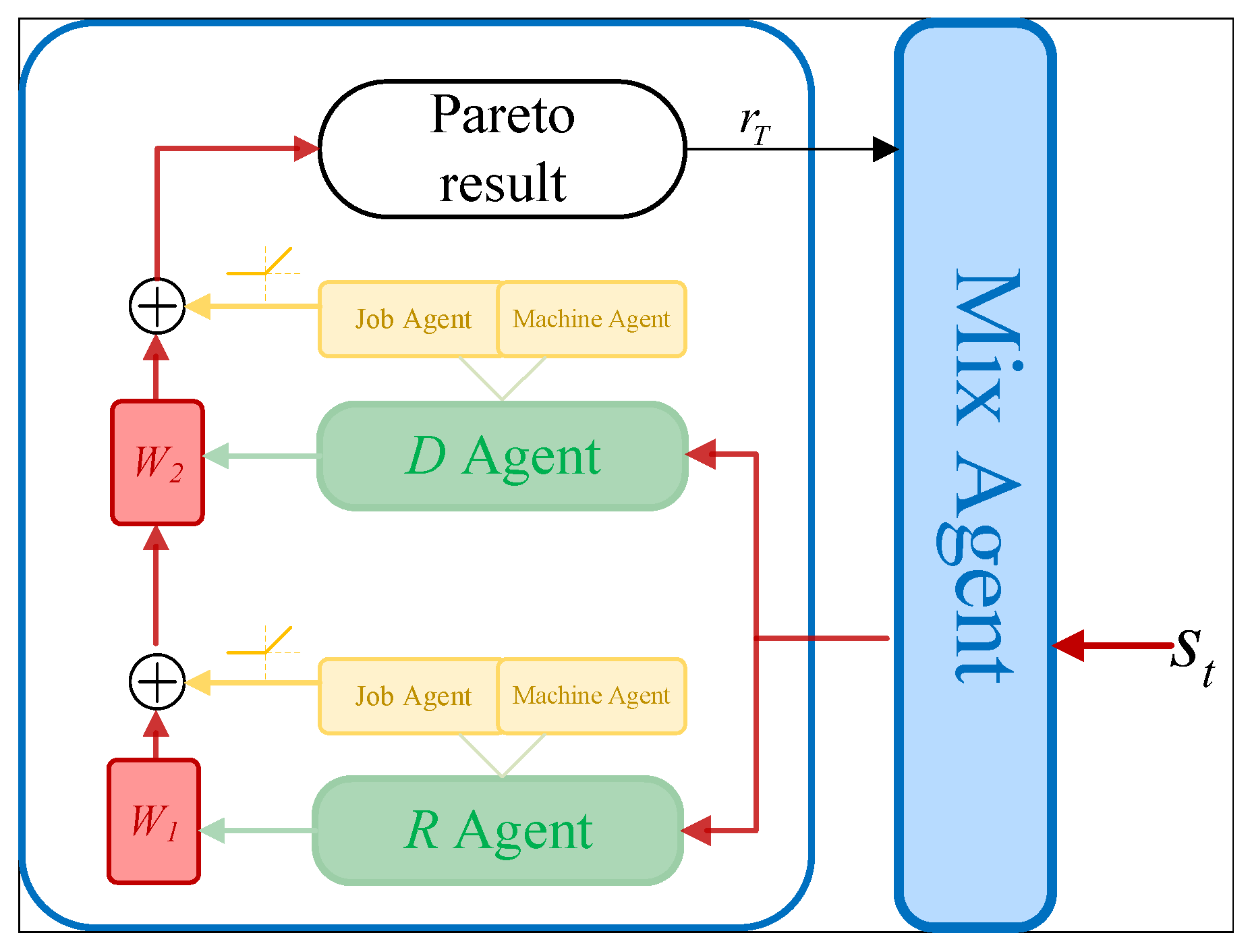

- Algorithm Characteristics: An improved Double Deep Q-network for dual-objective (IDDQN-II) DFJSP is proposed based on the DDQN framework. The hierarchical algorithm IDDQN-II cleverly decomposes the optimization difficulty of the dual objectives and decouples the selection of jobs and machines, realizing more combined dispatch rules to deal with different scheduling environments.

- Experiment results: In the experiment section, the IDDQN-II is compared with widely used multi-objective meta-heuristic algorithms on the benchmark. Additionally, the case derived from actual enterprises is introduced to validate the algorithm. The IDDQN-II algorithm has achieved excellent results and has been verified for effectiveness.

2. Problem Description and Mathematical Model

2.1. Problem Description

- (1)

- The transportation time of jobs between machines is empty.

- (2)

- The delivery time of jobs remains unchanged even if their assigned machines change, and after rescheduling, the processing time is independent of the machine’s current load status.

- (3)

- The processing time for each operation on available machines is known.

- (4)

- It is assumed that one machine breaks at the same time.

