Abstract

Eco-friendly packaging for functional foods aims to reduce environmental impact while maintaining product integrity and ensuring consumer safety. Both the food industry and consumers must transition toward packaging solutions that are sustainable, biodegradable, and non-toxic. Among the key benefits of using environmentally friendly materials for functional food packaging are their sustainability, growing consumer preference, and regulatory compliance. Functional foods are products that offer health benefits beyond basic nutrition, such as enhancing immunity, improving digestion, or promoting overall well-being. This review emphasizes that the packaging of functional foods using an eco-friendly design approach is aligned with the Sustainable Development Goals and the consumers’ preferences. It included the definition and regulatory framework of functional foods, the bioactivity and health effects of bioactive compounds/microorganisms, packaging requirements and solutions for functional foods, as well as conventional and innovative analytical techniques for bioactive compound analysis. Eco-friendly packaging for functional foods is environmentally vital for waste reduction, socially crucial for meeting conscious demand, and economically sound for driving sustainable innovation and green markets.

1. Introduction

Functional foods have garnered significant attention due to their potential health benefits beyond basic nutrition. These products contain bioactive compounds or beneficial microorganisms that contribute to improved health and disease prevention [1]. Bioactive compounds encompass a wide range of naturally occurring substances with physiological effects on the human body [2]. Some of the most important categories include polyphenols, omega-3 PUFAs, phytosterols, functional peptides, and pro-, pre-, post-, and synbiotics. However, consumer acceptance remains a key factor in the success of functional foods. Understanding consumer preferences, perceptions, and trust in these products is essential for their widespread adoption [3].

To ensure the efficacy and safety of functional foods, it is imperative to implement comprehensive quality control measures [4]. These procedures primarily focus on the identification of bioactive compounds/microorganisms and the determination of their concentrations within the functional food matrix, as variations in their concentration or chemical/biological nature can compromise the food’s effectiveness and, in some cases, result in adverse effects on the consumer [5]. Given the substantial diversity of these bioactive compounds/microorganisms, a broad spectrum of analytical techniques is available for their quantification and characterization. Among the most widely employed are separative techniques, such as HPLC and GC, with various types of detectors [5]. Additionally, for living organisms, culture-based techniques are routinely used [6]. In addition to the conventional techniques used in the quality control of these foods, ongoing research is exploring the potential of novel analytical tools that may offer rapid, cost-effective, and environmentally sustainable alternatives, thereby advancing the field of functional food quality control.

To preserve the quality of food from production to consumption, packaging plays a crucial role. Particularly during distribution, storage, retail, and even final processing—such as cooking or preparation—the packed food is exposed to surrounding environmental conditions, including temperature, humidity, oxygen concentration, pH, solar radiation, and mechanical stress from handling. Then, in order to protect food integrity and quality, the appropriate packaging must be specifically tailored to meet their particular requirements [7,8]. This has a direct impact on food security by reducing food losses, thereby contributing to the sustainability of food production. In this context, the sustainability of the packaging itself is of fundamental importance.

Eco-friendly packaging is specifically designed to minimize environmental impact [9,10,11]. All aspects involved in its production and its effects on packaging performance must be carefully considered. One of the most critical factors is the choice of material, which must be safe for food contact and comply with current regulations. Moreover, it should ideally be biodegradable, compostable, recyclable, or derived from renewable sources. Although there are still significant challenges to widespread adoption, biodegradable materials are generally preferred; otherwise, the end-of-life disposal of packaging becomes a major environmental concern [12,13,14].

In addition, innovative packaging incorporates materials with improved gas barrier properties, as well as active and intelligent packaging systems. Active packaging technologies go beyond basic protective functions by interacting with the food to extend shelf life and even enhance product quality. Meanwhile, intelligent packaging provides real-time information about the food quality [15]. Combining eco-friendly materials with innovative packaging technologies is challenging, yet it holds great promise for improving sustainability. Edible active packaging with bioactive compounds is an example of research and real-life application of this combination [16,17,18,19]. Furthermore, the profile of functional food consumers is likely to align with environmentally friendly packaging solutions.

The integration of bioactive compounds, sustainable materials, and smart packaging technologies in functional foods not only enhances health benefits but also promotes environmental responsibility. The future of food packaging lies in the combination of innovation, consumer education, and sustainability efforts to foster an eco-friendlier food industry.

2. Functional Foods

2.1. Definition and Regulatory Framework

The concept of functional foods has been widely discussed in scientific literature; however, there is no universally accepted definition. Despite attempts to regulate these foods, a clear distinction between functional foods, nutraceuticals, and dietary supplements remains unresolved. Generally, functional foods contain ingredients that provide health benefits beyond basic nutrition.

The term “functional food” was first introduced in Japan in 1984, when the government established the category “Food for Specific Health Uses.” This initiative provided a legal framework for foods with proven physiological benefits. The United States followed in the 1990s, implementing regulations for health claims, although no formal definition for functional foods was provided. European countries adopted the concept over a decade later, with Regulation (EU) No. 1924/2006 addressing nutritional and health claims but not defining functional foods explicitly [20].

According to this, diverse definitions for functional foods have been proposed. The FAO defines them as foods containing compounds/microorganisms beyond basic nutrition that may be beneficial to health. Similarly, the Mayo Clinic describes them as foods with potentially positive health effects beyond fundamental nutrition. The Functional Food Center proposed a definition in 2018, describing them as natural or processed foods containing biologically active compounds in effective and non-toxic amounts, offering clinically proven health benefits [21].

A key issue in defining functional foods is their broad classification. Some definitions include commonly consumed healthy foods such as whole grains, nuts, and fish, leading to confusion. Moreover, the term “beyond basic nutrition” remains ambiguous, as many bioactive compounds contribute both to basic nutrition and additional health benefits.

The absence of a standardized definition has resulted in a fragmented regulatory landscape, particularly in the European Union. While multiple regulations apply to functional foods, a dedicated legal framework is lacking. This regulatory gap discourages investment in research and development, as companies fear operating in a legal grey area. Existing regulations, such as Regulation (EU) No. 1924/2006 and No. 353/2008, address health claims but impose strict criteria that are difficult to meet due to the complexity of food matrices and the challenge of demonstrating clear cause–effect relationships [20].

Functional foods influence physiological processes at the gastrointestinal level by enhancing biochemical parameters and improving neuronal functions. They contribute to immune system optimization, reducing susceptibility to infections and chronic diseases. Health claims for functional foods include strengthening immune system function, reducing oxidative stress and cardiovascular disease risk, managing blood glucose levels, supporting bone and skin health, and enhancing cognitive and nervous system function. Despite their potential benefits, demonstrating these effects is challenging. Many claims are rejected due to insufficient scientific evidence, reinforcing the need for standardized evaluation criteria.

Considering the current inconsistencies, a new definition has been suggested: functional foods are novel foods formulated to contain substances or live microorganisms with potential health benefits or disease-preventing properties at concentrations that are both safe and effective. This definition emphasizes that functional foods are distinct from conventional foods and include added bioactive compounds.

The concept of functional foods continues to evolve, but the lack of a universally accepted definition poses regulatory and market challenges. While these foods offer promising health benefits, standardization in definition and regulation is crucial for advancing their development. A harmonized framework would facilitate scientific validation, consumer trust, and industry growth, ensuring that functional foods fulfill their potential in promoting health and preventing disease.

2.2. Global Market and Consumer Acceptability

According to a report published by Markets and Markets TM, it is estimated that the global market of functional foods will grow at a compound annual growth rate of 6.8% from 2024 to 2029, reaching 165.8 billion dollars [22]. This report emphasizes that the notable growth of this market is primarily related to the desire of the population worldwide to consume healthier foods and the current lifestyle that favors the occurrence of some diseases. These are the main reasons that lead consumers to purchase functional foods. According to Baker et al. [23], the key characteristics of functional foods that most influence consumers’ purchasing decisions include health benefits, organoleptic properties, and price.

