Abstract

This paper presents a modular hybrid mathematical model of bacterial fermentation developed by integrating a detailed kinetic model for the central carbon metabolism of Escherichia coli with a simplified four-compartment model of a large stirred bioreactor. The model describes the growth dynamics of E. coli, taking into account the hydrodynamic characteristics of the cultivation environment and spatial concentration gradients. The first module simulates liquid exchange flows between neighboring reactor zones and tracks the spatial distribution of substrate, acetate, dissolved oxygen, and biomass, while the second one, which is a kinetic model, includes main metabolic pathways such as glycolysis, the tricarboxylic acid cycle, and oxidative phosphorylation. Compared to most previous hybrid approaches relying on simplified kinetics, the present model integrates a detailed kinetic representation of E. coli central metabolism and is openly implemented on the BioUML platform, which ensures its reproducibility and extensibility. Numerical simulations reveal how mixing intensity affects concentration gradients and metabolic regimes across the reactor. Additionally, the model was used to identify an optimal mixing regime corresponding to the state where the system first enters the regime of complete aerobic substrate oxidation. The proposed model is applicable for numerical analysis of industrial-scale bioreactors and for predicting metabolic dynamics under various hydrodynamic conditions.

1. Introduction

The growing challenges of climate change demand effective and sustainable solutions to meet the needs of a rising global population while minimizing environmental impact [1]. Biomanufacturing is the biotechnological production of valuable chemicals [2] which has emerged as a key approach to address these challenges. By relying on renewable alternatives, biomanufacturing helps reduce dependence on fossil-based resources [2,3,4].

Continuous culturing is widely used in biomanufacturing, as it enables the controlled growth of microorganisms that produce target products. Advances in biological systems engineering have enabled laboratory-scale production of a wide range of compounds, including pharmaceuticals and precursors for materials and fuels, by utilizing microbial chassis at least in small amounts as a proof-of-concept [4,5,6,7,8,9]. There are also examples of biomanufacturing at an industrial scale, including the production of both high-value products (e.g., therapeutics, enzymes, antibiotics) and low-volume commodities (e.g., bioethanol, lactic acid, amino acids) [10]. However, the successful transition from a laboratory scale (with cultivation volumes ranging from milliliters to tens of liters) [11,12] to an industrial scale (with cultivation volumes reaching hundreds of cubic meters) [13,14] remains challenging and is often associated with significant physical, chemical, and biological limitations [2,12,15]. These constraints often prevent promising developments from being successfully translated into large-scale production [16,17].

One of the key limiting factors during scale-up is the emergence of spatial heterogeneity within large bioreactors. In laboratory-scale bioreactors, rapid mixing (on the order of seconds) results in a well-mixed, homogeneous environment. In contrast, industrial-scale bioreactors may require several minutes to reach ideal mixing conditions that lead to the formation of zones with concentration gradients of substrate, oxygen, and metabolic products [18,19]. For example, cells may shift toward anaerobic metabolism in zones with limited oxygen availability, leading to the accumulation of acetate—a byproduct that can inhibit microbial growth [20,21]. On the other hand, insufficient carbon source concentrations can trigger various stress responses associated with nutrient starvation [21,22].

Mathematical modeling plays a key role in analysis and optimization of industrial bioprocesses, as well as in mitigation of risks during scale-up from laboratory to industrial scale. Four main types of bioreactor models may broadly be distinguished: kinetic, compartment, computational fluid dynamics (CFD), and hybrid models. Kinetic models provide a detailed description of metabolic pathways based on chemical kinetics, while generally neglecting hydrodynamic properties of the reactor [23,24,25]. In contrast, compartment and CFD models simplify the metabolic representation and instead focus on predicting the formation of mixing gradients. Compartment models consider the reactor as multiple ideally mixed zones (compartments), simulate liquid exchange flows between adjacent zones, and capture concentration gradients of substrate, oxygen, and other key compounds [19,26,27,28]. CFD models, on the other hand, calculate fluid dynamics by solving the Navier–Stokes equations, treating the liquid phase as a continuous medium [29,30]. While CFD models provide high spatial resolution, they require significant computational resources, making compartment models a computationally inexpensive alternative when moderate detail is sufficient. Finally, hybrid models combine kinetic models with either compartment or CFD models, in order to predict the spatial distribution of compound concentrations under realistic hydrodynamic conditions [31,32,33,34].

The objective of this study was to develop a hybrid mathematical model of an industrial bioreactor that simulates the growth of E. coli while accounting for key processes in central carbon metabolism and the spatial environment heterogeneity induced by mixing. E. coli was selected as a model organism because it is one of the most commonly used production host in industrial biotechnology, with well-studied metabolic pathways. To this end, we reproduced results from two previously published models on the BioUML (Biological Universal Modeling Language) platform: a simplified four-compartment model of a large stirred bioreactor [35] and a detailed kinetic model for the central carbon metabolism of E. coli [36]. These models were then combined into a unified modular model. Compared to existing hybrid bioreactor models, which typically represent metabolism through simplified kinetics, the present modular model incorporates a detailed kinetic part. Furthermore, the model is implemented on the open-source BioUML platform which ensures reproducibility and extensibility. This contrasts with most previously published industrial-scale models, which remain unavailable to the research community due to commercial restrictions.

The structure of the paper is as follows. Section 2 provides a brief overview of the BioUML platform used for the model development and numerical simulations. In Section 3, the modular structure and main equations of the model are detailed. Section 4 presents the simulation results and their interpretation. Section 5 discusses the biological relevance of the results and outlines potential directions for further model refinement. Supplementary Materials (Tables S1–S3) provide the complete description of model equations, parameter values, and initial conditions.

2. Methods

2.1. Modeling Software

Model construction and numerical simulations were carried out using BioUML (https://sirius-web.org/bioumlweb/, version 2025.2, accessed on 9 October 2025), an open-source platform under active development [37,38]. BioUML is a Java-based software environment designed for modeling complex biological systems and analyzing biomedical data. It provides tools for visual representation of modeled biological systems and supports a wide range of systems biology standards, including Systems Biology Markup Language (SBML) [39] and Systems Biology Graphical Notation (SBGN) [40].

Model development in BioUML begins with representation of the modeled system as a compartmentalized graph. Based on this graph, the platform automatically generates Java code that defines the corresponding system of differential equations. Then this code is compiled and executed using internal numerical solvers to simulate the system’s dynamics.

To simplify the construction of models for complex systems, BioUML supports a modular approach, which enhances visual clarity and reduces the risk of technical errors. This approach, previously used to build various mathematical models [41,42], allows decomposition of any complex system into elementary components called modules (or submodels/blocks). Each module is defined independently and can follow its own formalism and level of abstraction. Interactions between modules are defined through variable connections, which, in the context of the bioreactor model, represent processes such as fluid exchange between adjacent compartments.

2.2. Model Parameters

The modular bioreactor model integrates two previously published models, using the same parameter values as reported in the original studies where they were originally described and validated [35,36].

2.3. Numerical Simulations

The unit of model time corresponds to one hour of real time. Numerical simulations were performed using the CVODE solver [43], ported to Java and integrated into the BioUML platform. All simulations presented in this paper were conducted for a duration of up to 1 h.

