The Relationship between Rehydration Time and Tenderness at Different Rehydrating Water Temperatures in Freeze-Dried Pork Loin

Abstract

:1. Introduction

2. Materials and Methods

2.1. Preparing Samples

2.2. Surface Analysis

2.3. Texture Analysis

2.4. Statistical Analysis

3. Results

3.1. Surface Analysis

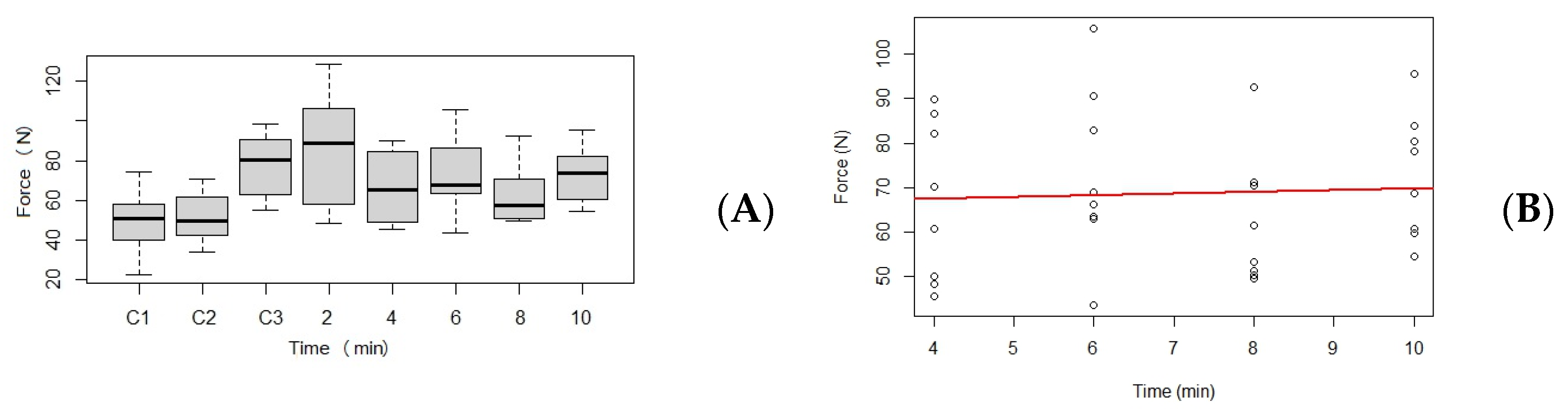

