New Method for Capacity Evaluation of Offshore Low-Permeability Reservoirs with Natural Fractures

Abstract

1. Introduction

2. Materials and Methods

2.1. Degree of Fracture Development and Fractal Dimension

2.2. Formations Consideration of Natural Fracture Evolution in Low-Permeability Reservoir Capacity Modeling

2.2.1. Permeability Characterization of Natural Fracture Networks

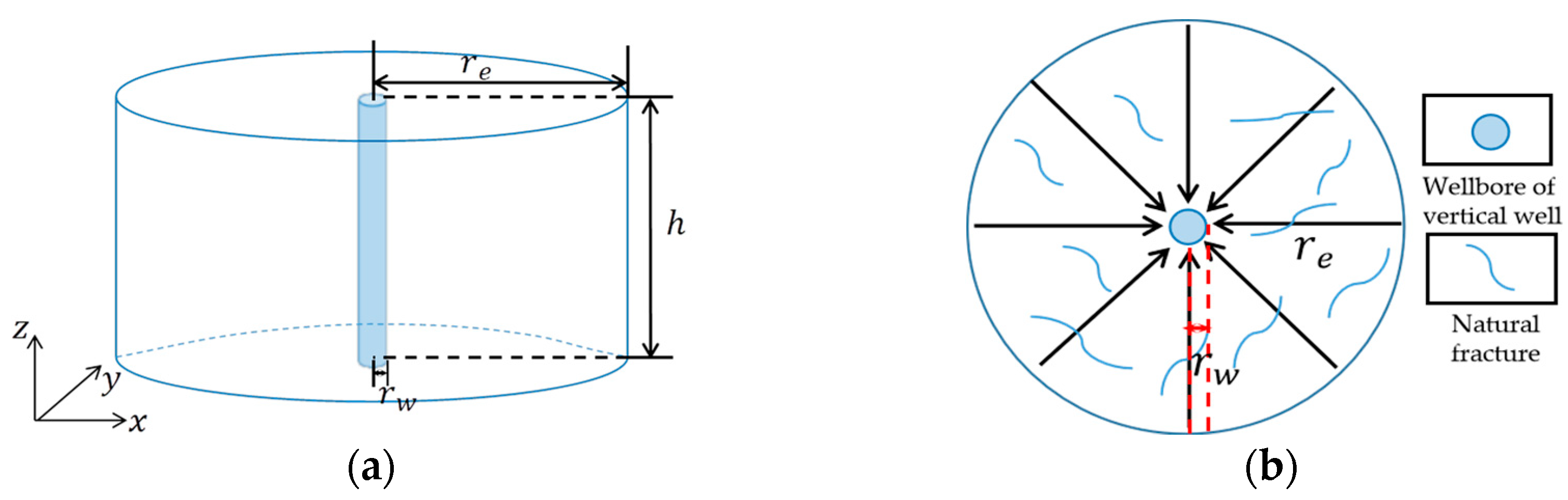

2.2.2. Modeling of Production Capacity of Vertical Wells Containing Natural Fractures

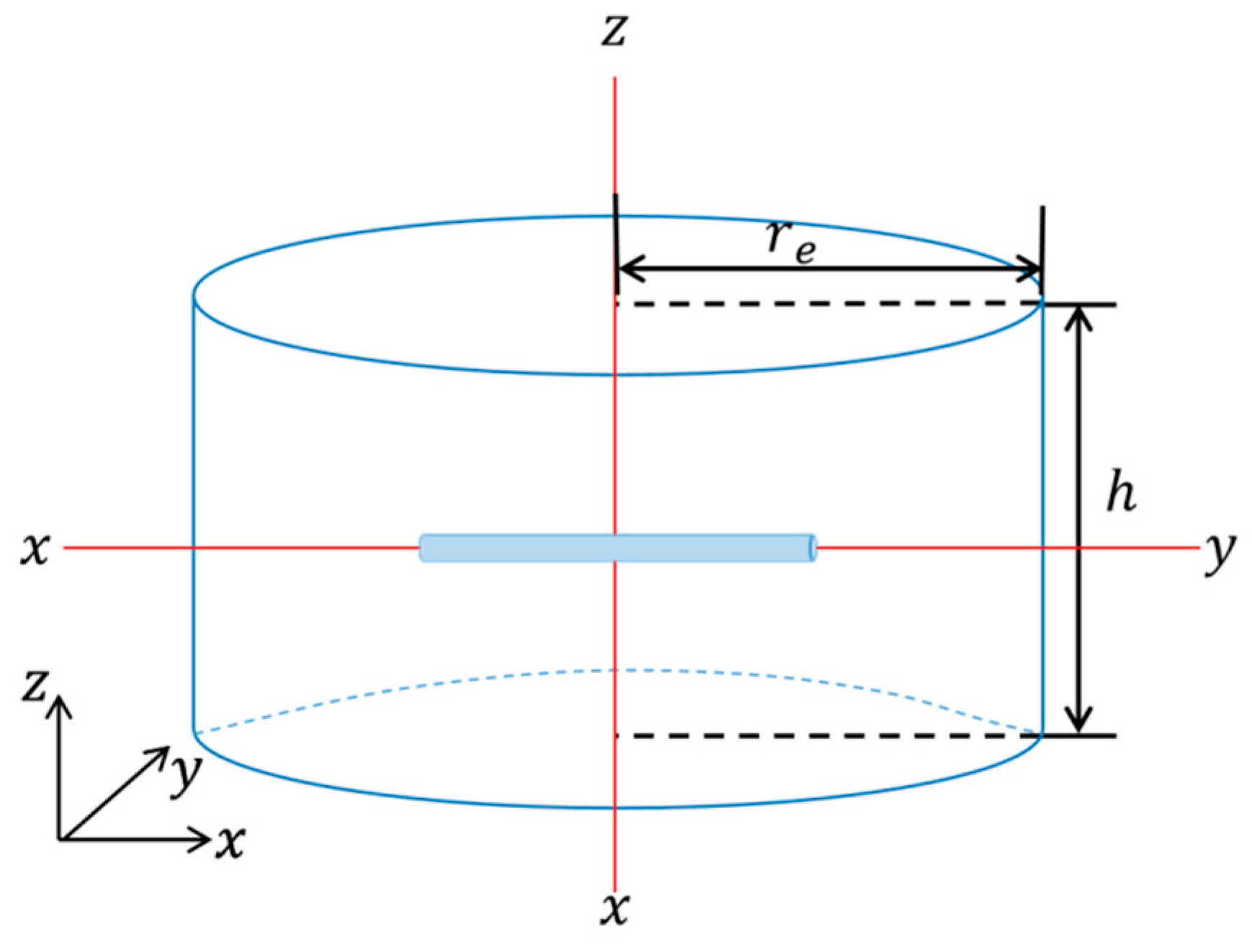

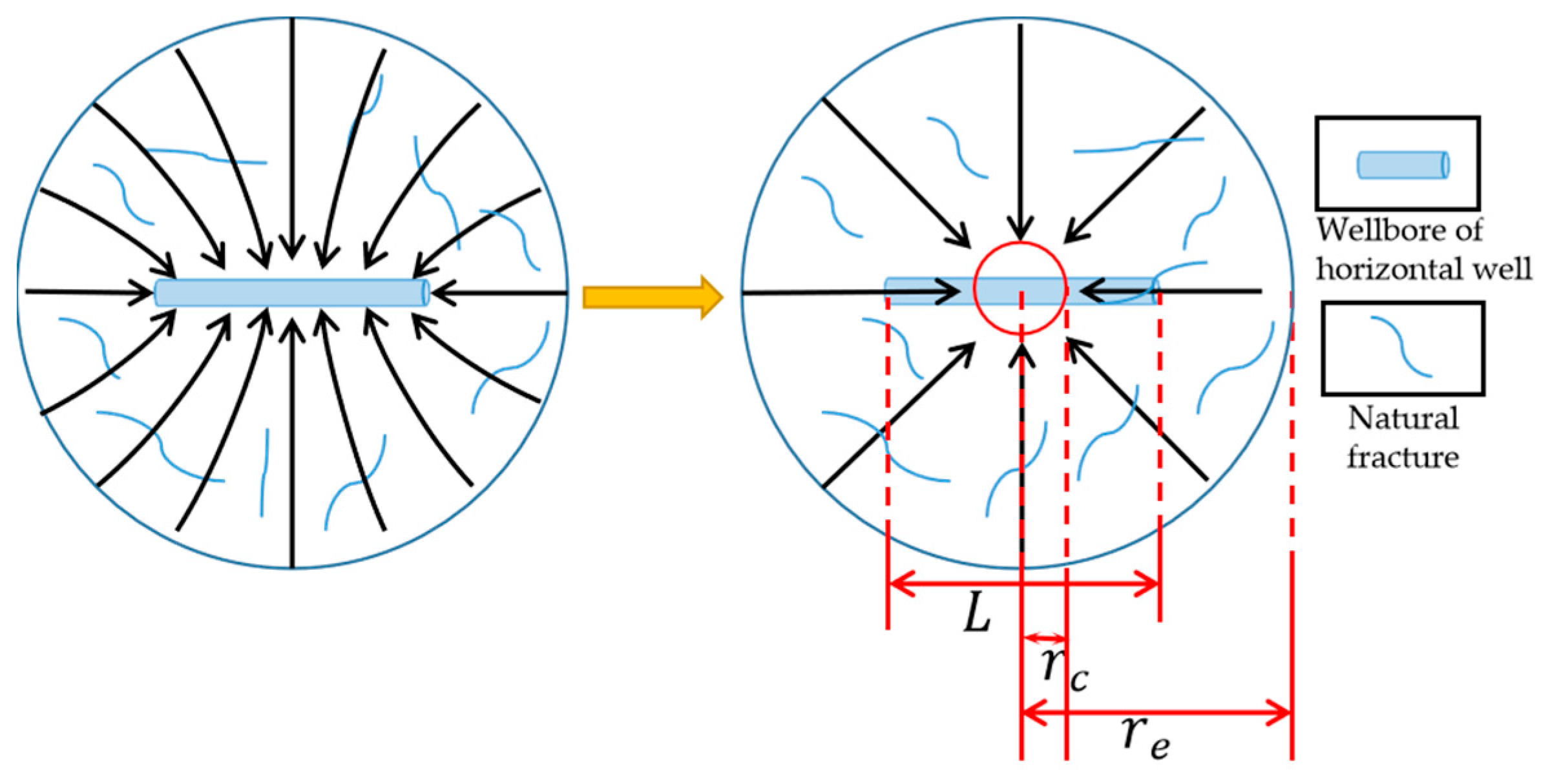