3. Modular Model

3.1. Bioreactor Compartmentalization

The bioreactor compartment model utilizes the geometry of a 90-cubic-meter stirred bioreactor with four Rushton turbines, as described in [14,44]. The total reactor volume is divided into four vertical compartments using three horizontal planes, positioned equidistantly between the turbines. Three of the lower compartments have a volume of 20 m3 each, while the top compartment has a volume of 30 m3. A schematic representation of the bioreactor compartmentalization is shown in Figure 1.

Figure 1.

Schematic representation of the bioreactor compartmentalization. Substrate is fed through the top of the reactor (). Bidirectional liquid exchange flows () occur between the compartments i and j. Air is supplied to the reactor from the bottom (air), with the molar airflow moving only upwards, and no back mixing of the gas phase is considered. Bioreactor geometry: reactor height H = 10.464 m, reactor diameter T = 3.476 m, distance between turbines L = 2.32 m, distance from the bottom turbine to the reactor bottom L1 = 1.271 m, turbine diameter D = 0.936 m.

3.2. Modular Model Structure

The mathematical model of a large stirred bioreactor, which describes the growth of E. coli and accounts for key processes in its central carbon metabolism as well as concentration gradients induced by mixing, was developed based on the principles of modular modeling for complex biological systems using the BioUML platform (see Section 2.1).

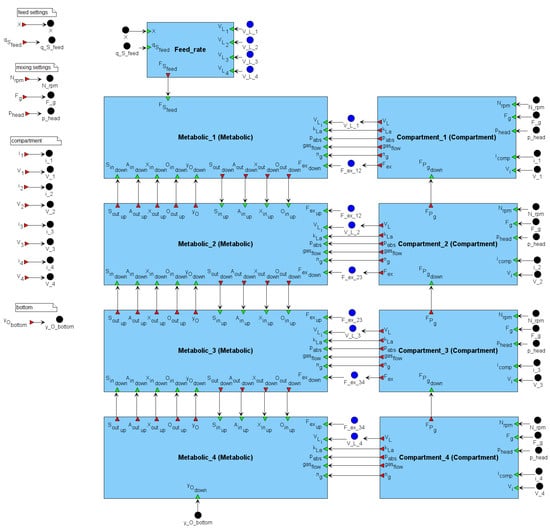

The BioUML implementation of the model consists of 9 modules: 4 metabolic modules (Metabolic_i) that calculate the dynamics of E. coli metabolism in the corresponding reactor zones; 4 compartment modules (Compartment_i) that calculate the liquid exchange flows between neighboring zones; and an auxiliary module (Feed_rate) that calculates the glucose feed rate to the top zone. The modular structure of the model in BioUML is shown in Figure 2.

Figure 2.

Modular structure of the model. The parameters , and specify the stirrer speed, gas inflow rate, and excess pressure in the top part of the bioreactor, respectively, and together define the mixing intensity. Depending on the mixing regime, the compartment modules (based on the original compartment model of a large stirred bioreactor [35]) calculate the following hydrodynamic quantities: liquid exchange flow , liquid volume in the compartment excluding gas hold-up , oxygen mass transfer coefficient , absolute pressure , gas flow rate , and the number of moles of gas in the compartment . These quantities are transferred to the corresponding metabolic blocks (based on the original kinetic model of the central carbon metabolism of E. coli [36]), where they are considered in the calculation of metabolic activity. Neighboring metabolic compartments exchange fluxes of substances, including concentrations of substrate (glucose) , acetate , biomass , dissolved oxygen , and the mole fraction of oxygen in the gas phase .

The model includes 166 variables, 57 differential equations, 378 parameters, and 96 assignment operations. Hereafter, it is referred to as the modular model of the bioreactor.

3.3. Main Equations of the Modular Model

This section provides a brief overview of the main equations underlying the modular model of the bioreactor (Equations (1)–(23)). A complete description of all equations, parameter values, and initial conditions is given in Supplementary Materials (Tables S1–S3).

The metabolic modules are based on a previously published kinetic model of the central carbon metabolism of E. coli [36]. This model includes the glycolytic pathway, tricarboxylic acid cycle, pentose phosphate pathway, Entner–Doudoroff pathway, anaplerotic pathway, glyoxylate shunt, oxidative phosphorylation, phosphotransferase and non- phosphotransferase systems, and alternative metabolic pathways. Regulation of metabolic activity is also incorporated through four key transcription factors: the cAMP receptor protein, the catabolite repressor/activator, the pyruvate dehydrogenase complex repressor, and the isocitrate lyase regulator.

The dynamics of each metabolic module are governed by the following set of equations (Equations (1)–(4)):

where denotes the biomass concentration in the compartment; is the vector of time-dependent intracellular variables (e.g., concentrations of metabolites, proteins and enzymes); is the vector of auxiliary variables, including intracellular regulatory proteins (such as transcription factors and their complexes with metabolites); is the vector of extracellular concentrations of glucose and acetate; the vector contains the concentrations of glucose and acetate in the feeding medium; is the vector of the kinetic parameters of the model; and is the dilution rate. The function defines the specific growth rate; corresponds to the specific uptake rates of glucose and acetate; and represents the system of intracellular mass balance equations.

To incorporate mixing dynamics, the system was extended with compartment modules based on the simplified compartment model of a bioreactor [31]. The total reactor volume was divided into four compartments (see Section 3.1). To simulate the mixing process, additional exchange terms were introduced into the right-hand side of the differential equations describing the extracellular concentrations of glucose, acetate, and biomass in the metabolic modules (Equations (5)–(7)):

where , and correspond to the extracellular concentrations of glucose, acetate, and biomass, respectively, and represents the liquid exchange flow between neighboring compartments i and j.

The calculation of liquid exchange between compartments was based on the volumetric pumping capacity of Rushton turbines under aerated conditions. It was assumed that half of the liquid flow generated by a turbine is directed downwards and the other half upwards [45,46]. Thus, the liquid exchange flow between compartments i and j () was defined as the average of the two volumetric flows meeting at the interface between these compartments (Equation (8)):

with the following expressions (Equations (9)–(15)) used to compute intermediate parameters:

where is the volumetric pumping capacity of a single Rushton turbine (with a power number ) in compartment i under aeration; is the ratio of aerated to unaerated power input; and are the Reynolds and Froude numbers, respectively; and are the impeller diameter and rotation speed; is the reactor diameter; is the liquid density; is the dynamic viscosity; is the gravitational acceleration; and denote the volumetric and mass flow rates of the gas, respectively; is the gas density; is the molecular weight of air; is the absolute pressure; is the universal gas constant; is the absolute temperature; is the height of the liquid above the impeller; is the excess (gauge) pressure in the headspace of the reactor; and is the atmospheric pressure.

The original kinetic model of E. coli central metabolism [36] did not account for changes in oxygen concentration. Therefore, in the modular model of the bioreactor developed in this study, oxygen dynamics were incorporated by adapting the gas–liquid mass transfer equations from the compartment model of the bioreactor [35].

The gas hold-up (i.e., the volume fraction of the gas relative to the total volume) in each compartment was calculated using the following expressions (Equations (16)–(18)):

where represents the volume fraction of the bulk liquid; is the compartment volume; is the power input by a single impeller under aeration; and is the superficial gas velocity. Due to the gas hold-up, the total liquid volume across all compartments is slightly reduced compared to the full bioreactor volume of 90 m3.

