Research into Acoustic Emission Monitoring in Similar Simulation of Coal Mining Under Roof-Confined Water Drainage

Abstract

1. Introduction

2. Methods and Experimental Model Production

2.1. Similarity Ratio Determination

2.2. Simulation Materials and Mixture Ratio

2.3. Production of the Drainage Module

2.4. Monitoring System and Sensor Layout

2.5. Calibration of Acoustic Emission Velocity During the Experimental Process

3. Analysis of Experimental Results

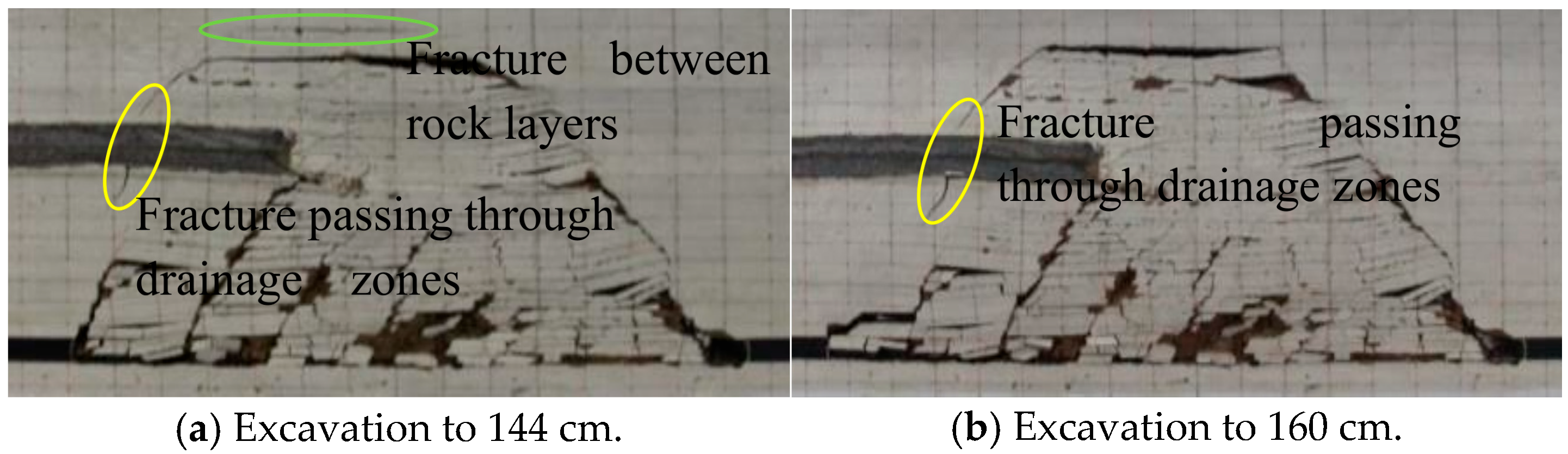

3.1. Fracture Development

- (1)

- Height of fracture development in similar simulation experiments

- (2)

