Integrating Acheta domesticus into Cocoa Cream Products: Nutritional Enhancement and Impact on Technological Properties

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of Cocoa Cream Samples

2.3. Chemical Composition of Cocoa Cream Samples

2.4. Particle Size Distribution of Protein and Cocoa Cream Samples

2.5. Rheological Properties of Cocoa Spread Samples

2.6. Thermal Properties of Cocoa Spreads

2.7. Textural Properties of Cocoa Spreads

2.8. Color Analysis

2.9. Sensory Evaluation

2.10. Statistical Analysis

3. Results and Discussion

3.1. Chemical Composition

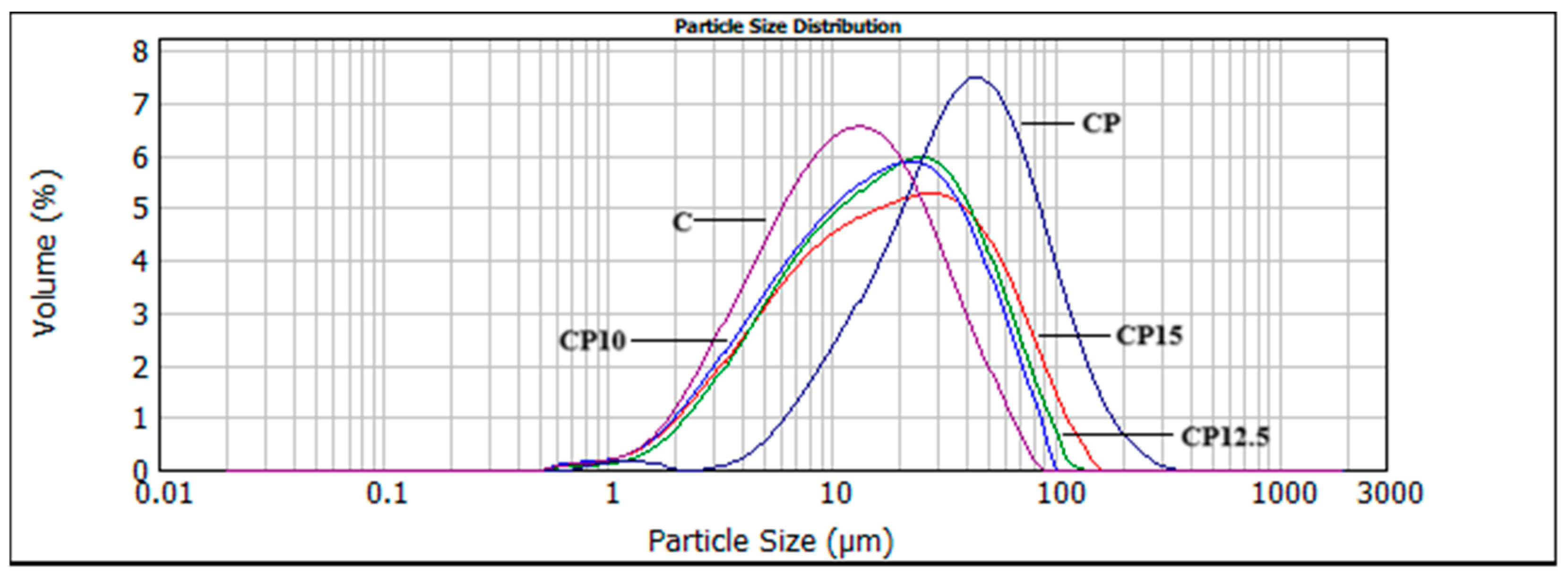

3.2. Particle Size Distribution

