Remanufacturing Process Under Uncertainty: Review, Challenges, and Future Directions

Abstract

1. Introduction

1.1. Research Background

1.2. Research Gaps and Research Questions

- (1)

- Current research on uncertainty and decision-making in remanufacturing production is fragmented, and a comprehensive theoretical framework that can integrate the entire process and multi-dimensional dynamic decision-making has not yet been established.

- (2)

- Most existing studies focus on single-dimensional optimization or static game assumptions, failing to fully reflect the dynamic evolution characteristics of uncertainty and neglecting the complex coupling mechanisms among technological, economic, and environmental factors. There is also insufficient attention paid to dynamic and real-time decision-making.

- (3)

- The existing literature pays insufficient attention to policy-related challenges and the implementation barriers faced by small and medium-sized enterprises (SMEs). This gap severely limits the feasibility and effectiveness of translating theoretical models into practice.

- (1)

- How has remanufacturing process (RP) decision-making under uncertainty evolved in recent years?

- (2)

- What are the roles of digital technologies (e.g., DTs, blockchain) and carbon-financial instruments in shaping these decisions?

- (3)

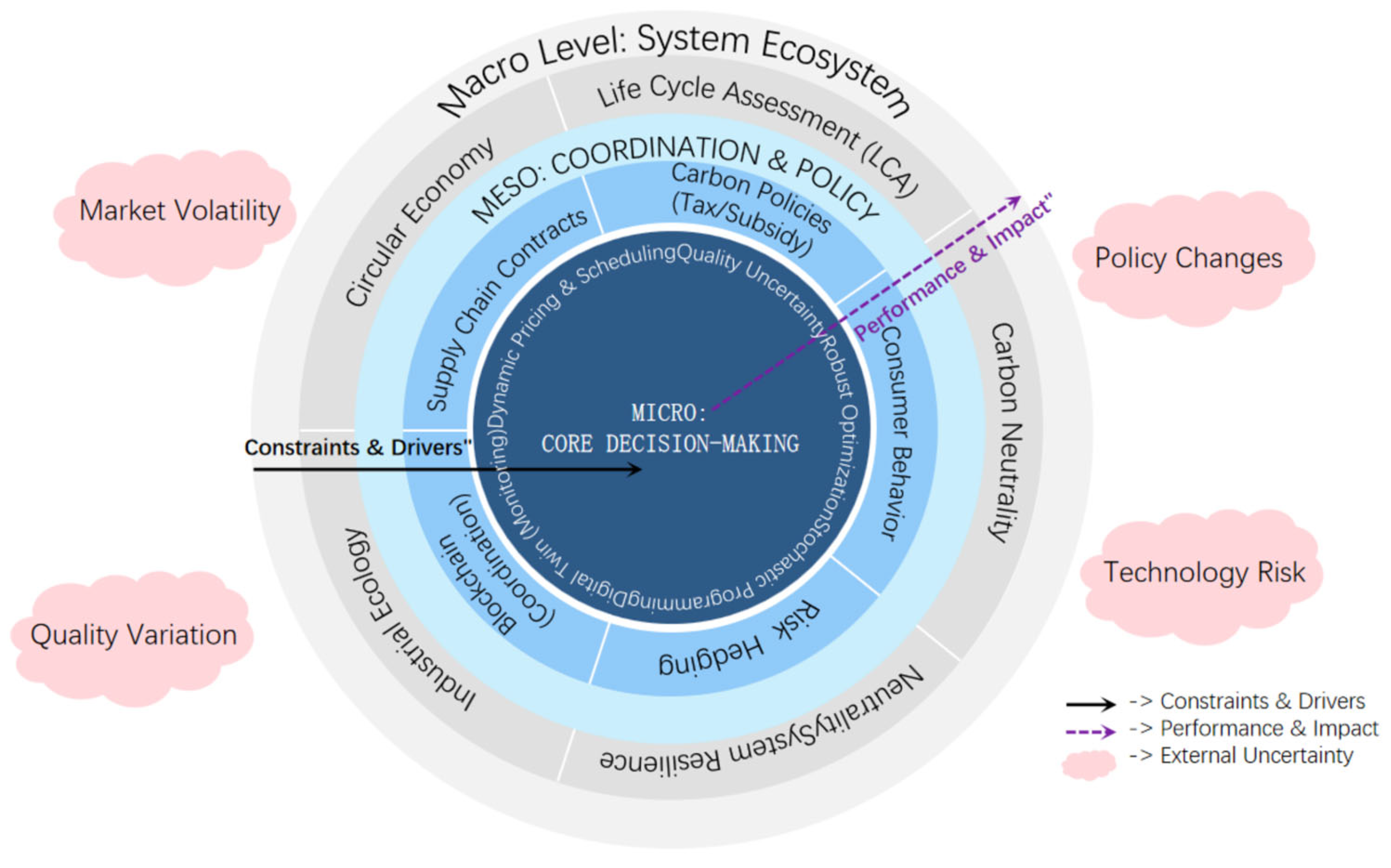

- How can a micro–meso–macro framework synthesize fragmented findings into a coherent theoretical system?

1.3. Research Contributions

- (1)

- This study proposes an innovative three-tier analysis framework of micro, meso and macro levels, which for the first time provides a systematic integrated theoretical perspective for the research on uncertainty in remanufacturing, reveals the interactions among factors at different levels, offers an unprecedented holistic perspective for understanding and analyzing the complex uncertainty in the remanufacturing system, and lays a solid foundation for future theoretical development.

- (2)

- It demonstrates the synergistic effects between digital technologies (e.g., DTs, blockchain) and financial tools (e.g., carbon options, quota collateralization), offering a technical-economic integration roadmap for industrial practice. It guides enterprises on how to combine and utilize these tools to effectively enhance dynamic response capabilities, strengthen system resilience, and achieve a win-win situation of economic and environmental benefits, providing an operational path for the digital transformation and green upgrade of remanufacturing.

- (3)

- It identifies implementable pathways for SMEs and diverse regions, enhancing the global applicability and practical inclusivity of the findings, and connects academic research with broader socioeconomic contexts. It provides a basis for policymakers to design more differentiated and dynamic incentive policies, and also offers directions for industry practitioners to evaluate the applicability of technologies and develop low-cost, modular solutions, ensuring the feasibility and effectiveness of remanufacturing theory on a global scale.

