Geographical Origin Classification of Oolong Tea Using an Electronic Nose: Application of Machine Learning and Gray Relational Analysis

Abstract

1. Introduction

2. Materials and Methods

2.1. Experimental Samples

2.2. Colorimetric Analysis

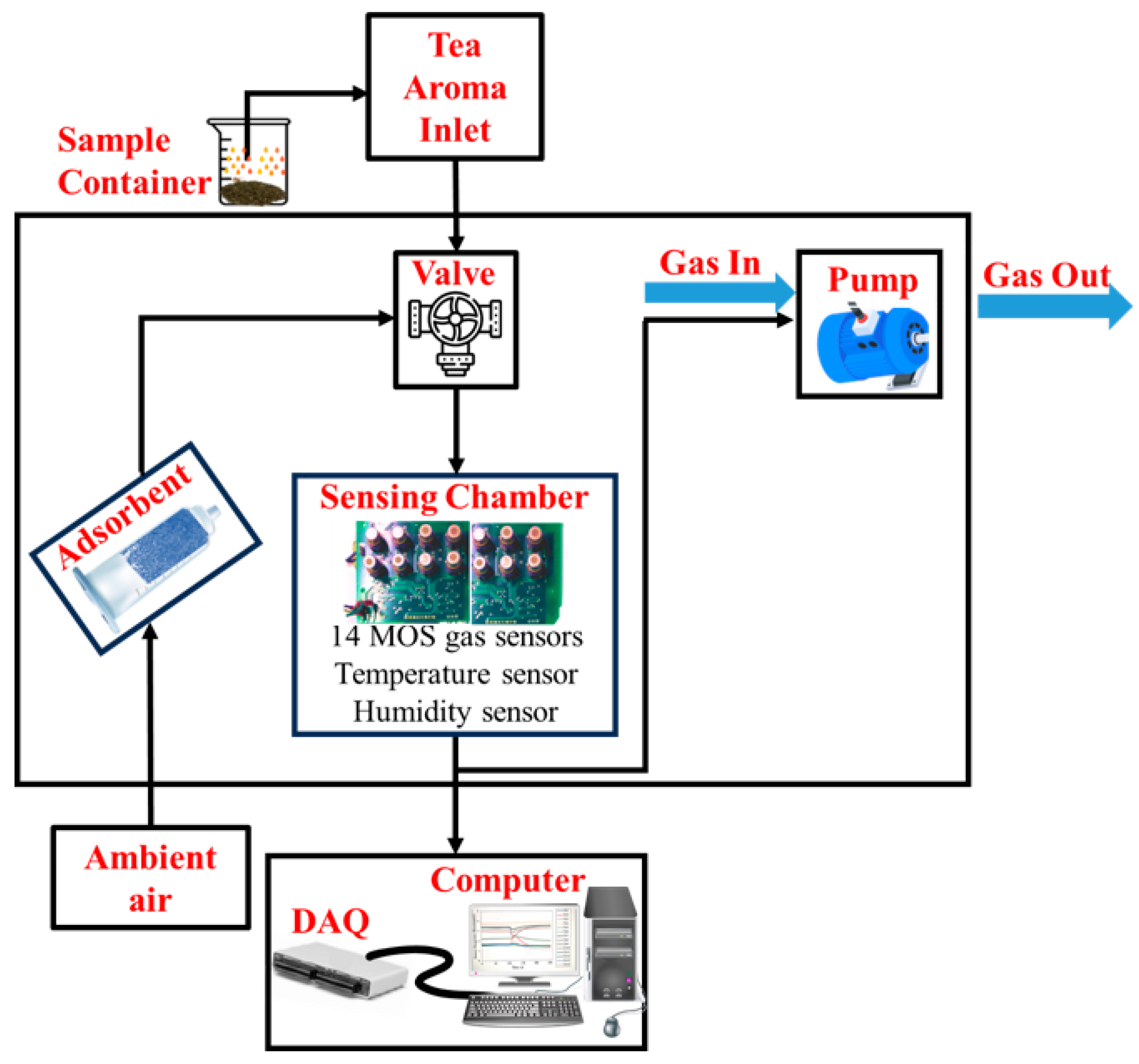

2.3. E-Nose Instrument Set Up

2.3.1. E-Nose Tea Sample Measurement

2.3.2. Data Acquisition and Feature Extraction