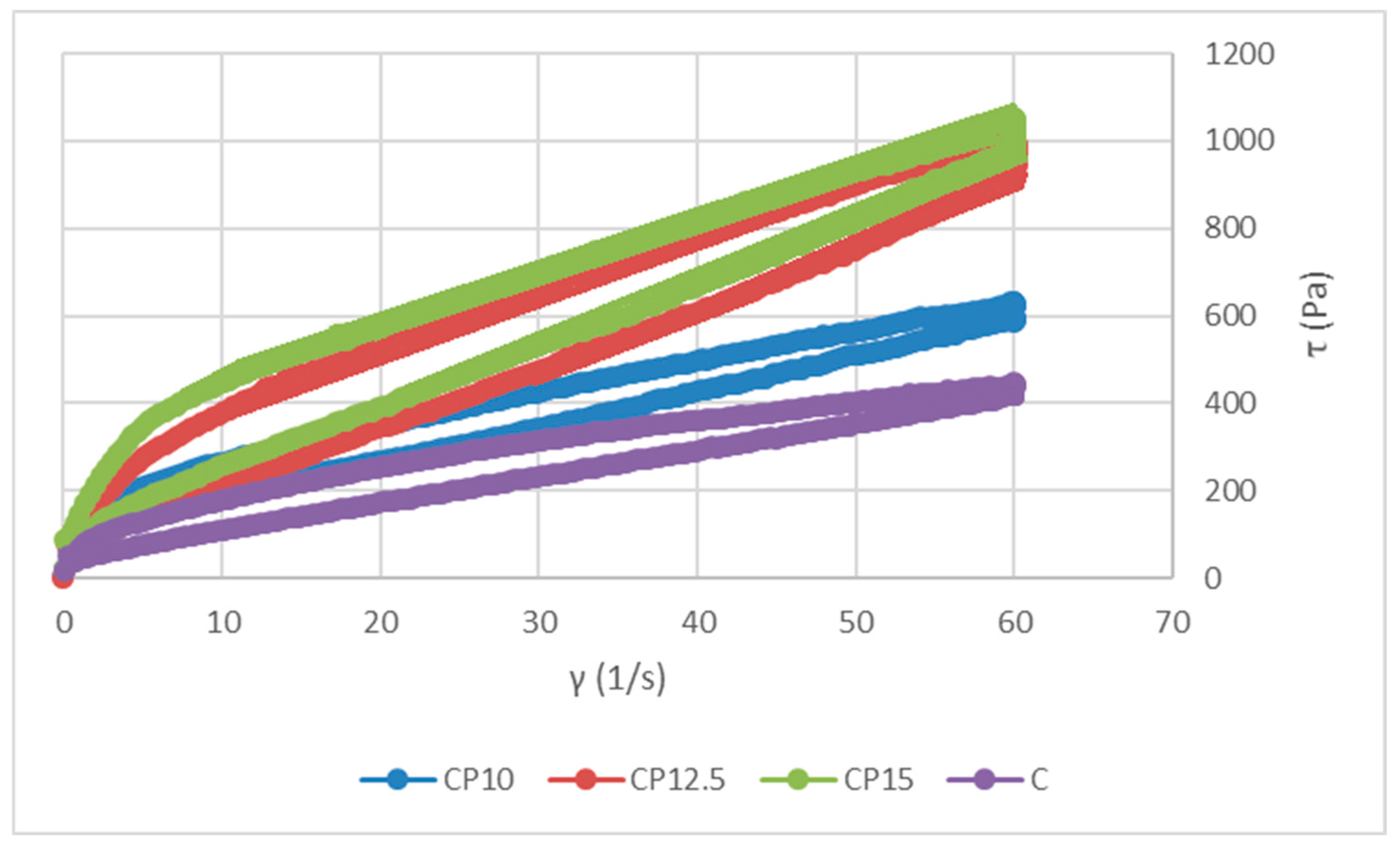

3.3. Rheological and Textural Properties

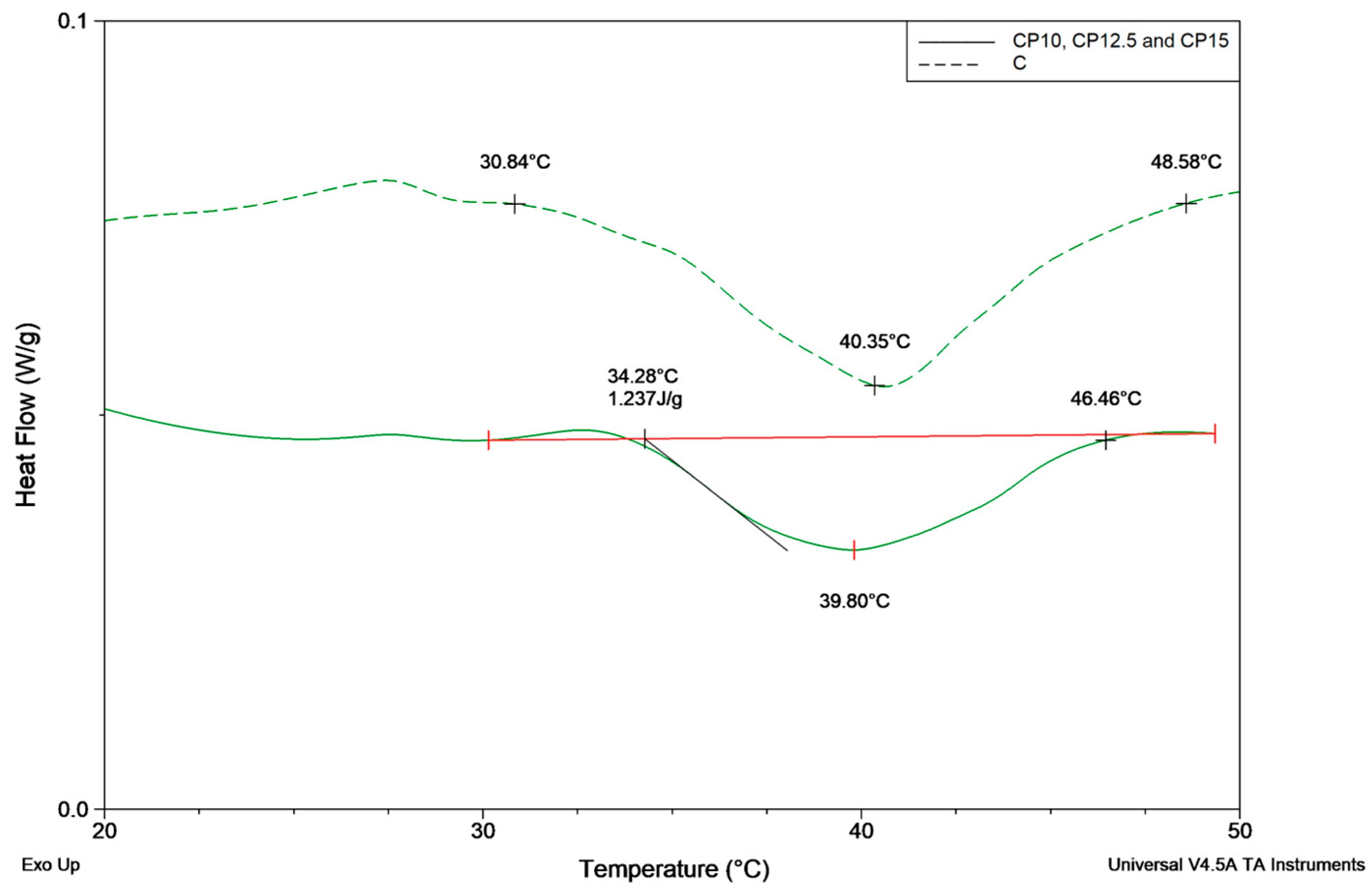

3.4. Thermal Properties

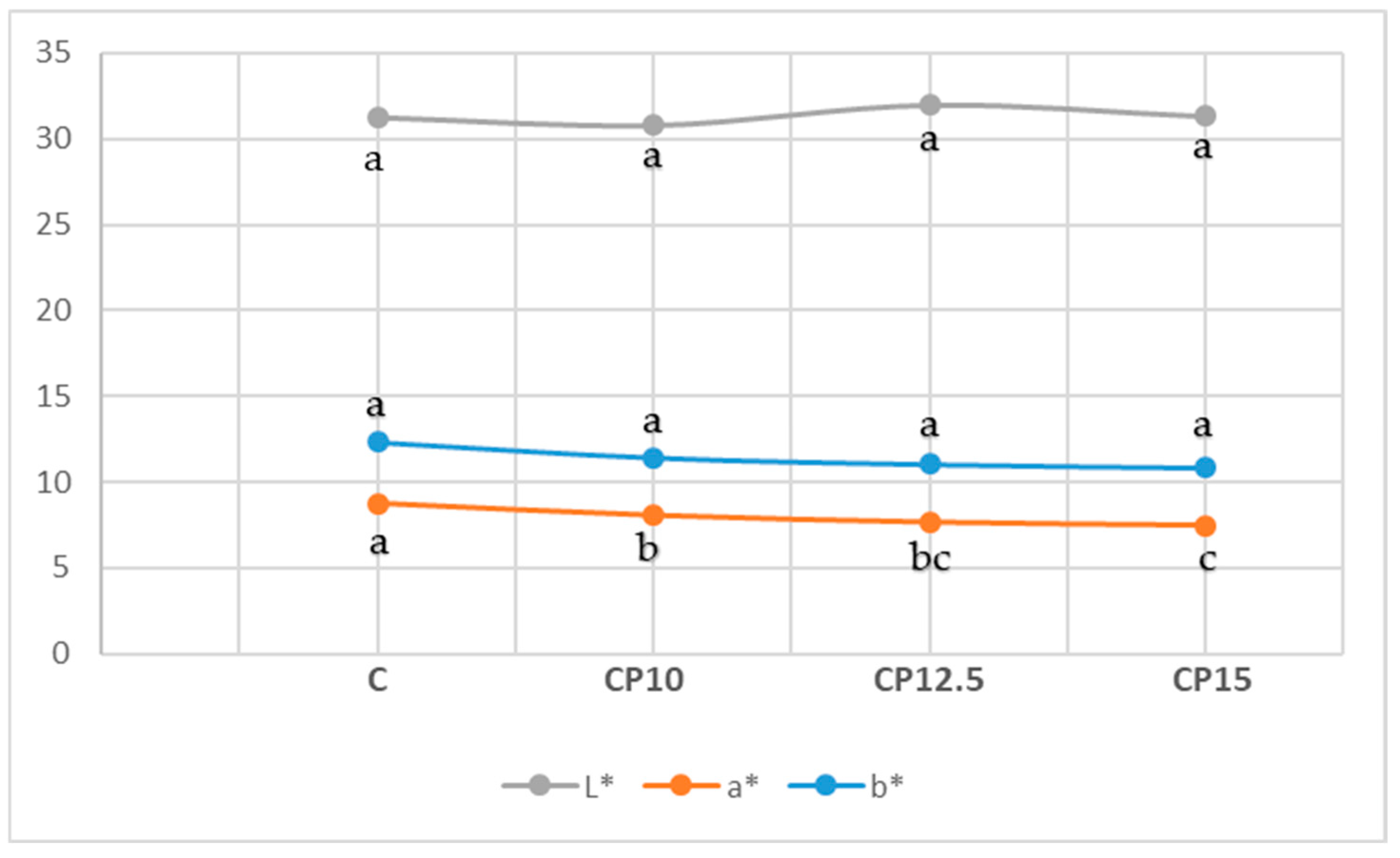

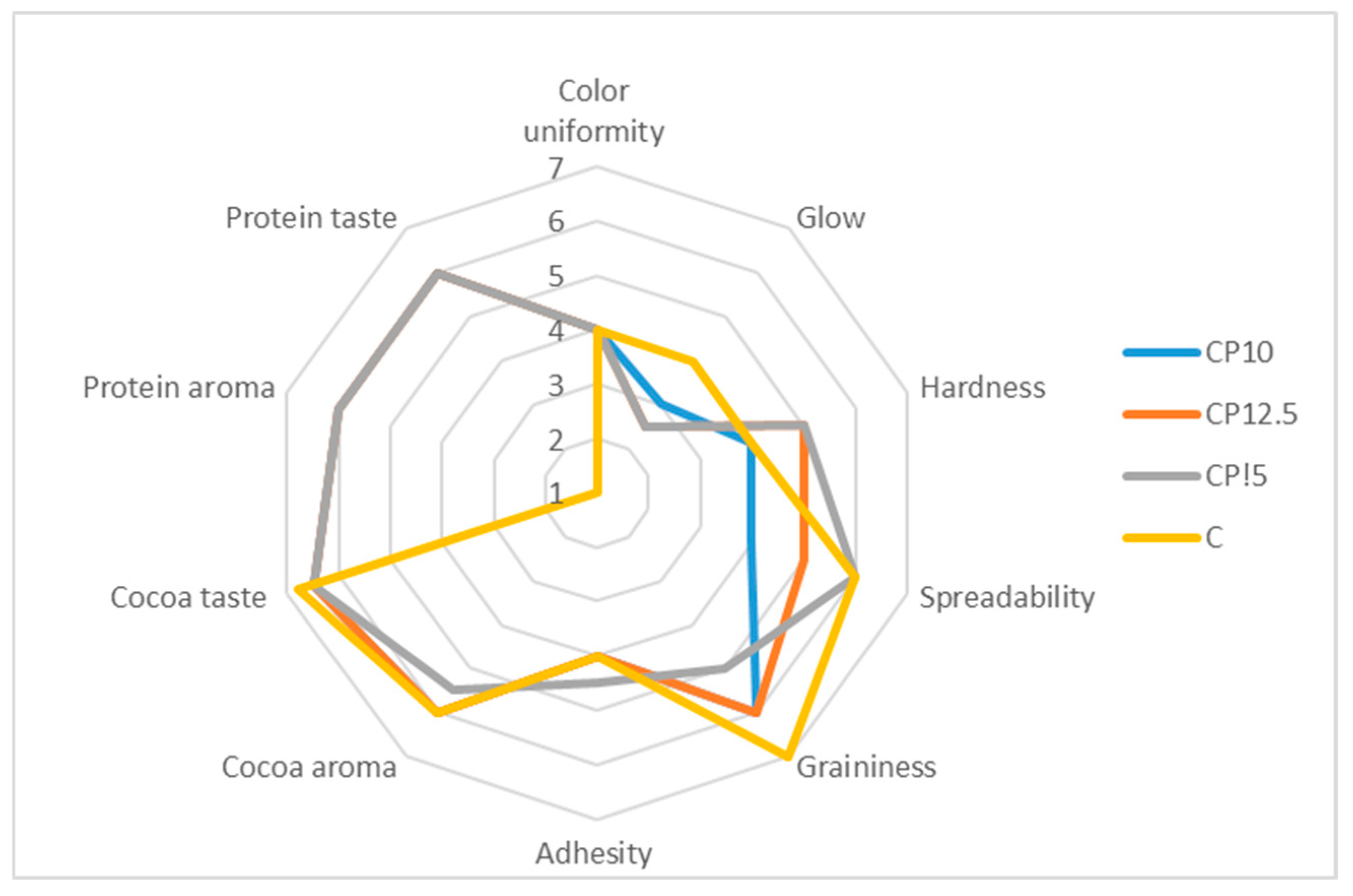

3.5. Color and Sensory Analysis

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| CP | Cricket protein |

| CP10 | Sample with 10% of cricket protein |

| CP12.5 | Sample with 12.5% of cricket protein |

| CP15 | Sample with 15% of cricket protein |

| PSD | Particle size distribution |

References

- Stožinić, M.; Ačkar, Đ.; Šojić, B.; Sedlar, T.; Popović, L.; Pajin, B.; Flanjak, I.; Bulatović, M.; Petrović, J.; Nikolić, I.; et