Low-Carbon Collaboration in the Supply Chain under Digital Transformation: An Evolutionary Game-Theoretic Analysis

Abstract

:1. Introduction

2. Literature Review

2.1. Low-Carbon Collaboration in the Supply Chain

2.2. Effect and Influence Factors of Low-Carbon Collaboration

2.3. Game Models of Low-Carbon Collaboration in the Supply Chain

2.4. Low-Carbon Collaboration and Digital Transformation

3. Evolutionary Game-Model Building

3.1. Model Assumptions

3.2. Strategy Combinations and Payoff Matrix

3.3. Replicator Dynamics Equations

3.4. Agents Stability Analysis

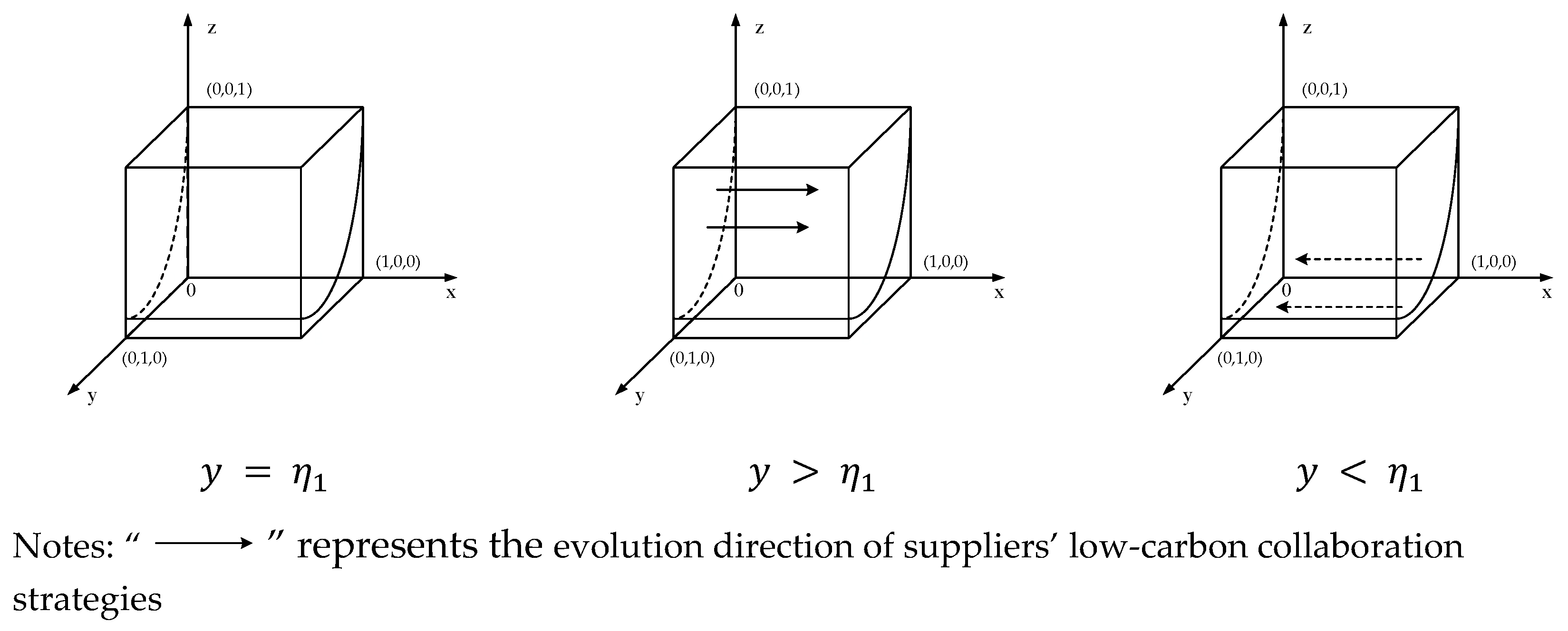

- When , all game strategies are at a steady state.

- When , supposing, thenare the stable points of.

- If , under the restraints of , and , then when (denoted as ), irrespective of what the suppliers choose for low-carbon collaboration, it is still a stable strategy and will not evolve.

- If , then let , get and two equilibrium points. This study assumes that the collaboration benefits obtained by each agent are more significant than the low-carbon input cost and strategic risk cost, that is: . Therefore, when , ; and when , . At this time, is the evolutionary stable point, which means that suppliers are in a stable state only when they choose the low-carbon collaboration strategies. □

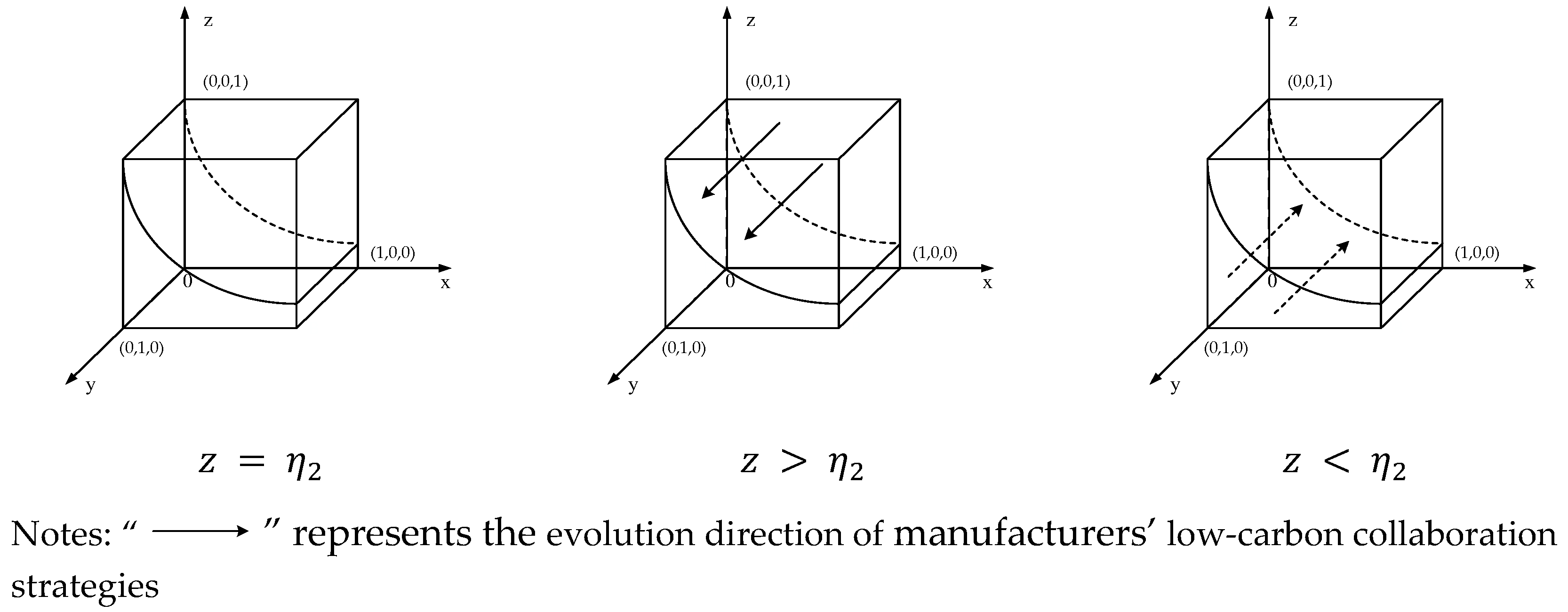

- When , all game strategies are at a steady state.