2.4. Unsupervised Principal Component Analysis (PCA)

2.5. Machine Learning Models

2.5.1. Linear Discriminant Analysis (LDA)

2.5.2. Support Vector Machine (SVM)

2.5.3. K-Nearest Neighbor (KNN)

2.5.4. Artificial Neural Network (ANN)

2.5.5. Random Forest (RF)

2.5.6. Model Evaluation Metrics

2.6. Gray Relational Analysis (GRA)

2.7. Software

3. Results and Discussion

3.1. Descriptive Statistics and Multivariate Tests for Color Analysis

3.2. E-Nose Results

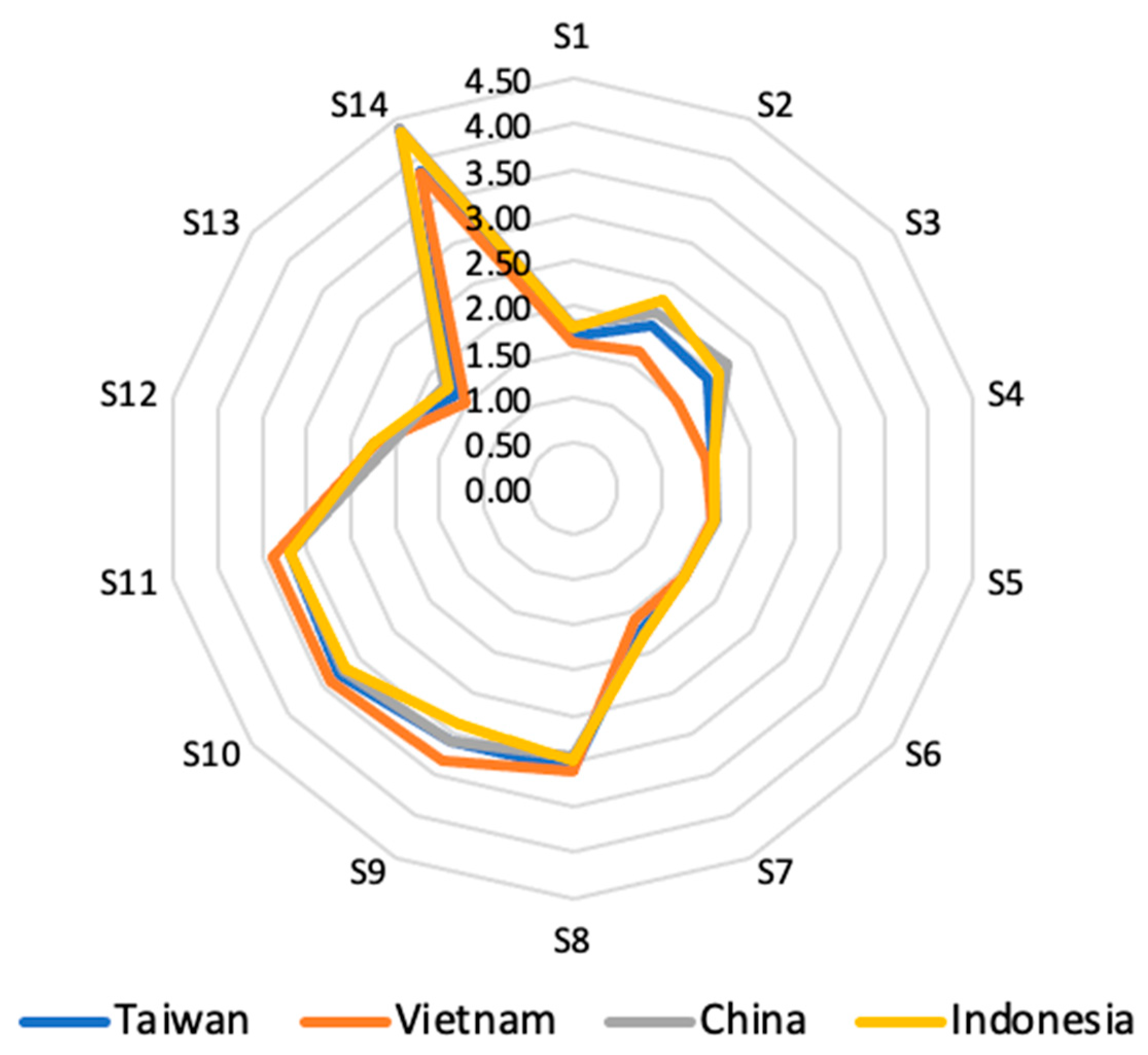

3.2.1. E-Nose Sensor Response

3.2.2. E-Nose Aroma Fingerprint

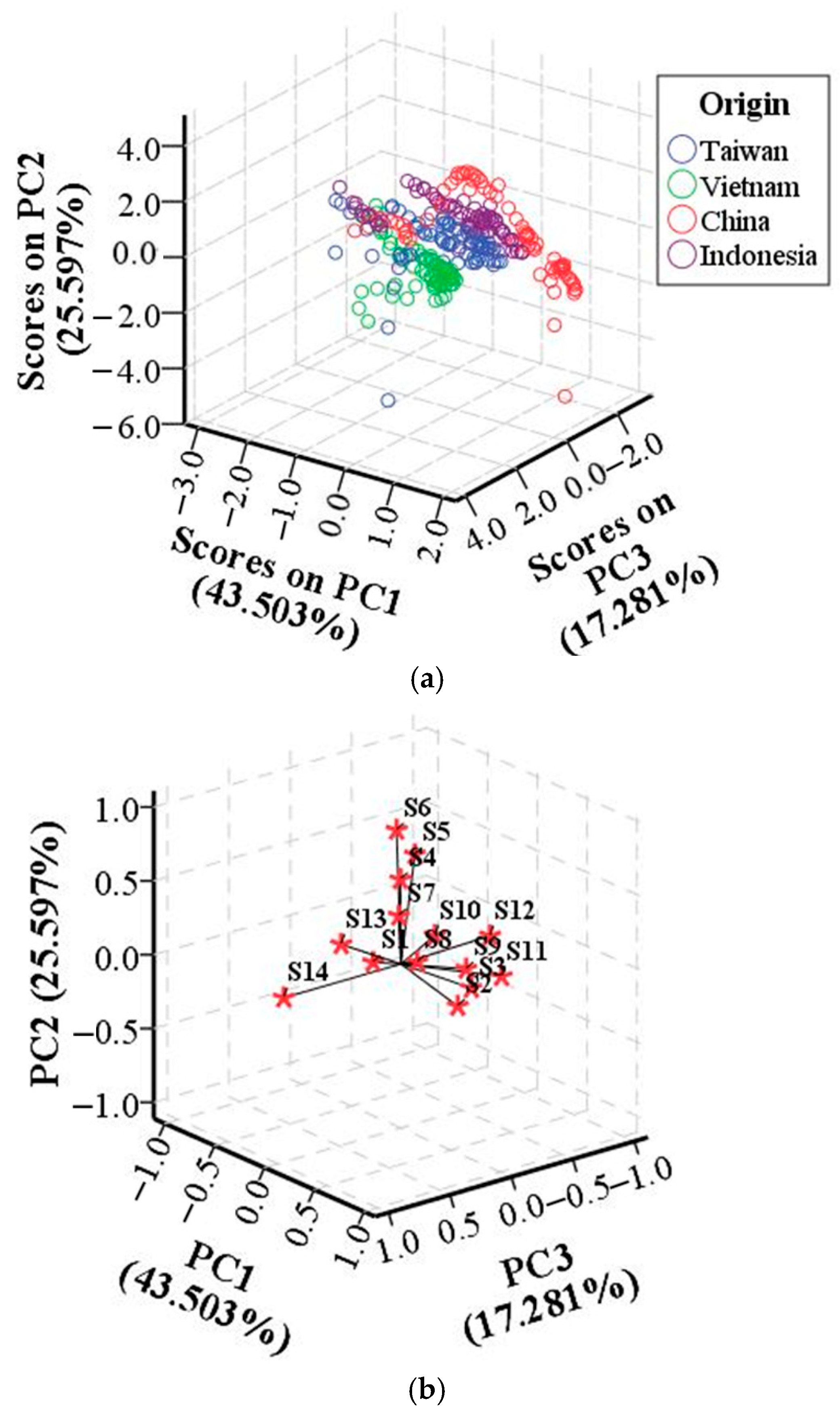

3.3. PCA of Sensor Data

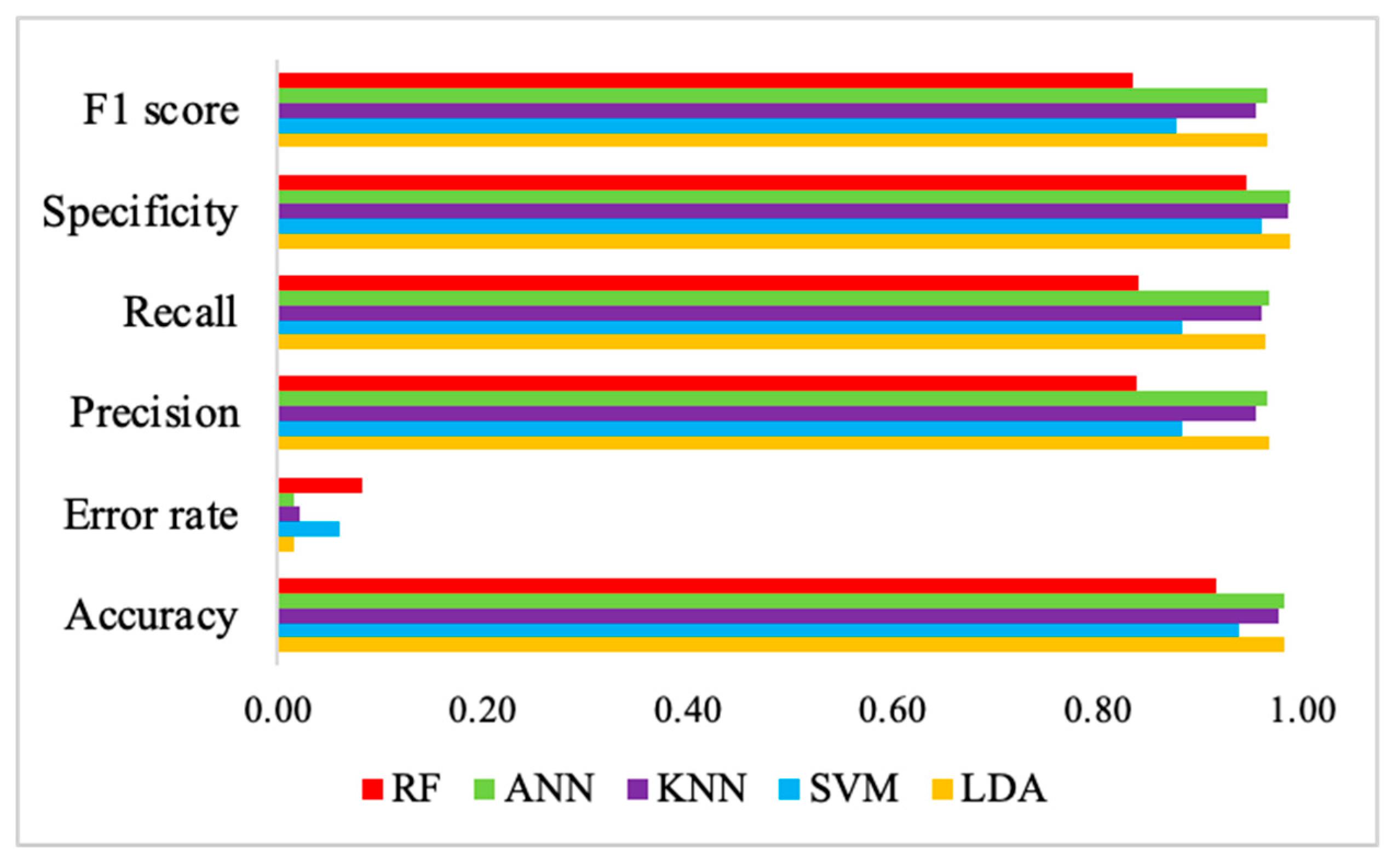

3.4. Comparison of Machine Learning Models

3.5. Gray Relational Analysis

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Gharibzahedi, S.M.T.; Barba, F.J.; Zhou, J.; Wang, M.; Altintas, Z. Electronic sensor technologies in monitoring quality of tea: A review. Biosensors 2022, 12, 356. [Google Scholar] [CrossRef]

- Hidayat, S.N.; Triyana, K.; Fauzan, I.; Julian, T.; Lelono, D.; Yusuf, Y.; Ngadiman, N.; Veloso, A.C.; Peres, A.M. The electronic nose coupled with chemometric tools for discriminating the quality of black tea samples in situ. Chemosensors 2019, 7, 29. [Google Scholar] [CrossRef]