al. Incorporation of Pork Meat and Blood Plasma Proteins into a Cocoa Cream Matrix: Characterization, Comparison of Functional Properties, and In Vitro Simulated Digestion. Foods 2025, 14, 2547. [Google Scholar] [CrossRef]

- Banovic, M.; Arvola, A.; Pennanen, K.; Duta, D.E.; Brückner-Gühmann, M.; Lähteenmäki, L.; Grunert, K.G. Foods with increased protein content: A qualitative study on European consumer preferences and perceptions. Appetite 2018, 125, 233–243. [Google Scholar] [CrossRef]

- Munialo, C.D. An exploration of alternative proteins as a potential sustainable solution to meeting the nutritional needs of the ever-increasing global population. Int. J. Food Sci. Technol. 2024, 59, 2846–2859. [Google Scholar] [CrossRef]

- Aiking, H. Future protein supply. Trends Food Sci. Technol. 2011, 22, 112–120. [Google Scholar] [CrossRef]

- Day, L. Proteins from land plants—Potential resources for human nutrition and food security. Trends Food Sci. Technol. 2013, 32, 25–42. [Google Scholar] [CrossRef]

- Popović, L. Proteins and Biochemical Transformations. Monography, Faculty of Technology Novi Sad, University on Novi Sad, Novi Sad, Serbia, 2022. [Google Scholar]

- Liceaga, A.M. Edible insects, a valuable protein source from ancient to modern times. Adv. Food Nutr. Res. 2022, 101, 129–152. [Google Scholar] [CrossRef] [PubMed]

- Goodland, R.; Anhang, J. Livestock and Climate Change: What if the Key Actors in Climate Change Are… Cows, Pigs, and Chickens? Washington, USA. 2009. Available online: https://awellfedworld.org/wp-content/uploads/Livestock-Climate-Change-Anhang-Goodland.pdf (accessed on 19 August 2025).

- Huis, A.V.; Itterbeeck, J.V.; Klunder, H.; Mertens, E.; Halloran, A.; Muir, G.; Vantomme, P. Edible Insects: Future Prospects for Food and Feed Security; Food And Agriculture Organization of the United Nations: Rome, Italy, 2013; Available online: http://www.fao.org/docrep/018/i3253e/i3253e.pdf (accessed on 20 September 2025).

