1. Introduction

Hydraulic fracturing is a key technology for unconventional oil and gas extraction [

1]. However, sand screenout leads to artificially induced crack-plugging [

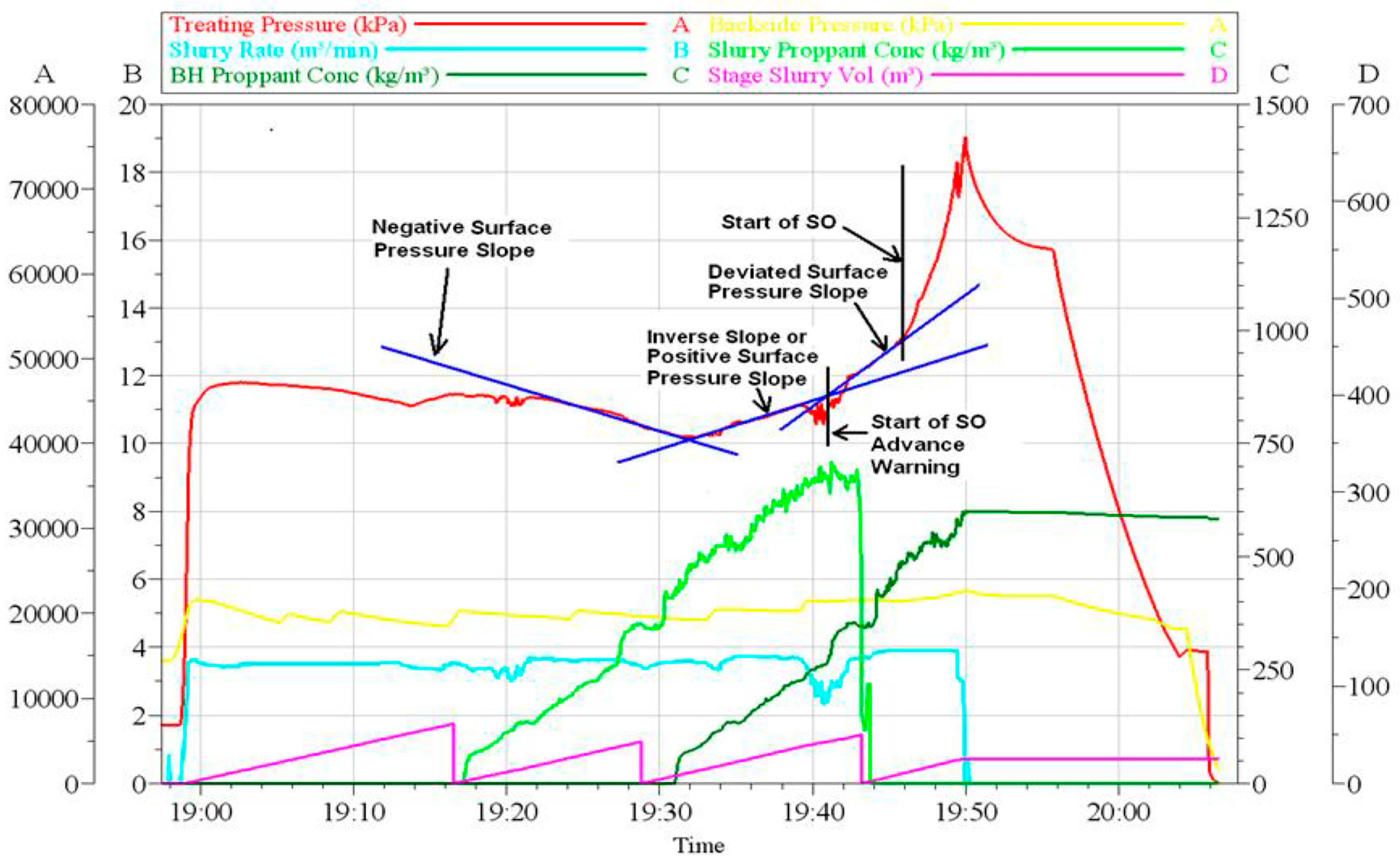

2], reducing extraction efficiency or even causing production disengagement. This significantly hinders the effective implementation of production-enhancing modifications. Some scholars have evaluated the likelihood of sand screenout using both work experience and mathematical models. For instance, in 1981, Nolte and Smith [

3] discovered the double logarithmic relationship between pressure and time at the fracture. This discovery introduced the Nolte diagram, a valuable tool for fracking and the first model assessing sand screenout likelihood. The Massaras Brothers developed the slope inversion method based on pressure fluctuation patterns during fracturing operations [

4]. While these two methods offer high theoretical prediction accuracy, they fail to account for objective factors such as human operations and abnormal pressure fluctuations. They heavily rely on engineers’ subjective judgment during operations, limiting their effectiveness in complex environments. In this context, with advances in computing power, deep learning (DL) has emerged as an effective approach for tackling complex problems and real-time computations [

5,

6]. DL excels at handling large datasets and uncovering hidden data sequence relationships [

7], and it is increasingly being adopted in the oil industry. For instance, DL has been applied to drilling speed prediction [

8,

9], wellbore stability analysis [

10], lithology prediction [

11,

12], and production forecasting [

13,

14]. These applications demonstrate DL’s effectiveness in complex data analysis and offer novel insights and methodologies for sand screenout early warning systems.