1.4. Paper Structure

2. Methodology

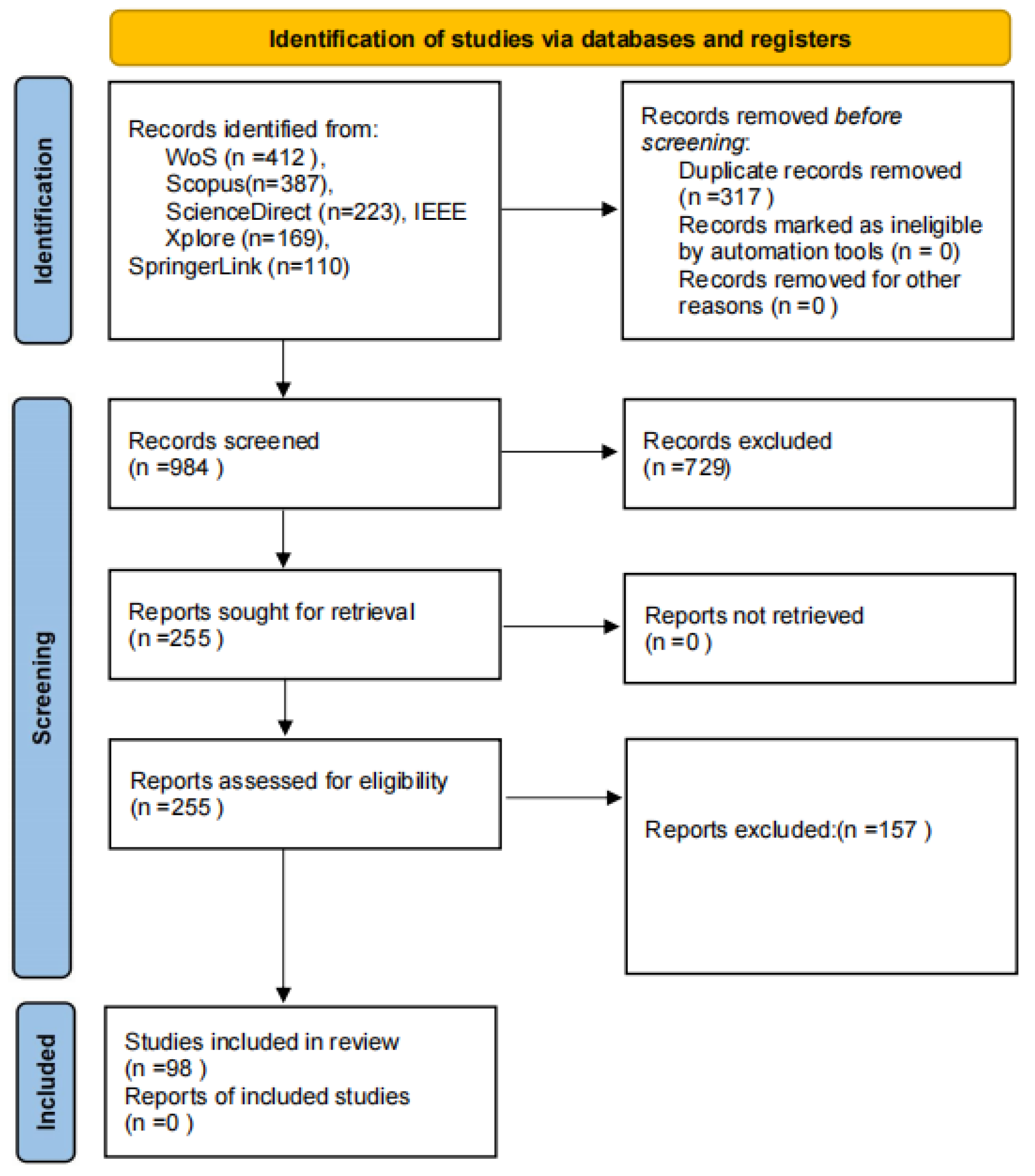

2.1. Search Strategy and Study Selection

2.1.1. Data Sources and Search String

2.1.2. Selection Process

2.2. Bibliometric Visualization

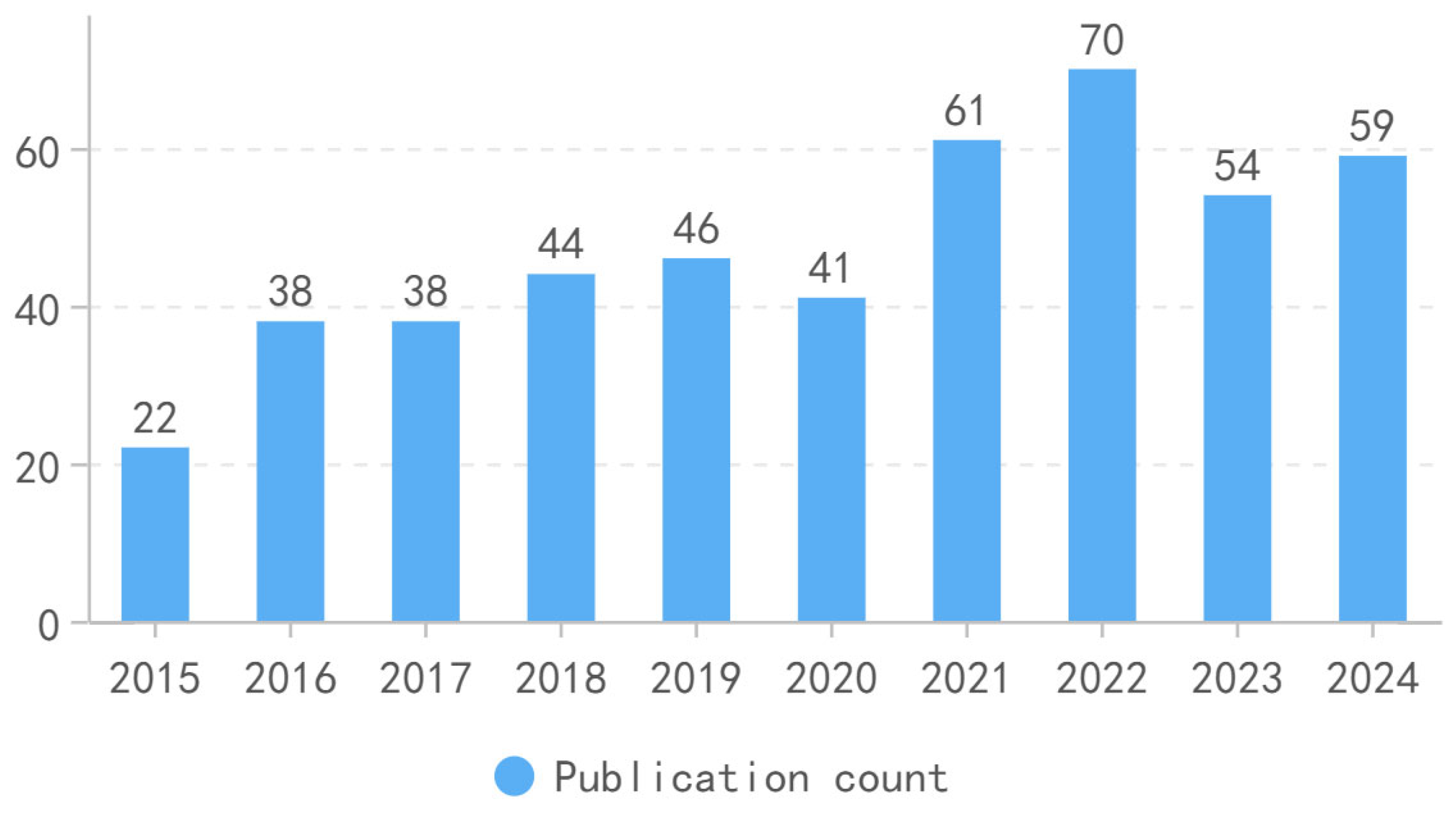

2.2.1. Annual Publication Output

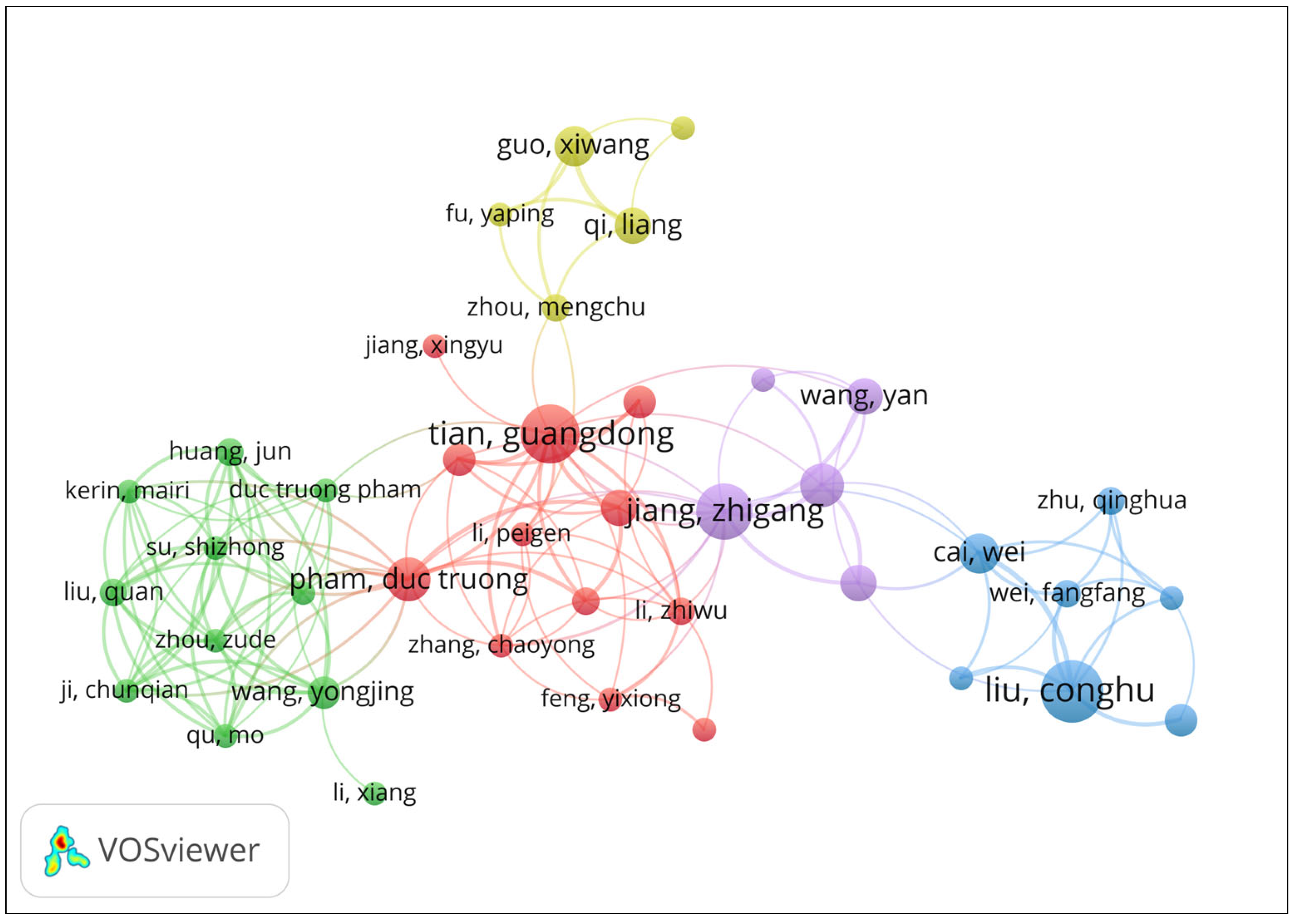

2.2.2. Author Co-Occurrence Network

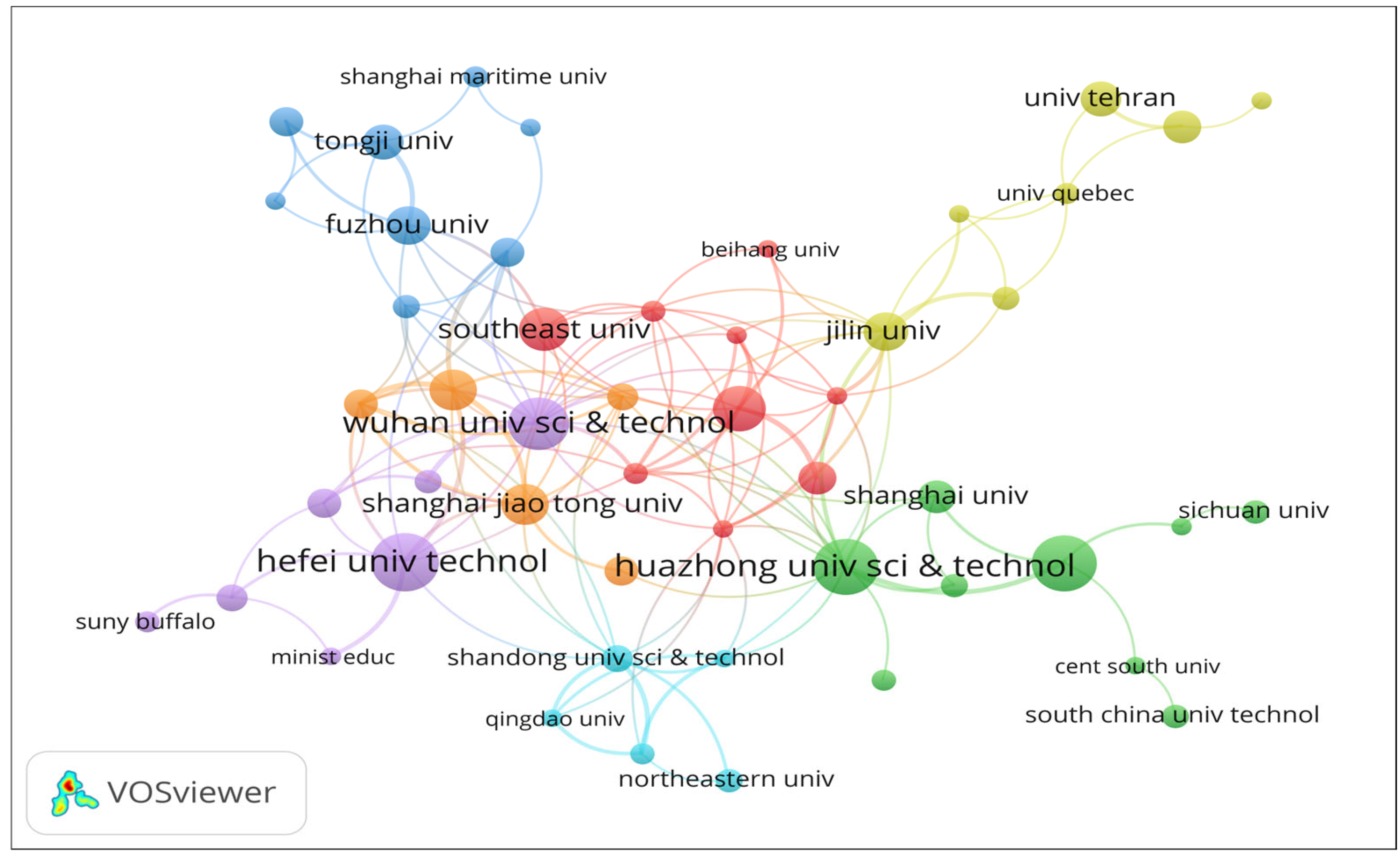