2.2. Mathematical Model

3. Algorithm Design

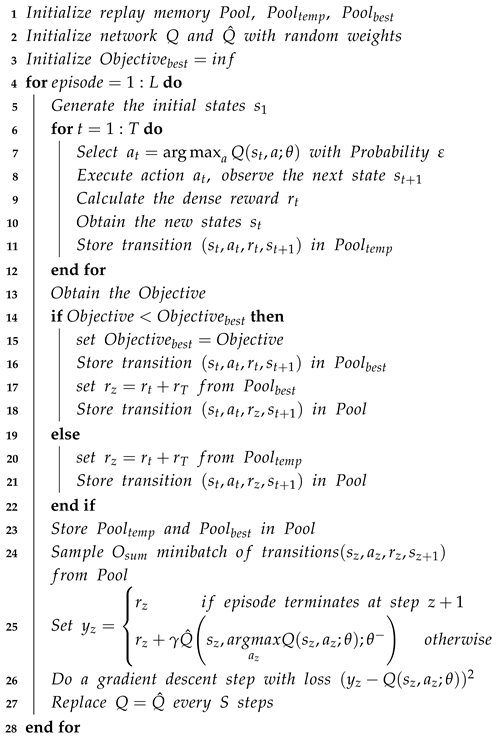

| Algorithm 1: The training process detail of Agent |

|

3.1. State Features

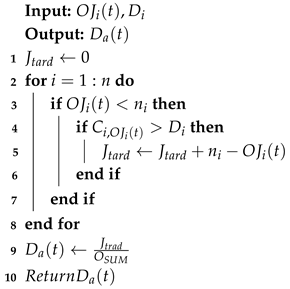

| Algorithm 2: |

|

| Algorithm 3: |

|

3.2. Action Space

- (1)

- Select the job with the most remaining operations at the current time.

- (2)

- Select the job with the lowest processing rate at the current time.

- (3)

- Select the job with the shortest time to tardiness at the current time.

- (4)

- Select the job with the largest estimated tardiness at the current time.

- (5)

- Select the job with the longest remaining processing time at the current time.

- (6)

- Select the job with the shortest remaining processing time at the current time.

- (7)

- Select the job that can be processed the earliest at the current time.

- (1)

- Select the machine with the lowest load rate at the current time.

- (2)

- Select the machine with the worst processing capability at the current time.

- (3)

- Select the machine that can start processing the earliest at the current time.