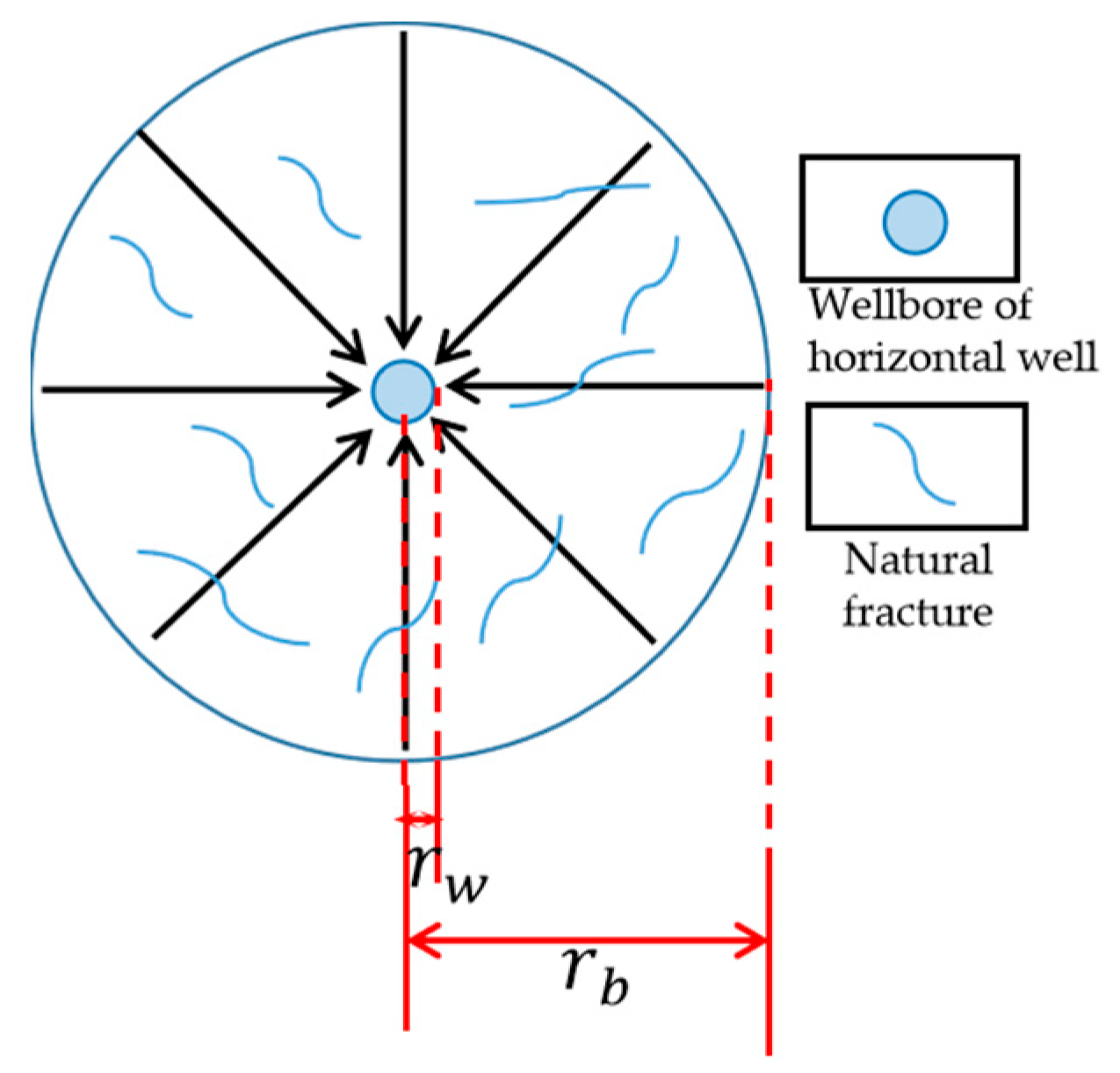

2.2.3. Capacity Modeling of Horizontal Wells with Natural Fractures

- xy-plane external seepage area

- xz-plane internal seepage zone

- Horizontal well steady-state capacity equation

3. Results

3.1. Example Applications

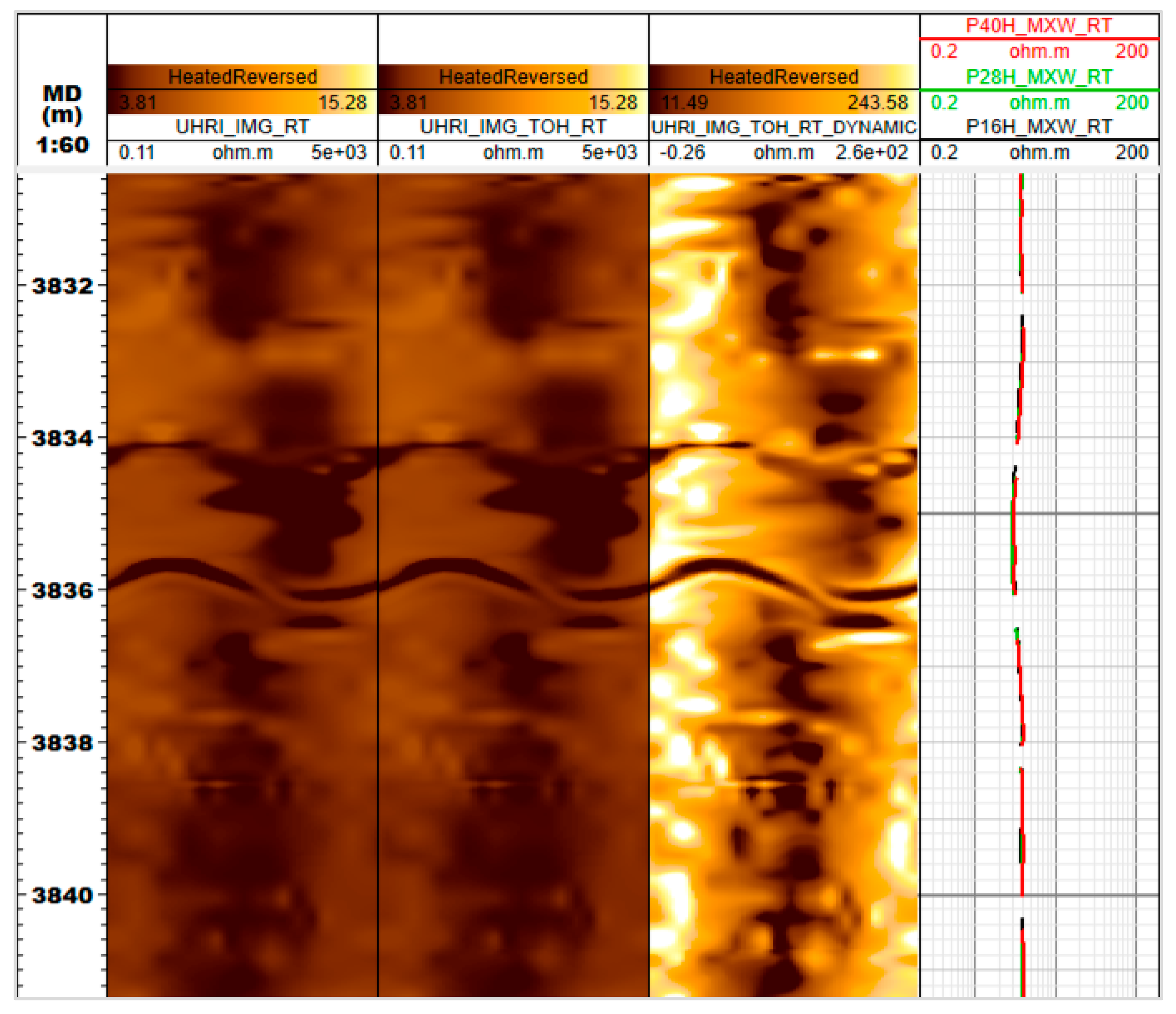

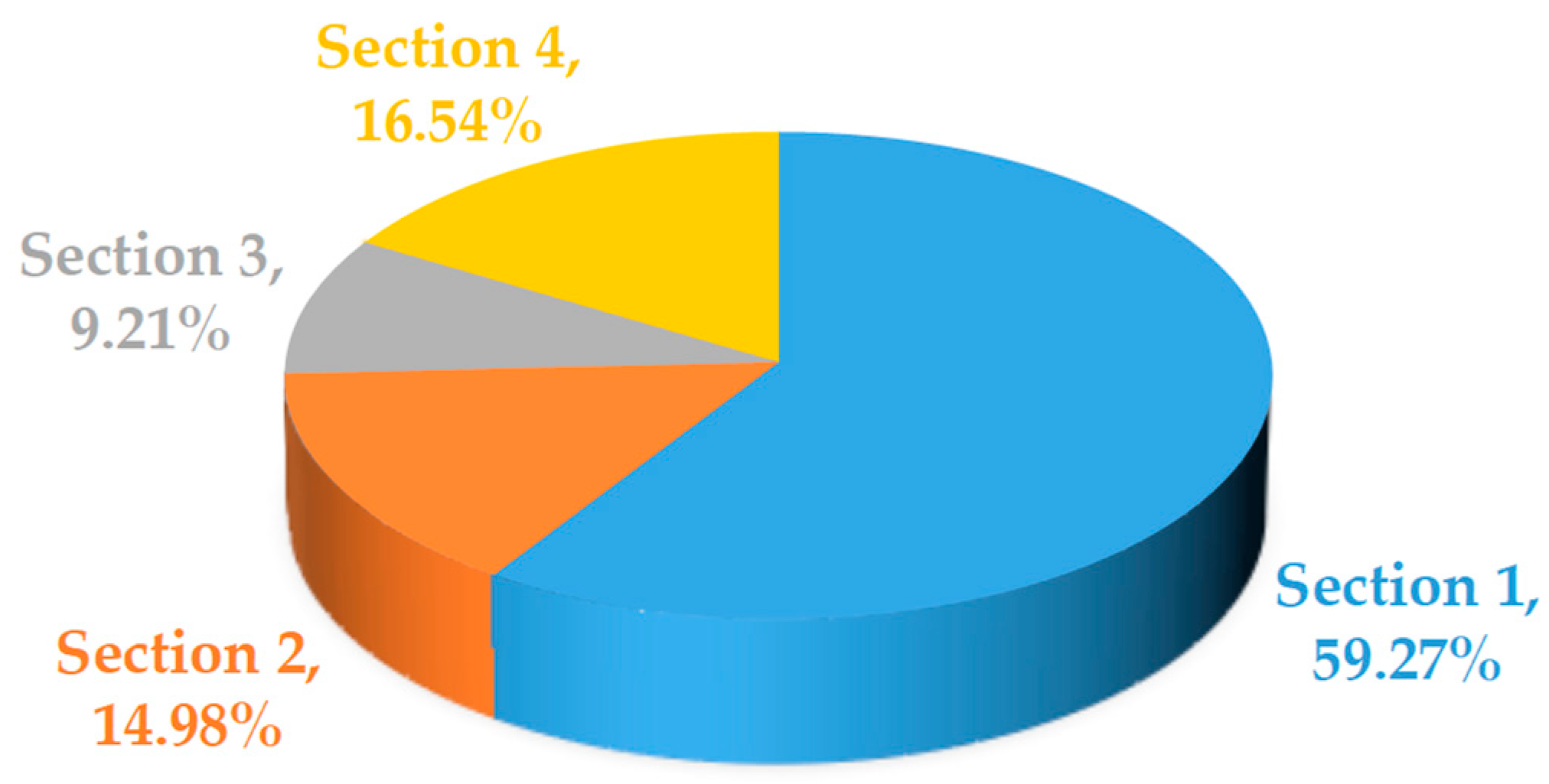

3.1.1. Overview of Foundations

3.1.2. Comparison and Validation of Capacity Forecasting Methods

- Example application and verification of horizontal wells

- Example application and verification of vertical wells

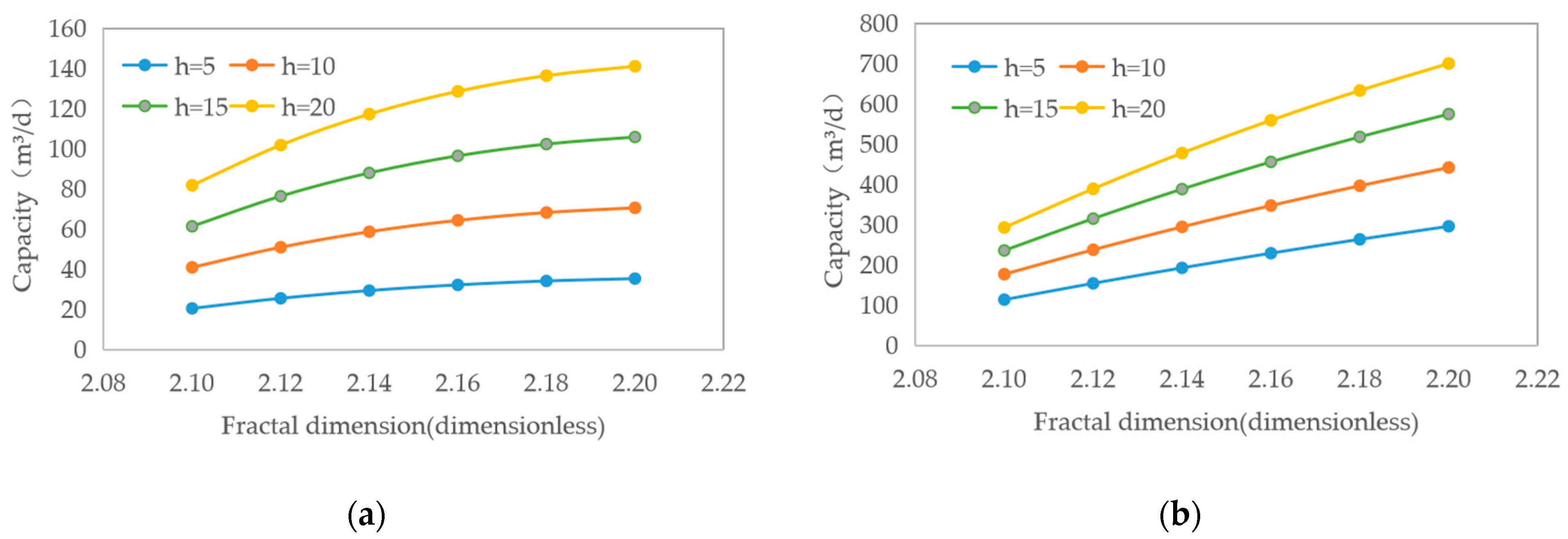