2.2.3. Institutional Collaboration Network

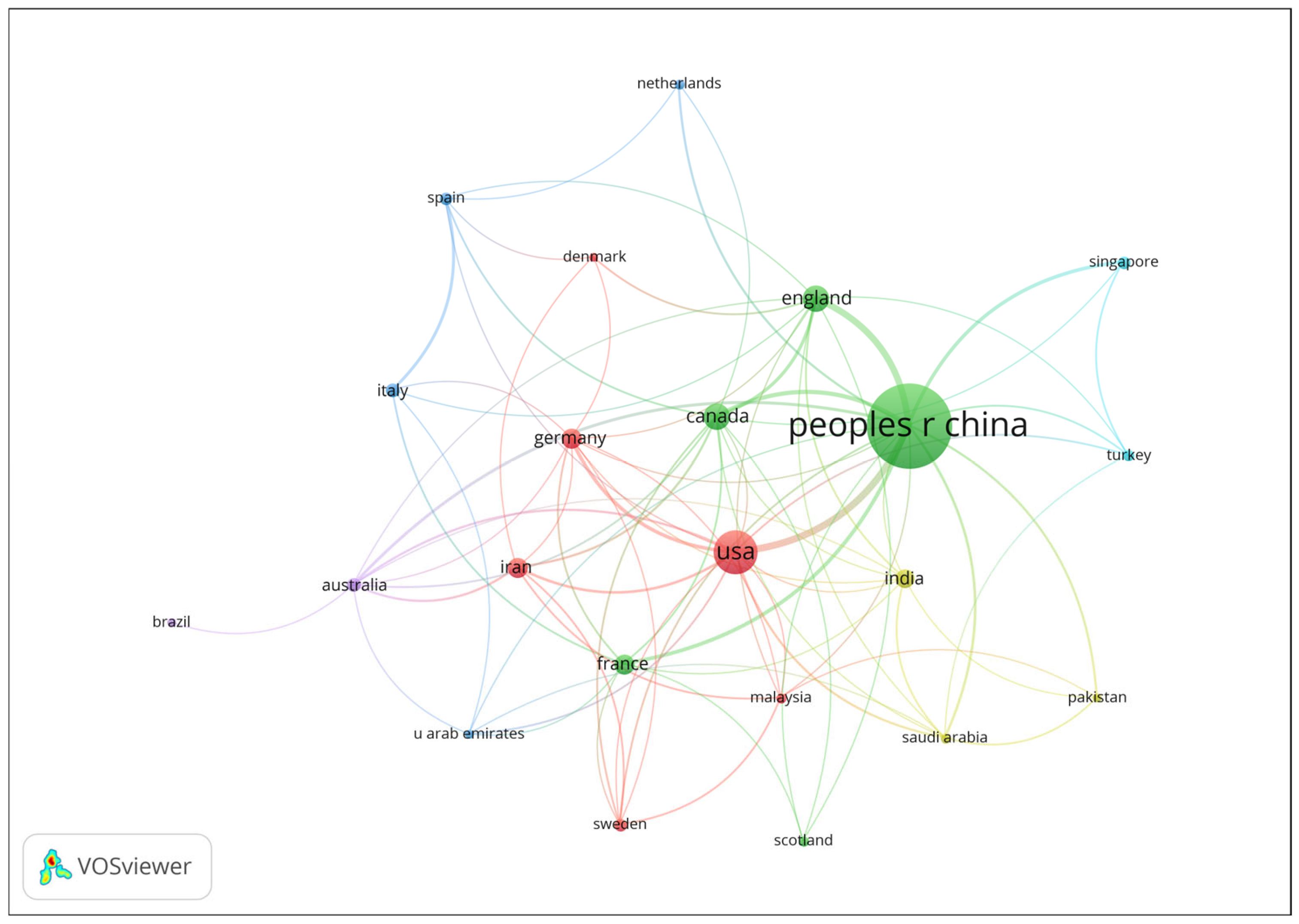

2.2.4. Country Collaboration Network

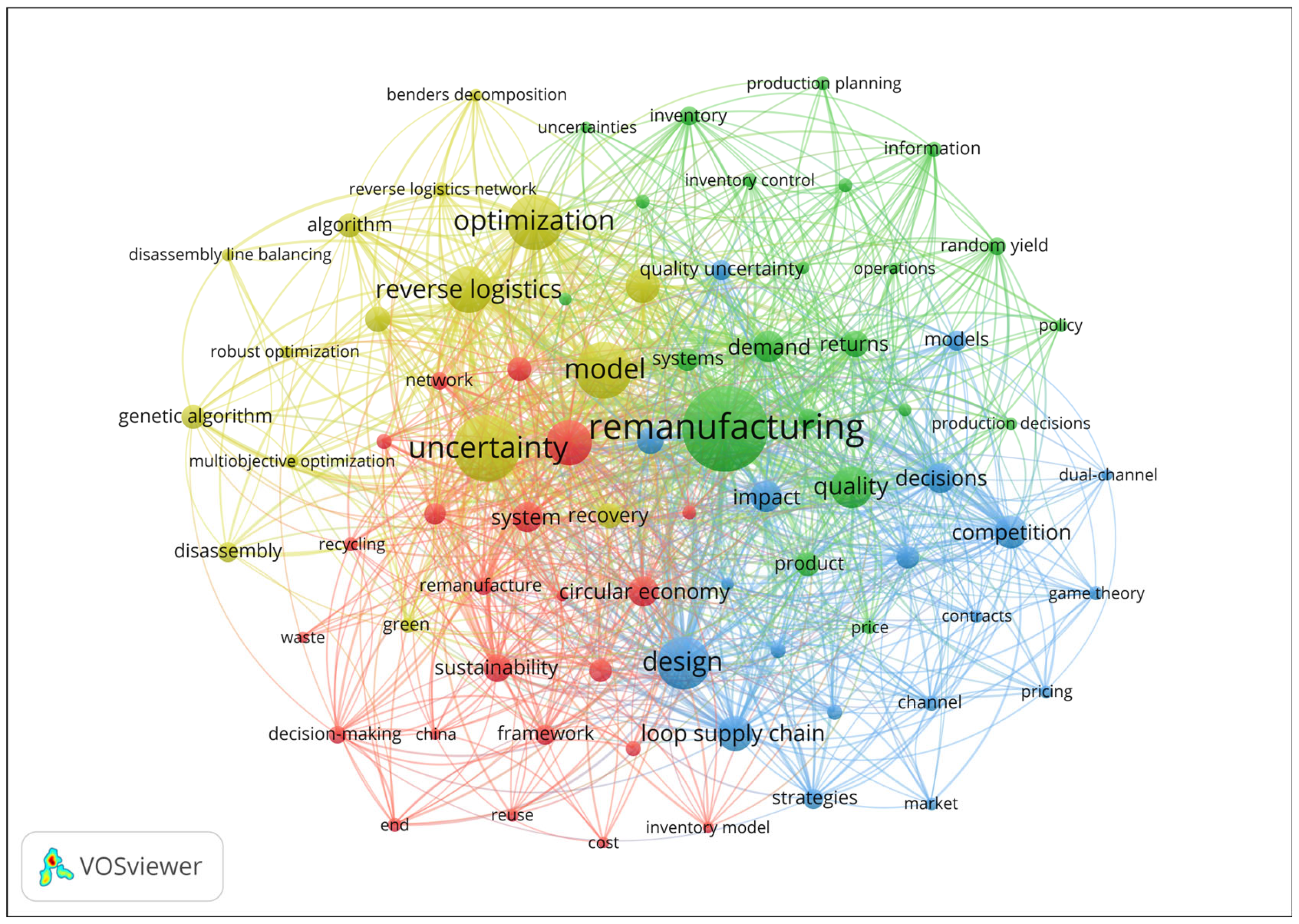

2.2.5. Keywords Co-Occurrence Analysis

- (1)

- Red (Macro-level Sustainability): Focus on “circular economy,” “sustainability,” and “management,” indicating a shift toward systemic and eco-strategic research.

- (2)

- Green (Scheduling and Inventory): Centers on “remanufacturing,” “inventory,” and “production planning,” emphasizing operational optimization under uncertainty.

- (3)

- Yellow (Reverse Logistics and Algorithms): Highlights “uncertainty,” “reverse logistics,” and “robust optimization,” reflecting algorithmic approaches to logistical challenges.

- (4)

- Blue (Supply Chain Contracts and Game Theory): Features “game theory,” “contracts,” and “competition,” exploring strategic interactions in CLSCs.

