Techno-Economic Assessment of Producer Gas from Heavy Oil and Biomass Co-Gasification Aiming Electricity Generation in Rankine Cycle

Abstract

1. Introduction

2. Materials and Methods

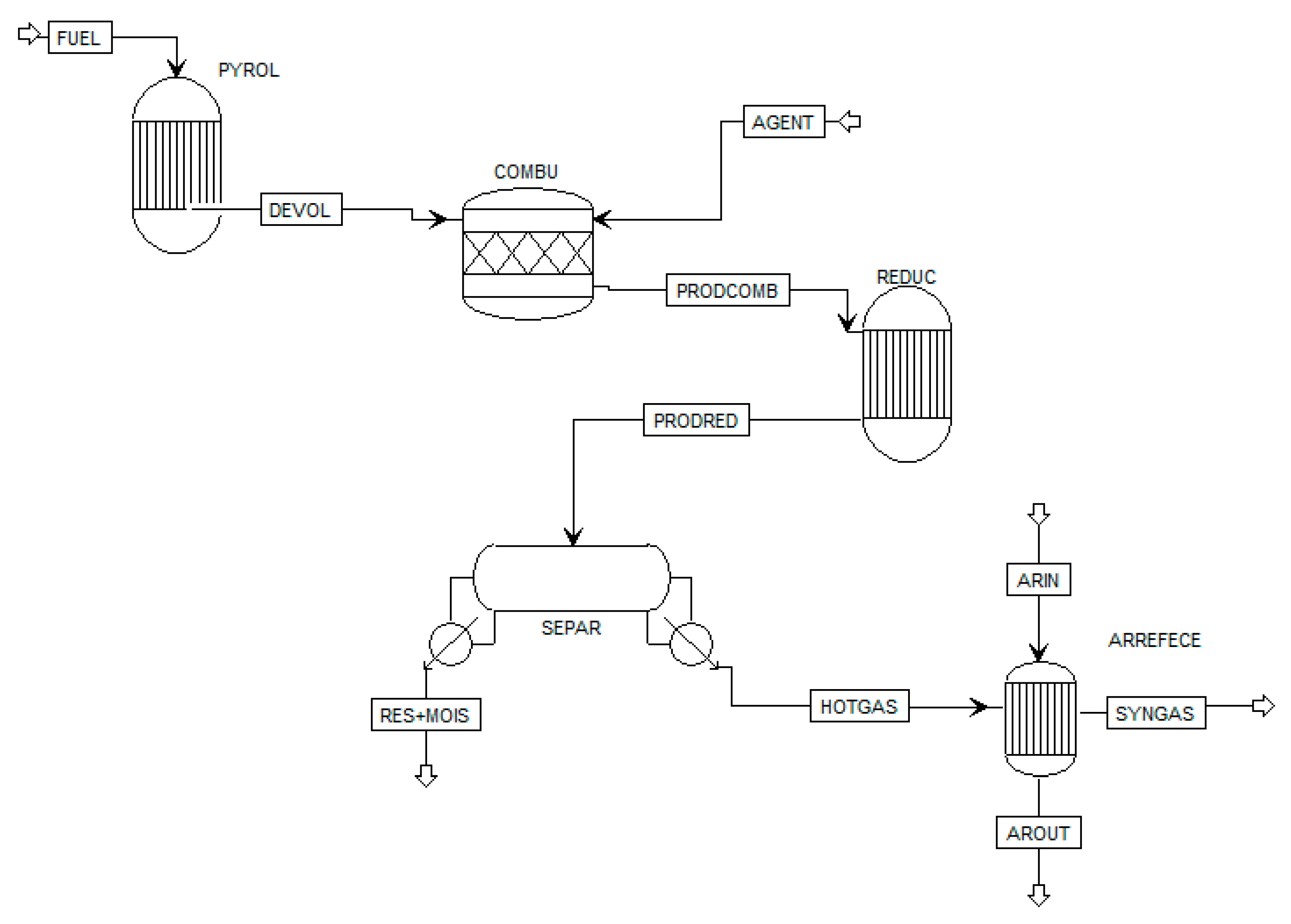

2.1. Description of Gasification Model

2.1.1. Assumptions Applied to Develop the Gasification Model

- The residence time is long enough to allow the chemical balance to be reached; thus, the gasification process occurs in a steady state regime;

- The reactor is entirely isothermal;

- Chemical reactions are considered time-independent;

- Tar formation is negligible;

- The process is adiabatic;

- The reactor operates at atmospheric pressure;

- Refinery facilities provide electricity auxiliary requirements for gasification;

- Both fuels (heavy oil and biomass) used in gasification are generated at the refinery as residues and, if not used to produce an energy vector (producer gas), may incur costs for their final destination.

2.1.2. Model Validation

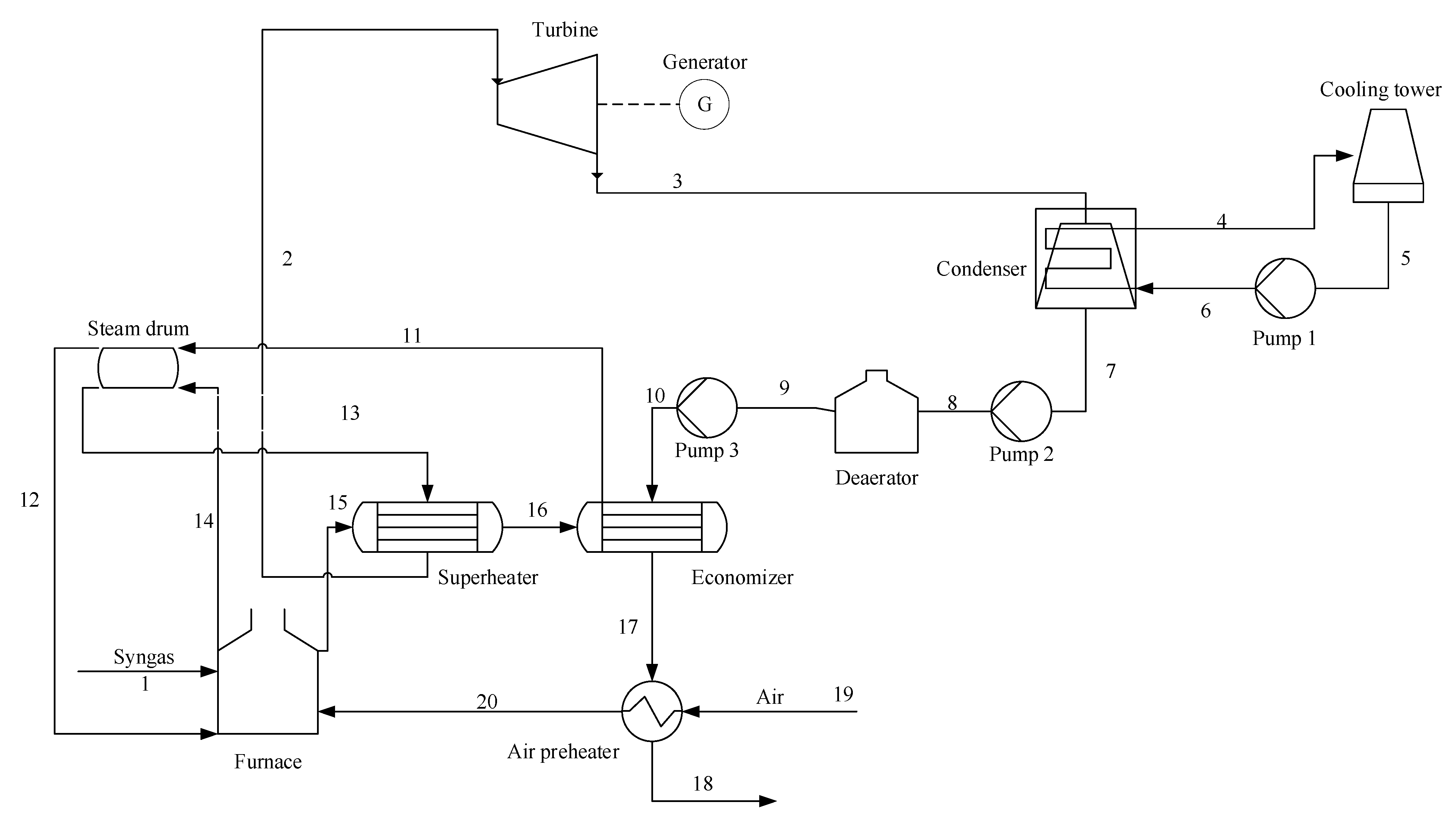

2.2. Rankine Cycle

- Steady-state process;

- It used a condensing turbine;

- The heat rejection of the steam cycle occurred through a water-cooled condenser and a wet cooling tower;

- Steam boiler was modeled considering its components (steam drum, furnace, superheater, economizer, air preheater), where the main input parameters that were considered, are presented in Table S1 of Supplementary Material.