- Murefu, T.; Macheka, L.; Musundire, R.; Manditsera, F. Safety of wild harvested and reared edible insects: A review. Food Control. 2019, 101, 209–224. [Google Scholar] [CrossRef]

- Van Huis, A. Potential of Insects as Food and Feed in Assuring Food Security. Annu. Rev. Entomol. 2013, 58, 563–583. [Google Scholar] [CrossRef] [PubMed]

- Nowak, V.; Persijnm, D.; Rittenschober, D.; Charrondiere, R. Review of food composition data for edible insects. Food Chem. 2016, 193, 39–46. [Google Scholar] [CrossRef]

- Mwangi, M.N.; Oonincx, D.G.A.B.; Stouten, T.; Veenenbos, M.; Melse-Boonstra, A.; Dicke, M.; van Loon, J.J.A. Insects as sources of iron and zinc in human nutrition. Nutr. Res. Rev. 2018, 31, 248–255. [Google Scholar] [CrossRef]

- Berg, J.; Wendin, K.; Langton, M.; Josell, Å.; Davidsson, F. State of the Art Report: Insects as food and feed. Ann. Exp. Biol. 2017, 5, 1–9. [Google Scholar]

- Zielińska, E.; Baraniak, B.; Karaś, M.; Rybczyńska, K.; Jakubczyk, A. Selected species of edible insects as a source of nutrient composition. Food Res. Int. 2015, 77, 460–466. [Google Scholar] [CrossRef]

- Pilco-Romero, G.; Chisaguano-Tonato, A.M.; Herrera-Fontana, M.E.; Chimbo-Gándara, L.F.; Sharifi-Rad, M.; Giampieri, F.; Battino, M.; Vernaza, M.G.; Álvarez-Suárez, J.M. House cricket (Acheta domesticus): A review based on its nutritional composition, quality, and potential uses in the food industry. Trends Food Sci. Technol. 2023, 142, 104226. [Google Scholar] [CrossRef]

- Giampieri, F.; Alvarez-Suarez, J.M.; Machì, M.; Cianciosi, D.; Navarro-Hortal, M.D.; Battino, M. Edible insects: A novel nutritious, functional, and safe food alternative. Food Front. 2022, 3, 358–365. [Google Scholar] [CrossRef]

- AOAC—Association of Official Analytical Chemists. International, Official Methods of Analysis of the Association of Official Analytical Hemists International, 17th ed.; Association of Official Analytical Communities: Gaithersburg, MD, USA, 2000. [Google Scholar]

- Hailu Kassegn, H. Determination of proximate composition and bioactive compounds of the Abyssinian purple wheat. Cogent Food Agric. 2018, 4, 1421415. [Google Scholar] [CrossRef]

- IOCCC. Viscosity of Cocoa and Chocolate Products. Anal. Method 2007, 46, 1–7. [Google Scholar]

- Aidoo, R.P.; Afoakwa, E.O.; Dewettinck, K. Rheological properties, melting behaviours and physical quality characteristics of sugar-free chocolates processed using inulin/polydextrose bulking mixtures sweetened with stevia and thaumatin extracts. LWT—Food Sci. Technol. 2015, 62, 592–597. [Google Scholar] [CrossRef]

- Lončarević, I.; Petrović, J.; Teslić, N.; Nikolić, I.; Maravić, N.; Pajin, B.; Pavlić, B. Cocoa Spread with Grape Seed Oil and Encapsulated Grape Seed Extract: Impact on Physical Properties, Sensory Characteristics and Polyphenol Content. Foods 2022, 11, 2730. [Google Scholar] [CrossRef] [PubMed]

- CIE. International Commission on Illumination, Colorimetry: Official Recommendation of the Inter-National Commission on Illumination; Publication CIE No. (E-1.31); CIE: Vienna, Austria, 1976. [Google Scholar]

- ISO 8586; Sensory Analysis—General Guidelines for the Selection, Training and Monitoring of Selected Assessors and Expert Sensory Assessors. ISO: Geneva, Switzerland, 2007.

- ISO 8589; Sensory Analysis-General Guidance for the Design of Test Rooms. ISO: Geneva, Switzerland, 2007.

- Rulebook of the Republic of Serbia on Nutrition and Health Claims Which Are Indicated on Food Declaration. No. 51/2018, 103/2018, 110/2023 and 62/2025). Available online: https://www.paragraf.rs/propisi/pravilnik-o-prehrambenim-zdravstvenim-izjavama-na-deklaraciji-hrane.html (accessed on 20 August 2025).

