Abstract

To promote the sustainability of mechanical production process, this study proposes an emergy-based sustainability evaluation method to evaluate the resource utilization and environmental pollution of the mechanical production process. Firstly, this study constructs the sustainability evaluation index system of the mechanical production process from the perspectives of economy and environment. Secondly, an emergy analysis method-based sustainable evaluation of the mechanical production process is constructed. Finally, taking the gear manufacturing process as an example, the method is tested. The results show that this method can effectively quantify and identify the sustainability of the gear manufacturing process and provide effective feedback to improve the process. The resulting improvements can aid in reconsidering the economic and environmental factors, improving the production efficiency and the sustainability of the production process, and reducing the difficulty of operating the lathe in the production process. This study provides method support for the sustainability evaluation of mechanical production process and decision support for its improvement.

1. Introduction

Industrial manufacturing plays a vital role in the national economy. The process of mechanical production involves the conversion of resources into semi-finished or finished products, which not only changes the traditional handcraft manufacturing model, but also significantly improves the efficiency and quality of the product [1]. However, significant problems faced by mechanical production processes are the high consumption of resources and the discharge of waste [2], which cause major pollution in the environment. With the increasing awareness of consumer sustainability and the emphasis of government policies on environmental protection and corporate social responsibility, this contradiction has aroused widespread concern among scholars [3], and some universities have established specialized institutions to study this issue [4]. Improving the sustainability of production processes is a major challenge facing the development of industrial manufacturing [5]. The development of objective sustainability assessment methods is a promising method of accelerating energy conservation and emission reduction in the manufacturing industry [6]. It is necessary to use an objective method to evaluate and analyze the sustainability of the mechanical production processes, propose optimization measures, improve the efficiency of resource utilization, and reduce resource consumption and environmental pollution, which have far-reaching implications for the sustainable development of products.

Regarding these challenges, scholars generally evaluate the sustainability of mechanical production processes using three sustainability criteria, namely, economical [7,8], social [9] and environmental [10,11], and have achieved good results [12,13]. In terms of the selection of evaluation indicators, the comprehensive sustainability indicators of environmental, economic, and social impacts are used to evaluate the adaptive sustainability of a cloud-based distributed mechanical manufacturing system [14]. Sproesser et al. selected three indicators that reflected the environmental and economic performance and applied the weight space division method to evaluate the sustainability performance of the two welding processes [15]. Saxena et al. combined sustainability indicators with other traditional manufacturing indicators and proposed a new framework [16]. Singh et al. used the mold-casting process sustainability analyzer to systematically analyze three sustainability indicators, namely energy utilization, solid waste, and carbon emissions [17]. Sihag et al. established the sustainability evaluation index of an industrial manufacturing system to help manufacturers and users objectively investigate the sustainability performance of machine tools [18]. The Delphi analytic hierarchy process (AHP) qualitative evaluation and sustainable value stream mapping quantitative analysis were combined to determine the manufacturing sustainability index [19]. In terms of sustainability evaluation methods, the life cycle assessment (LCA) is often used for the sustainability evaluation of mechanical production processes [20,21]. The LCA application has been improved to varying degrees. A hybrid framework combining six integrated methods of environmental LCA and life cycle cost calculation was used to improve environmental and economic performance [22]. Egilmez combined economic input–output LCA with data envelopment analysis (DEA) to analyze the ecological efficiency of the U.S. manufacturing sector [23]. Three LCA methods were proposed to comprehensively evaluate the sustainable impact of additive manufacturing in the triple bottom line [24]. Many other methods have also been used to evaluate the sustainability of mechanical production processes. Improved quality function deployment (QFD) tools, AHP and normalization techniques were used to address the expectations of manufacturers and multiple stakeholders on their sustainability priorities in manufacturing practices [25]. Eslami et al. adopted a formal concept analysis (FCA) to study the regularity of sustainability assessment methods and tools and proposed a new overall framework for the sustainability assessment of manufacturing organizations [26]. The multi-standard manufacturing process sustainability assessment method was used to assess the sustainability of a manufacturing process that requires less detailed data, time, and expert knowledge [19,27]. Considering the energy, economy, and environment in the mechanical manufacturing system, an energy benchmark method based on the technique for order preference by similarity to ideal solution (TOPSIS) method was proposed to promote the sustainability of mechanical manufacturing [28]. Based on the classic digital twin mapping system, a digital twin driven sustainability assessment information architecture for the dynamic evolution of the entire life cycle was proposed [29]. Comparative experiments were carried out on four test methods to evaluate the energy efficiency of machine tools [30].