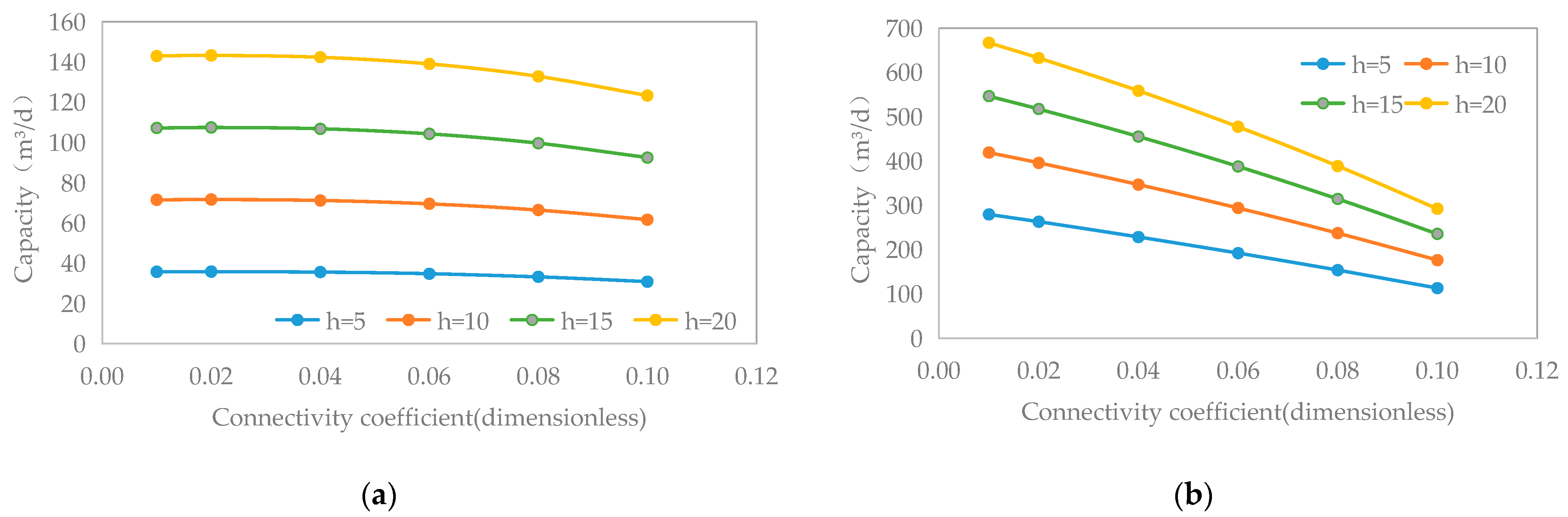

4. Discussion

5. Conclusions

- Aiming at the problems of traditional methods in predicting the production of offshore low-permeability reservoirs with natural fractures and the inappropriateness of traditional methods in capacity evaluation, the fractal theory is introduced to reasonably characterize the permeability of low-permeability reservoirs with natural fractures, and the steady-state capacity prediction model of vertical and horizontal wells are established, which comprehensively considers the effects of fractal fractures, threshold pressure gradient, and stress sensitivity of low-permeability limestone reservoirs. To further reveal the strong longitudinal heterogeneity during the drilling of vertical wells, it is suggested that considering the longitudinal gradient through logging curves in the evaluation of vertical well capacity can more accurately evaluate the capacity of this type of reservoir and characterize the strong longitudinal heterogeneity of this type of reservoir.

- Application examples demonstrate that our method significantly outperforms conventional models, with an average error reduction to less than 15%.