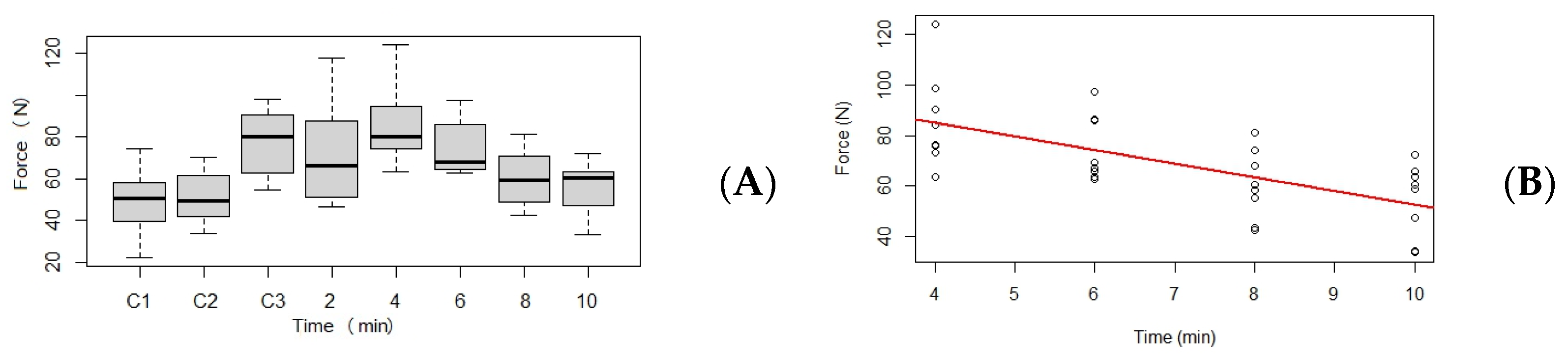

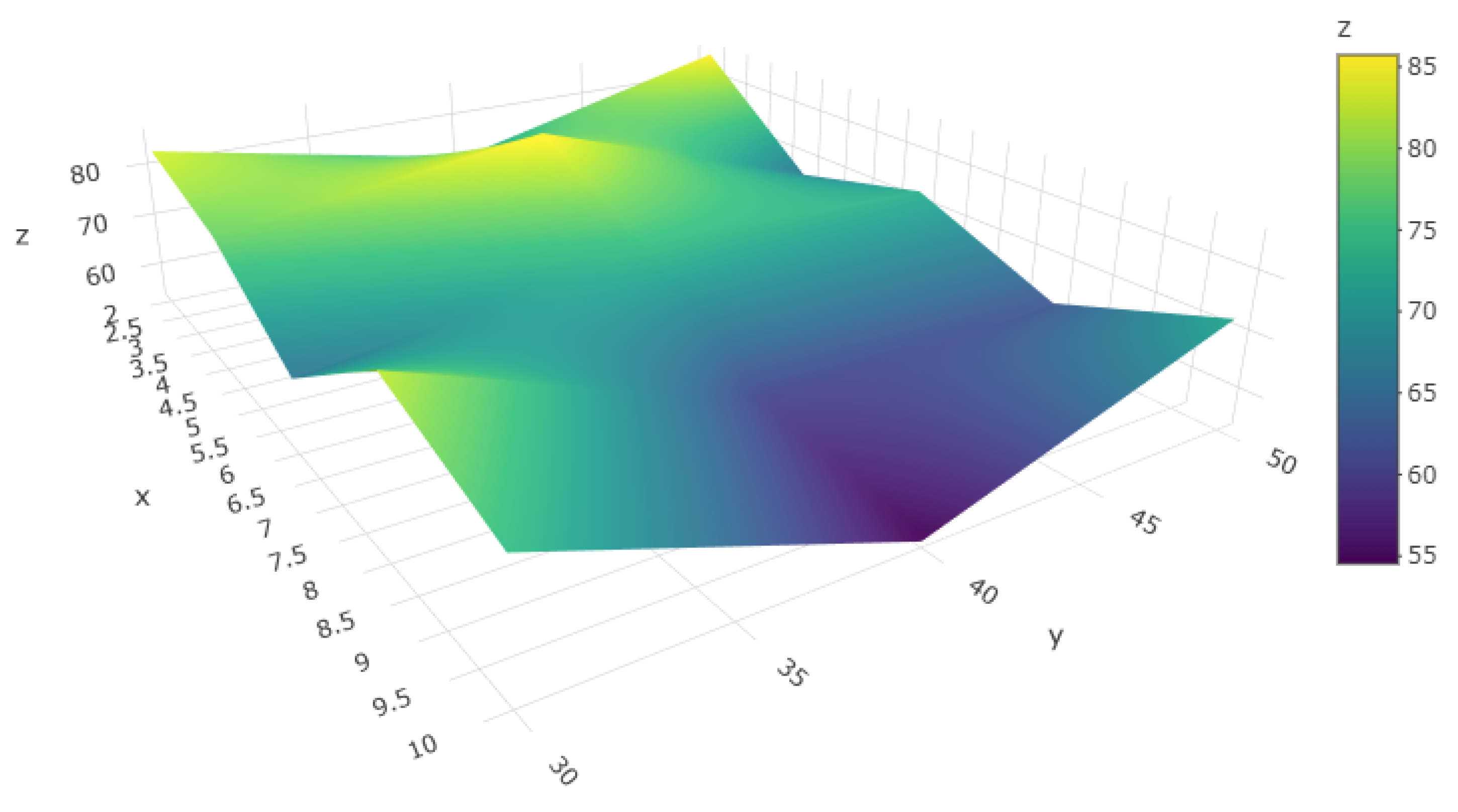

3.2. Texture Analysis

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Maltin, C.; Balcerzak, D.; Tilley, R.; Delday, M. Determinants of meat quality: Tenderness. Proc. Nutr. Soc. 2003, 62, 337–347. [Google Scholar] [CrossRef] [PubMed]