The health benefits of a functional food must be accurately reported on its label, as they are an essential factor in consumer acceptance. In this sense, accurately communicated health benefit information can enhance purchase intention [24]. Resistance to buying functional foods is typically linked to a lack of knowledge about their health benefits [25]. It is important to ensure that the information provided to consumers is accessible, such as using common names for bioactive compounds instead of scientific terms, to encourage the acceptance of functional foods [26,27]. The benefits of functional foods can be related to a reduction in both physiological and psychological diseases. However, some authors suggest that consumers tend to prefer functional foods that prevent or reduce the risk of physiological diseases, such as cancer, hypertension, or osteoporosis, over those that help alleviate fatigue or stress [28,29].

The organoleptic properties of functional foods play a crucial role in consumer acceptance, with flavor—encompassing both taste and aroma—being the primary determinant. Numerous statistical studies in the literature, based on consumer surveys from various countries, highlight the importance of functional foods being not only beneficial to health but also sensorially attractive [30,31,32,33,34,35].

Many consumers are willing to pay a premium for functional food, provided it is organoleptically appealing, safe, and reliable. This demands that the food industry adopt more efficient processing methods that produce equilibrated functional foods regarding their health benefits, sensory and safety properties, and cost (Figure 1).

Figure 1.

Equilibrated functional foods.

3. Bioactive Compounds/Microorganisms

3.1. Definition

As with the term “functional food,” there is still no consensus about the definition of “bioactive compound.” In scientific literature, different definitions have been proposed. In 1994, Kitts defined them as “extra nutritional” constituents naturally present in small quantities in the food matrix, produced upon either in vivo or industrial enzymatic digestion, the latter being a result of food-processing activities [36]. Another broader definition was introduced in 2006 by the Agriculture and Agri-Food Canada, defining bioactive compounds as “naturally occurring chemical compounds present in, or derived from a plant, animal, or marine source, that exert the desired health/wellness benefit” [37]. Additionally, at the 23rd Hohenheim Consensus Meeting in 2009, a group of specialized scientists arrived at an agreed definition of these bioactive substances: “essential and nonessential compounds (i.e., proteins vitamins or polyphenols) that occur in nature, are part of the food chain, and can be shown to have an effect on human health beyond the basic nutritional value of the product” [38]. The concept of “extra nutritional” or “beyond the basic nutritional value” suggests that nutrients, both micro- and macro-nutrients (i.e., proteins, lipids, carbohydrates, vitamins, and minerals), are excluded from this category. Nonetheless, recent research has revealed new physiological functions and preventive/therapeutic actions of specific groups of nutrients that have gained popularity as food ingredients intended to increase their biofunctionality. For instance, prebiotics are considered bioactive compounds, while most of them are classified as dietary fiber, a class of carbohydrate. This is the case with omega-3 PUFAs and phytosterols, which are included in the lipid classification.

“Bioactive microorganisms,” such as probiotics, fall outside the bioactive compounds category since they cannot be classified as compounds or substances. However, they are vastly used as food ingredients with the aim of exerting a positive effect on human health upon consumption. Therefore, they are included in the present review as bioactive ingredients for food formulations due to their gained popularity and wide acceptance in recent times.

In this context, the following bioactive compounds and microorganisms are considered in the present review:

- Polyphenols;

- Omega-3 PUFAs;

- Phytosterols;

- Pro-, pre-, post-, and symbiotics;

- Bioactive peptides.

3.2. Bioactivity and Health Effects of Bioactive Compounds

3.2.1. Polyphenols

Polyphenols are a group of numerous chemical compounds present in plants as secondary metabolites whose main action is linked to plant stress regulation. Chemically, they have a common structure of one or more aromatic rings with a single or multiple bound hydroxyl groups [39]. Most polyphenols in nature fall under the flavonoid category (flavonols, flavanols, flavones, flavanones, isoflavones, and anthocyanins), while the remaining phenolic compounds can be classified as non-flavonoid compounds (phenolic acids, hydroxycinnamic acids, lignans, stilbenes, and tannins) [40].

They are generally recognized for their antioxidant potential. During aerobic cellular metabolism, oxygen reactive molecules known as “free radicals” or ROS are generated. These molecules can cause permanent damage to cells, DNA, enzymes, and cell membranes [41]. This deleterious process can also occur due to exogenous ROS generated by smoking, UV radiation, and ionizing radiation. Cells have their own antioxidant defense system. Under normal physiological conditions, there is a balance between endogenous oxidants and antioxidants [42]. When this balance is disrupted, either by excessive generation of oxidants or a reduction in antioxidants, what is known as “oxidative stress” or “oxidative damage” occurs. Numerous studies have shown that oxidative stress is directly related to various degenerative diseases, such as cardiovascular diseases, cancer, diabetes, inflammatory disorders, and infectious illnesses [43]. Additionally, in 1956, Harman proposed the free radical theory of aging, which suggests that a dysfunction of the regulatory system would induce oxidative damage to biomolecules, which, in their accumulation, would be responsible for the aging process [44]. Like humans, and being aerobic organisms, plants also have mechanisms to control ROS levels and protect cells from oxidative stress. One of these mechanisms is the above-mentioned process of polyphenols’ synthesis.

In addition to their antioxidant action, various therapeutic effects have been attributed to polyphenols, such as cytotoxicity and anti-inflammatory, antihypertensive, and antidiabetic actions [20].

The antioxidant properties of polyphenols are responsible for their protective action; however, these same properties make them sensitive to light, heat, and oxygen. Thus, it is crucial to maintain conditions that minimize their degradation and ensure the claimed bioactivity throughout the entire production and distribution chain of functional foods.

3.2.2. Omega-3 PUFAs

Among omega-fatty acids, the omega-6 and omega-3 families are regarded as essential fatty acids since they are not synthesized by animals. The ratio of the most consumed omega-6 PUFA—linoleic acid (18:2ω-6)—to the omega-3 counterpart—α-linolenic acid (18:3ω-3)—in the typical Western diet is 5 to 15 [45]. The most studied metabolic product of linoleic acid is arachidonic acid (20:4ω-6), while for α-linolenic acid, there are two main fatty acids: EPA (20:5ω-3) and DHA (22:6ω-3). The metabolic pathways of linoleic acid and α-linolenic acid conversion to these long-chain fatty acids share the same enzymatic system, giving birth to a competition between linoleic acid and α-linolenic acid [25]. Given the imbalance in omega-3/omega-6 ratio consumption, the synthesis of EPA and DHA from α-linolenic acid is limited in most humans. And this feature accounts for the importance of dietary supplementation with omega-3 PUFAs. Their health effect is mostly attributed to their anti-inflammatory [46] and antioxidant action [47]. The preventive and therapeutic effects of omega-3 PUFAs on various diseases have been studied, i.e., cardiovascular diseases [48], mental health [49], and the immune system [50], among others. As mentioned, α-linolenic acid is found exclusively in plants, with green plant tissues, walnuts, and seeds of flax, chia, rapeseed, and soybean being good sources [51]. On the other hand, EPA and DHA are found in the oils of fish, particularly fatty fish [52], and in micro- and macro-algae [32,53]. The various double bonds found in omega-3 fatty acids make them prone to oxidation; therefore, packaging that provides an effective barrier against light and oxygen is highly advisable.

3.2.3. Phytosterols

Phytosterols are classified as lipids. They are sterols and stanols, which are present in plants. Each species has its own phytosterol profile, with more than 250 compounds recognized so far [54]. The most important pharmacological property of phytosterols is the potential to reduce total and low-density lipoprotein cholesterol levels, which is directly related to a lower risk of cardiovascular diseases [55]. Furthermore, they are also identified as molecules with the potential to modulate inflammation and the immune system and to exert antioxidant, anticancer, antiulcer, antibacterial, anti-obesity, antidiabetic, anti-microbial, and antifungal effects [54,55,56]. Moreover, evidence has attributed to phytosterols the potential to intervene in wound healing promotion and platelet aggregation inhibition. The richest sources of phytosterols in plants are unrefined oils from seeds and fruits [57,58]. In particular, the richest sources are rapeseed oil, wheat germ oil, and corn oil, while pistachio is the oily fruit containing the highest concentration of phytosterols [59]. Other good dietary sources of phytosterols are nuts, cereals, and legumes [56,60].

