A Review of CO2 Capture Utilization and Storage in China: Development Status, Cost Limits, and Strategic Planning

Abstract

1. Introduction

2. CCUS Projects: A Comparison Between China and Abroad

2.1. CCUS Industrial Model

2.2. Characteristics of CCUS Projects

3. Major CO2 Emission Sources and Distribution in China

3.1. CO2 Emission Calculation

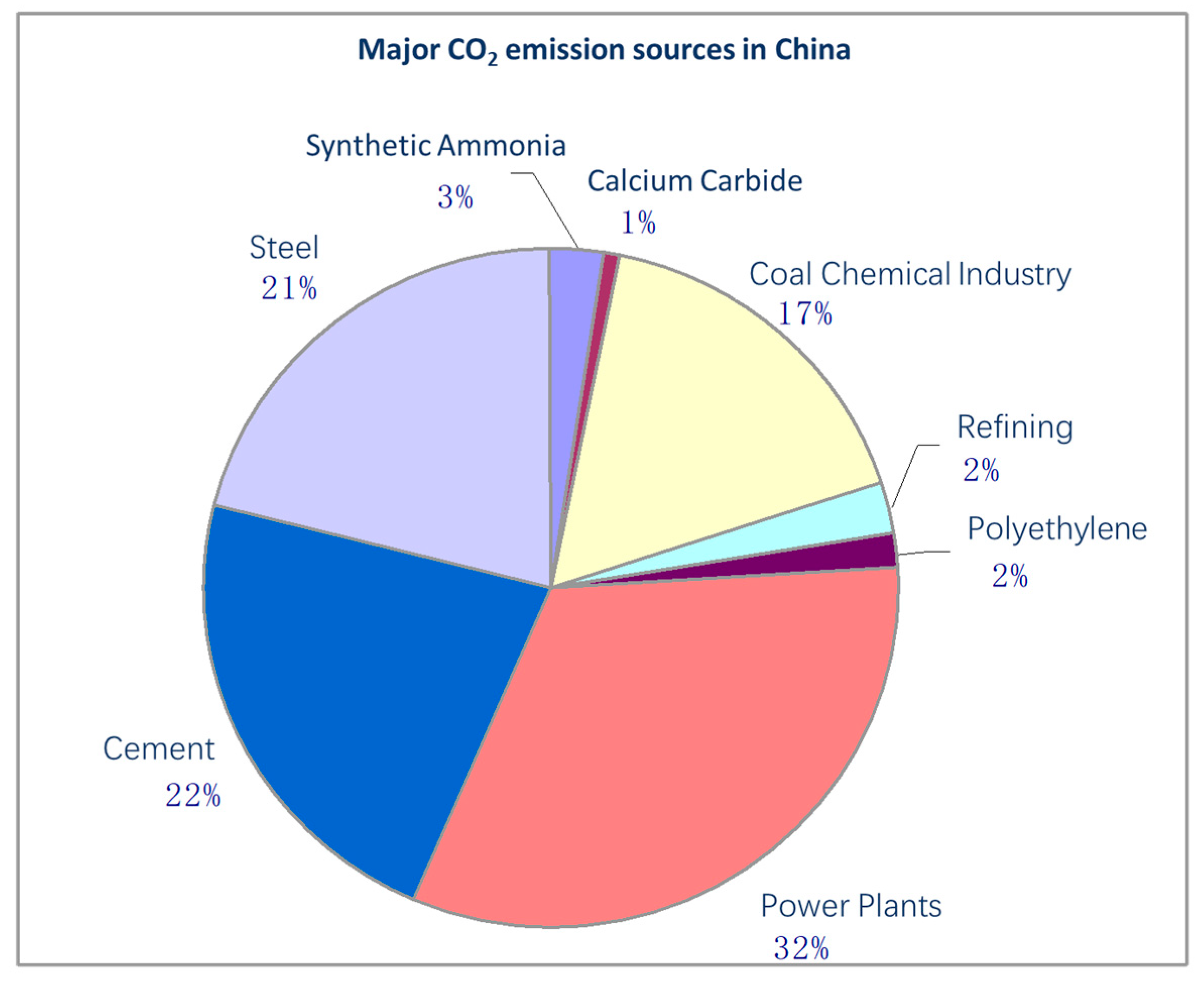

3.2. Scale and Composition of Major CO2 Emission Sources

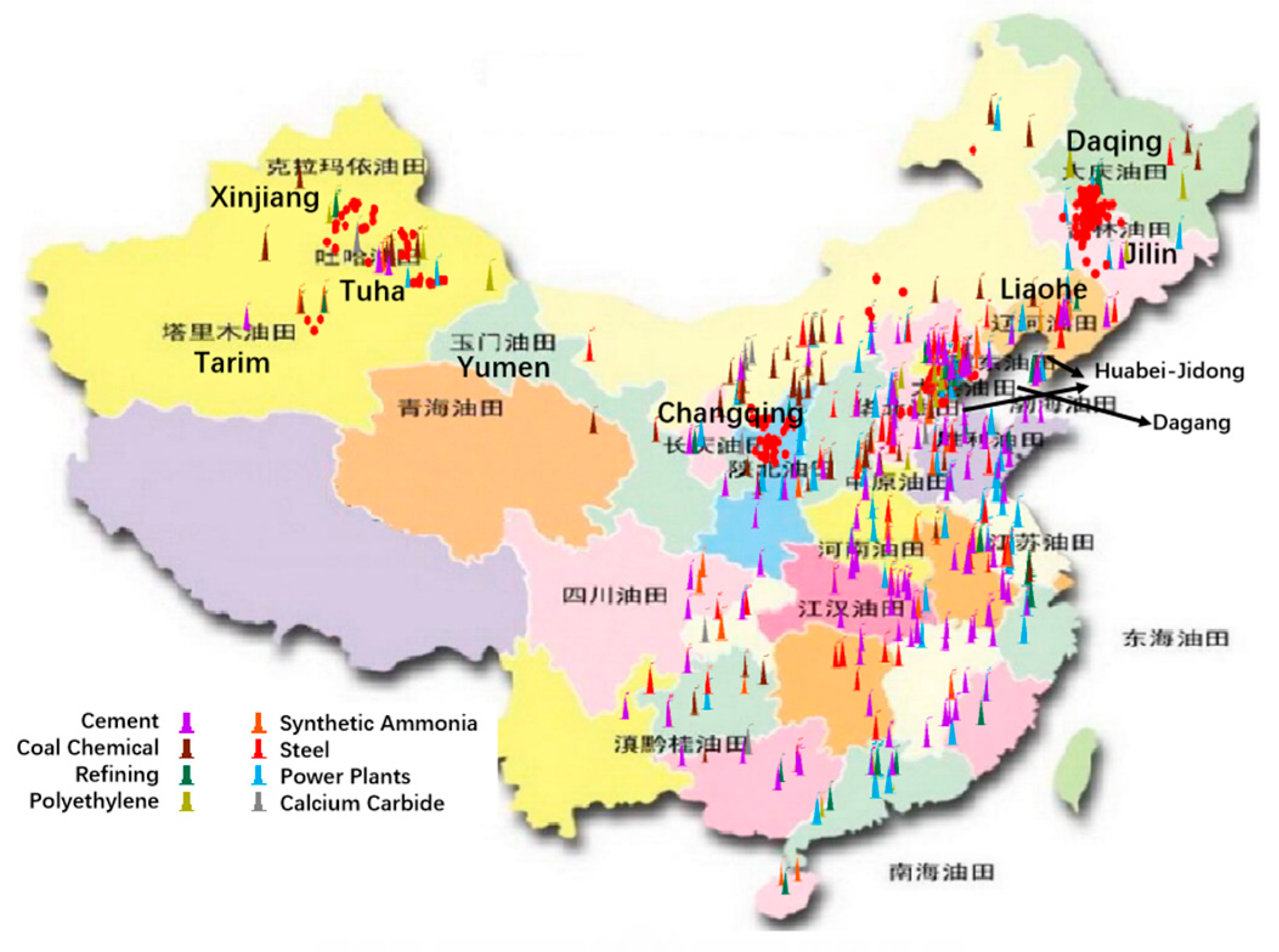

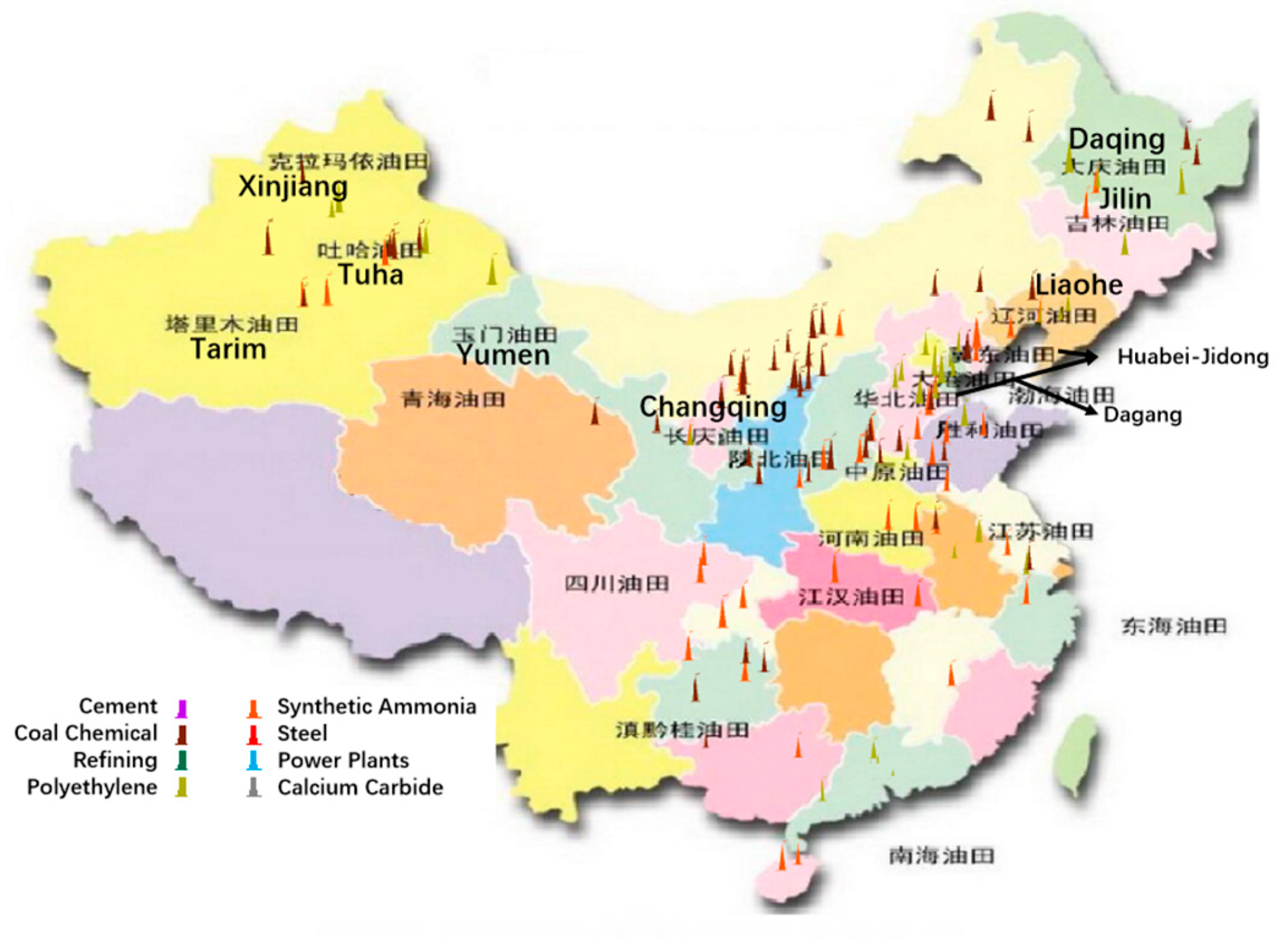