Emergy theory was founded by H. T. Odum. It is a method that can comprehensively and effectively use a unified measurement unit to scientifically compare, add, and subtract energy in the system (such as material flow, information flow, money flow, energy flow, etc.) [31]. It provides a framework for heterogeneity and quantitative comparison in environmental impact analysis [32] and can compare different environmental impact factors [33]. Therefore, it has been widely studied and applied by experts and scholars from around the world and has successfully been used to carry out ecological efficiency and sustainability evaluations covering countries [34], watersheds [35], provinces [36], cities [37], ecosystems of regional coasts [38], wetlands [39] and forests [40]. Because it can describe the relationship between the environmental friendliness and production cost of a system [41], it is also applied to environmental impact analysis and sustainability assessment of mechanical manufacturing processes [42,43]. The success of these studies proves the effectiveness and practicality of emergy theory. Therefore, emergy theory can be used to analyze the sustainability of mechanical production processes.

The aforedescribed research results provide a valuable reference for scholars to further study the sustainability of industrial production. However, there are still some gaps in the research as detailed below.

- (i)

- The mechanical production process is a multi-input and multi-output process. The use of unified standards for the accounting of various input resources is conducive to the comprehensive analysis of the material, energy and capital flows in the production process, and provides a theoretical basis for the sustainability evaluation. The emergy method solves this problem; however, studies of this method in mechanical production processes are limited.

- (ii)

- The real value of various material natural resources used in mechanical production activities, such as water, solar energy, wind energy, and the impact of resource consumption on the natural environment, is not prioritized. These factors have an im-pact on the sustainability of the production process.

- (iii)

- Existing research mainly focuses on the impact of material and energy consumption on sustainability at a level directly related to production in mechanical production processes, while ignoring the impact of waste discharge, management costs, personnel wages, and other resource consumption.

We propose an emergy-based approach to assess the environmental impact and sustainability of mechanical production processes. This method not only considers the impact of various natural resources on the sustainability of the manufacturing production process, but also converts all input and output elements into solar emergy for unified measurement, which is conducive to quantifying the production efficiency and environmental impact of the mechanical production process. Furthermore, in combination with the characteristics of the mechanical production process, factors such as personnel salaries, maintenance and waste discharge costs are fully considered in the evaluation. This method is used to evaluate the gear manufacturing process. According to the evaluation results, improvements of the production process in terms of production efficiency, environmental impact and sustainability are proposed.

This study has remarkable research significance. Theoretically, the environmental impact and sustainability of the mechanical production process is evaluated from the perspective of emergy, which provides quantitative support for sustainability improvement, enriches the application range of emergy theory and provides a new perspective for research on the sustainability of the mechanical production process. In practice, the manager can analyze the problems existing in the mechanical production process from the sustainability evaluation results and realize management and improvement gains of the production process so as to reduce the energy consumption, production input, and waste discharge; this can remarkably help protect the natural environment. Moreover, the production cost of the spur gear is effectively reduced, and the product efficiency of the spur gear is improved. In addition, this study demonstrates the effectiveness of this method in evaluating the sustainability of the mechanical production process and provides a reference for further research in related fields.

2. Materials and Methods

According to the basic steps of emergy analysis, this section first determines the boundary and content of the process, lists the main input and output items, then measures the emergy of various types of energy and substances and finally, according to the characteristics of the mechanical production processes, selects appropriate emergy evaluation indicators for sustainability evaluation, application, and optimization.

2.1. Boundary Definition and Emergy Flow Diagram

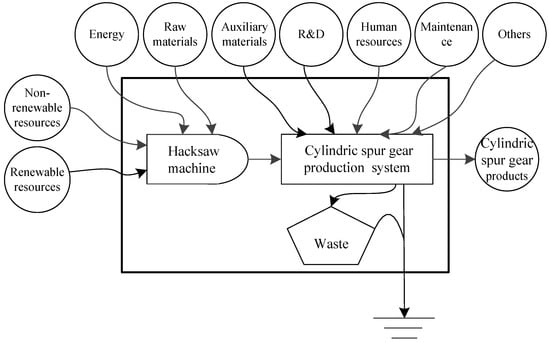

The first step of the emergy analysis method is based on mastering the data of all aspects of the production process, classifying the collected data according to the emergy processing requirements, and using the energy symbol legend to describe the emergy flow diagram, forming a clearly structured system diagram [44]. The system diagram contains the main environmental and economic components of the input and output resources and can fully reflect the roles and relationships between components. The environmental resource inputs include renewable resources (R) and non-renewable resources (N), and the economical feedback emergy of which a majority comprises the purchased emergy input (F). The output is mostly comprised the system output product (Y) and waste (W). Figure 1 shows the emergy flow of manufacturing a gear.

