Preliminary Experimental Results and Modelling Study of Olive Kernel Gasification in a 2 MWth BFB Gasifier

Abstract

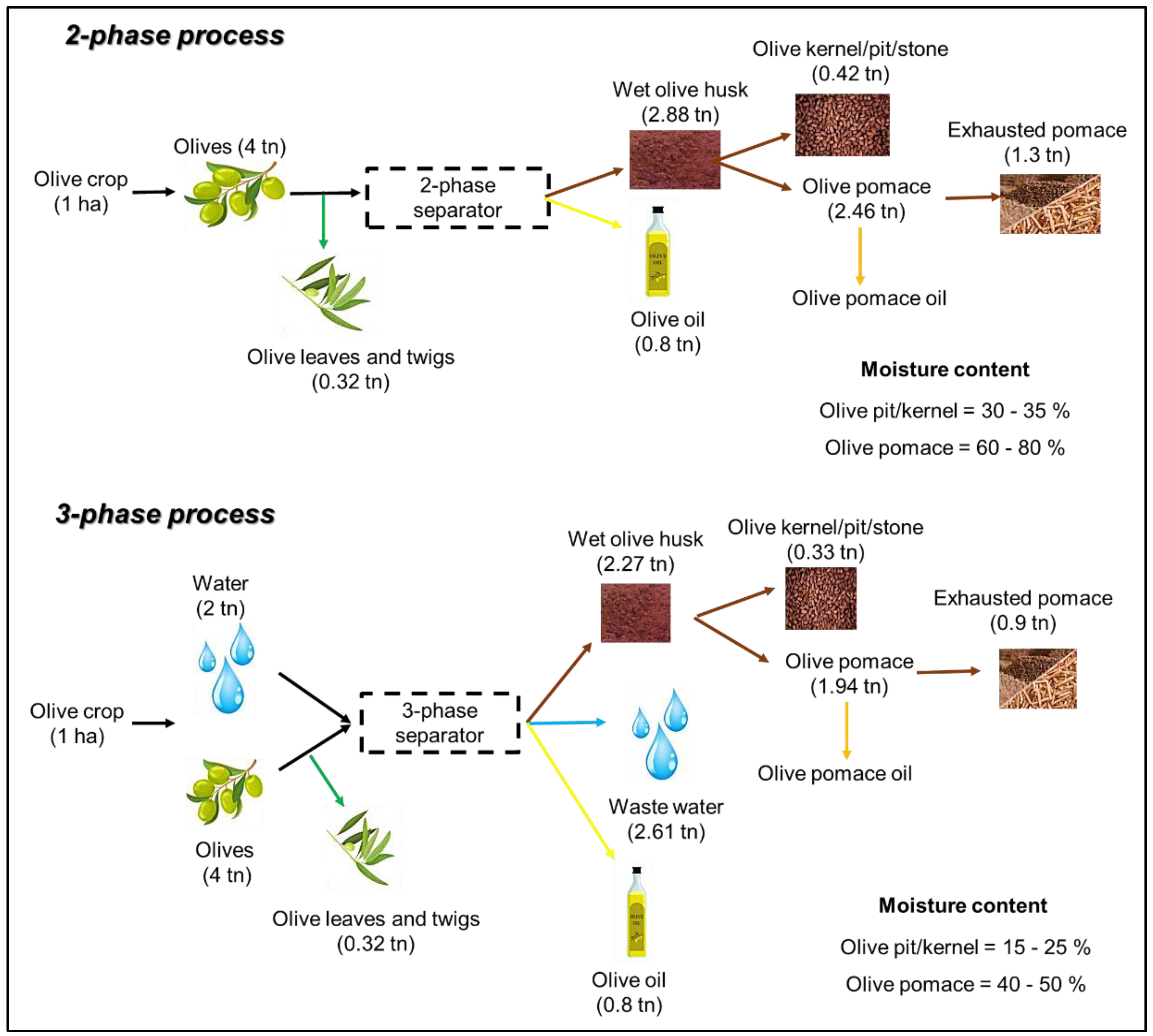

1. Introduction

2. Materials and Methods

2.1. Characterization of Olive Kernel and Bauxite

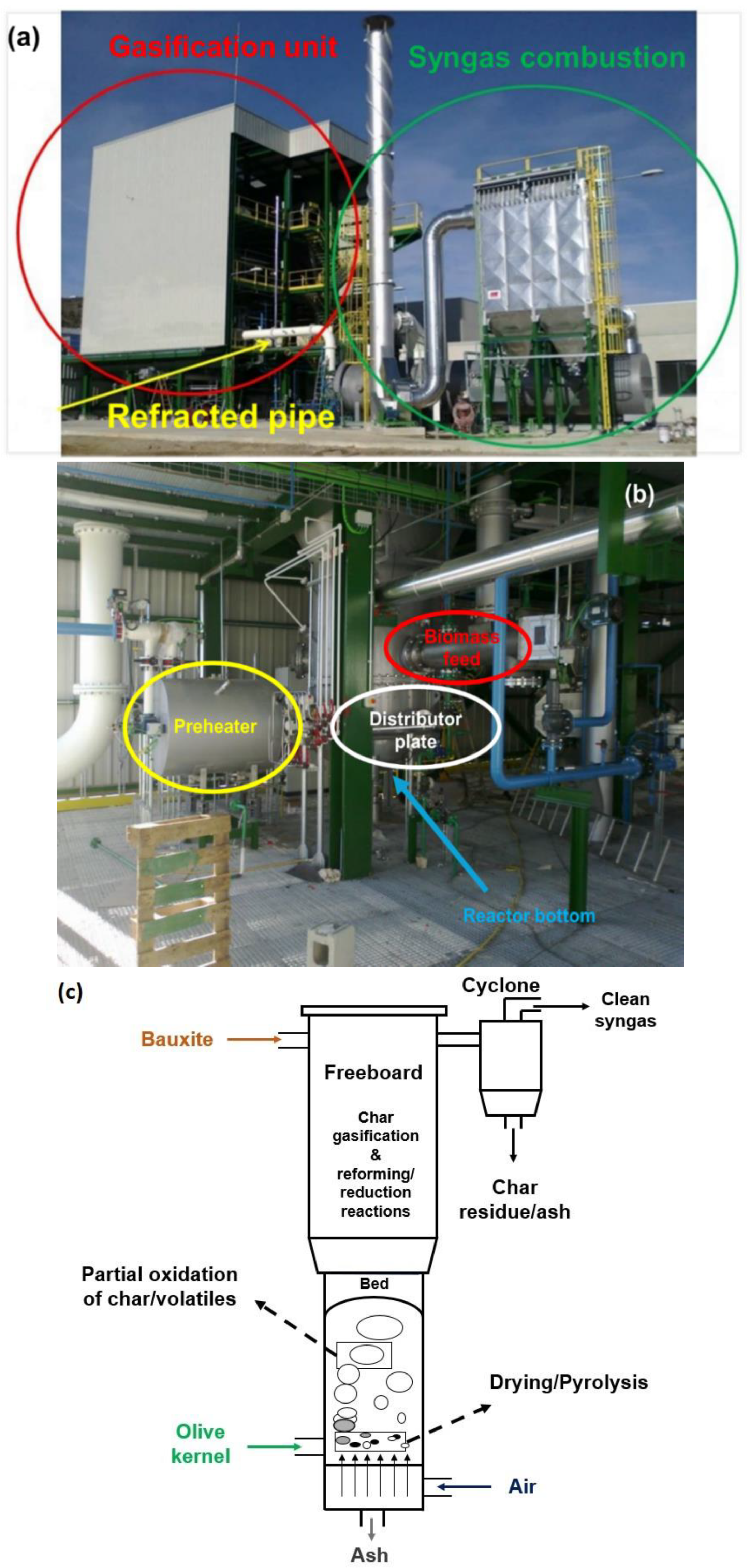

2.2. Pilot Plant Description