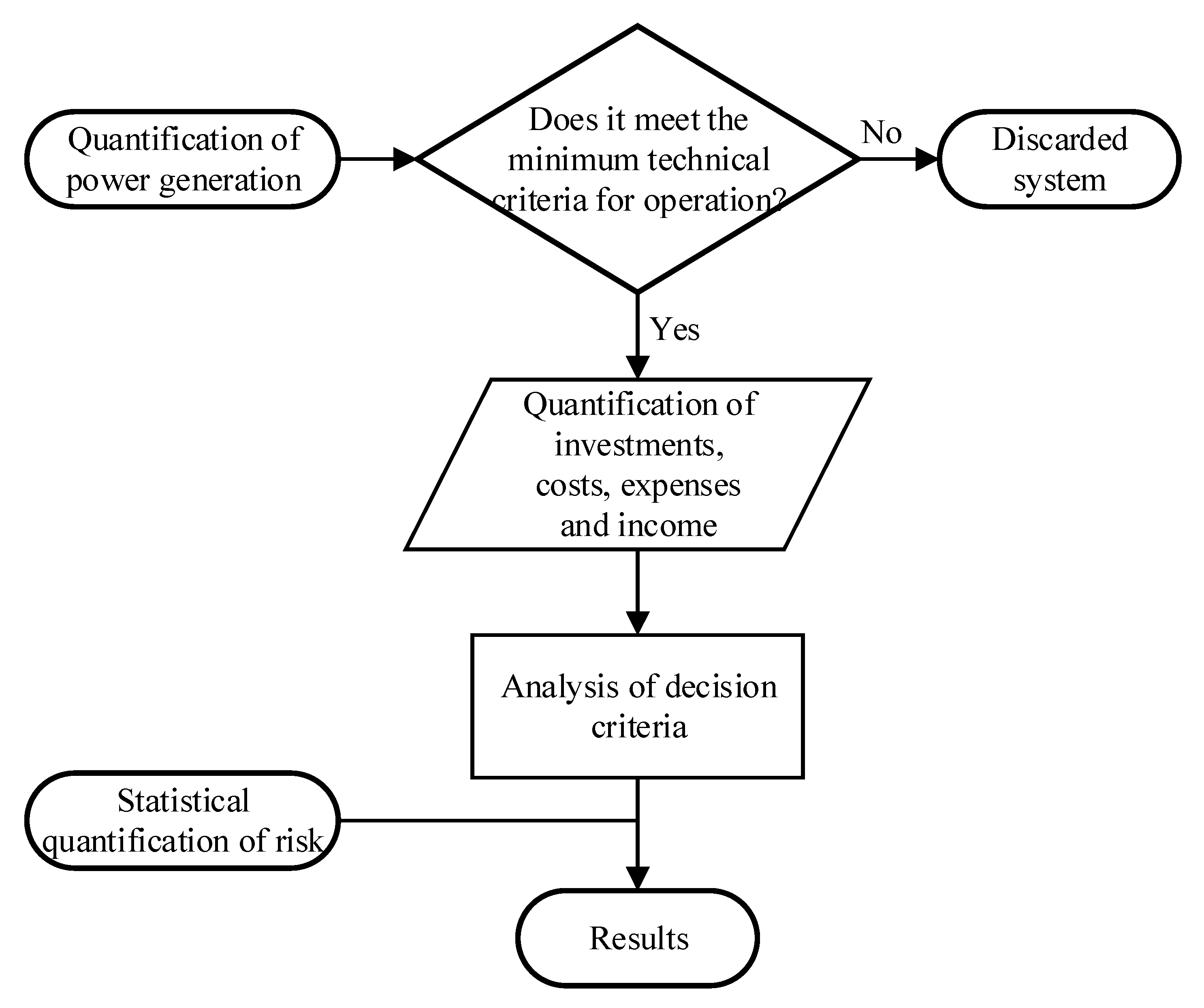

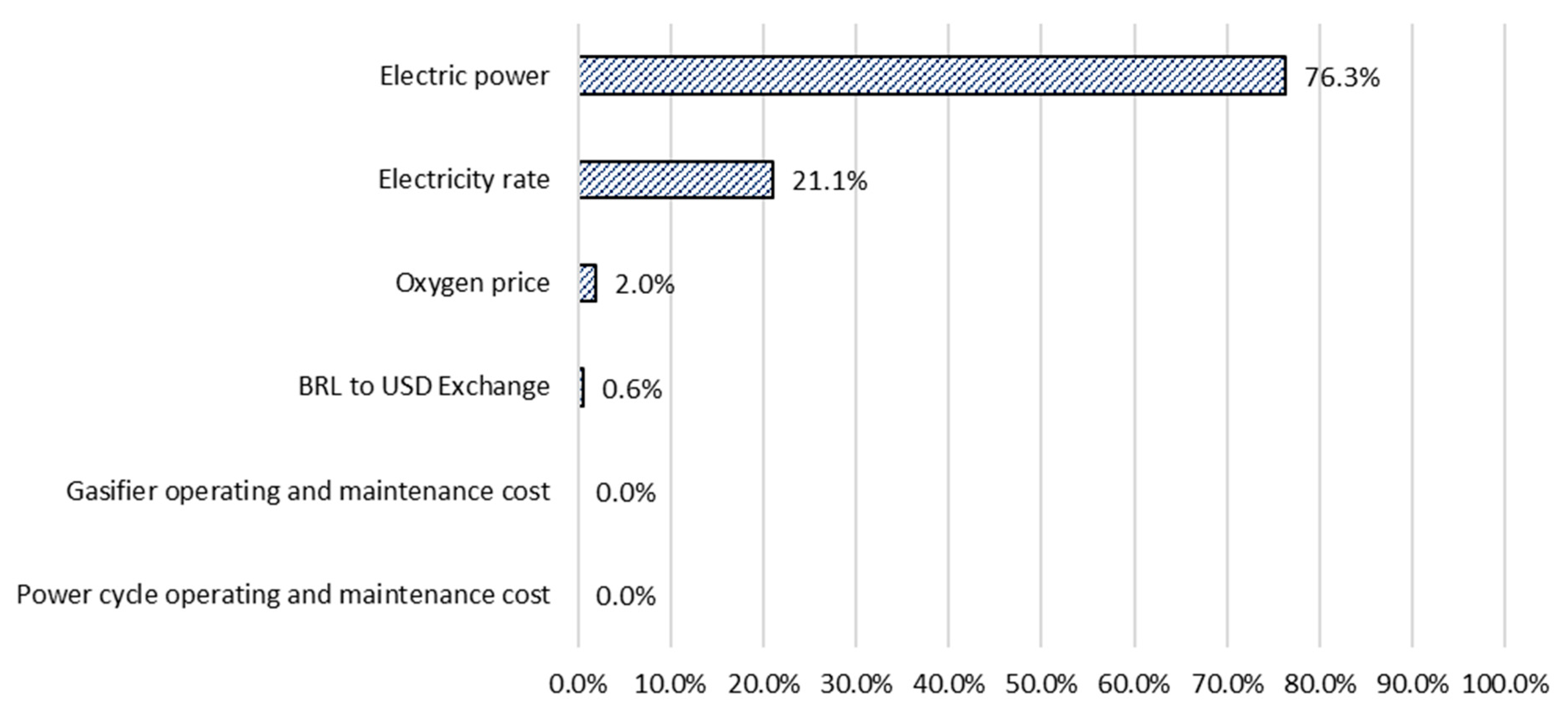

2.3. Economic Assessment

- Power delivered by the system,

- Gasifier operating and maintenance costs,

- Power cycle operating and maintenance costs,

- Local electricity tariff,

- United States Dollar and Brazilian Real exchange rate,

- Oxygen price (only in the scenario that uses oxygen as a gasification agent).

