Research and Testing on the Performance of Soft-Seal Structures in Liquid Hydrogen Globe Valves

Abstract

1. Introduction

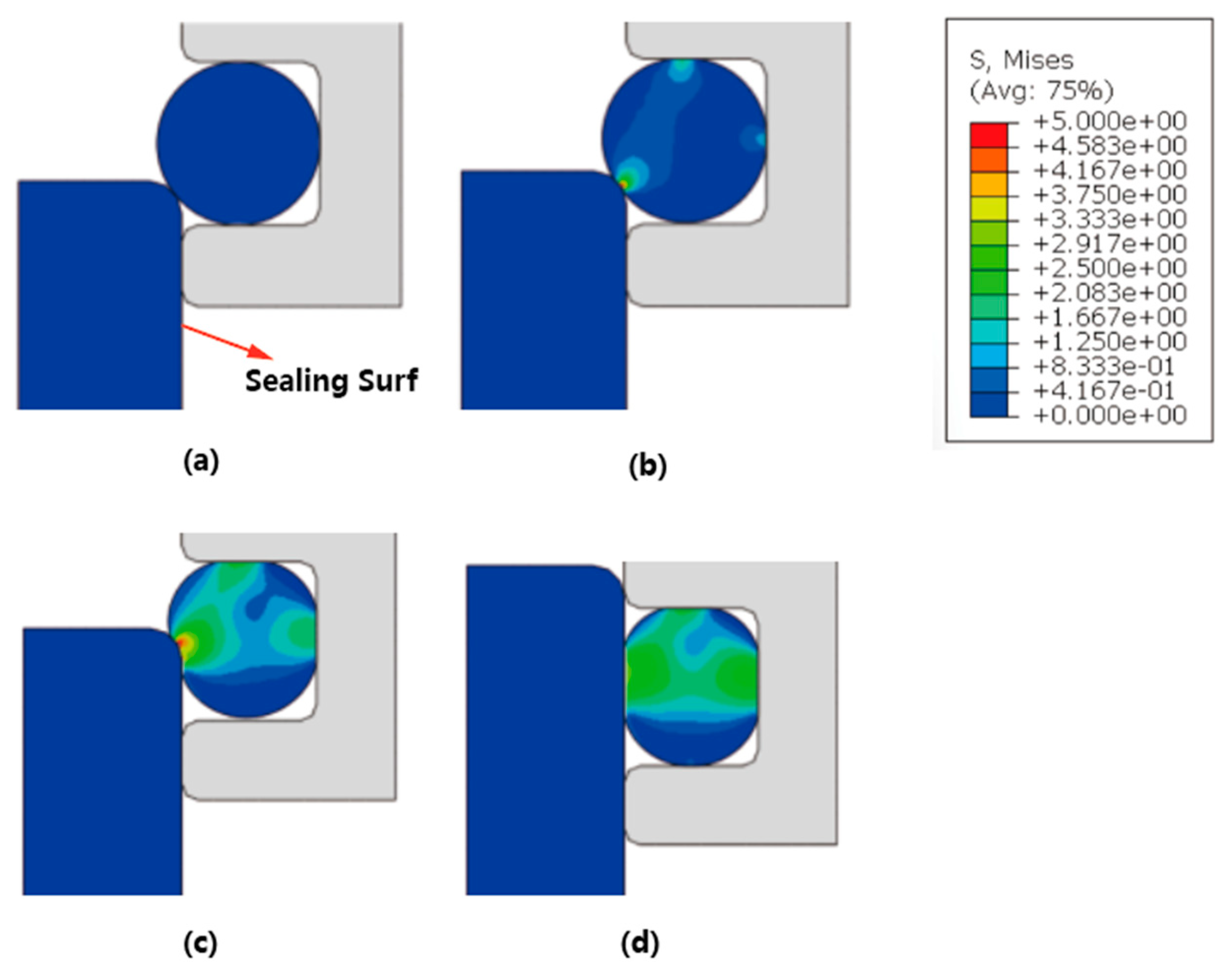

2. Finite Element Analyses

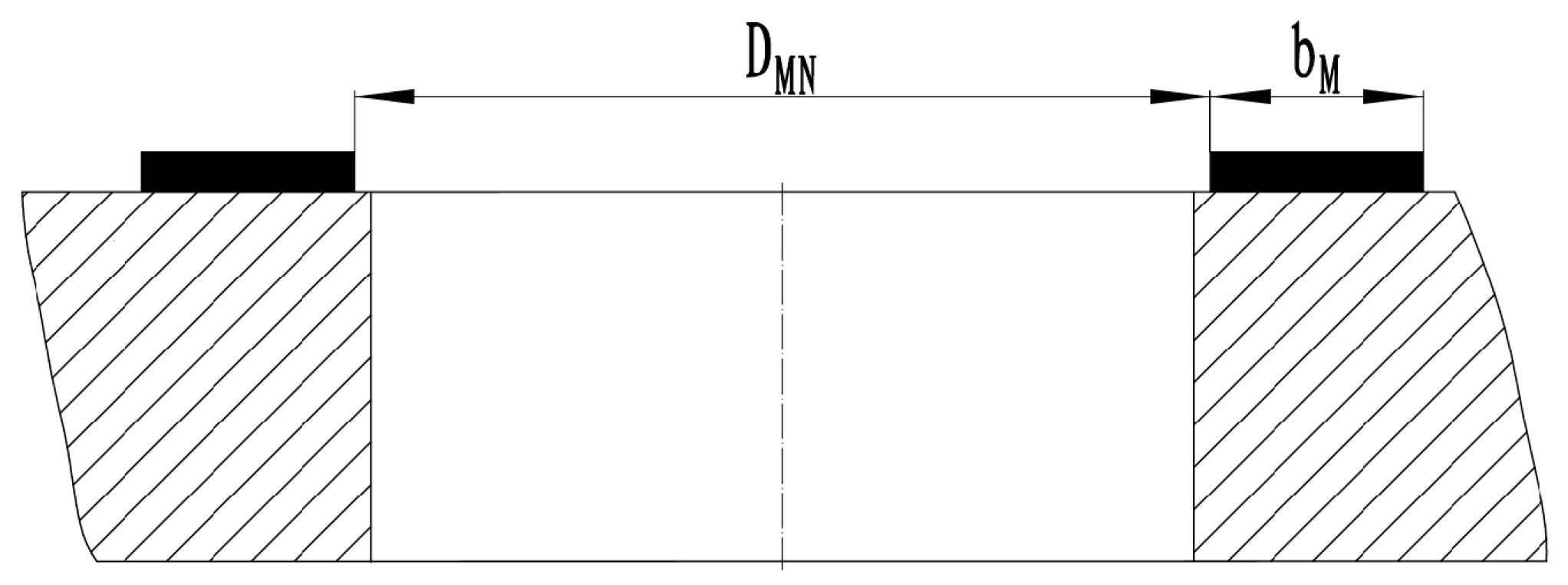

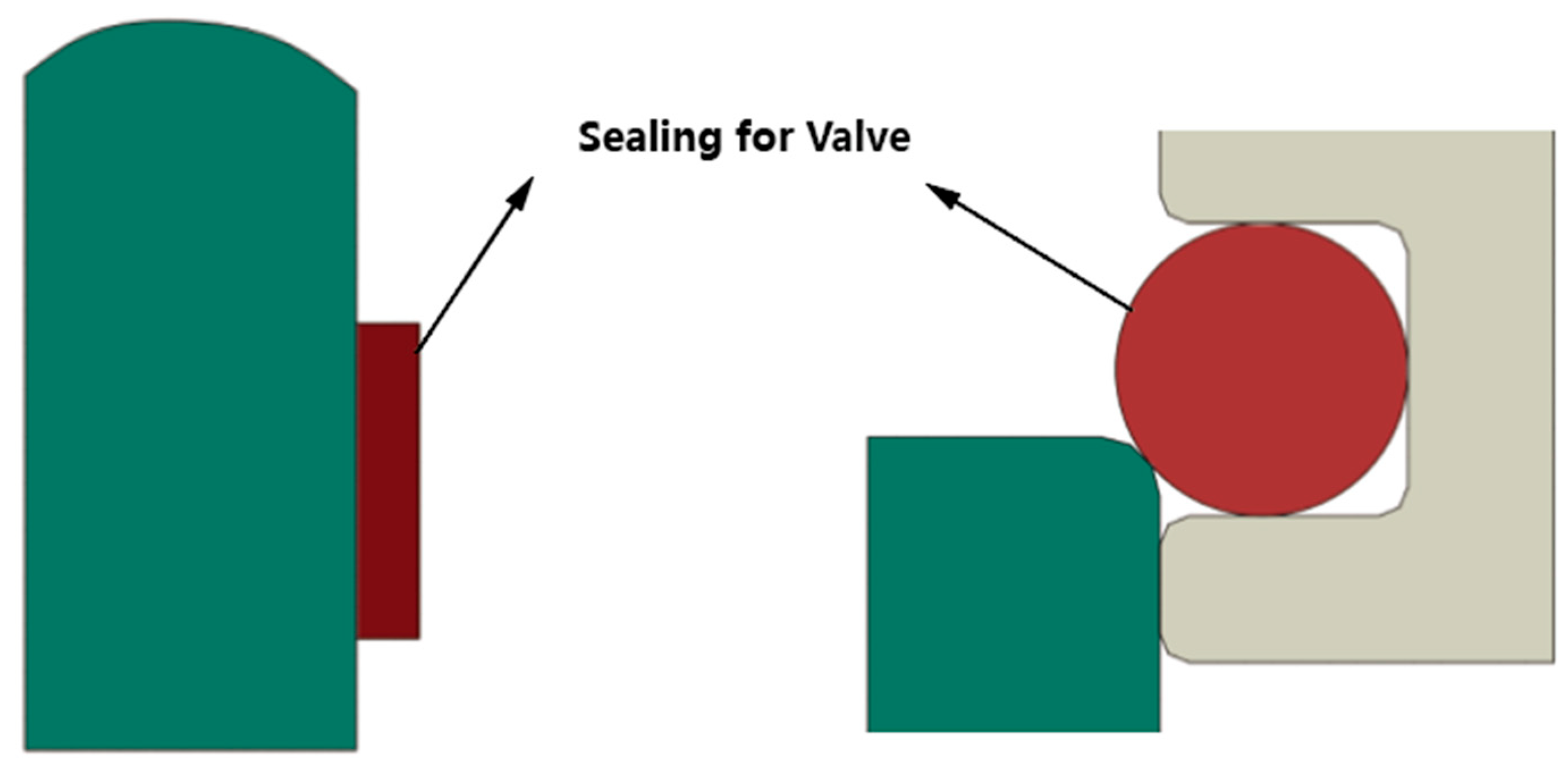

2.1. Sealing Structure in the Globe Valve

2.2. Material Properties

2.3. FE Model Establishment