Oxygen transfer from the gas phase to the bulk liquid in each compartment was modeled under the assumption that air bubbles do not coalesce. The following expressions (Equations (19)–(21)) were used:

where is the oxygen transfer rate; is the oxygen mass transfer coefficient; is the extracellular oxygen concentration; is the oxygen saturation concentration; is the bulk liquid volume; and is the mole fraction of oxygen in the gas phase.

The following expressions (Equations (22) and (23)) were incorporated into the metabolic modules to compute the extracellular oxygen concentration:

where is the gas flow rate and is the number of moles of gas in the compartment.

The resulting extracellular oxygen concentration is consumed by the cells and subsequently utilized in oxidative phosphorylation, with the corresponding reaction rate contributing to the calculation of the specific growth rate. It is worth to note that the original metabolic model considers adaptation to oxygen availability according to an assumption of the oxygen excess in the medium, which allows for the instantaneous recovery of ATP, while the rate of ATP consumption is used in the rate of biomass production (Equations (24)–(28)):

where is the biomass concentration; is the specific growth rate; is the total ATP production flux; is the adjustable constant; and are the specific ATP production fluxes through oxidative phosphorylation; and indicate the phosphate/oxygen ratios for NADH and FADH2, respectively, under aerobic conditions; and , , , , , , , , , , , , , are reaction rates for glucokinase, phosphofructokinase, glyceraldehyde 3-phosphate dehydrogenase, pyruvate kinase I, phosphoenolpyruvate synthase, acetate kinase, acetyl coenzyme A synthetase, α-keto-D-gluconate dehydrogenase, phosphoenolpyruvate carboxykinase, isocitrate dehydrogenase phosphatase/kinase, adenylate cyclase, pyruvate dehydrogenase, malate dehydrogenase, succinate dehydrogenase, respectively.

While in the proposed model, ATP is restored depending on the accumulated NADH and FADH2 and available oxygen (Equations (29)–(30)):

where , and are concentrations of NADH, FADH2 and intracellular oxygen, respectively; is the maximum oxidative phosphorylation rate; and are Michaelis–Menten constants.

Nevertheless, the process of oxidative phosphorylation is presented in a simplified form, taking into account the production of NADH, FADH2 and ATP. The absence of a complete oxidative phosphorylation process can become critical, especially in conditions of changing oxygen concentrations in the compartments of the bioreactor. This constraint is a jumping-off point of further development of the metabolic part of the modular model.

4. Results

4.1. Preliminary Information

In this study, we simulate carbon-limited fed-batch cultivation conditions with a focus on glucose and dissolved oxygen concentration gradients. In the context of the modular model of the bioreactor, we use the term «substrate» to denote the carbon source, i.e., glucose.

The results of the numerical simulations for the modular model of the bioreactor are presented for a total simulation time of 1 h, which was sufficient for the system to reach a quasi-steady state. In this study, we use the term «quasi-steady state» to denote the stabilization of the extracellular concentrations (substrate, acetate and oxygen), while biomass concentration continues to increase. Quasi-steady states were determined by inspecting plotted simulation results. Unlike original compartment model with fixed biomass concentration [35], a strict steady state cannot be achieved in our modular model. However, characteristic mixing and relaxation times are in the range of seconds to minutes, making one hour a sufficient interval to ensure reaching quasi-steady state. It should be noted that reaching the stationary growth phase in bacterial cultures typically requires a longer timescale (5–10 h) [47,48,49,50,51]. This highlights the need for further investigation of the factors and conditions influencing the long-term bioprocess dynamics, which will be addressed in future developments of the presented modular model.

Following [14,35], two different bioreactor mixing regimes were used: one corresponded to low mixing intensity (also referred to as “low settings”) with parameter values for stirrer speed rpm, gas inflow rate kg/s, and excess pressure in the top part of the bioreactor bar; and another corresponded to high mixing intensity (“high settings”) with rpm, kg/s, bar. Additional simulations were performed by varying the mixing parameters between these two boundaries in order to identify an optimal mixing regime.

In all simulations, the specific glucose feed rate was set to 0.08 g of substrate per gram of biomass per hour (gS/gX/h).

4.2. Simulation Results for the Boundary Mixing Regimes

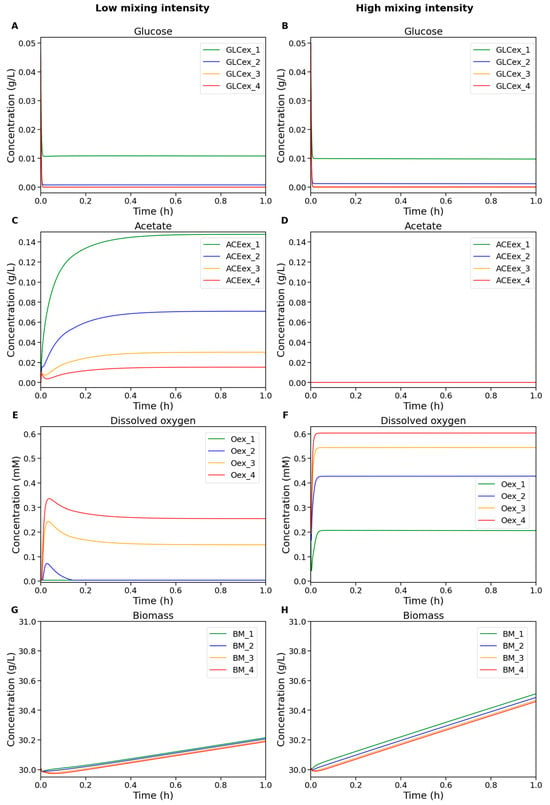

Figure 3 shows the dynamics of extracellular metabolite concentrations and biomass across different compartments of the bioreactor under low and high mixing intensities.

Figure 3.

Numerical simulation results of the modular model of the bioreactor under low (left column) and high (right column) mixing intensity. The plots show concentrations of (A,B) glucose, (C,D) acetate, (E,F) dissolved oxygen, and (G,H) biomass in the cultivation medium. Colors indicate compartment identity: green—compartment 1 (top), blue—2, orange—3, red—4 (bottom).

At low mixing intensity (Figure 3, left column), oxygen depletion occurs in the upper compartments of the reactor because the upward transport of oxygen from the bottom zones is insufficient to sustain active metabolism. In contrast, under high mixing intensity (Figure 3, right column), the oxygen concentration remains sufficiently high throughout all compartments, thereby preventing acetate accumulation caused by restricted oxygen availability. Since glucose feeding occurs only in the top compartment, substrate depletion is observed in the lower zones. However, under high mixing intensity, glucose distribution becomes slightly more uniform across compartments, and, combined with high oxygen availability, this leads to an accelerated biomass growth rate.

E. coli can simultaneously assimilate substrates through both aerobic and anaerobic pathways. Under oxygen-limited conditions, the proportion of anaerobic metabolism varies, leading to the development of distinct metabolic regimes depending on the ratio between anaerobic and total substrate uptake rates.