3.3. Reward Function

| Algorithm 4: Dense reward |

| Algorithm 5: Dense reward |

3.4. The Generation Pareto Results

4. Computational Experiments and Results

4.1. Experiment Preparation

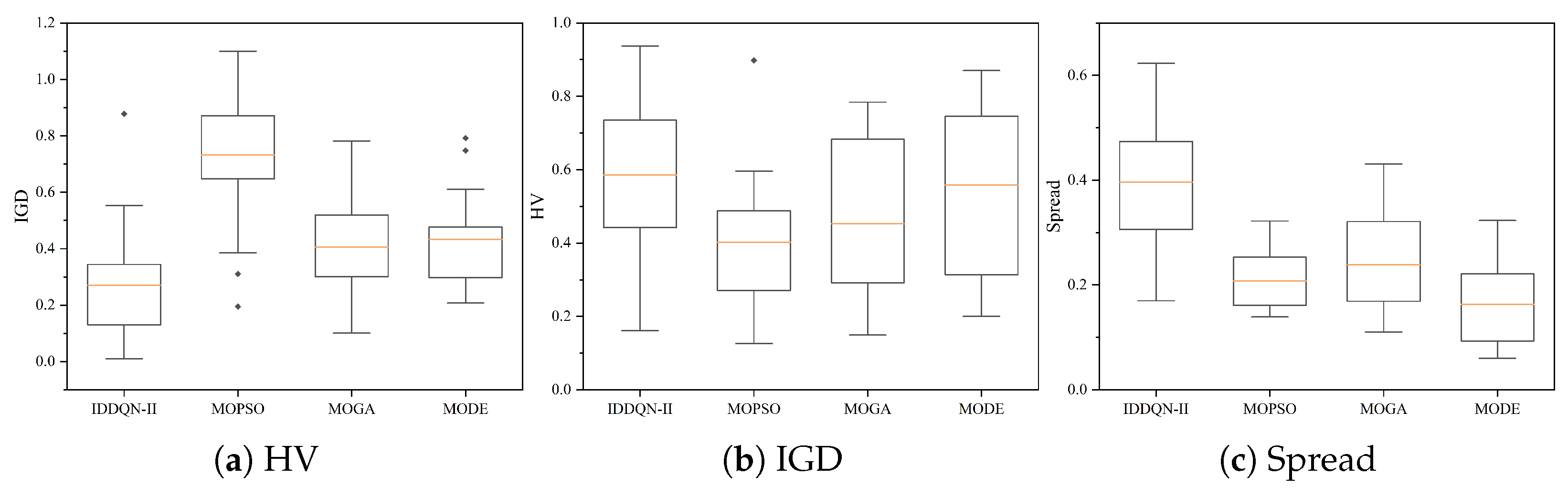

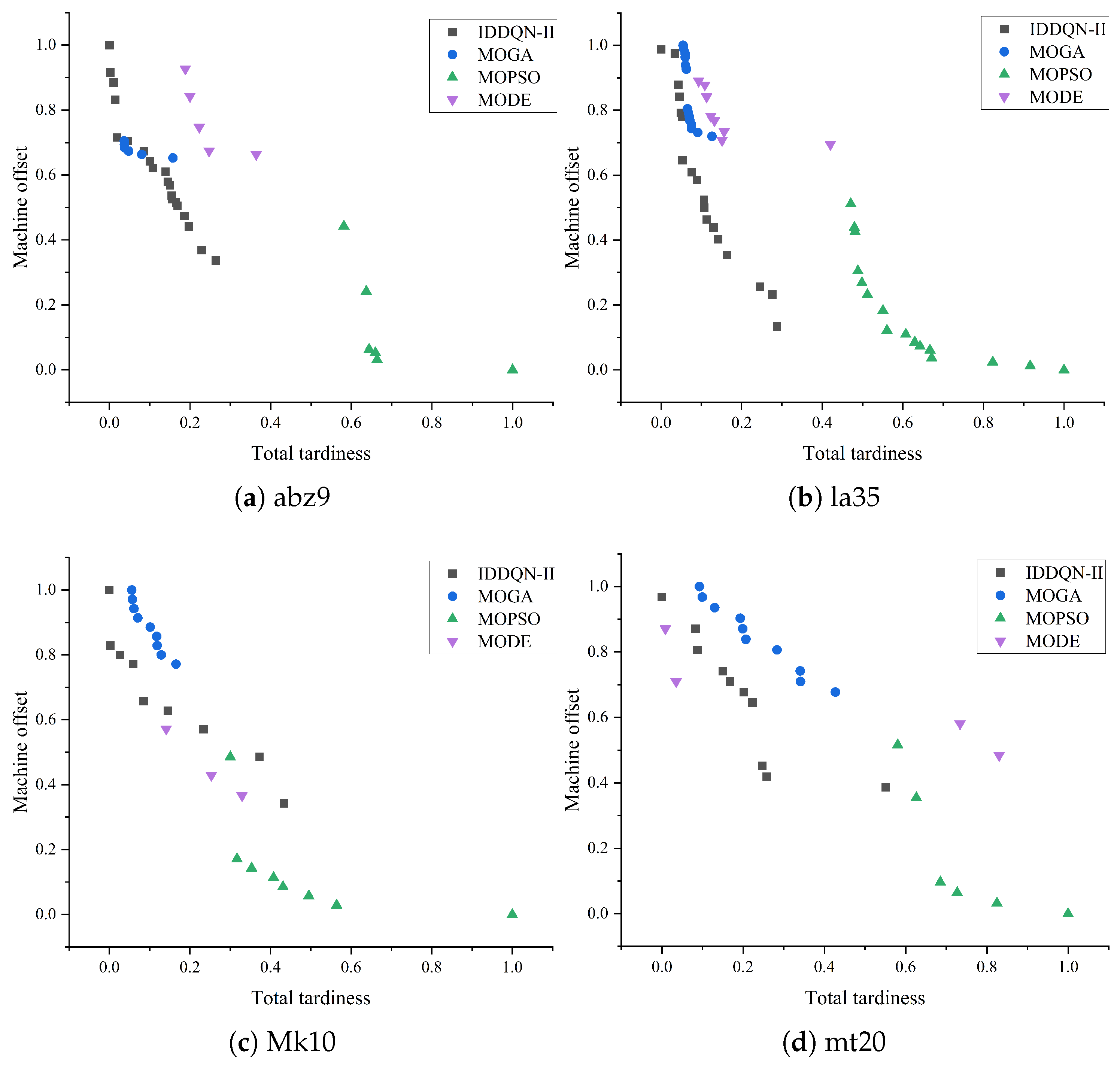

4.2. Pareto Front Comparison Results and Analysis

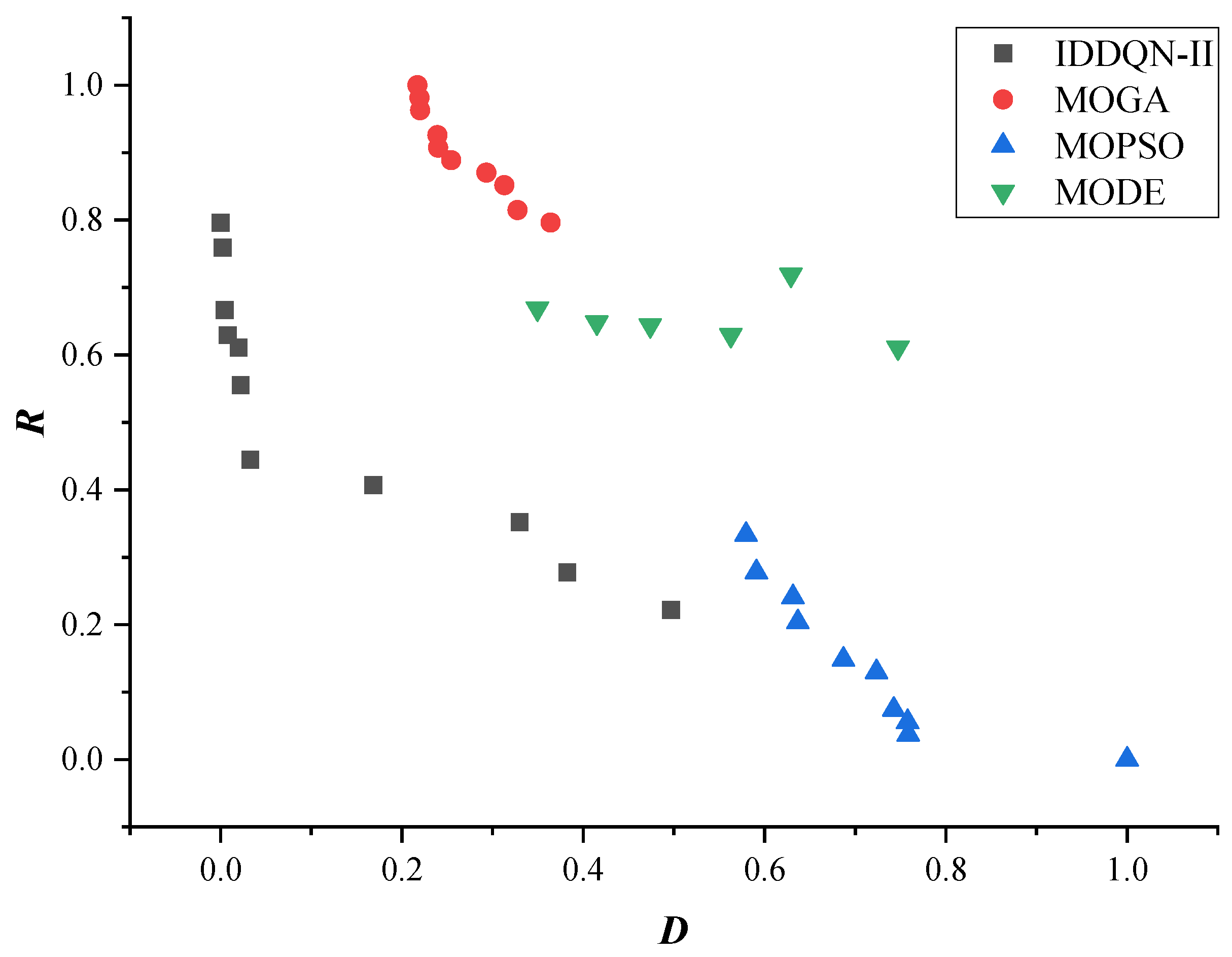

4.3. Validation Using Real Case from Enterprises

4.3.1. Case Study Description

4.3.2. Experimental Validation Results

5. Conclusions and Future Work

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| DRL | Deep reinforcement learning |

| DFJSP | Dynamic flexible job shop problem |

| IDDQN-II | Dual-objective for improved Double Deep Q-network |

| MOGA | Multi-Objective Genetic Algorithm |

| MOPSO | Multi-Objective Particle Swarm Optimization |

| MODE | Multi-Objective Differential Evolution |

Appendix A

| Number | Machine | Number | Machine |

|---|---|---|---|

| CNC double-column vertical lathe | CO2 Welding Machine | ||

| Conventional vertical lathe | CO2 Welding Machine | ||

| Conventional vertical lathe | CO2 Welding Machine | ||

| Conventional horizontal lathe | Welding Machine | ||

| Conventional horizontal lathe | Welding Machine | ||

| Conventional horizontal milling machine | Welding Machine | ||