2.4. Model Simplification and Meshing

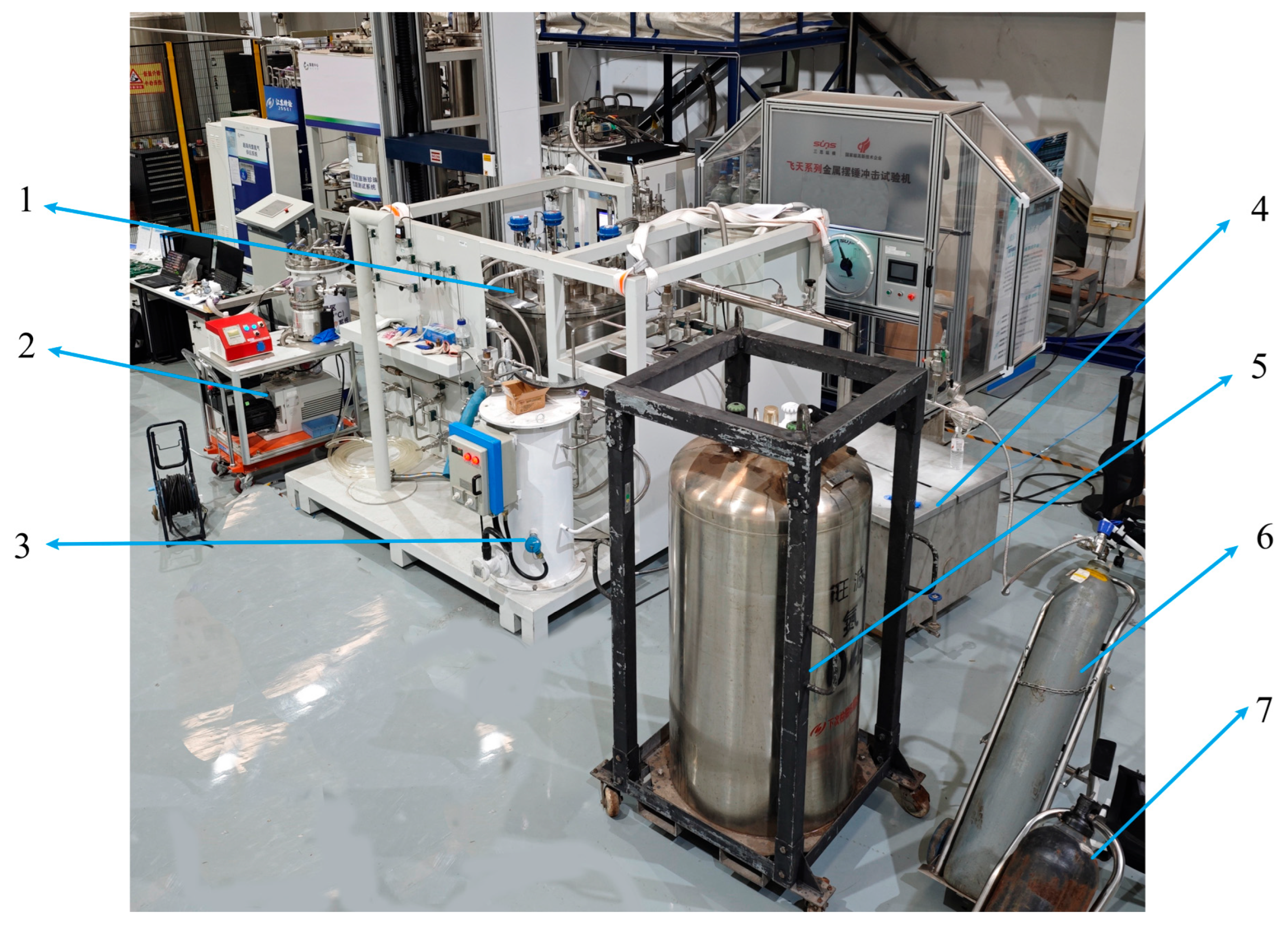

3. System Description and Testing

3.1. System Principle

3.2. Piping System

3.3. Selection of Test Media

3.4. Test Procedure and Results

4. Conclusions

- (1)

- The EPDM sealing ring is efficient with acquired deformation, however, when the temperature decreases, the sealing deformation distribution is observed to be considerably large in the contact area. Meanwhile, when using PCTFE as the sealing ring material and redesigning the sealing structure as plate sealing, the material degradation risk is reduced. Theoretical sealing formulas were introduced to calculate the sealing pressure; furthermore, FE simulation was performed, showing that PCTFE sealing was not damaged under 39.44 MPa pressure with a deformation of 0.009 mm.

- (2)

- The system accommodates pipeline valves below DN100 and cylinder valves for liquid hydrogen storage vessels. With a maximum test pressure of Class 600, it effectively covers conventional liquid hydrogen valve specifications and pressure ratings.

- (3)