- When , supposing, thenare the stable points of.

- If , under the restraints of , and , then when (denoted as ), no matter what the manufacturers choose for low-carbon collaboration, it is still a stable strategy and will not evolve.

- If , then let , get and two equilibrium points. Due to , when , ; and when , . At this time, is the evolutionary stable point, which means that manufacturers are in a stable state only when they choose low-carbon collaboration strategies. □

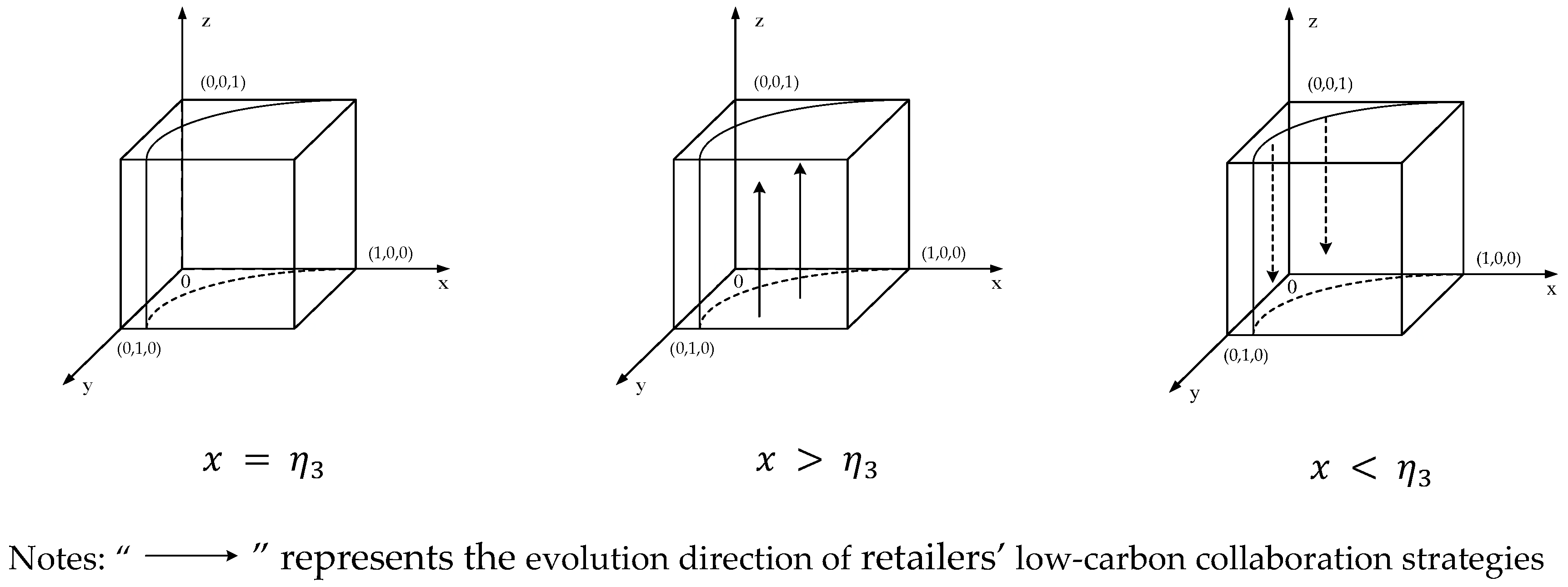

- When, all game strategies are at a steady state.

- When , supposing, thenare the stable points of.

- If , under the restraints of , and , then when (denoted as ), irrespective of what the retailers choose for low-carbon collaboration, it is still a stable strategy and will not evolve.

- If , get and two equilibrium points. Due to , when , ; when , . At this time, is the evolutionary stable point, which means that retailers are in a stable state only when they choose the low-carbon collaboration strategies. □

3.5. Tripartite Stability Analysis

- When,(1,1,1) are the ESS of.

- When ,(0,0,0) and(1,1,1) are the ESS of.

- If , that is, the government’s reward and punishment are more than the strategic risk cost of suppliers, manufacturers, and retailers, the stability of each equilibrium point is as shown in Table 5, Condition (1). In this condition, there is only one equilibrium point, (1,1,1), that has all negative eigenvalues. Currently, the corresponding evolutionarily stable strategy (ESS) in the supply chain are {collaborate, collaborate, collaborate}.

- If , that is, the government’s reward and punishment are less than the strategic risk cost of suppliers, manufacturers, and retailers, the stability of each equilibrium point is as shown in Table 5, Condition (2). There are two equilibrium points, and that have all negative eigenvalues. At this time, the corresponding evolutionarily stable strategy in supply chain are {non-collaborate, non-collaborate, non-collaborate}, {collaborate, collaborate, collaborate}.