Figure 1.

Emergy flow of gear manufacturing.

2.2. Emergy Measure

In the collected raw data, various types of energy, material and economy are transformed into common solar emergy units, and the emergy measurement can better evaluate their contribution and status in the system [45]. The basic expression is

where EM represents the solar emergy, UEV represents the emergy conversion rate of different substances, and N represents the input flow of different units (mass in grams or energy in joules).

EM = UEV × N,

Based on the above formula, the emergy measurement model of a mechanical production system is constructed as follows.

- (1)

- Renewable resource emergy

When evaluating the sustainability of mechanical production processes, this study fully considered the impact of natural resources such as solar energy, rainwater and wind energy provided by nature on the production process and measured it.

where represents the i-th renewable resource provided by nature, and is the total number of renewable resource types used in the production process.

- (2)

- Non-renewable resource emergy

Non-renewable resources refer to natural resources that cannot be regenerated for a long time after human development and utilization. Several non-renewable resources, such as coal, electricity, natural gas, etc., are used during the production process, which are calculated as follows.

where represents the i-th non-renewable resource, and is the total number of non-renewable resource types used during the production process.

- (3)

- Purchasing emergy

This emergy is also known as economic feedback emergy and refers to various means of production and labor services. This not only includes raw materials and parts required for production, but also includes production management costs, R&D costs and employee salaries. The emergy measurement formula is

where represents the i-th external purchase resource, and is the total number of purchase resource types used in the production process.

- (4)

- Waste emergy

Waste emergy refers to the emergy of environmental pollution caused by industrial waste of the production system. This includes the emergy of waste gas, wastewater, solid waste and waste oil produced in the production process. Its expression is

where represents the i-th type of waste, and is the total amount of waste generated in the production process.

2.3. Index Construction

Emergy analysis results in a series of emergy evaluation indicators which can reflect the impact of the system on the environment and sustainability of the system. In this study, the following emergy indexes were selected to evaluate the sustainability of a mechanical manufacturing process.

(1) The emergy yield ratio (EYR) refers to the ratio of emergy generated by the system during normal operations or mass production of products, to the emergy fed back by the system in economic activities. The calculation formula of EYR is generally defined as

EYR = (EMR + EMN + EMF)/EMF,

EYR is well suited to measure the energy production and utilization efficiency of the entire system. The great contribution of the system to social and economic production activities and the production utilization rate of the system’s residual energy can also be measured and reflected through this index. The EYR is directly proportional to the production quality and utilization efficiency of the product. However, this indicator also measures the competitiveness of a system’s economic activities and the sustainable development index of products. The EYR is directly proportional to the competitiveness of the system’s economic activities and the sustainable development index, which is suitable for long-term sustainable development.

(2) The emergy investment ratio (EIR) refers to the ratio of emergy input from an economic system to emergy input from an ecosystem.

EIR = EMF/(EMN + EMR),

The lower the EIR, the lower the degree of economic development of the machining process, and the higher the degree of dependence on natural resources.

(3) The environmental load ratio (ELR) refers to the ratio of the total amounts of non-renewable and renewable resource emergy invested by the environmental system. The basic calculation formula of the ELR is generally defined as

ELR = (EMF + EMN)/EMR,

The ELR can measure the load of the mechanical manufacturing process on the whole nature. The ELR is directly proportional to the utilized proportion of its non-renewable resources and the bearing pressure of the entire ecological environment. Thus, the manufacturing process will have a negative impact on the surrounding ecological environment at high ELR values, and production should be stopped immediately.

(4) The emergy waste ratio (EWR) is the ratio of the sum of emergies of the various wastes produced by the mechanical production process to the total emergy of the process input. It can directly reflect the degree of waste discharge and resource recycling of the mechanical manufacturing process. Lower values indicate better waste management, recycling management and utilization of the mechanical manufacturing process.