- Biomass feeding system

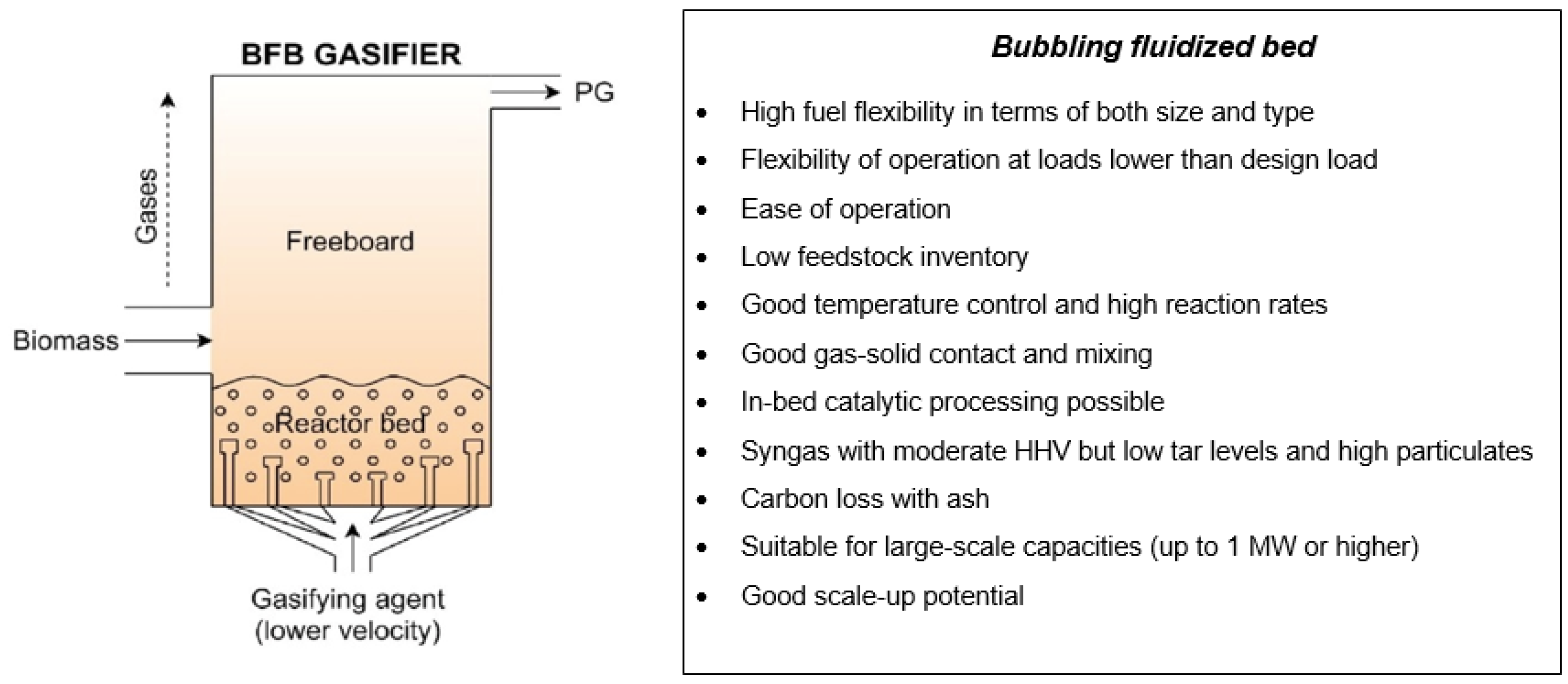

- Air-blown, atmospheric bubbling fluidized bed (ABFB) gasifier

- Syngas cleaning and discharge system

- Syngas combustion, flue gas cooling and cleaning system

- Distributed control system for remote and automatic operation (SCADA)