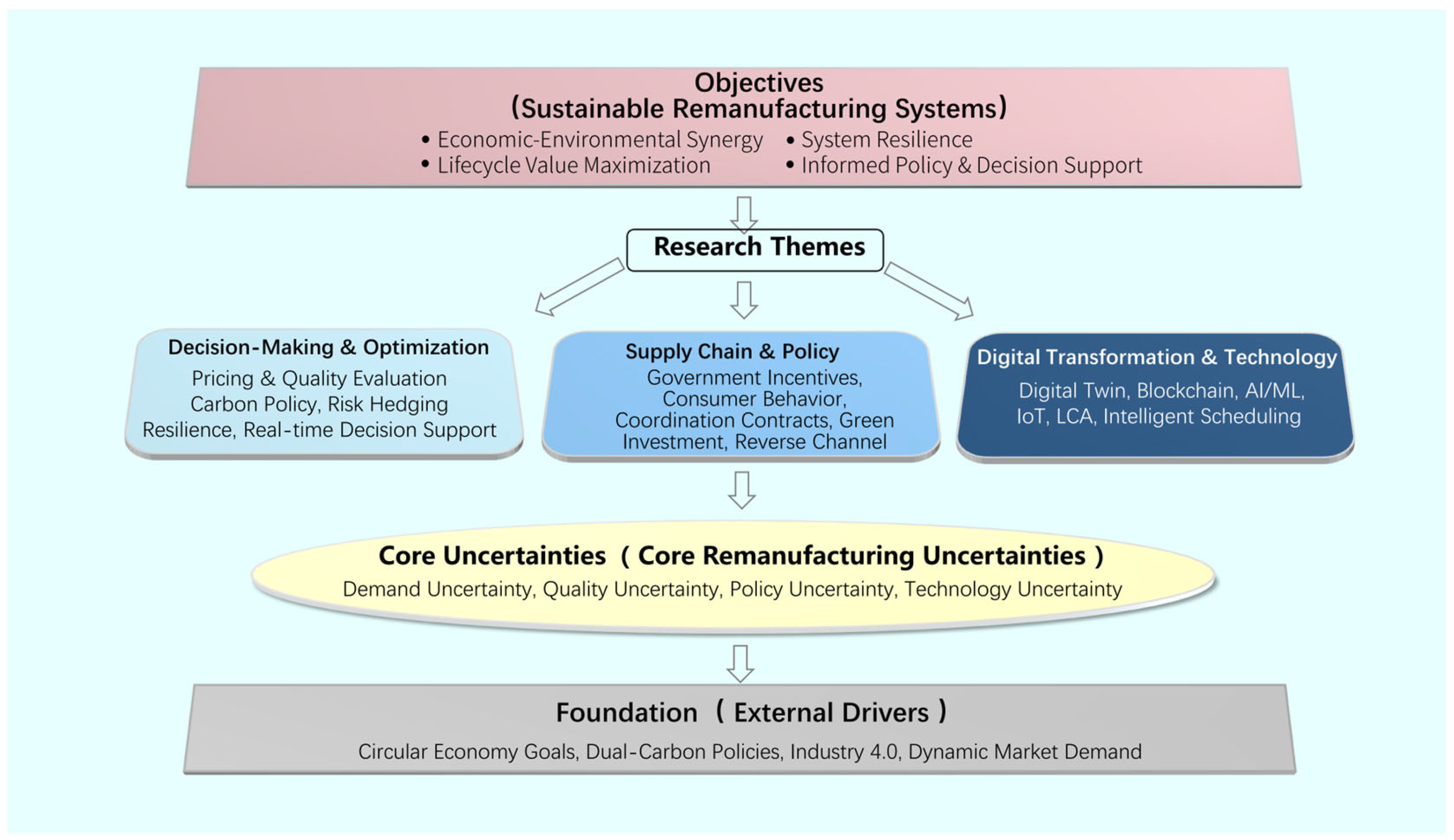

3. Thematic Review of Remanufacturing Production Under Uncertainty

3.1. Decision-Making and Optimization Under Uncertainty

3.1.1. Pricing, Quality Evaluation, and Risk Hedging Strategies

3.1.2. Integration of Carbon Policy and Financial Risk Management

3.1.3. Towards System Resilience and Adaptive Optimization

3.2. Supply Chain Coordination and Policy Mechanisms

3.2.1. The Central Role of Government Incentive Policies

3.2.2. The Intermediary Role of Consumer Behavior Heterogeneity

3.2.3. Collaborative Innovation for Supply Chain Resilience

3.3. Digital Transformation and Emerging Technologies

3.3.1. DTs and Blockchain for Trust and Transparency

3.3.2. AI and Heuristic Algorithms for Complex Optimization

3.3.3. System Integration and Technological Convergence

4. Research Summary and Framework Synthesis

4.1. Micro-Level: Theoretical Breakthroughs in Adaptive Decision-Making

4.2. Meso-Level: System Reconfiguration for Enhanced Resilience

4.3. Macro-Level: Sustainable Pathways Through Policy-Technology Integration

5. Results and Discussion

5.1. Main Research Findings

5.1.1. Transformation of Uncertain Decision-Making Paradigm

5.1.2. Synergistic Innovation Effect of Policy Tools

5.1.3. System Rebuilding Value of Technology Integration

5.1.4. Multi-Dimensional Improvement Paths for Supply Chain Resilience

5.2. Discussion

5.2.1. Integrated Thematic Findings

- (1)

- Blockchain technology significantly enhances transparency and trust within remanufacturing supply chains. It ensures secure and tamper-resistant transactions for remanufactured products and provides a robust foundation for environmental compliance management. Furthermore, blockchain-supported smart contracts enable the automated execution of agreements, reducing transaction costs and improving operational efficiency.

- (2)

- Intelligent algorithms, including machine learning and optimization techniques, play a critical role in optimizing RPs. By leveraging real-time data and predictive analytics, these algorithms facilitate complex decision-making tasks such as production scheduling and quality control, thereby enhancing dynamic resource allocation and overall system resilience.

- (3)

- Dynamic modeling captures the time-varying nature of uncertainties in remanufacturing systems. The integration of real-time data streams supports the development of adaptive strategies to address fluctuations in market demand, supply chain disruptions, and changes in policy environments.

5.2.2. Limitations of Current Research

- (1)

- Inadequate modeling of dynamic time-varying uncertainties and real-time response mechanisms

- (2)

- Lack of techno-economic assessments and industrial-scale validation for emerging technologies

- (3)

- Solation of technological, operational, and policy aspects, and weak cross-system integration

- (4)

- Insufficient focus on SME-specific and culturally adapted solutions

5.3. Future Research Directions

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| PRISMA | Preferred Reporting Items for Systematic Reviews and Meta-Analyses |

| DT | Digital Twin |

| RP | Remanufacturing Process |

| IMRaD | Introduction—Methods—Results—Discussion |

| SLR | Systematic Literature Review |

| WoS | Web of Science |

| IEEE | Institute of Electrical and Electronics Engineers |

| CLSC | Closed-Loop Supply Chain |

| SCI | Science Citation Index |

| SSCI | Social Sciences Citation Index |

| USA | United States |

| UK | United Kingdom of Great Britain and Northern Ireland |

| CVaR | Conditional Value at Risk |

| ROI | Return on Investment |

| SME | Small and Medium-sized Enterprise |

| OEM | Original Equipment Manufacturer |

| AI | Artificial Intelligence |

| PSO-GA | Particle Swarm Optimization—Genetic Algorith |

| NGWO | Nonlinear Gray Wolf Optimizer |

| CML | Constraint Movement Learning |

| DEACA | Dynamic Enhancement Algorithm for Constraint Adjustment |

| 3E | Economy-Energy-Environment |

| LCA | Life cycle assessment |

| BDHDTPREMfg | Big Data-driven Hyper-Digital Twin Process Reconfiguration Engineering Manufacturing |

| SLS-DED | Selective Laser Sintering—Directed Energy Deposition |

| MPC | Model Predictive Control |

| ERP | Enterprise Resource Planning |

| CRM | Customer Relationship Management |

References

- Zhang, X.; Cheng, Y.; Xia, Q.; Zhang, J. TImpact of Blockchain Technology on Remanufacturing Mode Selection under Carbon Tax Policies. Ind. Eng. J. 2025, 28, 133–146. [Google Scholar] [CrossRef]

- Thierry, M.; Salomon, M.; Van Nunen, J.; Van Wassenhove, L. Strategic issues in product recovery management. Calif. Manag. Rev. 1995, 37, 114–136. [Google Scholar] [CrossRef]

- Peng, S.; Ping, J.; Li, T.; Wang, F.; Zhang, H.; Liu, C. Environmental benefits of remanufacturing mechanical products: A harmonized meta-analysis of comparative life cycle assessment studies. J. Environ. Manag. 2022, 306, 114479. [Google Scholar] [CrossRef]

- Liu, C.; Yang, Y.; Liu, X. A holistic sustainability framework for remanufacturing under uncertainty. J. Manuf. Syst. 2024, 76, 540–552. [Google Scholar] [CrossRef]

- Xia, X.; Li, J.; Zhu, Q.; Ma, R. The Development Trends and Future Prospects on Remanufacturing. Chin. J. Manag. Sci. 2025, 33, 287–296. [Google Scholar] [CrossRef]

- Liu, L.; Urgo, M. Robust scheduling of remanufacturing processes for the repair of turbine blades. CIRP Ann. 2023, 72, 425–428. [Google Scholar] [CrossRef]

- Mustajib, M.I.; Ciptomulyono, U.; Kurniati, N. A novel multi-criteria sorting model based on AHP-entropy grey clustering for dealing with uncertain incoming core quality in remanufacturing systems. Appl. Sci. 2021, 11, 2731. [Google Scholar] [CrossRef]

- Rizova, M.I.; Wong, T.; Ijomah, W. A systematic review of decision-making in remanufacturing. Comput. Ind. Eng. 2020, 147, 106681. [Google Scholar] [CrossRef]

- Ropi, N.M.; Hishamuddin, H.; Abd Wahab, D.; Saibani, N. Optimisation Models of Remanufacturing Uncertainties in Closed-Loop Supply Chains–A Review. IEEE Access 2021, 9, 160533–160551. [Google Scholar] [CrossRef]

- Yan, G.; Ni, Y.; Yang, X. Optimal pricing in recycling and remanufacturing in uncertain environments. Sustainability 2020, 12, 3199. [Google Scholar] [CrossRef]

- Yang, F.; Wang, M.; Ang, S. Optimal remanufacturing decisions in supply chains considering consumers’ anticipated regret and power structures. Transp. Res. Part E Logist. Transp. Rev. 2021, 148, 102267. [Google Scholar] [CrossRef]

- Dai, L.; Peng, J.; Zheng, Y. Optimal decisions in a dual-channel remanufacturing supply chain with reference quality effect under WTP differentiation. Oper. Res. 2024, 24, 56. [Google Scholar] [CrossRef]

- Chakraborty, K.; Mukherjee, K.; Mondal, S.; Mitra, S. A systematic literature review and bibliometric analysis based on pricing related decisions in remanufacturing. J. Clean. Prod. 2021, 310, 127265. [Google Scholar] [CrossRef]

- Ullah, M.; Asghar, I.; Zahid, M.; Omair, M.; AlArjani, A.; Sarkar, B. Ramification of remanufacturing in a sustainable three-echelon closed-loop supply chain management for returnable products. J. Clean. Prod. 2021, 290, 125609. [Google Scholar] [CrossRef]

- Yanıkoğlu, İ.; Denizel, M. The value of quality grading in remanufacturing under quality level uncertainty. Int. J. Prod. Res. 2021, 59, 839–859. [Google Scholar] [CrossRef]

- Sun, H.; Li, Y. Optimal acquisition and production policies for remanufacturing with quality grading. Mathematics 2023, 11, 1665. [Google Scholar] [CrossRef]

- Yang, C.-H.; Ma, X.; Talluri, S.; Ivanov, D. Optimal core acquisition and remanufacturing decisions with discrete core quality grades. IEEE Trans. Eng. Manag. 2021, 70, 3792–3811. [Google Scholar] [CrossRef]

- Liu, C.; Chen, J.; Wang, X. Quantitative evaluation model of the quality of remanufactured product. IEEE Trans. Eng. Manag. 2023, 71, 7413–7424. [Google Scholar] [CrossRef]