- Kaushal, S.; Nayi, P.; Rahadian, D.; Chen, H.-H. Applications of electronic nose coupled with statistical and intelligent pattern recognition techniques for monitoring tea quality: A review. Agriculture 2022, 12, 1359. [Google Scholar] [CrossRef]

- Kombo, K.O.; Ihsan, N.; Syahputra, T.S.; Hidayat, S.N.; Puspita, M.; Wahyono; Roto, R.; Triyana, K. Enhancing classification rate of electronic nose system and piecewise feature extraction method to classify black tea with superior quality. Sci. Afr. 2024, 24, e02153. [Google Scholar] [CrossRef]

- Zeng, L.; Zhou, X.; Su, X.; Yang, Z. Chinese oolong tea: An aromatic beverage produced under multiple stresses. Trends Food Sci. Technol. 2020, 106, 242–253. [Google Scholar] [CrossRef]

- Chen, P.; Cai, J.; Zheng, P.; Yuan, Y.; Tsewang, W.; Chen, Y.; Xiao, X.; Liao, J.; Sun, B.; Liu, S. Quantitatively unravelling the impact of high altitude on oolong tea flavor from Camellia sinensis grown on the plateaus of Tibet. Horticulturae 2022, 8, 539. [Google Scholar] [CrossRef]

- Wang, Z.; Gan, S.; Sun, W.; Chen, Z. Quality characteristics of oolong tea products in different regions and the contribution of thirteen phytochemical components to its taste. Horticulturae 2022, 8, 278. [Google Scholar] [CrossRef]

- Wu, T.-H.; Tung, I.-C.; Hsu, H.-C.; Kuo, C.-C.; Chang, J.-H.; Chen, S.; Tsai, C.-Y.; Chuang, Y.-K. Quantitative analysis and discrimination of partially fermented teas from different origins using visible/near-infrared spectroscopy coupled with chemometrics. Sensors 2020, 20, 5451. [Google Scholar] [CrossRef]

- He, C.; Zhou, J.; Li, Y.; Ntezimana, B.; Zhu, J.; Wang, X.; Xu, W.; Wen, X.; Chen, Y.; Yu, Z. The aroma characteristics of oolong tea are jointly determined by processing mode and tea cultivars. Food Chem. X 2023, 18, 100730. [Google Scholar] [CrossRef]

- Su, T.-C.; Yang, M.-J.; Huang, H.-H.; Kuo, C.-C.; Chen, L.-Y. Using sensory wheels to characterize consumers’ perception for authentication of Taiwan specialty teas. Foods 2021, 10, 836. [Google Scholar] [CrossRef] [PubMed]

- Liu, T.-L.; Dai, J.-R.; Su, T.-C.; Chiu, C.-H.; Tsai, H.-T.; Chiu, C.-F.; Lin, J.-C.; Hu, C.-Y. Development and industrial application of geographical origin identification for Taiwanese oolong tea. J. Food Drug Anal. 2024, 32, 498. [Google Scholar] [CrossRef] [PubMed]

- Chiu, Y.-W. Environmental implications of Taiwanese oolong tea and the opportunities of impact reduction. Sustainability 2019, 11, 6042. [Google Scholar] [CrossRef]

- Lee, S.W.; Kim, B.H.; Seo, Y.H. Olfactory system-inspired electronic nose system using numerous low-cost homogenous and hetrogenous sensors. PLoS ONE 2023, 18, e0295703. [Google Scholar] [CrossRef]

- Jiménez-López, I.; Molina-Quiroga, J.; Gutiérrez, J.M. Classification of teas using different feature extraction methods from signals of a lab-made electronic nose. Eng. Proc. 2023, 48, 20. [Google Scholar]

- Gómez, I.; Lavega González, R.; Tejedor-Calvo, E.; Pérez Clavijo, M.; Carrasco, J. Odor profile of four cultivated and freeze-dried edible mushrooms by using sensory panel, electronic nose and GC-MS. J. Fungi 2022, 8, 953. [Google Scholar] [CrossRef]

- Putri, L.A.; Rahman, I.; Puspita, M.; Hidayat, S.N.; Dharmawan, A.B.; Rianjanu, A.; Wibirama, S.; Roto, R.; Triyana, K.; Wasisto, H.S. Rapid analysis of meat floss origin using a supervised machine learning-based electronic nose towards food authentication. npj Sci. Food 2023, 7, 31. [Google Scholar] [CrossRef]