- The influence of drainage modules on fracture propagation

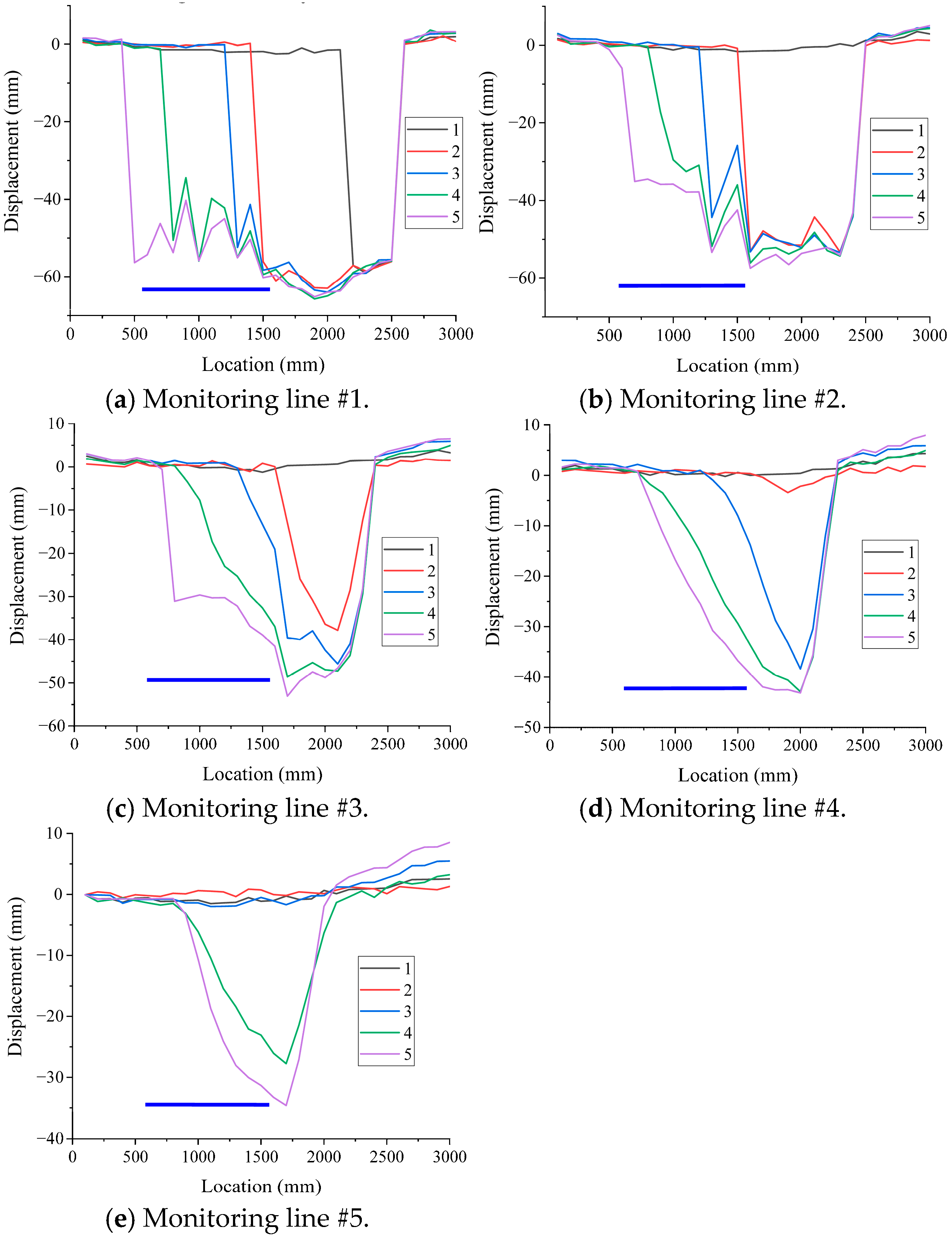

3.2. Monitoring of Rock Strata Displacement

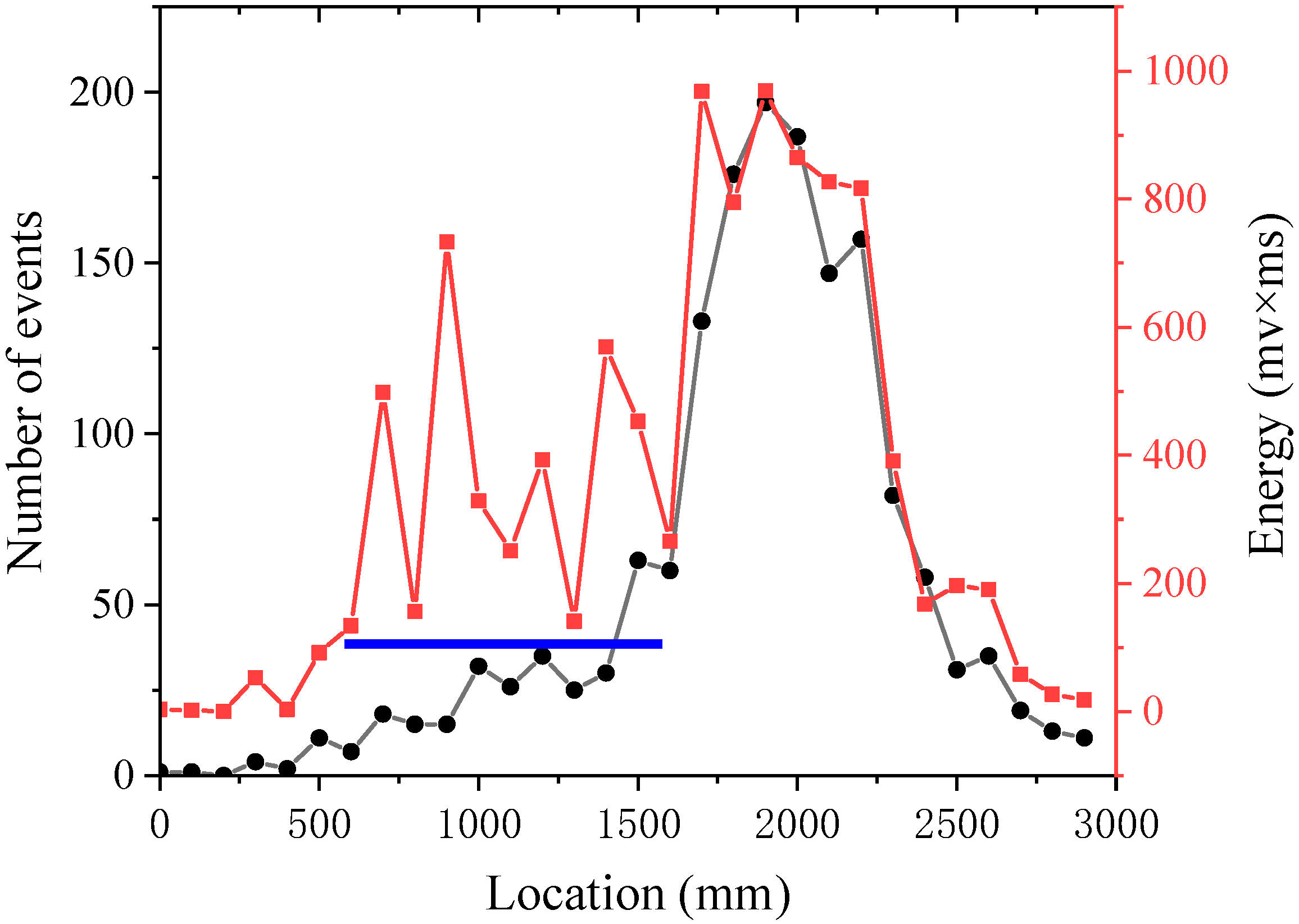

3.3. Acoustic Emission Monitoring

4. Verification of On-Site Monitoring Results

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ye, Y.; Li, W.; Yang, Z.; Li, X.; Wang, Q. The Prediction of Aquifer Water Abundance in Coal Mines Using a Convolutional Neural Network–Bidirectional Long Short-Term Memory Model: A Case Study of the 1301E Working Face in the Yili No. 1 Coal Mine. Water 2025, 17, 1595. [Google Scholar] [CrossRef]

- Huang, Z.; Wang, K.; Liu, X.; Zhao, Y.; Li, X.; Fu, B.; Zhou, Y. Risk Identification Method and Application of Roof Water Inrush Under Multi-Working Face Mining. Appl. Sci. 2025, 15, 3511. [Google Scholar] [CrossRef]

- Xiao, J.; Wang, Y.; Zhang, B.; Wang, T.; Liu, Y.; Wang, Y.; Sun, Y. Analysis of the Evolution Law of Mining-Induced Water Flowing Fracture of Composite Hard Roof in the Border Mining Area of Inner Mongolia and Shaanxi. Energy Sci. Eng. 2025, 13, 1720–1731. [Google Scholar] [CrossRef]

- Du, L.; Zhu, W.; Wang, L.; Li, H.; Jiao, X.; Qin, T. Using roof borehole electrical resistivity tomography to monitor roof water infiltration in a mine work face. Sci. Rep. 2025, 15, 2621. [Google Scholar] [CrossRef] [PubMed]