- Micro gas chromatograph (μ-GC) for gas analysis

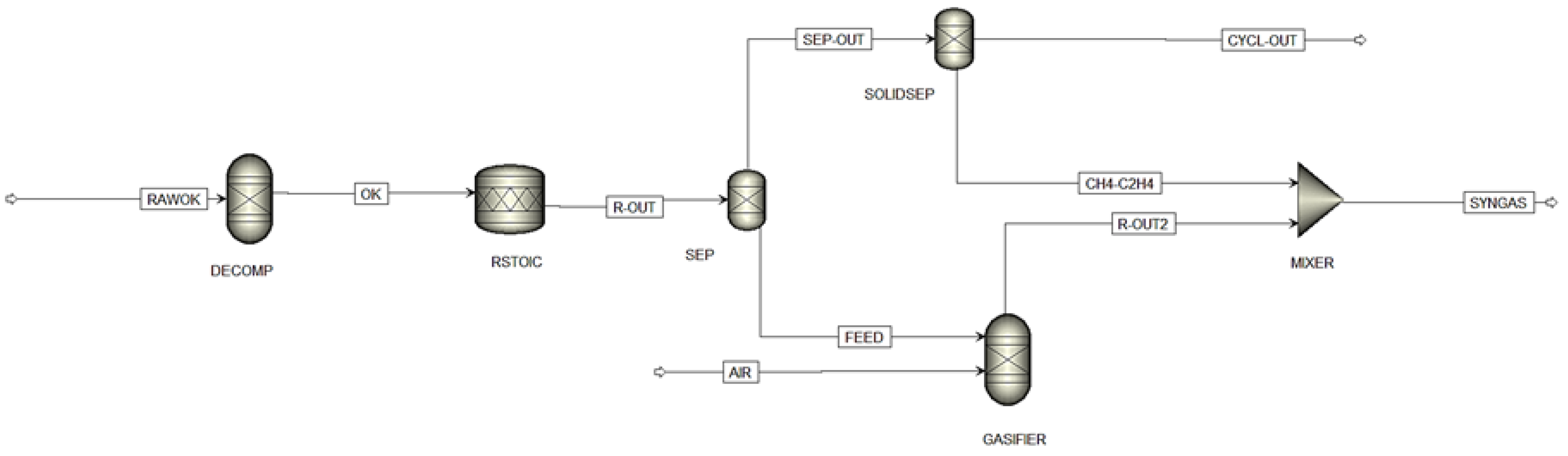

2.3. Simulation Methodology

3. Results and Discussion

3.1. Thermal/Kinetic Behavior of Olive Kernel under Air

- Thermal analysis

- Kinetic analysis

3.2. Experimental Results

3.3. Simulation Results

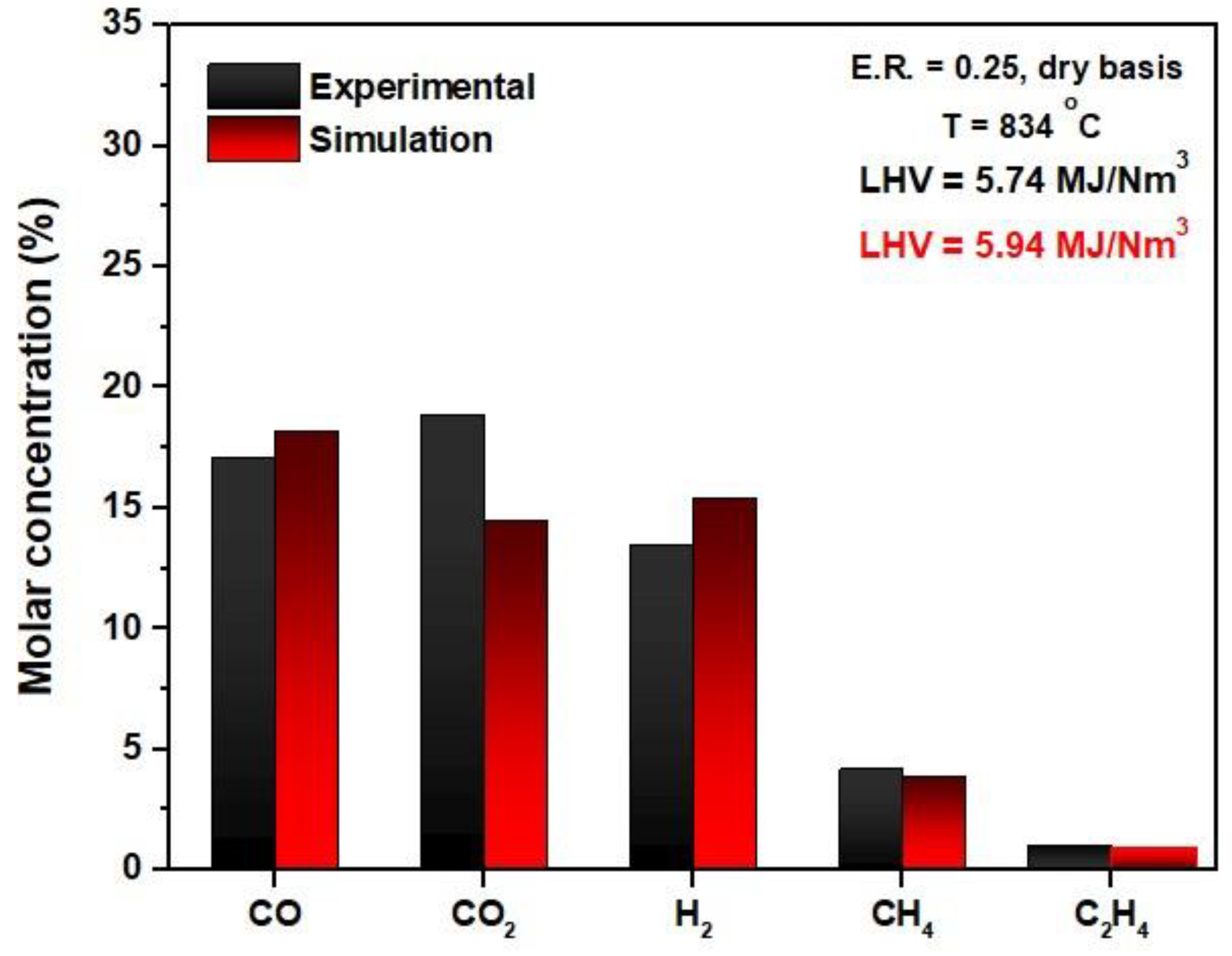

3.3.1. Experimental vs. Simulation Results

- are not cost-intensive and can be realistically applied in the unit with minor modifications,

- are not expected to induce significant changes in the reactor and combustion chamber temperatures, eliminating the need for changes in the safety protocols,

- can be meaningfully evaluated via the simulation methodology used herein.

- Air gasification of the as-received olive kernels with variable apparent equivalence ratios. In practice, this scenario involved alterations only in the biomass feeding system of the unit; specifically, replacement of the existing screw feeder with an apparatus able to handle lower mass flows of the existing olive kernel.

- Pre-treatment of biomass via drying prior to gasification. In this case, the high moisture content in the original olive kernels was largely reduced by means of a single air-drying step applied in situ in the plant without the need for external heat provision, leading to a residual H2O content of as low as 3 wt.%.