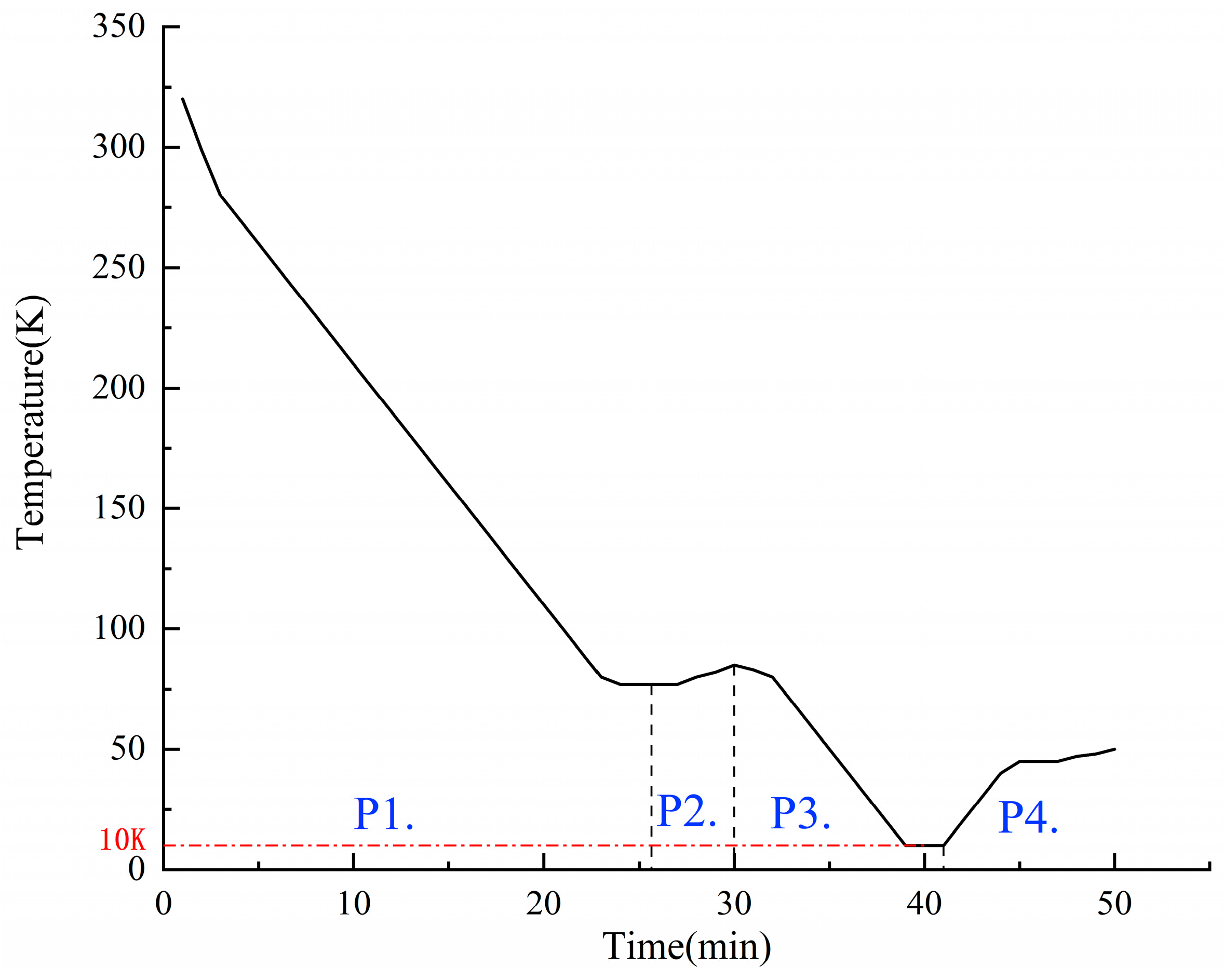

- The test platform utilizes a hybrid cooling approach combining liquid nitrogen pre-cooling with liquid helium internal cooling. This methodology achieves target liquid hydrogen temperatures within 1–2 h—significantly faster than GM cryocooler-based systems. An integrated liquid helium recovery system further ensures cost-effectiveness during testing.

- (4)

- Test results demonstrate that proper selection of soft-seal structures combined with application of specified tightening torques ensures that leakage rates at design temperatures meet requirements. Experimental data show consistent alignment with numerical simulations.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Dawood, F.; Anda, M.; Shafiullah, G.M. Hydrogen Production for Energy: An Overview. Int. J. Hydrogen Energy 2020, 45, 3847–3869. [Google Scholar] [CrossRef]

- Abe, J.O.; Popoola, A.P.I.; Ajenifuja, E.; Popoola, O.M. Hydrogen Energy, Economy and Storage: Review and Recommendation. Int. J. Hydrogen Energy 2019, 44, 15072–15086. [Google Scholar] [CrossRef]

- Rampai, M.M.; Mtshali, C.B.; Seroka, N.S.; Khotseng, L. Hydrogen Production, Storage, and Transportation: Recent Advances. RSC Adv. 2024, 14, 6699–6718. [Google Scholar] [CrossRef]

- Zhang, Y.; Jia, Z.; Yuan, Z.; Yang, T.; Qi, Y.; Zhao, D. Development and Application of Hydrogen Storage. J. Iron Steel Res. Int. 2015, 22, 757–770. [Google Scholar] [CrossRef]

- Aziz, M. Liquid Hydrogen: A Review on Liquefaction, Storage, Transportation, and Safety. Energies 2021, 14, 5917. [Google Scholar] [CrossRef]