4. System Dynamics Simulation Analysis

4.1. System Dynamics Assumptions

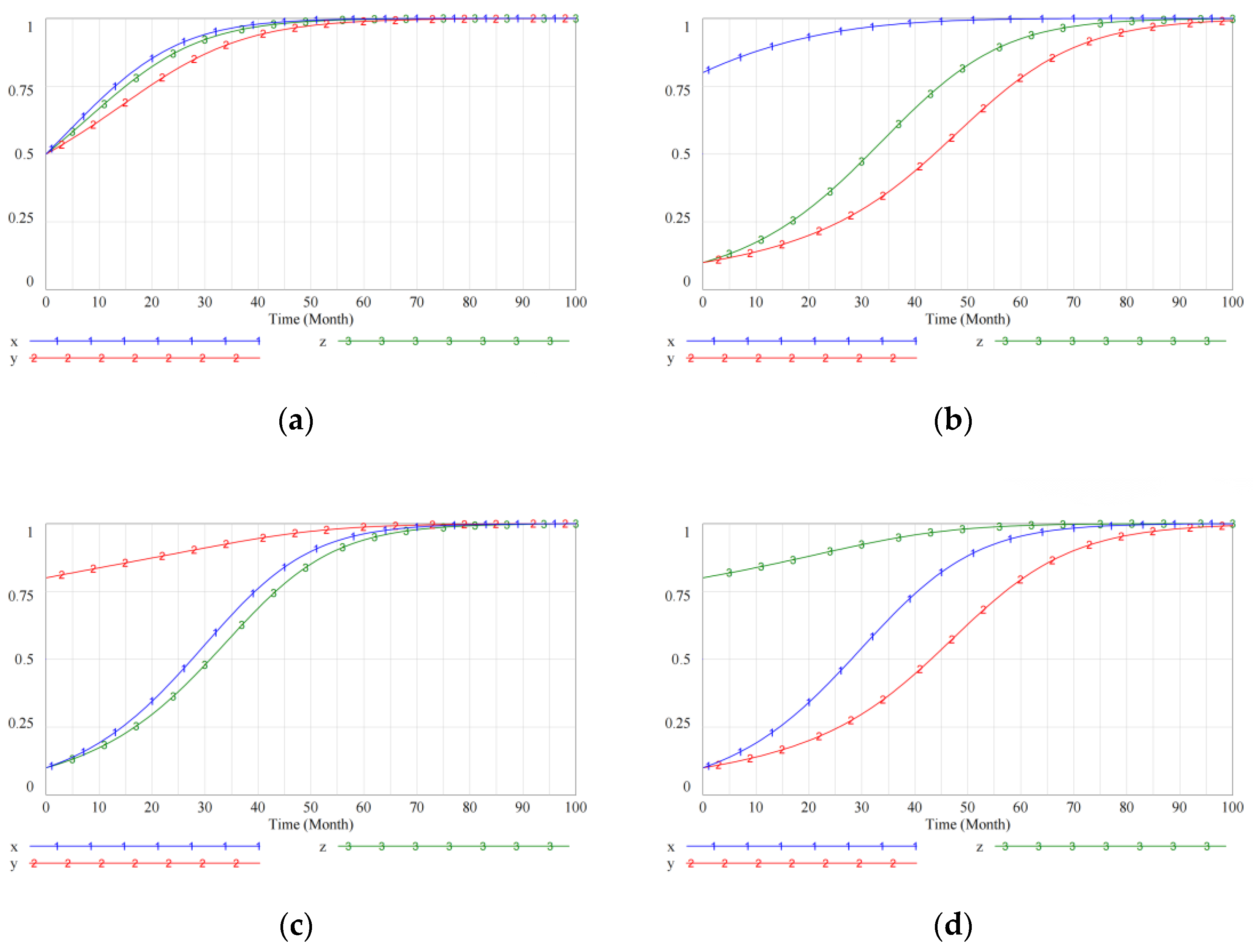

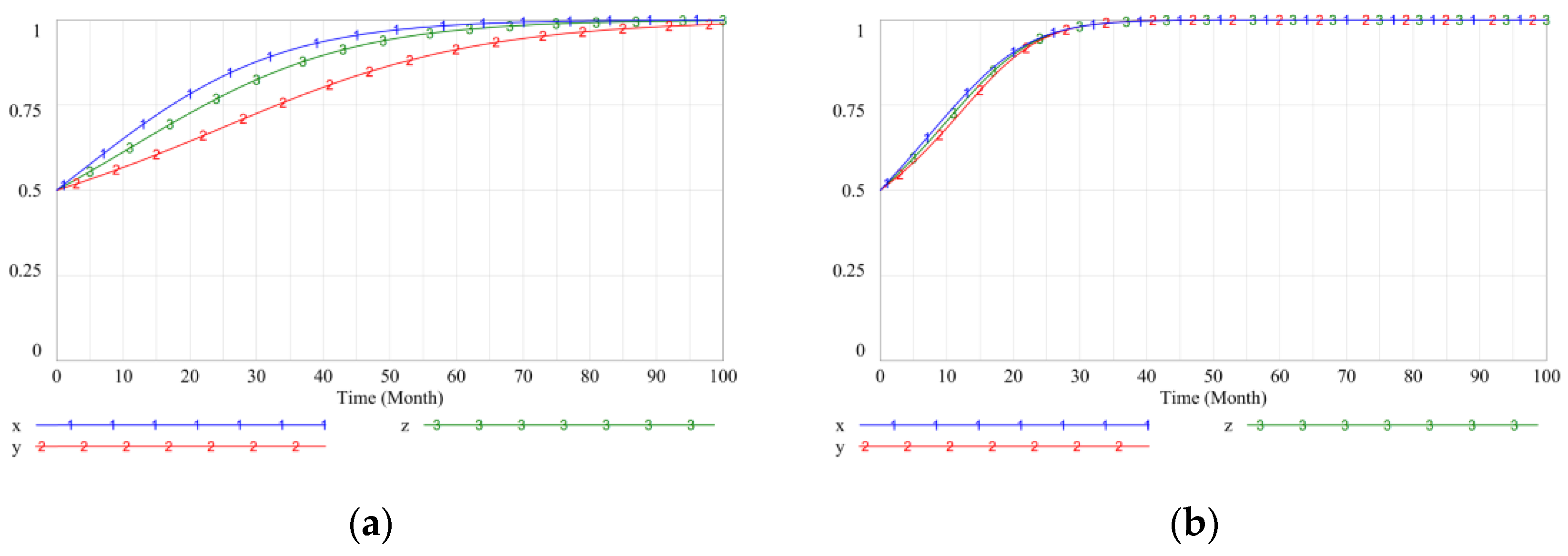

4.2. Fundamental Simulation

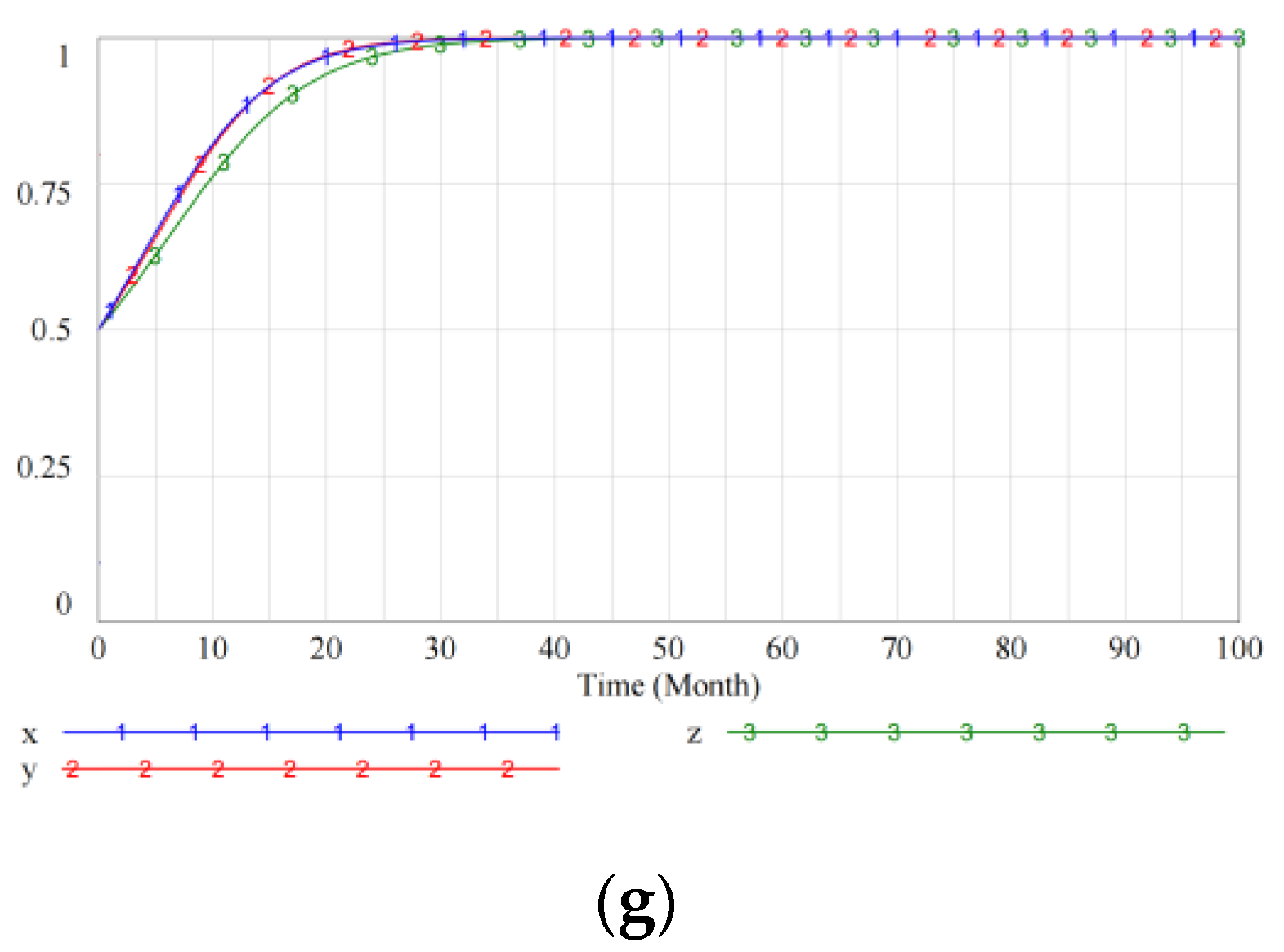

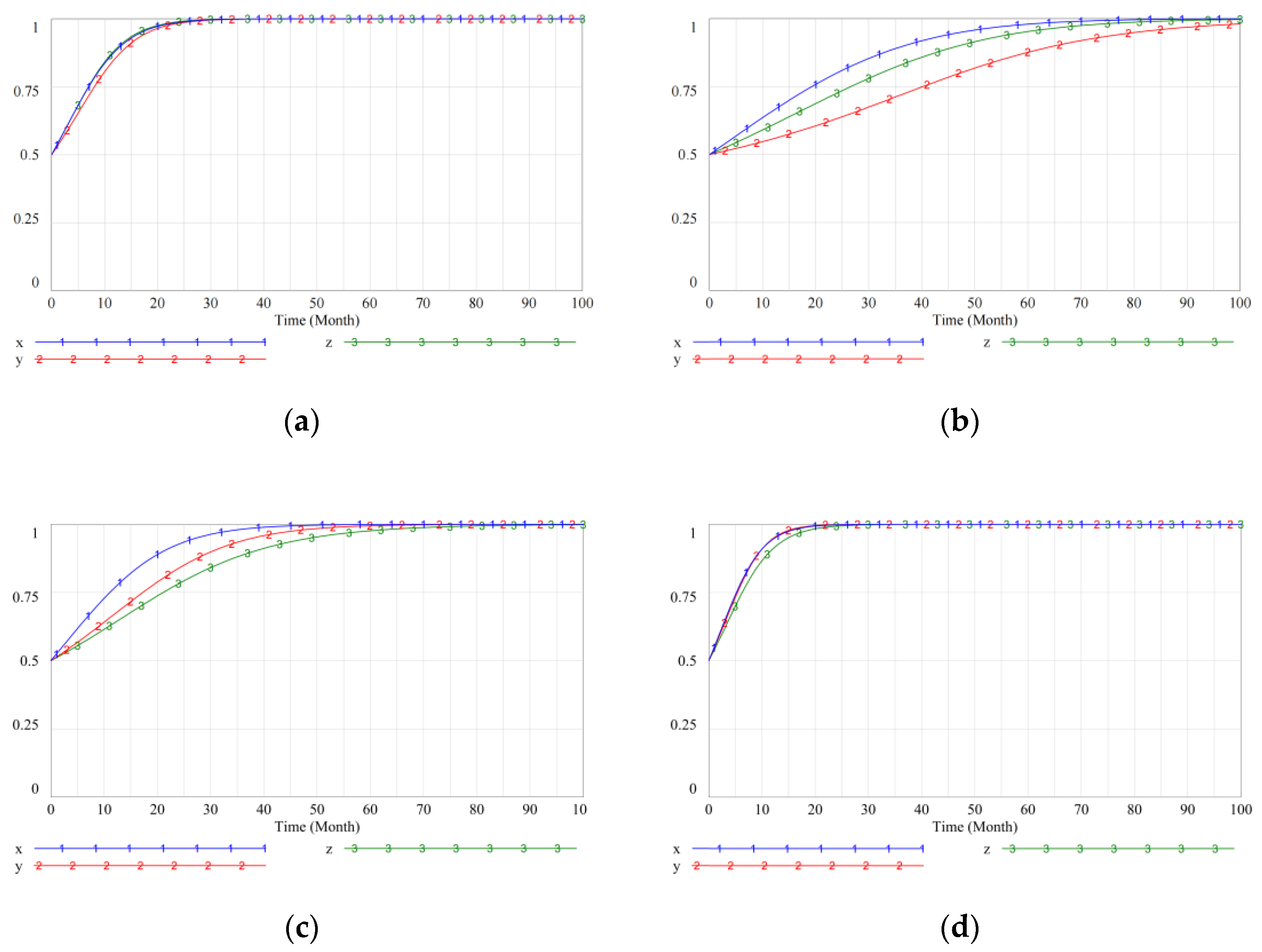

4.3. Digital Transformation Simulation

4.4. Additional Benefits and Benefit-Sharing Simulation

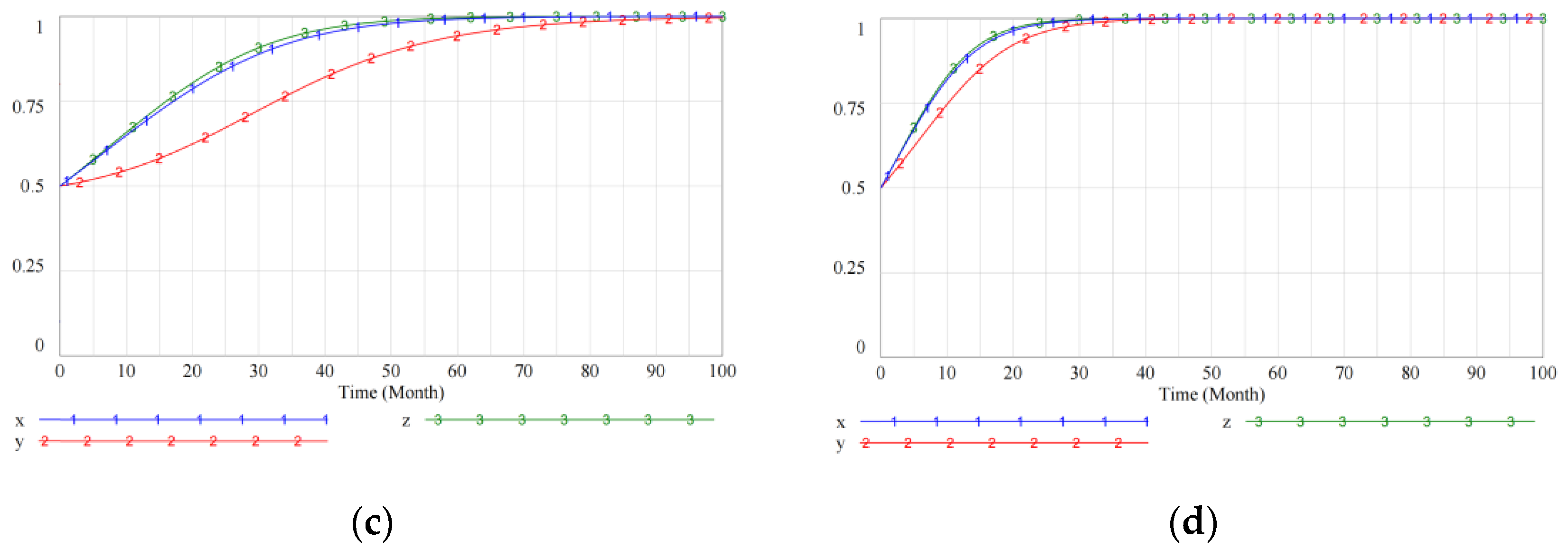

4.5. Government Rewards and Punishments Simulation

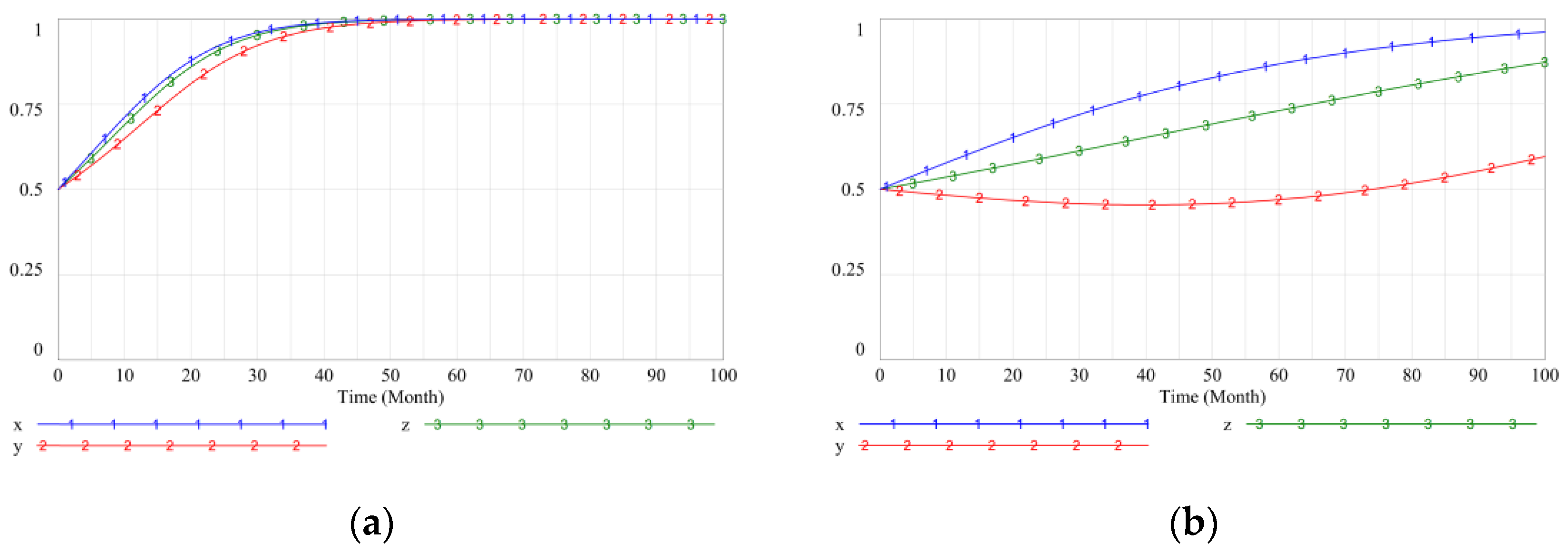

4.6. Other Parameters Simulation

5. Conclusions and Implications

5.1. Conclusions

5.2. Implications

5.3. Limitations

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Gür, T.M. Carbon Dioxide Emissions, Capture, Storage and Utilization: Review of Materials, Processes and Technologies. Prog. Energy Combust. Sci. 2022, 89, 100965. [Google Scholar] [CrossRef]

- Mikhaylov, A.; Moiseev, N.; Aleshin, K.; Burkhardt, T. Global climate change and greenhouse effect. Entrep. Sustain. Issues 2020, 7, 2897–2913. [Google Scholar] [CrossRef]