EWR = EMW/(EMR + EMN + EMF),

(5) The emergy sustainability index (ESI) refers to the ratio of the EYR to ELR of a mechanical manufacturing process. The calculation formula is

ESI = EYR/ELR,

This index can be combined with social and economic benefits and ecological environmental pressure simultaneously to obtain a high-performance composite evaluation index. The higher the ESI, the higher the social and economic benefits achieved under the pressure of the environment and the social and economic potential for sustainable development in the future.

3. Case Study

3.1. Gear Production Process

This study takes a spur gear independently developed by enterprise A as the research object, combined with the relevant knowledge of emergy theory, evaluates the economic and ecological sustainability of the production process, and optimizes the processing technology in order to improve the sustainable development performance of the production process. The spur gears are mass produced. The entire production process is roughly divided into the following main steps: drawing design, blank manufacturing, gear processing, gear detection, painting, and parts packaging. The specific process flow is shown in Table 1 and Figure 2.

Table 1.

Process card of spur gear machining.

Figure 2.

Stages of the gear during the manufacturing process.

3.2. Results

In order to analyze the emergy of the spur gear production process, the production data of spur gears were collected according to the production process of spur gears. This included the collection of raw data on energy, materials, equipment, production management, human resources, waste and products. Data collection was carried out by means of field research, sample collection and analysis, interviews and so on. According to the collected original data and the calculation formula of emergy, the global emergy power benchmark of 9.44 × 1024 sej/yr was adopted to convert the original data of each component into emergy and establish an emergy analysis table.

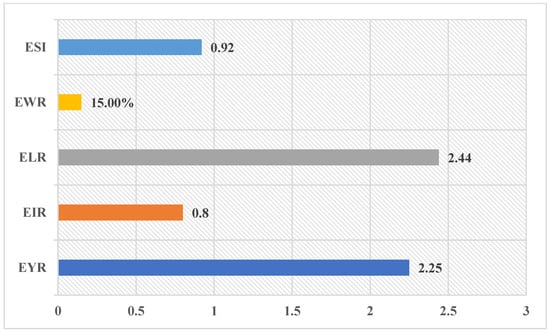

According to Table 2, the sustainable development indicators are calculated as shown in Table 3 and Figure 3. 8 × 104.

Table 2.

Emergy analysis of spur gear production process.

Table 3.

Various emergy flows and results.

Figure 3.

Sustainable development indicators of manufacturing a spur gear.

The following conclusions can be drawn:

- (1)

- Analysis of production efficiency indicators. The EYR of the spur gear production process is only 2.25, and the emergy ratio of products and services is 16.3%. The production efficiency is low, the economic competitiveness is weak, and the utilization efficiency of the spur gear production process for resources is medium. Combined with the process, it is found that the reason for the low EYR is that the production process has invested too much in purchasing emergy, particularly in equipment and management emergy.

- (2)

- Analysis of economic efficiency indicators. The EIR of the spur gear production process is only 0.80, indicating that the production process is less dependent on natural resources, which is consistent with the characteristics of the mechanical production process. In addition, the process has low economic benefits and a poor economic development level.

- (3)

- Analysis of ecological efficiency indicators. From the perspective of ELR and EWR, it reflects that the ecological efficiency of this production process is low. The main reason is that the waste discharge is too high, in which the emergy output of waste oil is as high as 1.81 × 1012, accounting for 68.8% of the total waste emergy. Enterprises should pay attention to the discharge of waste oil and reduce waste discharge during the production process.

- (4)

- Analysis of sustainable development index. The ESI of the spur gear production process is 0.92, which is low in the long run. The main reason is that the EYR is low, the ELR is high, and the waste emission of the production process is too large, especially during the lathe manufacturing and heat-treatment processes.

3.3. Improvement for Spur Gear Production Process

To enhance the production efficiency and sustainability of spur gears, the gear material processing technology was improved. The horizontal lathe replaced the vertical drilling machine and slotting machine, and the reaming and keyway insertion processes were completed on the horizontal lathe, to effectively reduce the input of purchasing emergy and use of cutting fluid, coolant, and hydraulic oil.

After the process improvement of manufacturing spur gears according to the above method, the emergy of each element is shown in Table 4.