3. Results and Discussion

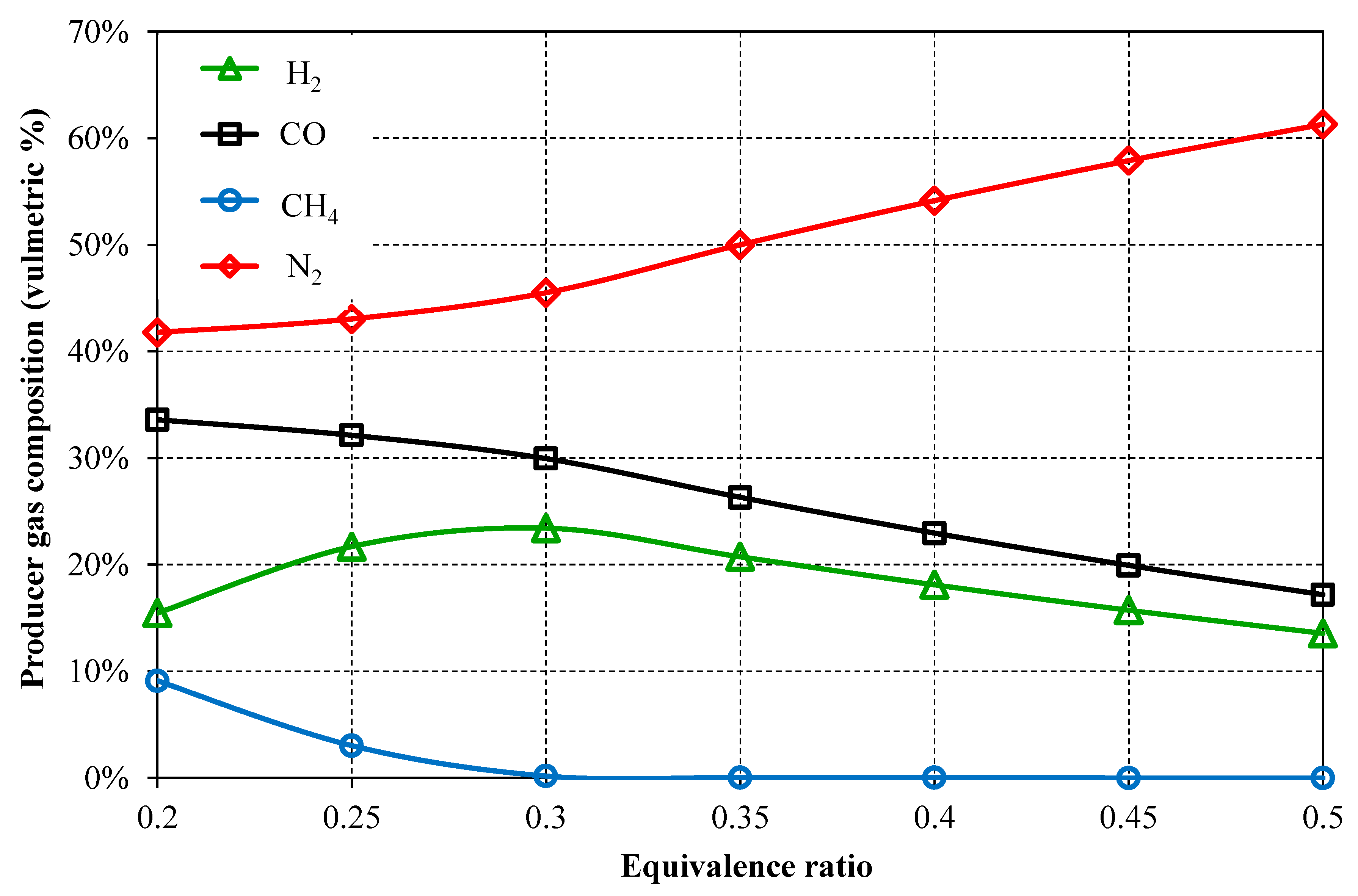

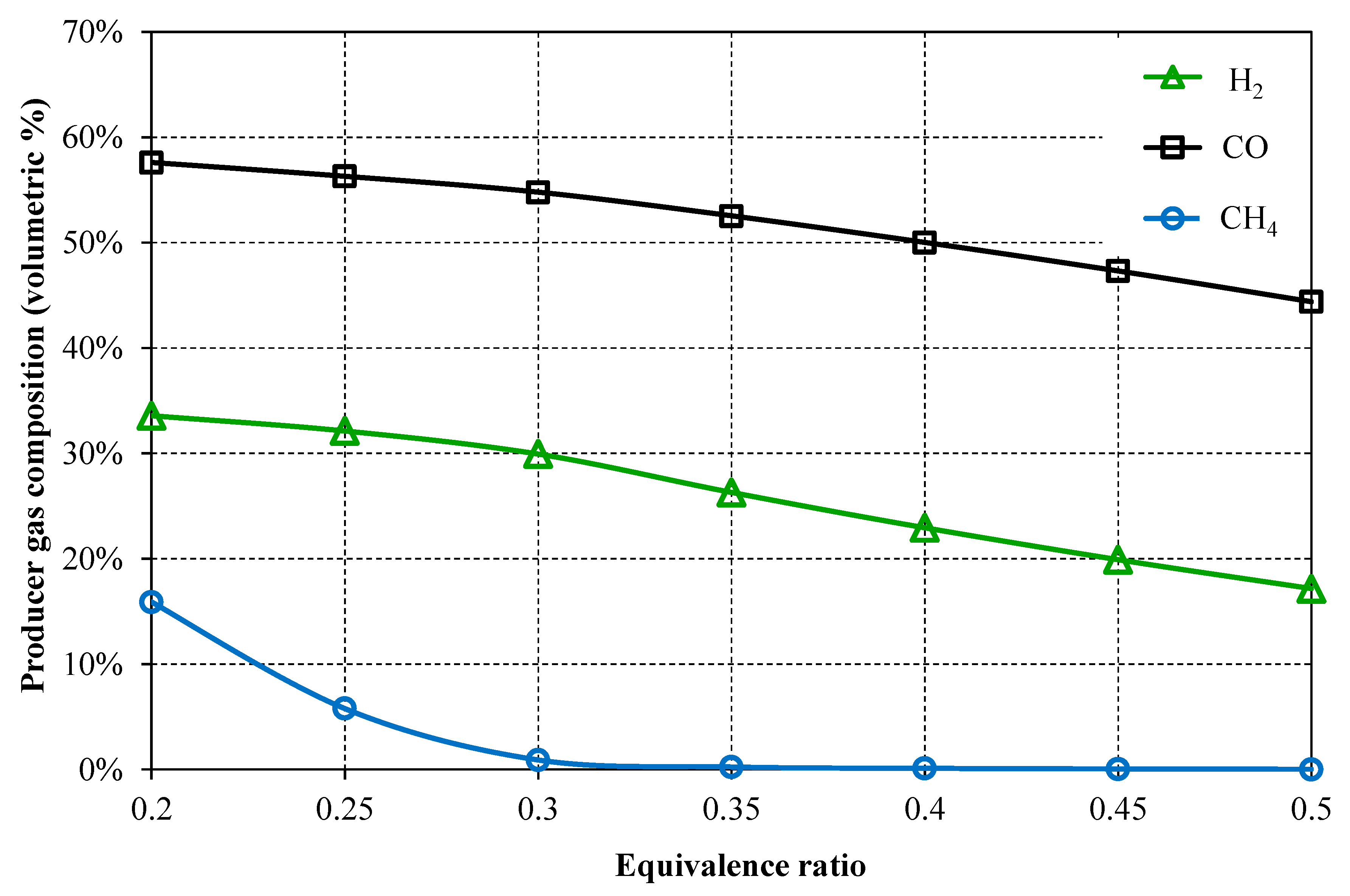

3.1. Producer Gas Composition

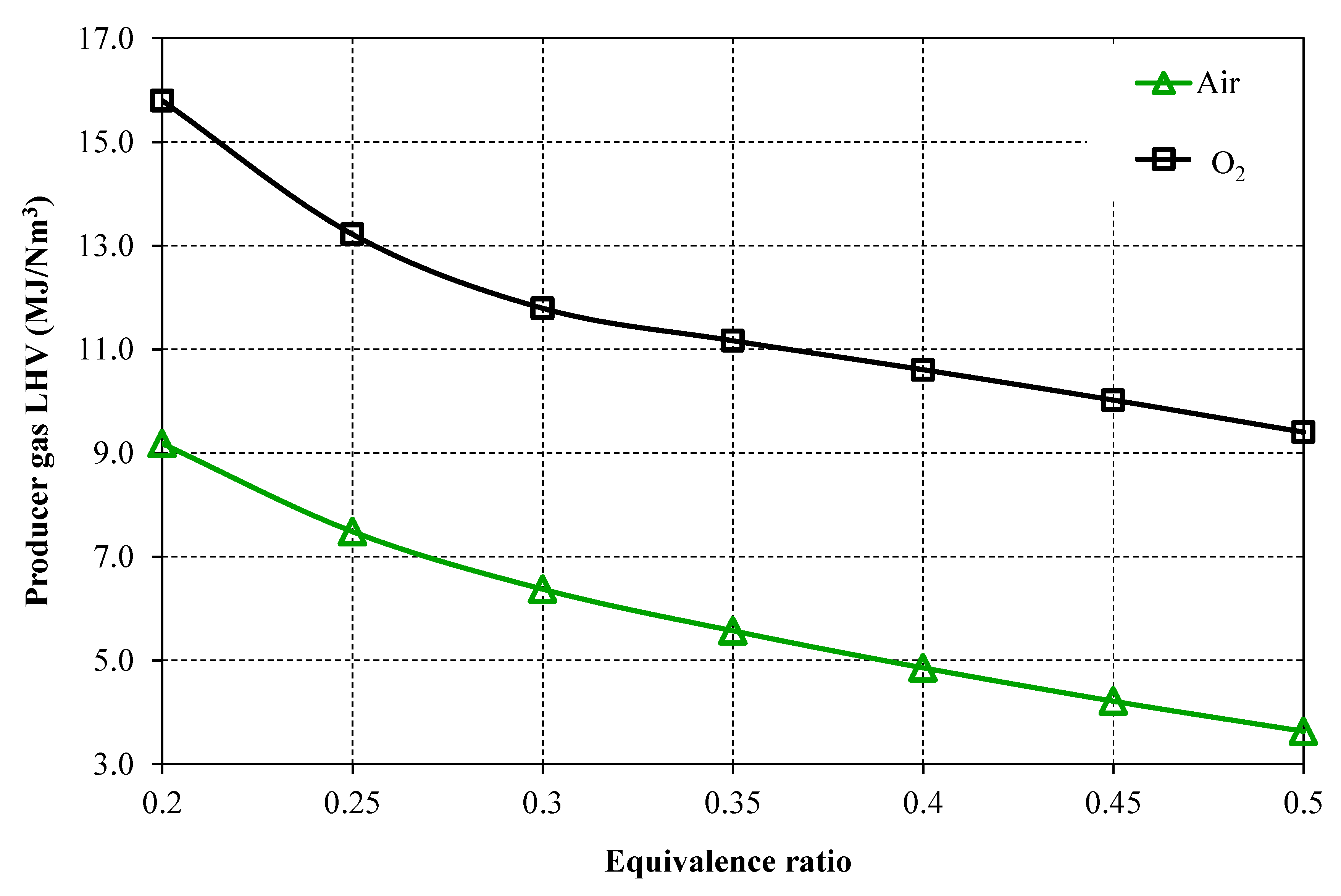

3.2. Producer Gas LHV

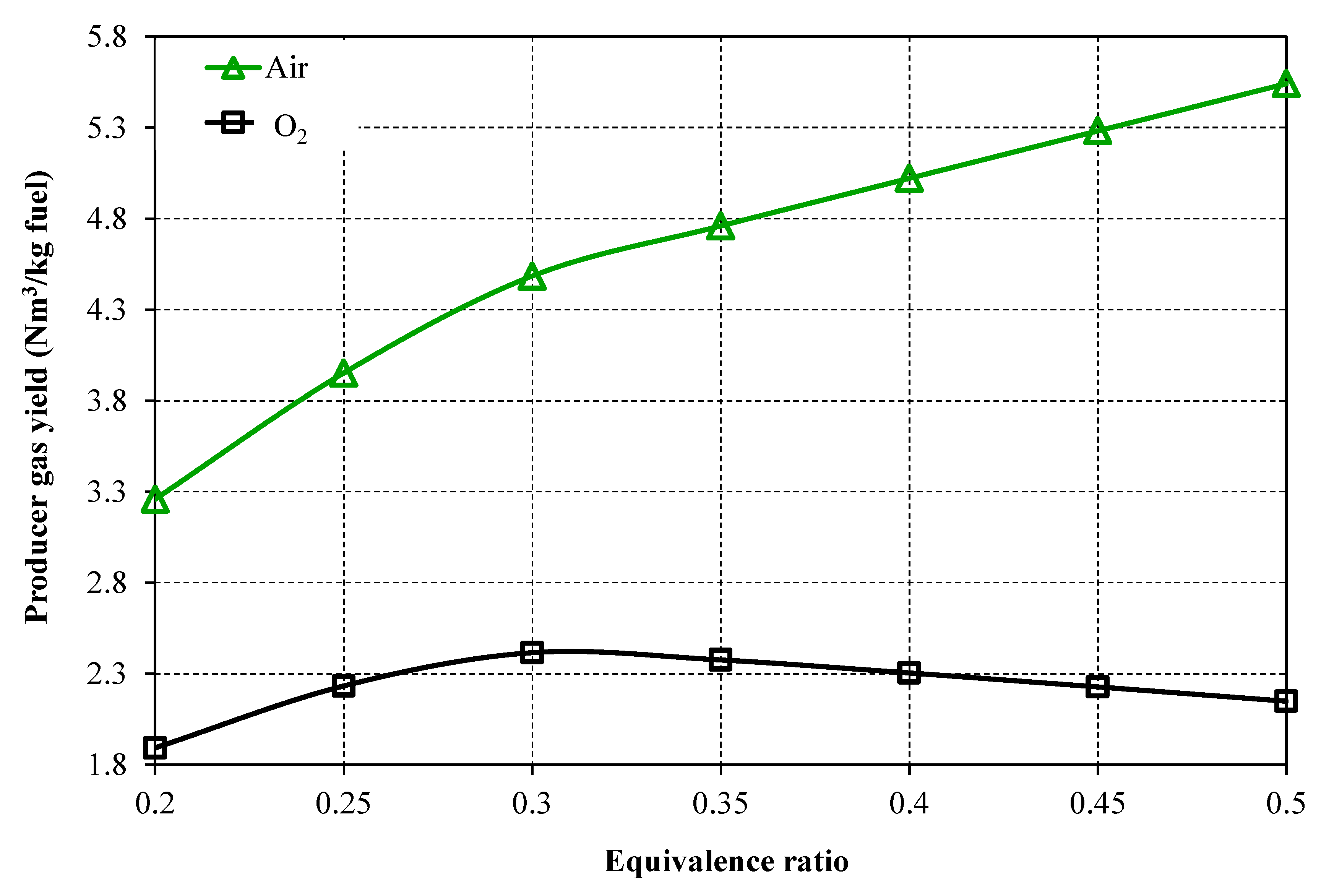

3.3. Producer Gas Yield

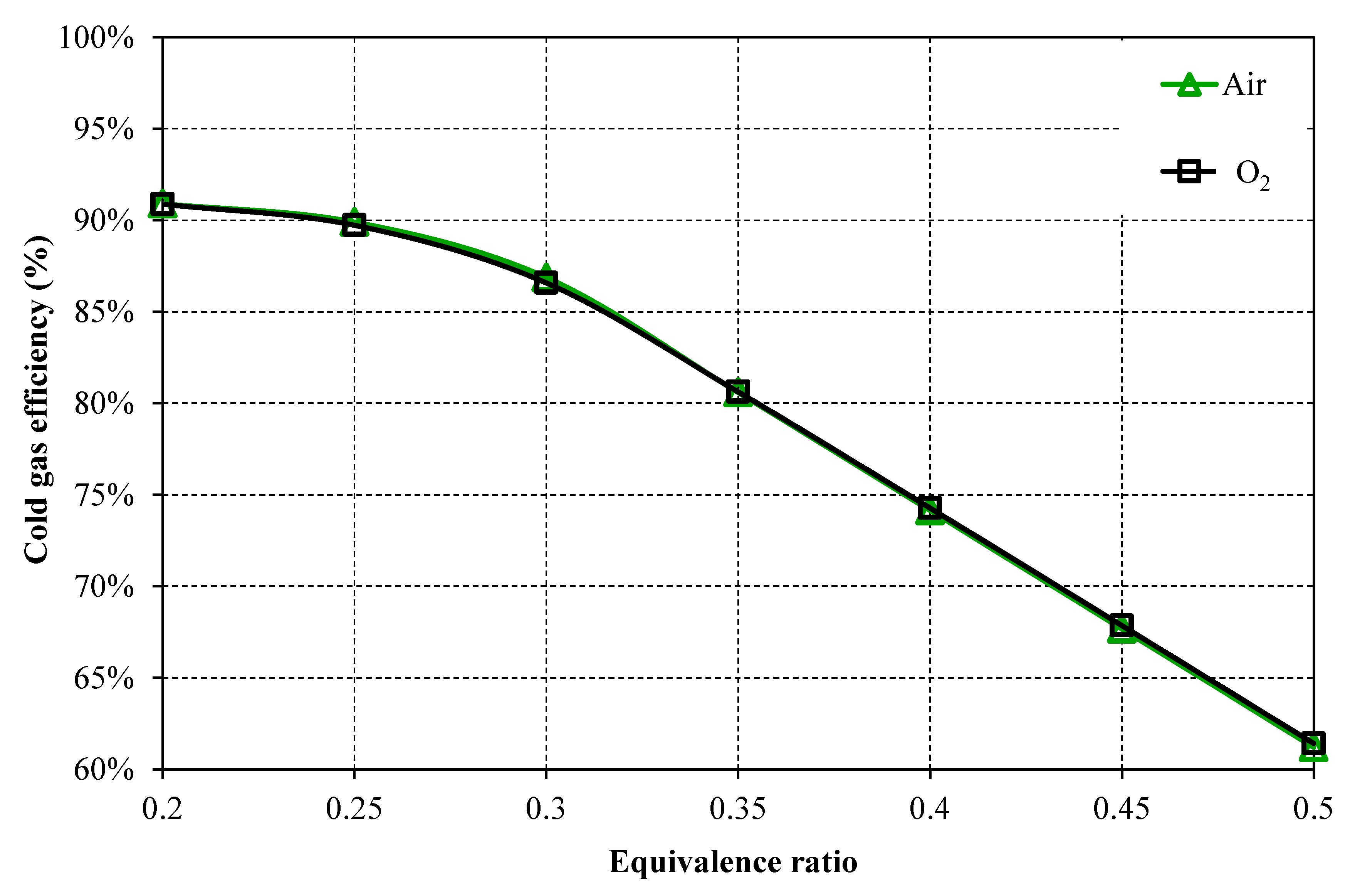

3.4. Cold Gas Efficiency

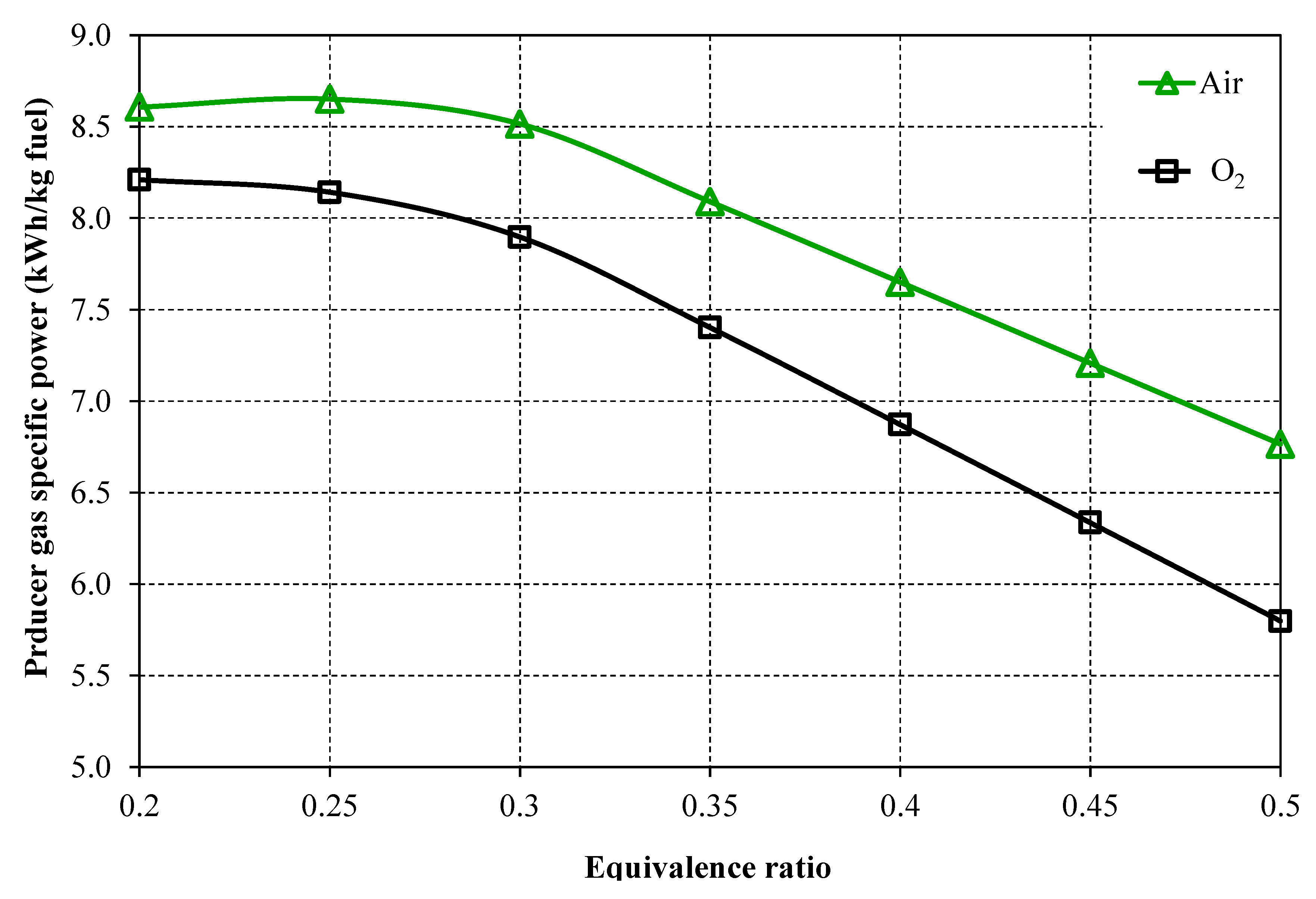

3.5. Producer Gas Specific Energy

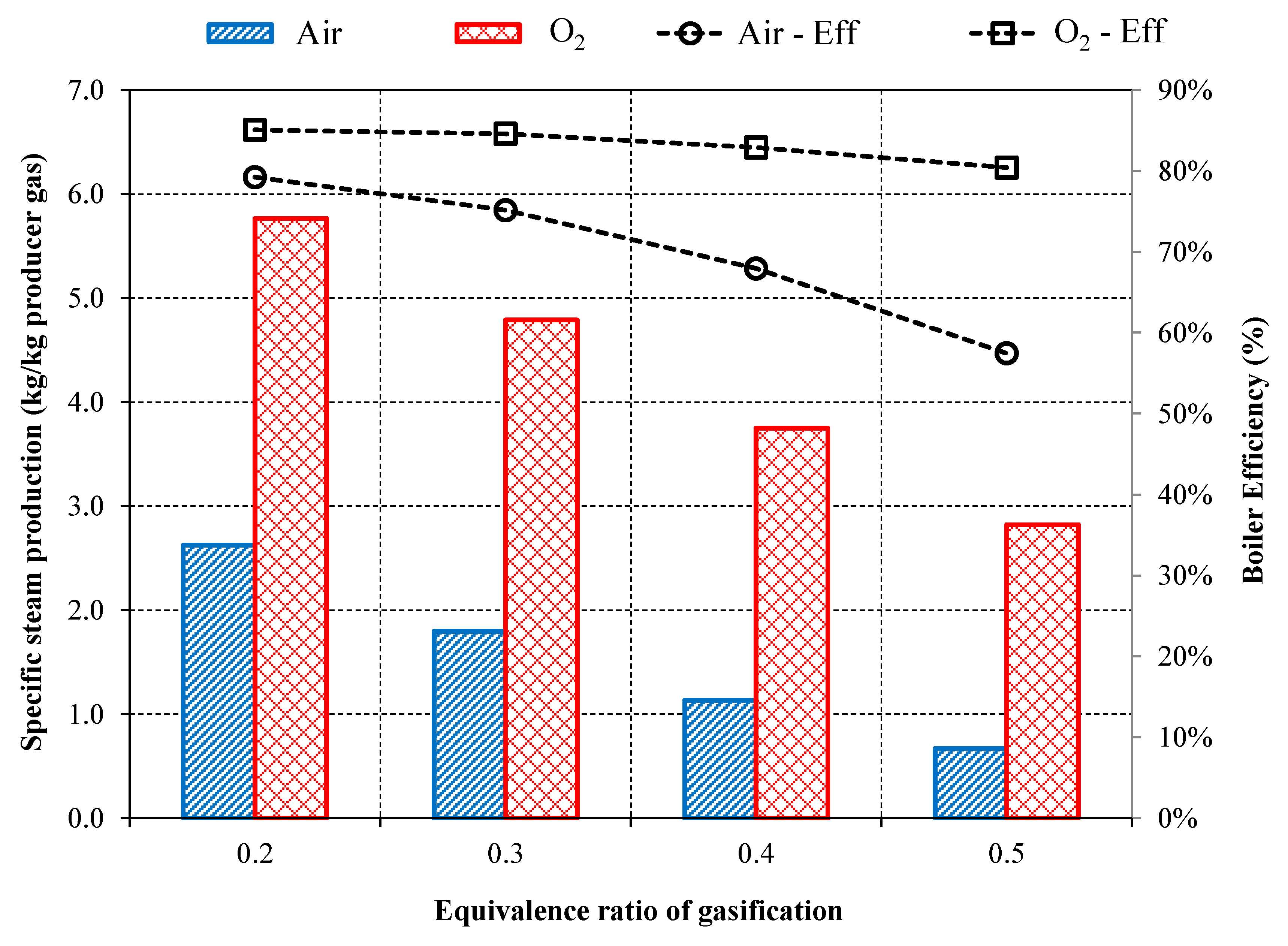

3.6. Electricity Generation Obtained from Rankine Cycle

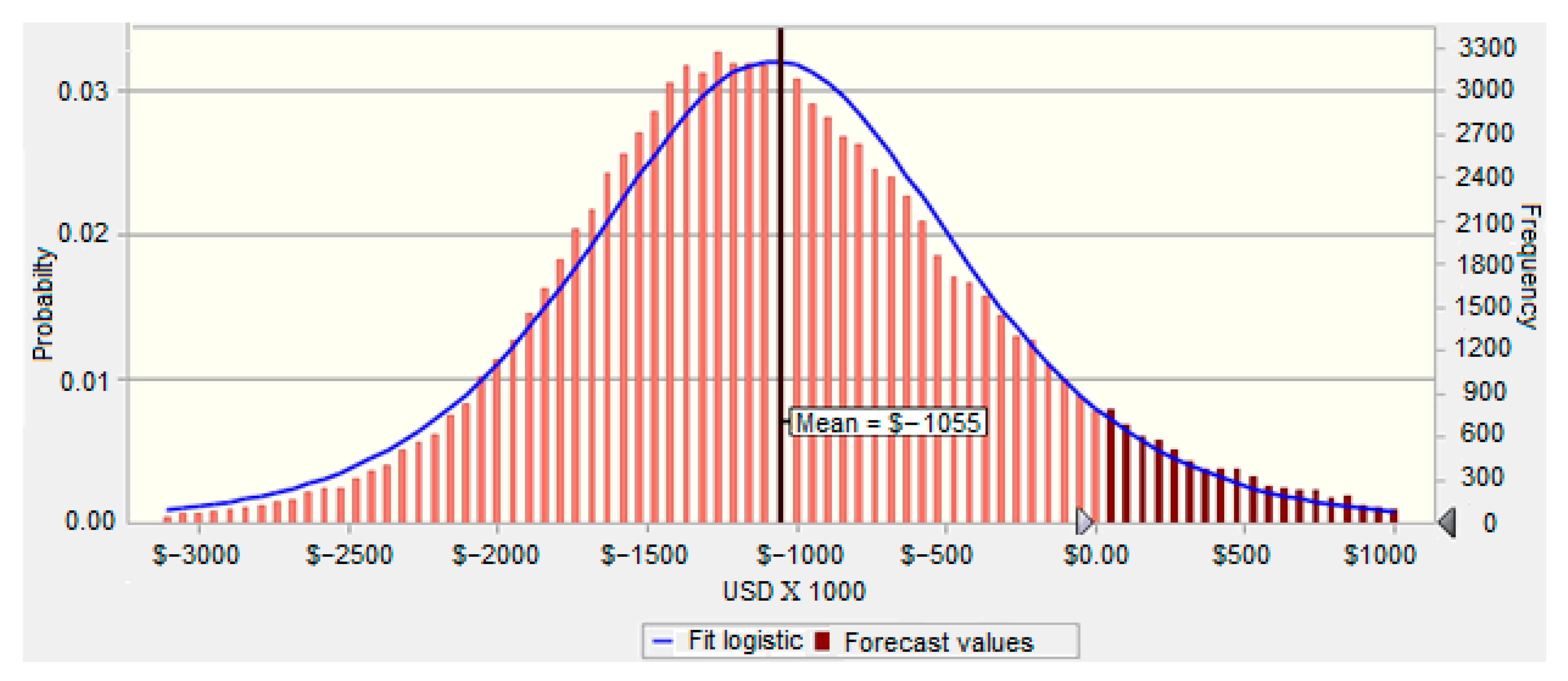

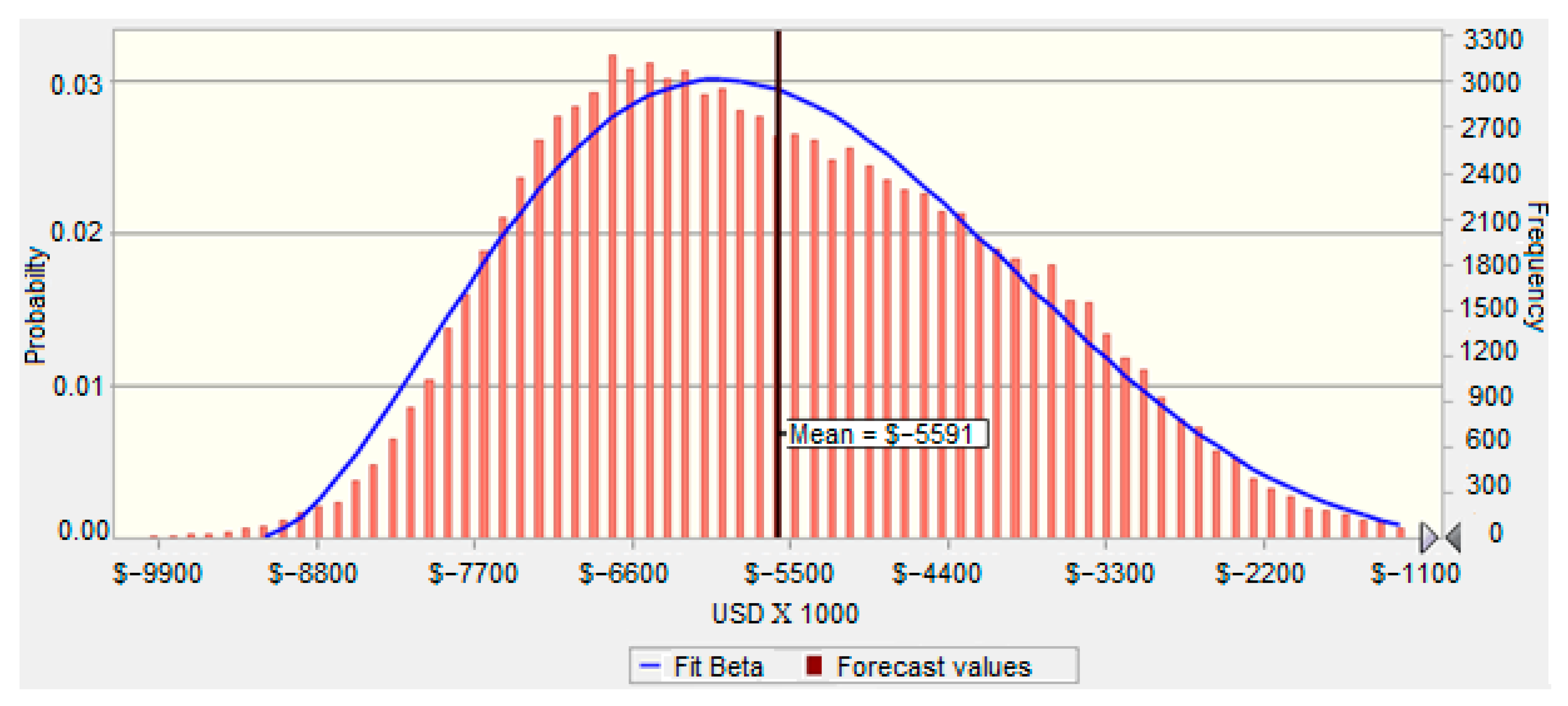

3.7. Economic Analysis

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| APR | Annual percentage rate |

| CGE | Cold gas efficiency |

| ER | Equivalence ratio |

| IRR | Internal return rate |

| LHV | Lower heating value |

| MARR | Minimum attractive rate of return |

| NPV | Net present value |

| WACC | Weighted average cost of capital |

| Mass Flow (kg/h) | |

| Market value of debt (-) | |

| Market value of equity (-) | |

| Financing rate (%) | |

| Cost of equity (%) | |

| Risk-free rate (%) | |

| Expected return of the market (%) | |

| Corporate tax rate (%) |

References

- Organization of the Petroleum Exporting Countries. World Oil Outlook 2040; Organization of the Petroleum Exporting Countries: Vienna, Austria, 2019. [Google Scholar]