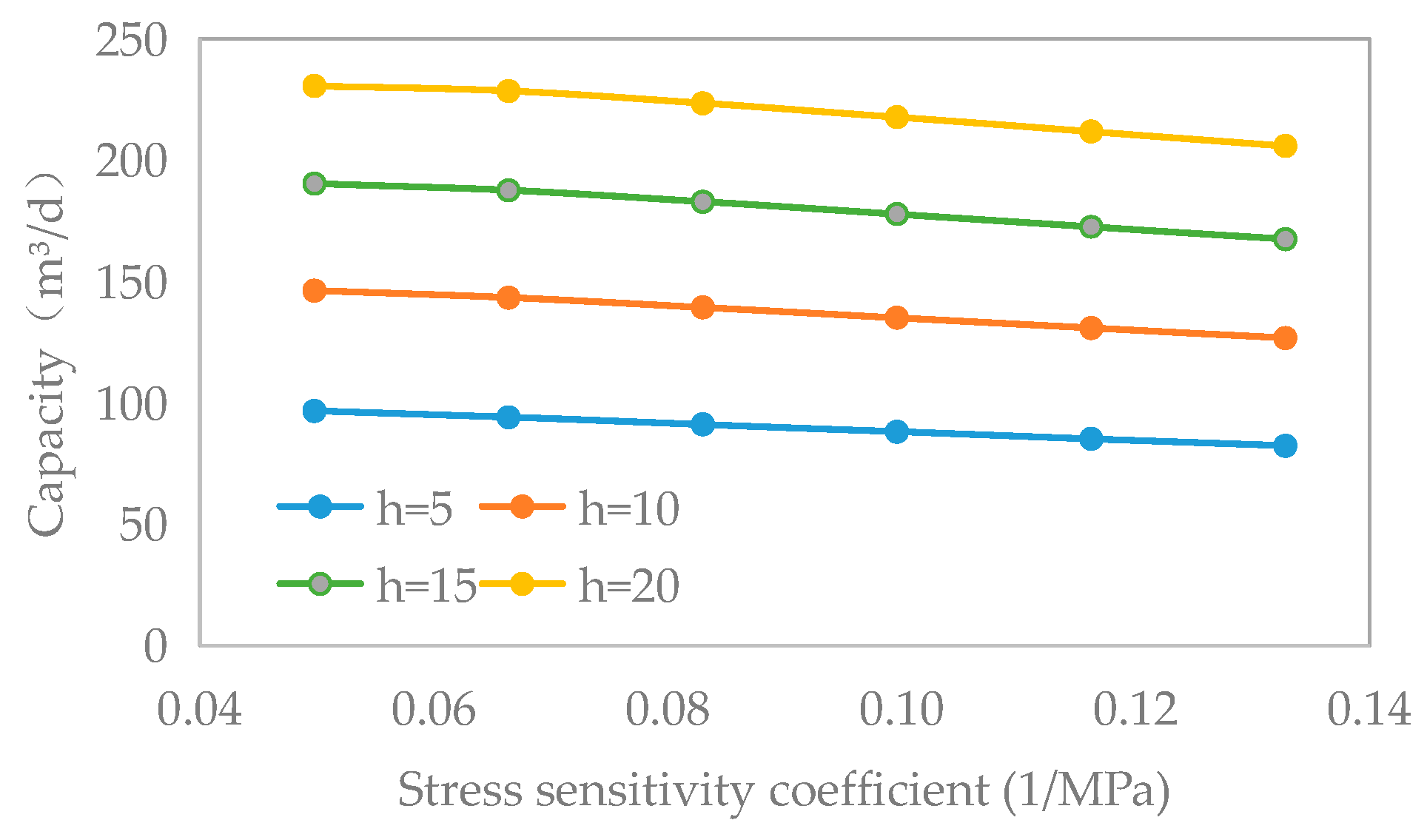

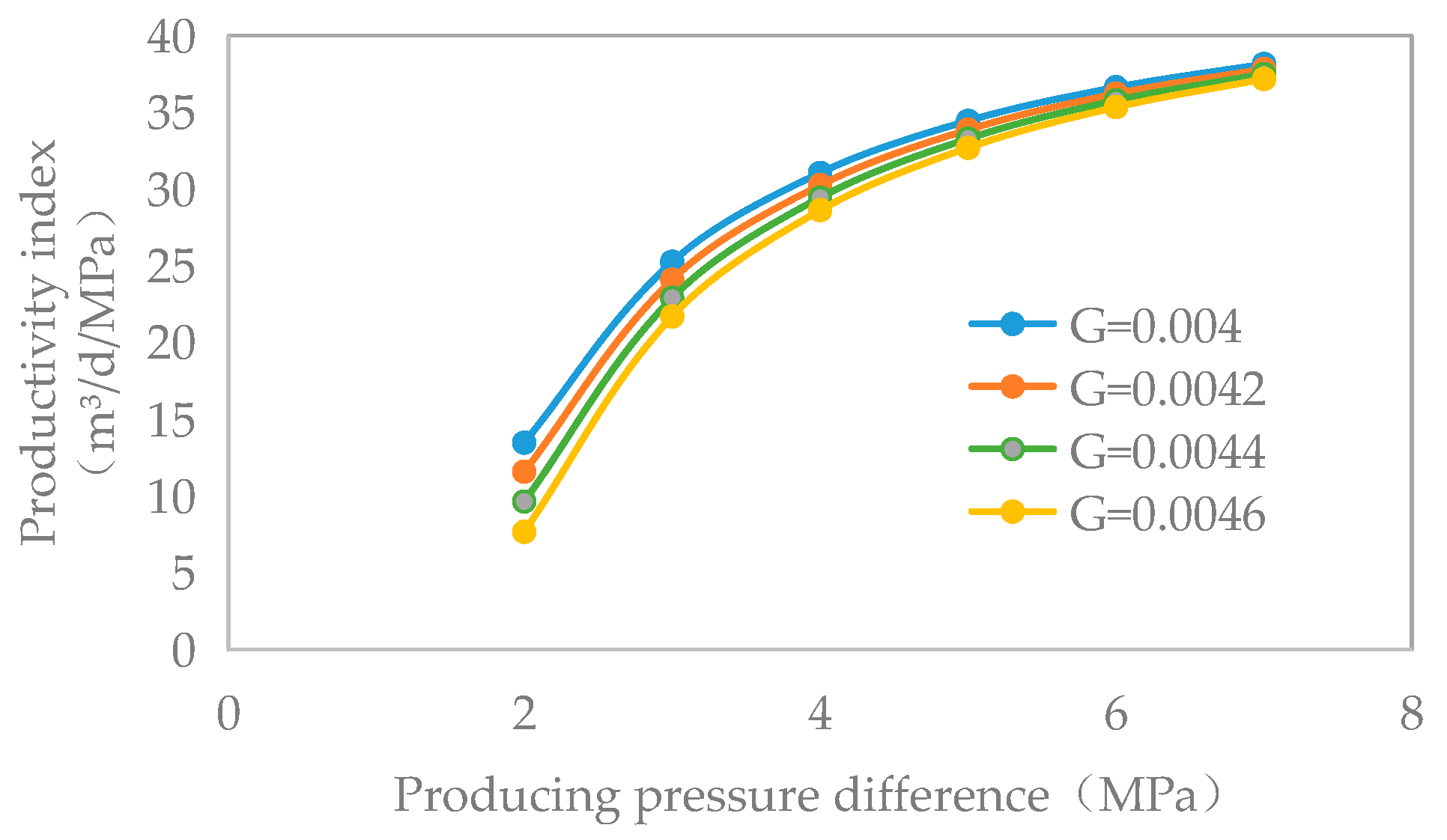

- A high-density fracture network increases the permeability and fluid mobility of the rock, which significantly improves well capacity. In addition, the increase in fractal dimension reflects the increased complexity of the fracture network, which further increases the probability of intersection between horizontal wells and effective fractures, thus facilitating the oil recovery. A lower connectivity coefficient θ is associated with higher production capacity, indicating that optimizing the connectivity of the fracture network is critical for the aggregation and seepage of crude oil. A lower threshold pressure gradient is favorable to achieve higher oil recovery efficiency under smaller producing pressure difference. The relationship between the production pressure difference and productivity index is not a simple linear relationship; it is not recommended that horizontal wells in low-permeability reservoirs containing natural fractures produce under an excessive producing pressure difference.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhu, W. Advancements of Oil and Gas Exploration in China Offshore Area: Overview and Perspective. Strateg. Study CAE 2010, 12, 18–24. [Google Scholar]

- Ashraf, U.; Zhang, H.; Anees, A.; Ali, M.; Zhang, X.; Abbasi, S.S.; Mangi, H.N. Controls on Reservoir Heterogeneity of a Shallow-Marine Reservoir in Sawan Gas Field, SE Pakistan: Implications for Reservoir Quality Prediction Using Acoustic Impedance Inversion. Water 2020, 12, 2972. [Google Scholar] [CrossRef]

- Liu, J.; Liu, J. Machine Learning Technique for the Quantitative Evaluation of Tight Sandstone Reservoirs Using High-Pressure Mercury-Injection Data; Oral, 2020. Available online: https://meetingorganizer.copernicus.org/EGU2020/EGU2020-17007.html (accessed on 8 January 2024).

- Nzekwu, A.I.; Abraham-A, R.M. Reservoir Sands Characterisation Involving Capacity Prediction in NZ Oil and Gas Field, Offshore Niger Delta, Nigeria. AIMS Geosci. 2022, 8, 159–174. [Google Scholar] [CrossRef]

