1. Introduction

The crushing of cylindrical structures has been extensively studied for two main causes: structural integrity maintenance and energy absorption applications. In the context of structural integrity, the lateral crushing analysis of pipes focuses on understanding mechanisms of indentation and rupture damage [

1,

2], assessing the remaining load-carrying capacity after damage [

3], and estimating the fatigue life of dented pipes [

4]. As reported by Lam [

5], the third-party excavation and corrosion accounts for approximately 75% of incidents in gas transmission pipelines. Additionally, potential threats such as ship collision [

6,

7], pipeline dropping during installation [

8], and anchor impacts [

9] pose significant risks to offshore platforms and undersea pipelines. For example, Firouzsalari and Showkati [

10] investigated the quasi-static lateral crushing of long free-spanned pipelines subject to axial preloaded forces. They found that the presence of axial force reduced the crushing force. A similar dynamic impact scenario was experimentally studied by Zeinoddini et al. [

11], who notably used disk springs to compensate for the short-time axial force magnitude variation. Similarly, Zhi et al. [

12] used a bladder accumulator instead to maintain the axial force magnitude over a short duration.

Despite the detrimental damage due to crushing, by large plastic dissipation, circular tubes or short-width circular rings are commonly used in energy absorption applications to dissipate the kinetic energy. In such cases, the energy absorption capacity and force-displacement response are the primary considerations, rather than the material damage to the structure itself. For instance, Santosa et al. [

13] conducted both experimental and numerical FEM analyses on the axial crushing of beams with cross-sections filled with aluminum foam, focusing on the total absorbed energy.

The circular ring has been frequently employed in energy absorption applications due to its nearly constant crushing force over a large displacement range and its large dissipated energy amount. For example, Baroutaji et al. [

14] studied the crushing behavior of short-width circular rings between two rigid plates with functionally graded thickness distribution. Innovatively, the 3D additive manufacturing technique of selective laser melting (SLM) was utilized to produce the rings of non-uniform thickness with residual stress reduced carefully by heat treatment. Niknejad and Javan [

15] theoretically analyzed the absorbed energy of circular metal tubes during crushing by a wedge-shaped indenter. Using a rigid plastic formulation, they estimated the total energy dissipation; however, their approach provided a prediction of the averaged force instead of the detailed force-displacement relationships. Wang et al. [

16] extended this work [

15] by a dynamic analysis, treating cross-sectional moments as generalized forces and deriving a 1D dynamic governing equation using the Hamiltonian principle. To account for linear hardening, the plastic hinge length was artificially assigned as four times the material thickness [

16].

In addition to the circular ring, recent studies have explored the use of elliptic rings which have demonstrated the advantages of longer stroke and more constant force over larger displacement ranges. Morris et al. [

17] conducted a quasi-static experiment and finite element analysis (FEA) on nested circular and non-circular rings and observed a softening phase during the crushing of elliptic rings. Notably, the elliptic rings in their experiments were formed by plastically cold-forming the circular ring, a process that inevitably introduced residual stresses. Wu and Carney [

18] performed an initial collapse analysis of braced elliptic rings using classic upper and lower bound theorems to determine the initial collapse load. They found that elliptical shapes exhibited larger collapse strokes and increased energy dissipation per unit mass. Baroutaji et al. [

19] conducted experimental tests and FEM analyses on the lateral crushing of non-circular rings (not perfectly elliptical) which were cold-formed into oblong shapes by two inserted cylindrical bars at the top and bottom. They also employed the response surface method to maximize the energy absorption capacity. More recently, Yang K et al. [

20] proposed a way of connecting two elliptic rings by inner flat connections to avoid the splash of tubes during dynamic crushing and conducted a rigid plastic analysis on the “self-locked” elliptic rings. Yang X et al. [

21] innovatively combined an elliptic ring and circular ring into a nested tube system, and a rigid-perfectly plastic analysis by a linear hardening material model was adopted to extract the force and displacement response, which indicated that the nested system is extremely stable for the plateau force. An alternative nested system by combining elliptic rings and corrugated tubes was proposed by Wu et al. [

22], and high energy absorption efficiency was observed in experimental tests.

Despite extensive numerical and experimental research on the rings, there are only a few theoretical analyses in the literature. For example, DeRuntz and Hodge [

15] developed a four-hinge model to predict the crushing force of a circular ring compressed between two rigid plates without accounting for material hardening. This model was later used by Palmer and Martin [

23] to predict the energy absorption of a collapsed pipe (with circular cross-sections) under external pressure, specifically in the context of buckle propagation. Yan et al. [

24] adopted this four-hinge 2D ring model, coupled with axial membrane strain, to analytically study the indentation process of pipelines subject to lateral wedge impact in the presence of external pressure.