- Zhao, F.; Liu, Y.; Lu, N.; Xu, T.; Zhu, G.; Wang, K. A review on upgrading and viscosity reduction of heavy oil and bitumen by underground catalytic cracking. Energy Rep. 2021, 7, 4249–4272. [Google Scholar] [CrossRef]

- Zhang, X.; Liu, Q.; Fan, Z.; Liu, Y. Enhanced heavy oil recovery and performance by application of catalytic in-situ combustion. Pet. Sci. Technol. 2019, 37, 493–499. [Google Scholar] [CrossRef]

- Rocha, J.W.S.; Vicente, M.A.; Melo, B.N.; de Lourdes, S.P.; Marques, M.; Guimarães, R.C.L.; Sad, C.M.S.; Castro, E.V.R.; Santos, M.F.P. Investigation of electrical properties with medium and heavy Brazilian crude oils by electrochemical impedance spectroscopy. Fuel 2019, 241, 42–52. [Google Scholar] [CrossRef]

- Li, Y.; Wang, Z.; Hu, Z.; Xu, B.; Li, Y.; Pu, W.; Zhao, J. A review of in situ upgrading technology for heavy crude oil. Petroleum 2021, 7, 117–122. [Google Scholar] [CrossRef]

- Batlle, E.A.O.; Julio, A.A.V.; Santiago, Y.C.; Palácio, J.C.E.; Bortoni, E.D.C.; Nogueira, L.A.H.; Dias, M.V.X.; González, A.M. Brazilian integrated oilpalm-sugarcane biorefinery: An energetic, exergetic, economic, and environmental (4E) assessment. Energy Convers. Manag. 2022, 268, 116066. [Google Scholar] [CrossRef]

- Alexandre, V.M.F.; de Castro, T.M.S.; de Araújo, L.V.; Santiago, V.M.J.; Freire, D.M.G.; Cammarota, M.C. Minimizing solid wastes in an activated sludge system treating oil refinery wastewater. Chem. Eng. Process. 2016, 103, 53–62. [Google Scholar] [CrossRef]