Table 1 and Table 2 summarize the simulated substrate uptake rates and the corresponding metabolic regimes under different mixing conditions. Metabolic regimes were classified based on quantitative thresholds of specific uptake rates, following the definitions in the original compartment model [35]. Substrate starvation was defined as a negligible total substrate uptake rate, set to less than 5% of the maximal substrate uptake rate (, corresponding to 0.04 gS/gX/h). Oxygen limitation was defined by the onset of anaerobic substrate uptake ( gS/gX/h), indicating that fully oxidative metabolism is no longer possible due to insufficient oxygen transfer. In all other cases, metabolism was considered substrate-limited.

Table 1.

Simulated substrate uptake rates and corresponding metabolic regimes in bioreactor compartments under low mixing intensity.

Table 2.

Simulated substrate uptake rates and corresponding metabolic regimes in bioreactor compartments under high mixing intensity.

It should be noted that, due to mixing, biomass concentration may still increase in zones classified as substrate starvation as a result of inflow from adjacent compartments, even though local growth is not possible.

Three metabolic regimes were identified from the simulations: oxygen limitation, substrate limitation, and substrate starvation. Under oxygen limitation, the oxygen transfer rate into the liquid phase is insufficient to fully oxidize the available substrate, forcing cells to partially shift to anaerobic metabolism. Substrate starvation occurs when the substrate uptake rate is too low to sustain cell growth, while metabolism remains fully aerobic. In the substrate limitation regime, growth is constrained by the availability of substrate, and all consumed substrate is completely oxidized without switching to anaerobic pathways.

It can be seen that adjusting the mixing parameters primarily influences whether glucose is consumed aerobically or anaerobically in the upper part of the reactor, while the lower compartments still experience significant substrate depletion. Interestingly, increasing the mixing intensity did not reduce the overall extent of substrate starvation across the reactor. This observation is consistent with the well-known fact that Rushton turbines promote efficient radial mixing but do not contribute to better axial (vertical) mixing [19,52]. As a result, glucose remains unevenly distributed along the height of the reactor, and enhanced mixing primarily improves oxygen transfer rather than homogenizing substrate concentrations.

4.3. Optimal Mixing Regime Identification

In addition to the two boundary regimes (with low and high mixing intensity), a series of simulations was conducted by varying three mixing-related parameters within the range defined by their respective boundary values using linear interpolation:

where is the new value of the interpolated parameter; and are its values under low and high mixing settings, respectively; and is the interpolation coefficient. A value of corresponds to the low settings, while corresponds to the high settings.

The aim of this analysis was to determine the minimum value of at which the equilibrium acetate concentration in all compartments stabilizes at zero. This state was interpreted as an optimal mixing regime, in which anaerobic metabolism is fully suppressed at a lower mixing intensity than in the high-settings scenario. This regime avoids excessive energy consumption stirring while maintaining optimal conditions for biomass growth.

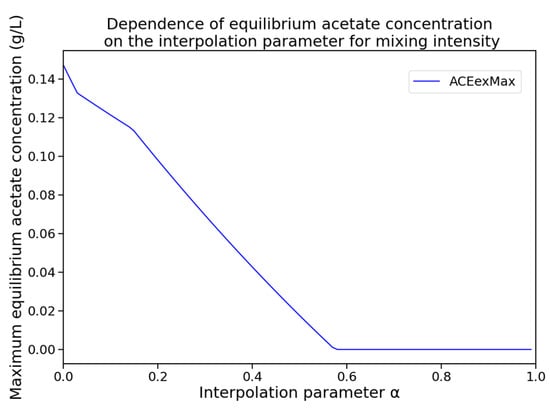

For each value of with a step size of 0.01, a numerical simulation was performed, and the maximum acetate concentration across all compartments was recorded at the final simulation time point. Additionally, it was verified that the system had reached quasi-steady state. The resulting dependency is shown in Figure 4. The dynamics of extracellular metabolite and biomass concentrations for the identified optimal mixing regime are shown in Figure 5.

Figure 4.

Dependence of the maximum equilibrium acetate concentration (ACEexMax) across all compartments on the interpolation parameter , which defines the mixing intensity.

Figure 5.

Numerical simulation results of the modular model of the bioreactor under the optimal mixing regime. The plots show concentrations of (A) glucose, (B) acetate, (C) dissolved oxygen, and (D) biomass in the cultivation medium. Color coding for compartments is the same as in Figure 3.

The acetate concentration was found to reach zero for the first time at , which corresponds to a mixing regime with the following parameter values: rpm, kg/s, bar.

Thus, the simulation results identified a minimum combination of mixing-related parameters at which acetate accumulation associated with insufficient oxygen supply was suppressed in all compartments. This transition to fully aerobic substrate oxidation represents an optimal operating regime that sustains biomass growth rates comparable to those under high mixing conditions, while requiring lower energy demands for mixing.

5. Discussion

Fermentation processes in industrial-scale bioreactors are the focus of extensive experimental and computational research [18,53,54,55]. In this study, we developed a modular mathematical model of an industrial-scale stirred bioreactor capable of simulating the dynamics of metabolic processes in E. coli within different bioreactor zones, while explicitly accounting for concentration gradients induced by mixing. The main advantage of the model lies in its integration of a detailed kinetic description of the central carbon metabolism with a simplified hydrodynamic representation of the cultivation environment. This hybrid modeling approach provides an improved capability to capture how mixing conditions and spatial concentration gradients affect the metabolic responses of cell cultures.

The simulation results demonstrated that mixing intensity has a substantial impact on the overall dynamics within the reactor. Under low mixing intensity, oxygen limitation was observed in the upper reactor compartments, forcing cells to partially switch to anaerobic metabolism and leading to acetate accumulation. In contrast, under high mixing intensity, both substrate and oxygen are more evenly distributed, preventing acetate formation linked to oxygen deficit and enhancing biomass growth. Additionally, computational analysis allowed identification of an optimal mixing regime, characterized by zero equilibrium acetate concentration at more than 40% lower mixing intensity compared to the high-mixing scenario. This result highlights the model’s potential in identifying energy-efficient bioreactor operating conditions, which simultaneously improve oxygen availability for aerobic metabolism and reduce risks of mechanical stress on cells associated with excessively high mixing rates [56,57]. The exact position of the optimum depends on the assumptions applied to describe gas flow and oxygen transfer. Nevertheless, the modular model enables the identification of an optimal regime for any given set of parameter values and functional dependencies, and therefore can be further refined by incorporating more detailed oxygen transfer descriptions. It is worth noting that in this study the definition of optimality focused primarily on hydrodynamic efficiency, while a more detailed multi-criteria assessment should be addressed in future studies.

The current implementation of the modular model relies on a simplified four-compartment representation of hydrodynamics, which does not account for potential intra-compartmental gradients of substrate and oxygen concentrations. This simplification leads to artificially steep transitions between metabolic regimes. In realistic systems, it is reasonable to expect an intermediate region between zones of oxygen limitation and substrate starvation—where substrate is still available but no longer sufficient to meet the full metabolic demands of the cells. The existence of such transitional regions has been computationally confirmed using CFD-based models [35]. A simple increase in the number of compartments within the current compartmentalization scheme may slightly smooth transitions between adjacent zones. However, it would not provide qualitative improvements in the predicted dynamics but would substantially increase computational complexity. Therefore, future improvements of the presented model should focus on incorporating more refined spatial concentration distributions, either by increasing the complexity of compartmentalization or by integrating CFD approaches.