- Sørheim, O.; Idland, J.; Halvorsen, E.C.; Frøystein, T.; Lea, P.; Hildrum, K.I. Influence of beef carcass stretching and chilling rate on tenderness of m. longissimus dorsi. Meat Sci. 2001, 57, 79–85. [Google Scholar] [CrossRef]

- Tornberg, E. Biophysical aspects of meat tenderness. Meat Sci. 1996, 43, 175–191. [Google Scholar] [CrossRef]

- Karwacka, M.; Ciurzyńska, A.; Galus, S.; Janowicz, M. Freeze-dried snacks obtained from frozen vegetable by-products and apple pomace—Selected properties, energy consumption and carbon footprint. Innov. Food Sci. Emerg. Technol. 2022, 77, 102949. [Google Scholar] [CrossRef]

- Szcześniak, A.S.; Torgeson, K.W. Methods of meat texture measurement viewed from the background of factors affecting tenderness. Adv. Food Res. 1965, 14, 33–165. [Google Scholar] [CrossRef] [PubMed]

- Floor, K.G.; Schreuders; Schlangen, M.; Kyriakopoulou, K.; Boom, R.M.; Jan van der Goot, A. Texture methods for evaluating meat and meat analogue structures. Food Control. 2021, 127, 108103. [Google Scholar] [CrossRef]

- AMSA. Research Guidelines for Cookery, Sensory Evaluation, and Instrumental Tenderness Measurements of Meat, 2nd ed.; American Meat Science Association: Champaign, IL, USA, 2015. [Google Scholar]

- Wheeler, T.L.; Koohmaraie, M.; Cundiff, L.V.; Dikeman, M.E. Effects of cooking and shearing methodology on variation in warner-bratzler shear force values in beef. J. Anim. Sci. 1994, 72, 2325–2330. [Google Scholar] [CrossRef] [PubMed]

- Boccard, R.; Buchter, L.; Casteels, E.; Cosentino, E.; Dransfield, E.; Hood, D.E.; Joseph, R.L.; Macdougall, D.B.; Rhodes, D.N.; Schön, I.; et al. Procedures for Measuring Meat Quality Characteristics in Beef Production Experiments; Report of a Working Group in the Commission of the European Communities’ (cec), Beef Production Research Programme; Livestock Production Science Elsevier Scientific Publishing Company: Amsterdam, The Netherlands, 1981; Volume 8, pp. 385–397. [Google Scholar] [CrossRef]

- Nethery, T.N.; Boler, D.D.; Harsh, B.N.; Dilger, A.C. Relationship between Inherent Cooking Rate and Warner-Bratzler Shear Force of Pork Chops Cooked to Two Degrees of Doneness. Foods 2022, 11, 131. [Google Scholar] [CrossRef]

- Møller, A.J. Analysis of warner-bratzler shear pattern with regard to myofibrillar and connective tissue components of tenderness. Meat Sci. 1981, 5, 247–260. [Google Scholar] [CrossRef]

- Mckenna, D.R.; King, D.A.; Savell, J.W. Comparison of clam-shell cookers and electric broilers and their effects on cooking traits and repeatability of warner-bratzler shear force values. Meat Sci. 2004, 66, 225–229. [Google Scholar] [CrossRef]

- Wheeler, T.L.; Shackelford, S.D.; Koohmaraie, M. Sampling, cooking, and coring effects on warner-bratzler shear force values in beef. J. Anim. Sci. 1996, 74, 1553–1562. [Google Scholar] [CrossRef]