- Vendramel, S.; Bassin, J.P.; Dezotti, M.; Sant’Anna, G.L. Treatment of petroleum refinery wastewater containing heavily polluting substances in an aerobic submerged fixed-bed reactor. Environ. Technol. 2015, 36, 2052–2059. [Google Scholar] [CrossRef]

- González-Arias, J.; Carnicero, A.; Sánchez, M.E.; Martínez, E.J.; López, R.; Cara-Jiménez, J. Management of off-specification compost by using co-hydrothermal carbonization with olive tree pruning. Assessing energy potential of hydrochar. Waste Manag. 2021, 124, 224–234. [Google Scholar] [CrossRef]

- Suárez Useche, M.A.; Castillo Santiago, Y.; Restrepo, J.B.; Albis Arrieta, A.R.; Agámez Salgado, K.P. Evaluation of the Zinc Sulfate Catalytic Effect in Empty Fruit Bunches Pyrolysis. Processes 2022, 10, 1748. [Google Scholar] [CrossRef]

- Kim, S.W. Pyrolysis conditions of biomass in fluidized beds for production of bio-oil compatible with petroleum refinery. J. Anal. Appl. Pyrolysis 2016, 117, 220–227. [Google Scholar] [CrossRef]

- Zhang, L.; Hu, X.; Li, C.; Zhang, S.; Wang, Y.; Esmaeili, V.; Gholizadeh, M. Fates of heavy organics of bio-oil in hydrotreatment: The key challenge in the way from biomass to biofuel. Sci. Total Environ. 2021, 778, 146321. [Google Scholar] [CrossRef] [PubMed]