Table 4.

Comparison of emergy after process improvement of the spur gear production.

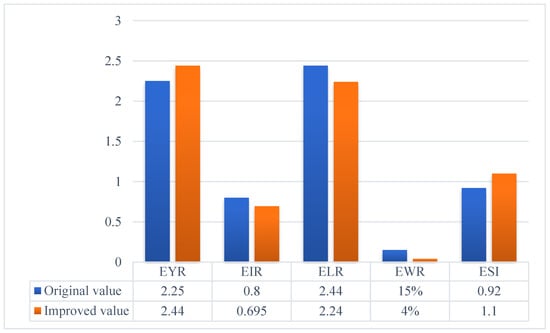

The changes of each index are shown in Figure 4.

Figure 4.

Comparison of indicators before and after improvement of the spur gear production process.

From the perspective of EYR, the production efficiency of the improved spur gear production process is higher than before, and its economic competitiveness is strong. Its EYR increased to 2.44, and the production efficiency improved. The EIR was 0.80 before improvement and 0.695 after improvement, indicating that the economic development of the spur gear production process is still very low, but the social benefits are improved. According to the analysis of the improved ecological efficiency index, both ELR and EWR reflect that the ecological efficiency of the production process is improved. After improving, the ESI of the production process increased from 0.92 to 1.10, which shows that the sustainability of the spur gear production process improved over the long run.

After improvement, from the perspective of the production process, the processing technology became simpler, the technical skill requirements of the operators were lower than those before the improvement, and the physiological health and production enthusiasm of the operators also improved. From the perspective of production management, the equipment requirements for the spur gear production process were reduced, thereby reducing the large amount of input of auxiliary materials, materials and equipment emergy, which could save a considerable part of the purchase and disposal costs. As an enterprise, the enterprise benefits and personnel wages improved, and the saved funds can be invested in product R&D and transformation, while the enterprise sustainable development index improved considerably.

3.4. Management Insights

Compared with the existing sustainable research on mechanical production processes, this study has the following advantages: (1) using emergy as a common measure to connect the various material, energy and capital flows of mechanical production processes, so that energy and materials from different sources and of different properties can be fairly compared against the same standard; (2) when constructing the sustainability evaluation index system of mechanical production processes, the impact of natural resources and waste discharge is fully considered, which can better reflect the characteristics of such processes; (3) the method is applied to the sustainable evaluation of the process of manufacturing spur gears, and the evaluation results verify the effectiveness of the method. According to the evaluation results, a targeted optimization strategy for the sustainability of production processes is proposed. In view of the above results, this study draws the following implications for management.

First, the sustainability evaluation of mechanical production processes is a complex problem, which involves a wide range of system boundaries, objectives and complex influencing factors. The use of different system boundaries, analysis methods, and influencing factors will lead to great variation in the evaluation results. The construction of an objective, scientific and complete sustainability evaluation system has an important impact on the sustainability evaluation of mechanical production processes.

Second, a mechanical production system is different from an ecosystem. The material flow in the ecosystem can be recycled, so the impact of waste discharge on the environment and system sustainability is generally not included in the evaluation. However, the waste discharge of a mechanical production system has a great impact on the environment. We should choose a production process with the best economic benefits, the least impact on the ecological environment and the most sustainability as much as possible to meet the needs of economic development and environmental protection. Simply applying the index system of an ecosystem cannot objectively reflect the sustainability of mechanical production processes.

Third, the production process of the machinery manufacturing industry should not only consider economic benefits, but also organically combine economic benefits with environmental protection, improve the utilization efficiency of energy and resources as much as possible, reduce waste discharge and environmental pollution, and realize the coordinated development of the natural environment and human economy.

4. Conclusions

The global energy shortage and environmental pollution have led to new development models, such as sustainable development, being adopted globally. The largescale expansion of the machinery manufacturing industry and the impact of manufacturing activities on the natural environment require methods to quantitatively analyze and evaluate the sustainability of machinery production processes.