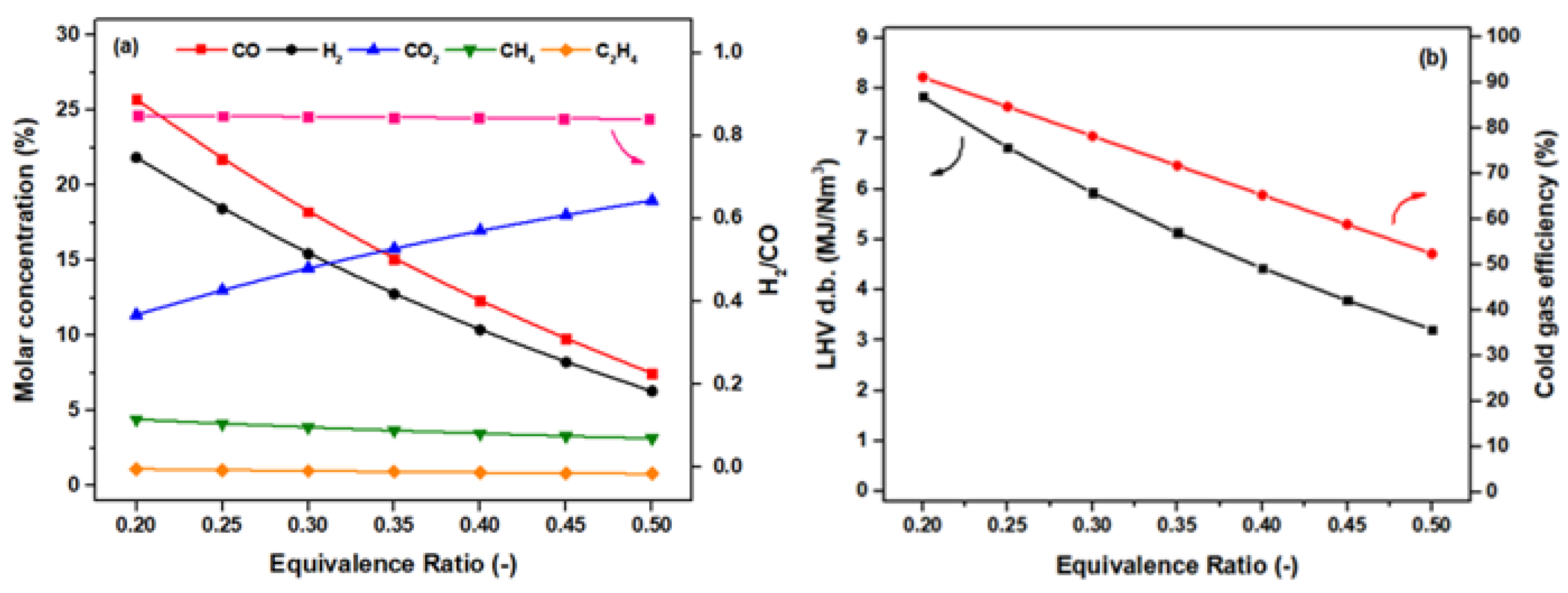

3.3.2. Effect of Equivalence Ratio

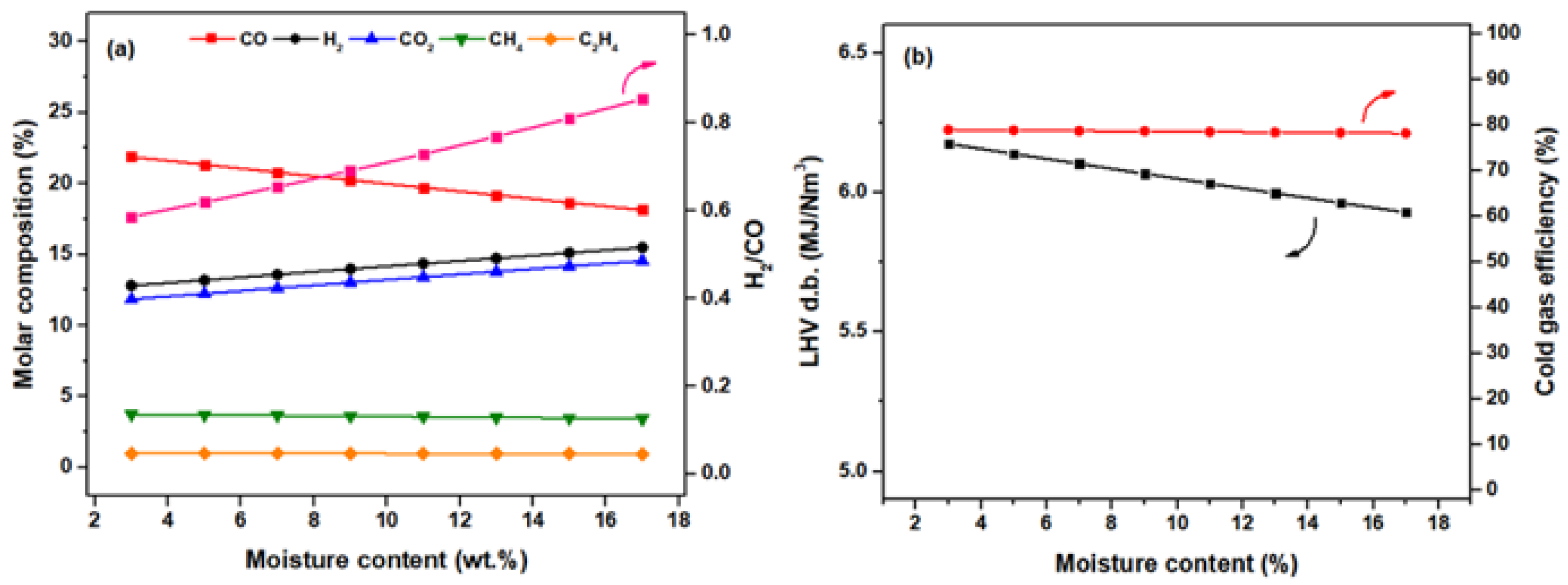

3.3.3. Effect of Biomass Drying

3.4. Syngas Exploitation for District Heating

4. Conclusions and Outlooks

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- International Energy Agency. Global Energy Review 2019. Glob. Energy Rev. 2020. Available online: https://www.oecd-ilibrary.org/energy/global-energy-review-2019_90c8c125-en (accessed on 30 August 2022). [CrossRef]

- European Commission. Europe’s 2030 Climate and Energy Targets/Research and Innovation Actions. 2021. Available online: https://op.europa.eu/en/publication-detail/-/publication/1c8ab88a-e44d-11eb-895a-01aa75ed71a1 (accessed on 30 August 2022). [CrossRef]

- Pelkmans Luc, I.B.T. IEA Bioenergy Countries’ Report—Update 2021. Implementation of Bioenergy in the IEA Bioenergy Member Countries. 2021. Available online: https://www.ieabioenergy.com/blog/publications/iea-bioenergy-countries-report-update-2021/ (accessed on 25 July 2022).

- Ramos, J.S.; Ferreira, A.F. Techno-economic analysis and life cycle assessment of olive and wine industry co-products valorisation. Renew. Sustain. Energy Rev. 2022, 155, 111929. [Google Scholar] [CrossRef]

- Puig-Gamero, M.; Parascanu, M.M.; Sánchez, P.; Sanchez-Silva, L. Olive pomace versus natural gas for methanol production: A life cycle assessment. Environ. Sci. Pollut. Res. 2021, 28, 30335–30350. [Google Scholar] [CrossRef] [PubMed]

- Parascanu, M.M.; Puig Gamero, M.; Sánchez, P.; Soreanu, G.; Valverde, J.L.; Sanchez-Silva, L. Life cycle assessment of olive pomace valorisation through pyrolysis. Renew. Energy 2018, 122, 589–601. [Google Scholar] [CrossRef]

- Duman, A.K.; Özgen, G.Ö.; Üçtuğ, F.G. Environmental life cycle assessment of olive pomace utilization in Turkey. Sustain. Prod. Consum. 2020, 22, 126–137. [Google Scholar] [CrossRef]

- Di Giuliano, A.; Funcia, I.; Pérez-Vega, R.; Gil, J.; Gallucci, K. Novel application of pretreatment and diagnostic method using dynamic pressure fluctuations to resolve and detect issues related to biogenic residue ash in chemical looping gasification. Processes 2020, 8, 1137. [Google Scholar] [CrossRef]

- IEA Net Zero by 2050: A Roadmap for the Global Energy Sector. Int. Energy Agency 2021, 224. Available online: https://unfccc.int/documents/278467?gclid=EAIaIQobChMIqvjZkPjP-gIVIdWWCh3fwA_XEAAYASAAEgL_D_D_BwE (accessed on 4 September 2022).

- Bioelectricity—Bioenergy Europe. Available online: https://bioenergyeurope.org/article/307-bioelectricity-2.html (accessed on 4 September 2022).