- Gai, G.; Qiu, M.; Zhang, W.; Shi, L. Evaluation of water richness in coal seam roof aquifer based on factor optimization and random forest method. Sci. Rep. 2024, 14, 24421. [Google Scholar] [CrossRef]

- Chen, G. Study on the Deep Transfer and Storage Mechanism of Mine Water in the Eastern Margin of Ordos Basin. Ph.D. Thesis, China University of Mining and Technology, Xuzhou, China, 2020. [Google Scholar] [CrossRef]

- Shu, C.; Jiang, F.; Wang, B.; Du, X.; Wen, J. Mechanism and Treatment of Rock Burst on the Deep Working Face Induced by Drainage in Water-Rich Areas. Geotech. Geol. Eng. 2021, 39, 871–882. [Google Scholar] [CrossRef]

- Wang, B.; Jiang, F.; Zhu, S.; Zhang, X.; Shang, X.; Gu, Y.; Wu, Z. Investigating on the mechanism and prevention of rock burst induced by high intensity mining of drainage area in deep mines. J. China Coal Soc. 2020, 45, 3054–3064. [Google Scholar] [CrossRef]

- Li, F.; Cheng, Y.; Zhang, X.; Huang, S.; Li, D. Change Characteristics of the Advance Stress and Strata Fracture Structure of Spatial Isolated Island Formed by Roof Drainage. Processes 2023, 11, 2246. [Google Scholar] [CrossRef]