This study proposes a sustainable evaluation method of mechanical production processes based on emergy. Its innovation lies in (i) converting the input and output energy and materials of the mechanical production process into a unified standard emergy to measure and analyze by objectively quantifying the production efficiency and sustainability of the mechanical production process; (ii) considering not only the impact of natural resource consumption on sustainability, but also the personnel salaries, maintenance and waste discharge costs, a sustainability index system more aligned with the mechanical production process was constructed to evaluate its economic and ecological efficiency, and sustainable development level; (iii) using the production process of a spur gear as an example, the sustainability of the system was quantitatively evaluated using the method given in this study, the main influencing factors were analyzed, and targeted improvement metrics were put forward. After the improvement, the production efficiency and sustainability were enhanced. The research results show that this method is applicable to different mechanical production processes and provides a theoretical basis for guiding the benign operation and sustainable development of mechanical production processes.

Emergy theory has been widely used in natural ecosystems, but it is relatively new to mechanical production processes. The major focus of this study is on improving the application of the emergy method and evaluation index system in mechanical production processes. While this study proposes some emergy indicators and applies them to the sustainability evaluation of a specific mechanical production process to verify their effectiveness, the breadth and depth of study need to be further expanded. The data used in this study were acquired from the gear production workshop of a vehicle bridge factory. The emergy calculated in the research are all single products, and the research results are only improved for the processing technology, which inevitably has certain limitations. In future, emergy theory can be used to guide the mechanical production processes to improve its sustainability, including strengthening the utilization of renewable resources and reducing the consumption of non-renewable energy and waste emissions. In addition, this study does not consider the external factors of the mechanical production processes, which can be addressed in further studies.

Author Contributions

Conceptualization, Y.Y. and C.Z.; methodology, C.Z.; validation, Y.Y., C.Z. and C.W.; investigation, C.W.; resources, Y.Y.; data curation, C.W.; writing—original draft preparation, Y.Y.; writing—review and editing, C.Z.; supervision, C.W.; funding acquisition, C.Z. All authors have read and agreed to the published version of the manuscript.

Funding

This research was supported by 2021 Anhui Social Sciences Innovation and Development Research Project (Nos. 2021CX069, 2021CX064).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Moldavska, A.; Welo, T. A Holistic approach to corporate sustainability assessment: Incorporating sustainable development goals into sustainable manufacturing performance evaluation. J. Manuf. Syst. 2019, 50, 53–68. [Google Scholar] [CrossRef]

- Gao, M.; Li, L.; Wang, Q.; Liu, C. Energy efficiency and dynamic analysis of a novel hydraulic system with double actuator. Int. J. Precis. Eng. Manuf. Green Technol. 2020, 7, 643–655. [Google Scholar] [CrossRef]

- Liu, C.; Zhu, Q.; Wei, F.; Rao, W.; Liu, J.; Hu, J.; Cai, W. A review on remanufacturing assembly management and technology. Int. J. Adv. Manuf. Technol. 2019, 105, 4797–4808. [Google Scholar]

- Sustainability|Michigan Technological University (mtu.edu). 2022. Available online: https://www.mtu.edu/sustainability/ (accessed on 20 June 2022).

- Rodger, J.; Bey, N. Sustainability Assessment in manufacturing and target setting in highly automated production. In Eco-Factories Future; Springer: Cham, Switzerland, 2019; pp. 69–84. [Google Scholar]

- Luthra, S.; Mangla, S.; Kharb, R. Sustainable assessment in energy planning and management in Indian perspective. Renew. Sustain. Energy Rev. 2015, 47, 58–73. [Google Scholar] [CrossRef]

- Shivajee, V.; Singh, R.; Rastogi, S. Manufacturing conversion cost reduction using quality control tools and digitization of real-time data. J. Clean Prod. 2019, 237, 117678. [Google Scholar] [CrossRef]

- Molenda, P.; Drews, T.; Oechsle, O.; Butzer, S.; Steinhilper, R. A simulation-based framework for the economic evaluation of flexible manufacturing systems. Procedia CIRP 2017, 63, 201–206. [Google Scholar] [CrossRef]

- Lu, T.; Rotella, G.; Feng, S.C.; Badurdeen, F.; Dillon, O.W., Jr.; Rouch, K.; Jawahir, I.S. Metrics-Based Sustainability Assessment of a Drilling Process. In Sustainable Manufacturing; Springer: Berlin/Heidelberg, Germany, 2012; pp. 59–64. [Google Scholar]

- Balogun, V.A.; Edem, I.F.; Gu, H.; Mativenga, P.T. Energy centric selection of machining conditions for minimum cost. Energy 2018, 164, 655–663. [Google Scholar] [CrossRef]