- Aravani, V.P.; Sun, H.; Yang, Z.; Liu, G.; Wang, W.; Anagnostopoulos, G.; Syriopoulos, G.; Charisiou, N.D.; Goula, M.A.; Kornaros, M.; et al. Agricultural and livestock sector’s residues in Greece & China: Comparative qualitative and quantitative characterization for assessing their potential for biogas production. Renew. Sustain. Energy Rev. 2022, 154, 111821. [Google Scholar] [CrossRef]

- Vourdoubas, J. Use of Renewable Energy Sources for Energy Generation in Rural Areas in the Island of Crete, Greece. Eur. J. Environ. Earth Sci. 2020, 1, 1–7. [Google Scholar] [CrossRef]

- Vourdoubas, J. Description and Assessment of a Small Renewable Energy Community in the Island of Crete, Greece. Open J. Energy Effic. 2017, 6, 97–111. [Google Scholar] [CrossRef][Green Version]

- Alatzas, S.; Moustakas, K.; Malamis, D.; Vakalis, S. Biomass potential from agricultural waste for energetic utilization in Greece. Energies 2019, 12, 1095. [Google Scholar] [CrossRef]

- del Mar Contreras, M.; Romero, I.; Moya, M.; Castro, E. Olive-derived biomass as a renewable source of value-added products. Process Biochem. 2020, 97, 43–56. [Google Scholar] [CrossRef]

- Aguado, R.; Vera, D.; López-García, D.A.; Torreglosa, J.P.; Jurado, F. Techno-economic assessment of a gasification plant for distributed cogeneration in the agrifood sector. Appl. Sci. 2021, 11, 660. [Google Scholar] [CrossRef]

- Christoforou, E.; Fokaides, P.A. A review of olive mill solid wastes to energy utilization techniques. Waste Manag. 2016, 49, 346–363. [Google Scholar] [CrossRef]

- Ongen, A.; Ozgu, C.; Ayol, A. Biomass gasification for sustainable energy production: A review. Int. J. Hydrog. Energy 2022, 47, 15419–15433. [Google Scholar] [CrossRef]

- Narnaware, S.L.; Panwar, N.L. Biomass gasification for climate change mitigation and policy framework in India: A review. Bioresour. Technol. Rep. 2022, 17, 100892. [Google Scholar] [CrossRef]

- Ren, S.; Feng, X.; Wang, Y. Emergy evaluation of the integrated gasification combined cycle power generation systems with a carbon capture system. Renew. Sustain. Energy Rev. 2021, 147, 111208. [Google Scholar] [CrossRef]

- Allesina, G.; Pedrazzi, S. Barriers to success: A technical review on the limits and possible future roles of small scale gasifiers. Energies 2021, 14, 6711. [Google Scholar] [CrossRef]

- Motta, I.L.; Miranda, N.T.; Maciel Filho, R.; Wolf Maciel, M.R. Biomass gasification in fluidized beds: A review of biomass moisture content and operating pressure effects. Renew. Sustain. Energy Rev. 2018, 94, 998–1023. [Google Scholar] [CrossRef]

- Pala, L.P.R.; Wang, Q.; Kolb, G.; Hessel, V. Steam gasification of biomass with subsequent syngas adjustment using shift reaction for syngas production: An Aspen Plus model. Renew. Energy 2017, 101, 484–492. [Google Scholar] [CrossRef]

- Marcantonio, V.; Ferrario, A.M.; Di Carlo, A.; Del Zotto, L.; Monarca, D.; Bocci, E. Biomass steam gasification: A comparison of syngas composition between a 1-d matlab kinetic model and a 0-d aspen plus quasi-equilibrium model. Computation 2020, 8, 86. [Google Scholar] [CrossRef]

- Song, Y.; Tian, Y.; Zhou, X.; Liang, S.; Li, X.; Yang, Y.; Yuan, L. Simulation of air-steam gasification of pine sawdust in an updraft gasification system for production of hydrogen-rich producer gas. Energy 2021, 226, 120380. [Google Scholar] [CrossRef]

- Vera, D.; De Mena, B.; Jurado, F.; Schories, G. Study of a downdraft gasifier and gas engine fueled with olive oil industry wastes. Appl. Therm. Eng. 2013, 51, 119–129. [Google Scholar] [CrossRef]

- Zabaniotou, A.; Rovas, D.; Monteleone, M. Management of Olive Grove Pruning and Solid Waste from Olive Oil Extraction via Thermochemical Processes. Waste Biomass Valorization 2015, 6, 831–842. [Google Scholar] [CrossRef]

- Vera, D.; Jurado, F.; Margaritis, N.K.; Grammelis, P. Experimental and economic study of a gasification plant fuelled with olive industry wastes. Energy Sustain. Dev. 2014, 23, 247–257. [Google Scholar] [CrossRef]

- Manara, P.; Zabaniotou, A. Indicator-based economic, environmental, and social sustainability assessment of a small gasification bioenergy system fuelled with food processing residues from the Mediterranean agro-industrial sector. Sustain. Energy Technol. Assess. 2014, 8, 159–171. [Google Scholar] [CrossRef]

- Lampropoulos, A.; Kaklidis, N.; Athanasiou, C.; Montes-Morán, M.A.; Arenillas, A.; Menéndez, J.A.; Binas, V.D.; Konsolakis, M.; Marnellos, G.E. Effect of Olive Kernel thermal treatment (torrefaction vs. slow pyrolysis) on the physicochemical characteristics and the CO2 or H2O gasification performance of as-prepared biochars. Int. J. Hydrogen Energy 2021, 46, 29126–29141. [Google Scholar] [CrossRef]

- Maisano, S.; Urbani, F.; Cipitì, F.; Freni, F.; Chiodo, V. Syngas production by BFB gasification: Experimental comparison of different biomasses. Int. J. Hydrog. Energy 2019, 44, 4414–4422. [Google Scholar] [CrossRef]

- Ajorloo, M.; Ghodrat, M.; Scott, J.; Strezov, V. Recent advances in thermodynamic analysis of biomass gasification: A review on numerical modelling and simulation. J. Energy Inst. 2022, 102, 395–419. [Google Scholar] [CrossRef]

- Pio, D.T.; Tarelho, L.A.C. Industrial gasification systems (>3 MWth) for bioenergy in Europe: Current status and future perspectives. Renew. Sustain. Energy Rev. 2021, 145, 111108. [Google Scholar] [CrossRef]

- Chambon, C.L.; Karia, T.; Sandwell, P.; Hallett, J.P. Techno-economic assessment of biomass gasification-based mini-grids for productive energy applications: The case of rural India. Renew. Energy 2020, 154, 432–444. [Google Scholar] [CrossRef]

- Situmorang, Y.A.; Zhao, Z.; Yoshida, A.; Abudula, A.; Guan, G. Small-scale biomass gasification systems for power generation (<200 kW class): A review. Renew. Sustain. Energy Rev. 2020, 117, 109486. [Google Scholar] [CrossRef]

- Ren, J.; Cao, J.P.; Zhao, X.Y.; Yang, F.L.; Wei, X.Y. Recent advances in syngas production from biomass catalytic gasification: A critical review on reactors, catalysts, catalytic mechanisms and mathematical models. Renew. Sustain. Energy Rev. 2019, 116, 109426. [Google Scholar] [CrossRef]

- Mishra, S.; Upadhyay, R.K. Review on biomass gasification: Gasifiers, gasifying mediums, and operational parameters. Mater. Sci. Energy Technol. 2021, 4, 329–340. [Google Scholar] [CrossRef]