- Li, F.; Gu, Y.; Cheng, Y.; Li, D.; Wang, Y.; Zhang, S. Influence of roof confined water drainage on stress distribution in coal seam. Sci. Rep. 2024, 14, 24040. [Google Scholar] [CrossRef] [PubMed]

- Dou, L.; Zhou, K.; Cao, A.; Hou, T.; Gong, S.; Kan, J.; Ma, X. Rockburst mechanism caused by the mining-induced drain-age of confined water in deep extra-thick aquifer. J. China Coal Soc. 2024, 49, 351–366. [Google Scholar] [CrossRef]

- Zhou, K. Effect of Extra-Thick and Water-Bearing KeyStrata and Its Inducing Rock burst Mechanism by the Drainage of Confined Water through Stress Adjustment and Energy Accumulation. Ph.D. Thesis, China University of Mining and Technology, Xuzhou, China, 2022. [Google Scholar] [CrossRef]

- Wang, G. Study on Rock Burst under the Condition of Roof Drainage in Water-Rich Mine. Ph.D. Thesis, Liaoning Technical University, Fuxin, China, 2021. [Google Scholar] [CrossRef]

- Shao, J.; Zhang, Q.; Zhang, W.; Wang, Z.; Wu, X. Effects of the borehole drainage for roof aquifer on local stress in underground mining. Geomech. Eng. 2021, 24, 479–490. [Google Scholar] [CrossRef]

- Li, Q.; Yang, S.; Yue, H.; Kong, D. Study on Caving Characteristics of Roof and Floor and Law of Ground Pressure Behavior in Near-Vertical Coal Seams Mining: A Three-Dimensional Similarity Simulation Experiment. Rock Mech. Rock Eng. 2025, 1–34. [Google Scholar] [CrossRef]

- Sun, Q.; Zhao, R.; Zhang, J.; Chen, L.; Li, P. The law of overburden failure and water conservation mining method of extra thick coal seams covered by extremely thick soil layers. J. Min. Saf. Eng. 2025, 42, 1129–1140. [Google Scholar] [CrossRef]

- Wang, J.; Liu, S.; Yu, X.; Gu, H.; Liu, H.; Liu, C. Characteristics of Overlying Rock Breakage and Fissure Evolution in the Mining of Extra-Thick Coal Seams in Anticline Structural Area. Appl. Sci. 2025, 15, 8812. [Google Scholar] [CrossRef]

- Gai, Q.; He, M.; Li, S.; Gao, Y. Study on strike failure characteristics of floor in a new type of pillarless gob-side entry retaining technology above confined water. Tunn. Undergr. Space Technol. Inc. Trenchless Technol. Res. 2025, 161, 106596. [Google Scholar] [CrossRef]

- Tang, L.; Tu, S.; Tu, H.; Zhang, L.; Miao, K.; Zhao, H.; Ma, J. Interaction law between mining stress and fault activation and the effect of fault dip angle in longwall working face. Sci. Rep. 2024, 14, 25654. [Google Scholar] [CrossRef] [PubMed]

- Zhai, X.; Guo, Z.; Fang, J.; Zhang, Z.; Zhao, X. Study on deformation zoning of overlying strata and simulation of rock pressure behavior in longwall top coal caving mining. Coal Sci. Technol. 2025, 53, 96–106. [Google Scholar]

- Hu, T.; Han, K.; Song, C.; Che, J.; Li, B.; Huo, T.; Hu, T. Development Law of Water-Conducting Fracture Zones in Overburden above Fully Mechanized Top-Coal Caving Face: A Comprehensive Study. Processes 2024, 12, 2076. [Google Scholar] [CrossRef]

- Wang, K.; Meng, X.; Cheng, X.; Zhao, G.; Qi, M. Research on the evolution and application of mining-induced fractures based on the optical frequency domain reflection technology. J. Min. Saf. Eng. 2024, 41, 1000–1010. [Google Scholar] [CrossRef]

- Liu, Y.; Kong, D.; Li, P.; Wen, Z.; Li, F.; Zuo, Y.; Wu, G. The migration and evolution law of overlying strata and the instability and failure characteristics of end face roof under the condition of ascending mining in close distance coal seam: Case study. Eng. Fail. Anal. 2024, 165, 108809. [Google Scholar] [CrossRef]

- Zhang, X.; Yang, Z.; Ying, G. Acoustic Emission Assisted Inspection of Punching Shear Failure in Reinforced Concrete Slab–Column Structures. Buildings 2025, 15, 3226. [Google Scholar] [CrossRef]