Additionally, in real industrial fermentation processes, operational parameters such as feed rate, aeration, and agitation are dynamically adjusted in response to real-time process conditions. In contrast, our modular model applies these parameters as constant values, corresponding to fixed process settings. Therefore, the modular model does not aim to reproduce dynamic process control strategies but rather to provide mechanistic insight into how fixed hydrodynamic regimes shape microbial physiology. It can serve as a foundation for more advanced models that include feedback-based control of operational parameters.

The metabolic part of the proposed modular model also has some functional limitations that should be further addressed under oxygen-limited conditions. For instance, the original kinetic model of the E. coli metabolism employed in the study does not take into account redox regulation mediated by the transcription factors Fnr and ArcA/B that play essential roles in metabolic regulation in E. coli under oxygen limitation [58]. However, the particular regulatory issue can be resolved using a kinetic model that describes the dynamics of the metabolism in response to different dissolved oxygen levels considering transcription regulation mechanisms via these transcription factors [59]. The absence of these global regulators as well as fine-tuned mechanisms of their regulation is a limitation of the proposed model in the context of the description of mechanisms activating or repressing in response to an external factor like oxygen depletion. However, the time scale of these regulatory processes orchestrated by external factors is measured in minutes or even faster, both in cell cultures [60] and in continuous cultivation [61]. It means that the transition processes and related variables will be in a steady state on the hourly time scale that corresponds to the developed modular model. Apparently, the consideration of ArcA and FNR transcription factors and mechanisms of their regulation does impact the initial dynamics of the response but does not affect a steady state level of variables of the modeled metabolic system as a whole. On the other hand, the mechanistic model of the bacterial metabolism does not include ethanol and formate production pathways, which are experimentally detected as fermented products in anaerobic conditions [62]. It also omits the activation of pyruvate oxidation pathway regulated by sigma factor RpoS under carbon limited condition and contributing to the acetate production [63]. Nevertheless, all the abovementioned constraints of the current version of modular model in regard to the metabolic module can be consequently resolved via follow-up mechanistic modifications of the model via modular approach implemented in the original BioUML platform [64,65,66].

6. Conclusions

In this study, we developed a modular mathematical model of an industrial-scale stirred bioreactor, integrating key aspects of E. coli metabolism with hydrodynamic properties of the cultivation environment. The model combines a simplified four-compartment model of a large stirred bioreactor with a detailed kinetic model for the central carbon metabolism of E. coli.

The compartment model divides the reactor volume into distinct zones and calculates local concentrations of glucose, oxygen, acetate, and biomass, as well as liquid exchange flows between adjacent compartments. The kinetic model incorporates detailed metabolic pathways, including glycolysis, the tricarboxylic acid cycle, and oxidative phosphorylation, and accounts for shifts between aerobic and anaerobic metabolism based on oxygen availability.

Compared to existing hybrid models that combine metabolic kinetics with hydrodynamic effects, the presented model provides the most detailed kinetic component, enabling more accurate simulation of metabolic pathways. Furthermore, the implementation on the open-source BioUML platform ensures transparency, reproducibility, and extensibility of the model, in contrast to most previously published industrial-scale bioreactor models that remain unavailable due to commercial restrictions.

Numerical simulation results demonstrated the substantial impact of mixing parameters on spatial distributions of compounds and corresponding metabolic regimes within the bioreactor. Additionally, computational analysis identified an optimal mixing regime that eliminates anaerobic metabolism while reducing energy consumption for stirring. Importantly, the modular model enables the identification of an optimal regime for any given set of parameter values and functional dependencies and therefore provides a basis for incorporating more detailed process descriptions, guided by specific industrial requirements.

This study also has several limitations. Simulations were limited to one hour, sufficient for reaching a quasi-steady state of extracellular concentrations but not for capturing long-term culture transitions. The compartmentalization was restricted to four zones reflecting the reactor geometry, and the direct validation against pilot- or industrial-scale data was not feasible due to limited data availability.

Nevertheless, the developed model provides a computational tool for simulating cultivation processes in industrial bioreactors and analyzing metabolic dynamics under various hydrodynamic conditions.

Supplementary Materials

The following supporting information can be downloaded at: https://www.mdpi.com/article/10.3390/pr13103288/s1, Table S1: Model Reactions; Table S2: Model Variables; Table S3: Model Parameters; File S1: Mathematical Model (.omex), [35,36].

Author Contributions

Conceptualization, P.Y.K., I.R.A. and F.A.K.; methodology, P.Y.K., I.R.A. and F.A.K.; software, F.A.K.; validation, P.Y.K., V.A.K. and I.R.A.; formal analysis, P.Y.K. and V.A.K.; investigation, P.Y.K.; writing—original draft preparation, P.Y.K. and V.A.K.; writing—review and editing, P.Y.K., V.A.K., I.R.A. and F.A.K.; visualization, P.Y.K.; supervision, F.A.K.; funding acquisition, F.A.K. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the grant of the state program of the «Sirius» Federal Territory «Scientific and technological development of the «Sirius» Federal Territory» (Agreement №18-03 date 10 September 2024).

Data Availability Statement

The implementation of the model is available in the web version of the BioUML platform and is stored in the GitLab repository at: https://gitlab.sirius-web.org/bioreactor/modular-model-of-bioreactor, accessed on 9 October 2025.

Conflicts of Interest

The authors declare no conflicts of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript; or in the decision to publish the results.

Abbreviations

The names of enzymatic reactions used in the model are based on abbreviations of corresponding enzymes. Abbreviations are as follows:

| αKG | α-ketoglutarate |

| 6PG | 6-phosphogluconate |

| 6PGL | 6-phosphogluconolactonase |

| AcCoA | acetyl-CoA |

| AcP | acetyl phosphate |

| ACEex | external acetate |

| ATP | adenosine-5’-triphosphate |

| ADP | adenosine-5’-diphosphate |

| AMP | adenosine-5’-monophosphate |

| cAMP | cyclic AMP |

| CoA | coenzyme A |

| E4P | erythrose-4-phosphate |

| F6P | fructose-6-phosphate |

| FBP | fructose-1,6-bisphosphate |

| FUM | fumarate |

| G6P | glucose-6-phosphate |

| GAP | glyceraldehyde-3-phosphate |

| GLCex | external glucose |

| GOX | glyoxylate |

| ICIT | isocitrate |

| KDPG | 2-keto-3-deoxy-6-phosphogluconate |

| MAL | malate |

| NAD | nicotinamide adenine dinucleotide |

| NADH | nicotinamide adenine dinucleotide, reduced |

| NADP | dihydronicotinamide adenine dinucleotide phosphate |

| NADPH | dihydronicotinamide adenine dinucleotide phosphate, reduced |

| OAA | oxaloacetate |

| PEP | phosphoenol pyruvate |

| PYR | pyruvate |

| Pi | inorganic phosphate |

| R5P | ribose-5-phosphate |

| RU5P | ribulose-5-phosphate |

| S7P | sedoheptulose-7-phosphate |

| SUC | succinate |

| X5P | xylulose-5-phosphate |

| αkgdh | α-keto-D-gluconate dehydrogenase |

| 6Pgdh | 6-phosphogluconate dehydrogenase |

| AceK | isocitrate dehydrogenase phosphatase/kinase |

| Ack | acetate kinase |

| Acs | acetyl coenzyme A synthetase |

| Cra | catabolite repressor/activator |

| Crp | cAMP receptor protein |

| Cs | citrate synthase |

| Cya | adenylate cyclase |

| Eda | 2-keto-3-deoxygluconate 6-phosphate aldolase |

| Edd | 6-phosphate dehydrase |

| EIIA | unphosphorylated Pts protein EIIA |

| EIIA-P | phosphorylated Pts protein EIIA |

| Fba | fructose-1,6-bisphosphate aldolase class II |

| Fbp | fructose-1,6-bisphosphatase |

| Fum | fumarase |

| G6pdh | glucose-6-phosphate dehydrogenase |

| Gapdh | glyceraldehyde 3-phosphate dehydrogenase |

| Glk | glucokinase |

| Icdh | isocitrate dehydrogenase |

| Icdh-P | phosphorylated isocitrate dehydrogenase |

| Icl | isocitrate lyase |

| IclR | isocitrate lyase regulator |

| Ms | malate synthase |

| Mez | malic enzyme |

| Mdh | malate dehydrogenase |

| Pck | phosphoenolpyruvate carboxykinase |

| Pdh | pyruvate dehydrogenase |

| PdhR | pyruvate dehydrogenase complex repressor |

| Pfk | phosphofructokinase |

| Pgi | phosphoglucose isomerase/glucosephosphate isomerase |

| Pgl | phosphogluconolactonase |

| Pta | phosphotransacetylase |

| Pyk | pyruvate kinase I |

| Rpe | ribulose phosphate 3-epimerase |

| Rpi | ribulose 5-phosphate 3-isomerase |

| Sdh | succinate dehydrogenase |

| Tal | transaldolase |

| TktA | transketolase I |

| TktB | transketolase II |

References

- Calvin, K.; Dasgupta, D.; Krinner, G.; Mukherji, A.; Thorne, P.W.; Trisos, C.; Romero, J.; Aldunce, P.; Barrett, K.; Blanco, G.; et al. Climate Change 2023: Synthesis Report. Contribution of Working Groups I, II and III to the Sixth Assessment Report of the Intergovernmental Panel on Climate Change; Lee, H., Romero, J., Eds.; Intergovernmental Panel on Climate Change (IPCC): Geneva, Switzerland, 2023. [Google Scholar] [CrossRef]

- Cordell, W.T.; Avolio, G.; Takors, R.; Pfleger, B.F. Milligrams to kilograms: Making microbes work at scale. Trends Biotechnol. 2023, 41, 1442–1457. [Google Scholar] [CrossRef]

- Noorman, H.J.; Heijnen, J.J. Biochemical engineering’s grand adventure. Chem. Eng. Sci. 2017, 170, 677–693. [Google Scholar] [CrossRef]

- Straathof, A.J.J.; Wahl, S.A.; Benjamin, K.R.; Takors, R.; Wierckx, N.; Noorman, H.J. Grand research challenges for sustainable industrial biotechnology. Trends Biotechnol. 2019, 37, 1042–1050. [Google Scholar] [CrossRef]

- Keasling, J.D. Manufacturing molecules through metabolic engineering. Science 2010, 330, 1355–1358. [Google Scholar] [CrossRef] [PubMed]

- Stephanopoulos, G. Synthetic biology and metabolic engineering. ACS Synth. Biol. 2012, 1, 514–525. [Google Scholar] [CrossRef] [PubMed]

- Casini, A.; Chang, F.-Y.; Eluere, R.; King, A.M.; Young, E.M.; Dudley, Q.M.; Karim, A.; Pratt, K.; Bristol, C.; Forget, A.; et al. A pressure test to make 10 molecules in 90 days: External evaluation of methods to engineer biology. J. Am. Chem. Soc. 2018, 140, 4302–4316. [Google Scholar] [CrossRef] [PubMed]

- Lee, S.Y.; Kim, H.U.; Chae, T.U.; Cho, J.S.; Kim, J.W.; Shin, J.H.; Kim, D.I.; Ko, Y.-S.; Jang, W.D.; Jang, Y.-S. A comprehensive metabolic map for production of bio-based chemicals. Nat. Catal. 2019, 2, 18–33. [Google Scholar] [CrossRef]

- Voigt, C.A. Synthetic biology 2020–2030: Six commercially-available products that are changing our world. Nat. Commun. 2020, 11, 6369. [Google Scholar] [CrossRef]

- Jullesson, D.; David, F.; Pfleger, B.; Nielsen, J. Impact of synthetic biology and metabolic engineering on industrial production of fine chemicals. Biotechnol. Adv. 2015, 33, 1395–1402. [Google Scholar] [CrossRef]

- Hemmerich, J.; Noack, S.; Wiechert, W.; Oldiges, M. Microbioreactor systems for accelerated bioprocess development. Biotechnol. J. 2018, 13, 1700141. [Google Scholar] [CrossRef]

- Crater, J.S.; Lievense, J.C. Scale-up of industrial microbial processes. FEMS Microbiol. Lett. 2018, 365, fny138. [Google Scholar] [CrossRef]

- Noorman, H. An industrial perspective on bioreactor scale-down: What we can learn from combined large-scale bioprocess and model fluid studies. Biotechnol. J. 2011, 6, 934–943. [Google Scholar] [CrossRef]

- Nadal-Rey, G. Modelling of Gradients in Industrial Aerobic Fed-Batch Fermentation Processes. Ph.D. Thesis, Technical University of Denmark, Kongens Lyngby, Denmark, 2020. Available online: https://backend.orbit.dtu.dk/ws/portalfiles/portal/244849808/201001_PhDThesis_GiselaNadalRey.pdf (accessed on 9 October 2025).

- Biggs, B.W.; Alper, H.S.; Pfleger, B.F.; Tyo, K.E.J.; Santos, C.N.S.; Ajikumar, P.K.; Stephanopoulos, G. Enabling commercial success of industrial biotechnology. Science 2021, 374, 1563–1565. [Google Scholar] [CrossRef]

- Kampers, L.F.C.; Asin-Garcia, E.; Schaap, P.J.; Wagemakers, A.; Martins dos Santos, V.A.P. From innovation to application: Bridging the valley of death in industrial biotechnology. Trends Biotechnol. 2021, 39, 1240–1242. [Google Scholar] [CrossRef] [PubMed]

- de Lorenzo, V.; Couto, J. The important versus the exciting: Reining contradictions in contemporary biotechnology. Microb. Biotechnol. 2018, 12, 32–34. [Google Scholar] [CrossRef] [PubMed]

- Nadal-Rey, G.; McClure, D.D.; Kavanagh, J.M.; Cornelissen, S.; Fletcher, D.F.; Gernaey, K.V. Understanding gradients in industrial bioreactors. Biotechnol. Adv. 2021, 46, 107660. [Google Scholar] [CrossRef] [PubMed]

- Vrábel, P.; van der Lans, R.G.J.M.; Luyben, K.C.A.M.; Boon, L.; Nienow, A.W. Mixing in large-scale vessels stirred with multiple radial or radial and axial up-pumping impellers: Modelling and measurements. Chem. Eng. Sci. 2000, 55, 5881–5896. [Google Scholar] [CrossRef]