- Castillo Santiago, Y.; Pérez, J.F.; Sphaier, L.A. Reaction-front and char characterization from a palm kernel shell—Oil sludge mixture under oxygen lean regimes in a fixed-bed gasifier. Fuel 2022, 333, 126402. [Google Scholar] [CrossRef]

- Castillo Santiago, Y.; Martínez González, A.; Venturini, O.J.; Sphaier, L.A.; Ocampo Batlle, E.A. Energetic and environmental assessment of oil sludge use in a gasifier/gas microturbine system. Energy 2022, 244, 123103. [Google Scholar] [CrossRef]

- Watson, J.; Zhang, Y.; Si, B.; Chen, W.-T.; de Souza, R. Gasification of biowaste: A critical review and outlooks. Renew. Sustain. Energy Rev. 2018, 83, 1–17. [Google Scholar] [CrossRef]

- Ghassemi, H.; Beheshti, S.M.; Shahsavan-Markadeh, R. Mathematical modeling of extra-heavy oil gasification at different fuel water contents. Fuel 2015, 162, 258–263. [Google Scholar] [CrossRef]

- Yang, X.; Hamidzadeh, A.; Ilkhani, M.; Foroughi, A.; Esfahani, M.J.; Motahari-Nezhad, M. Aspen plus simulation of heavy oil gasification in a fluidized bed gasifier. Pet. Sci. Technol. 2016, 34, 1530–1533. [Google Scholar] [CrossRef]

- Bader, A.; Hartwich, M.; Richter, A.; Meyer, B. Numerical and experimental study of heavy oil gasification in an entrained-flow reactor and the impact of the burner concept. Fuel Process. Technol. 2018, 169, 58–70. [Google Scholar] [CrossRef]