This work is illuminated by the valuable contributions about plastic crushing behaviors of circular and elliptic rings from Reid and Reddy [

25] and Liu et al. [

26]. Reid and Reddy [

25] demonstrated that the neglect of the material hardening led to a significantly under-estimated crushing force of a circular ring compressed between two plates when experimental results are compared. They developed a plastic model, which was solved analytically by the elliptical integrals. A key observation from Reid and Reddy [

25] was that the length of the plastic region initially increased and smoothly decreased during deformation, based on the fully plastic cross-sectional resultant moment derived from the yielding stress (referred to as the M

0 criterion in this paper). However, their study [

25] was limited to circular rings. For elliptic rings, recently Liu et al. [

26] modified Reid and Reddy’s formulation [

25] to include the ovality effect, allowing for the analysis of the elliptic ring crushed between plates based on the linear hardening model. Liu et al. [

26] interestingly assigned the length of the plastic region proportional to a rotation angle during deformation. Also, although the theoretical formulation [

25] predicts a “first increases, then smoothly decreases” pattern for circular rings, no quantitative comparison of fully plastic region length between FEA and theoretical models is found in the literature.

Thus, this paper addresses this gap by comparing the theoretical predictions with the active yielding region obtained from FEA in ABAQUS. The results unexpectedly indicate that the fully plastic criterion (M

0 criterion [

25]) significantly over-estimates the plastic region length from FEA. Thus we propose a modified criterion based on the highest moment during loading history, which significantly improves estimation accuracy. In the literature, experimental specimens of elliptic rings are typically produced by cold-forming circular rings [

17]. This process inevitably introduces residual stresses and results in imperfect elliptic shapes making it challenging to directly compare experimental and theoretical results. Additionally, existing theoretical formulations [

25,

26] are limited to the linear hardening material models. To address these issues, this paper employs CNC milling to produce precise elliptic shapes, minimizing residual stresses and ensuring geometric accuracy. Furthermore, Ludwik’s material model, which incorporates non-linear power-law hardening, is adopted in theoretical formulation. Linear hardening is treated as a special case within this framework, enabling a simple analytical solution by elliptic integrals. Finally by adopting a constant initial curvature assumption at the bottom plastic region, purely analytical solutions without solving differential equations are formulated to allow efficient force-displacement relation prediction.

This paper is structured as follows:

Section 2 presents the general theoretical fully plastic model formulation solved by shooting method by following the theoretical framework of Reid and Reddy [

25] and Liu et al. [

26] by extension from linear hardening model to general power-law hardening model;

Section 3 discusses the experimental results and

Section 4 analyzes the collapse mechanism through FEA, theoretical and experimental comparisons including the evolution of plastic regions.

Section 5 provides corresponding force-displacement results for the special case of linear hardening.

Section 6 proposes a robust extraction of fully plastic region length from FEA and discusses the theoretical estimation of plastic region length, and also the plastic energy dissipation distribution between the bottom and upper plastic region quantitatively.

Section 7 presents analytical elliptic integral-based solutions for the linear hardening case.

Section 8 conducts parametric analyses to further explore the behavior of non-circular rings.

Appendix A presents some geometric analysis;

Appendix B presents Castigliano’s second theorem-based initial elastic phase analysis;

Appendix C presents the constant curvature assumption-based analytical solutions without necessity to solve differential equations for general hardening exponent;

Appendix D presents analytical solutions for special hardening exponent 1/2 by using radicals;

Appendix E presents the mesh independence check of FEA.

This paper aims to enhance the understanding of the crushing behavior of non-circular rings, with applications in structural integrity and energy absorption.

2. Theoretical Fully Plastic Model of Crushing Elliptic Ring Between Flat Plates

2.1. General Formulation by Ludwik’s Material Model

Considering an elliptic ring crushed between two parallel plates in

Figure 1a, the ring has a horizontal semi-axis of length

and a vertical semi-axis of length

b with a ratio

. The upper and lower plates are rigid. The dotted curve represents the corresponding circle tangent to the ellipse at point A with an angular coordinate

. The arc-length coordinate is denoted as

s, which is geometrically described using the incomplete elliptic integral of the second kind

by

where

is the eccentricity of the ellipse.

By symmetry, a quarter-model is analyzed, as shown in

Figure 1b. Point C is a tangent point to the upper plate, while points A and D are the end points. The plastic hinge moment due to initial yielding stress is given by

, where

t is the thickness,

is the yielding stress,

l is the width of the ring. Assuming the existence of a moving plastic hinge at C and a fixed plastic hinge at A, deformed arc

of length

is the extent of the plastic hinge, where the moment at B is equal to

. Arc

is assumed to be rigid. Due to material hardening,

is non-zero (see also Reid and Reddy [

25]). The moving plastic hinge C is assumed to have a fixed moment

. The existence of theoretical top moving and lower plastic hinge regions is clearly validated through the visualization of the active yielding zones (where instantaneous plastic yielding occurs) in FEA (e.g., see Figures 8, 9, 11 and 12 in this paper).

At arc

AB as depicted in

Figure 1d, the vertical force magnitude is

P/2. Consequently, the shear force is

. The moment balance at

s yields Equation (1) where

is the cross-section resultant moment along coordinate

s and

is the normal vector’s angle about the X axis with differentiation notation

.