Phytosterols’ chemical structure includes a double bond, which is prone to oxidation when exposed to external factors such as heat, light, and oxygen [61].

3.2.4. Pro-, Pre-, Syn-, and Postbiotics

The worldwide widely accepted definition of probiotics is the one given in 2013 by an expert panel convened by the International Scientific Association for Probiotics and Prebiotics, which states that a probiotic is “live microorganisms that, when administered in adequate amounts, confer a health benefit on the host” [62]. It is important to state that not all microorganisms present in foods can be called probiotics. This term is reserved to characterize strains with a scientifically demonstrated effect on health [63]. The most common probiotics include Lactobacillus spp., Bifidobacterium spp., Streptococcus spp., Enterococcus spp., and Saccharomyces boulardii [64]. Within the field of functional foods, the segment of probiotic foods became the one with the fastest-growing rate [65]. In recent years, there has been a growing interest in gut microbiota and the link between this specific microbiome and health. Research has indicated that various diseases, such as inflammatory, immune, and nervous system-related ones, are linked to an imbalance in the gut’s bacterial composition, known as dysbiosis. One of the factors influencing the population of these microorganisms is diet [66]. Dietary interventions may help modulate the composition of microbial communities, having a direct impact on health, helping to prevent and treat diseases [67,68]. Probiotics can be isolated from three main sources in nature: (1) humans and animals, (2) foods, and (3) the environment [69].

Prebiotics are defined as “a substrate that is selectively utilized by host microorganisms conferring a health benefit” [63]. Some types of soluble fiber, such as FOS, GOS, and inulin, cannot be digested by human enzymes in the small intestine, so they reach the colon and are metabolized by beneficial microbes, generating health-beneficial short-chain fatty acids [70,71]. In this manner, consumption of prebiotics also helps modulate gut microbiota. Among the sources of FOS, fruits, vegetables, and cereals like bananas, sugar beets, asparagus, garlic, onions, tomatoes, wheat, and barley can be mentioned. GOS are present mainly in human and cow milk, while inulin’s most common sources are globe artichoke, chicory, Jerusalem artichoke, and elecampane [72].

Related to these concepts of healthy microorganisms and substrates, another possible food ingredient is the group of “synbiotic” compounds. They are defined as “a mixture, comprising live microorganisms and substrate(s) selectively utilized by host microorganisms, that confers a health benefit on the host” [73]. Those substrates are usually prebiotics, although they are not limited to them.

Another term that has been recently incorporated into the biotics family is “postbiotic.” According to a panel of experts convened by the International Scientific Association for Probiotics and Prebiotics in 2019, a postbiotic is a “preparation of inanimate microorganisms and/or their components that confers a health benefit on the host” [74]. In the food industry, fermentation is the most common source of postbiotics, such as bacterial lysates with cell surface proteins, bacterial enzymes and peptides, metabolites produced by bacteria such as teichoic acids, peptidoglycan-derived neuropeptides, polysaccharides, short-chain fatty acids, and lower organic acids, for instance, lactic acid [75,76].

3.2.5. Bioactive Peptides

Bioactive peptides, or biopeptides, are specific protein fractions that show a wide range of physiological actions when released from the protein by hydrolysis [77,78]. Protein breakdown can be achieved by enzymatic, chemical, or microbial methods [79]. The latter refers to microbial fermentation [80]; so, as mentioned above, in this type of process, the released peptides are categorized as postbiotics. Bioactive peptides have shown antihypertensive, antioxidant, antidiabetic, anti-inflammatory, antimicrobial, and anticoagulant effects [77,78,81], reducing the risk of non-communicable diseases and improving consumer health. Several foods of animal and plant origin are a source of biopeptides: milk, dairy products, nuts, cereal germ, soybeans, fermented products, eggs, marine organisms, edible insects, and meat proteins (e.g., beef, chicken, pork, and fish) [76,77,78,82,83,84].

A compilation of recent scientific studies on functional food products is shown in Table 1.

Table 1.

Summary of some recent publications on functional foods and their bioactive compounds/microorganisms.

3.3. Determination and Quantification of Bioactive Compounds/Microorganisms

The growing interest in functional foods has driven the implementation of various analytical techniques for both qualitative and quantitative analysis. Traditional analytical techniques have long served as the foundation for identifying and quantifying these compounds. However, advancements in analytical chemistry now provide a range of innovative alternatives, including improved sample preparation, advanced separation techniques, and the development of environmentally friendly methods. This knowledge allows evaluating the packaging performance to preserve bioactive compounds/microorganisms’ function. Moreover, in the case of active packaging, analytical assays are used to test the release kinetics of the active agents and their concentration within the food matrix. This section aims to provide an overview of recent advances in analytical tools and their contributions to the determination and quantification of bioactive compounds/microorganisms that ensure food functionality. Figure 2 summarizes the most employed analytical techniques for the qualitative and quantitative analysis of bioactive compounds and microorganisms.

Figure 2.

Analytical techniques for the qualitative and quantitative analysis of bioactive compounds and microorganisms.

3.3.1. Polyphenols

Polyphenols are bioactive compounds present in many foods, known for their antioxidant properties and health benefits. Accurate quantification of polyphenols is crucial for assessing the nutritional and functional quality of foods. Both the total amount of polyphenols and the identification of individual polyphenols present in functional foods are of interest. For this reason, various methods have been developed to evaluate total polyphenol content, as well as others that allow for their identification and quantification. Typically, the total amount of polyphenols is determined by the Folin–Ciocalteu method [138]. This method is based on a redox reaction between polyphenols and the Folin–Ciocalteu reagent, which produces an intense blue complex whose absorbance can be measured spectrophotometrically. Although the Folin–Ciocalteu method is useful for a quick and general estimate of polyphenol content, the spectrometric response is highly affected by non-phenolic interferences [139]. Thus, other spectroscopic techniques have emerged to provide valuable insights into polyphenol content, their structural properties, and concentrations within a given sample [140]. Among these techniques, infrared (IR) spectroscopy is a non-destructive, rapid, and simple analytical method used to estimate the total polyphenol content in food samples. When combined with chemometrics, IR becomes a powerful tool for extracting meaningful information from the spectral data obtained. In this regard, MIR spectroscopy was applied to evaluate the phenolic compounds present in moringa powder [141], wines [142], and different fruits [143], while NIR spectroscopy coupled to partial least square regression was successfully applied for predicting catechins in tea [144] and total polyphenols in vine tea through a smartphone-based portable NIR device [145]. The combination of MIR and NIR techniques constitutes a superior strategy, providing complementary information for the characterization and analysis of polyphenol compounds in complex food samples [146,147].

Electrochemical techniques have gained attention in the determination of polyphenols owing to their rapid and sensitive response. Voltammetry, including cyclic voltammetry, differential pulse voltammetry, and square wave voltammetry, provides different approaches for assessing total polyphenols in various food matrices [97]. However, electrochemical biosensors, which are constituted with a biorecognition element, establish specific interaction with the target polyphenols, adding selectivity to the inherent sensitivity of these systems [148]. The output signals correspond to changes in the properties of the electroactive species by producing a redox reaction that occurs on the electrode surface. Among recognition elements, enzymes exhibit high specificity of enzyme–substrate interactions, allowing the detection of low concentrations of the target compounds. Laccase and tyrosinase are the primary enzymes used in the construction of biosensors for monitoring polyphenols in functional foods. For instance, laccase was applied to the development of a biosensor used to determine quercetin in beverages [149] and gallic acid and catechin in agri-foods [139]. Also, tyrosinase was implemented as a bio-element for the quantification of chlorogenic acid in green coffee beans [150]. An interesting approach is the use of crude polyphenol oxidase extract, avoiding the need for separation and purification of the enzymes [151]. Although there are some examples of the use of these enzymes for the specific detection of certain polyphenols, in general, they are used for the selective detection of total polyphenolic content [152].