- Banisaeed, M.; Rezaee-Manesh, A. A parametric study for gasification of liquid fuels. Pet. Sci. Technol. 2016, 34, 976–979. [Google Scholar] [CrossRef]

- Zhang, X.; Wu, L.; Wang, X.; Ju, G. Comparative study of waste heat steam SRC, ORC and S-ORC power generation systems in medium-low temperature. Appl. Therm. Eng. 2016, 106, 1427–1439. [Google Scholar] [CrossRef]

- Oyedepo, S.O.; Fakeye, B.A.; Mabinuori, B.; Babalola, P.O.; Leramo, R.O.; Kilanko, O.; Dirisu, J.O.; Udo, M.; Efemwenkiekie, U.K.; Oyebanji, J.A. Thermodynamics analysis and performance optimization of a reheat—Regenerative steam turbine power plant with feed water heaters. Fuel 2020, 280, 118577. [Google Scholar] [CrossRef]

- Ahmadi, M.H.; Alhuyi Nazari, M.; Sadeghzadeh, M.; Pourfayaz, F.; Ghazvini, M.; Ming, T.; Meyer, J.P.; Sharifpur, M. Thermodynamic and economic analysis of performance evaluation of all the thermal power plants: A review. Energy Sci. Eng. 2019, 7, 30–65. [Google Scholar] [CrossRef]

- Dovichi Filho, F.B.; Castillo Santiago, Y.; Silva Lora, E.E.; Escobar Palacio, J.C.; Almazan del Olmo, O.A. Evaluation of the maturity level of biomass electricity generation technologies using the technology readiness level criteria. J. Clean. Prod. 2021, 295, 126426. [Google Scholar] [CrossRef]

- Vaezi, M.; Passandideh-Fard, M.; Moghiman, M.; Charmchi, M. Gasification of heavy fuel oils: A thermochemical equilibrium approach. Fuel 2011, 90, 878–885. [Google Scholar] [CrossRef]

- Safarian, S.; Ebrahimi Saryazdi, S.M.; Unnthorsson, R.; Richter, C. Gasification of Woody Biomasses and Forestry Residues: Simulation, Performance Analysis, and Environmental Impact. Fermentation 2021, 7, 61. [Google Scholar] [CrossRef]

- ANP. Anuário Estatístico Brasileiro do Petróleo, Gás Natural e Biocombustíveis; ANP: Rio de Janeiro, Brazil, 2018. [Google Scholar]

- Khesa, N.; Mulopo, J. Performance evaluation, Optimization and exergy analysis of a high temperature co-electrolysis power to gas process using Aspen Plus®—A model based study. Energy Sci. Eng. 2021, 9, 1950–1960. [Google Scholar] [CrossRef]

- Tungalag, A.; Lee, B.; Yadav, M.; Akande, O. Yield prediction of MSW gasification including minor species through ASPEN plus simulation. Energy 2020, 198, 117296. [Google Scholar] [CrossRef]

- Allegue, L.B.; Hinge, J. Biogas Upgrading Evaluation of Methods for H2S Removal; Danish technological institute: Taastrup, Danmark, 2014. [Google Scholar]

- Marques, T.E.; Castillo Santiago, Y.; Renó, M.L.; Yepes Maya, D.M.; Sphaier, L.A.; Shi, Y.; Ratner, A. Environmental and Energetic Evaluation of Refuse-Derived Fuel Gasification for Electricity Generation. Processes 2021, 9, 2255. [Google Scholar] [CrossRef]

- Ashizawa, M.; Hara, S.; Kidoguchi, K.; Inumaru, J. Gasification characteristics of extra-heavy oil in a research-scale gasifier. Energy 2005, 30, 2194–2205. [Google Scholar] [CrossRef]

- de Oliveira Vilela, A.; Lora, E.S.; Quintero, Q.R.; Vicintin, R.A.; Pacceli da Silva e Souza, T. A new technology for the combined production of charcoal and electricity through cogeneration. Biomass Bioenergy 2014, 69, 222–240. [Google Scholar] [CrossRef]

- Leme, M.M.V.; Venturini, O.J.; Lora, E.E.S.; Rocha, M.H.; Luz, F.C.; de Almeida, W.; de Moura, D.C.; de Moura, L.F. Electricity generation from pyrolysis gas produced in charcoal manufacture: Technical and economic analysis. J. Clean. Prod. 2018, 194, 219–242. [Google Scholar] [CrossRef]

- Teixeira, M.A.; Escobar Palacio, J.C.; Sotomonte, C.R.; Silva Lora, E.E.; Venturini, O.J.; Aßmann, D. Assaí—An energy view on an Amazon residue. Biomass Bioenergy 2013, 58, 76–86. [Google Scholar] [CrossRef]

- Castillo Santiago, Y.; Martínez González, A.; Venturini, O.J.; Yepes Maya, D.M. Assessment of the energy recovery potential of oil sludge through gasification aiming electricity generation. Energy 2021, 215, 119210. [Google Scholar] [CrossRef]

- Turner, M.J.; Pinkerton, L.L. Quality Guidelines for Energy System Studies: Capital Cost Scaling Methodology; National Energy Technology Laboratory: Pittsburgh, PA, USA, 2013.

- Food and Agriculture Organization (FAO). Bioenergy and Food Security Rapid Appraisal: User Manual; FAO: Roma, Italy, 2014. [Google Scholar]

- Holmgren, K.M. Investment Cost Estimates for Gasificationbased Biofuel Production Systems; IVL Swedish Environmental Research Institute: Stockholm, Switzerland, 2015. [Google Scholar]

- Davidson, K.; Hite, R.; Jones, D.; Howley, A. A Comprehensive Assessment of Small Combined Heat and Power Technical and Market Potential in California; California Energy Commission: Sacramento, CA, USA, 2019.

- Reyhani, H.A.; Meratizaman, M.; Ebrahimi, A.; Pourali, O.; Amidpour, M. Thermodynamic and economic optimization of SOFC-GT and its cogeneration opportunities using generated syngas from heavy fuel oil gasification. Energy 2016, 107, 141–164. [Google Scholar] [CrossRef]

- Sagani, A.; Hagidimitriou, M.; Dedoussis, V. Perennial tree pruning biomass waste exploitation for electricity generation: The perspective of Greece. Sustain. Energy Technol. Assess. 2019, 31, 77–85. [Google Scholar] [CrossRef]

- Valor Consulting Índice de Preços ao Produtor (IPP). Available online: https://www.valor.srv.br/indices/ipp.php?pagina=1 (accessed on 28 October 2022).

- Banco Central do Brasil Cotações e Boletins. Available online: https://www.bcb.gov.br/estabilidadefinanceira/historicocotacoes (accessed on 1 March 2022).

- ANEEL. Nota Técnica no 37/2019-SRM/ANEEL; ANEEL: Brasilia, Brazil, 2019.

- Receita Federal do Brasil Tabela de Depreciação. Available online: http://www.fazenda.rj.gov.br/sefaz/content/conn/UCMServer/uuid/dDocName%3AWCC201632 (accessed on 2 March 2022).

- Han, J.; Liang, Y.; Hu, J.; Qin, L.; Street, J.; Lu, Y.; Yu, F. Modeling downdraft biomass gasification process by restricting chemical reaction equilibrium with Aspen Plus. Energy Convers. Manag. 2017, 153, 641–648. [Google Scholar] [CrossRef]

- Martínez González, A.; Silva Lora, E.E.; Escobar Palacio, J.C.; Almazán del Olmo, O.A. Hydrogen production from oil sludge gasification/biomass mixtures and potential use in hydrotreatment processes. Int. J. Hydrogen Energy 2018, 43, 7808–7822. [Google Scholar] [CrossRef]

- Upadhyay, D.S.; Sakhiya, A.K.; Panchal, K.; Patel, A.H.; Patel, R.N. Effect of equivalence ratio on the performance of the downdraft gasifier—An experimental and modelling approach. Energy 2019, 168, 833–846. [Google Scholar] [CrossRef]

- Richardson, Y.; Drobek, M.; Julbe, A.; Blin, J.; Pinta, F. Biomass Gasification to Produce Syngas. In Recent Advances in Thermo-Chemical Conversion of Biomass; Pandey, A., Bhaskar, T., Stöcker, M., Sukumaran, R., Eds.; Elsevier: Boston, MA, USA, 2015; pp. 213–250. ISBN 978-0-444-63289-0. [Google Scholar]

- Mohd Salleh, M.A.; Nsamba, H.K.; Yusuf, H.M.; Idris, A.; Karim, W.A.W.A.; Salleh, M.A.M.; Nsamba, H.K.; Yusuf, H.M.; Idris, A.; Wan Ab, W.A. Effect of Equivalence Ratio and Particle Size on EFB Char Gasification. Energy Sources Part A Recover. Util. Environ. Eff. 2015, 37, 1647–1662. [Google Scholar] [CrossRef]

- Henao, N.C.; Lora, E.E.S.; Maya, D.M.Y.; Venturini, O.J.; Franco, E.H.M. Technical feasibility study of 200 kW gas microturbine coupled to a dual fluidized bed gasifier. Biomass Bioenergy 2019, 130, 105369. [Google Scholar] [CrossRef]

- Wang, M.; Wan, Y.; Guo, Q.; Bai, Y.; Yu, G.; Liu, Y.; Zhang, H.; Zhang, S.; Wei, J. Brief review on petroleum coke and biomass/coal co-gasification: Syngas production, reactivity characteristics, and synergy behavior. Fuel 2021, 304, 121517. [Google Scholar] [CrossRef]

- Zoungrana, L.; Sidibé, S.D.; Herman, B.; Coulibaly, Y.; Jeanmart, H. Design of a Gasification Reactor for Manufacturing and Operation in West Africa. Designs 2021, 5, 76. [Google Scholar] [CrossRef]

- Peng, W.X.; Wang, L.S.; Mirzaee, M.; Ahmadi, H.; Esfahani, M.J.; Fremaux, S. Hydrogen and syngas production by catalytic biomass gasification. Energy Convers. Manag. 2017, 135, 270–273. [Google Scholar] [CrossRef]

- Couto, N.; Rouboa, A.; Silva, V.; Monteiro, E.; Bouziane, K. Influence of the Biomass Gasification Processes on the Final Composition of Syngas. Energy Procedia 2013, 36, 596–606. [Google Scholar] [CrossRef]

- Odeh, N.; Harmsen, R.; Minett, S.; Edwards, P.; Perez-Lopez, A.; Hu, J. Review of the Reference Values for High-Efficiency Cogeneration; European Commission: Didcot, UK, 2015.