- Liao, H.; Zhang, Q.; Shen, N.; Li, L. Stochastic analysis of quality uncertainty and optimal acquisition strategies for engine remanufacturing. J. Clean. Prod. 2020, 261, 121088. [Google Scholar] [CrossRef]

- Nadar, E.; Akan, M.; Debo, L.; Scheller-Wolf, A. Optimal procurement in remanufacturing systems with uncertain used-item condition. Oper. Res. 2023, 71, 1441–1453. [Google Scholar] [CrossRef]

- Ke, Q.; Li, J.; Huang, H.; Liu, G.; Zhang, L. Performance evaluation and decision making for pre-decision remanufacturing timing with on-line monitoring. J. Clean. Prod. 2021, 283, 124606. [Google Scholar] [CrossRef]

- Ke, C.; Yan, B. Trade-in value effects of used products in remanufacturing with considering consumer purchase behavior. J. Oper. Res. Soc. 2022, 73, 608–633. [Google Scholar] [CrossRef]

- Ding, J.; Chen, W. Remanufacturing supply chain coordination through option contracts under uncertain demand. Ann. Oper. Res. 2023, 1–31. [Google Scholar] [CrossRef]

- Xu, H.; Fang, C.; Zhang, S. A new integrated remanufacturing process planning and scheduling model under uncertainties using extended non-dominated sorting genetic algorithm-II. J. Intell. Fuzzy Syst. 2024, 46, 2123–2145. [Google Scholar] [CrossRef]

- Dominguez, R.; Cannella, S.; Framinan, J.M. Remanufacturing configuration in complex supply chains. Omega 2021, 101, 102268. [Google Scholar] [CrossRef]

- Zhao, P.; Deng, Q.; Zhou, J.; Han, W.; Gong, G.; Jiang, C. Optimal production decisions for remanufacturing end-of-life products under quality uncertainty and a carbon cap-and-trade policy. Comput. Ind. Eng. 2021, 162, 107646. [Google Scholar] [CrossRef]

- Liao, H.; Wu, D.; Wang, Y.; Lyu, Z.; Sun, H.; Nie, Y.; He, H. Impacts of carbon trading mechanism on closed-loop supply chain: A case study of stringer pallet remanufacturing. Socio-Econ. Plan. Sci. 2022, 81, 101209. [Google Scholar] [CrossRef]

- Ma, X.; Chen, W. Optimal ordering and production decisions for remanufacturing firms with carbon options under demand uncertainty. Environ. Sci. Pollut. Res. 2023, 30, 34378–34393. [Google Scholar] [CrossRef] [PubMed]

- Fu, R.; Ding, J. Optimal Decisions for Medical Equipment Remanufacturing under Carbon Price Fluctuation with Carbon Options. IEEE Access 2024, 12, 34378–34393. [Google Scholar] [CrossRef]

- Zhao, J.; Xue, Z.; Li, T.; Ping, J.; Peng, S. An energy and time prediction model for remanufacturing process using graphical evaluation and review technique (GERT) with multivariant uncertainties. Environ. Sci. Pollut. Res. 2021, 1–13. [Google Scholar] [CrossRef]

- Ding, J.; Chen, W. Effects of trade credit insurance on remanufacturing decisions under carbon tax and emissions abatement. Eur. J. Ind. Eng. 2022, 16, 679–705. [Google Scholar] [CrossRef]

- Zheng, Y.; Zhao, Y.; Wang, N.; Meng, X.; Yang, H. Financing decision for a remanufacturing supply chain with a capital constrained retailer: A study from the perspective of market uncertainty. Int. J. Prod. Econ. 2022, 245, 108397. [Google Scholar] [CrossRef]

- Li, Q.; Zhang, Y.; Chen, W. Optimal production and emission reduction policies for a remanufacturing firm considering deferred payment strategy. J. Ind. Manag. Optim. 2021, 17, 2475–2503. [Google Scholar] [CrossRef]

- Zhang, Y.; Chen, W.; Li, Q. Third-party remanufacturing mode selection for a capital-constrained closed-loop supply chain under financing portfolio. Comput. Ind. Eng. 2021, 157, 107315. [Google Scholar] [CrossRef]

- Liu, J.; Xia, S.; Wang, Z.; Nie, J.; Ameen, N.; Yan, C.; Lim, M.K. How to balance economic profits and environmental protection: The impacts of cash hedging on remanufacturing firms. Int. J. Prod. Econ. 2023, 258, 108783. [Google Scholar] [CrossRef]

- Zhang, Z.; Chen, W.; Li, C. Repurchase or pledge? Financing and production decisions of engineering machinery remanufacturing firms. J. Clean. Prod. 2023, 429, 139309. [Google Scholar] [CrossRef]

- Li, K.; Zhou, T.; Liu, B. The comparison between selling and leasing for new and remanufactured products with quality level in the electric vehicle industry. J. Ind. Manag. Optim. 2021, 17, 1506–1529. [Google Scholar] [CrossRef]

- Mat Ropi, N.; Hishamuddin, H.; Wahab, D.A.; Jauhari, W.A.; Rashid, F.A.A.; Khamis, N.K.; Mohamed, I.F.; Mohd Sabri, M.A.; Abu Mansor, M.R. Optimal lot-sizing decisions for a remanufacturing production system under spare parts supply disruption. Mathematics 2023, 11, 4053. [Google Scholar] [CrossRef]

- Francas, D.; Öner-Közen, M.; Minner, S. Is it beneficial to invest in flexible capacity for hybrid remanufacturing? Int. J. Prod. Res. 2024, 62, 7836–7859. [Google Scholar] [CrossRef]

- Quezada, F.; Gicquel, C.; Kedad-Sidhoum, S. A stochastic dual dynamic integer programming based approach for remanufacturing planning under uncertainty. Int. J. Prod. Res. 2023, 61, 5992–6012. [Google Scholar] [CrossRef]

- Reddy, K.N.; Kumar, A.; Velaga, N.R. Scenario-based two-stage stochastic programming for a Hybrid Manufacturing-Remanufacturing System with the uncertainty of returns, quality and demand. Sādhanā 2021, 46, 1–9. [Google Scholar] [CrossRef]

- Li, X.; Li, N.; Kolmanovsky, I.; Epureanu, B.I. Stochastic model predictive control for remanufacturing system management. J. Manuf. Syst. 2021, 59, 355–366. [Google Scholar] [CrossRef]

- Lv, Y.; Li, C.; Zhao, X.; Li, L.; Li, J. A novel approach for remanufacturing process planning considering uncertain and fuzzy information. Front. Mech. Eng. 2021, 16, 546–558. [Google Scholar] [CrossRef]

- Zhang, W.; Shi, J.; Zhang, S.; Chen, M. Scenario-based robust remanufacturing scheduling problem using improved biogeography-based optimization algorithm. IEEE Trans. Syst. 2022, 53, 3414–3427. [Google Scholar] [CrossRef]

- Guo, Y.; Shi, Q.; Guo, C.; Li, J.; You, Z.; Wang, Y. Designing a sustainable-remanufacturing closed-loop supply chain under hybrid uncertainty: Cross-efficiency sorting multi-objective optimization. Comput. Ind. Eng. 2022, 172, 108639. [Google Scholar] [CrossRef]

- Zhang, W.; Wang, J.; Liu, X.; Zhang, S. A new uncertain remanufacturing scheduling model with rework risk using hybrid optimization algorithm. Environ. Sci. Pollut. Res. 2023, 30, 62744–62761. [Google Scholar] [CrossRef] [PubMed]

- Zhu, C.; Ma, J.; Li, J. Dynamic production and carbon emission reduction adjustment strategies of the brand-new and the remanufactured product under hybrid carbon regulations. Comput. Ind. Eng. 2022, 172, 108517. [Google Scholar] [CrossRef]

- Zhou, Y.; Bao, M.; Chen, X.; Xu, X. Co-op advertising and emission reduction cost sharing contracts and coordination in low-carbon supply chain based on fairness concerns. J. Clean. Prod. 2016, 133, 402–413. [Google Scholar] [CrossRef]

- Zhu, C.; Xi, X.; Goh, M. Differential game analysis of joint emission reduction decisions under mixed carbon policies and CEA. J. Environ. Manag. 2024, 358, 120913. [Google Scholar] [CrossRef]

- Attila, Ö.N.; Agra, A.; Akartunalı, K.; Arulselvan, A. Robust formulations for economic lot-sizing problem with remanufacturing. Eur. J. Oper. Res. 2021, 288, 496–510. [Google Scholar] [CrossRef]

- Polotski, V.; Kenné, J.-P.; Gharbi, A. Estimation-based production control of manufacturing–remanufacturing systems with uncertain seasonal return and imprecise demand and inventory. Int. J. Prod. Res. 2024, 62, 4595–4622. [Google Scholar] [CrossRef]