In the research on sand screenout in the last decade, the Nolte diagram and the slope inversion method provide a theoretical basis for real-time warning of sand screenout, and some scholars have applied a time series prediction model to the research related to real-time warning of sand screenout, taking into account that sand screenout has the characteristic of cyclic changes. For example, Madasu and Rangarajan [

15] introduced a wellhead pressure prediction model using Deep Recurrent Neural Networks (DRNN) to predict wellhead pressure fluctuations during hydraulic fracturing in real time. This was the first time that DL had been introduced to fracturing pressure prediction. Liang, et al. [

16] used a coupled autoregressive integral sliding average model (ARIMA) and a generalised regression neural network (GRNN) for fracture pressure prediction. They then used slope change combined with a double logarithmic curve model to achieve an early sand screenout warning. Hu, et al. [

17] predicted fracture pressure by the locally weighted linear regression (LWLR) method, and they optimised it by combining the particle filter (PF) algorithm and ARMA, which outperformed the reverse slope method. Yu, et al. [

18] proposed a sand screenout classification model based on Gaussian Hidden Markov Models (GHMMs), which learnt to simulate the change of surface pressure signals for sand screenout early warning, with 86% accuracy of sand screenout. However, all these models mentioned above are single neural networks, which may make it difficult to predict the true value of the fracturing pressure considering the large variations in the input parameters, and there are some limitations in their application to complex situations. With a model integration strategy, we can maximise the unique strengths of each model to achieve a stronger overall performance [

5]. Recent studies involve the integration of different models; for example, Sun, et al. [

19] proposed a real-time sand screenout warning model by combining the inverse slope method with the CNN-LSTM neural network. Bin, et al. [

20] used a combination of Attention and Bidirectional Long Short-Term Memory (BiLSTM) networks to construct a real-time prediction model for fracturing pressure in the fracturing process and to improve the Unet++ network for the recognition of events in the category of ‘stage’, which includes sand screenout.

In summary, deep learning models have been increasingly applied in sand screenout early warning systems. By forecasting fracturing pressure and integrating conventional warning methods, these models contribute to more reliable and proactive decision-making, thereby significantly reducing construction costs and risks. However, two major challenges remain in current research on sand screenout prediction. First, the development of deep learning models often relies on subjectively selected hyperparameters or empirical comparisons across multiple architectures, which compromises model robustness and generalizability. Second, traditional sand screenout warning approaches tend to generate false alarms under complex field conditions, limiting their practical effectiveness and failing to provide accurate guidance for field engineers. These limitations underscore the need for more intelligent, adaptive, and robust prediction frameworks tailored to real-world hydraulic fracturing scenarios, which forms the core motivation of this study.