The Ludwik’s material model

is employed, with

C and

n as material parameters where

is the circumferential plastic strain. Assuming inextensible middle axis and thus neglecting the membrane strain,

where

is the curvature change and

z is the spatial coordinate in thickness direction. By integration over

z, the expression of the cross-sectional moment is given by Equation (2).

When

n = 1 (linearly hardening case), Equation (2) reduces to the conventional linear hardening model in the literature [

25,

26]:

where

(equal to C) is the plastic modulus and

is the moment of inertia.

The curvature change

at

s is related to the angles

by

where

is the angle of the normal vector about axis X in the undeformed configuration (see

Figure 1a). Thus, Equations (1), (2) and (4) together yield the following:

where

. Note that for a perfectly circular ring

identically since it has a fixed curvature, while for an elliptic ring

.

Equation (5a) reduces to

in the special linear hardening case. By relation

and

,

To solve Equation (5a), the angle continuity condition and curvature continuity condition at point B (see

Figure 1b) are imposed as Equations (6) and (7):

where

α is the rotation angle of the rigid arc

DB.

By representing the undeformed configuration as

, some geometric analysis implies Equations (8a) and (8b).

To complete the description, a moment equilibrium analysis on the arc

BC (see

Figure 1c) yields the following:

where

L is the horizontal distance between point B and the tangent point C.

Due to the rigidity assumption of arc

DB, as derived in

Appendix A,

L can be represented by Equation (10).

The denting displacement

δ (crushing distance, see

Figure 1b) could be shown in

Appendix A to be represented as follows:

where

are represented as follows:

This theoretical formulation is solved by the shooting method in

Section 2.2 and verified by experiments and FEA in

Section 4. We comment further that due to symmetry and force and moment equilibrium, point D in

Figure 1b has no reaction force and thus the resultant internal force is zero, and the cross-section internal moment is constant along the DC segment. The contact is assumed to be a point contact at tangent point C, which is validated by an FEA contact pressure visualization in

Section 6.5.

2.2. Solution by Numerical Shooting Method

The theoretical formulation is solved by the shooting method, which converts the boundary condition problem to an equivalent initial value problem using the Newton–Raphson iteration. For convenience, the independent variable θ is used instead of arc-length s as Equations (5b), (8a) and (8b) are based on θ.

Five variables are introduced as

where differentiation with respect to

yields the first order ordinary differential equation system (initial value problem with

as the “time” variable) as in Equations (13a)–(13e).

Set initial conditions where c is unknown together with two other unknowns ( and P). Thus, for each specified angle , there are three unknowns with three boundary conditions (Equations (8a), (8b) and (9) at ). Of course, for specific , if is known, the initial value problem could be solved via the Runge–Kutta algorithm through the ode45 solver in Matlab software 2018. So we firstly guess some values of and then use Newton–Raphson iteration to correct them until the three boundary conditions are simultaneously satisfied (convergence) for each . During the iterations, under parameters , the extent of non-satisfactions of these three conditions (“residual”) is represented as a three-dimensional column vector (by taking the difference rhs-lhs of Equations (8a), (8b) and (9) at where rhs is the right-hand side and lhs is the left-hand side of the equations).

Newton–Raphson iteration is illustrated briefly: (1) obtain the residual arrays (denote by respectively) for four sets of parameters , where are artificially assigned small enough quantities (e.g., 1 × 10−4); (2) the approximate matrix Jacobian matrix ; (3) Obtaining the corrections by matrix inversion, update . Repeat the above iteration until convergence of parameters.

After convergence, the denting displacement

is obtained by substituting converged values of

into Equation (11). Incrementing angle

from zero value yields continuous variation in denting displacement

and load

P. Although the shooting method coupled with Newton–Raphson iteration for solving boundary value problems is conventional (see also our previous work [

27]), in our case, there is some subtlety in numerically implementing Equation (13b) since

may lead to complex values (non-real numbers) when −1 <

n – 1 < 0. Thus, in practice,

is replaced by

to circumvent this problem, which trick does not affect the converged result since

inside the plastic hinge region arc AB.

5. Collapse Mechanism Analysis for Linear Hardening Cases

When

C =

Ep and

n = 1, the Ludwik material model reduces to the conventional linear hardening model [

25,

26]. FEA using linear isotropic hardening, and a theoretical analysis was conducted. The parameters were

(linear hardening material parameters used throughout this paper except in

Section 8),

for

[

26]. Elastic modulus = 200 GPa.