- Ustolin, F.; Campari, A.; Taccani, R. An Extensive Review of Liquid Hydrogen in Transportation with Focus on the Maritime Sector. J. Mar. Sci. Eng. 2022, 10, 1222. [Google Scholar] [CrossRef]

- Hossain Bhuiyan, M.M.; Siddique, Z. Hydrogen as an Alternative Fuel: A Comprehensive Review of Challenges and Opportunities in Production, Storage, and Transportation. Int. J. Hydrogen Energy 2025, 102, 1026–1044. [Google Scholar] [CrossRef]

- Ajanovic, A.; Sayer, M.; Haas, R. The Economics and the Environmental Benignity of Different Colors of Hydrogen. Int. J. Hydrogen Energy 2022, 47, 24136–24154. [Google Scholar] [CrossRef]

- Yin, L.; Ju, Y. Review on the Design and Optimization of Hydrogen Liquefaction Processes. Front. Energy 2020, 14, 530–544. [Google Scholar] [CrossRef]

- Kim, J.H.; Park, D.K.; Kim, T.J.; Seo, J.K. Thermal-Structural Characteristics of Multi-Layer Vacuum-Insulated Pipe for the Transfer of Cryogenic Liquid Hydrogen. Metals 2022, 12, 549. [Google Scholar] [CrossRef]

- Tiwari, S.; Pekris, M.J.; Doherty, J.J. A Review of Liquid Hydrogen Aircraft and Propulsion Technologies. Int. J. Hydrogen Energy 2024, 57, 1174–1196. [Google Scholar] [CrossRef]

- Andersson, J.; Grönkvist, S. Large-Scale Storage of Hydrogen. Int. J. Hydrogen Energy 2019, 44, 11901–11919. [Google Scholar] [CrossRef]

- Zhang, C.; Shao, Y.; Shen, W.; Li, H.; Nan, Z.; Dong, M.; Bian, J.; Cao, X. Key Technologies of Pure Hydrogen and Hydrogen-Mixed Natural Gas Pipeline Transportation. ACS Omega 2023, 8, 19212–19222. [Google Scholar] [CrossRef]

- Witkowski, A.; Rusin, A.; Majkut, M.; Stolecka, K. Analysis of Compression and Transport of the Methane/Hydrogen Mixture in Existing Natural Gas Pipelines. Int. J. Press. Vessel. Pip. 2018, 166, 24–34. [Google Scholar] [CrossRef]

- Wijayanta, A.T.; Oda, T.; Purnomo, C.W.; Kashiwagi, T.; Aziz, M. Liquid Hydrogen, Methylcyclohexane, and Ammonia as Potential Hydrogen Storage: Comparison Review. Int. J. Hydrogen Energy 2019, 44, 15026–15044. [Google Scholar] [CrossRef]

- Omori, K.M.; Mazon-Cartagena, R.; Fernández-Torres, M.J.; Caballero, J.A.; Ravagnani, M.A.S.S.; Pavão, L.V.; Costa, C.B.B. Sensitivity Analysis in Simple Cycles for Hydrogen Liquefaction. Processes 2025, 13, 3076. [Google Scholar] [CrossRef]

- Shen, J.; Liu, Y.; Hao, Y.; Li, F.; Zhou, H. Study on the Thermodynamic Behavior of Large Volume Liquid Hydrogen Bottle Under the Coupling of Different Motion States and Operational Parameters. Processes 2025, 13, 3340. [Google Scholar] [CrossRef]

- Cava, C.; Gagliardi, G.G.; Piscolla, E.; Borello, D. Techno-Economic Analysis of Hydrogen Transport via Truck Using Liquid Organic Hydrogen Carriers. Processes 2025, 13, 1081. [Google Scholar] [CrossRef]

- Qu, J.; Zhou, T.; Zhao, H.; Deng, J.; Luo, Z.; Cheng, F.; Wang, R.; Chen, Y.; Shu, C. Risk Analysis of Hydrogen Leakage at Hydrogen Producing and Refuelling Integrated Station. Processes 2025, 13, 437. [Google Scholar] [CrossRef]

- Sotoodeh, K. A Review of Valve Stem Sealing to Prevent Leakage from the Valve and Its Effect on Valve Operation. J. Fail. Anal. Preven. 2021, 21, 9–16. [Google Scholar] [CrossRef]