3.3. Distribution of CO2 Emission Sources

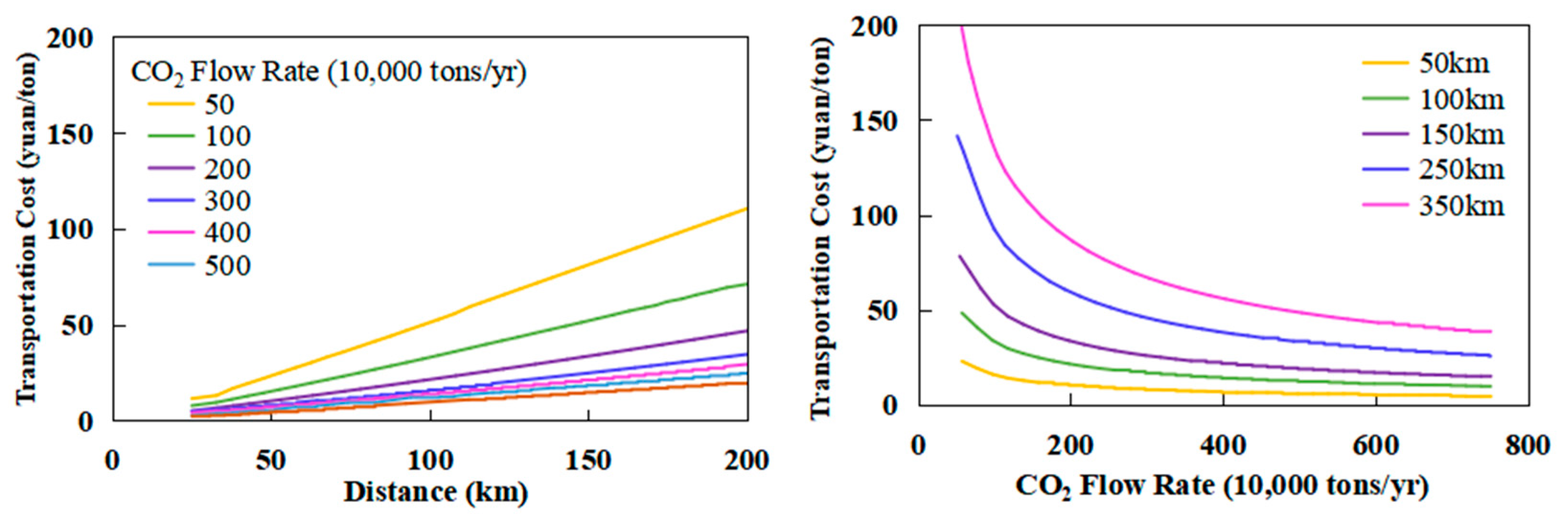

4. CO2 Source Cost and CO2-EOR Affordable Cost Limits

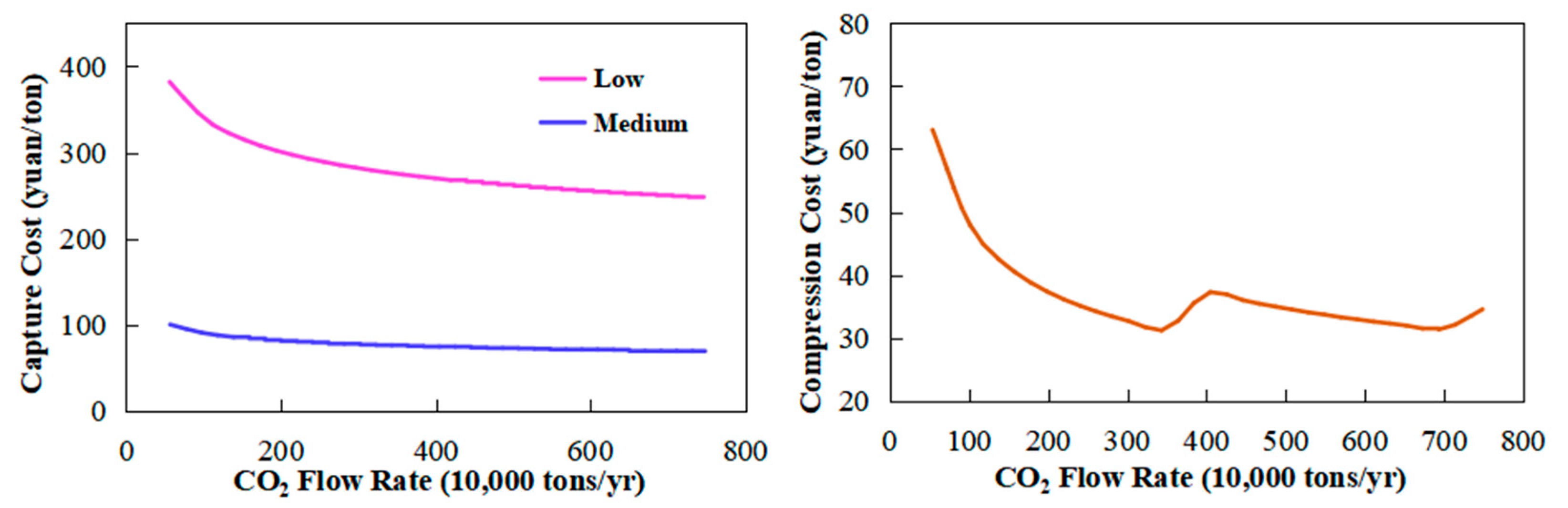

4.1. CO2 Source Cost and Influencing Factors

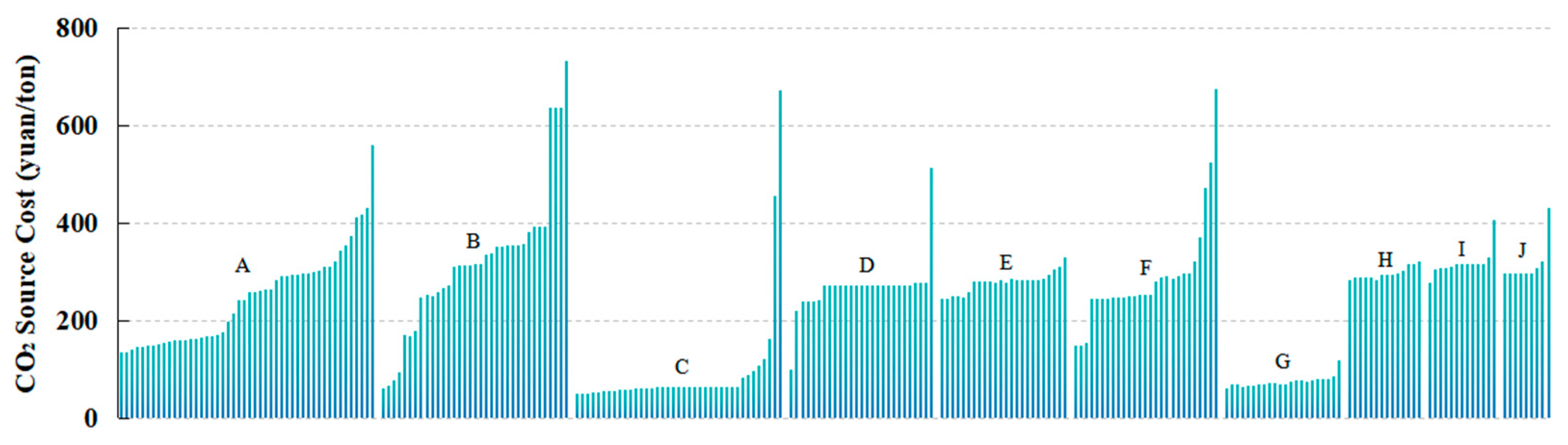

4.2. CO2 Source Cost of Each Oil Region