- Afoakwa, E.O.; Paterson, A.; Fowler, M. Effects of particle size distribution and composition on rheological properties of dark chocolate. Eur. Food Res. Technol. 2008, 226, 1259–1268. [Google Scholar] [CrossRef]

- Bolenz, S.; Holm, M.; Langkrär, C. Improving particle size distribution and flow properties of milk chocolate produced by ball mill and blending. Eur. Food Res. Technol. 2013, 238, 139–147. [Google Scholar] [CrossRef]

- Stožinić, M.V.; Zarić, D.B.; Rakin, M.B.; Lončarević, I.S.; Pajin, B.S.; Bulatović, M.L. Impact of whey bioactive hydrolysates on the quality of fat fillings for confectionery products. Food Feed. Res. 2024, 51, 189–198. [Google Scholar] [CrossRef]

- Afoakwa, E.O.; Paterson, A.; Fowler, M. Factors influencing rheological and textural qualities in chocolate—A review. Trends Food Sci. Technol. 2007, 18, 290–298. [Google Scholar] [CrossRef]

- Tárrega, A.; Ramírez-Sucre, M.O.; Vélez-Ruiz, J.F.; Costell, E. Effect of whey and pea protein blends on the rheological and sensory properties of protein-based systems flavoured with cocoa. J. Food Eng. 2012, 109, 467–474. [Google Scholar] [CrossRef]

- Barišić, V.; Ačkar, Đ.; Lončarević, I.; Petrović, J.; Benšić, M.; Paulik, D.; Doko, K.; Jozinović, A.; Babić, J.; Šubarić, D.; et al. Cocoa Shell as a Bulking Agent in Nutritionally Improved Cocoa Spreads with Sugar Substitutes. Curr. Res. Nutr. Food Sci. 2024, 12, 1118–1130. [Google Scholar] [CrossRef]

- Do, T.A.; Hargreaves, J.M.; Wolf, B.; Hort, J.; Mitchell, J.R. Impact of particle size distribution on rheological and textural properties of chocolate models with reduced fat content. J. Food Sci. 2007, 72, E541–E552. [Google Scholar] [CrossRef]

- Sokmen, A.; Gunes, G. Influence of some bulk sweeteners on rheological properties of chocolate. LWT—Food Sci. Technol. 2006, 39, 1053–1058. [Google Scholar] [CrossRef]

- Shakerardekani, A.; Karim, R.; Ghazali, H.M.; Chin, N.L. Textural, Rheological and Sensory Properties and Oxidative Stability of Nut Spreads—A Review. Int. J. Mol. Sci. 2013, 14, 4223–4241. [Google Scholar] [CrossRef]

- Jovanović, P.; Pajin, B.; Lončarić, A.; Jozinović, A.; Petrović, J.; Fišteš, A.; Zarić, D.; Tumbas Šaponjac, V.; Ačkar, Đ.; Lončarević, I. Whey as a Carrier Material for Blueberry Bioactive Components: Incorporation in White Chocolate. Sustainability 2022, 14, 14172. [Google Scholar] [CrossRef]

- Creusen, M.E.; Schoormans, J.P. The different roles of product appearance in consumer choice. J. Prod. Innov. Manag. 2005, 22, 63–81. [Google Scholar] [CrossRef]

- Mugge, R.; Dahl, D.W.; Schoormans, J.P. “What you see, is what you get?” Guidelines for influencing consumers’ perceptions of consumer durables through product appearance. J. Prod. Innov. Manag. 2018, 35, 309–329. [Google Scholar] [CrossRef]

- Setser, C.S. Sensory evaluation. In Advances in Baking Technology; Springer: Boston, MA, USA, 1993; pp. 254–291. [Google Scholar]

- Fröhling, A.; Bußler, S.; Durek, J.; Schlüter, O.K. Thermal impact on the culturable microbial diversity along the processing chain of flour from crickets (Acheta domesticus). Front. Microbiol. 2020, 11, 884. [Google Scholar] [CrossRef] [PubMed]

- Kumar, P. Process optimization for the preparation of chocolate spread incorporating whey protein concen-trate, cocoa powder, olive oil, and butterfat using response surface methodology. J. Food Process. Preserv. 2015, 39, 745–757. [Google Scholar] [CrossRef]