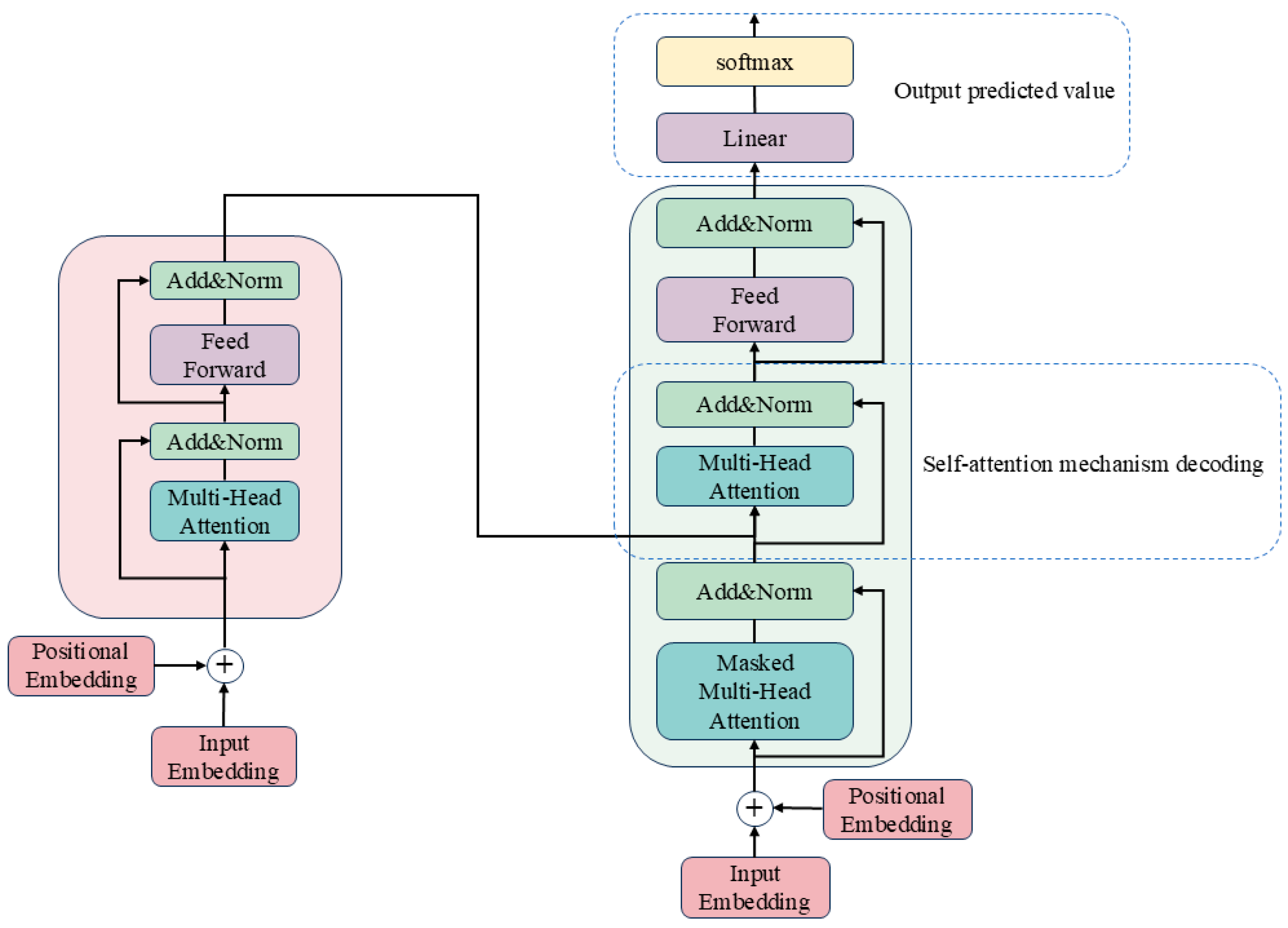

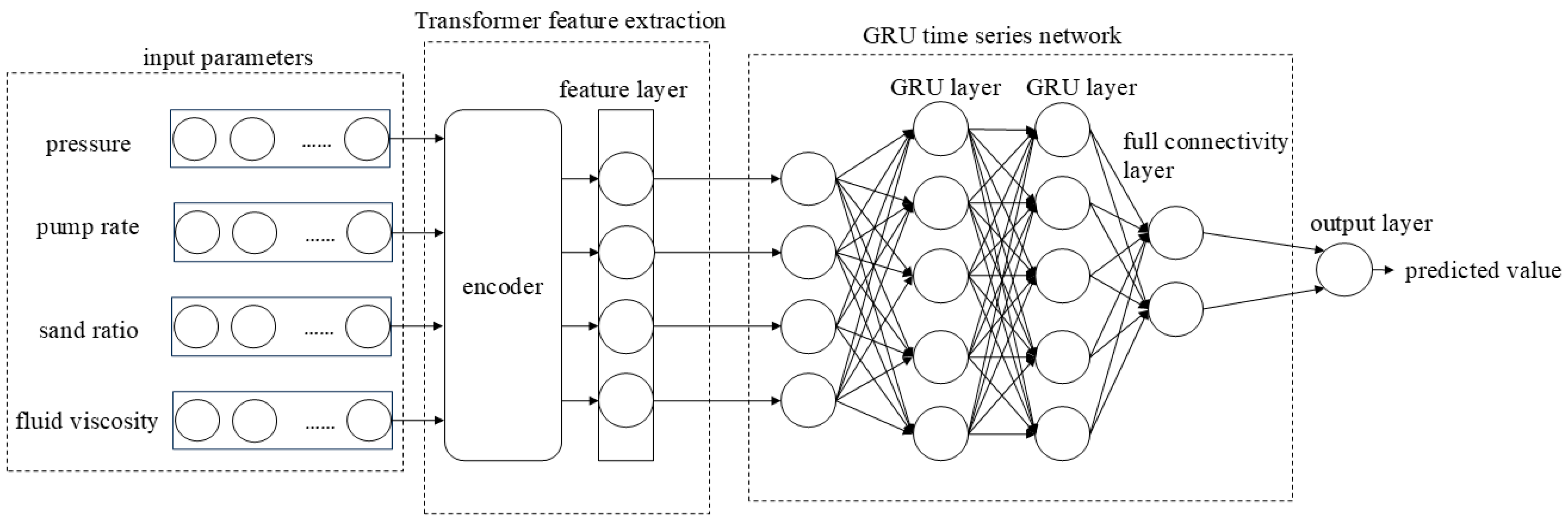

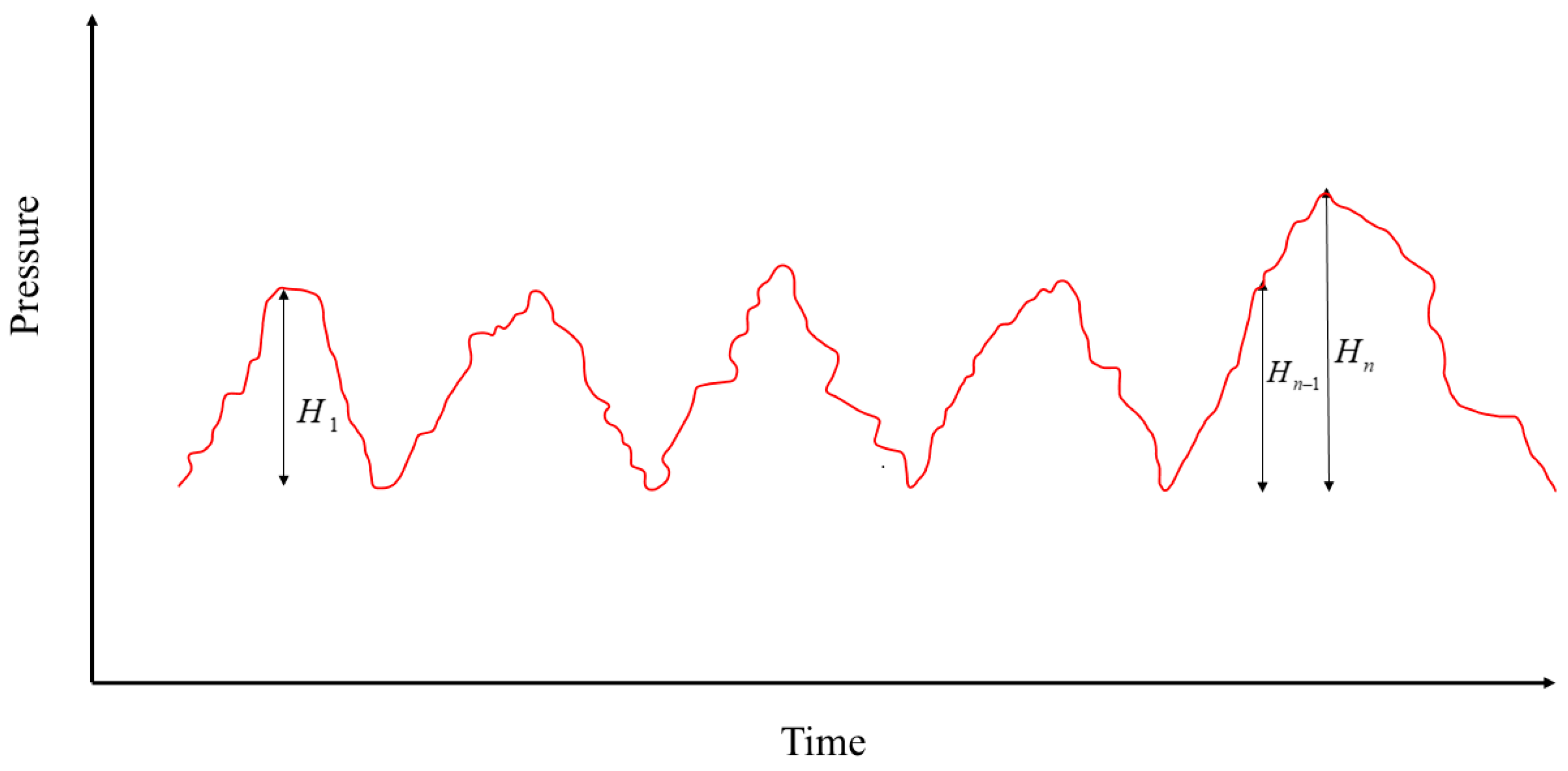

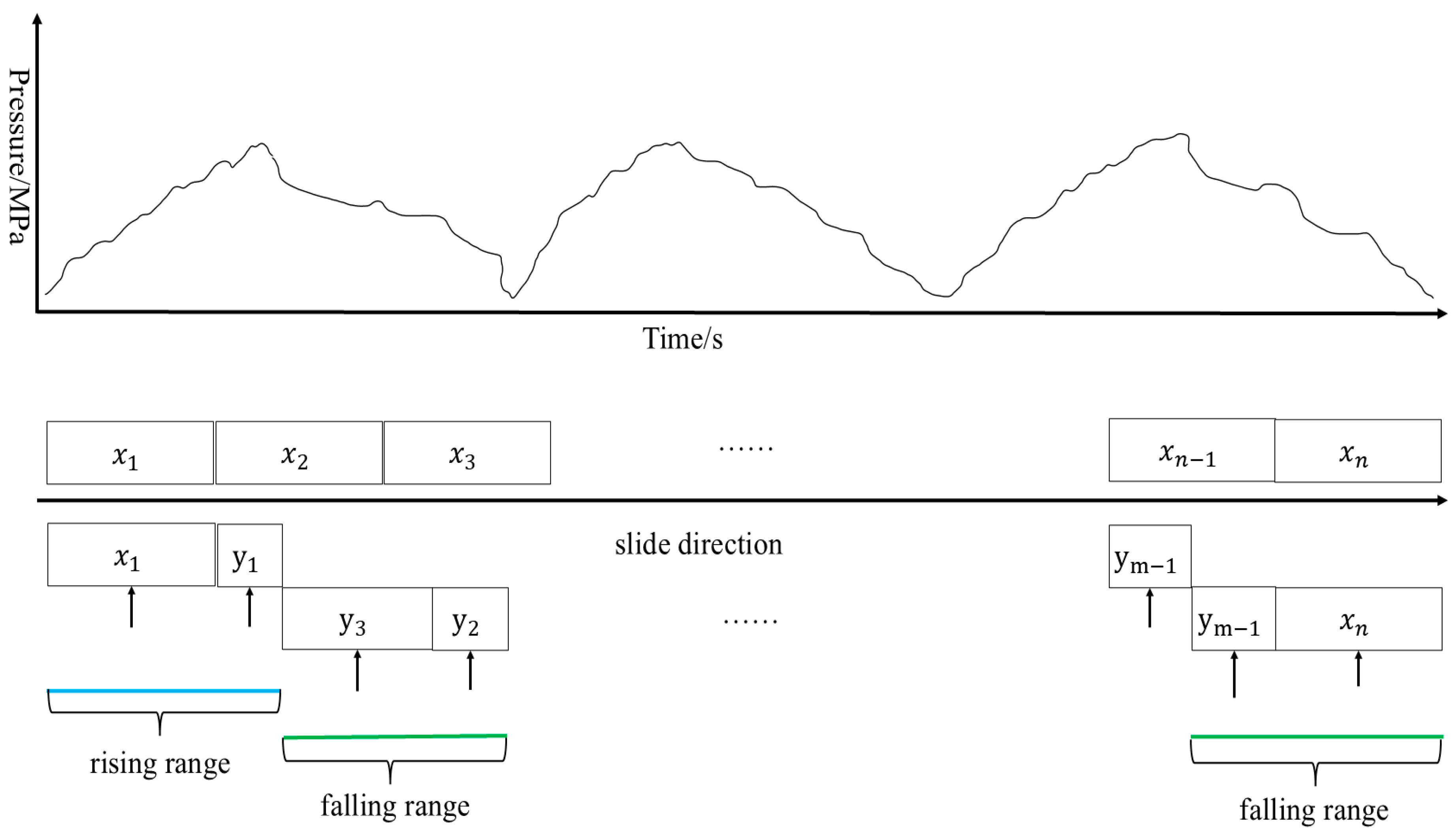

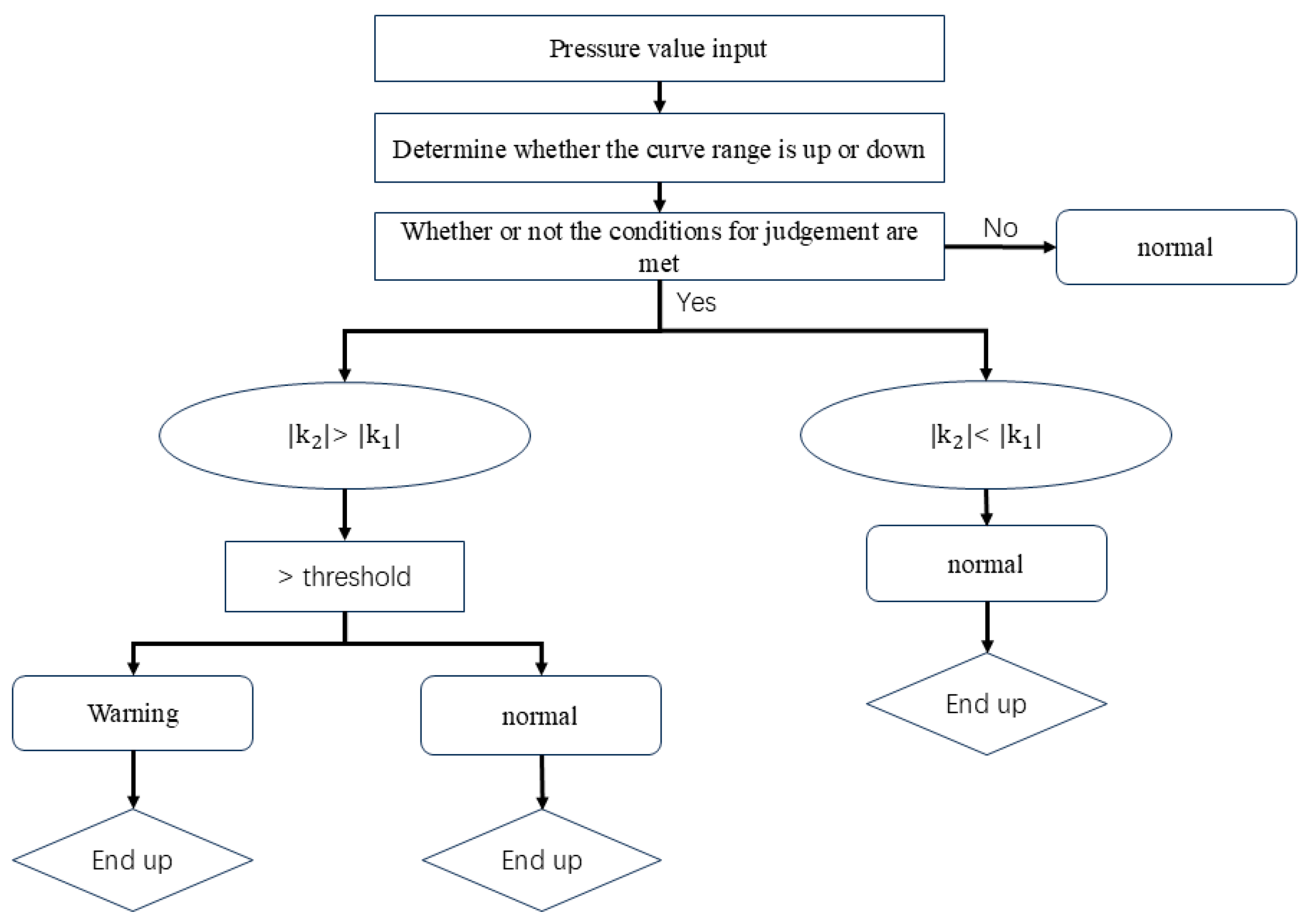

Therefore, this paper proposes a new sand screenout early warning model, which is mainly composed of two parts: a combinatorial neural network and a physical model. In the combinatorial neural network part, Transformer is used to capture the long-term fluctuation characteristics of hydraulic structure parameter data, the Gate Control Unit (GRU) is numerically predicted, and the Crested Porcupine Optimizer (CPO) is used to optimize the hyperparameters of the GRU-Transformer to better capture dependencies between construction parameters. At the same time, the physical model is improved by the traditional slope inversion method, and the difference between the maximum and minimum pressure values is calculated to adapt to the complex structural situation. Finally, the real-time predicted pressure is input into the physical model for sand screenout judgement, which provides a faster and more accurate method for the sand screenout early warning model.