- Liu, Z.; Deng, Z.; Davis, S.J.; Giron, C.; Ciais, P. Monitoring global carbon emissions in 2021. Nat. Rev. Earth Environ. 2022, 3, 217–219. [Google Scholar] [CrossRef] [PubMed]

- Feng, T.; Jiang, Y.; Xu, D.J. The dual-process between green supplier collaboration and firm performance: A behavioral perspective. J. Clean. Prod. 2020, 260, 121073. [Google Scholar] [CrossRef]

- He, W. Overview of China’s digital economy development. Inf. Commun. Technol. Policy 2021, 47, 1–7. [Google Scholar] [CrossRef]

- Singh, S.; Sharma, M.; Dhir, S. Modeling the effects of digital transformation in Indian manufacturing industry. Technol. Soc. 2021, 67, 101763. [Google Scholar] [CrossRef]

- Gebayew, C.; Hardini, I.R.; Panjaitan, G.; Kurniawan, N.B.; Suhardi. A Systematic Literature Review on Digital Transformation. In Proceedings of the 2018 International Conference on Information Technology Systems and Innovation (ICITSI), Bandung, Indonesia, 22–26 October 2018. [Google Scholar] [CrossRef]

- Piccinini, E.; Hanelt, A.; Gregory, R.; Kolbe, L. Transforming Industrial Business: The Impact of Digital Transformation on Automotive Organizations. In Proceedings of the International Conference on Information Systems, Fort Worth, TX, USA, 13–16 December 2015. [Google Scholar]

- Zhai, H.; Yang, M.; Chan, K. Does digital transformation enhance a firm’s performance? Evidence from China. Technol. Soc. 2021, 68, 101841. [Google Scholar] [CrossRef]

- Magistretti, S.; Pham, C.T.A.; Dell’Era, C. Enlightening the dynamic capabilities of design thinking in fostering digital transformation. Ind. Mark. Manag. 2021, 97, 59–70. [Google Scholar] [CrossRef]

- Vial, G. Understanding digital transformation: A review and a research agenda. J. Strateg. Inf. Syst. 2019, 28, 118–144. [Google Scholar] [CrossRef]

- Simpson, D.F.; Power, D.J. Use the supply relationship to develop lean and green suppliers. Supply Chain Manag. Int. J. 2005, 10, 60–68. [Google Scholar] [CrossRef]