- Opris, G.A.; Rosan, C.A.; Vicas, S.J. Development and Characterization of a Novel Sweet Product Rich in Polyphenols and Protein Derived from Acheta domesticus. Bull. Univ. Agric. Sci. Vet. Med. Cluj-Napoca Food Sci. Technol. 2025, 82, 184–196. [Google Scholar] [CrossRef] [PubMed]

| Sample | Protein | Fat | Carbohydrates | Dietary Fiber | Moisture | Ash | Energy |

|---|---|---|---|---|---|---|---|

| C | 4.41 ± 0.31 a | 34.01 ± 1.07 a | 54.87 ± 0.15 a | 3.96 ± 1.31 a | 0.99 ± 0.02 a | 1.76 ± 0.01 a | 2297.81 ± 1.15 a |

| CP10 | 11.88 ± 0.17 b | 30.54 ± 0.04 b | 49.12 ± 0.01 b | 5.27 ± 0.02 b | 1.27 ± 0.02 b | 1.92 ± 0.03 b | 2209.14 ± 1.00 b |

| CP12.5 | 12.83 ± 0.14 c | 28.53 ± 0.16 c | 48.52 ± 0.01 c | 6.78 ± 0.60 c | 1.23 ± 0.01 c | 2.11 ± 0.04 c | 2152.80 ± 1.75 c |

| CP15 | 14.34 ± 0.41 c | 27.87 ± 0.10 d | 48.28 ± 0.08 d | 7.13 ± 0.0.13 d | 1.19 ± 0.02 d | 1.19 ± 0.01 d | 2152.80 ± 1.48 c |

| Particle Size Distribution Parameters (µm) | ||||

|---|---|---|---|---|

| Samples | d(0,1) | d(0,5) | d(0,9) | D[4,3] |

| CP | 11.11 ± 0.07 a | 39.04 ± 0.14 a | 102.44 ± 0.00 a | 50.06 ± 0.01 a |

| C | 3.53 ± 0.01 b | 11.89 ± 0.06 b | 35.10 ± 0.01 b | 16.15 ± 0.13 b |

| CP10 | 3.84 ± 0.00 c | 15.82 ± 0.01 c | 48.45 ± 0.07 c | 21.60 ± 0.00 c |

| CP12.5 | 3.82 ± 0.07 d | 16.83 ± 0.04 d | 57.65 ± 0.01 d | 24.86 ± 0.04 d |

| CP15 | 4.00 ± 0.07 e | 18.11 ± 0.00 e | 62.90 ± 0.04 e | 26.86 ± 0.02 e |

| Rheological Parameters | Textural Properties | ||

|---|---|---|---|

| Samples | Casson Viscosity (Pa*s) | Yield Stress (Pa) | Hardness (kg) |

| C | 3.847 ± 0.84 a | 1.846 ± 0.02 a | 2.260 ± 0.31 a |

| CP10 | 6.417 ± 0.35 b | 3.016 ± 0.15 b | 2.601 ± 0.02 b |

| CP12.5 | 8.617 ± 0.46 c | 0.862 ± 0.46 c | 2.804 ± 0.12 c |

| CP15 | 15.39 ± 0.01 d | 0.928 ± 0.08 c | 2.920 ± 0.14 d |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Stožinić, M.; Lončarević, I.; Šojić, B.; Zarić, D.; Ačkar, Đ.; Pajin, B.; Gere, A. Integrating Acheta domesticus into Cocoa Cream Products: Nutritional Enhancement and Impact on Technological Properties. Processes 2025, 13, 3162. https://doi.org/10.3390/pr13103162

Stožinić M, Lončarević I, Šojić B, Zarić D, Ačkar Đ, Pajin B, Gere A. Integrating Acheta domesticus into Cocoa Cream Products: Nutritional Enhancement and Impact on Technological Properties. Processes. 2025; 13(10):3162. https://doi.org/10.3390/pr13103162

Chicago/Turabian StyleStožinić, Milica, Ivana Lončarević, Branislav Šojić, Danica Zarić, Đurđica Ačkar, Biljana Pajin, and Attila Gere. 2025. "Integrating Acheta domesticus into Cocoa Cream Products: Nutritional Enhancement and Impact on Technological Properties" Processes 13, no. 10: 3162. https://doi.org/10.3390/pr13103162

APA StyleStožinić, M., Lončarević, I., Šojić, B., Zarić, D., Ačkar, Đ., Pajin, B., & Gere, A. (2025). Integrating Acheta domesticus into Cocoa Cream Products: Nutritional Enhancement and Impact on Technological Properties. Processes, 13(10), 3162. https://doi.org/10.3390/pr13103162