- Xu, B.; Jahic, M.; Enfors, S.-O. Modeling of overflow metabolism in batch and fed-batch cultures of Escherichia coli. Biotechnol. Prog. 1999, 15, 81–90. [Google Scholar] [CrossRef]

- Wolfe, A.J. The acetate switch. Microbiol. Mol. Biol. Rev. 2005, 69, 12–50. [Google Scholar] [CrossRef]

- Neubauer, P.; Åhman, M.; Törnkvist, M.; Larsson, G.; Enfors, S.-O. Response of guanosine tetraphosphate to glucose fluctuations in fed-batch cultivations of Escherichia coli. J. Biotechnol. 1995, 43, 195–204. [Google Scholar] [CrossRef]

- Almquist, J.; Cvijovic, M.; Hatzimanikatis, V.; Nielsen, J.; Jirstrand, M. Kinetic models in industrial biotechnology—Improving cell factory performance. Metab. Eng. 2014, 24, 38–60. [Google Scholar] [CrossRef]

- Neubauer, P.; Häggström, L.; Enfors, S.-O. Influence of substrate oscillations on acetate formation and growth yield in Escherichia coli glucose limited fed-batch cultivations. Biotechnol. Bioeng. 1995, 47, 139–146. [Google Scholar] [CrossRef] [PubMed]

- Tang, W.; Deshmukh, A.T.; Haringa, C.; Wang, G.; van Gulik, W.; van Winden, W.; Reuss, M.; Heijnen, J.J.; Xia, J.; Chu, J.; et al. A 9-pool metabolic structured kinetic model describing days to seconds dynamics of growth and product formation by Penicillium chrysogenum. Biotechnol. Bioeng. 2017, 114, 1733–1743. [Google Scholar] [CrossRef]

- Vrábel, P.; van der Lans, R.G.J.M.; Cui, Y.Q.; Luyben, K.C.A.M. Compartment model approach. Chem. Eng. Res. Des. 1999, 77, 291–302. [Google Scholar] [CrossRef]

- Oosterhuis, N.M.G.; Kossen, N.W.F. Dissolved oxygen concentration profiles in a production-scale bioreactor. Biotechnol. Bioeng. 1984, 26, 546–550. [Google Scholar] [CrossRef]

- Reuss, M.; Bajpai, R. Stirred tank models. In Biotechnology; Wiley: Hoboken, NJ, USA, 1991; pp. 299–348. [Google Scholar] [CrossRef]

- Spann, R.; Glibstrup, J.; Pellicer-Alborch, K.; Junne, S.; Neubauer, P.; Roca, C.; Kold, D.; Lantz, A.E.; Sin, G.; Gernaey, K.V.; et al. CFD predicted pH gradients in lactic acid bacteria cultivations. Biotechnol. Bioeng. 2018, 116, 769–780. [Google Scholar] [CrossRef]

- Kuschel, M.; Takors, R. Simulated oxygen and glucose gradients as a prerequisite for predicting industrial scale performance a priori. Biotechnol. Bioeng. 2020, 117, 2760–2770. [Google Scholar] [CrossRef] [PubMed]

- Spann, R.; Gernaey, K.V.; Sin, G. A compartment model for risk-based monitoring of lactic acid bacteria cultivations. Biochem. Eng. J. 2019, 151, 107293. [Google Scholar] [CrossRef]

- Pigou, M.; Morchain, J. Investigating the interactions between physical and biological heterogeneities in bioreactors using compartment, population balance and metabolic models. Chem. Eng. Sci. 2015, 126, 267–282. [Google Scholar] [CrossRef]

- Vrábel, P.; van der Lans, R.G.J.M.; van der Schot, F.N.; Luyben, K.C.A.M.; Xu, B.; Enfors, S.-O. CMA: Integration of fluid dynamics and microbial kinetics in modelling of large-scale fermentations. Chem. Eng. J. 2001, 84, 463–474. [Google Scholar] [CrossRef]

- Wang, G.; Tang, W.; Xia, J.; Chu, J.; Noorman, H.; van Gulik, W.M. Integration of microbial kinetics and fluid dynamics toward model-driven scale-up of industrial bioprocesses. Eng. Life Sci. 2014, 15, 20–29. [Google Scholar] [CrossRef]

- Bafna-Rührer, J. Strategies and Tools to Select E. coli Fermenterphiles for Industrial Application. Ph.D. Thesis, Technical University of Denmark, Kongens Lyngby, Denmark, 2024. Available online: https://orbit.dtu.dk/files/375573898/Submission_version_PhD_thesis_JBR.pdf (accessed on 9 October 2025).

- Jahan, N.; Maeda, K.; Matsuoka, Y.; Sugimoto, Y.; Kurata, H. Development of an accurate kinetic model for the central carbon metabolism of Escherichia coli. Microb. Cell Factories 2016, 15, 112. [Google Scholar] [CrossRef]

- Kolpakov, F.; Akberdin, I.; Kashapov, T.; Kiselev, I.; Kolmykov, S.; Kondrakhin, Y.; Kutumova, E.; Mandrik, N.; Pintus, S.; Ryabova, A.; et al. BioUML: An integrated environment for systems biology and collaborative analysis of biomedical data. Nucleic Acids Res. 2019, 47, W225–W233. [Google Scholar] [CrossRef]

- Kolpakov, F.; Akberdin, I.; Kiselev, I.; Kolmykov, S.; Kondrakhin, Y.; Kulyashov, M.; Kutumova, E.; Pintus, S.; Ryabova, A.; Sharipov, R.; et al. BioUML—Towards a universal research platform. Nucleic Acids Res. 2022, 50, W124–W131. [Google Scholar] [CrossRef]

- Hucka, M.; Bergmann, F.T.; Chaouiya, C.; Dräger, A.; Hoops, S.; Keating, S.M.; König, M.; Novère, N.L.; Myers, C.J.; Olivier, B.G.; et al. The Systems Biology Markup Language (SBML): Language specification for Level 3 Version 2 Core Release 2. J. Integr. Bioinform. 2019, 16, 20190021. [Google Scholar] [CrossRef] [PubMed]

- Novère, N.L.; Hucka, M.; Mi, H.; Moodie, S.; Schreiber, F.; Sorokin, A.; Demir, E.; Wegner, K.; Aladjem, M.I.; Wimalaratne, S.M.; et al. The Systems Biology Graphical Notation. Nat. Biotechnol. 2009, 27, 735–741. [Google Scholar] [CrossRef]

- Kutumova, E.O.; Akberdin, I.R.; Egorova, V.S.; Kolesova, E.P.; Parodi, A.; Pokrovsky, V.S.; Zamyatnin, A.A., Jr.; Kolpakov, F.A. Physiologically based pharmacokinetic model for predicting the biodistribution of albumin nanoparticles after induction and recovery from acute lung injury. Heliyon 2024, 10, e30962. [Google Scholar] [CrossRef] [PubMed]

- Miroshnichenko, M.I.; Kolpakov, F.A.; Akberdin, I.R. A modular mathematical model of the immune response for investigating the pathogenesis of infectious diseases. Viruses 2025, 17, 589. [Google Scholar] [CrossRef] [PubMed]

- Hindmarsh, A.C.; Brown, P.N.; Grant, K.E.; Lee, S.L.; Serban, R.; Shumaker, D.E.; Woodward, C.S. SUNDIALS: Suite of nonlinear and differential/algebraic equation solvers. ACM Trans. Math. Softw. 2005, 31, 363–396. [Google Scholar] [CrossRef]

- Nadal-Rey, G.; McClure, D.D.; Kavanagh, J.M.; Cassells, B.; Cornelissen, S.; Fletcher, D.F.; Gernaey, K.V. Development of dynamic compartment models for industrial aerobic fed-batch fermentation processes. Chem. Eng. J. 2021, 420, 130402. [Google Scholar] [CrossRef]

- Oosterhuis, N.M.G. Scale-Up of Bioreactors: A Scale-Down Approach. Ph.D. Thesis, TU Delft, Delft, The Netherlands, 1984. Available online: http://resolver.tudelft.nl/uuid:03a887b7-8c20-4052-8d6b-7fe76918d7ec (accessed on 9 October 2025).