- Bandara, J.C.; Jaiswal, R.; Nielsen, H.K.; Moldestad, B.M.E.; Eikeland, M.S. Air gasification of wood chips, wood pellets and grass pellets in a bubbling fluidized bed reactor. Energy 2021, 233, 121149. [Google Scholar] [CrossRef]

- Pio, D.T.; Tarelho, L.A.C.; Matos, M.A.A. Characteristics of the gas produced during biomass direct gasification in an autothermal pilot-scale bubbling fluidized bed reactor. Energy 2017, 120, 915–928. [Google Scholar] [CrossRef]

- Puig-Gamero, M.; Pio, D.T.; Tarelho, L.A.C.; Sánchez, P.; Sanchez-Silva, L. Simulation of biomass gasification in bubbling fluidized bed reactor using aspen plus®. Energy Convers. Manag. 2021, 235, 113981. [Google Scholar] [CrossRef]

- Porcu, A.; Sollai, S.; Marotto, D.; Mureddu, M.; Ferrara, F.; Pettinau, A. Techno-economic analysis of a small-scale biomass-to-energy BFB gasification-based system. Energies 2019, 12, 494. [Google Scholar] [CrossRef]

- Park, S.J.; Son, S.H.; Kook, J.W.; Ra, H.W.; Yoon, S.J.; Mun, T.Y.; Moon, J.H.; Yoon, S.M.; Kim, J.H.; Kim, Y.K.; et al. Gasification operational characteristics of 20-tons-per-Day rice husk fluidized-bed reactor. Renew. Energy 2021, 169, 788–798. [Google Scholar] [CrossRef]

- Sarker, S.; Bimbela, F.; Sánchez, J.L.; Nielsen, H.K. Characterization and pilot scale fluidized bed gasification of herbaceous biomass: A case study on alfalfa pellets. Energy Convers. Manag. 2015, 91, 451–458. [Google Scholar] [CrossRef]

- Alauddin, Z.A.B.Z.; Lahijani, P.; Mohammadi, M.; Mohamed, A.R. Gasification of lignocellulosic biomass in fluidized beds for renewable energy development: A review. Renew. Sustain. Energy Rev. 2010, 14, 2852–2862. [Google Scholar] [CrossRef]

- Ismail, T.M.; Ramos, A.; Monteiro, E.; El-Salam, M.A.; Rouboa, A. Parametric studies in the gasification agent and fluidization velocity during oxygen-enriched gasification of biomass in a pilot-scale fluidized bed: Experimental and numerical assessment. Renew. Energy 2020, 147, 2429–2439. [Google Scholar] [CrossRef]

- Berdugo Vilches, T.; Marinkovic, J.; Seemann, M.; Thunman, H. Comparing Active Bed Materials in a Dual Fluidized Bed Biomass Gasifier: Olivine, Bauxite, Quartz-Sand, and Ilmenite. Energy Fuels 2016, 30, 4848–4857. [Google Scholar] [CrossRef]

- Hanchate, N.; Ramani, S.; Mathpati, C.S.; Dalvi, V.H. Biomass Gasification Using Dual Fluidized Bed Gasification Systems: A Review; Elsevier Ltd.: Amsterdam, The Netherlands, 2021; Volume 280, ISBN 4613491031291. [Google Scholar]

- Marinkovic, J.; Seemann, M.; Schwebel, G.L.; Thunman, H. Impact of Biomass Ash-Bauxite Bed Interactions on an Indirect Biomass Gasifier. Energy Fuels 2016, 30, 4044–4052. [Google Scholar] [CrossRef]

- Cherukumilli, K.; Delaire, C.; Amrose, S.; Gadgil, A.J. Factors Governing the Performance of Bauxite for Fluoride Remediation of Groundwater. Environ. Sci. Technol. 2017, 51, 2321–2328. [Google Scholar] [CrossRef] [PubMed]

- Fryda, L.; Panopoulos, K.D.; Kakaras, E. Integrated CHP with autothermal biomass gasification and SOFC-MGT. Energy Convers. Manag. 2008, 49, 281–290. [Google Scholar] [CrossRef]

- Michailos, S.; Zabaniotou, A. Simulation of Olive Kernel Gasification in a Bubbling Fluidized Bed Pilot Scale Reactor. J. Sustain. Bioenergy Syst. 2012, 2, 145–159. [Google Scholar] [CrossRef]

- Dhyani, V.; Bhaskar, T. A comprehensive review on the pyrolysis of lignocellulosic biomass. Renew. Energy 2018, 129, 695–716. [Google Scholar] [CrossRef]

- Fernandez, A.; Soria, J.; Rodriguez, R.; Baeyens, J.; Mazza, G. Macro-TGA steam-assisted gasification of lignocellulosic wastes. J. Environ. Manage. 2019, 233, 626–635. [Google Scholar] [CrossRef]

- Niu, M.; Huang, Y.; Jin, B.; Wang, X. Simulation of syngas production from municipal solid waste gasification in a bubbling fluidized bed using aspen plus. Ind. Eng. Chem. Res. 2013, 52, 14768–14775. [Google Scholar] [CrossRef]

- Grimekis, D.; Delgado Calvo, M.A.; Panopoulos, K.; Karellas, S. Modelling of a 3 MWTH BFB gasifier in aspenplusTM. Eur. Biomass Conf. Exhib. Proc. 2018, 2018, 713–721. [Google Scholar] [CrossRef]

- Grimekis, D.T. Experimental and Modeling Investigation of Cleaning Technologies for Carbon Dioxide, Tar and Sulfur Compounds Contained in Gasification Product Gases. Ph.D. Thesis, National Technical University of Athens, Athens, Greece, 2019. [Google Scholar] [CrossRef]

- Kim, Y.D.; Yang, C.W.; Kim, B.J.; Kim, K.S.; Lee, J.W.; Moon, J.H.; Yang, W.; Yu, T.U.; Lee, U. Do Air-blown gasification of woody biomass in a bubbling fluidized bed gasifier. Appl. Energy 2013, 112, 414–420. [Google Scholar] [CrossRef]

- Abdoulmoumine, N.; Kulkarni, A.; Adhikari, S. Effects of temperature and equivalence ratio on pine syngas primary gases and contaminants in a bench-scale fluidized bed gasifier. Ind. Eng. Chem. Res. 2014, 53, 5767–5777. [Google Scholar] [CrossRef]

- Monteiro, E.; Ismail, T.M.; Ramos, A.; Abd El-Salam, M.; Brito, P.; Rouboa, A. Experimental and modeling studies of Portuguese peach stone gasification on an autothermal bubbling fluidized bed pilot plant. Energy 2018, 142, 862–877. [Google Scholar] [CrossRef]

- Volpe, R.; Zabaniotou, A.A.; Skoulou, V. Synergistic Effects between Lignin and Cellulose during Pyrolysis of Agricultural Waste. Energy Fuels 2018, 32, 8420–8430. [Google Scholar] [CrossRef]

- Rodríguez, G.; Lama, A.; Rodríguez, R.; Jiménez, A.; Guillén, R.; Fernández-Bolaños, J. Olive stone an attractive source of bioactive and valuable compounds. Bioresour. Technol. 2008, 99, 5261–5269. [Google Scholar] [CrossRef]