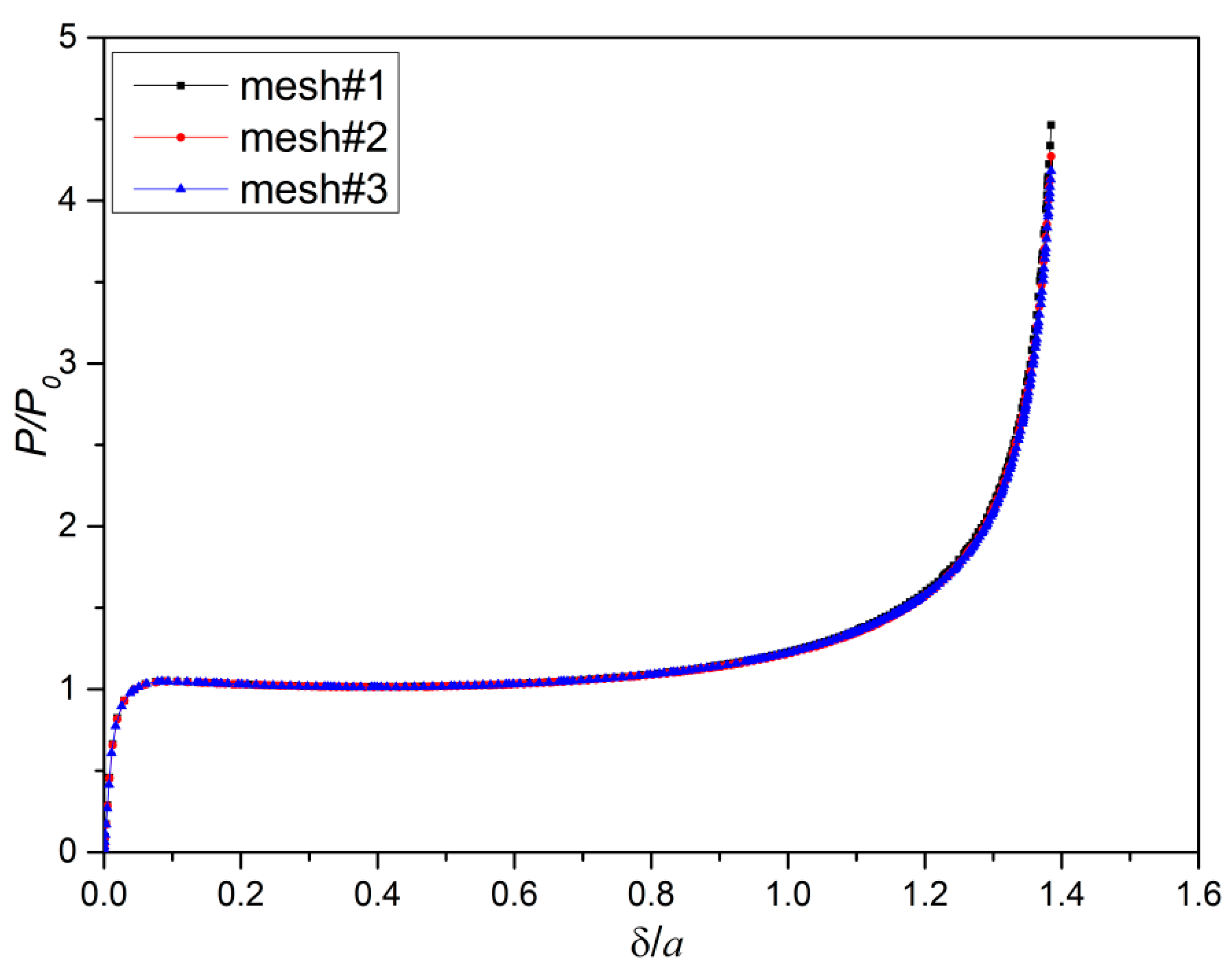

The comparison of FEA results and theoretical results is shown in

Figure 10. The initial phase of the theoretical result is derived from an elastic analysis in

Appendix B. The slope of the force-displacement curve during the initial phase decreases as

h increases. The load

P is normalized by

by the classic four plastic hinge model for small deformations (see [

25,

26]).

For a circular ring (

h = 1.0),

P/

P0 increases steeply to 1.0 and then continues to grow monotonically in an accelerated manner, reaching

P/

P0 = 6 at

= 0.9. For

h = 1.2,

P/

P0 also increases to 1.0, but grows more slowly compared to the case of

h = 1.0. However, when

h = 1.4,

P/

P0 remains almost constant when

and then grows slowly when

before transitioning to accelerated growth. For

h = 1.6, consistent with results in

Section 4,

P/

P0 initially decreases (softening phase) and then grows very slowly until accelerated growth occurs. Notably,

P/

P0 remains around 1.0 over a long displacement range

verifying the advantage of the elliptic ring in providing a longer stroke with nearly constant force resistance. The theoretical results, including the initial phase, agree well with the FEA results. Only at very large deformations, theoretical results slightly underestimate the force level.