- Wheeler, T.L.; Shackelford, S.D.; Johnson, L.P.; Miller, M.F.; Miller, R.K.; Koohmaraie, M. A comparison of warner-bratzler shear force assessment within and among institutions. J. Anim. Sci. 1997, 75, 2423–2432. [Google Scholar] [CrossRef] [PubMed]

- Apple, J.K.; Rakes, L.K.; Watson, H.B. Cooking and shearing methodology effects on warner-bratzler shear force values of pork. J. Muscle Foods 1999, 10, 269–277. [Google Scholar] [CrossRef]

- Kerth, C.R.; Blair-Kerth, L.K.; Jones, W.R. Warner-bratzler shear force repeatability in beef longissimus steaks cooked with a convection oven, broiler, or clam-shell grill. J. Food Sci. 2003, 68, 668–669. [Google Scholar] [CrossRef]

- Crouse, J.D.; Theer, L.K.; Seideman, S.C. The measurement of shear force by core location in longissimus dorsi beef steaks from four tenderness groups1. J. Food Qual. 1989, 11, 341–347. [Google Scholar] [CrossRef]

- Jeremiah, L.E.; Murray, A.C. The influence of anatomical location within the longissimus dorsi muscle on overall tenderness and on the concentration and solubility of intramuscular collagen. Can. J. Anim. Sci. 1984, 64, 1045–1047. [Google Scholar] [CrossRef]

- Francis, S.J.; Allen, D.M.; Kastner, C.L.; De Felicio, P.E. The effect of coring method on beef longissimus muscle shear force values. J. Anim. Sci. 1981, 52, 1294–1297. [Google Scholar] [CrossRef]

- Adams, G. The principles of freeze-drying. Methods Mol. Biol. 2007, 368, 15–38. [Google Scholar] [CrossRef] [PubMed]

- Jia, Y.; Khalifa, I.; Hu, L.; Zhu, W.; Li, J.; Li, K.; Li, C. Influence of three different drying techniques on persimmon chips’ characteristics: A comparison study among hot-air, combined hot-air-microwave, and vacuum-freeze drying techniques. Food Bioprod. Process. 2019, 118, 67–76. [Google Scholar] [CrossRef]

- Meda, L.; Ratti, C. Rehydration of freeze-dried strawberries at varying temperatures. J. Food Process Eng. 2005, 28, 233–246. [Google Scholar] [CrossRef]

- Tang, X.; Pikal, M.J. Design of freeze-drying processes for pharmaceuticals: Practical advice. Pharm. Res. 2004, 21, 191–200. [Google Scholar] [CrossRef] [PubMed]

- Nowak, D.; Jakubczyk, E. The freeze-drying of foods—The characteristic of the process course and the effect of its parameters on the physical properties of food materials. Foods 2020, 9, 1488. [Google Scholar] [CrossRef] [PubMed]

- Ratti, C. 3-Freeze drying for food powder production. In Handbook of Food Powders; Woodhead Publishing Series in Food Science, Technology and Nutrition; Bhandari, B., Bansal, N., Zhang, M., Schuck, P., Eds.; Woodhead Publishing Witney: Oxford, UK, 2013; pp. 57–84. [Google Scholar] [CrossRef]

- Sablani, S.S. Drying of fruits and vegetables: Retention of nutritional/functional quality. Dry. Technol. 2006, 24, 123–135. [Google Scholar] [CrossRef]

- Mayer, A.M.; Harel, E. Polyphenol oxidases in plants. Phytochemistry 1979, 18, 193–215. [Google Scholar] [CrossRef]

- Bonnie, T.P.; Choo, Y. Oxidation and thermal degradation of carotenoids. J. Oil Palm Res. 1999, 1, 62–78. [Google Scholar]

- Bird, K. Freeze-Dried Foods: Palatability Tests; U.S. Dept. Of Agriculture, Economic Research Service, Marketing Economics Division: Washington, DC, USA, 1963.