- Jahirul, M.I.; Rasul, M.G.; Chowdhury, A.A.; Ashwath, N. Biofuels production through biomass pyrolysis—A technological review. Energies 2012, 5, 4952–5001. [Google Scholar] [CrossRef]

- Sher, F.; Iqbal, S.Z.; Liu, H.; Imran, M.; Snape, C.E. Thermal and kinetic analysis of diverse biomass fuels under different reaction environment: A way forward to renewable energy sources. Energy Convers. Manag. 2020, 203, 112266. [Google Scholar] [CrossRef]

- Abadir, M.F.; Barakat, F.I.; Salam, N.F.A. Kinetics of Pyrolysis of Olive Kernels Kinetics of Pyrolysis of Olive Kernels. IOSR J. Appl. Chem. (IOSR-JAC) 2019, 12, 50–56. [Google Scholar] [CrossRef]

- Manara, P.; Vamvuka, D.; Sfakiotakis, S.; Vanderghem, C.; Richel, A.; Zabaniotou, A. Mediterranean agri-food processing wastes pyrolysis after pre-treatment and recovery of precursor materials: A TGA-based kinetic modeling study. Food Res. Int. 2015, 73, 44–51. [Google Scholar] [CrossRef]

- Roncancio, R.; Gore, J.P. CO2 char gasification: A systematic review from 2014 to 2020. Energy Convers. Manag. X 2021, 10, 100060. [Google Scholar] [CrossRef]

- Li, S.; Song, H.; Hu, J.; Yang, H.; Zou, J.; Zhu, Y.; Tang, Z.; Chen, H. CO2 gasification of straw biomass and its correlation with the feedstock characteristics. Fuel 2021, 297, 120780. [Google Scholar] [CrossRef]

- Edreis, E.M.A.; Li, X.; Luo, G.; Sharshir, S.W.; Yao, H. Kinetic analyses and synergistic effects of CO2 co-gasification of low sulphur petroleum coke and biomass wastes. Bioresour. Technol. 2018, 267, 54–62. [Google Scholar] [CrossRef] [PubMed]

- Kozlov, A.N.; Svishchev, D.A.; Khudiakova, G.I.; Ryzhkov, A.F. A kinetic analysis of the thermochemical conversion of solid fuels (A review). Solid Fuel Chem. 2017, 51, 205–213. [Google Scholar] [CrossRef]

- Munir, S.; Daood, S.S.; Nimmo, W.; Cunliffe, A.M.; Gibbs, B.M. Thermal analysis and devolatilization kinetics of cotton stalk, sugar cane bagasse and shea meal under nitrogen and air atmospheres. Bioresour. Technol. 2009, 100, 1413–1418. [Google Scholar] [CrossRef]

- Valderrama Rios, M.L.; González, A.M.; Lora, E.E.S.; Almazán del Olmo, O.A. Reduction of tar generated during biomass gasification: A review. Biomass Bioenergy 2018, 108, 345–370. [Google Scholar] [CrossRef]

- Valdés, C.F.; Chejne, F.; Marrugo, G.; Macias, R.J.; Gómez, C.A.; Montoya, J.I.; Londoño, C.A.; De La Cruz, J.; Arenas, E. Co-gasification of sub-bituminous coal with palm kernel shell in fluidized bed coupled to a ceramic industry process. Appl. Therm. Eng. 2016, 107, 1201–1209. [Google Scholar] [CrossRef]

- Suraj, P.; George, J.; Arun, P.; Muraleedharan, C. Theoretical and experimental feasibility study of groundnut shell gasification in a fluidized bed gasifier. Biomass Convers. Biorefinery 2020, 10, 735–742. [Google Scholar] [CrossRef]

- Karmakar, M.K.; Datta, A.B. Generation of hydrogen rich gas through fluidized bed gasification of biomass. Bioresour. Technol. 2011, 102, 1907–1913. [Google Scholar] [CrossRef]

- Dillibabu, V.; Lakshmanan, T.; Natarajan, E. Air and Oxygen Gasification Simulation Analysis of Sawdust. Therm. Sci. 2019, 23, 1043–1053. [Google Scholar]

- Eri, Q.; Wu, W.; Zhao, X. Numerical investigation of the air-steam biomass gasification process based on thermodynamic equilibrium model. Energies 2017, 10, 2163. [Google Scholar] [CrossRef]

- Rodriguez-Alejandro, D.A.; Nam, H.; Maglinao, A.L.; Capareda, S.C.; Aguilera-Alvarado, A.F. Development of a modified equilibrium model for biomass pilot-scale fluidized bed gasifier performance predictions. Energy 2016, 115, 1092–1108. [Google Scholar] [CrossRef]

- Gu, H.; Tang, Y.; Yao, J.; Chen, F. Study on biomass gasification under various operating conditions. J. Energy Inst. 2019, 92, 1329–1336. [Google Scholar] [CrossRef]

- Mutlu, Ö.Ç.; Zeng, T. Challenges and Opportunities of Modeling Biomass Gasification in Aspen Plus: A Review. Chem. Eng. Technol. 2020, 43, 1674–1689. [Google Scholar] [CrossRef]

- Islam, M.W. Effect of different gasifying agents (steam, H2O2, oxygen, CO2, and air) on gasification parameters. Int. J. Hydrogen Energy 2020, 45, 31760–31774. [Google Scholar] [CrossRef]

- Borello, D.; Pantaleo, A.M.; Caucci, M.; De Caprariis, B.; De Filippis, P.; Shah, N. Modeling and experimental study of a small scale olive pomace gasifier for cogeneration: Energy and profitability analysis. Energies 2017, 10, 1930. [Google Scholar] [CrossRef]

- Elias, A.; Boumeddane, B.; Vera, D.; Jurado, F. Gasification of olive mill solid wastes for cogeneration applications in Tizi Ouzou region: Thermo-economic assessment. Int. J. Sustain. Energy 2021, 40, 1002–1026. [Google Scholar] [CrossRef]

- Gómez-Barea, A.; Arjona, R.; Ollero, P. Pilot-plant gasification of olive stone: A technical assessment. Energy Fuels 2005, 19, 598–605. [Google Scholar] [CrossRef]

- Ramzan, N.; Ashraf, A.; Naveed, S.; Malik, A. Simulation of hybrid biomass gasification using Aspen plus: A comparative performance analysis for food, municipal solid and poultry waste. Biomass Bioenergy 2011, 35, 3962–3969. [Google Scholar] [CrossRef]

- Huang, F.; Jin, S. Investigation of biomass (pine wood) gasification: Experiments and Aspen Plus simulation. Energy Sci. Eng. 2019, 7, 1178–1187. [Google Scholar] [CrossRef]

- Damartzis, T.; Michailos, S.; Zabaniotou, A. Energetic assessment of a combined heat and power integrated biomass gasification-internal combustion engine system by using Aspen Plus®. Fuel Process. Technol. 2012, 95, 37–44. [Google Scholar] [CrossRef]

- Begum, S.; Rasul, M.G.; Akbar, D.; Ramzan, N. Performance analysis of an integrated fixed bed gasifier model for different biomass feedstocks. Energies 2013, 6, 6508–6524. [Google Scholar] [CrossRef]