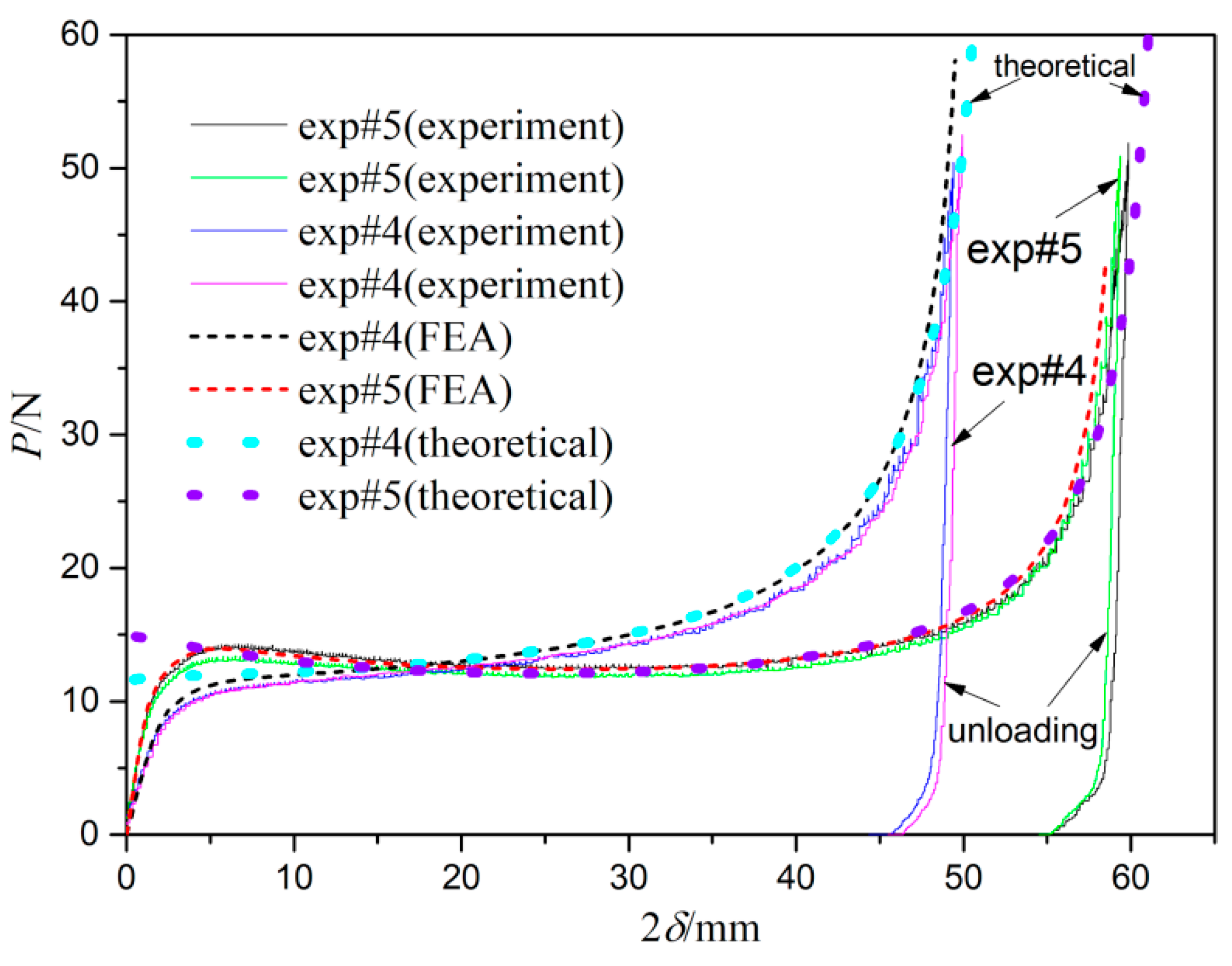

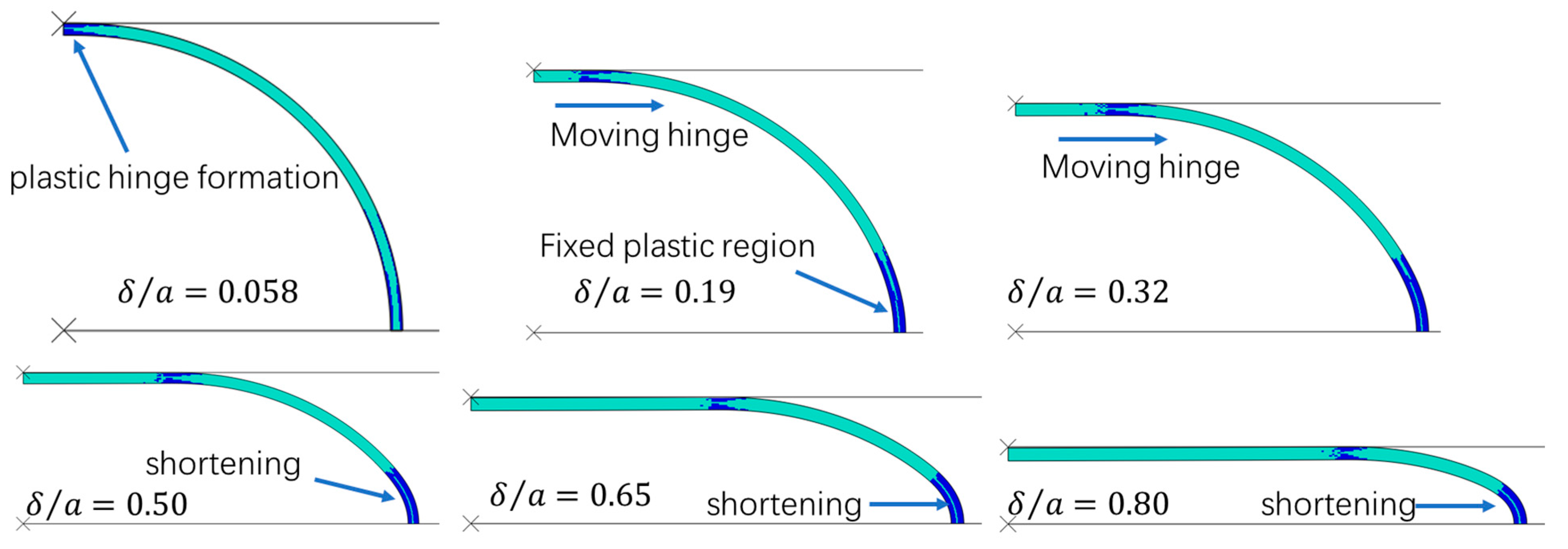

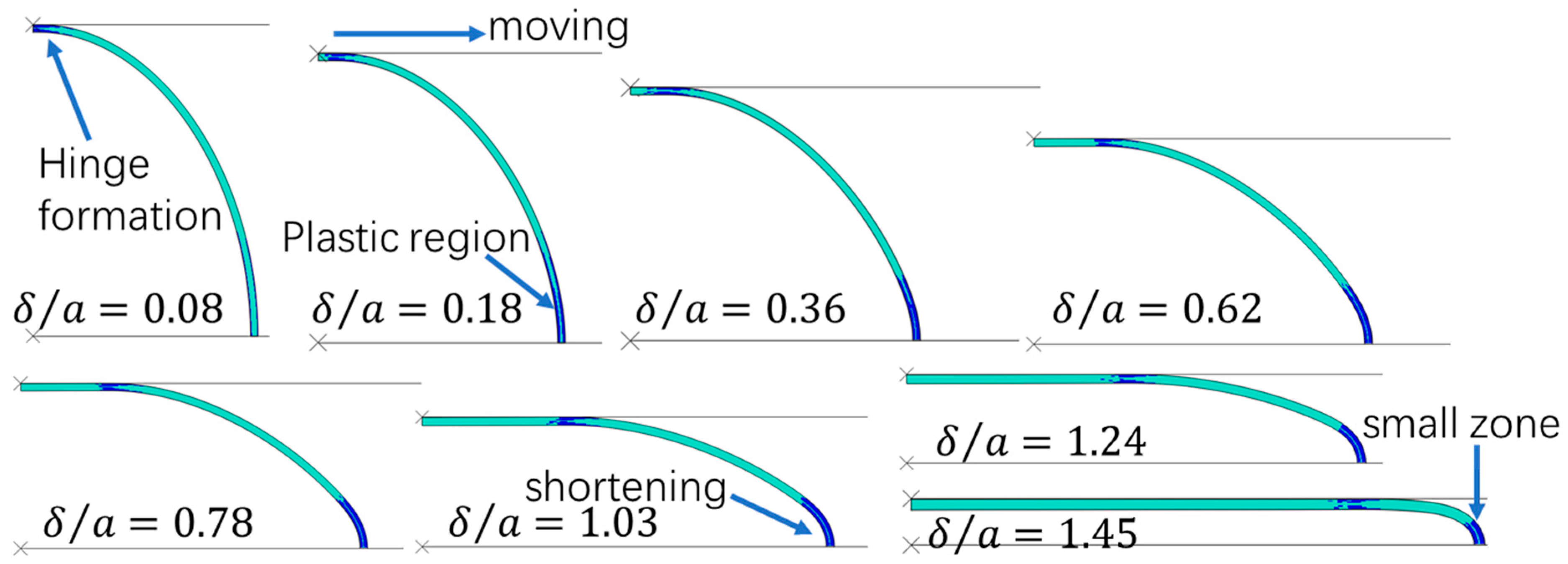

Figure 11 and

Figure 12 present visualizations of the active yielding regions from FEA for the circular case (

h = 1.0) and the elliptic case (

h = 1.6), where instantaneous plastic dissipation occurs at areas highlighted in blue. In

Figure 11 (circular case), when

, a plastic hinge forms at the crown point. Similarly, in

Figure 12 (elliptic case), when

, the plastic hinge also forms at the crown point. Again, as in

Figure 8 and

Figure 9, this behavior is not coincidental and is fully explained in

Appendix B through a moment distribution analysis during the initial elastic phase. In

Figure 11, after the formation of the plastic hinge, the hinge moves horizontally, accompanied by the continuous extension of a flat portion. A fixed plastic region of considerable length emerges at the right-lower area at

. At

the fixed plastic region starts to shrink in size. For the elliptic case in

Figure 12, in contrast, the extension of the flat region is slower than in the circular case: when

the flat portion’s length is about a 1/4 of the whole length, whereas in

Figure 11, at

the flat portion’s length is about 1/3 of the whole length. This observation aligns with the experimental results in

Figure 4 (compare the flat portions in exp#1 and exp#4 for clarity). In

Figure 12, at

, a fixed plastic region develops at the right-lower areas and continuously shrinks (comparing the results at

and 0.65) and finally becomes quite small when

.

When compared with results in

Section 4.3, these discussions demonstrate that the patterns of plastic region evolution are consistent regardless of the hardening model.