Similarly, cell-based biosensors exploit living cells as the recognition element [153]. In this case, ROS are generated due to intracellular oxidative stress and react with catalytic species on the surface of the electrode, leading to variations in electrochemical signals [154].

On the other hand, electrochemical nanosensors, which use nanoscale materials such as metal nanoparticles, quantum dots, polymer nanoparticles, or carbon nanomaterials as sensing materials, have also been exploited to selectively detect polyphenols in food samples [140]. Among sensing materials, gold nanoparticles combined with carbon nanomaterials have been widely applied to detect different phenolic acids [155,156,157,158], stilbenes [159,160,161], and flavonoids [162,163,164,165,166]. A more complex architecture of the nanosensor includes not only nanomaterials but also enzymes. Thus, nanobiosensors were developed and applied to assess the polyphenol content [167,168].

Among the analytical techniques used to assess polyphenol content in different functional foods, the identification and individual quantification of these compounds are undoubtedly performed by chromatographic techniques [140]. In addition, complex food matrices represent a potential source of error due to matrix effects and the presence of interferences. In this regard, chromatographic methods are of great interest not only for quantifying individual polyphenolic compounds but also for establishing correlations between the results and total polyphenol content [169]. Regarding this, polyphenol profile has been determined by gas chromatography and liquid chromatography associated with different detection techniques. Concerning liquid chromatography, HPLC with a photodiode array detector is widely used for the development of various methods aimed at identifying polyphenols in functional foods and determining their concentration [170,171,172,173,174]. Commonly, HPLC is coupled with MS to provide additional information about the structure and molecular mass, offering compositional fingerprints of the polyphenols present in foods. Another interesting advantage is that both targeted and untargeted determination of polyphenols is possible, allowing the screening and identification of unknown compounds [175]. In this sense, HPLC-MS and UHPLC-MS were applied to the determination of phenolic acids and flavonoids in apple pomace [176], wild and cultivated grapes [177], and tea-macerated wines [178], among others. As some polyphenols can be found at trace concentration levels, MS/MS offers a detailed examination of specific ions, leading to more accurate results. In this regard, LC-MS/MS has been used for the identification of polyphenols in prickly pear and in a gluten-free pasta made from rice and field bean flours enriched with dehydrated prickly pear fruit [179]. Also, the polyphenolic composition of raspberry leaf, a by-product of raspberry production, was assessed by using LC-MS/MS [180]. For some polyphenols that are unstable and highly reactive as o-quinone compounds, derivatization prior to their quantification by LC is necessary to guarantee their direct, sensitive, and reliable determination [181].

Regarding gas chromatography, the combination with GC-MS is the most widely employed technique for determining polyphenols in functional foods. However, GC-MS has certain limitations related to thermal stability and the possible interactions of the hydroxyl groups of the phenolic compounds and the silanol groups of the stationary phase. Thus, a derivatization step to reduce their polarity is frequently required [175,182,183].

In conclusion, the assessment of polyphenols in functional foods can be performed using spectroscopic, electrochemical, and chromatographic techniques, either for evaluating total polyphenol content or for identifying and quantifying them.

3.3.2. Omega-3 Fatty Acids

The omega-3 (n-3) PUFAs, such as ALA, EPA, and DHA, are widely recognized for their protective effects against various metabolic disorders, promoting human health [36]. Thus, the identification and quantification of omega-3 PUFAs, as well as the quality assurance of the functional foods containing them, are highly required. Consequently, different methods using diverse analytical techniques, such as GC, HPLC, and IR spectroscopy, have been developed.

GC has been extensively reported for separating and determining omega-3 PUFAs [184]. Before analysis, it is necessary to convert these compounds into fatty acid methyl esters to make them volatile enough for GC separation in order to obtain accurate results. Typically, GC is coupled to a flame ionization detector to determine the omega-3 PUFAs in fish [185,186,187], crabs [188], matcha tea [189], and seeds [190].

GC coupled to MS spectrometry has also become a widely used technique for the confirmation and quantification of omega-3 PUFAs using selective ion monitoring of their characteristic ion fragments. As a result, GC-MS spectrometry provides a highly sensitive determination of the target compounds, detailed information about the molecular structure, and reduced possible signal interferences [191]. For instance, the monitoring of the oxidation of different edible oils containing a high proportion of omega-3 PUFAs during simulated conditions of transport, storage, and consumption was possible by performing the acquisition of the mass spectra and the comparison with the NIST Mass Spectral Library (National Institute of Standards and Technology, Gaithersburg, MD, USA) [192].

Although GC-FID and GC-MS are considered standard techniques for analyzing omega-3 PUFAs, the extraction and derivatization procedures involved are often labor-intensive and time-consuming. Moreover, the high temperatures used during injections and separation can compromise the stability of the analytes. Thus, HPLC-MS is preferred since a derivatization step is avoided [193,194].

Molecular spectroscopic techniques offer straightforward, rapid, and reliable analytical solutions for studying functional foods rich in omega-3 PUFAs, as they can extract extensive information from molecular spectra. In this regard, NIR, MIR, and Raman spectroscopies, when coupled with multivariate data analysis, are commonly employed [195]. Alotaibi et al. [196] review different spectroscopic methods developed for the analysis of omega-3 PUFAs in cocoa butter. Also, to ensure the quality and authenticity of virgin olive oil, omega-3 PUFAs can be detected using NIR, MIR, and Raman techniques through fingerprinting and profiling studies [197]. In addition, NIR and MIR spectroscopy associated with appropriate chemometric multivariate calibration approaches have been effectively utilized to determine the fatty acid content in fish oil samples [154]. Indeed, a portable device based on NIR spectroscopy, combined with multivariate calibration, was used to determine omega-3 PUFAs and obtain the fatty acid profile of fish oils in the fish by-product industry in a rapid and non-destructive manner [198].

3.3.3. Phytosterols

Various foods containing phytosterols, such as oils, mayonnaise, and flours, have been developed. However, these compounds exhibit low solubility [199]. These bioactive molecules are found within complex matrices, including fruits, vegetables, nuts, seeds, cereals, and legumes. Regular consumption of these sterols has been shown to reduce total cholesterol levels, primarily by lowering low-density lipoprotein cholesterol, thereby helping to prevent cardiovascular diseases [200]. Additionally, these fat-soluble bioactive compounds are used in the development of functional foods due to their ability to prevent or reduce polymer formation (antipolymerizing effect) in lipids during heat treatments [201,202]. Hence, it is crucial to develop analytical methods that enable the identification and quantification of phytosterols. These methods involve a series of operations, from extracting these compounds from the sample to obtaining accurate results.

A wide variety of phytosterols from different plant matrices are currently known, with β-sitosterol, stigmasterol, and campesterol being the most prevalent [203]. Therefore, developing analytical strategies that ensure the efficient extraction of phytosterols is essential. The literature highlights saponification as a key step in the extraction of these bioactive molecules. Saponification enhances the extraction of phytosterols, as they are typically bound to sterols or triglycerides in vegetable oils and fats. Given the complexity of plant matrices, the saponification process—which involves organic solvents such as sodium hydroxide or potassium hydroxide (alkaline saponification)—not only facilitates the release of phytosterols but also improves the purification of these bioactive compound extracts [95,204].