- Connell, J.J. Some aspects of the texture of dehydrated fish. J. Sci. Food Agric. 1957, 9, 526–537. [Google Scholar] [CrossRef]

- Aykın, E.; Erbaş, M. Quality properties and adsorption behavior of freeze-dried beef meat from the biceps femoris and semimembranosus muscles. Meat Sci. 2016, 121, 272–277. [Google Scholar] [CrossRef]

- Destefanis, G.; Brugiapaglia, A.; Barge, M.T.; Dal Molin, E. Relationship between beef consumer tenderness perception and warner–bratzler shear force. Meat Sci. 2008, 78, 153–156. [Google Scholar] [CrossRef]

- Nowacka, M.; Mannozzi, C.; Dalla Rosa, M.; Tylewicz, U. Sustainable Approach for Development Dried Snack Based on Actinidia deliciosa Kiwifruit. Appl. Sci. 2023, 13, 2189. [Google Scholar]

- Defense Logistics Agency. The Nation’s Combat Logistics Support Agency. Available online: https://www.dla.mil/Portals/104/Documents/TroopSupport/Subsistence/Rations/pcrs/misc/dehybib/b053b.pdf (accessed on 10 September 2023).

- 2R Core Team. R: A Language and Environment for Statistical Computing. R Foundation for Statistical Computing, Vienna, Austria. 2022. Available online: https://www.R-project.org/ (accessed on 26 February 2023).

- Cama-Moncunill, R.; Cafferky, J.; Augier, C.; Sweeney, T.; Allen, P.; Ferragina, A.; Sullivan, C.; Cromie, A.; Hamill, R.M. Prediction of warner-bratzler shear force, intramuscular fat, drip-loss and cook-loss in beef via raman spectroscopy and chemometrics. Meat Sci. 2020, 167, 108–157. [Google Scholar] [CrossRef]

- Shackelford, S.D.; Wheeler, T.L.; Koohmaraie, M. Evaluation of slice shear force as an objective method of assessing beef longissimus tenderness. J. Anim. Sci. 1999, 77, 2693–2699. [Google Scholar] [CrossRef]

- Wyrwisz, J.; Moczkowska, M.; Kurek, M.A.; Karp, S.; Atanasov, A.G.; Wierzbicka, A. Evaluation of wbsf, color, cooking loss of longissimus lumborum muscle with fiber optic near-infrared spectroscopy (ft-nir), depending on aging time. Molecules 2019, 24, 757. [Google Scholar] [CrossRef]

- Suden, J.R.; Pearson, A.M.; Dugan, L.R., Jr. Rehydration of Freeze-Dried Pork as Related to pH and Protein Denaturation. J. Food Sci. 1964, 29, 192–197. [Google Scholar] [CrossRef]

- Lee, S.; Choi, Y.S.; Jo, K.; Jeong, H.G.; Yong, H.I.; Kim, T.K.; Jung, S. Processing Characteristics of Freeze-Dried Pork Powder for Meat Emulsion Gel. Food Sci. Anim. Resour. 2021, 41, 997–1011. [Google Scholar] [CrossRef]

- Watson, E.L.; Ni, Y.W.; Richards, J.F. Effect of Irradiation and Freezing Rate on Rehydration of Freeze dried Beef. Can. Inst. Food Sci. Technol. J. 1974, 7, 232–235. [Google Scholar] [CrossRef]

- Ayrosa, A.M.I.B.; Pitombo, R.N.D.M. Influence of plate temperature and mode of rehydration on textural parameters of precooked freeze-dried beef. J. Food Process. Preserv. 2003, 27, 173–180. [Google Scholar] [CrossRef]

- Szcześniak, A.S. Effect of mode of rehydration on textural parameters of precooked freeze-dried sliced beef. J. Texture Stud. 1971, 2, 18–30. [Google Scholar] [CrossRef]