- Schaltegger, S.; Burritt, R.; Petersen, H. An Introduction to Corporate Environmental Management: Striving for Sustainability; Routledge: Abingdon, UK, 2017. [Google Scholar]

- Saad, M.H.; Nazzal, M.A.; Darras, B.M. A general framework for sustainability assessment of manufacturing processes. Ecol. Indic. 2019, 97, 211–224. [Google Scholar] [CrossRef]

- Swarnakar, V.; Singh, A.R.; Antony, J.; Tiwari, A.K.; Cudney, E. Development of a conceptual method for sustainability assessment in manufacturing. Comput. Ind. Eng. 2021, 158, 107403. [Google Scholar] [CrossRef]

- Nagarajan, H.P.; Raman, A.S.; Haapala, K.R. A sustainability assessment framework for dynamic cloud-based distributed manufacturing. Procedia CIRP 2018, 69, 136–141. [Google Scholar] [CrossRef]

- Sproesser, G.; Schenker, S.; Pittner, A.; Borndörfer, R.; Rethmeier, M.; Chang, Y.-J.; Finkbeiner, M. Sustainable welding process selection based on weight space partitions. Procedia CIRP 2016, 40, 127–132. [Google Scholar] [CrossRef] [Green Version]

- Saxena, P.; Stavropoulos, P.; Kechagias, J.; Salonitis, K. Sustainability assessment for manufacturing operations. Energies 2020, 13, 2730. [Google Scholar] [CrossRef]

- Singh, R.K.; Murty, H.R.; Gupta, S.K.; Dikshit, A.K. An overview of sustainability assessment methodologies. Ecol. Indic. 2012, 15, 281–299. [Google Scholar] [CrossRef]

- Sihag, N.; Sangwan, K.S. Development of a sustainability assessment index for machine tools. Procedia CIRP 2019, 80, 156–161. [Google Scholar] [CrossRef]

- Hartini, S.; Ciptomulyono, U.; Anityasari, M. Manufacturing sustainability assessment using a lean manufacturing tool: A case study in the Indonesian wooden furniture industry. Int. J. Lean Six Sigma 2020, 11, 943–971. [Google Scholar] [CrossRef]

- Chang, Y.-J.; Sproesser, G.; Neugebauer, S.; Wolf, K.; Scheumann, R.; Pittner, A.; Rethmeier, M.; Finkbeiner, M. Environmental and social life cycle assessment of welding technologies. Procedia CIRP 2015, 26, 293–298. [Google Scholar] [CrossRef]

- Norris, G.A. Integrating life cycle cost analysis and LCA. Int. J. Life Cycle Assess 2001, 6, 118–120. [Google Scholar] [CrossRef]

- Miah, J.; Koh, S.; Stone, D. A hybridised framework combining integrated methods for environmental Life Cycle Assessment and Life Cycle Costing. J. Clean Prod. 2017, 168, 846–866. [Google Scholar] [CrossRef]

- Egilmez, G.; Kucukvar, M.; Tatari, O. Sustainability assessment of US manufacturing sectors: An economic input output-based frontier approach. J. Clean. Prod. 2013, 53, 91–102. [Google Scholar] [CrossRef]

- Ribeiro, I.; Matos, F.; Jacinto, C.; Salman, H.; Cardeal, G.; Carvalho, H.; Peças, P. Framework for life cycle sustainability assessment of additive manufacturing. Sustainability 2020, 12, 929. [Google Scholar] [CrossRef]

- Rasheed, A.; Lon, W. A Novel Approach towards Sustainability Assessment in Manufacturing and Stakeholder’s Role. Sustainability 2022, 14, 3221. [Google Scholar] [CrossRef]

- Eslami, Y.; Lezoche, M.; Panetto, H.; Dassisti, M. On analysing sustainability assessment in manufacturing organisations: A survey. Int. J. Prod. Res. 2021, 59, 4108–4139. [Google Scholar] [CrossRef]

- Kluczek, A. Application of multi-criteria approach for sustainability assessment of manufacturing processes. Manag. Prod. Eng. Rev. 2016, 7, 62–78. [Google Scholar] [CrossRef]

- Cai, W.; Liu, F.; Xie, J.; Zhou, X. An energy management approach for the mechanical manufacturing industry through developing a multi-objective energy benchmark. Energy Convers Manag. 2017, 132, 361–371. [Google Scholar] [CrossRef]