Recently, numerous studies have highlighted significant efforts to optimize methods, particularly in the extraction, separation, and purification of phytosterols. This growth is closely linked to the expanding phytosterols market, driven by the increasing popularity of functional foods and beverages. The global market is estimated to reach approximately 364 billion dollars in 2024 and is projected to grow to 790 billion dollars by 2032 [205]. In the case of phytosterols, an increase of 8.1% in the compound annual growth rate is expected from the period between 2024 and 2032 [206]. To achieve both qualitative and quantitative determination of phytosterols in functional foods, separation techniques such as GC [164,207,208,209], HPLC [210], or SFC [211] are commonly used. It is important to note that many of the methods employing these chromatographic techniques require a derivatization step for phytosterols. For instance, in HPLC coupled to UV detection, derivatization is often necessary because these compounds generally lack chromophore groups and exhibit low sensitivity due to their lipophilic nature [212]. Additionally, other techniques, such as NIR spectrometry, can also be used [213,214].

It is important to note that, for foods containing phytosterols, proper controls are essential to ensure the functionality of these fat-soluble molecules [215]. Amaral et al. [216] evaluated the thermogravimetric profile of goat milk cream cheese and concluded that the process should be limited to temperatures of 110 °C in order to preserve the functionality of the phytosterols.

3.3.4. Pro-, Pre-, and Postbiotics

Three major groups of compounds responsible for the beneficial properties of functional foods are probiotics, prebiotics, and postbiotics. As mentioned in the previous section, probiotics are bacterial or fungal species that are part of our intestinal microbiota and are recognized for their positive effects on health [217]. These mainly include bacteria and yeasts such as lactic acid bacteria, Bifidobacterium spp., and Saccharomyces spp. [218].

The quality of a probiotic is determined by its safety, efficacy, and stability [6]. Two main objectives in efficiency evaluation are the precise identification of the probiotic and the quantification of viable bacteria per food dose. There are molecular and non-molecular methods for quality control of probiotic foods [219]. Molecular techniques have enabled significant advances in detecting and identifying probiotic species, facilitating their taxonomic characterization. The taxonomy of probiotic organisms is established based on their biochemical, morphological, and physiological characteristics using phenotypic and genomic approaches based on molecular techniques [218].

Several reviews have addressed these methodologies in depth, such as those by Ranjan et al. [218] and Georgieva et al. [219]. Georgieva et al. [219] present graphical schemes on the commonly used steps for identifying probiotics through molecular methods, while Ranjan et al. [218] thoroughly explore approaches based on ribosomal RNA analysis, whole genome sequencing, and proteomic profiling. Numerous methods and techniques are employed for this purpose, some of which are outlined next. Molecular methods used for probiotic characterization based on ribosomal RNA include, among others, 16S rRNA sequencing, molecular ribotyping, denaturing gradient gel electrophoresis, and temperature gradient gel electrophoresis. Genomic-based techniques encompass amplified fragment length polymorphism, randomly amplified polymorphic DNA, and real-time polymerase chain reaction. Protein-based approaches involve, among others, whole-cell protein profiling (particularly via polymerase chain reaction) and MS [218].

On the other hand, there are non-molecular methods. Among them, conventional culture-based techniques allow for detecting, enumerating, and identifying probiotic strains through growth in selective/differential culture media [220]. Additionally, fluorescence-based methods have proven to be effective for assessing bacterial viability. These techniques are capable of distinguishing between viable, damaged, stressed, and dead cells using fluorescent dyes, which can be detected through fluorescence microscopy, fluorometry, flow cytometry, or fluorescence in situ hybridization [219].

Vibrational techniques are gaining relevance in probiotic quality control. FT-IR has been used for the detection, discrimination, identification, and classification of probiotics, being capable of distinguishing between viable, damaged, and dead bacteria [219]. Papadopoulou et al. [221] used FT-IR to quantitatively estimate the microbiological content of yogurt and assess its sensory status. In addition, NIR spectroscopy has also begun to be applied in this field; in fact, Aguinaga Bósquez et al. [222] employed NIR to predict the number of colony-forming units in probiotic powders.

In conclusion, quality controls in probiotics are numerous and varied, as the goal is not only to quantify a chemical compound but to characterize and evaluate living organisms. Therefore, studies must be approached from multiple perspectives to ensure the efficacy, safety, and stability of probiotic-containing functional foods.

On the other hand, prebiotics are substrates, typically indigestible carbohydrates (by the mammalian host) found in food, which selectively stimulate the growth and metabolic activity of beneficial gut microbes. These compounds are primarily utilized by microorganisms that confer health benefits to the host [223]. Beyond being considered beneficial for humans, variations in the type and quantity of prebiotics can influence their effects, and excessive intake may be detrimental. Therefore, it is crucial to implement adequate quality control for these functional foods [5]. Many compounds can be classified as prebiotics. Most studies focus on non-digestible carbohydrates, such as FOS, inulin, GOS, MOS, and XOS. However, other compounds may also exhibit prebiotic properties, such as CLA, polyphenolic compounds, and PUFAs [4]. This section will focus specifically on non-digestible carbohydrates, as they are the most extensively studied. On the other hand, polyphenolic compounds and PUFAs are addressed in the sections dedicated to antioxidants and omega-3 PUFAs, respectively. Regarding oligosaccharides, the review article by Catenza et al. [5] presents the commonly employed methods and emerging trends for the determination of the oligosaccharides FOS, GOS, MOS, and XOS in functional foods. This review highlights separation techniques such as HPLC, GC, and CE, which are often coupled with various detection systems, including RID, ELSD, PAD, and MS detection. Similarly, Corradini et al. [224] conducted a comprehensive review of analytical methods used for the screening and identification of FOS and inulin in functional foods. The authors emphasize that the most widely employed technique for characterizing these molecules is HPAEC-PED, followed by MS, particularly MALDI-TOF-MS. Additionally, Iqbal et al. [225] provide an overview of the most commonly used techniques for quality control of functional foods containing GOS. The authors describe various analytical methods and highlight that the most frequently employed techniques for GOS assessment include HPLC, in conjunction with RID, pulsed PAD, mass spectrometry sensors, and fluorescence detection.

In addition to the commonly used chromatographic techniques and NMR, vibrational techniques such as NIR and MIR have also been explored. While chromatographic techniques remain the most widely applied, methods based on MIR and NIR are gaining increasing relevance [226,227,228]. These techniques are currently under investigation to fully assess their potential for quality control in functional foods, as they are particularly valued for their simplicity, minimal or no sample preparation requirements, environmental sustainability, and suitability for real-time and in-line analysis [229].

Another important group of bioactive compounds to highlight is postbiotics, which include teichoic acids, enzymes, antimicrobial peptides, and short-chain fatty acids [230]. These compounds result from the metabolic activity of probiotic microorganisms, typically after their interaction with prebiotic compounds. Consequently, postbiotics are the substances that remain once the bacteria that produced them are no longer alive or present [231]. The qualitative and quantitative determination, as well as the characterization of these compounds, requires a multidisciplinary approach and the use of various analytical techniques based on their chemical or functional properties. In this context, recent advances in omics sciences, particularly metabolomics, offer valuable tools for discovering potential postbiotics and understanding their interactions with the host organism. Progenesis MetaScope databases are used to identify molecular weights, while the HMDB is employed to retrieve potential biomarkers in untargeted metabolomics [232]. Additionally, MetaboAnalyst 5.0 [232] enables the evaluation of metabolite changes between samples and facilitates principal component analysis. Numerous studies report on the use of liquid and gas chromatography techniques for postbiotic analysis [233,234]. Targeted metabolomics, which focuses on the study of specific metabolites, also relies on chromatographic separation techniques [235,236]. In conclusion, based on the authors’ perspective, untargeted metabolomics is currently one of the most widely used tools for postbiotic analysis.