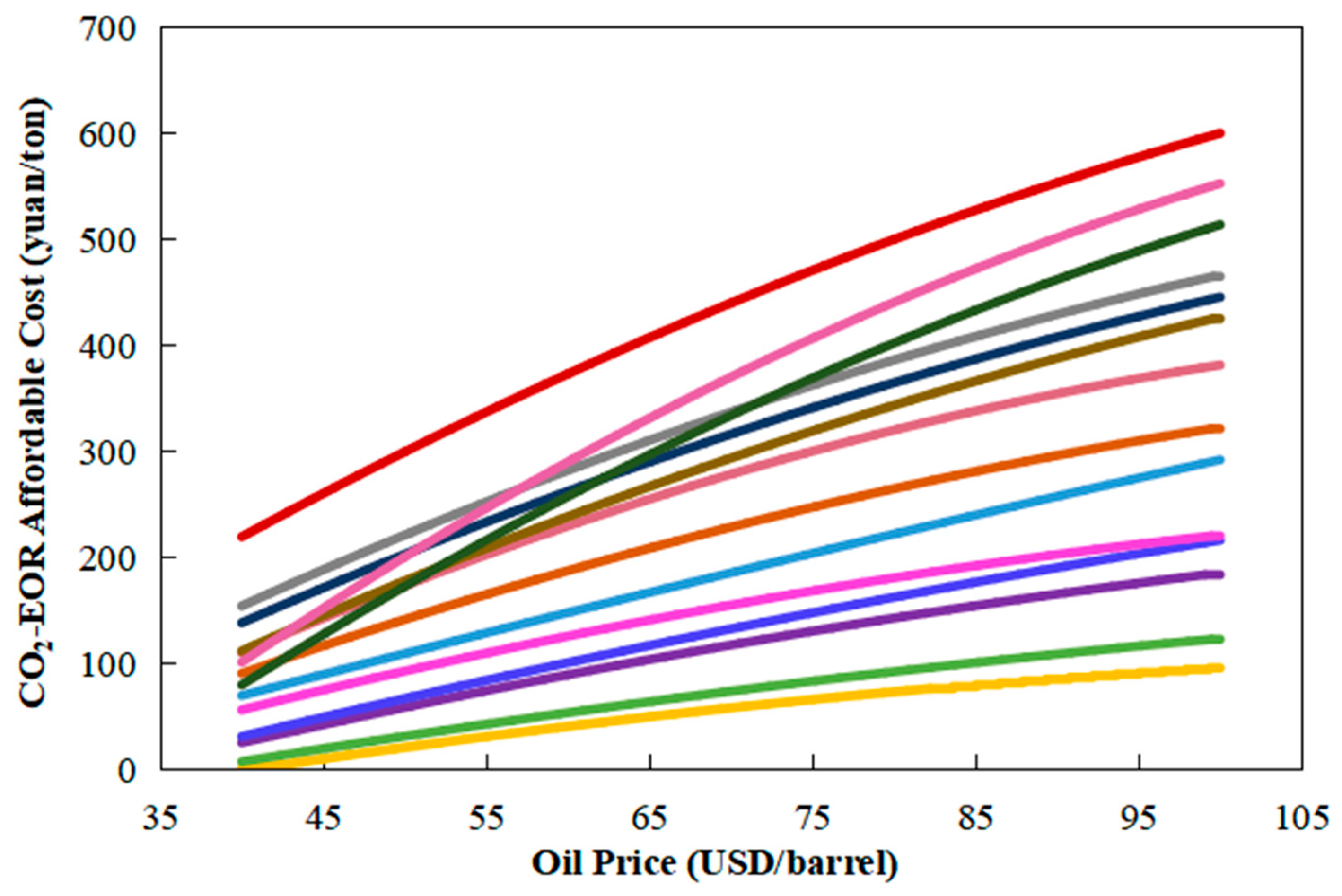

4.3. CO2-EOR Affordable Cost Limit

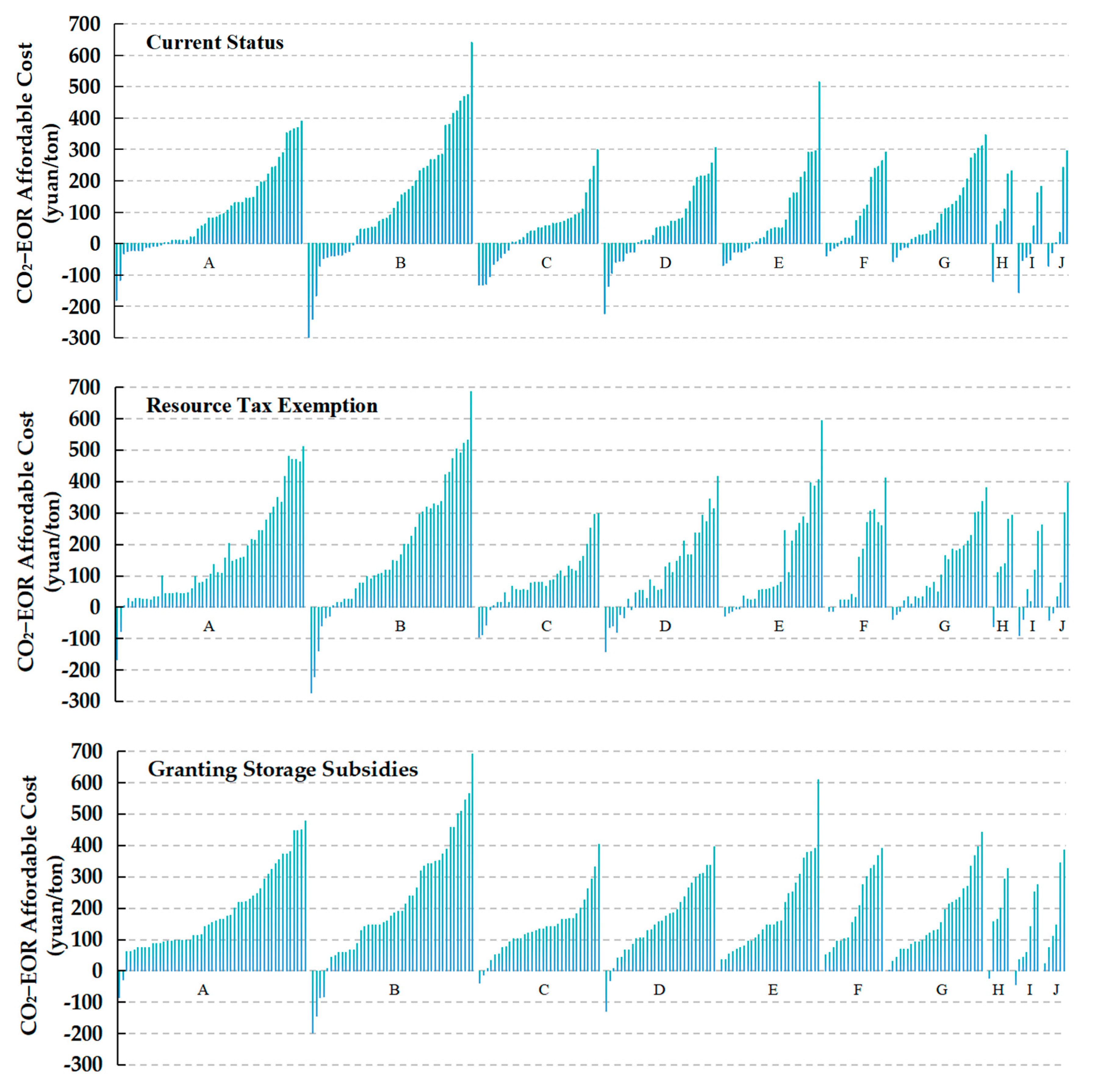

4.4. Possible Ways to Fill the Gap

5. CCUS Resource Optimization Allocation and Strategic Planning

5.1. Resource Allocation Optimization Model