- Li, L.; Qu, T.; Liu, Y.; Zhong, R.Y.; Xu, G.; Sun, H.; Ma, C. Sustainability assessment of intelligent manufacturing supported by digital twin. IEEE Access 2020, 8, 174988–175008. [Google Scholar] [CrossRef]

- Schudeleit, T.; Züst, S.; Weiss, L.; Wegener, K. The total energy efficiency index for machine tools. Energy 2016, 102, 682–693. [Google Scholar] [CrossRef]

- Odum, H.T.; Diamond, C.; Brown, M.T. Emergy Analysis Overview of the Mississippi River Basin, Report to the Cousteau Society; Center for Wetlands (Pub—Iication87-1); University of Florida: Gainesville, FL, USA, 1987. [Google Scholar]

- Santagata, R.; Zucaro, A.; Fiorentino, G.; Lucagnano, E.; Ulgiati, S. Developing a procedure for the integration of life cycle assessment and emergy accounting approaches. Amalfi. Pap. Case Study. Ecol. Ind. 2020, 117, 15. [Google Scholar]

- Zhao, Y.; Yu, M.; Xiang, Y.; Kong, F.; Li, L. A sustainability comparison between green concretes and traditional concrete using an emergy ternary diagram. J. Clean Prod. 2020, 256, 120421. [Google Scholar] [CrossRef]

- Lan, S.F.; Odum, H.T. Emergy synthesis of the environmental resources basis and economy in China. Ecol. Sci. 1994, 14, 63–74. [Google Scholar]

- Chen, B.; Chen, G.Q. Emergy-based energy and material metabolism of the Yellow River basin. Commun. Nonlinear Sci. Numer. Simul. 2009, 14, 923–934. [Google Scholar] [CrossRef]

- Wang, C.; Zhang, Y.; Liu, C.; Hu, F.; Zhou, S.; Zhu, J. Emergy-based assessment and suggestions for sustainable development of regional ecological economy: A case study of Anhui province, China. Sustainability 2021, 13, 2988. [Google Scholar] [CrossRef]

- Pan, Y.; Zhang, B.; Wu, Y.; Tian, Y. Sustainability assessment of urban ecological-economic systems based on emergy analysis: A case study in Simao, China. Ecol. Indic. 2021, 121, 107157. [Google Scholar] [CrossRef]

- Liu, C.; Liu, G.; Yang, Q.; Luo, T.; He, P.; Franzese, P.P.; Lombardi, G.V. Emergy-based evaluation of world coastal ecosystem services. Water Res. 2021, 204, 117656. [Google Scholar] [CrossRef]

- Siracusa, G.; La Rosa, A.D. Design of a constructed wetland for wastewater treatment in a Sicilian town and environmental evaluation using the emergy analysis. Ecol. Model. 2006, 197, 490–497. [Google Scholar] [CrossRef]

- Campbell, E.T.; Brown, M.T. Environmental accounting of natural capital and ecosystem services for the US National Forest System. Environ. Dev. Sustain. 2012, 14, 691–724. [Google Scholar] [CrossRef]

- Alkhuzaim, L.; Zhu, Q.Y.; Sarkis, J. Evaluating emergy analysis at the nexus of circular economy and sustainable supply chain management. Sustain. Prod. Consum. 2021, 25, 413–424. [Google Scholar] [CrossRef]

- Liu, C.; Cai, W.; Jia, S.; Zhang, M.; Guo, H.; Hu, L.; Jiang, Z. Emergy-based evaluation and improvement for sustainable manufacturing systems considering resource efficiency and environment performance. Energy Convers. Manag. 2018, 177, 176–189. [Google Scholar] [CrossRef]

- Zhang, X.; Xu, L.; Zhang, H.; Jiang, Z.; Wang, Y. Emergy based sustainability evaluation model for retired machineries integrating energy, environmental and social factors. Energy 2021, 235, 121331. [Google Scholar] [CrossRef]

- Lan, S.; Qin, P. Emergy analysis of ecosystems. Ying Yong Sheng tai xue bao. J. Appl. Ecol. 2001, 12, 129–131. [Google Scholar]

- Ulgiati, S.; Brown, M.T. Quantifying the environmental support for dilution and abatement of process emissions: The case of electricity production. J. Clean Prod. 2002, 10, 335–348. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).