- Wieland, A. Dancing the Supply Chain: Toward Transformative Supply Chain Management. J. Supply Chain Manag. 2021, 57, 58–73. [Google Scholar] [CrossRef]

- Luthra, S.; Sharma, M.; Kumar, A.; Joshi, S.; Collins, E.; Mangla, S. Overcoming barriers to cross-sector collaboration in circular supply chain management: A multi-method approach. Transp. Res. Part E Logist. Transp. Rev. 2022, 157, 102582. [Google Scholar] [CrossRef]

- Yuchen, L. Research on Collaborative Governance Mechanism of Supply Chain Environment. Master’s Thesis, Hebei University of Technology, Tianjin, China, 2019. [Google Scholar] [CrossRef]

- Harfeldt-Berg, L.; Broberg, S.; Ericsson, K. The Importance of Individual Actor Characteristics and Contextual Aspects for Promoting Industrial Symbiosis Networks. Sustainability 2022, 14, 4927. [Google Scholar] [CrossRef]

- Wang, Y.; Yu, Z.; Jin, M.; Mao, J. Decisions and coordination of retailer-led low-carbon supply chain under altruistic preference. Eur. J. Oper. Res. 2021, 293, 910–925. [Google Scholar] [CrossRef]

- Shah, N.; Soomro, B.A. Internal green integration and environmental performance: The predictive power of proactive environmental strategy, greening the supplier, and environmental collaboration with the supplier. Bus. Strategy Environ. 2020, 30, 1333–1344. [Google Scholar] [CrossRef]

- Sharma, A.; Pathak, S.; Borah, S.B.; Adhikary, A. Collaboration strategies in buyer-supplier relational (BSR) networks and sustainable firm performance: A trade-off story. Int. J. Prod. Econ. 2022, 253, 108558. [Google Scholar] [CrossRef]

- Todeschini, B.V.; Cortimiglia, M.N.; Medeiros, J. Collaboration practices in the fashion industry: Environmentally sustainable innovations in the value chain. Environ. Sci. Policy 2020, 106, 1–11. [Google Scholar] [CrossRef]

- Neij, L.; Nemet, G. Accelerating the low-carbon transition will require policy to enhance local learning. Energy Policy 2022, 167, 113043. [Google Scholar] [CrossRef]

- Trujillo-Gallego, M.; Castro, W.; Sellitto, M.A. Identification of practices that facilitate manufacturing companies’ environmental collaboration and their influence on sustainable production. Sustain. Prod. Consum. 2021, 27, 1372–1391. [Google Scholar] [CrossRef]

- Yu, W.; Wang, Y.; Feng, W.; Bao, L.; Han, R. Low carbon strategy analysis with two competing supply chain considering carbon taxation. Comput. Ind. Eng. 2022, 169, 108203. [Google Scholar] [CrossRef]

- Yuan, X.; Zheng, C. Research on evolutionary game of low-carbon technology collaborative innovation based on tripartite game. Math. Pract. Theory 2022, 52, 31–43. [Google Scholar]

- Guo, Y.; Yu, J.; Allaoui, H.; Choudhary, A. Lateral collaboration with cost-sharing in sustainable supply chain optimisation: A combinatorial framework. Transp. Res. Part E Logist. Transp. Rev. 2022, 157, 102593. [Google Scholar] [CrossRef]

- Ma, L.; Huang, K. Research on the co-evolution mechanism of internal and external drivers of government and enterprise low-carbon management. Enterp. Econ. 2015, 6, 22–26. [Google Scholar] [CrossRef]

- Chen, J.; Li, Z.; Dong, Y.; Song, M.; Shahbaz, M.; Xie, Q. Coupling coordination between carbon emissions and the eco-environment in China. J. Clean. Prod. 2020, 276, 123848. [Google Scholar] [CrossRef]

- Bai, C.; Sarkis, J.; Dou, Y. Constructing a process model for low-carbon supply chain cooperation practices based on the DEMATEL and the NK model. Supply Chain Manag. 2017, 22, 237–257. [Google Scholar] [CrossRef]

- Jiang, J.; Zhang, D.; Meng, Q. Impact analysis of investment coordination mechanisms in regional low-carbon logistics network design. Transp. Res. Part D Transp. Environ. 2021, 92, 102735. [Google Scholar] [CrossRef]

- Lin, J.; Fan, R.; Tan, X.; Zhu, K. Dynamic decision and coordination in a low-carbon supply chain considering the retailer’s social preference. Socio-Econ. Plan. Sci. 2021, 77, 101010. [Google Scholar] [CrossRef]

- Yang, H.; Chen, W. Retailer-driven carbon emission abatement with consumer environmental awareness and carbon tax: Revenue-sharing versus Cost-sharing. Omega 2018, 78, 179–191. [Google Scholar] [CrossRef]

- Mishra, R.; Singh, R.K.; Rana, N.P. Developing environmental collaboration among supply chain partners for sustainable consumption & production: Insights from an auto sector supply chain. J. Clean. Prod. 2022, 338, 130619. [Google Scholar] [CrossRef]

- Xia, X.; Li, C.; Zhu, Q. Game analysis for the impact of carbon trading on low-carbon supply chain. J. Clean. Prod. 2020, 276, 123220. [Google Scholar] [CrossRef]

- Mao, Z.; Li, X.; Shan, Z. Low carbon supply chain firm integration and firm performance in China. J. Clean. Prod. 2016, 153, 354–361. [Google Scholar] [CrossRef]

- Lee, K.-H. Integrating carbon footprint into supply chain management: The case of Hyundai Motor Company (HMC) in the automobile industry. J. Clean. Prod. 2011, 19, 1216–1223. [Google Scholar] [CrossRef]

- Liu, T.-L.; Song, Q.-J.; Jiaqi, L.; Qi, Y. An integrated approach to evaluating the coupling coordination degree between low-carbon development and air quality in Chinese cities. Adv. Clim. Chang. Res. 2021, 12, 710–722. [Google Scholar] [CrossRef]

- Yu, B.; Wang, J.; Lu, X.; Yang, H. Collaboration in a low-carbon supply chain with reference emission and cost learning effects: Cost sharing versus revenue sharing strategies. J. Clean. Prod. 2020, 250, 119460. [Google Scholar] [CrossRef]

- Jaber, M.Y.; Glock, C.H.; Saadany, A.M.A.E. Supply chain coordination with emissions reduction incentives. Int. J. Prod. Res. 2013, 51, 69–82. [Google Scholar] [CrossRef]

- Liu, L.; Li, F. Differential game modelling of joint carbon reduction strategy and contract coordination based on low-carbon reference of consumers. J. Clean. Prod. 2020, 277, 123798. [Google Scholar] [CrossRef]

- Zhang, Z.; Yu, L. Altruistic mode selection and coordination in a low-carbon closed-loop supply chain under the government’s compound subsidy: A differential game analysis. J. Clean. Prod. 2022, 366, 132863. [Google Scholar] [CrossRef]