- Carrillo, J.K.; Durán, C.M.; Cáceres, J.M.; Cuastumal, C.A.; Ferreira, J.; Ramos, J.; Bahder, B.; Oates, M.; Ruiz, A. Assessment of E-senses performance through machine learning models for Colombian herbal teas classification. Chemosensors 2023, 11, 354. [Google Scholar] [CrossRef]

- Xu, M.; Wang, J.; Zhu, L. Tea quality evaluation by applying E-nose combined with chemometrics methods. J. Food Sci. Technol. 2021, 58, 1549–1561. [Google Scholar] [CrossRef]

- Liu, H.; Li, Q.; Gu, Y. Convenient and accurate method for the identification of Chinese teas by an electronic nose. Qual. Assur. Saf. Crop. Foods 2018, 11, 79–88. [Google Scholar] [CrossRef]

- Ogundile, O.M.; Owoade, A.A.; Ogundile, O.O.; Babalola, O.P. Linear discriminant analysis based hidden Markov model for detection of Mysticetes’ vocalisations. Sci. Afr. 2024, 24, e02128. [Google Scholar] [CrossRef]

- Zhang, Y.; Deng, L.; Zhu, H.; Wang, W.; Ren, Z.; Zhou, Q.; Lu, S.; Sun, S.; Zhu, Z.; Gorriz, J.M.; et al. Deep learning in food category recognition. Inf. Fusion 2023, 98, 101859. [Google Scholar] [CrossRef]

- Liu, H.; Li, Q.; Yan, B.; Zhang, L.; Gu, Y. Bionic electronic nose based on MOS sensors array and machine learning algorithms used for wine properties detection. Sensors 2019, 19, 45. [Google Scholar] [CrossRef]

- Tan, J.; Xu, J. Applications of electronic nose (e-nose) and electronic tongue (e-tongue) in food quality-related properties determination: A review. Artif. Intell. Agric. 2020, 4, 104–115. [Google Scholar] [CrossRef]

- Stangierski, J.; Weiss, D.; Kaczmarek, A. Multiple regression models and artificial neural network (ANN) as prediction tools of changes in overall quality during the storage of spreadable processed Gouda cheese. Eur. Food Res. Technol. 2019, 245, 2539–2547. [Google Scholar] [CrossRef]

- Chen, G.; Zhang, X.; Wu, Z.; Su, J.; Cai, G. An efficient tea quality classification algorithm based on near infrared spectroscopy and random Forest. J. Food Process Eng. 2021, 44, e13604. [Google Scholar] [CrossRef]

- Huang, C.; Gu, Y. A machine learning method for the quantitative detection of adulterated meat using a MOS-based E-nose. Foods 2022, 11, 602. [Google Scholar] [CrossRef] [PubMed]

- Yu, D.; Gu, Y. A machine learning method for the fine-grained classification of green tea with geographical indication using a MOS-based electronic nose. Foods 2021, 10, 795. [Google Scholar] [CrossRef]

- Deng, J.L. Introduction to grey system theory. J. Grey Syst. 1989, 1, 1–24. [Google Scholar]

- Du, Z.; Hu, Y.; Buttar, N.A. Analysis of mechanical properties for tea stem using grey relational analysis coupled with multiple linear regression. Sci. Hortic. 2020, 260, 108886. [Google Scholar] [CrossRef]

- Du, Z.; Zhang, L.; Xie, X.; Li, D.; Li, X.; Zhang, Z.; Pang, J. Application of grey relational analysis and multiple linear regression to establish the cutting force model of oil peony stalk. Math. Probl. Eng. 2022, 2022, 2341766. [Google Scholar] [CrossRef]

- Chung, P.-L.; Liaw, E.-T.; Gavahian, M.; Chen, H.-H. Development and optimization of Djulis sourdough bread using taguchi grey relational analysis. Foods 2020, 9, 1149. [Google Scholar] [CrossRef] [PubMed]