- Li, B.; Sun, X.; Wang, E.; Li, N.; Liu, X.; Cao, X.; Liu, W. Time-frequency-fractal Characteristics of Acoustic Emission Signals During Coal-rock Rupture at Different Loading Rates. Rock Mech. Rock Eng. 2025, 1–17. [Google Scholar] [CrossRef]

- Liu, Z.; Ma, C.; Wei, X.; Yi, W.; Lei, J. Failure mechanisms of coarse-grained sandstone under pure mode I/II loading: Insights from energy evolution and acoustic emission. Nondestruct. Test. Eval. 2025, 40, 4415–4435. [Google Scholar] [CrossRef]

- Jiao, Z.; Ma, J.; Ni, Z.; Bao, W.; Lan, J.; Dong, C. Study on Mechanical Response and Failure Characteristics of Coal Specimens Under the Coupling Effect of Joints and Drillings. Processes 2025, 13, 2605. [Google Scholar] [CrossRef]

- Qin, X.; Su, H.; Yu, L.; Pham, T.N.; Zhao, E.; Zhang, M. Thermal Effects on the Generalized Mode III Fracture Behavior of Transversely Isotropic Sandstone: A Study Using Acoustic Emission Localization and 3D Scanning Reconstruction. Rock Mech. Rock Eng. 2025, 1–23. [Google Scholar] [CrossRef]

- Gai, Q.; He, M.; Gao, Y.; Tao, Z.; Zhang, C. Distribution characteristics of floor four zones and water preservation effectevaluation in 110 mining method above confined water. J. China Coal Soc. 2025. [Google Scholar] [CrossRef]

- Xiao, M.; Ju, F.; He, Z.; Wang, D. Investigation of mining-induced fracture evolution and water inflow patterns in water-rich coal seams of atypical Jurassic mining area. J. Min. Saf. Eng. 2025, 42, 890–903. [Google Scholar] [CrossRef]

- Zhao, B.; Gao, X.; Zhu, W.; Ding, J.; Gao, P. A Novel Carbon Fiber Composite Material for the Simulation of Damage Evolution in Thick Aquifers. Appl. Sci. 2025, 15, 7314. [Google Scholar] [CrossRef]

- Zhao, B.; Gao, X.; Zhu, W.; Ding, J.; Gao, P. A coustic behavior and time prediction method for water inrush of tunnel floor under osmotic water pressure. Results Eng. 2025, 26, 105547. [Google Scholar] [CrossRef]

- Zheng, K.; Yuan, L.; Zhang, P.; Wang, L. Rock bursts induced by thick-hard roof with compound key strata: Mechanisms and technical modes for prevention. Coal Geol. Explor. 2024, 52, 14–24. [Google Scholar] [CrossRef]

| Geometric Similarity Ratio | Similarity Ratio of Bulk Density | Similarity Ratio of Strength | Similarity Ratio of Time |

|---|---|---|---|

| 1/100 | 3/5 | 6/1000 | 1/12 |

| Serial Number | Rock Stratum Name | Weight of Similar Simulation Material | ||

|---|---|---|---|---|

| Sand | Lime | Gypsum | ||

| 1 | sandy mudstone | 7 | 7 | 3 |

| 2 | medium grained sandstone | 8 | 3 | 2 |

| 3 | fine sandstone | 6 | 3 | 2 |

| 4 | siltstone | 9 | 5 | 5 |

| 5 | kern stone | 6 | 3 | 2 |

| 6 | 2-2 coal | 10 | 5 | 5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, F.; Li, D.; Gu, Y. Research into Acoustic Emission Monitoring in Similar Simulation of Coal Mining Under Roof-Confined Water Drainage. Processes 2025, 13, 3287. https://doi.org/10.3390/pr13103287

Li F, Li D, Gu Y. Research into Acoustic Emission Monitoring in Similar Simulation of Coal Mining Under Roof-Confined Water Drainage. Processes. 2025; 13(10):3287. https://doi.org/10.3390/pr13103287

Chicago/Turabian StyleLi, Fenghui, Dong Li, and Yuming Gu. 2025. "Research into Acoustic Emission Monitoring in Similar Simulation of Coal Mining Under Roof-Confined Water Drainage" Processes 13, no. 10: 3287. https://doi.org/10.3390/pr13103287

APA StyleLi, F., Li, D., & Gu, Y. (2025). Research into Acoustic Emission Monitoring in Similar Simulation of Coal Mining Under Roof-Confined Water Drainage. Processes, 13(10), 3287. https://doi.org/10.3390/pr13103287