- Chengdong, S.; Xiuxia, Y.; Wentao, C. Study on the synergetic mechanism of low carbon cooperative emission reduction. Contemp. Econ. Manag. 2018, 40, 28–34. [Google Scholar] [CrossRef]

- Liu, K.; Song, H. Contract and incentive mechanism in low-carbon R&D cooperation. Supply Chain Manag. 2017, 22, 270–283. [Google Scholar] [CrossRef]

- Gold, S.; Seuring, S.; Beske, P. Sustainable supply chain management and inter-organizational resources: A literature review. Corp. Soc. Responsib. Environ. Manag. 2010, 17, 230–245. [Google Scholar] [CrossRef]

- Fitzgerald, M.; Kruschwitz, N.; Bonnet, D.; Welch, M. Embracing Digital Technology: A New Strategic Imperative. MIT Sloan Manag. Rev. 2014, 55, 1–12. [Google Scholar]

- Reis, J.C.G.d.; Amorim, M.P.C.; Melão, N.F.R.; Matos, P.S.L. Digital Transformation: A Literature Review and Guidelines for Future Research. In Proceedings of the Trends and Advances in Information Systems and Technologies, Naples, Italy, 27–29 March 2018; pp. 411–421. [Google Scholar] [CrossRef]

- Setzke, D.S.; Riasanow, T.; Böhm, M.; Krcmar, H. Pathways to Digital Service Innovation: The Role of Digital Transformation Strategies in Established Organizations. Inf. Syst. Front. 2021, 1, 1–21. [Google Scholar] [CrossRef]

- Berman, S.J. Digital transformation: Opportunities to create new business models. Strategy Leadersh. 2012, 40, 16–24. [Google Scholar] [CrossRef]

- Hanelt, A.; Bohnsack, R.; Marz, D.; Antunes Marante, C. A systematic review of the literature on digital transformation: Insights and implications for strategy and organizational change. J. Manag. Stud. 2021, 58, 1159–1197. [Google Scholar] [CrossRef]

- Nasiri, M.; Ukko, J.; Saunila, M.; Rantala, T. Managing the digital supply chain: The role of smart technologies. Technovation 2020, 96, 96–97. [Google Scholar] [CrossRef]

- Shashi; Centobelli, P.; Cerchione, R.; Ertz, M. Agile supply chain management: Where did it come from and where will it go in the era of digital transformation? Ind. Mark. Manag. 2020, 90, 324–345. [Google Scholar] [CrossRef]

- Yusuf, Y.Y.; Gunasekaran, A.; Adeleye, E.O.; Sivayoganathan, K. Agile supply chain capabilities: Determinants of competitive objectives. Eur. J. Oper. Res. 2004, 159, 379–392. [Google Scholar] [CrossRef]

- Lu, M.; Gao, Y.; Wan, Q. Research on Evolutionary Game of Collaborative Innovation in Supply Chain under Digitization Background. Math. Probl. Eng. 2021, 2021, 3511472. [Google Scholar] [CrossRef]

- Feroz, A.K.; Zo, H.; Chiravuri, A. Digital transformation and environmental sustainability: A review and research agenda. Sustainability 2021, 13, 1530. [Google Scholar] [CrossRef]

- Rowan, N.J.; Murray, N.; Qiao, Y.; O’Neill, E.; Clifford, E.; Barceló, D.; Power, D.M. Digital transformation of peatland eco-innovations (‘Paludiculture’): Enabling a paradigm shift towards the real-time sustainable production of ‘green-friendly’products and services. Sci. Total Environ. 2022, 838, 156328. [Google Scholar] [CrossRef]

- Tsakalidis, A.; Gkoumas, K.; Pekár, F. Digital transformation supporting transport decarbonisation: Technological developments in EU-funded research and innovation. Sustainability 2020, 12, 3762. [Google Scholar] [CrossRef]

- Itten, R.; Hischier, R.; Andrae, A.S.G.; Bieser, J.T.; Cabernard, L.; Falke, A.; Ferreboeuf, H.; Hilty, L.M.; Keller, R.L.; Lees-Perasso, E.; et al. Digital transformation—life cycle assessment of digital services, multifunctional devices and cloud computing. Int. J. Life Cycle Assess. 2020, 25, 2093–2098. [Google Scholar] [CrossRef]

- Nizam, H.A.; Zaman, K.; Khan, K.B.; Batool, R.; Khurshid, M.A.; Shoukry, A.M.; Sharkawy, M.A.; Aldeek, F.; Khader, J.; Gani, S. Achieving environmental sustainability through information technology:“Digital Pakistan” initiative for green development. Environ. Sci. Pollut. Res. 2020, 27, 10011–10026. [Google Scholar] [CrossRef] [PubMed]

- Smith, J.; Price, G.R. The logic of animal conflict. Nature 1973, 246, 15–18. [Google Scholar] [CrossRef]

- Easley, D.; Kleinberg, J. Networks, Crowds, and Markets: Reasoning about a Highly Connected World; Cambridge University Press: Cambridge, UK, 2010. [Google Scholar]

- Weibull, J.W. Evolutionary Game Theory; MIT Press: Cambridge, MA, USA, 1997. [Google Scholar]

- Waldner, F.; Klages, R. Symmetric Jacobian for local Lyapunov exponents and Lyapunov stability analysis revisited. Chaos Solitons Fractals 2012, 45, 325–340. [Google Scholar] [CrossRef]

- Yang, Y.; Yang, W.; Chen, H.; Li, Y. China’s energy whistleblowing and energy supervision policy: An evolutionary game perspective. Energy 2020, 213, 118774. [Google Scholar] [CrossRef]

- Zuo, W.; Wang, Q.; Li, P. Rent-seeking decisions of the main participants in construction projects based on evolutionary-game and system dynamics. J. Civ. Eng. Manag. 2022, 28, 106–119. [Google Scholar] [CrossRef]

- Liu, Y.; Dong, F. What are the roles of consumers, automobile production enterprises, and the government in the process of banning gasoline vehicles? Evidence from a tripartite evolutionary game model. Energy 2022, 238, 122004. [Google Scholar] [CrossRef]

- Barari, S.; Agarwal, G.; Zhang, W.C.; Mahanty, B.; Tiwari, M. A decision framework for the analysis of green supply chain contracts: An evolutionary game approach. Expert Syst. Appl. 2012, 39, 2965–2976. [Google Scholar] [CrossRef]

- Zhi, B.; Liu, X.; Chen, J.; Jia, F. Collaborative carbon emission reduction in supply chains: An evolutionary game-theoretic study. Manag. Decis. 2019, 57, 1087–1107. [Google Scholar] [CrossRef]

- Zhiwen, Z.; Yujun, X.; Junxing, L.; Limin, G.; Long, W. Supply chain logistics information collaboration strategy based on evolutionary game theory. IEEE Access 2020, 8, 46102–46120. [Google Scholar] [CrossRef]

- Zhou, Y.; Bao, M.; Chen, X.; Xu, X. Co-op advertising and emission reduction cost sharing contracts and coordination in low-carbon supply chain based on fairness concerns. Chin. J. Manag. Sci. 2017, 133, 402–413. [Google Scholar] [CrossRef]