- Rana, P.; Liaw, S.-Y.; Lee, M.-S.; Sheu, S.-C. Discrimination of four Cinnamomum species with physico-functional properties and chemometric techniques: Application of PCA and MDA models. Foods 2021, 10, 2871. [Google Scholar] [CrossRef] [PubMed]

| Sensor No. | Gas Sensor | Target Application | Target Gas |

|---|---|---|---|

| S1 | TGS-2600 | Air Contaminants | Carbon Monoxide, Ethanol, Methane, Hydrogen, Iso-butane |

| S2 | TGS-2602 | Air Contaminants | Ammonia, Hydrogen Sulfide, Toluene, Hydrogen, Ethanol |

| S3 | TGS-2603 | Odor and Air Contaminants | Hydrogen, Methyl Mercaptan, Ethanol, Trimethyl Amine, Hydrogen Sulfide |

| S4 | TGS-2610 | Liquefied Petroleum (LP) Gas | Ethanol, Iso-butane/Propane, Methane, Hydrogen |

| S5 | TGS-2611 | Methane | Iso-butane, Ethanol, Hydrogen, Methane |

| S6 | TGS-2612 | Methane and LP Gas | Methane, Iso-Butane, Propane, Ethanol |

| S7 | TGS-2620 | Solvent Vapors | Iso-butane, Hydrogen, Ethanol, Methane, Carbon Monoxide |

| S8 | SB-51-00 | Hydrogen Sulfide (H2S) | Ethanol, Hydrogen, Carbon Monoxide, Hydrogen Sulfide |

| S9 | SB-53-00 | Ammonia | Ethanol, Hydrogen, Carbon Monoxide, Iso-butane, Hydrogen Sulfide, Ethylene, Methyl Mercaptan, Ammonia, Trimethylamine |

| S10 | SB-AQI-06 | VOCs | Methane, Iso-butane, Hydrogen, Ethanol, Carbon Monoxide |

| S11 | SB-30-04 | Alcohol | Iso-butane, Hydrogen, Ethanol |

| S12 | SP3S-AQ2 | VOCs | Methane, Iso-butane, Hydrogen, Ethanol, Carbon Monoxide |

| S13 | SP-53B-00 | Ammonia | Ethanol, Hydrogen, Carbon Monoxide, Methane, Iso-butane, Ammonia, Nitrogen Monoxide, Nitrogen Dioxide |

| S14 | SP3-61-00 | Ozone | Ozone, Iso-butane, Carbon Monoxide, Hydrogen, Ethyl Alcohol, Nitric Oxide/Nitrogen Dioxide (NO/NO2) |

| Origin | Color Characteristics | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| L* | a* | b* | ||||||||||

| Mean | SD | Min | Max | Mean | SD | Min | Max | Mean | SD | Min | Max | |

| Taiwan | 19.86 c | 0.87 | 18.16 | 22.50 | 1.24 b | 0.37 | 0.68 | 2.09 | 9.47 c | 0.87 | 8.08 | 11.29 |

| Vietnam | 22.18 b | 1.86 | 17.05 | 25.70 | 2.08 a | 0.50 | 0.78 | 3.16 | 11.94 b | 2.49 | 6.04 | 15.15 |

| China | 26.91 a | 4.13 | 16.47 | 33.52 | 0.52 c | 0.29 | 0.01 | 1.88 | 11.43 b | 2.07 | 0.59 | 14.89 |

| Indonesia | 22.35 b | 3.56 | 14.10 | 27.06 | 1.99 a | 0.42 | 1.07 | 3.22 | 13.43 a | 2.22 | 8.28 | 16.53 |