| Conventional vertical milling machine | Welding Machine | ||

| Conventional vertical milling machine | Welding Machine | ||

| CNC floor-type milling and boring machine | Bench Drill | ||

| Plasma cutting machine | Bench Drill | ||

| Plasma cutting machine | Electric Double-Girder Overhead Crane | ||

| CNC flame and plasma cutting machine | Horizontal Boring Machine | ||

| Hydraulic Shearing Machine | Marking-Out Table | ||

| Hydraulic Bending Machine | Marking-Out Table | ||

| Universal Radial Drilling Machine | Resistance Furnace | ||

| Radial Drilling Machine | Resistance Furnace | ||

| Radial Drilling Machine |

| Index | Jobs | Number | Operation, Machine and Processing Time | |||||

|---|---|---|---|---|---|---|---|---|

| Wear-Resistant Ring of Roller Press | 5 | Lathe rough | Lathe finish | Quench | ||||

| VerticalLathe(9) | VerticalLathe(5) | Induction Hardening Furnace(12) | ||||||

| Bearing Retainer of Roller Press | 5 | Lathe rough | Lathe finish | Quench | ||||

| VerticalLathe(12) | VerticalLathe(3) | Induction Hardening Furnace(10) | ||||||

| Upper Rocker Arm of Vertical Mill | 5 | Boring | Drilling | |||||

| Boring Machine, Boring-Milling Machine(12) | Radial Drilling Machine(4) | |||||||

| Bearing Cover of Vertical Mill | 5 | Scribe | Milling | Scribe | Drilling | |||