4. Conclusions

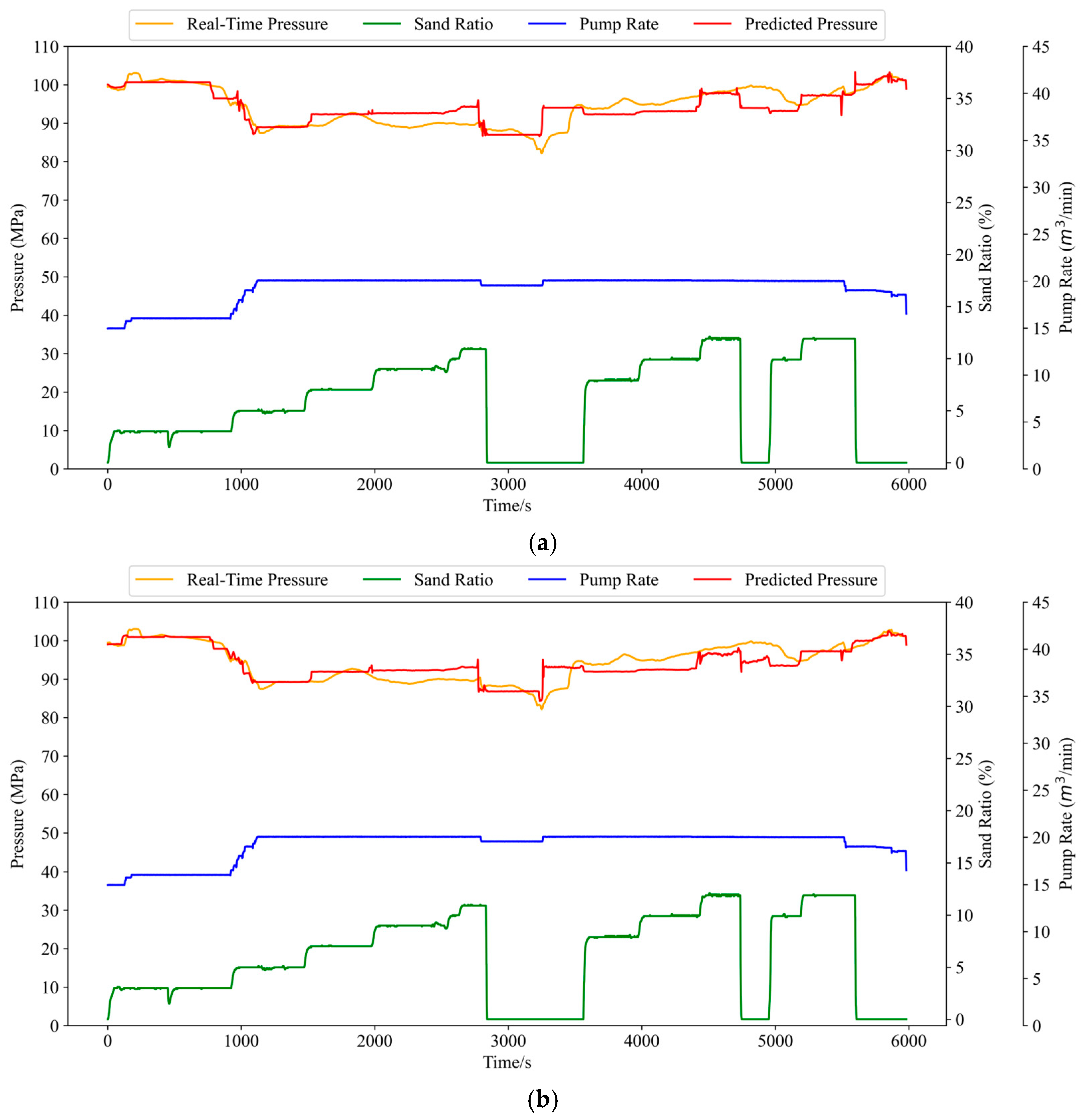

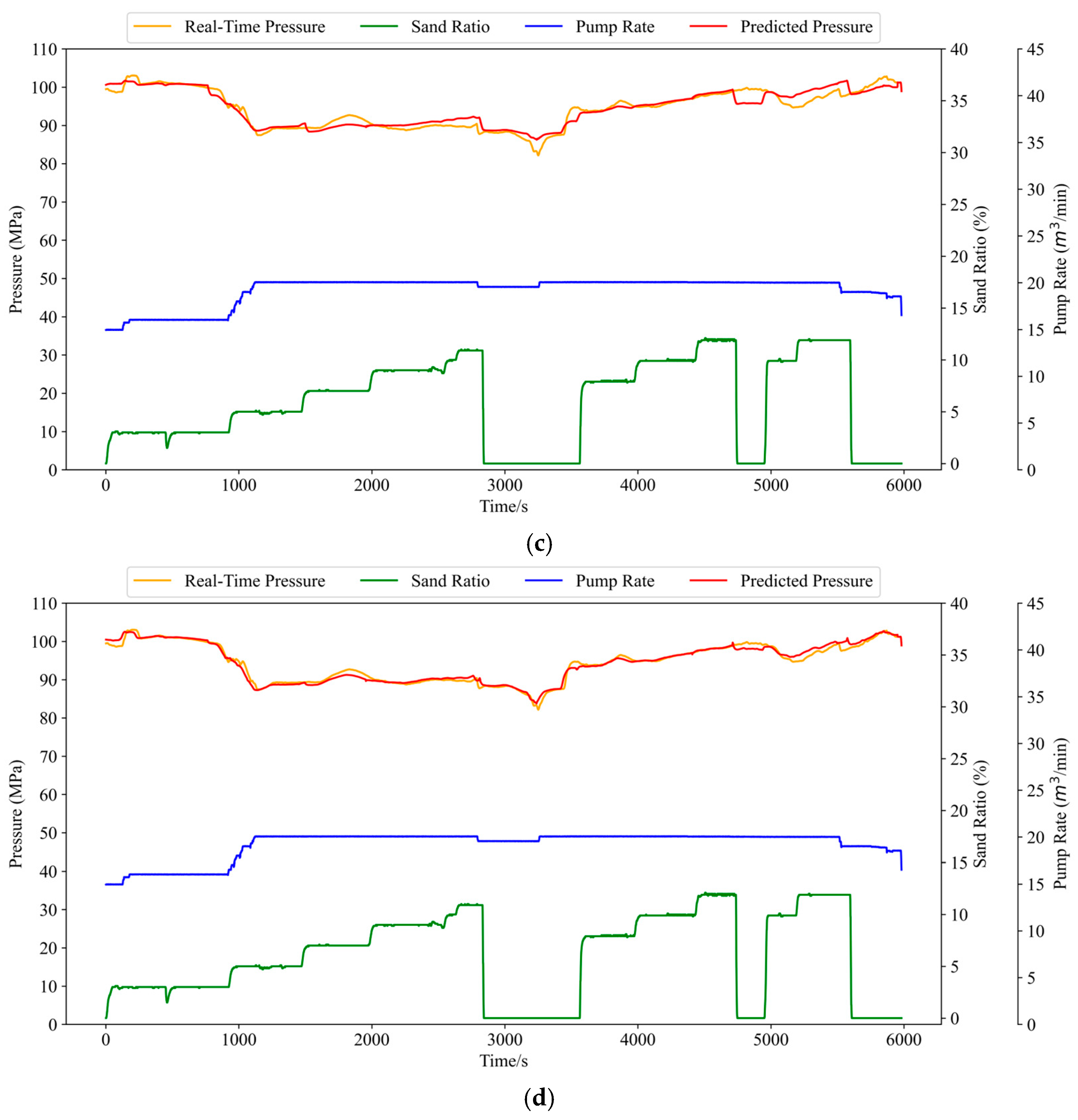

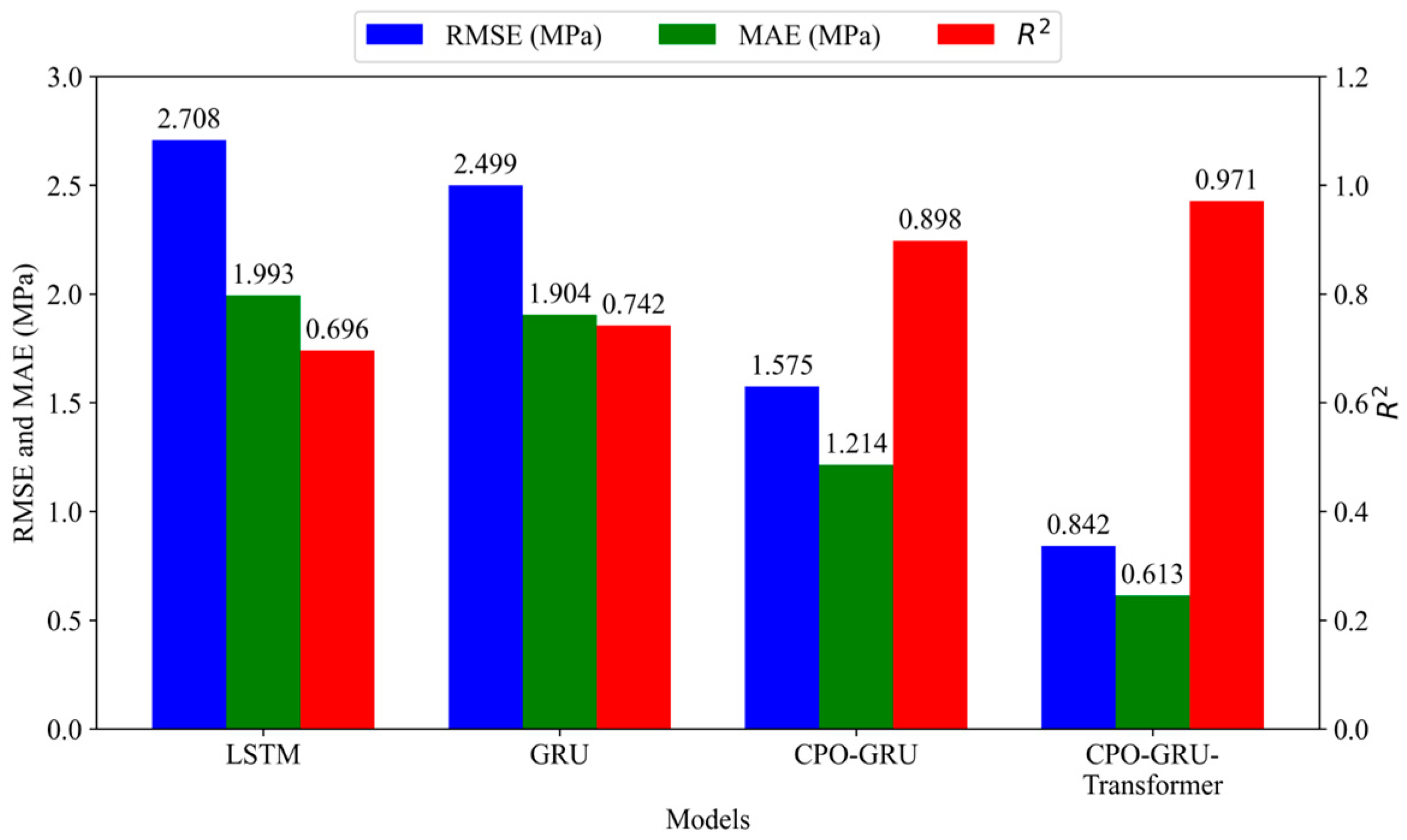

The combined neural network pressure prediction model constructed in this paper, CPO-GRU-Transformer, was compared with LSTM, GRU and CPO-GRU. It had the smallest MAE and RMSE and the largest , 0.613, 0.842 and 0.971, respectively, and it was the prediction method that best fit the pressure curve. It was experimentally verified that this model has the following advantages over LSTM, GRU and CPO-GRU in fracture pressure prediction: compared with other neural network models, this model has higher prediction accuracy, faster learning speed and faster convergence.