- Marabi, A.; Livings, S.; Jacobson, M.; Saguy, I.S. Normalized Weibull distribution for modeling rehydration of food particulates. Eur. Food Res. Technol. 2003, 217, 311–318. [Google Scholar] [CrossRef]

- Roos, Y.H. Glass Transition Temperature and Its Relevance in Food Processing. Ann. Rev. Food Sci. Tech. 2010, 1, 469–496. [Google Scholar] [CrossRef]

- Khalloufi, S.; El-Maslouhi, Y.; Ratti, C. Mathematical model for prediction of glass transition temperature of fruit powders. J. Food Sci. 2000, 65, 842–848. [Google Scholar] [CrossRef]

| Cooked Temperature (°C) | Rehydration Water Temperature (°C) | Rehydration Time (min) | Maximum Shear Force Mean ± SD (N) | Maximum Shear Force Coefficient of Variation (N) | Maximum Shear Force Standard Error (N) |

|---|---|---|---|---|---|

| 100 | 80 | Control | 49.8 ± 14.1 | 28.4 | 3.65 |

| 120 | 80 | Control | 51.3 ± 11.4 | 22.2 | 2.55 |

| 120 | 50 | Control | 77.8 ± 14.8 | 19.0 | 4.68 |

| 120 | 40 | Control | 89.6 ± 18.2 | 20.3 | 8.15 |

| 120 | 50 | 2 | 85.4 ± 29.6 | 34.6 | 10.45 |

| 120 | 50 | 4 | 66.6 ± 18.1 | 27.1 | 6.4 |

| 120 | 50 | 6 | 73.0 ± 19.2 | 26.3 | 6.8 |

| 120 | 50 | 8 | 62.5 ± 15.0 | 24.0 | 5.31 |

| 120 | 50 | 10 | 72.7 ± 14.1 | 19.4 | 4.98 |

| 120 | 40 | 2 | 71.7 ± 25.1 | 35.0 | 8.87 |

| 120 | 40 | 4 | 85.7 ± 18.8 | 22.0 | 6.66 |

| 120 | 40 | 6 | 74.7 ± 13.2 | 17.6 | 4.66 |

| 120 | 40 | 8 | 60.3 ± 13.7 | 22.8 | 4.86 |

| 120 | 40 | 10 | 54.5 ± 14.5 | 26.6 | 5.13 |

| 120 | 30 | 2 | 83.4 ± 18.2 | 21.8 | 7.42 |

| 120 | 30 | 4 | 77.9 ± 19.2 | 24.7 | 7.26 |

| 120 | 30 | 6 | 66.4 ± 33.1 | 49.9 | 12.51 |

| 120 | 30 | 8 | 82.3 ± 25.4 | 30.9 | 9.60 |

| 120 | 30 | 10 | 74.7 ± 19.3 | 25.9 | 8.64 |

| p Values of Difference between Rehydrating Times | ||||

|---|---|---|---|---|

| Rehydrating Time (min) | 4 | 6 | 8 | 10 |

| 4 | - | 0.06247 | 0.079516 | 0.006072 * |

| 6 | - | 0.734841 | 0.209545 | |

| 8 | - | 0.509765 | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Répás, Z.; Prokisch, J.; Győri, Z.; Sipos, P. The Relationship between Rehydration Time and Tenderness at Different Rehydrating Water Temperatures in Freeze-Dried Pork Loin. Processes 2023, 11, 2822. https://doi.org/10.3390/pr11102822

Répás Z, Prokisch J, Győri Z, Sipos P. The Relationship between Rehydration Time and Tenderness at Different Rehydrating Water Temperatures in Freeze-Dried Pork Loin. Processes. 2023; 11(10):2822. https://doi.org/10.3390/pr11102822

Chicago/Turabian StyleRépás, Zoltán, József Prokisch, Zoltán Győri, and Péter Sipos. 2023. "The Relationship between Rehydration Time and Tenderness at Different Rehydrating Water Temperatures in Freeze-Dried Pork Loin" Processes 11, no. 10: 2822. https://doi.org/10.3390/pr11102822