- Arslan, O. Performance analysis of a novel heat recovery system with hydrogen production designed for the improvement of boiler effectiveness. Int. J. Hydrogen Energy 2021, 46, 7558–7572. [Google Scholar] [CrossRef]

- Kalisz, S.; Pronobis, M.; Baxter, D. Co-firing of biomass waste-derived syngas in coal power boiler. Energy 2008, 33, 1770–1778. [Google Scholar] [CrossRef]

- Craig, K.R.; Mann, M.K. Cost and Performance Analysis of Biomass-Based Integrated Gasification Combined-Cycle (BIGCC) Power Systems; National Renewable Energy Laboratory: Golden, CO, USA, 1996.

- Ministério da Economia. Tarifa Externa Comum (TEC); Goverrno do Brasil: Brasília, Brazil, 2019.

- Presidência da República do Brasil. Decreto no 9514/2018; Goverrno do Brasil: Brasília, Brazil, 2018.

- Presidência da República do Brasil. Lei no 13137/2015; Goverrno do Brasil: Brasília, Brazil, 2015.

- Governo do Estado de Minas Gerais. Decreto no 43080/2002; Goverrno de MG: Belo Horizonte, Brazil, 2002.

| Parameter | Composition (wt.%) |

|---|---|

| Fixed carbon | 67.31% |

| Volatiles | 32.59% |

| Moisture | 0.3% |

| Ash | 0.1% |

| Ultimate analysis | |

| Carbon | 86.25% |

| Hydrogen | 11.05% |

| Sulfur | 2.2% |

| Nitrogen | 0.4% |

| Ash | 0.1% |

| Parameter | Composition (wt.%) |

|---|---|

| Volatiles | 82.2% |

| Fixed carbon | 15.1% |

| Moisture | 9.0% |

| Ash | 2.7% |

| Ultimate analysis | |

| Carbon | 50.5% |

| Oxygen | 40.2% |

| Hydrogen | 6.1% |

| Ash | 2.7% |

| Nitrogen | 0.5% |

| Block Name | Aspen Plus ID | Description |

|---|---|---|

| PYROL | Ryield | Decomposes fuel into conventional components. |

| COMBU | RStoic | Simulate oxidation reactions of volatiles and char produced in the pyrolysis zone. |

| REDUC | RGibbs | Simulate reduction reactions considering Gibbs free energy minimization method. |

| SEPAR | Sep | Separate all contaminants that change the composition of producer gases. |

| ARREFECE | HeatX | Cool the hot gas to obtain the producer gas. |

| Operational Parameter | Value |

|---|---|

| Pressure | 18.75 atm |

| Gasification agent | Oxygen |

| Equivalence ratio | 0.4 |

| Ultimate analysis (wt.% on dry basis) | |

| Carbon | 84.28% |

| Hydrogen | 10.33% |

| Sulfur | 3.95% |

| Nitrogen | 0.64% |

| Oxygen | 0.55% |

| Ash | 0.25% |

| Proximate analysis (wt.% on dry basis) | |

| Volatiles | 81.71% |

| Moisture | 28.80% |

| Fixed carbon | 18.04% |

| Ash | 0.25% |

| Parameter | Ashizawa et al. [31] | This Work |

|---|---|---|

| CO | 38.70% | 40.69% |

| H2 | 39.40% | 35.73% |

| H2O | 11.85% | 14.45% |

| CO2 | 8.67% | 8.01% |

| Other | 1.30% | 1.02% |

| CH4 | 0.08% | 0.10% |

| H2/CO ratio | 1.02 | 0.88 |

| RMS | - | 0.02 |

| Steam Turbine | Steam Boiler | ||

|---|---|---|---|

| Type | Condensation | Steam temperature | 360 °C |

| Live steam temperature | 350 °C | Steam pressure | 23 bar (g) |

| Shaft power | 300 kW | Condenser | |

| Isentropic efficiency | 60% | Pressure | 0.12 bar (abs) |

| Live steam pressure | 23 bar (g) | Maximum cooling water temperature | 32 °C |

| Exhaust pressure | 0.12 bar (g) | Pump | |

| Generator | Discharge Pressure | 23 bar (g) | |

| Efficiency | 96% | Rotation | 3600 rpm |

| Power factor | 0.8 | Isentropic efficiency | 70% |

| Factor | Unit | Value | Reference |

|---|---|---|---|

| System service life | Year | 15 | - |

| BRL to USD Exchange | BRL/USD | 4.92–5.79 | [43] |

| Depreciation | % APR | 10.00 | [45] |

| MARR (WAAC) | % APR | 10.32 | - |

| Feature or Item | Unit | Air Operation | Oxygen Operation |

|---|---|---|---|

| Active power | kW | 92.53–189.39 | 129.9–203.4 |

| Availability | % | 95.00 | 95.00 |

| Annual energy generated | kWh/year | 770,094–1,576,071 | 1,081,051–1,692,861 |

| Investment | |||

| Power cycle | USD | 268,381 | 268,381 |

| Gasifier | USD | 310,274 | 310,274 |

| Balance of plant—BOP [59] | USD | 115,731 | 115,731 |

| Taxes | USD | 59,101 | 59,101 |

| Total | USD | 753,487 | 753,487 |

| Tax | Value | Ref. |

|---|---|---|

| TEC Mercosur—Common External Tariff | 0.00% | [60] |

| IPI—Tax on Industrialized Products | 8.00% | [61] |

| PIS—Social Integration Program | 2.10% | [62] |

| COFINS—Contribution to Social Security Financing | 9.65% | [62] |

| ICMS—Tax on Movement of Goods and Services | 18.00% | [63] |

| Total | 37.75% |

| Parameter | Unit | Air Operation | Oxygen Operation |

|---|---|---|---|

| Electricity rate (before taxes) | BRL/kWh | 0.53–1.54 | 0.53–1.54 |

| Electricity generation rate (before taxes) | BRL/kWh | 1.53–3.45 | 4.82–10.89 |

| BRL to USD Exchange | BRL/USD | 4.92–5.79 | 4.92–5.79 |

| Electricity taxes (B3 class) | % | 25.00 | 25.00 |

| Annual revenue | BRL/year | 2,981,217 | 3,200,123 |

| Annual Expenses | Unit | Air Operation | Oxygen Operation |

|---|---|---|---|

| Gasifier operating and maintenance cost | USD | 12,072 | 15,213 |

| Power cycle operating and maintenance cost | USD | 27,406 | 32,390 |

| Oxygen | USD | 0.00 | 333,688 |

| Heavy oil and biomass cost * | USD | 441,066 | 441,066 |

| Total | USD | 480,544 | 822,356 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Castillo Santiago, Y.; Henao, N.C.; Venturini, O.J.; Sphaier, L.A.; Duarte, S.V.; de Rezende, T.T.G.; Ochoa, G.V. Techno-Economic Assessment of Producer Gas from Heavy Oil and Biomass Co-Gasification Aiming Electricity Generation in Rankine Cycle. Processes 2022, 10, 2358. https://doi.org/10.3390/pr10112358

Castillo Santiago Y, Henao NC, Venturini OJ, Sphaier LA, Duarte SV, de Rezende TTG, Ochoa GV. Techno-Economic Assessment of Producer Gas from Heavy Oil and Biomass Co-Gasification Aiming Electricity Generation in Rankine Cycle. Processes. 2022; 10(11):2358. https://doi.org/10.3390/pr10112358

Chicago/Turabian StyleCastillo Santiago, York, Nelson Calderon Henao, Osvaldo José Venturini, Leandro A. Sphaier, Stefany Vera Duarte, Túlio Tito Godinho de Rezende, and Guillermo Valencia Ochoa. 2022. "Techno-Economic Assessment of Producer Gas from Heavy Oil and Biomass Co-Gasification Aiming Electricity Generation in Rankine Cycle" Processes 10, no. 11: 2358. https://doi.org/10.3390/pr10112358

APA StyleCastillo Santiago, Y., Henao, N. C., Venturini, O. J., Sphaier, L. A., Duarte, S. V., de Rezende, T. T. G., & Ochoa, G. V. (2022). Techno-Economic Assessment of Producer Gas from Heavy Oil and Biomass Co-Gasification Aiming Electricity Generation in Rankine Cycle. Processes, 10(11), 2358. https://doi.org/10.3390/pr10112358