| Test | Value | F-Value | Hypothesis df | Error df | p-Value | Partial η2 |

|---|---|---|---|---|---|---|

| Pillai’s trace | 1.295 | 71.868 | 9 | 852 | 0.000 | 0.432 |

| Wilks’ Λ | 0.107 | 114.982 | 9 | 686.465 | 0.000 | 0.526 |

| Hotelling’s trace | 4.999 | 155.907 | 9 | 842 | 0.000 | 0.625 |

| Roy’s largest root | 4.333 | 410.218 | 3 | 284 | 0.000 | 0.812 |

| Models | Origin | Evaluation Metrics | |||||

|---|---|---|---|---|---|---|---|

| Accuracy | Error Rate | Precision | Recall | Specificity | F1 Score | ||

| LDA | Taiwan | 0.9778 | 0.0222 | 0.9500 | 0.9500 | 0.9857 | 0.9500 |

| Vietnam | 0.9667 | 0.0333 | 0.9231 | 0.9600 | 0.9692 | 0.9412 | |

| China | 1.0000 | 0.0000 | 1.0000 | 1.0000 | 1.0000 | 1.0000 | |

| Indonesia | 0.9889 | 0.0111 | 1.0000 | 0.9500 | 1.0000 | 0.9744 | |

| Average | 0.9833 | 0.0167 | 0.9683 | 0.9650 | 0.9887 | 0.9664 | |

| SVM | Taiwan | 0.9556 | 0.0444 | 0.9000 | 0.9000 | 0.9714 | 0.9000 |

| Vietnam | 0.9565 | 0.0435 | 0.9200 | 0.9200 | 0.9701 | 0.9200 | |

| China | 0.9222 | 0.0778 | 0.9500 | 0.7600 | 0.9846 | 0.8444 | |

| Indonesia | 0.9222 | 0.0778 | 0.7600 | 0.9500 | 0.9143 | 0.8444 | |

| Average | 0.9391 | 0.0609 | 0.8825 | 0.8825 | 0.9601 | 0.8772 | |

| KNN | Taiwan | 0.9778 | 0.0222 | 0.9091 | 1.0000 | 0.9714 | 0.9524 |

| Vietnam | 0.9778 | 0.0222 | 1.0000 | 0.9200 | 1.0000 | 0.9583 | |

| China | 0.9778 | 0.0222 | 1.0000 | 0.9200 | 1.0000 | 0.9583 | |

| Indonesia | 0.9778 | 0.0222 | 0.9091 | 1.0000 | 0.9714 | 0.9524 | |

| Average | 0.9778 | 0.0222 | 0.9545 | 0.9600 | 0.9857 | 0.9554 | |

| ANN | Taiwan | 0.9889 | 0.0111 | 0.9524 | 1.0000 | 0.9857 | 0.9756 |

| Vietnam | 0.9889 | 0.0111 | 1.0000 | 0.9600 | 1.0000 | 0.9796 | |

| China | 0.9778 | 0.0222 | 0.9600 | 0.9600 | 0.9846 | 0.9600 | |

| Indonesia | 0.9778 | 0.0222 | 0.9500 | 0.9500 | 0.9857 | 0.9500 | |

| Average | 0.9833 | 0.0167 | 0.9656 | 0.9675 | 0.9890 | 0.9663 | |

| RF | Taiwan | 0.9111 | 0.0889 | 0.7727 | 0.8500 | 0.9286 | 0.8095 |

| Vietnam | 0.9444 | 0.0556 | 1.0000 | 0.8000 | 1.0000 | 0.8889 | |

| China | 0.8778 | 0.1222 | 0.7917 | 0.7600 | 0.9231 | 0.7755 | |

| Indonesia | 0.9333 | 0.0667 | 0.7917 | 0.9500 | 0.9286 | 0.8636 | |

| Average | 0.9167 | 0.0833 | 0.8390 | 0.8400 | 0.9451 | 0.8344 | |

| Origin | Sensors | ||

|---|---|---|---|

| GRC Range | GRG Range | Dominant Sensors | |

| Taiwan | 0.350–0.689 | 0.497–0.570 | S4, S6, S14 |

| Vietnam | 0.333–0.610 | 0.497–0.540 | S3, S8, S12 |

| China | 0.336–0.595 | 0.497–0.530 | S1, S5, S11 |

| Indonesia | 0.340–0.580 | 0.497–0.520 | S2, S7, S10 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kaushal, S.; Rana, P.; Chung, C.-C.; Chen, H.-H. Geographical Origin Classification of Oolong Tea Using an Electronic Nose: Application of Machine Learning and Gray Relational Analysis. Chemosensors 2025, 13, 295. https://doi.org/10.3390/chemosensors13080295

Kaushal S, Rana P, Chung C-C, Chen H-H. Geographical Origin Classification of Oolong Tea Using an Electronic Nose: Application of Machine Learning and Gray Relational Analysis. Chemosensors. 2025; 13(8):295. https://doi.org/10.3390/chemosensors13080295

Chicago/Turabian StyleKaushal, Sushant, Priya Rana, Chao-Chin Chung, and Ho-Hsien Chen. 2025. "Geographical Origin Classification of Oolong Tea Using an Electronic Nose: Application of Machine Learning and Gray Relational Analysis" Chemosensors 13, no. 8: 295. https://doi.org/10.3390/chemosensors13080295

APA StyleKaushal, S., Rana, P., Chung, C.-C., & Chen, H.-H. (2025). Geographical Origin Classification of Oolong Tea Using an Electronic Nose: Application of Machine Learning and Gray Relational Analysis. Chemosensors, 13(8), 295. https://doi.org/10.3390/chemosensors13080295