3.3.5. Bioactive Peptides

Bioactive peptides, produced during gastrointestinal digestion or food production (enzymatic hydrolysis or fermentation), are protein segments composed of short chains of amino acids [237]. Their participation is key in the development of functional foods due to their ability to modulate physiological functions and contribute to the prevention of diseases, as mentioned above. The literature reports the importance of peptide isolation, purification, and analysis processes to optimize their extraction and thus achieve adequate sample pretreatments [238]. By virtue of improving extraction efficiency and the use of sustainable and environmentally friendly technologies such as ultrasound-assisted extraction, microwave-assisted extraction, the application of pulsed electric fields, and high-pressure processing is proposed that allow the performance and selectivity of the extracted compounds be improved while reducing energy consumption and the use of chemical solvents [239,240,241]. The most commonly used analytical techniques to determine functional peptides include chromatographic, spectroscopic, and enzyme-linked immunosorbent methods, selected according to the type of peptide and the objectives of the study [242]. Guerra-Fajardo et al. [243] report that to detect peptide bioactivities, the combination of high-performance thin-layer chromatography with bioassays in effects-directed analysis is considered an emerging technology, complementary to the most common analytical methods such as capillary electrophoresis and HPLC. Della Cerra et al. [244] propose the use of ultra-high-performance nanoliquid chromatography coupled to a mass spectrometer to determine the peptide profile of blue buffalo milk cheese, with β-casein being the predominant one. It is concluded from the above that it is crucial to take into account that bioactive peptides must be isolated and extracted from natural sources, playing a key role in the purification, quantification, and verification of their structure. Therefore, the analytical techniques used in bioactive peptides that make up functional foods are considered fundamental tools to address the concerns associated with the safety, quality, and efficacy of these molecules.

Table 2 presents examples of studies in which different bioactive molecules or microorganisms were determined in functional foods.

Table 2.

Analytical techniques used for the determination of bioactive compounds/microorganisms in functional foods.

4. Food Packaging

Packaging is an item that contains and protects products, allowing them to be transported, portioned, stored, and communicated to consumers. Packaging specifically designed and manufactured to enclose an essential product for human survival, such as food, is of great significance. Food is, indeed, one of the most consumed, transported, and commercialized goods worldwide. One of the biggest and most ancient problems with food is that, like all organic products, it spoils and deteriorates over time, leading to significant losses and waste [257]. One of the ways to slow down this harmful process is by using appropriate packaging [7,8].

Conventional packaging aims to preserve food safety and increase food shelf life by protecting it from chemical, physical, and biological contamination. Packaging is designed to diminish, and even avoid, substance spills, attacks by microorganisms, and effects of environmental factors such as temperature, moisture, oxygen, light, and physical damage [258,259]. The selection of materials and the design of the packaging must be made according to the specific requirements of the food to be contained and its economic and manufacturing viability [260].

4.1. Innovative Packaging

Innovative and functional food packaging goes beyond these functions, evolving from a passive protective role to an active one. It seeks not only to maintain food quality and increase shelf life but also to improve it [261]. Food quality encompasses its organoleptic properties, including color, aroma, flavor, and texture, as well as microbiological and chemical safety, which are essential for maintaining its stability [262]. Additionally, food quality includes its nutritional value and the health benefits associated with the presence of bioactive compounds/microorganisms [263]. In pursuit of this objective, the concepts of active, intelligent, and smart packaging have emerged [12].

Active food packaging is a dynamic system where the packaging materials, the packaged food, and its surroundings interact, being modified accordingly to maintain or improve the conditions that affect food quality. Scavenging and emitting are the main interaction mechanisms of these active systems [264]. Scavenger is applied to absorb unwanted substances or those present in harmful quantities, such as moisture, ethylene, oxygen, carbon dioxide [265], odors, flavors, and toxins. To achieve this, specific scavenging materials are incorporated into the packaging, including mineral and metal particles, metallic acids, salts and oxides [266], organic acids, activated carbon, clays, zeolites, glucose oxidase, halloysite nanotubes [267], bio-based materials [268], and natural phenolic compounds [269], among others [270]. On the other hand, emitting is applied to deliver specific actives, such as antimicrobials, antioxidants, gases, and nutraceuticals and probiotics to a lesser extent, through different release and retention strategies [271,272,273]. Antimicrobials are among the most commonly used active ingredients in active packaging and include typical food preservatives such as natamycin and benzoic acid, natural compounds such as essential oils and vegetable extracts, enzymes, clays, mineral and metal particles, and many others. The antioxidant releasers are most often of natural origin, such as essential oils, polyphenols, polyunsaturated fatty acids, vitamins, lignins, and also nanoparticles of minerals such as selenium, among others [267,272,274,275]. Antimicrobials and antioxidants are often incorporated together into packaging, and many of them, such as essential oils, have both activities [271,276]. Regarding gas release, the gases of interest include carbon dioxide, ethanol, chlorine dioxide, and volatile compounds, which are either added inside an emitter system to the packaging or generated on-site [277]. In the work of Vilela et al. [278], commercial active agents are detailed and classified. There are certain limitations on the agents added to the packaging, as they must be food-safe and within permitted concentrations. Recently, the incorporation of metal and metal oxide nanoparticles, such as zinc, silver, copper, and titanium dioxide, into food packaging materials has gained attention due to their ability to provide multifunctional benefits. These include typical active packaging functionalities, such as antimicrobial, photocatalytic, and oxygen scavenging activities, along with enhancements in mechanical, optical, and barrier properties through the formation of nanocomposite materials [279,280,281,282]. However, potential health hazards and environmental impacts remain insufficiently understood and must be carefully considered [279,283]. Among these mechanisms, there are others, such as antimicrobial packaging covalently grafted on the surface and packaging loaded with light and UV radiation blockers [284,285,286,287].

Intelligent packaging materials are designed to detect changes in packaged food and report its condition. These packaging systems sense the state of the food and/or its environmental conditions and are capable of monitoring and even tracking, recording, and reporting this information. Knowing relevant data about package integrity, food freshness, ripeness, refrigeration maintenance, or contamination enhances food security, safety, and convenience, and food losses and foodborne illnesses are reduced. Sensors, indicators, and data carriers are the main applied technologies [288]. There are chemical, electrochemical, optical, bio-based, and even edible sensors. These are small electronic devices that must be powered and integrated into the packaging, which is still a challenge. Most indicators are colorimetric labels, which change color when chemically reacting with a compound, such as moisture or pH variation, or due to the effect of temperature. Sensitive dyes or pigments of natural origin, such as anthocyanins, curcumin, shikonin, alizarin, and betalain, or synthetic origin, such as methyl red, cresol red, bromocresol green, and bromocresol purple, are used [289,290,291,292,293]. Regarding data carrier devices, barcode labels and systems of RFID tags are the most widespread [281,294].

Smart packaging integrates both intelligent and active packaging technologies; however, the term is sometimes used interchangeably to refer to either one or the other [259]. The combined packaging systems allow the packaging to detect and respond to changes or needs of the food or surrounding environments to improve or restore their conditions with a synergic effect [232,295]. These packaging systems, whether combined or not, achieve remarkable customization of the packaging to suit the food. Furthermore, taking advantage of new developments in materials with improved mechanical and barrier properties can achieve the highest food preservation performance [296,297].

Regulatory requirements are essential for active and intelligent packaging, with the European Union providing a leading example. Framework Regulation (EC) No 1935/2004 sets out general safety requirements for all materials intended to come into contact with food. Regulation (EC) No. 450/2009 specifically governs the use and pre-market authorization of active and intelligent materials, requiring safety evaluations prior to their commercialization. Additionally, Regulation (EC) No 2023/2006 mandates compliance with GMP to ensure product safety and quality throughout the production process [298].

The widespread adoption of active and intelligent packaging technologies continues to face several critical challenges. One of the most significant barriers is the high initial investment cost associated with advanced materials and specialized infrastructure. Furthermore, the integration of these technologies into existing production lines often entails complex modifications, requiring technical expertise and workforce training.

Consumer acceptance remains another considerable challenge. Public concerns regarding cost and the perceived complexity of these systems contribute to skepticism. As such, transparent risk communication and consumer education are essential to foster trust and understanding [299]. From an environmental standpoint, while these technologies aim to improve sustainability by reducing food waste, components such as embedded electronics and batteries raise concerns about lifecycle impacts, recyclability, and resource sourcing [300].