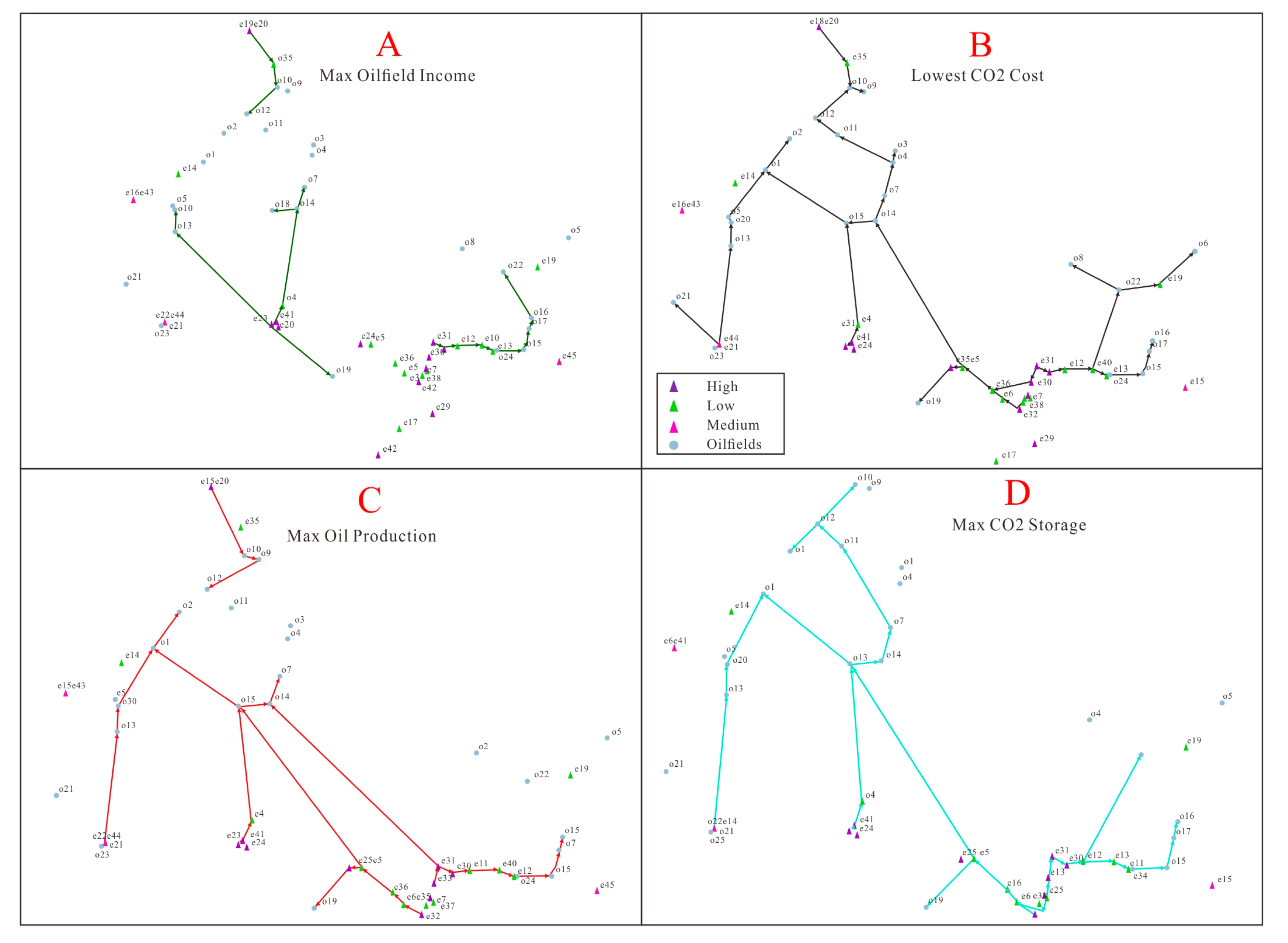

5.2. Result of Optimal Allocation of Resources

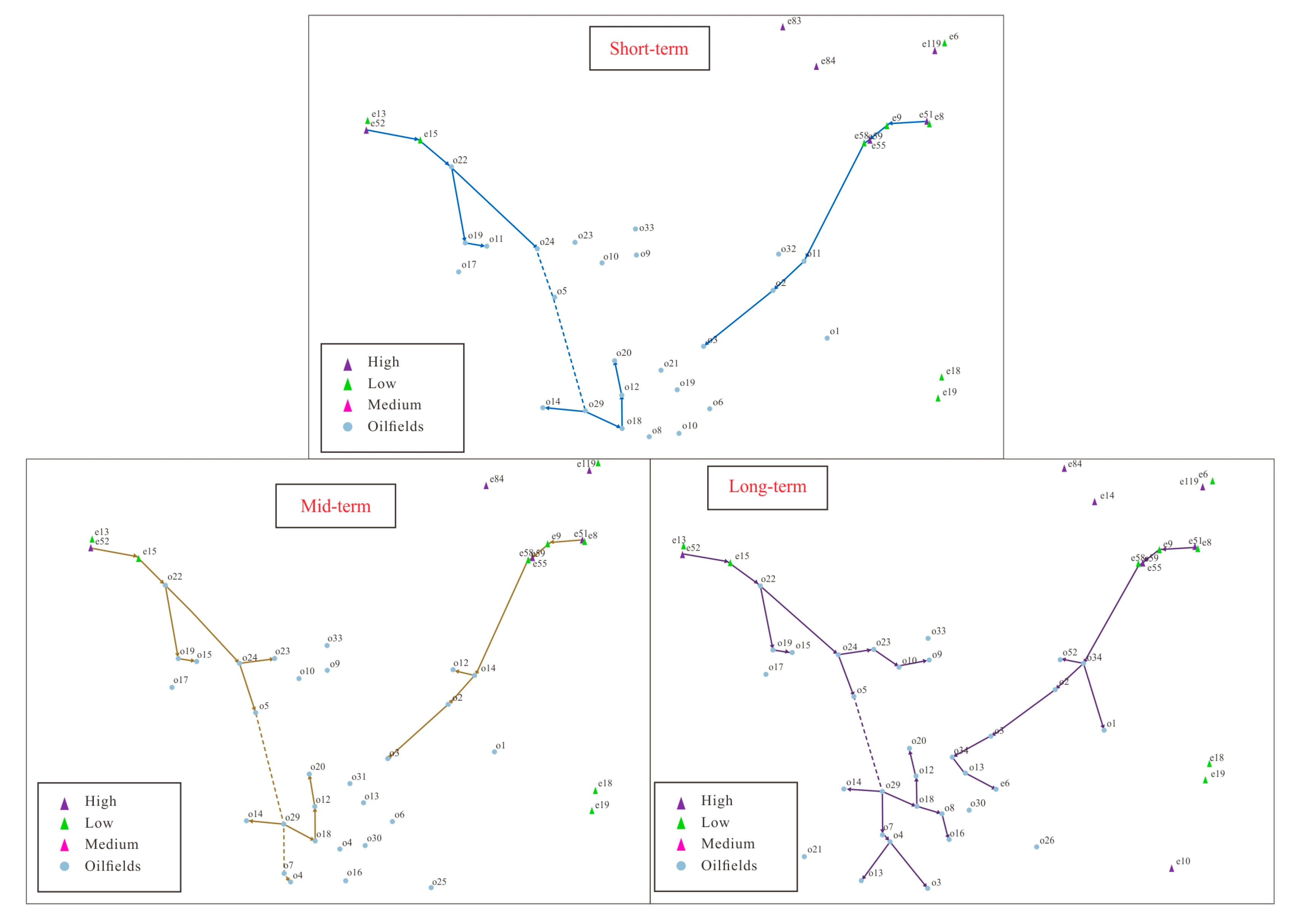

5.3. CCUS Strategic Planning Design

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| CCUS | Carbon capture, utilization, and storage |