- Tavana, M.; Shaabani, A.; Raeesi Vanani, I.; Kumar Gangadhari, R. A Review of Digital Transformation on Supply Chain Process Management Using Text Mining. Processes 2022, 10, 842. [Google Scholar] [CrossRef]

- Batista, L.; Bourlakis, M.; Smart, P.; Maull, R. In search of a circular supply chain archetype–a content-analysis-based literature review. Prod. Plan. Control 2018, 29, 438–451. [Google Scholar] [CrossRef]

- Ralston, P. Supply Chain Collaboration: A Literature Review and Empirical Analysis to Investigate Uncertainty and Collaborative Benefits in Regards to Their Practical Impact on Collaboration and Performance. Ph.D. Thesis, Iowa State University, Ames, IA, USA, 2014. [Google Scholar] [CrossRef]

- Hu, Y.; Li, Y. Study on Evolutionary Game between Core-Enterprise and Suppliers in Green Supply Chain. In Proceedings of the 2011 International Conference on Computer and Management (CAMAN), Wuhan, China, 19–21 May 2011; pp. 1–4. [Google Scholar] [CrossRef]

- Lohmann, C. Coordination of supply chain investments and the advantage of revenue sharing. Z. Betr. 2010, 80, 969–990. [Google Scholar] [CrossRef]

- Zhu, Q.-H.; Dou, Y.-J. Evolutionary game model between governments and core enterprises in greening supply chains. Syst. Eng.-Theory Pract. 2007, 27, 85–89. [Google Scholar] [CrossRef]

- Huang, M. Evolutionary game analysis of cooperation mechanism for collaborative product development in supply chain. Chin. J. Manag. Sci. 2010, 18, 155–162. [Google Scholar] [CrossRef]

| Variables | Meaning | Range |

|---|---|---|

| The probability that suppliers choose low-carbon collaboration strategies | ||

| The probability that suppliers choose non-low-carbon collaboration strategies | ||

| The probability that manufacturers choose low-carbon collaboration strategies | ||

| The probability that manufacturers choose non-low-carbon collaboration strategies | ||

| The probability that retailers choose low-carbon collaboration strategies | ||

| The probability that retailers choose non-low-carbon collaboration strategies |

| Parameters | Meaning | Range |

|---|---|---|

| Suppliers’ digital-transformation degree | ||

| Manufacturers’ digital-transformation degree | ||

| Retailers’ digital-transformation degree | ||

| The fundamental benefits of suppliers | ||

| The fundamental benefits of manufacturers | ||

| The fundamental benefits of retailers | ||

| Additional benefits from tripartite agents’ low-carbon collaboration in the supply chain | ||

| Additional benefits from two agents’ low-carbon collaboration in the supply chain | ||

| The tripartite agents’ low-carbon collaboration additional-benefits-distribution coefficient of suppliers | ||

| The tripartite agents’ low-carbon collaboration additional-benefits-distribution coefficient of manufacturers | ||

| The tripartite agents’ low-carbon collaboration additional-benefits-distribution coefficient of retailers | ||

| The two agents’ low-carbon collaboration additional-benefits-distribution coefficient of suppliers | ||

| The two agents’ low-carbon collaboration additional-benefits-distribution coefficient of manufacturers | ||

| The two agents’ low-carbon collaboration additional-benefits-distribution coefficient of retailers | ||

| Government rewards for suppliers choosing low-carbon collaboration | ||

| Government rewards for manufacturers choosing low-carbon collaboration | ||

| Government rewards for retailers choosing low-carbon collaboration | ||

| Government punishments for suppliers not choosing low-carbon collaboration | ||

| Government punishments for manufacturers not choosing low-carbon collaboration | ||

| Government punishments for retailers not choosing low-carbon collaboration | ||

| The strategic risk cost of suppliers choosing low-carbon collaboration | ||

| The strategic risk cost of manufacturers choosing low-carbon collaboration | ||

| The strategic risk cost of retailers choosing low-carbon collaboration | ||

| The input cost of suppliers choosing low-carbon collaboration | ||

| The input cost of manufacturers choosing low-carbon collaboration | ||

| The input cost of retailers choosing low-carbon collaboration | ||

| The exclusion loss of suppliers not choosing low-carbon collaboration | ||

| The exclusion loss of manufacturers not choosing low-carbon collaboration | ||

| The exclusion loss of retailers not choosing low-carbon collaboration |

| Strategies | Suppliers | Manufacturers | Retailers |

|---|---|---|---|

| . | |||

| Equilibrium Point | Eigenvalues |

|---|---|

| (0,0,0) | |

| (1,0,0) | |

| (0,1,0) | |

| (0,0,1) | |

| (1,1,0) | |

| (1,0,1) | |

| (0,1,1) | |

| (1,1,1) |

| Equilibrium Points | Condition (1) | Condition (2) | ||

|---|---|---|---|---|

| Eigenvalue Sign | Stability | Eigenvalue Sign | Stability | |

| (+,+,+) | unstable point | (−,−,−) | ESS | |

| (−,+,+) | saddle point | (+,+,+) | unstable point | |

| (−,+,+) | saddle point | (+,+,+) | unstable point | |

| (−,+,+) | saddle point | (+,+,+) | unstable point | |

| (−,−,+) | saddle point | (−,−,+) | saddle point | |

| (−,−,+) | saddle point | (−,−,+) | saddle point | |

| (−,−,+) | saddle point | (−,−,+) | saddle point | |

| (−,−,−) | (−,−,−) | ESS | ||

| Parameters | Initial Value | Parameters | Initial Value | Parameters | Initial Value |

|---|---|---|---|---|---|

| 1 | 0.3 | 80 | |||

| 1 | 0.4 | 120 | |||

| 1.2 | 0.3 | 100 | |||

| 120 | 0.5 | 30 | |||

| 180 | 0.5 | 45 | |||

| 150 | 0.5 | 40 | |||

| 150 | 60 | 40 | |||

| 80 | 70 | 50 | |||

| 70 | 50 | 45 | |||

| 70 | 60 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, G.; Yu, H.; Lu, M. Low-Carbon Collaboration in the Supply Chain under Digital Transformation: An Evolutionary Game-Theoretic Analysis. Processes 2022, 10, 1958. https://doi.org/10.3390/pr10101958

Li G, Yu H, Lu M. Low-Carbon Collaboration in the Supply Chain under Digital Transformation: An Evolutionary Game-Theoretic Analysis. Processes. 2022; 10(10):1958. https://doi.org/10.3390/pr10101958

Chicago/Turabian StyleLi, Gang, Hu Yu, and Mengyu Lu. 2022. "Low-Carbon Collaboration in the Supply Chain under Digital Transformation: An Evolutionary Game-Theoretic Analysis" Processes 10, no. 10: 1958. https://doi.org/10.3390/pr10101958

APA StyleLi, G., Yu, H., & Lu, M. (2022). Low-Carbon Collaboration in the Supply Chain under Digital Transformation: An Evolutionary Game-Theoretic Analysis. Processes, 10(10), 1958. https://doi.org/10.3390/pr10101958