- Zhou, Q.; Yuen, K.F. Analyzing the effect of government subsidy on the development of the remanufacturing industry. Int. J. Environ. Res. Public Health 2020, 17, 3550. [Google Scholar] [CrossRef]

- Guo, J.; Wang, G.; Wang, Z.; Liang, C.; Gen, M. Research on remanufacturing closed loop supply chain based on incentive-compatibility theory under uncertainty. Ann. Oper. Res. 2022, 331, 917–938. [Google Scholar] [CrossRef]

- Zhou, Y.; Liu, X.-Q.; Wong, K.-H. Remanufacturing policies options for a closed-loop supply chain network. Sustainability 2021, 13, 6640. [Google Scholar] [CrossRef]

- Hao, H.; Ran, G.; Liu, H.-m.; Han, H.; Gu, Q. Pricing strategies for remanufacturing with government incentives. Neural Comput. Appl. 2024, 36, 2187–2200. [Google Scholar] [CrossRef]

- Liu, K.; Wang, C.; Liu, L.; Xu, L. Which group should governmental policies target? Effects of incentive policy for remanufacturing industry. RAIRO-Oper. Res. 2021, 55, 1579–1602. [Google Scholar] [CrossRef]

- Dominguez, R.; Cannella, S.; Ponte, B.; Framinan, J.M. On the dynamics of closed-loop supply chains under remanufacturing lead time variability. Omega 2020, 97, 102106. [Google Scholar] [CrossRef]

- Niu, B.; Ruan, Y.; Zeng, F. Promoting remanufacturing through subsidy and environment tax: Channel co-opetition, incentive alignment and regulation optimization. Transp. Res. Part ELogistics Transp. Rev. 2022, 166, 102880. [Google Scholar] [CrossRef]

- Yan, X.; Han, X. Optimal pricing and remanufacturing entry strategies of manufacturers in the presence of online reviews. Ann. Oper. Res. 2022, 316, 59–92. [Google Scholar] [CrossRef]

- Dai, L.; Shu, T.; Zheng, Y.; Wang, S. Models for dual-channel remanufacturing supply chain with reference price effect under static and dynamic games. RAIRO-Oper. Res. 2024, 58, 4437–4475. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, X. The implications of carbon tax policy, product design and consumer’s perceptions on competition between new and remanufactured products. Environ. Dev. Sustain. 2024, 27, 1–35. [Google Scholar] [CrossRef]

- Cheng, Y.; Wang, J. Decision-Making in Remanufacturing Supply Chains: Game Theory Analysis of Recycling Models and Consumer Value Perception. Sustainability 2024, 16, 10476. [Google Scholar] [CrossRef]

- Zhang, X.; Zhou, G.; Cao, J.; Lu, J. A remanufacturing supply chain network with differentiated new and remanufactured products considering consumer preference, production capacity constraint and government regulation. PLoS ONE 2023, 18, e0289349. [Google Scholar] [CrossRef]

- Modak, I.; Bardhan, S.; Giri, B.C. Random pricing, product collection, and green investment strategies in a closed-loop supply chain with price dependent demand and remanufacturing. J. Clean. Prod. 2025, 486, 144523. [Google Scholar] [CrossRef]

- Sarkar, B.; Ullah, M.; Sarkar, M. Environmental and economic sustainability through innovative green products by remanufacturing. J. Clean. Prod. 2022, 332, 129813. [Google Scholar] [CrossRef]

- Bakhshi, A.; Heydari, J. An optimal put option contract for a reverse supply chain: Case of remanufacturing capacity uncertainty. Ann. Oper. Res. 2023, 324, 37–60. [Google Scholar] [CrossRef]

- Vedantam, A.; Iyer, A. Revenue-Sharing Contracts Under Quality Uncertainty in Remanufacturing. Prod. Oper. Manag. 2021, 30, 2008–2026. [Google Scholar] [CrossRef]

- Gong, H.; Zhang, Z.-H. Benders decomposition for the distributionally robust optimization of pricing and reverse logistics network design in remanufacturing systems. Eur. J. Oper. Res. 2022, 297, 496–510. [Google Scholar] [CrossRef]

- Alkahtani, M.; Salah, B.; Ziout, A.; Alatefi, M. Collection System of Air Conditioners Remanufacturing: Development and Optimization under Probabilistic Uncertainty. Math. Probl. Eng. 2022, 2022, 3428247. [Google Scholar] [CrossRef]

- Fadeyi, J.A.; Monplaisir, L. Instilling lifecycle costs into modular product development for improved remanufacturing-product service system enterprise. Int. J. Prod. Econ. 2022, 246, 108404. [Google Scholar] [CrossRef]

- Ata, M.; Corum, A. The impact of return disposal on order variance in a hybrid manufacturing and remanufacturing system. IEEE Trans. Eng. Manag. 2021, 70, 2574–2583. [Google Scholar] [CrossRef]

- Shafiq, M.; Ayub, S.; Prabhu, M.R. AI-driven Life Cycle Assessment for sustainable hybrid manufacturing and remanufacturing. Int. J. Adv. Manuf. Technol. 2024, 1–9. [Google Scholar] [CrossRef]

- Paul, M.; Kerkhoff, F.; Ballenberger, T.; Reinbold, N.; Reinhart, G. Remanufacturing implementation on the shop floor–Insights from an industrial perspective. Sustain. Prod. Consum. 2025, 54, 215–226. [Google Scholar] [CrossRef]

- Manupati, V.K.; Kulatunga, A.; Ray, P.; Rofin, T. Sustainable management of EOL tyres: A remanufacturing supply chain network design. J. Clean. Prod. 2024, 434, 140115. [Google Scholar] [CrossRef]

- Putz, B.; Dietz, M.; Empl, P.; Pernul, G. Ethertwin: Blockchain-based secure digital twin information management. Inf. Process. Manag. 2021, 58, 102425. [Google Scholar] [CrossRef]

- Kapteyn, G.; Pretorius, V.; Willcox, E. A probabilistic graphical model foundation for enabling predictive digital twins at scale. Nat. Comput. Sci. 2021, 1, 337–347. [Google Scholar] [CrossRef]

- Kantaros, A.; Piromalis, D.; Tsaramirsis, G.; Papageorgas, P.; Tamimi, H. 3D printing and implementation of digital twins: Current trends and limitations. Appl. Syst. Innov. 2021, 5, 7. [Google Scholar] [CrossRef]

- Niu, B.; Xu, H.; Chen, L. Creating all-win by blockchain in a remanufacturing supply chain with consumer risk-aversion and quality untrust. Transp. Res. Part E Logist. Transp. Review 2022, 163, 102778. [Google Scholar] [CrossRef]

- Yang, T.; Li, C.; Bian, Z. Recycling strategies in a collector-led remanufacturing supply chain under blockchain and uncertain demand. Processes 2023, 11, 1426. [Google Scholar] [CrossRef]

- Wang, Z.; Ye, C.; Guo, J. Game analysis on two-tier remanufacturing green closed-loop supply chain considering incentive compatibility under uncertain demand. Int. J. Syst. Sci. Oper. Logist. 2024, 11, 2368132. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, S.; Yang, B.; Zhu, L.; Liu, F. Big data driven Hierarchical Digital Twin Predictive Remanufacturing paradigm: Architecture, control mechanism, application scenario and benefits. J. Clean. Prod. 2020, 248, 119299. [Google Scholar] [CrossRef]

- Kerin, M.; Pham, D.T.; Huang, J.; Hadall, J. A generic asset model for implementing product digital twins in smart remanufacturing. Int. J. Adv. Manuf. Technol. 2023, 124, 3021–3038. [Google Scholar] [CrossRef]

- Yu, H.; Sun, X. Uncertain remanufacturing reverse logistics network design in industry 5.0: Opportunities and challenges of digitalization. Eng. Appl. Artif. Intell. 2024, 133, 108578. [Google Scholar] [CrossRef]

- Wang, Z.; Jiang, X.; Yang, G.; Song, B.; Ni, Z.; Zhang, R. A novel method of optimized selective assembly for remanufactured products. Int. J. Adv. Manuf. Technol. 2024, 132, 2631–2641. [Google Scholar] [CrossRef]

- Zhang, S.; Xu, H.; Zhang, H.; Yang, S. Game-relationship-based remanufacturing scheduling model with sequence-dependent setup times using improved discrete particle swarm optimization algorithm. Concurr. Eng. 2022, 30, 424–441. [Google Scholar] [CrossRef]