| Surface Plate(3) | Boring Machine, Boring-Milling Machine(15) | Surface Plate(2) | Radial Drilling Machine(8) | |||||

| Lower Crossbeam of Roller Press | 5 | Scribe | Milling | |||||

| Surface Plate(3) | Milling Machine, Boring-Milling Machine(8) | |||||||

| End Component of Roller Press | 5 | Notched edge | Scribe | Group pairing | Welding | Group pairing | Welding | |

| Cutting machine(7) | Surface Plate(2) | Electrode Welding Machine(5) | Gas shielded welding(3) | Electrode Welding Machine(5) | Gas shielded welding(3) | |||

| Group pairing | Welding | Milling | Drilling | Pre-drilled hole | ||||

| Electrode Welding Machine(5) | Gas shielded welding(3) | Milling Machine, Boring-Milling Machine(8) | Radial Drilling Machine(5) | Radial Drilling Machine(3) | ||||

| Floating Roller Bearing Seat of Roller Press | 5 | Lathe rough | Drilling | Boring | ||||

| VerticalLathe(16) | Radial Drilling Machine(6) | Boring Machine, Boring-Milling Machine(18) | ||||||

| Base Beam of Frame | 5 | Scribe | Boring | Drilling | Milling | |||

| Surface Plate(6) | Boring Machine, Boring-Milling Machine(21) | Radial Drilling Machine(7) | Milling machine(8) | |||||

| Separator Cage | 5 | Lathe rough | Scribe | Drilling | ||||

| VerticalLathe(8) | Surface Plate(3) | Radial Drilling Machine(5) | ||||||

| Gearbox Base Plate of Vertical Mill | 5 | Lathe rough | Lathe finish | Boring | Drilling | |||

| VerticalLathe(11) | VerticalLathe(8) | Boring Machine, Boring-Milling Machine(23) | Radial Drilling Machine(11) | |||||

| Grinding Disc of Vertical Mill | 5 | Semi-finish turning | Lathe finish | Boring | Scribe | Drilling | Drilling | |

| VerticalLathe(13) | VerticalLathe(18) | Boring Machine, Boring-Milling Machine(15) | Surface Plate(3) | Radial Drilling Machine(6) | Radial Drilling Machine(8) | |||

| Counterweight Rod of Airlock Valve | 5 | Lathe rough | Lathe finish | Milling of inner circle and end face | Wire EDM | Welding | ||

| HorizontalLathe(11) | HorizontalLathe(6) | Milling Machine, Boring-Milling Machine(15) | Cutting machine(14) | Electrode Welding Machine(8) | ||||

| Gear of Slide Gate Valve | 5 | Lathe rough | Lathe finish | Wire EDM | Quench | Wire EDM | Drilling | |

| HorizontalLathe(9) | HorizontalLathe(5) | Cutting machine(10) | Induction Hardening Furnace(12) | Cutting machine(6) | Radial Drilling Machine(7) | |||

References

- Li, R.; Gong, W.; Wang, L.; Lu, C.; Dong, C. Co-Evolution with Deep Reinforcement Learning for Energy-Aware Distributed Heterogeneous Flexible Job Shop Scheduling. IEEE Trans. Syst. Man Cybern. Syst. 2024, 54, 201–211. [Google Scholar] [CrossRef]

- Dauzère-Pérès, S.; Ding, J.; Shen, L.; Tamssaouet, K. The Flexible Job Shop Scheduling Problem: A Review. Eur. J. Oper. Res. 2023, 314, S037722172300382X. [Google Scholar] [CrossRef]

- Jiang, B.; Ma, Y.; Chen, L.; Huang, B.; Huang, Y.; Guan, L. A Review on Intelligent Scheduling and Optimization for Flexible Job Shop. Int. J. Control. Autom. Syst. 2023, 21, 3127–3150. [Google Scholar] [CrossRef]

- Yao, Y.J.; Liu, Q.H.; Li, X.Y.; Gao, L. A Novel MILP Model for Job Shop Scheduling Problem with Mobile Robots. Robot. Comput.-Integr. Manuf. 2023, 81, 102506. [Google Scholar] [CrossRef]

- Shi, S.; Xiong, H. Solving the Multi-Objective Job Shop Scheduling Problems with Overtime Consideration by an Enhanced NSGA-II. Comput. Ind. Eng. 2024, 190, 110001. [Google Scholar] [CrossRef]

- Ding, J.; Chen, M.; Wang, T.; Zhou, J.; Fu, X.; Li, K. A Survey of AI-enabled Dynamic Manufacturing Scheduling: From Directed Heuristics to Autonomous Learning. ACM Comput. Surv. 2023, 55, 307:1–307:36. [Google Scholar] [CrossRef]

- Tariq, A.; Khan, S.A.; But, W.H.; Javaid, A.; Shehryar, T. An IoT-enabled Real-Time Dynamic Scheduler for Flexible Job Shop Scheduling (FJSS) in an Industry 4.0-Based Manufacturing Execution System (MES 4.0). IEEE Access 2024, 12, 49653–49666. [Google Scholar] [CrossRef]