- Tuomi, S.; Kurkela, E.; Hannula, I.; Berg, C.G. The impact of biomass drying on the efficiency of a gasification plant co-producing Fischer-Tropsch fuels and heat—A conceptual investigation. Biomass Bioenergy 2019, 127, 105272. [Google Scholar] [CrossRef]

- Rezaei, M.; Sameti, M.; Nasiri, F. Biomass-fuelled combined heat and power: Integration in district heating and thermal-energy storage. Clean Energy 2021, 5, 44–56. [Google Scholar] [CrossRef]

- Difs, K.; Wetterlund, E.; Trygg, L.; Söderström, M. Biomass gasification opportunities in a district heating system. Biomass Bioenergy 2010, 34, 637–651. [Google Scholar] [CrossRef]

- Kirsanovs, V.; Blumberga, D.; Karklina, K.; Veidenbergs, I.; Rochas, C.; Vigants, E.; Vigants, G. Biomass Gasification for District Heating. Energy Procedia 2017, 113, 217–223. [Google Scholar] [CrossRef]

| Gasifying Agent | Advantages | Disadvantages |

|---|---|---|

| Air |  Heat generation from combustion Heat generation from combustion

Low/moderate char and tar content Low/moderate char and tar content Inexpensive Inexpensive |  Low heating value (4–7 MJ/Nm3) Low heating value (4–7 MJ/Nm3) N2 dilution N2 dilution |

| O2 |  N2-free syngas N2-free syngas High heating value (10–20 MJ/Nm3) High heating value (10–20 MJ/Nm3) |  Cost-intensive Cost-intensive |

| H2O |  High heating value (10–18 MJ/Nm3) High heating value (10–18 MJ/Nm3) H2-rich syngas H2-rich syngas N2-free syngas N2-free syngas |  Very endothermic Very endothermic Relatively low CO concentration Relatively low CO concentration |

| CO2 |  Moderate heating value (10–15 MJ/Nm3) Moderate heating value (10–15 MJ/Nm3) High CO and low CO2 content High CO and low CO2 content |  Very endothermic Very endothermic Low H2 concentration Low H2 concentration |

| Gasification Parameter | Gasifier Type | |||

|---|---|---|---|---|

| Downdraft | Updraft | BFB | CFB | |

| Pressure (bar) | 1 | 1 | 1.35 | 1.19 |

| Temperature (°C) | 700–1200 | 700–900 | 650–950 | 800–1000 |

| LHV (MJ/Nm3) | 5–6 | 4.5–5 | 4–7.5 | 4–7.5 |

| Thermal input (MWth) | <5 | <20 | 3–100 | 20–100 |

| Tar content (g/Nm3) | 0.015–0.5 | 30–150 | 1–50 | 1–30 |

| Particulates | Low | Low | Very low (cyclone) | |

| Particle size (mm) | 20–100 | 5–100 | 10–100 | |

| Moisture (wt.%) | <15 | <50 | <40 | |

| Ash (wt.%, d.b.) | <5 | <15 | <20 | |

| Morphology | Uniform | Uniform | Uniform | |

| Density (kg/m3) | >500 | >400 | >100 | |

| Ultimate Analysis (wt.% d.a.f.) | Immediate Analysis (wt.%) | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| C | O | H | N | H2O | Ash d.b. | LHV w.b. (MJ/kg) | LHV d.b. (MJ/kg) | LHV d.a.f (MJ/kg) | Bulk Density (kg/m3) |

| 50.9 | 43.0 | 6.0 | 0.1 | 16.8 | 0.6 | 15.3 | 18.9 | 19.0 | 730 |

| Process Data | |

|---|---|

| Reactor Type | Atmospheric Bubbling Fluidized Bed (ABFB) |

| Nominal power (MWth) | 2.0 |

| Minimum power (MWth) | 1.2 |

| Operating pressure (barg) | 0.3 |

| Bed temperature (°C) | 650–950 |

| Freeboard temperature (°C) | 700–1000 |

| Inertization/purge gas | CO2 |

| Biomass feed specifications | |

| Bulk density (kg/m3) | 80–800 |

| Moisture content (%) | <30 |

| Particle size (mm) | <30 |

| Volatile matter (% d.a.f.) | 68–87 |

| Ash (% d.b.) | <13 |

| Lower heating value (MJ/kg d.b.) | 15.3–20.8 |

| Bed material specifications | |

| Bulk density (kg/m3) | 1000–5000 |

| Particle size (mm) | <1 |

| Minimum fluidization velocity (m/s) | 0.17 |

| Fluidization velocity ratio | <2 |

| Oxidative Degradation Zone | ||||

|---|---|---|---|---|

| Temperature Range (°C) | Tpeak (°C) | Mass Loss (%) | Maximum Rate of Weight Loss (%/min) | Activation Energy Range a (kJ/mol) |

| 100–460 | 395 | 70 | 5.6 | 56–110 |

| Char Combustion Zone | ||||

| Temperature Range (°C) | Tpeak (°C) | Mass Loss (%) | Maximum Rate of Weight Loss (%/min) | Activation Energy Range a (kJ/mol) |

| 460–650 | 530 | 20 | 2.2 | 47–85 |

| H2 | CO | CO2 | N2 | CH4 | C2H4 | C2H6 | LHV (MJ/Nm3) | LHV (MJ/kg) | H2/CO |

| 13.5 | 17.1 | 18.9 | 44.7 | 4.2 | 1.1 | <0.1 | |||

| C2H2 | C3H8 | C4H10 | C5H12 | C6H14 | C6H6 | C7H8 | 5.74 | 5.00 | 0.79 |

| <0.1 | <0.2 | trace | trace | trace | 0.05 | n.d. |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lampropoulos, A.; Zubillaga, I.G.; Pérez-Vega, R.; Ntavos, N.; Fallas, Y.; Varvoutis, G. Preliminary Experimental Results and Modelling Study of Olive Kernel Gasification in a 2 MWth BFB Gasifier. Processes 2022, 10, 2020. https://doi.org/10.3390/pr10102020

Lampropoulos A, Zubillaga IG, Pérez-Vega R, Ntavos N, Fallas Y, Varvoutis G. Preliminary Experimental Results and Modelling Study of Olive Kernel Gasification in a 2 MWth BFB Gasifier. Processes. 2022; 10(10):2020. https://doi.org/10.3390/pr10102020

Chicago/Turabian StyleLampropoulos, Athanasios, Idoya Goñi Zubillaga, Raúl Pérez-Vega, Nikolaos Ntavos, Yannis Fallas, and Georgios Varvoutis. 2022. "Preliminary Experimental Results and Modelling Study of Olive Kernel Gasification in a 2 MWth BFB Gasifier" Processes 10, no. 10: 2020. https://doi.org/10.3390/pr10102020

APA StyleLampropoulos, A., Zubillaga, I. G., Pérez-Vega, R., Ntavos, N., Fallas, Y., & Varvoutis, G. (2022). Preliminary Experimental Results and Modelling Study of Olive Kernel Gasification in a 2 MWth BFB Gasifier. Processes, 10(10), 2020. https://doi.org/10.3390/pr10102020