- Wang, K.; Li, L.; Chen, X.; Liang, W.; Yang, Y.; Yan, Z.; Dai, J.; Li, W.; Wang, Y.; Wang, W.; et al. A New Method for Research on Unsteady Pressure Dynamics and Productivity of Ultralow-Permeability Reservoirs. Geofluids 2021, 2021, 9926853. [Google Scholar] [CrossRef]

- Alali, Z.H.; Horne, R.N. A Comparative Study of Deep Learning Models and Traditional Methods in Forecasting Oil Production in the Volve Field. In Proceedings of the SPE Annual Technical Conference and Exhibition, San Antonio, TX, USA, 21–23 November 2023; SPE: San Antonio, Texas, USA, 2023; p. D031S032R003. [Google Scholar]

- Chen, Y.; Lan, W.; Wang, C. Application of MES System in Offshore Oil and Gas Field Production Management. J. Big Data 2019, 1, 47–54. [Google Scholar] [CrossRef]

- Babanezhad, M.; Behroyan, I.; Nakhjiri, A.T.; Marjani, A.; Shirazian, S. Performance and application analysis of ANFIS artificial intelligence for pressure prediction of nanofluid convective flow in a heated pipe. Sci. Rep. 2021, 11, 902. [Google Scholar] [CrossRef]

- He, X.; Zhu, W.; Santoso, R.; Alsinan, M.; Kwak, H.; Hoteit, H. Fracture Permeability Estimation Under Complex Physics: A Data-Driven Model Using Machine Learning; OnePetro: Richardson, TX, USA, 2021. [Google Scholar]

- Gao, L.; Tang, Y.T.; Wu, S.; Deev, A.; Olson, R.; Mosca, F.; Zhang, S.; Ni, Y.; Qu, Q.; LaFollette, R.; et al. The gas isotope interpretation tool: A novel method to better predict production decline. AAPG Bull. 2017, 101, 1263–1275. [Google Scholar] [CrossRef]

- Arps, J. Analysis of Decline Curves. Trans. AIME 1945, 160, 228–247. [Google Scholar] [CrossRef]

- Shin, H.-J.; Lim, J.-S.; Shin, S.-H. Estimated ultimate recovery prediction using oil and gas production decline curve analysis and cash flow analysis for resource play. Geosystem Eng. 2014, 17, 78–87. [Google Scholar] [CrossRef]

- Harsh, A. Semi-Analytical Modeling of Water Injection under Fracturing Conditions by Capturing Effects of Formation Damage Mechanisms to Predict Fracture Propagation. Master’s Thesis, Delft University of Technology, Delft, The Netherlands, 2017. [Google Scholar]