| CCS | Carbon capture and storage |

| EOR | Enhanced oil recovery |

| CO2 | Carbon dioxide |

| CO2-EOR | Enhanced oil recovery by carbon dioxide flooding |

| CU | Capture and utilization |

| CTUS | Capture, transport, utilization, and storage |

| CTS | Capture, transport, and storage |

| ECO2 | Carbon dioxide emission (ton CO2 year−1) |

| EF | Carbon dioxide emission factor (ton CO2/ton product) |

| P | Product output (ton product year−1) |

| PC | Product annual production capacity (ton product year−1) |

| a | Capacity utilization factor |

| T | Average utilization time of equipment (hours) |

| f | Objective function |

| g | Constraint condition |

| x | Continuous variable |

| y | 0, 1 binary variable |

References

- Calvillo, C.; Race, J.; Chang, E.; Turner, K.; Katris, A. Characterisation of UK Industrial Clusters and Techno-Economic Cost Assessment for Carbon Dioxide Transport and Storage Implementation. Int. J. Greenh. Gas Control 2022, 119 (Suppl. C), 103695. [Google Scholar] [CrossRef]

- Hanson, E.; Nwakile, C.; Hammed, V.O. Carbon capture, utilization, and storage (CCUS) technologies: Evaluating the effectiveness of advanced CCUS solutions for reducing CO2 emissions. Results Surf. Interfaces 2025, 18, 100381. [Google Scholar] [CrossRef]

- HU, Y.; HAO, M.; CHEN, G.; SUN, R.; LI, S. Technologies and practice of CO2 flooding and sequestration in China. Pet. Explor. Dev. 2019, 46, 753–766. [Google Scholar] [CrossRef]

- Liu, Y.; Hao, M.; Bi, R.; Bian, C.; Wang, X. Research on Gas Channeling Identification Using the Fuzzy Comprehensive Evaluation Method. Energies 2024, 17, 3908. [Google Scholar] [CrossRef]

- Zhao, X.; Liao, X.; Wang, W.; Chen, C.; Rui, Z.; Wang, H. The CO2 storage capacity evaluation: Methodology and determination of key factors. J. Energy Inst. 2014, 87, 297–305. [Google Scholar] [CrossRef]

- Kovscek, A.R. Screening criteria for CO2 storage in oil reservoirs. Pet. Sci. Technol. 2002, 20, 841–866. [Google Scholar] [CrossRef]

- Malik, Q.M.; Islam, M.R. CO2 Injection in the Weyburn Field of Canada: Optimization of Enhanced Oil Recovery and Greenhouse Gas Storage with Horizontal Wells. Soc. Pet. Eng. J. 2000, SPE-59327-MS. [Google Scholar] [CrossRef]

- Zhao, X.; Liao, X. Evaluation Method of CO2 Sequestration and Enhanced Oil Recovery in an Oil Reservoir, as Applied to the Changqing Oilfields, China. Energy Fuels 2012, 26, 5350–5354. [Google Scholar] [CrossRef]

- Edwards, K. CO in Alberta-A Vision of the Future. J. Can. Pet. Technol. 2000, 39, 9. [Google Scholar] [CrossRef]

- Bachu, S.; Shaw, J. Evaluation of the CO2 Sequestration Capacity in Alberta’s Oil and Gas Reservoirs at Depletion and the Effect of Underlying Aquifers. J. Can. Pet. Technol. 2003, 42, 51–61. [Google Scholar] [CrossRef]

- Agency, I.E. CCUS in Clean Energy Transitions. 2020. Available online: https://www.iea.org/reports/ccus-in-clean-energy-transitions (accessed on 19 November 2024).

- Holtz, M.H.; Nance, P.K.; Finley, R.J. Reduction of Greenhouse Gas Emissions through CO2 EOR in Texas. Environ. Geosci. 2001, 8, 187–199. [Google Scholar] [CrossRef]

- Miao, L.; Feng, L.; Ma, Y. Comprehensive evaluation of CCUS technology: A case study of China’s first million-tonne CCUS-EOR project. Environ. Impact Assess. Rev. 2025, 110, 107684. [Google Scholar] [CrossRef]

- Zhang, Z.; Wang, T.; Blunt, M.J.; Anthony, E.J.; Park, A.-H.A.; Hughes, R.W.; Webley, P.A.; Yan, J. Advances in carbon capture, utilization and storage. Appl. Energy 2020, 278, 115627. [Google Scholar] [CrossRef]

- Cao, C.; Hou, M.Z.; Zhang, L.; Zhao, Y.; Liu, H. Advances in Carbon Capture, Utilization and Storage (CCUS). Energies 2024, 17, 4784. [Google Scholar] [CrossRef]

- Phillips, C.; Haghighi, H. Industry Guidelines for Setting the CO2 Specification in CCUS Chains. In Proceedings of the ADIPEC, Abu Dhabi, United Arab Emirates, 3–6 November 2024; p. 222455. [Google Scholar]

- Sahak, M.Z.M.; Zain, M.M.; Alias, A.; Zulkifli, M.Y.; Rohani, S.N.; Rostani, K. Establishing Key Process Design Considerations for Carbon Capture, Utilization and Storage (CCUS) Towards Decarbonization of Existing Assets Operations. In Proceedings of the ADIPEC, Abu Dhabi, United Arab Emirates, 4–7 November 2024; p. 221884. [Google Scholar]

- Mon, M.T.; Tansuchat, R.; Yamaka, W. CCUS Technology and Carbon Emissions: Evidence from the United States. Energies 2024, 17, 1748. [Google Scholar] [CrossRef]

- Aydin, G.; Karakurt, I.; Aydiner, K. Evaluation of geologic storage options of CO2: Applicability, cost, storage capacity and safety-ScienceDirect. Energy Policy 2010, 38, 5072–5080. [Google Scholar] [CrossRef]

- Carpenter, C. Study Examines Economics of CCUS Projects in Conjunction with Large offshore Gas Projects. J. Pet. Technol. 2024, 76, 66–69. [Google Scholar] [CrossRef]

- Benz, E.; Trück, S. Modeling the price dynamics of CO2 emission allowances. Energy Econ. 2009, 31, 4–15. [Google Scholar] [CrossRef]

- Zou, C.; Wu, S.; Yang, Z.; Pan, S.; Wang, G.; Jiang, X.; Guan, M.; Yu, C.; Yu, Z.; Shen, Y. Progress, challenge and significance of building a carbon industry system in the context of carbon neutrality strategy. Petroleum Explor. Dev. 2023, 50, 210–228. [Google Scholar] [CrossRef]

- Mccoy, S.T.; Rubin, E.S. An engineering-economic model of pipeline transport of CO2 with application to carbon capture and storage. Int. J. Greenh. Gas Control 2008, 2, 219–229. [Google Scholar] [CrossRef]

- Rui, Z.; Zeng, L.; Dindoruk, B. Challenges in the Large-Scale Deployment of CCUS. Engineering 2024, 44, 17–20. [Google Scholar] [CrossRef]

- Shiyi, Y.; Desheng, M.; Junshi, L.; Tiyao, Z.; Zemin, J.; Haishui, H. Progress and prospects of carbon dioxide capture, EOR-utilization and storage industrialization. Pet. Explor. Dev. 2022, 49, 955–962. [Google Scholar]