- Liu, A.; Luh, P.B.; Sun, K.; Bragin, M.A.; Yan, B. Integrating Machine Learning and Mathematical Optimization for Job Shop Scheduling. IEEE Trans. Autom. Sci. Eng. 2024, 21, 4829–4850. [Google Scholar] [CrossRef]

- Huang, G.; Hu, M.; Yang, X.; Lin, P.; Wang, Y. Addressing Constraint Coupling and Autonomous Decision-Making Challenges: An Analysis of Large-Scale UAV Trajectory-Planning Techniques. Drones 2024, 8, 530. [Google Scholar] [CrossRef]

- Wang, J.; Liu, Y.; Ren, S.; Wang, C.; Ma, S. Edge Computing-Based Real-Time Scheduling for Digital Twin Flexible Job Shop with Variable Time Window. Robot. Comput.-Integr. Manuf. 2023, 79, 102435. [Google Scholar] [CrossRef]

- Destouet, C.; Tlahig, H.; Bettayeb, B.; Mazari, B. Flexible Job Shop Scheduling Problem under Industry 5.0: A Survey on Human Reintegration, Environmental Consideration and Resilience Improvement. J. Manuf. Syst. 2023, 67, 155–173. [Google Scholar] [CrossRef]

- Yao, Y.; Wang, Q.; Wang, C.; Li, X.; Gao, L.; Xia, K. Knowledge-Based Multi-Objective Evolutionary Algorithm for Energy-Efficient Flexible Job Shop Scheduling with Mobile Robot Transportation. Adv. Eng. Inform. 2024, 62, 102647. [Google Scholar] [CrossRef]

- Sun, J.; Zhang, Z.; Zhang, G.; Huang, Z. Multi-Objective Evolutionary Algorithm Based Flexible Assembly Job-Shop Rescheduling with Component Sharing for Order Insertion. Comput. Oper. Res. 2024, 169, 106744. [Google Scholar] [CrossRef]

- Xie, J.; Li, X.; Gao, L.; Gui, L. A Hybrid Genetic Tabu Search Algorithm for Distributed Flexible Job Shop Scheduling Problems. J. Manuf. Syst. 2023, 71, 82–94. [Google Scholar] [CrossRef]

- Burmeister, S.C.; Guericke, D.; Schryen, G. A Memetic NSGA-II for the Multi-Objective Flexible Job Shop Scheduling Problem with Real-Time Energy Tariffs. Flex. Serv. Manuf. J. 2024, 36, 1530–1570. [Google Scholar] [CrossRef]

- Zhang, F.; Shi, G.; Mei, Y.; Zhang, M. Multiobjective Dynamic Flexible Job Shop Scheduling with Biased Objectives via Multitask Genetic Programming. IEEE Trans. Artif. Intell. 2025, 6, 169–183. [Google Scholar] [CrossRef]

- Gui, Y.; Tang, D.; Zhu, H.; Zhang, Y.; Zhang, Z. Dynamic Scheduling for Flexible Job Shop Using a Deep Reinforcement Learning Approach. Comput. Ind. Eng. 2023, 180, 109255. [Google Scholar] [CrossRef]

- Hammami, N.E.H.; Lardeux, B.; Hadj-Alouane, A.B.; Jridi, M. Design and Calibration of a DRL Algorithm for Solving the Job Shop Scheduling Problem under Unexpected Job Arrivals. Flex. Serv. Manuf. J. 2024. [Google Scholar] [CrossRef]

- Zhao, L.; Fan, J.; Zhang, C.; Shen, W.; Zhuang, J. A DRL-based Reactive Scheduling Policy for Flexible Job Shops with Random Job Arrivals. IEEE Trans. Autom. Sci. Eng. 2024, 21, 2912–2923. [Google Scholar] [CrossRef]

- Gan, X.; Zuo, Y.; Yang, G.; Zhang, A.; Tao, F. Dynamic Scheduling for Dual-Objective Job Shop with Machine Breakdown by Reinforcement Learning. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2024, 238, 3–17. [Google Scholar] [CrossRef]

- Das, K. A Comparative Study of Exponential Distribution vs. Weibull Distribution in Machine Reliability Analysis in a CMS Design. Comput. Ind. Eng. 2008, 54, 12–33. [Google Scholar] [CrossRef]

- Chen, J.; Zhao, Y.; Wang, M.; Yang, K.; Ge, Y.; Wang, K.; Lin, H.; Pan, P.; Hu, H.; He, Z.; et al. Multi-Timescale Reward-Based DRL Energy Management for Regenerative Braking Energy Storage System. IEEE Trans. Transp. Electrif. 2025. early access. [Google Scholar] [CrossRef]

- Nguyen, T.T.; Nguyen, N.D.; Vamplew, P.; Nahavandi, S.; Dazeley, R.; Lim, C.P. A Multi-Objective Deep Reinforcement Learning Framework. Eng. Appl. Artif. Intell. 2020, 96, 103915. [Google Scholar] [CrossRef]