- Noorman, H.J.; van Winden, W.; Heijnen, J.J.; van der Lans, R.G.J.M. Intensified fermentation processes and equipment. In Intensification of Biobased Processes; The Royal Society of Chemistry: London, UK, 2018; pp. 1–41. [Google Scholar] [CrossRef]

- Hewitt, C.J.; Boon, L.A.; McFarlane, C.M.; Nienow, A.W. The use of flow cytometry to study the impact of fluid mechanical stress on Escherichia coli W3110 during continuous cultivation in an agitated bioreactor. Biotechnol. Bioeng. 1998, 59, 612–620. [Google Scholar] [CrossRef]

- Guardia Alba, M.J.; García Calvo, E. Characterization of bioreaction processes: Aerobic Escherichia coli cultures. J. Biotechnol. 2000, 84, 107–118. [Google Scholar] [CrossRef]

- Lapin, A.; Schmid, J.; Reuss, M. Modeling the dynamics of E. coli populations in the three-dimensional turbulent field of a stirred-tank bioreactor—A structured–segregated approach. Chem. Eng. Sci. 2006, 61, 4783–4797. [Google Scholar] [CrossRef]

- Glazyrina, J.; Materne, E.-M.; Dreher, T.; Storm, D.; Junne, S.; Adams, T.; Greller, G.; Neubauer, P. High cell density cultivation and recombinant protein production with Escherichia coli in a rocking-motion-type bioreactor. Microb. Cell Factories 2010, 9, 42. [Google Scholar] [CrossRef]

- Zambrano, J.; Carlsson, B.; Diehl, S. Optimal steady-state design of zone volumes of bioreactors with Monod growth kinetics. Biochem. Eng. J. 2015, 100, 59–66. [Google Scholar] [CrossRef]

- Lapin, A.; Müller, D.; Reuss, M. Dynamic behavior of microbial populations in stirred bioreactors simulated with Euler−Lagrange methods: Traveling along the lifelines of single cells. Ind. Eng. Chem. Res. 2004, 43, 4647–4656. [Google Scholar] [CrossRef]

- Garcia-Ochoa, F.; Gomez, E. Bioreactor scale-up and oxygen transfer rate in microbial processes: An overview. Biotechnol. Adv. 2009, 27, 153–176. [Google Scholar] [CrossRef]

- Tarlak, F. The use of predictive microbiology for the prediction of the shelf life of food products. Foods 2023, 12, 4461. [Google Scholar] [CrossRef] [PubMed]

- de Mello, A.F.M.; de Souza Vandenberghe, L.P.; Herrmann, L.W.; Letti, L.A.J.; Burgos, W.J.M.; Scapini, T.; Manzoki, M.C.; de Oliveira, P.Z.; Soccol, C.R. Strategies and engineering aspects on the scale-up of bioreactors for different bioprocesses. Syst. Microbiol. Biomanufacturing 2023, 4, 365–385. [Google Scholar] [CrossRef]

- de Lamotte, A.; Delafosse, A.; Calvo, S.; Delvigne, F.; Toye, D. Investigating the effects of hydrodynamics and mixing on mass transfer through the free-surface in stirred tank bioreactors. Chem. Eng. Sci. 2017, 172, 125–142. [Google Scholar] [CrossRef]

- Garcia-Ochoa, F.; Gomez, E.; Santos, V.E. Fluid dynamic conditions and oxygen availability effects on microbial cultures in STBR: An overview. Biochem. Eng. J. 2020, 164, 107803. [Google Scholar] [CrossRef]

- Bettenbrock, K.; Bai, H.; Ederer, M.; Green, J.; Hellingwerf, K.J.; Holcombe, M.; Kunz, S.; Rolfe, M.D.; Sanguinetti, G.; Sawodny, O.; et al. Towards a systems level understanding of the oxygen response of Escherichia coli. In Advances in Microbial Physiology; Poole, R.K., Ed.; Elsevier: Amsterdam, The Netherlands, 2014; pp. 65–114. [Google Scholar] [CrossRef]

- Matsuoka, Y.; Kurata, H. Modeling and simulation of the redox regulation of the metabolism in Escherichia coli at different oxygen concentrations. Biotechnol. Biofuels 2017, 10, 183. [Google Scholar] [CrossRef] [PubMed]

- Cesar, S.; Sun, J.; Huang, K.C. Cellular memory of rapid growth is sensitive to nutrient depletion during starvation. Front. Microbiol. 2022, 13, 1016371. [Google Scholar] [CrossRef] [PubMed]

- DeLisa, M.P.; Li, J.; Rao, G.; Weigand, W.A.; Bentley, W.E. Monitoring GFP-operon fusion protein expression during high cell density cultivation of Escherichia coli using an on-line optical sensor. Biotechnol. Bioeng. 1999, 65, 54–64. [Google Scholar] [CrossRef] [PubMed]

- Clark, D.P. The fermentation pathways of Escherichia coli. FEMS Microbiol. Lett. 1989, 63, 223–234. [Google Scholar] [CrossRef]

- Olvera, L.; Mendoza-Vargas, A.; Flores, N.; Olvera, M.; Sigala, J.C.; Gosset, G.; Morett, E.; Bolívar, F. Transcription analysis of central metabolism genes in Escherichia coli: Possible roles of σ38 in their expression, as a response to carbon limitation. PLoS ONE 2009, 4, e7466. [Google Scholar] [CrossRef]

- Akberdin, I.R.; Kiselev, I.N.; Pintus, S.S.; Sharipov, R.N.; Vertyshev, A.Y.; Vinogradova, O.L.; Popov, D.V.; Kolpakov, F.A. A modular mathematical model of exercise-induced changes in metabolism, signaling, and gene expression in human skeletal muscle. Int. J. Mol. Sci. 2021, 22, 10353. [Google Scholar] [CrossRef]

- Kutumova, E.; Kiselev, I.; Sharipov, R.; Lifshits, G.; Kolpakov, F. Thoroughly calibrated modular agent-based model of the human cardiovascular and renal systems for blood pressure regulation in health and disease. Front. Physiol. 2021, 12, 746300. [Google Scholar] [CrossRef]

- Kutumova, E.O.; Kiselev, I.N.; Sharipov, R.N.; Lavrik, I.N.; Kolpakov, F.A. A modular model of the apoptosis machinery. In Advances in Experimental Medicine and Biology; Springer: New York, NY, USA, 2011; pp. 235–245. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).