6. Plastic Region Length Prediction by Theoretical Estimation

From the FEA results in

Section 4 and

Section 5, for elliptic rings crushed between two parallel plates, there are top horizontally moving plastic hinges whose sizes remain nearly constant during deformation. However, the lower stationary plastic regions once developed are initially large in length but continuously shrink in size, eventually becoming very small. This pattern of plastic region length variation was previously discussed theoretically by Reid and Reddy [

25] for perfectly circular rings, where the authors demonstrated an initial increase followed by a subsequent shrinkage in length by directly studying the theoretical plastic hinge (denoted as

s0 in our notation in

Section 2). This approach is equivalent to using the moment criterion

M =

M0 to determine the plastic region. However, in this paper, it is shown that this criterion significantly over-estimates the plastic region length obtained from FEA. To address this, we propose the modified criterion based on the highest moment during the deformation history by a careful study of the theoretical moment distribution evolution patterns in the plastic hinge region

. We remark that bending moment

could be larger than

due to material hardening since

is defined by initial yielding stress

and by material hardening, the stress could exceed the yielding stress significantly.

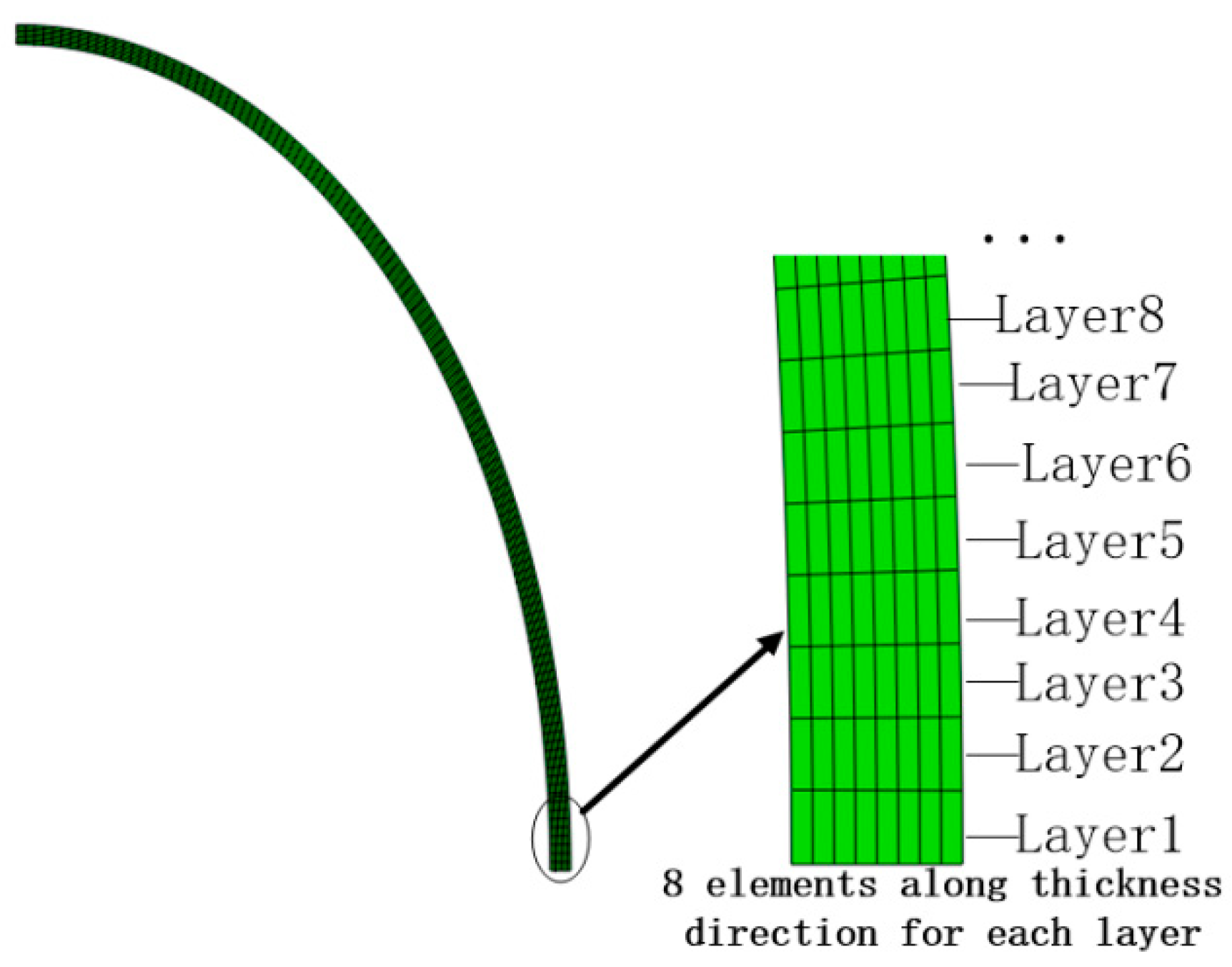

6.1. Proposed Robust Extraction Method of Fully Plastic Region Length in FEA

In order to obtain the fully plastic region length (denoted by

) from FEA, circumferentially, the structural elements are indexed by layer 1, layer 2, layer 3, etc., as shown in

Figure 13. The programmable steps are listed below.