- Shi, J.; Zhang, W.; Zhang, S.; Chen, J. A new bifuzzy optimization method for remanufacturing scheduling using extended discrete particle swarm optimization algorithm. Comput. Ind. Eng. 2021, 156, 107219. [Google Scholar] [CrossRef]

- Roudbari, E.S.; Ghomi, S.F.; Sajadieh, M.S. Reverse logistics network design for product reuse, remanufacturing, recycling and refurbishing under uncertainty. J. Manuf. Syst. 2021, 60, 473–486. [Google Scholar] [CrossRef]

- Xue, Z.; Li, T.; Peng, S. A model to predict bottlenecks over time in a remanufacturing system under uncertainty. Environ. Sci. Pollut. Res. 2021, 1–15. [Google Scholar] [CrossRef]

- Rafiei, R.; Nourelfath, M.; Santa-Eulalia, L.A. A decomposition method for production planning under demand uncertainty in wood remanufacturing. Int. J. Ind. Eng. Theory Appl. 2021, 28, 594–607. [Google Scholar] [CrossRef]

- Liu, Q.; Wei, X.; Wang, Q.; Song, J.; Lv, J.; Liu, Y.; Tang, O. An investigation of mixed-model assembly line balancing problem with uncertain assembly time in remanufacturing. Comput. Ind. Eng. 2024, 198, 110676. [Google Scholar] [CrossRef]

- Li, W.; Zhang, C.; Liu, C.; Liu, X. Error propagation model and optimal control method for the quality of remanufacturing assembly. J. Intell. Fuzzy Syst. 2022, 42, 2533–2547. [Google Scholar] [CrossRef]

- Zhang, X.; Zou, B.; Feng, Z.; Wang, Y.; Yan, W. A review on remanufacturing reverse logistics network design and model optimization. Processes 2021, 10, 84. [Google Scholar] [CrossRef]

- Yan, W.; He, X.; Zhang, H. A multisource data-driven approach for carbon footprint analysis of remanufacturing systems. Energy Sci. Eng. 2023, 11, 4446–4462. [Google Scholar] [CrossRef]

- Zhang, X.; Shen, W.; Suresh, V.; Hamilton, J.; Yeh, L.-H.; Jiang, X.; Zhang, Z.; Li, Q.; Li, B.; Rivero, I.V. In situ monitoring of direct energy deposition via structured light system and its application in remanufacturing industry. Int. J. Adv. Manuf. Technol. 2021, 116, 959–974. [Google Scholar] [CrossRef]

- Zhang, W.; Zheng, Y.; Ma, W.; Ahmad, R. Multi-task scheduling in cloud remanufacturing system integrating reuse, reprocessing, and replacement under quality uncertainty. J. Manuf. Syst. 2023, 68, 176–195. [Google Scholar] [CrossRef]

- Deng, R.; Chang, N.; Lunardi, M.M.; Dias, P.; Bilbao, J.; Ji, J.; Chong, C.M. Remanufacturing end-of-life silicon photovoltaics: Feasibility and viability analysis. Prog. Photovolt. 2021, 29, 760–774. [Google Scholar] [CrossRef]

- Liu, C.; Cai, W.; Zhang, C.; Wei, F. Data-driven intelligent control system in remanufacturing assembly for production and resource efficiency. Int. J. Adv. Manuf. Technol. 2023, 128, 3531–3544. [Google Scholar] [CrossRef]

- Qin, L.; Chen, W.; Zhang, Y.; Ding, J. Cooperation or competition? The remanufacturing strategy with quality uncertainty in construction machinery industry. Comput. Ind. Eng. 2023, 178, 109106. [Google Scholar] [CrossRef]

- Gong, Q.; Xiong, Y.; Jiang, Z.; Yang, J.; Chen, C. Timing decision for active remanufacturing based on 3E analysis of product life cycle. Sustainability 2022, 14, 8749. [Google Scholar] [CrossRef]

- Zhu, Z.; Xiang, Y.; Zhao, M.; Shi, Y. Data-driven remanufacturing planning with parameter uncertainty. Eur. J. Oper. Res. 2023, 309, 102–116. [Google Scholar] [CrossRef]

- Kimita, K.; Matschewsky, J.; Sakao, T. A method for remanufacturing process planning and control using loosely coupled systems. J. Manuf. Sci. Eng.-Trans. ASME 2021, 143, 101001. [Google Scholar] [CrossRef]

- Zhang, X.; Liu, W. Complex equipment remanufacturing schedule management based on multi-layer graphic evaluation and review technique network and critical chain method. IEEE Access 2020, 8, 108972–108987. [Google Scholar] [CrossRef]

| Category | Inclusion Criteria | Exclusion Criteria |

|---|---|---|

| Publication Type | Peer-reviewed journal articles in English | Conference papers, books, book chapters, non-English publications |

| Indexing | Indexed in SCI/SSCI | Non-SCI/SSCI indexed publications |

| Content Focus | Mathematical modeling, optimization, decision-making under uncertainty in remanufacturing | Qualitative studies, case studies without quantitative models, non-remanufacturing contexts |

| Methodology | Game theory, stochastic programming, robust optimization, simulation, empirical models | Studies lacking a quantitative decision-making framework |

| Research Theme | Key Insights (Contributions and Findings) | Major Limitations and Future Gaps |

|---|---|---|

| Pricing, Quality and Risk Hedging |

|

|

| Supply Chain Coordination and Policy |

|

|

| Digital Transformation and Tech Integration |

|

|

| Model Type | Specific Model/Methodology | Motivation | Key Advantages | Major Limitations | Representative Studies |

|---|---|---|---|---|---|

| Dynamic Game Models | Stackelberg Game Pricing | Model strategic interactions under demand/cost uncertainty | Captures power asymmetry; quantifies equilibrium; integrates policy impacts | Assumes rational agents; often static/multi-period; struggles with behavioral factors | [31,59,98] |

| Option Contracts (Put Options) | Hedge supply disruption/quality risks | Reduces over/understocking; flexible risk allocation; improves resilience | Requires precise cost estimation; contract enforcement challenges | [23,66,67] | |

| Robust Optimization | Phi-Divergence Robust Model | Handle quality/distribution ambiguity | Performs well under severe uncertainty; avoids unrealistic assumptions | Computationally intensive; conservative solutions | [15,17] |

| Scenario-Based CVaR Optimization | Minimize worst-case losses under uncertainty | Quantifies downside risk; balances cost/robustness | Curse of dimensionality; assumes fixed probabilities | [39,44] | |

| LCA | Dynamic LCA + Carbon Footprint | Quantify real-time emissions; support eco-design | Links operations to environmental impact; identifies hotspots | Relies on coarse-grained data; lacks standardization; overlooks social dimensions | [72,93,99] |

| Level | Core Theoretical Breakthroughs | Key Benefits | Major Limitations |

|---|---|---|---|

| Micro (Decision-Making) | Dynamic response models; real-time quality mapping via DTs; carbon-finance integration. | 30% better quality evaluation; 20% lower emission costs; 15% quality improvement with time-lag models. | Static agent assumptions; behavioral factors unmodeled; SME barriers unaddressed. |

| Meso (Coordination) | Decentralized trust via blockchain; networked optimization; risk-hedging contracts. | 40% faster disruption recovery; 35% higher parts-matching success; up to 14% profit rise. | Legal enforceability of smart contracts untested; high computational complexity. |

| Macro (System) | Policy-market coupling; lifecycle sustainability quantification; system-level circularity. | 23% lower carbon emissions; 20% cost reduction; 15% higher resource efficiency. | Social dimensions omitted in LCA; cross-border policy conflicts; cultural gaps in developing economies. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tu, Y.; Si, X.; Wu, Y.; Shen, X.; Chen, J. Remanufacturing Process Under Uncertainty: Review, Challenges, and Future Directions. Processes 2025, 13, 3068. https://doi.org/10.3390/pr13103068

Tu Y, Si X, Wu Y, Shen X, Chen J. Remanufacturing Process Under Uncertainty: Review, Challenges, and Future Directions. Processes. 2025; 13(10):3068. https://doi.org/10.3390/pr13103068

Chicago/Turabian StyleTu, Yaoyao, Xiaoxiao Si, Yimin Wu, Xuehong Shen, and Jianqing Chen. 2025. "Remanufacturing Process Under Uncertainty: Review, Challenges, and Future Directions" Processes 13, no. 10: 3068. https://doi.org/10.3390/pr13103068

APA StyleTu, Y., Si, X., Wu, Y., Shen, X., & Chen, J. (2025). Remanufacturing Process Under Uncertainty: Review, Challenges, and Future Directions. Processes, 13(10), 3068. https://doi.org/10.3390/pr13103068