4.2. Barrier Packaging Strategies

In food packaging, gas barrier properties—particularly against oxygen and water vapor—are among the most critical factors for preserving packed food [301,302]. Common industrial strategies for enhancing gas barrier properties of polymers include metal coatings and multilayer films. Metalized films, typically incorporating aluminum, have long been favored for their excellent barrier to gases and moisture. However, this technology still faces both technical and environmental challenges. Achieving defect-free and long-term stable coatings remains difficult. Plasma or corona pretreatments are often required to ensure good metal-to-substrate adhesion. These treatments can increase the rigidity of the polymer film, render it opaque, and make it incompatible with microwave use. Moreover, metalized films have limited recyclability due to the difficulty of separating thin metallic layers. As alternatives, transparent surface coatings such as Al2O3, SiOx, and DLC are being explored for their advantages in transparency and microwave compatibility. However, these coatings can exacerbate existing issues, including microcrack formation. Multilayer systems, on the other hand, combine polymers with complementary barrier, mechanical, and processing properties, enabling optimized performance. Coextrusion is the most widely used manufacturing technique due to its versatility, allowing independent adjustment of layer composition and thickness, as well as the inclusion of tie layers. Typical multilayer films are primarily composed of polyolefins (e.g., LDPE, PP, HDPE), PET, adhesives, and aluminum coatings and are produced by cast film or blown film coextrusion [302,303]. However, multilayer films also face technical and environmental concerns, such as incompatibility between layers, which may result in interfacial adhesion failures and delamination; challenges in controlling layer thickness and uniformity; and recycling difficulties due to the presence of immiscible polymers [301,303,304].

To address sustainability and recyclability concerns, new strategies are focus on enhancing the barrier properties of single-component films through polymer blending, nanocomposite formation, modification of crystalline structure, and combined approaches [303,305,306]. In polymer blends, high-barrier materials such as PE, PEN, PVA, and EVOH are dispersed within conventional polymer matrices like PE or PET. Depending on the processing method, materials, and conditions, the dispersed phase may adopt various morphologies—such as spherical particles, micro/nanofibers, or layered structures—which influence the resulting barrier properties. Common techniques include melt compounding and solution casting. There is a difficulty in that while polar dispersed phases improve oxygen barrier performance, they can reduce water vapor resistance. Key challenges in polymer blending involve achieving good interfacial compatibility, maintaining morphological stability, and ensuring uniform dispersion. Regarding polymer nanocomposites, the addition of impermeable nanoparticles to the polymer matrix introduces a “tortuous path” effect that slows gas molecule diffusion. Common nanoparticles include nanoclays, graphite, graphene, and inorganic fillers. Nanoparticle aspect ratio, interfacial adhesion, and dispersion quality significantly affect the performance of the nanocomposite. These fillers can also enhance mechanical properties and influence matrix crystallinity, further improving barrier function. Despite their potential, all of these strategies face technological scaling challenges, compatibility issues, and risks of polymer matrix degradation. Moreover, economic barriers remain due to the high costs of nanotechnology, and health and environmental impacts are still under investigation and require further study [304].

A recent combined strategy is the use of LbL assembly technology, a multilayer coating technique capable of forming nanocomposite materials through the incorporation of nanoscale fillers in a nanostructured arrangement. By employing non-vacuum techniques such as dip coating, spin coating, or spraying, alternating nanostructured thin layers are deposited. This architecture increases the tortuosity of diffusion paths, thereby enhancing the gas barrier properties of the material. Additional advantages of this approach include favorable mechanical performance, transparency, microwave compatibility, and—due to the extremely thin nature of the coatings—potential recyclability. However, its application remains largely at the laboratory scale [307].

Another recent strategy that enables substantial barrier enhancement at low nanofiller loadings is the fabrication of three-dimensional (3D) segregated network nanocomposites [305,308]. This approach increases the tortuosity of gas diffusion pathways by forming a continuous network of nanofillers within the polymer matrix through an efficient spatial arrangement that maximizes obstruction to gas permeation. The selection of suitable nanofillers is critical to the success of this method. Graphene nanoplatelets, for instance, are widely employed due to their high aspect ratio and intrinsic impermeability to gases [308,309,310]. The formation of segregated structures is based on the excluded volume theory, which predicts that nanofillers in a segregated system preferentially localize at the interfaces between polymer particles rather than being randomly dispersed. The fabrication process typically involves (1) dispersing nanofillers in a volatile solvent using ultrasonication or high-shear mixing; (2) adding polymer particles to the dispersion and stirring to facilitate coating of their surfaces; (3) solvent removal through drying; and (4) compression molding of the coated particles to form a consolidated composite. In addition to the advantage of low filler loading, this approach also preserves the optical clarity and mechanical flexibility of the final material. However, several challenges remain for the industrial scaling of this technology. Most notably, the commonly used method for nanofiller exfoliation—solvent blending assisted by ultrasonication—is often inefficient, costly, and environmentally burdensome due to solvent use and disposal concerns, which limits its sustainability. Moreover, compression molding temperature is a critical processing parameter that must be carefully optimized. It must be high enough to achieve sufficient interparticle cohesion without creating interfacial voids, but not so high as to significantly reduce the polymer’s viscosity, which could lead to unwanted diffusion of the nanofillers and the loss of network structure [305].

A comprehensive description of all existing strategies for enhancing the barrier properties of polymers is beyond the scope of this review. However, it is worth briefly highlighting some prominent developments in the field of barrier films for food packaging. Two notable areas are: (i) the development of bio-based materials with improved barrier performance, driven by increasing sustainability concerns; and (ii) the integration of barrier films into smart packaging systems, in line with current trends in food packaging. The first approach addresses a critical challenge, as bio-based polymers typically exhibit poor barrier properties [311]. Strategies to overcome these limitations are discussed in detail in Section 4.7. The second area involves the incorporation of functional nanomaterials—such as metals, metal oxides, graphene, and others—into polymer matrices, either through surface coating techniques [312] or nanocomposite formation [227,280,281,282,283]. These materials not only improve barrier and mechanical properties but also impart additional functionalities, such as antimicrobial activity or gas scavenging capacity. Moreover, barrier films also play a key role in smart packaging applications, where sensors are embedded to monitor the composition or concentration of specific gases, thereby providing real-time indicators of food quality, gas leakage, or package integrity [313,314]. For example, synthetic multilayer films have been developed to monitor the freshness of fish [315], while bilayer assemblies of bio-based polymers have been investigated to monitor and preserve seafood quality [316].

4.3. Modified Atmosphere Packaging

Thanks to the development of polymeric packaging materials with enhanced and tailored gas barrier properties, MAP, an advanced food packaging technology, can be widely used. This technology is applied to extend the shelf life and preserve the quality of perishable food products by altering the composition of the internal atmosphere within the package. This technology typically involves the reduction in O2 levels and the enrichment of CO2 and/or N2, in order to inhibit microbial growth, retard oxidative reactions, and slow down enzymatic activity. MAP systems can be broadly categorized into passive and active approaches. In passive MAP, the desired atmosphere is achieved naturally through the interaction between the respiration rate of the product (e.g., fresh produce) and the gas permeability of the packaging material over time. In contrast, active MAP involves the direct modification of the internal gas composition through vacuuming and gas flushing techniques or by incorporating functional additives such as oxygen scavengers, CO2 emitters, or moisture regulators, allowing for immediate atmosphere control [317]. Conventional gas mixtures vary depending on the food type: low O2/high CO2 atmospheres are commonly used for meat, fish, and dairy to suppress aerobic microbial growth [318], whereas high N2 environments are employed in dry or lipid-rich products such as nuts and snacks to prevent oxidation. For fresh fruits and vegetables, EMAP is often applied, balancing the product’s respiration with the packaging film’s gas transmission properties.