- Li, M.; Bi, G.; Shi, Y.; Zhao, K. A semi-analytical two-phase flow model of fractured horizontal well with complex fracture networks in natural fractured reservoirs. Energy Explor. Exploit. 2022, 40, 174–192. [Google Scholar] [CrossRef]

- Salih, I.S.; Baker, H.A. Development of a Semi-Analytical Type Curve of Transient Pressure Response in Complex Well-Reservoir Architectures. Iraqi J. Chem. Pet. Eng. 2019, 20, 61–69. [Google Scholar] [CrossRef]

- Jing, W.; Xiao, L.; Haixia, H.; Wei, L. Productivity Prediction and Simulation Verification of Fishbone Multilateral Wells. Geofluids 2022, 2022, 3415409. [Google Scholar] [CrossRef]

- Liu, Z.; Li, S.; Li, L. Research on oil and gas production prediction process based on machine learning. Int. J. Energy 2023, 2, 76–79. [Google Scholar] [CrossRef]

- Zhang, H.; Peng, W.; Hao, P.; Du, M. A heterogeneous model for simulating fluid flow in naturally fractured-vuggy carbonate reservoirs. Int. J. Oil. Gas Coal Technol. 2019, 20, 397–419. [Google Scholar] [CrossRef]

- Gong, J.; Cao, L.; Guan, Y.; Tian, J.; Wang, T. Productivity Prediction Methods of Multi-Fractured Horizontal Wells in Low-Permeability Reservoirs: Progress and Challenges. Front. Energy Res. 2022, 10, 861333. [Google Scholar] [CrossRef]

- Li, J.; Xu, H.; Xiong, Q.; Yi, Y.; Zhou, W.; Zhang, L.; Chen, S.; Lian, L.; Zeng, M.; Yang, X.; et al. Study on the Influence of Natural Fracture Modeling on Hydraulic Fracture Propagation for Horizontal Wells in Unconventional Resource—A Case Study from China. In Proceedings of the Abu Dhabi International Petroleum Exhibition and Conference, Dubai, United Arab Emirates, 31 October–2 November 2022; SPE: Dubai, United Arab Emirates, 2022; p. D032S180R007. [Google Scholar]

- Xia, D.; Yang, Z.; Li, D.; Zhang, Y.; He, Y.; Luo, Y.; Zhang, A.; Wang, W.; Zhao, X. Evaluation Method of the Vertical Well Hydraulic Fracturing Effect Based on Production Data. Geofluids 2021, 2021, 9952719. [Google Scholar] [CrossRef]

- Yang, Y.; Xiong, W.; Liao, G.; Gao, S.; Shen, R.; Zhang, J.; Li, Q. Flow mechanism of production decline during natural depletion after hydraulic fracturing of horizontal wells in tight oil reservoirs. Pet. Sci. Technol. 2022, 40, 383–400. [Google Scholar] [CrossRef]

- Wang, F. Hydrogeological and Engineering Geological Significance of Fault Debris Fractal Dimension. In Proceedings of the GeoCongress 2012, American Society of Civil Engineers, Oakland, CA, USA, 29 March 2012; pp. 3543–3552. [Google Scholar]

- Babadagli, T.; Develi, K. Fractal Analysis of Natural and Synthetic Fracture Surfaces of Geothermal Reservoir Rocks. In Proceedings of the World Geothermal Congress, Kyushu-Tohoku, Japan, 28 May 2000. [Google Scholar]

- Yang, Y.; Liu, Z.; Yao, J.; Zhang, L.; Ma, J.; Hejazi, S.H.; Luquot, L.; Ngarta, T.D. Flow Simulation of Artificially Induced Microfractures Using Digital Rock and Lattice Boltzmann Methods. Energies 2018, 11, 2145. [Google Scholar] [CrossRef]

- Sheng, G.; Su, Y.; Wang, W.; Javadpour, F.; Tang, M. Application of Fractal Geometry in Evaluation of Effective Stimulated Reservoir Volume in Shale Gas Reservoirs. Fractals 2017, 25, 1740007. [Google Scholar] [CrossRef]

- Zhu, W.; Lei, G.; He, X.; Patzek, T.W.; Wang, M. Fractal and multifractal characterization of stochastic fracture networks and real outcrops. J. Struct. Geol. 2022, 155, 104508. [Google Scholar] [CrossRef]

- Cao, J.; Song, C. Calculation and improvement of the fractal dimension. Inf. Technol. Informatiz. 2017, 10, 19–23. [Google Scholar] [CrossRef]

- Xie, B.; Jiang, J.; Jia, J.; Ren, L.; Huang, B.; Huang, X. Partition seepage model and productivity analysis of fractured horizontal wells in tight reservoirs. Fault-Block Oil Gas Field 2019, 26, 324–328. [Google Scholar] [CrossRef]

- Li, X.; Liu, S.; Chen, Q.; Su, Y.; Sheng, G. An Evaluation of the Stimulation Effect of Horizontal Well Volumetric Fracturing in Tight Reservoirs with Complex Fracture Networks. Pet. Drill. Tech. 2019, 47, 73–82. [Google Scholar] [CrossRef]

- He, G.; Tang, H. Petrophysics; Petroleum Industry Press: Beijing, China, 2011. [Google Scholar]

- Joshi, S. Augmentation of Well Productivity With Slant and Horizontal Wells (includes associated papers 24547 and 25308). J. Pet. Technol. 1988, 40, 729–739. [Google Scholar] [CrossRef]

- Li, L. A boundary modification for water and electricity analogy experiment of fractured horizontal wells. Pet. Reserv. Eval. Dev. 2019, 9, 61–63+71. [Google Scholar] [CrossRef]

- Tian, W.; Deng, R.; Liu, Y.; Wang, M.; Gao, Z.; Hu, C.; Qiu, Y.; Zhao, Z. Effect of Drilling Fluid on Reservoir Damage and Productivity of Marine Reservoir. Sci. Technol. Eng. 2022, 22, 129–135. [Google Scholar] [CrossRef]

- Chen, Y. Derivation and Correlation of Production Rate Formula for Horizontal Well. Xinjiang Pet. Geol. 2008, 29, 68–71. [Google Scholar]

- Shan, B.; Fu, Y. Discussion and Analysis about Horizontal Well Productivity Formulas. Xinjiang Pet. Geol. 2015, 36, 624–628. [Google Scholar] [CrossRef]

- Chen, Y. Calculation Methods for Oil and Gas Reservoir Engineering; Petroleum Industry Press: Beijing, China, 1990. [Google Scholar]