- Gorash, Y.; Dempster, W.; Nicholls, W.D.; Hamilton, R.; Anwar, A.A. Study of Mechanical Aspects of Leak Tightness in a Pressure Relief Valve Using Advanced FE-Analysis. J. Loss Prev. Process Ind. 2016, 43, 61–74. [Google Scholar] [CrossRef]

- Lin, Z.; Yu, L.; Hua, T.; Jin, Z.; Qian, J. Seal Contact Performance Analysis of Soft Seals on High-Pressure Hydrogen Charge Valves. J. Zhejiang Univ. Sci. A 2022, 23, 247–256. [Google Scholar] [CrossRef]

- Cao, C.; Zhao, J.; Li, G.; Jin, X.; Cao, Z. Dynamic and Static Sealing Performance of Elastic Check Valve Spool. J. Eng. 2019, 2019, 28–31. [Google Scholar] [CrossRef]

- Barbosa Teles, D.; Da Silva Gehlen, G.; Lasch, G.; Yesukai De Barros, L.; Muniz Dias, Y.; Neis, P.D.; Ferreira, N.F.; De Souza, A.J. Tribological Investigation of Contact Pairs Applied in Metallic Gate Valve Seals for Onshore Application. Wear 2023, 523, 204750. [Google Scholar] [CrossRef]

- Sreekanth, N.; Sankaran, S.; Kenned, J.J. Development of Soft Seal and Experimental Investigation of Soft Seated Safety Relief Valves for Cryogenic Applications. Cryogenics 2025, 146, 101005. [Google Scholar] [CrossRef]

- Zhang, N.; Li, Q.; Li, Q.; Hu, Z.; Hu, K. Seat Tightness of Pneumatic Cryogenic Control Valve. Sci. China Technol. Sci. 2013, 56, 2066–2069. [Google Scholar] [CrossRef]

- Zhang, G.; Wang, W.W.; Wu, Z.Y.; Chen, D.S.; Kim, H.D.; Lin, Z. Effect of the Opening Degree on Evolution of Cryogenic Cavitation through a Butterfly Valve. Energy 2023, 283, 128543. [Google Scholar] [CrossRef]

- Li, S.; Zheng, M.; Wang, Y.; Yang, L.; Ma, T. Multi-Objective Optimization Design of Double Resilient Groove Metal Seat for Ball Valve in Liquid Hydrogen Receiving Stations. J. Braz. Soc. Mech. Sci. Eng. 2024, 46, 34. [Google Scholar] [CrossRef]

- Lyu, B.; Xu, D.; Li, L.; Nishimura, A.; Liu, H.; Zhang, H.; Wang, T.; Huang, R.; Huang, C. A 20 K Cryogen-Free Leak Detection System for Cryogenic Valves by Using a GM Cryocooler. Cryogenics 2021, 117, 103332. [Google Scholar] [CrossRef]

- Townsend, A.; Mishra, R. Design and Development of a Helium Injection System to Improve External Leakage Detection during Liquid Nitrogen Immersion Tests. Cryogenics 2016, 79, 17–25. [Google Scholar] [CrossRef]

- Pinho, J.; Peveroni, L.; Vetrano, M.R.; Buchlin, J.-M.; Steelant, J.; Strengnart, M. Experimental and Numerical Study of a Cryogenic Valve Using Liquid Nitrogen and Water. Aerosp. Sci. Technol. 2019, 93, 105331. [Google Scholar] [CrossRef]

- Davies, E.; Ehrmann, A.; Schwenzfeier-Hellkamp, E. Safety of Hydrogen Storage Technologies. Processes 2024, 12, 2182. [Google Scholar] [CrossRef]

- ASTM D638; Standard Test Method for Tensile Properties of Plastics. ASTM International: West Conshohocken, PA, USA, 2022.

- ASTM D785; Standard Test Method for Rockwell Hardness of Plastics and Electrical Insulating Materials. ASTM International: West Conshohocken, PA, USA, 2023.

- ASTM D2240; Standard Test Method for Rubber Property—Durometer Hardness. ASTM International: West Conshohocken, PA, USA, 2021.

- ASTM D695; Standard Test Method for Compressive Properties of Rigid Plastics. ASTM International: West Conshohocken, PA, USA, 2023.

- ASTM D790; Standard Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Material. ASTM International: West Conshohocken, PA, USA, 2017.

- ASTM D792; Standard Test Methods for Density and Specific Gravity (Relative Density) of Plastics by Displacement. ASTM International: West Conshohocken, PA, USA, 2020.