MAP offers significant advantages, including prolonged shelf life, preservation of sensory and nutritional attributes, and reduced dependence on chemical preservatives. However, challenges persist, such as the need for precise gas composition control, the high cost of specialized equipment and multilayer films, and limited recyclability due to polymer incompatibility in multilayer structures. Furthermore, insufficient oxygen control can lead to anaerobic microbial growth, particularly under temperature abuse conditions [319].

Advances in this technology are associated with the development of new materials with improved or controllable barrier properties, such as microporous MAP [320] or temperature-dependent permeability [321], intelligent MAP systems that allow monitoring of gas composition and product freshness [314], the combination with active packaging systems by the incorporation and release of antioxidants and antimicrobials [322], and the use of bio-based [323] or recyclable single-component barrier films. Figure 3 schematizes smart, barrier, and MAP packaging systems.

Figure 3.

Smart, barrier, and MAP packaging systems.

4.4. Effect of Industrial Food Processing on Packaging

Food processing techniques can significantly impact food products’ quality, including nutritional value and organoleptic properties, such as texture, flavor, and color. Subjecting foods to certain preservation processes, which are essential for controlling biochemical and microorganism-mediated degradation reactions and ensuring food safety, can seriously affect bioactive compound retention if not properly applied. The most popular traditional preservation techniques are heating, drying, and freezing [324], while more innovative methods based on irradiation, cold plasma, pulsed electric fields, pulsed light, microwaves, ultrasound, and pressure-assisted treatments, among others, have been developed in recent years [325,326]. Production lines can be designed in such a way that the preservation step comes either before or after the packaging one. In the former, and when food is intended to be stored at room temperature, the so-called “aseptic packaging” method is applied. Food and packaging materials are sterilized independently, and the filling takes place under aseptic conditions [327]. In the latter case, both food and package material are simultaneously exposed to the chosen preservation method, thus preventing undesirable downstream recontamination and packaging pre-sterilization. This is the so-called “in-pack” processing [314]. For both processing configurations, packaging materials are subjected to processes that can alter their structure and eventually their mechanical and barrier properties.

Conventional thermal processing operations are known to be aggressive in terms of food organoleptic and nutritional properties. Packaging materials used in these types of processes are expected to exhibit certain thermal stability. To date, advanced synthetic polymers have proven suitable, while sustainable packaging materials are being evaluated at the research level [328]. Thermal processing not only has the drawback of being aggressive to both food and packaging, but it is also a unit operation characterized by low energy efficiency and high-water consumption. Therefore, it is essential to develop a new generation of technologies capable of producing safe, high-quality foods with minimal environmental impact. The above-mentioned innovative techniques are examples of NTP. Some of them are also used to modify or functionalize packaging materials; thus, an enhancement of certain material properties could take place during the preservation process [326]. Nilsen-Nygaard et al. [326] have comprehensively reviewed the impact of NTP on bio-based and biodegradable—and also conventional—food packaging materials. Another work that addressed the effect of NTP on packaging materials—bio-based polymers, edible films, and nanomaterials—is the one authored by Gabric et al. [325]. Several material properties have been analyzed, and those that exhibited a greater tendency to undergo modifications were chemical migration, gas transmission rate (mainly oxygen, water vapor, and carbon dioxide), thermal stability, roughness, water contact angle, tensile/puncture strength, elongation at break, free volume fraction, relative crystallinity, digestibility (in the case of edible materials), viscosity, firmness, hydrophilicity, and glass transition temperature. The combination of NTP-packaging material should be carefully analyzed since every processing technique exerts a differential impact on each material property. Moreover, the inclusion of active compounds, biocomposites, and nanosized particles enhances the resistance of biomaterials to food processing technologies. Nonetheless, they contribute to higher complexity and cost while also reducing biodegradability [326].

4.5. Eco-Friendly Packaging

Terms such as eco-friendly packaging, sustainable packaging, green packaging, environmentally friendly packaging, and eco-designed packaging refer to packaging solutions strategically developed to minimize environmental impact throughout their lifecycle. This encompasses all aspects of packaging, including the materials used, the manufacturing process, its functionality, and its final disposal. It aims to reduce waste, energy consumption, and carbon footprint while maintaining functionality and product protection. Particularly, when discussing “sustainable packaging,” the economic and social impacts must also be considered [9,10,11].

Polymers are among the most widely used materials in packaging for all types of food due to their beneficial cost-performance ratio, great versatility, easy processability, and innocuity, among other advantages. However, there is an important concern about its negative effects on the environment [13]. In this context, the use of bio-based and biodegradable polymers is gaining ground over petroleum derivatives [259]. In fact, in recent years, a significant portion of research in the field of food packaging materials has concentrated on this type of material. Table 3 presents a compilation of reviews on biopolymers and food packaging published over the past five years. The design of active, intelligent, and/or smart packaging based on biomaterials can have a synergistic effect on sustainability. These packaging solutions help reduce food waste and lower energy costs associated with storage and distribution by enabling perishable foods, such as fruits, to be stored without refrigeration while also extending the shelf life of packaged products. These benefits are further complemented by the environmental advantages of bio-based and biodegradable materials [14].

Table 3.

Reviews related to green food packaging (in the last five years).

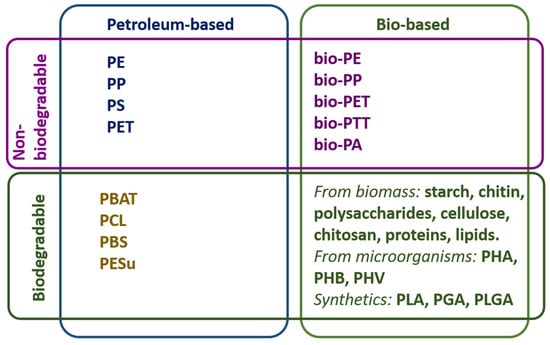

Packaging material is one of the aspects that is most taken into account with regard to eco-friendly design and to which consumers pay a lot of attention. Such materials can be made from renewable or recycled resources, and/or they can be recyclable, compostable, or biodegradable. Furthermore, they should not constitute hazardous materials at any stage of the packaging life cycle and should facilitate effective recovery through closed-loop systems. Among packaging materials, polymer-based materials stand out for their convenient cost/performance ratio and are the most widely used [338,339]. Polymeric packaging materials can be classified according to their origin as bio-based or petroleum-based and if they are biodegradable or non-biodegradable (Figure 4), according to ASTM D6400 (industrial compostability) or ISO 14855 standards [10].

Figure 4.

Most common polymeric packaging materials.

The most conventional packaging materials are petroleum-based and non-biodegradable plastics, mainly polyolefins such as PE, PP, PS, and PET [338]. Although not preferred for eco-packaging, these materials, when used responsibly, can be recycled and may allow for some reuse. Given their excellent characteristics that make them suitable for packaging applications, such as lightweight, barrier properties, processability, and low cost, they are still difficult to replace.

The category of biodegradable petroleum-based polymers includes some aliphatic polyesters such as PBAT [340] and PCL [341], some aromatic-aliphatic copolyesters such as PBS [342,343,344] and PESu [345], and other copolymers [10]. Unlike conventional petroleum-based polymers (e.g., PE, PP, PET), these materials break down into CO2, water, and biomass through natural degradation processes. It is worth mentioning oxo-degradable plastics, which, although not biodegradable, contain pro-degradant additives that accelerate the degradation process. However, the environmental impact of these materials is highly controversial, since instead of mitigating environmental pollution, they could aggravate it by generating microplastics. For this reason, they have been banned in Europe since 2021 [346,347].

Regarding non-biodegradable and bio-based polymers, they are designed to be identical to conventional plastics, but they are made from biomass instead of fossil fuels. Mainly, bioethanol, obtained through biomass fermentation and hydrolysis, is used as a renewable resource. Examples of these are bio-PE, bio-PP, bio-PET, bio-PTT, bio-PA, and polyol-polyurethane. They can be recycled as conventional polymers [348].