- Lu, S.; Wang, Y.; Kong, M.; Wang, W.; Tan, W.; Song, Y. A Double Deep Q-Network Framework for a Flexible Job Shop Scheduling Problem with Dynamic Job Arrivals and Urgent Job Insertions. Eng. Appl. Artif. Intell. 2024, 133, 108487. [Google Scholar] [CrossRef]

- Dorfman, R. A Formula for the Gini Coefficient. Rev. Econ. Stat. 1979, 61, 146–149. [Google Scholar] [CrossRef]

- Vaswani, A.; Shazeer, N.; Parmar, N.; Uszkoreit, J.; Jones, L.; Gomez, A.N.; Kaiser, L.; Polosukhin, I. Attention Is All You Need. arXiv 2023, arXiv:1706.03762. [Google Scholar] [CrossRef]

- Doh, H.H.; Yu, J.M.; Kim, J.S.; Lee, D.H.; Nam, S.H. A Priority Scheduling Approach for Flexible Job Shops with Multiple Process Plans. Int. J. Prod. Res. 2013, 51, 3748–3764. [Google Scholar] [CrossRef]

- Jeong, K.C.; Kim, Y.D. A Real-Time Scheduling Mechanism for a Flexible Manufacturing System: Using Simulation and Dispatching Rules. Int. J. Prod. Res. 1998, 36, 2609–2626. [Google Scholar] [CrossRef]

- Priore, P.; Ponte, B.; Puente, J.; Gómez, A. Learning-Based Scheduling of Flexible Manufacturing Systems Using Ensemble Methods. Comput. Ind. Eng. 2018, 126, 282–291. [Google Scholar] [CrossRef]

- Adams, J.; Balas, E.; Zawack, D. The Shifting Bottleneck Procedure for Job Shop Scheduling. Manag. Sci. 1988, 34, 391–401. [Google Scholar] [CrossRef]

- Lawrence, S. Resouce Constrained Project Scheduling: An Experimental Investigation of Heuristic Scheduling Techniques (Supplement); Graduate School of Industrial Administration, Carnegie-Mellon University: Pittsburgh, PA, USA, 1984. [Google Scholar]

- Fisher, H.; Thompson, G.L. Probabilistic Learning Combinations of Local Job-Shop Scheduling Rules. In Industrial Scheduling; Muth, J.F., Thompson, G.L., Eds.; Prentice-Hall: Englewood Cliffs, NJ, USA, 1963; pp. 225–251. [Google Scholar]

- Brandimarte, P. Routing and Scheduling in a Flexible Job Shop by Tabu Search. Ann. Oper. Res. 1993, 41, 157–183. [Google Scholar] [CrossRef]

- Shang, K.; Ishibuchi, H.; He, L.; Pang, L.M. A Survey on the Hypervolume Indicator in Evolutionary Multiobjective Optimization. IEEE Trans. Evol. Comput. 2021, 25, 1–20. [Google Scholar] [CrossRef]

- He, L.; Chiong, R.; Li, W.; Dhakal, S.; Cao, Y.; Zhang, Y. Multiobjective Optimization of Energy-Efficient JOB-shop Scheduling with Dynamic Reference Point-Based Fuzzy Relative Entropy. IEEE Trans. Ind. Inform. 2022, 18, 600–610. [Google Scholar] [CrossRef]

- Sun, Y.; Yen, G.G.; Yi, Z. IGD Indicator-Based Evolutionary Algorithm for Many-Objective Optimization Problems. IEEE Trans. Evol. Comput. 2019, 23, 173–187. [Google Scholar] [CrossRef]

- Yin, L.; Li, X.; Gao, L.; Lu, C.; Zhang, Z. A Novel Mathematical Model and Multi-Objective Method for the Low-Carbon Flexible Job Shop Scheduling Problem. Sustain. Comput. Inform. Syst. 2017, 13, 15–30. [Google Scholar] [CrossRef]

- Esmaeilion, F.; Ahmadi, A.; Dashti, R. Exergy-Economic-Environment Optimization of the Waste-to-Energy Power Plant Using Multi-Objective Particle-Swarm Optimization (MOPSO). Sci. Iran. 2021, 28, 2733–2750. [Google Scholar] [CrossRef]

- Xiao, B.; Zhao, Z.; Wu, Y.; Zhu, X.; Peng, S.; Su, H. An Improved MOEA/D for Multi-Objective Flexible Job Shop Scheduling by Considering Efficiency and Cost. Comput. Oper. Res. 2024, 167, 106674. [Google Scholar] [CrossRef]

- Sun, Y.; Wang, J.; Wang, X. Fault Diagnosis of Mechanical Equipment in High Energy Consumption Industries in China: A Review. Mech. Syst. Signal Process. 2023, 186, 109833. [Google Scholar] [CrossRef]