- Middleton, R.S.; Bielicki, J.M. A scalable infrastructure model for carbon capture and storage: SimCCS. Energy Policy 2009, 37, 1052–1060. [Google Scholar] [CrossRef]

- Song, X.; Wang, F.; Ma, D.; Gao, M.; Zhang, Y. Progress and prospect of carbon dioxide capture, utilization and storage in CNPC oilfields. Pet. Explor. Dev. 2023, 50, 229–244. [Google Scholar] [CrossRef]

- Han, J.-H.; Lee, I.-B. Development of a Scalable and Comprehensive Infrastructure Model for Carbon Dioxide Utilization and Disposal. Ind. Eng. Chem. Res. 2011, 50, 6297–6315. [Google Scholar] [CrossRef]

- Kemp, A.G.; Kasim, S. A Futuristic Least-cost Optimisation Model of CO2 Transportation and Storage in the UK/UK Continental Shelf. Energy Policy 2009, 38, 3652–3667. [Google Scholar] [CrossRef]

- Klokk; Schreiner, P.F.; Pages-Bemaus, A.; Tomasgard, A. Optimizing a CO2 value chain for the Norwegian Continental Shelf. Energy Policy 2010, 38, 6604–6614. [Google Scholar] [CrossRef]

- Davison, J. Performance and costs of power plants with capture and storage of CO2. Energy 2007, 32, 1163–1176. [Google Scholar] [CrossRef]

- Rubin, E.S.; Chen, C.; Rao, A.B. Cost and performance of fossil fuel power plants with CO2 capture and storage. Energy Policy 2007, 35, 4444–4454. [Google Scholar] [CrossRef]

- Vulin, D.; Močilac, I.K.; Jukić, L.; Arnaut, M.; Vodopić, F.; Saftić, B.; Sedlar, D.K.; Cvetković, M. Development of CCUS clusters in Croatia. Int. J. Greenh. Gas Control 2023, 124 (Suppl. C), 103857. [Google Scholar] [CrossRef]

- Wang, F.; Liao, G.; Su, C.; Wang, F.; Ma, J.; Yang, Y. Carbon emission reduction accounting method for a CCUS-EOR project. Pet. Explor. Dev. 2023, 50, 989–1000. [Google Scholar] [CrossRef]

- Gaspar, A.T.F.S.; Lima, G.A.C.; Suslick, S.B. CO2 Capture and Storage in Mature Oil Reservoir: Physical Description, EOR and Economic Valuation of a Case of a Brazilian Mature Field. In Proceedings of the SPE Europec/EAGE Annual Conference, Madrid, Spain, 13–16 June 2005. [Google Scholar]

- Mccollum, D.L.; Ogden, J.M. Techno-Economic Models for Carbon Dioxide Compression, Transport, and Storage & Correlations for Estimating Carbon Dioxide Density and Viscosit; Working Paper Series; Institute of Transportation Studies: Davis, CA, USA, 2006. [Google Scholar]

- Rubin, E.S.; Yeh, S.; Antes, M.; Berkenpas, M.; Davison, J. Use of experience curves to estimate the future cost of power plants with CO2 capture. Int. J. Green House Gas Control 2007, 1, 188–197. [Google Scholar] [CrossRef]

- Stalkup, F.I. Carbon Dioxide Miscible Flooding: Past, Present, and Outlook for the Future. J. Pet. Technol. 1978, 30, 1102–1112. [Google Scholar] [CrossRef]

- Zhao, X.; Xiao, J.; Hou, J.; Wu, J.; Lyu, X.; Zhang, J.; Liu, Y. Economic and scale prediction of CO2 capture, utilization and storage technologies in China. Pet. Explor. Dev. 2023, 50, 751–764. [Google Scholar] [CrossRef]

- Zhou, J.; Chen, Z.; Wu, S.; Yang, C.; Wang, Y.; Wu, Y. Potential assessment and development obstacle analysis of CCUS layout in China: A combined interpretive model based on GIS-DEMATEL-ISM. Energy 2024, 310, 133225. [Google Scholar] [CrossRef]

| Industries | Coal Chemical | ||||||

|---|---|---|---|---|---|---|---|

| Methanol Synthesis | Olefin Synthesis | Coal Liquefaction (Direct) | Coal Liquefaction (Direct) | ||||

| Emission Factors | 2 | 6 | 2.1 | 3.3 | |||

| Industries | Power Plants | Cement | Steel | Synthetic Ammonia | Refining | Polyethylene | Calcium Carbide |

| Emission Factors | 1 | 0.882 | 1.27 | 3.8 | 0.219 | 2.541 | 5.2 |

| Industries | Power Plants | Coal Chemical | Cement | Calcium Carbide | Refining | Synthetic Ammonia | Steel | Polyethylene |

|---|---|---|---|---|---|---|---|---|

| Average CO2 emissions | 1085.36 | 931.68 | 473.01 | 281.65 | 297.16 | 218.09 | 731.82 | 164.11 |

| Oil Regions | A | B | C | D | E | F | G | H | I | J |

|---|---|---|---|---|---|---|---|---|---|---|

| Highest Cost | 557 | 731 | 669 | 511 | 327 | 672 | 117 | 406 | 320 | 430 |

| Lowest Cost | 133 | 60 | 48 | 98 | 243 | 147 | 60 | 276 | 282 | 294 |

| Average Cost | 244 | 328 | 61 | 258 | 273 | 276 | 74 | 314 | 296 | 298 |

| Variance | 95.72 | 155.72 | 115.34 | 60.14 | 20.92 | 111.26 | 11.32 | 12.74 | 29.28 | 44.09 |

| Oil Regions | Technology Feasible Projects | Economically Feasible Projects | ||||

|---|---|---|---|---|---|---|

| CO2 <0 CNY/ton | CO2 0–200 CNY/ton | CO2 200–400 CNY/ton | CO2 >400 CNY/ton | |||

| A | Projects | 50 | 12 | 28 | 10 | |

| Percentage | 100% | 24% | 56% | 20% | ||

| B | Projects | 39 | 11 | 14 | 9 | 5 |

| Percentage | 100% | 28.2% | 35.9% | 23.08% | 12.82% | |

| C | Projects | 34 | 8 | 23 | 3 | |

| Percentage | 100% | 23.53% | 67.65% | 8.82% | ||

| D | Projects | 27 | 8 | 14 | 5 | |

| Percentage | 100% | 29.63% | 51.85% | 18.52% | ||

| E | Projects | 25 | 8 | 11 | 5 | 1 |

| Percentage | 100% | 32% | 44% | 20% | 4% | |

| F | Projects | 12 | 4 | 4 | 4 | |

| Percentage | 100% | 33.33% | 33.33% | 33.33% | ||

| G | Projects | 24 | 6 | 14 | 4 | |

| Percentage | 100% | 25% | 58.33% | 16.67% | ||

| H | Projects | 7 | 4 | 3 | ||

| Percentage | 100% | 57.14% | 42.86% | |||

| I | Projects | 6 | 1 | 3 | 2 | |

| Percentage | 100% | 16.67% | 50% | 33.33% | ||

| J | Projects | 6 | 2 | 2 | 2 | |

| Percentage | 100% | 33.33% | 33.33% | 33.33% | ||

| Sum | Projects | 230 | 64 | 116 | 44 | 6 |

| Percentage | 100% | 27.83% | 50.43% | 19.13% | 2.61% | |

| Oil Regions | Tech. Feasible Oilfields | Current Situation | Source Cost Reduction 20% | Source Cost Reduction 30% | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Cost Diff. <= 0 (CNY/ton) | Cost Diff. > 0 (CNY/ton) | Eco. Feasible Percent | Cost Diff. <= 0 (CNY/ton) | Cost Diff. > 0 (CNY/ton) | Eco. Feasible Percent | Cost Diff. <= 0 (CNY/ton) | Cost Diff. > 0 (CNY/ton) | Eco. Feasible Percent | ||