- Borisov, J.P. Oil Production Using Horizontal and Multiple Deviation Wells; Nedra: Moscow, Russia, 1964; Volume 364. [Google Scholar]

| Parameters | Reservoir | Unit (of Measure) | |

|---|---|---|---|

| Zone A | Zone B | ||

| Crude oil volume factor | 1.041 | 1.041 | - |

| Formation Crude Oil Viscosity | 5.6 | 5.6 | mPa·s |

| Effective reservoir thickness | 4.9 | 5.7 | m |

| Permeability of matrix block | 0.0179 | 0.0412 | darcy |

| Natural fracture density | 0.006~0.0187 | 0.0005~0.001 | 1/cm |

| Average width of natural fracture | 186~778 | 189 | μm |

| Stress sensitivity factor | 0.0016~0.0034 | 0.0012~0.0028 | MPa−1 |

| Threshold pressure gradient | 0.004145499 | 0.001792092 | MPa/m |

| Initial formation pressure | 17.970~18.511 | 17.970~18.511 | MPa |

| Serial Number | Serial Number | Water-Soluble Tracer | Actual Lowering Position (m) | Permeability (mD) | Stratum (Geology) | |

|---|---|---|---|---|---|---|

| 1 | ZFFA-SRT01 | DWT-6 | 4050.8 | 4058.9 | 0.1–1 | Zone A |

| 2 | ZFFA-SRT02 | DWT-10 | 3570.5 | 3578.6 | 350–400 | Zone B |

| 3 | ZFFA-SRT03 | DWT-11 | 3248.5 | 3256.6 | 40–60 | Zone B |

| 4 | ZFFA-SRT04 | DWT-12 | 2786.3 | 2794.4 | 0.5–1 | Zone A |

| Notation | Physical Meaning | Parameter Value (Zone A) | Parameter Value (Zone B) | Unit (of Measure) |

|---|---|---|---|---|

| Bo | Crude oil volume factor | 1.041 | 1.041 | dimensionless |

| h | Effective reservoir thickness | 4.9 | 5.7 | m |

| km | Permeability of matrix block | 0.001 | 0.0412 | darcy |

| s | Natural fracture density | 0.0095 | 0.0016 | 1/cm |

| b | Average width of natural fracture | 380 | 210 | μm |

| D | Fractal dimension (math.) | 2.1 | 2.1 | dimensionless |

| θ | Abnormal diffusion coefficient (physics) | 0.05 | 0.05 | dimensionless |

| βk | Stress sensitivity factor | 0.0083 | 0.0027 | 1/MPa |

| µeff | Formation Crude Oil Viscosity | 5.6 | 5.6 | mPa·s |

| pe | Initial formation pressure | 17.97 | 17.97 | MPa |

| pw | Bottom hole pressure | 12.95 | 12.95 | MPa |

| G | Threshold pressure gradient | 0.0074 | 0.0018 | MPa/m |

| re | Supply radius | 720 | 2240 | m |

| L | Horizontal section length | 242 | 1120 | m |

| rw | Wellbore radius | 0.2159 | 0.2159 | m |

| Name of Well | Stratum (Geology) | Actual Capacity (m3/d) | Joshi Correction Formula (m3/d) | Chen Capacity Formula (m3/d) | New Capacity Formula (m3/d) | Error 1 (%) | Error 2 (%) | Error 3 (%) |

|---|---|---|---|---|---|---|---|---|

| 3H | Zone A/B | 90.20 | 48.24 | 32.26 | 82.56 | −46.52 | −64.23 | −8.47 |

| 4M | Zone A/B | 416.50 | 197.75 | 111.14 | 469.20 | −52.52 | −73.32 | 12.65 |

| 5M | Zone A/B | 459.60 | 218.61 | 135.37 | 393.68 | −52.43 | −70.55 | −14.34 |

| 6H | Zone A/B | 142.00 | 72.79 | 46.16 | 148.92 | −48.74 | −67.49 | 4.87 |

| 7M | Zone A | 239.00 | 53.37 | 37.43 | 207.52 | −77.67 | −84.34 | −13.17 |

| 8M | Zone A | 398.00 | 88.70 | 67.03 | 454.59 | −77.71 | −83.16 | 14.22 |

| 9H | Zone A/B | 288.00 | 192.45 | 104.83 | 307.15 | −33.18 | −63.60 | 6.65 |

| 10M | Zone A | 447.00 | 82.06 | 54.94 | 508.36 | −81.64 | −87.71 | 13.73 |

| 11H | Zone A/B | 307.30 | 154.20 | 101.70 | 324.51 | −49.82 | −66.90 | 5.60 |

| Notation | Physical Meaning | Parameter Value (Zone A) | Parameter Value (Zone B) | Unit (of Measure) |

|---|---|---|---|---|

| Bo | Crude oil volume factor | 1.041 | 1.041 | dimensionless |

| h | Effective reservoir thickness | 16 | 7 | m |

| km | Permeability of matrix block | 0.0231 | 0.0279 | darcy |

| s | Natural fracture density | 0.0172 | 0.0016 | 1/cm |

| b | Average width of natural fractures | 385 | 210 | μm |

| D | Fractal dimension (math.) | 2.2 | 2.2 | dimensionless |

| θ | Abnormal diffusion coefficient (physics) | 0.05 | 0.1 | dimensionless |

| βk | Stress sensitivity factor | 0.0032 | 0.003 | 1/MPa |

| μeff | Formation Crude Oil Viscosity | 5.6 | 5.6 | mPa·s |

| pe | Initial formation pressure | 17.97 | 17.97 | MPa |

| pw | Bottom hole pressure | 12.636 | 12.636 | MPa |

| G | Threshold pressure gradient | 0.0032 | 0.0027 | MPa/m |

| re | Supply radius | 1000 | 1000 | m |

| rw | Wellbore radius | 0.155 | 0.155 | m |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, K.; Xie, M.; Liu, W.; Li, L.; Liu, S.; Huang, R.; Feng, S.; Liu, G.; Li, M. New Method for Capacity Evaluation of Offshore Low-Permeability Reservoirs with Natural Fractures. Processes 2024, 12, 347. https://doi.org/10.3390/pr12020347

Wang K, Xie M, Liu W, Li L, Liu S, Huang R, Feng S, Liu G, Li M. New Method for Capacity Evaluation of Offshore Low-Permeability Reservoirs with Natural Fractures. Processes. 2024; 12(2):347. https://doi.org/10.3390/pr12020347

Chicago/Turabian StyleWang, Kun, Mingying Xie, Weixin Liu, Li Li, Siyu Liu, Ruijie Huang, Shasha Feng, Guotao Liu, and Min Li. 2024. "New Method for Capacity Evaluation of Offshore Low-Permeability Reservoirs with Natural Fractures" Processes 12, no. 2: 347. https://doi.org/10.3390/pr12020347

APA StyleWang, K., Xie, M., Liu, W., Li, L., Liu, S., Huang, R., Feng, S., Liu, G., & Li, M. (2024). New Method for Capacity Evaluation of Offshore Low-Permeability Reservoirs with Natural Fractures. Processes, 12(2), 347. https://doi.org/10.3390/pr12020347