- Ramakrishna Balaji, C.; de Azevedo, A.R.G.; Madurwar, M. Sustainable Perspective of Ancillary Construction Materials in Infrastructure Industry: An Overview. J. Clean. Prod. 2022, 365, 132864. [Google Scholar] [CrossRef]

| Notations | Description |

|---|---|

| The index of job | |

| The index of operation | |

| n | Total number of jobs |

| m | Total number of machines |

| i-th job | |

| The number of operations for | |

| k-th machine | |

| The available machine set for the | |

| The j-th operation of | |

| The start processing time of operation | |

| The completion time of operation | |

| The completion time of | |

| The processing time of operation on machine | |

| The due date of | |

| If operation is processed on , = 1; else = 0 | |

| If is the previous operation adjacent to , = 1; If is the next operation adjacent to , ; else = 0 | |

| t | Scheduling time |

| Machine status at time t, if the machine breakdown , else = 1 |

| Parameter | Value |

|---|---|

| Learning rate | 0.01 |

| Number of training iterations | |

| The capacity of experience pool | |

| Sample batch size | |

| Coefficients in greedy strategy | 0.99 to 0.001 |

| Update steps | |

| Discount factor | 0.9 |

| Prioritize experience replay alpha | 0.6 |

| Prioritize experience replay beta0 | 0.4 |

| 0.01 to 1 |

| Benchmark | Source |

|---|---|

| abz5, abz6, abz7, abz8, abz9 | Adams et al. [30] |

| la30, la31, la32, la33, la34, la35 | S [31] |

| mt06, mt10, mt20 | H [32] |

| Mk01, Mk05, Mk10 | Brandimarte [33] |

| Data | MOPSO | MOGA | MODE | IDDQN-II | |||

|---|---|---|---|---|---|---|---|

| abz5 | + | + | + | ||||

| abz6 | + | + | + | ||||

| abz7 | + | − | − | ||||

| abz8 | + | − | − | ||||

| abz9 | + | + | + | ||||

| la30 | + | − | − | ||||

| la31 | + | + | + | ||||

| la32 | + | + | + | ||||

| la33 | + | + | + | ||||

| la34 | + | + | + | ||||

| la35 | + | + | + | ||||

| mt06 | − | − | − | ||||

| mt10 | + | + | − | ||||

| mt20 | + | + | − | ||||

| Mk01 | − | − | − | ||||

| Mk05 | + | + | + | ||||

| Mk10 | + | + | + | ||||

| +/−/= | 15/2/0 | 12/5/0 | 10/7/0 | ||||

| Data | MOPSO | MOGA | MODE | IDDQN-II | |||

|---|---|---|---|---|---|---|---|

| abz5 | + | − | − | ||||

| abz6 | + | + | + | ||||

| abz7 | + | − | + | ||||

| abz8 | + | + | + | ||||

| abz9 | + | + | + | ||||

| la30 | + | + | + | ||||

| la31 | + | + | + | ||||

| la32 | + | + | + | ||||

| la33 | + | + | + | ||||

| la34 | + | + | + | ||||

| la35 | + | + | + | ||||

| mt06 | − | − | − | ||||

| mt10 | + | + | − | ||||

| mt20 | + | + | + | ||||

| Mk01 | − | − | − | ||||

| Mk05 | + | − | + | ||||

| Mk10 | + | + | + | ||||

| +/−/= | 15/2/0 | 12/5/0 | 13/4/0 | ||||

| Data | MOPSO | MOGA | MODE | IDDQN-II | |||

|---|---|---|---|---|---|---|---|

| abz5 | + | − | + | ||||

| abz6 | + | + | + | ||||

| abz7 | + | + | + | ||||

| abz8 | + | + | + | ||||

| abz9 | + | + | + | ||||

| la30 | + | + | + | ||||

| la31 | + | + | + | ||||

| la32 | + | + | − | ||||

| la33 | + | + | + | ||||

| la34 | + | + | + | ||||

| la35 | + | + | + | ||||

| mt06 | + | − | + | ||||

| mt10 | + | + | + | ||||

| mt20 | + | + | + | ||||

| Mk01 | − | − | − | ||||

| Mk05 | + | + | + | ||||

| Mk10 | + | − | − | ||||

| +/−/= | 16/1/0 | 13/4/0 | 14/3/0 | ||||

| Indicators | Algorithms | |||

|---|---|---|---|---|

| IDDQN-II | MOGA | MOPSO | MODE | |

| HV | ||||

| IGD | ||||

| Spread | ||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, R.; Zheng, J.; Yin, X. Dynamic Scheduling for Multi-Objective Flexible Job Shops with Machine Breakdown by Deep Reinforcement Learning. Processes 2025, 13, 1246. https://doi.org/10.3390/pr13041246

Wu R, Zheng J, Yin X. Dynamic Scheduling for Multi-Objective Flexible Job Shops with Machine Breakdown by Deep Reinforcement Learning. Processes. 2025; 13(4):1246. https://doi.org/10.3390/pr13041246

Chicago/Turabian StyleWu, Rui, Jianxin Zheng, and Xiyan Yin. 2025. "Dynamic Scheduling for Multi-Objective Flexible Job Shops with Machine Breakdown by Deep Reinforcement Learning" Processes 13, no. 4: 1246. https://doi.org/10.3390/pr13041246

APA StyleWu, R., Zheng, J., & Yin, X. (2025). Dynamic Scheduling for Multi-Objective Flexible Job Shops with Machine Breakdown by Deep Reinforcement Learning. Processes, 13(4), 1246. https://doi.org/10.3390/pr13041246