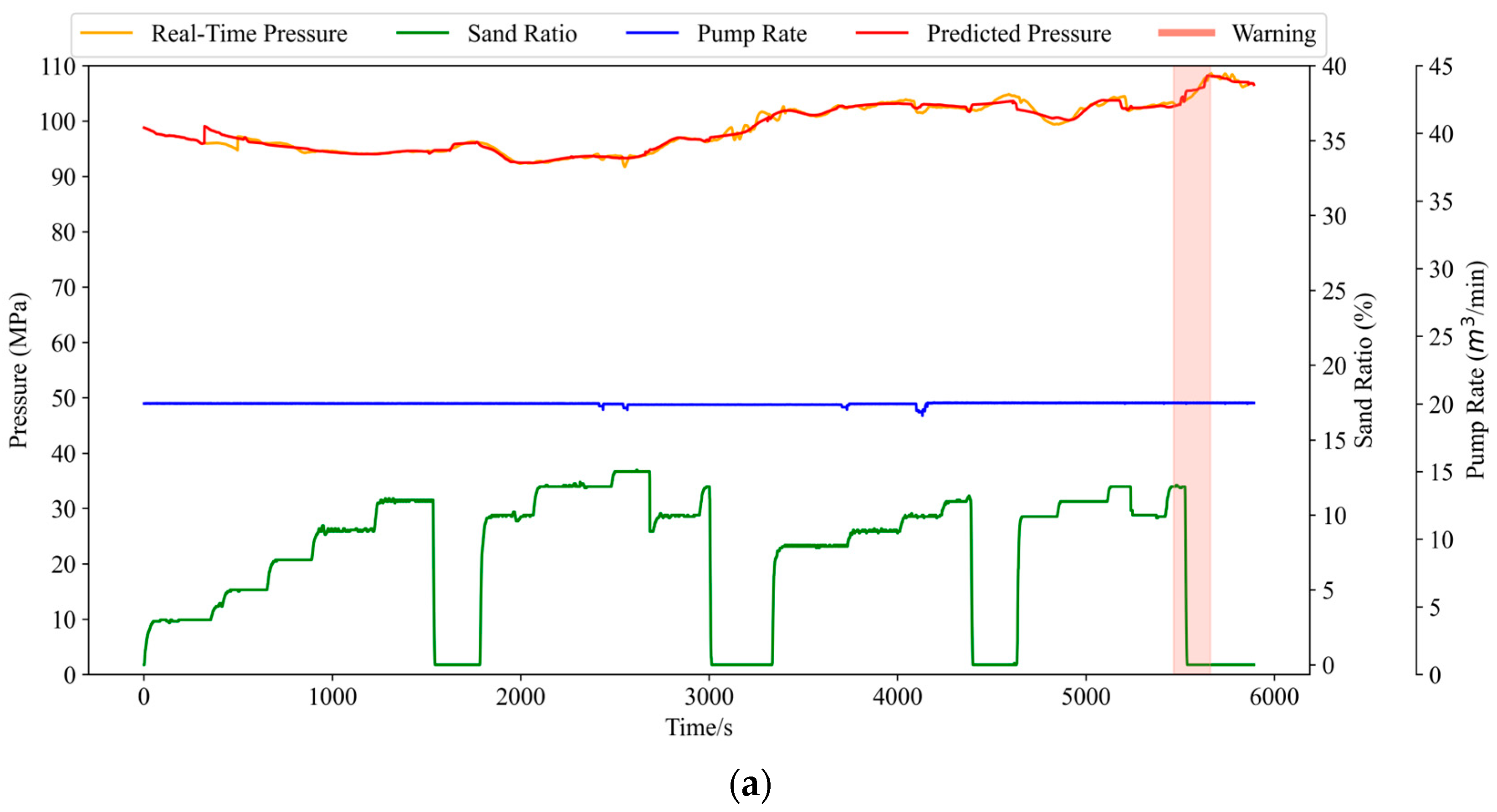

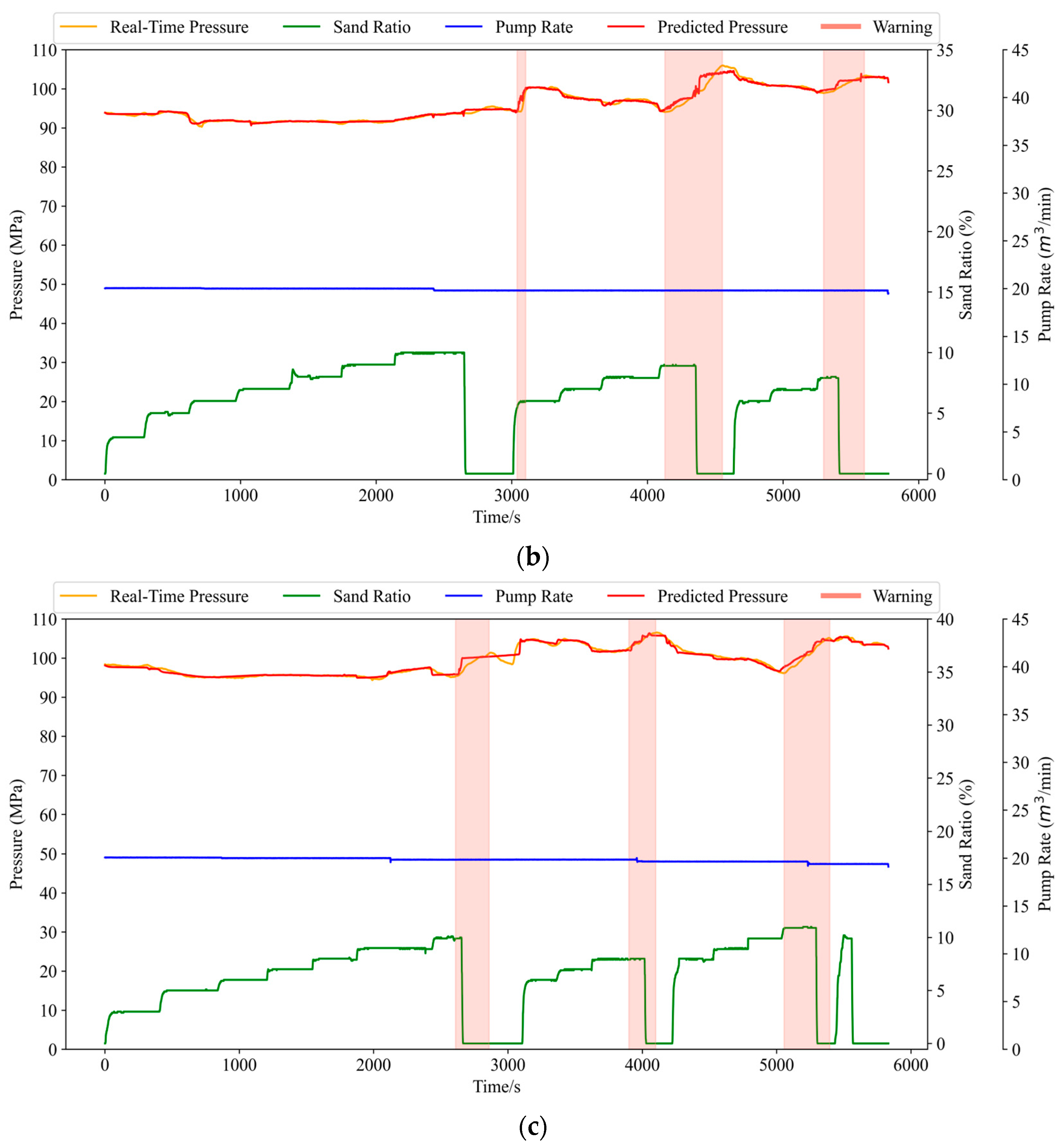

Three fracturing sections were verified in the field, with six successful alarms and one false alarm, resulting in an early warning rate of 85.71%, and the alarm point was 73.5 s earlier than the artificial sand stopping point on average, which greatly avoided the possibility of sand screenout. However, the study presented in this paper has limitations. Firstly, the sliding window size and thresholds must be set for different geological environments, which is too dependent on empirical judgement; secondly, the model requires a certain amount of computational resources, which may not be available in working environments where computational resources are scarce, which will limit the robustness of the model and prevent it from reaching the optimal prediction state. The method proposed in this paper provides a faster calculation and the most accurate warning method for sand blockage warning, which greatly avoids the occurrence of false alarms and provides effective sand screenout warning information for operators.