- ASTM D570; Standard Test Method for Water Absorption of Plastics. ASTM International: West Conshohocken, PA, USA, 2022.

- Tietze, V.; Luhr, S.; Stolten, D. Bulk Storage Vessels for Compressed and Liquid Hydrogen. In Hydrogen Science and Engineering: Materials, Processes, Systems and Technology; Stolten, D., Emonts, B., Eds.; Wiley: Hoboken, NJ, USA, 2016; pp. 659–690. ISBN 978-3-527-33238-0. [Google Scholar]

- Xu, X.; Xu, H.; Zheng, J.; Chen, L.; Wang, J. A High-Efficiency Liquid Hydrogen Storage System Cooled by a Fuel-Cell-Driven Refrigerator for Hydrogen Combustion Heat Recovery. Energy Convers. Manag. 2020, 226, 113496. [Google Scholar] [CrossRef]

- Ding, Y.; Shao, D.; Jin, S.; Yu, M.; Wang, Y.; Jiang, L. Numerical Study on Composite Multilayer Insulation Material for Liquid Hydrogen Storage. Coatings 2024, 14, 1417. [Google Scholar] [CrossRef]

- Zheng, C.; Yu, W. Effect of Low-Temperature on Mechanical Behavior for an AISI 304 Austenitic Stainless Steel. Mater. Sci. Eng. A 2018, 710, 359–365. [Google Scholar] [CrossRef]

- Ustolin, F.; Paltrinieri, N.; Berto, F. Loss of Integrity of Hydrogen Technologies: A Critical Review. Int. J. Hydrogen Energy 2020, 45, 23809–23840. [Google Scholar] [CrossRef]

- Qiu, Y.; Yang, H.; Tong, L.; Wang, L. Research Progress of Cryogenic Materials for Storage and Transportation of Liquid Hydrogen. Metals 2021, 11, 1101. [Google Scholar] [CrossRef]

- Aasadnia, M.; Mehrpooya, M. Large-Scale Liquid Hydrogen Production Methods and Approaches: A Review. Appl. Energy 2018, 212, 57–83. [Google Scholar] [CrossRef]

| Property | PCTFE (Light Yellow Semi-Transparent) | Applicable Temperature −250 °C~+150 °C | |

|---|---|---|---|

| Finished Product Performance and Testing Requirements | Mechanical or Physical Properties | Test Standard | PCTFE |

| Tensile Strength | ASTM D638 [33] | 31.4~37.2 MPa | |

| Hardness | ASTM D785 [34] | 75~85 Shore D | |

| ASTM D2240 [35] | 70~80 Shore D | ||

| Compressive Strength (1% strain at 25 °C) | ASTM D695 [36] | 8.96~13.7 MPa | |

| Flexural Strength | ASTM D790 [37] | 67.6~72.5 MPa | |

| Elongation at Break | ASTM D638 [33] | 50~200% | |

| Density | ASTM D792 [38] | 2.11~2.16 g/cm3 | |

| Water Absorption | ASTM D570 [39] | 0.00% | |

| Design Parameters | Value |

|---|---|

| Nominal direct | DN50 |

| Nominal pressure | PN25 |

| Design temperature | −253 °C~+80 °C |

| Applicable medium | LH2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Meng, Z.; Jin, S.; Yu, M.; Li, F. Research and Testing on the Performance of Soft-Seal Structures in Liquid Hydrogen Globe Valves. Processes 2025, 13, 3858. https://doi.org/10.3390/pr13123858

Meng Z, Jin S, Yu M, Li F. Research and Testing on the Performance of Soft-Seal Structures in Liquid Hydrogen Globe Valves. Processes. 2025; 13(12):3858. https://doi.org/10.3390/pr13123858

Chicago/Turabian StyleMeng, Zhiwen, Suke Jin, Meng Yu, and Fanding Li. 2025. "Research and Testing on the Performance of Soft-Seal Structures in Liquid Hydrogen Globe Valves" Processes 13, no. 12: 3858. https://doi.org/10.3390/pr13123858

APA StyleMeng, Z., Jin, S., Yu, M., & Li, F. (2025). Research and Testing on the Performance of Soft-Seal Structures in Liquid Hydrogen Globe Valves. Processes, 13(12), 3858. https://doi.org/10.3390/pr13123858