| A | 50 | 45 | 5 | 10% | 40 | 10 | 20% | 36 | 14 | 28% |

| B | 39 | 28 | 11 | 28% | 27 | 12 | 31% | 26 | 13 | 33% |

| C | 34 | 26 | 8 | 24% | 24 | 10 | 29% | 23 | 11 | 32% |

| D | 27 | 26 | 1 | 4% | 23 | 4 | 15% | 22 | 5 | 19% |

| E | 25 | 21 | 4 | 16% | 20 | 5 | 20% | 19 | 6 | 24% |

| F | 12 | 10 | 2 | 17% | 9 | 3 | 25% | 8 | 4 | 33% |

| G | 24 | 13 | 11 | 46% | 13 | 11 | 46% | 13 | 11 | 46% |

| H | 7 | 7 | 7 | 7 | ||||||

| I | 6 | 6 | 6 | 5 | 1 | 17% | ||||

| J | 6 | 5 | 1 | 17% | 4 | 2 | 33% | 4 | 2 | 33% |

| Sum | 230 | 187 | 43 | 19% | 173 | 57 | 25% | 163 | 67 | 29% |

| Oil Regions | Tech. Feasible Oilfields | Current Situation | Resource Tax Exemption | Storage Subsidies | ||||||

| Cost Diff. <= 0 (CNY/ton) | Cost Diff. > 0 (CNY/ton) | Eco. Feasible Percent | Cost Diff. <= 0 (CNY/ton) | Cost Diff. > 0 (CNY/ton) | Eco. Feasible Percent | Cost Diff. <= 0 (CNY/ton) | Cost Diff. > 0 (CNY/ton) | Eco. Feasible Percent | ||

| A | 50 | 45 | 5 | 10% | 35 | 15 | 30% | 31 | 19 | 38% |

| B | 39 | 28 | 11 | 28% | 25 | 14 | 36% | 24 | 15 | 38% |

| C | 34 | 26 | 8 | 24% | 18 | 16 | 47% | 10 | 24 | 71% |

| D | 27 | 26 | 1 | 4% | 22 | 5 | 19% | 20 | 7 | 26% |

| E | 25 | 21 | 4 | 16% | 20 | 5 | 20% | 19 | 6 | 24% |

| F | 12 | 10 | 2 | 17% | 9 | 3 | 25% | 8 | 4 | 33% |

| G | 24 | 13 | 11 | 46% | 11 | 13 | 54% | 4 | 20 | 83% |

| H | 7 | 7 | 7 | 0% | 7 | 0% | ||||

| I | 6 | 6 | 5 | 1 | 17% | 4 | 2 | 33% | ||

| J | 6 | 5 | 1 | 17% | 5 | 1 | 17% | 4 | 2 | 33% |

| Sum | 230 | 187 | 43 | 19% | 157 | 73 | 32% | 131 | 99 | 43% |

| Oil Regions | Tech. Feasible Oilfields | Current Situation | Cost Red. 20% and Tax Exemp. | Cost Red. 30% and Subsidies | ||||||

| Cost Diff. <= 0 (CNY/ton) | Cost Diff. > 0 (CNY/ton) | Eco. Feasible Percent | Cost Diff. <= 0 (CNY/ton) | Cost Diff. > 0 (CNY/ton) | Eco. Feasible Percent | Cost Diff. <= 0 (CNY/ton) | Cost Diff. > 0 (CNY/ton) | Eco. Feasible Percent | ||

| A | 50 | 45 | 5 | 10% | 34 | 16 | 32% | 24 | 26 | 52% |

| B | 39 | 28 | 11 | 28% | 25 | 14 | 36% | 19 | 20 | 51% |

| C | 34 | 26 | 8 | 24% | 15 | 19 | 56% | 9 | 25 | 74% |

| D | 27 | 26 | 1 | 4% | 18 | 9 | 33% | 18 | 9 | 33% |

| E | 25 | 21 | 4 | 16% | 18 | 7 | 28% | 17 | 8 | 32% |

| F | 12 | 10 | 2 | 17% | 8 | 4 | 33% | 7 | 5 | 42% |

| G | 24 | 13 | 11 | 46% | 10 | 14 | 58% | 2 | 22 | 92% |

| H | 7 | 7 | 6 | 1 | 14% | 5 | 2 | 29% | ||

| I | 6 | 6 | 4 | 2 | 33% | 3 | 3 | 50% | ||

| J | 6 | 5 | 1 | 17% | 4 | 2 | 33% | 4 | 2 | 33% |

| Sum | 230 | 187 | 43 | 19% | 142 | 88 | 38% | 108 | 122 | 53% |

| Oil Regions | A | B | C | D | E | F | G | H | I | J |

|---|---|---|---|---|---|---|---|---|---|---|

| No. of Preferred Emission Sources | 36 | 23 | 3 | 5 | 3 | 4 | 11 | 4 | 2 | 1 |

| Annual Capture (10,000 tons) | 2199 | 12,657 | 2414 | 2899 | 941 | 1873 | 3321 | 591 | 682 | 304 |

| No. of Oilfields for Storage | 50 | 39 | 34 | 27 | 25 | 24 | 24 | 7 | 14 | 6 |

| Cumulative storage (million tons) | 330 | 1899 | 362 | 435 | 141 | 281 | 498 | 89 | 102 | 46 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hao, M.; Bi, R.; Liu, Y. A Review of CO2 Capture Utilization and Storage in China: Development Status, Cost Limits, and Strategic Planning. Processes 2025, 13, 905. https://doi.org/10.3390/pr13030905

Hao M, Bi R, Liu Y. A Review of CO2 Capture Utilization and Storage in China: Development Status, Cost Limits, and Strategic Planning. Processes. 2025; 13(3):905. https://doi.org/10.3390/pr13030905

Chicago/Turabian StyleHao, Mingqiang, Ran Bi, and Yang Liu. 2025. "A Review of CO2 Capture Utilization and Storage in China: Development Status, Cost Limits, and Strategic Planning" Processes 13, no. 3: 905. https://doi.org/10.3390/pr13030905

APA StyleHao, M., Bi, R., & Liu, Y. (2025). A Review of CO2 Capture Utilization and Storage in China: Development Status, Cost Limits, and Strategic Planning. Processes, 13(3), 905. https://doi.org/10.3390/pr13030905