Step (1). Calculate the centroid coordinate

of all elements of the

i-th layer in the undeformed configuration. Set the bottom reference coordinate as

(see the Cartesian coordinate system in

Figure 5).

Step (2). After each increment of the static step, for each layer

, count the number

of “active yielding” elements (with “AC Yield” field value equal to 1 in Abaqus) [

28];

Step (3). Set a threshold integer . Define layer as “fully plastic” if the ;

Step (4). If layer 1 is not fully plastic, then assign , otherwise, check for layer 1, layer 2, …, layer m sequentially until layer m + 1 is not fully plastic, then the fully plastic length is assigned as where is the Euclidean distance between two points

The above step (1), …, step (4) enables automatic and efficient extraction of the fully plastic regions’ length variation in FEA as crushing displacement increases. We remark that all length extraction procedures are automatically performed via Python coding under the Python Development Environment (PDE) provided by ABAQUS software (6.13).

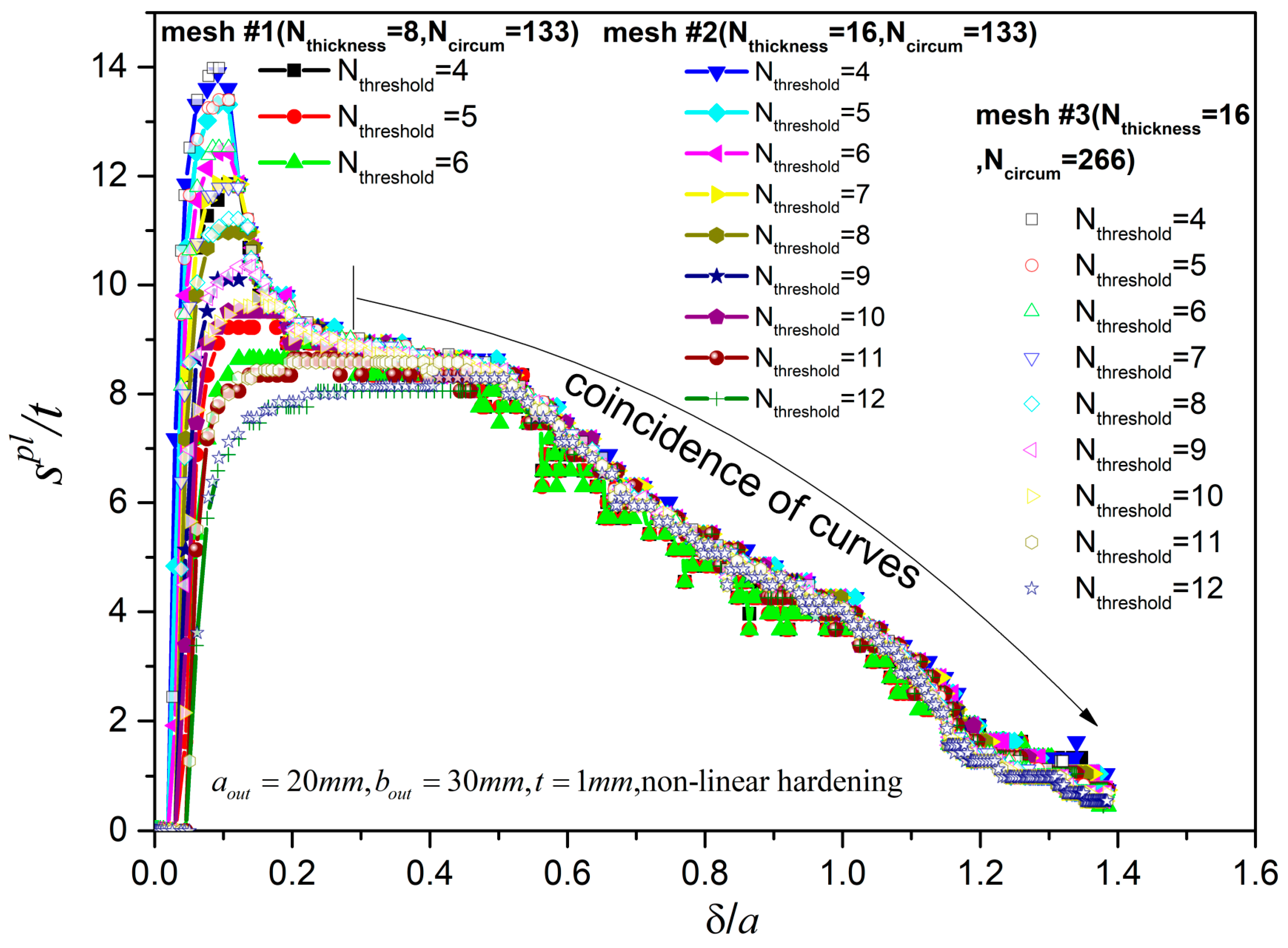

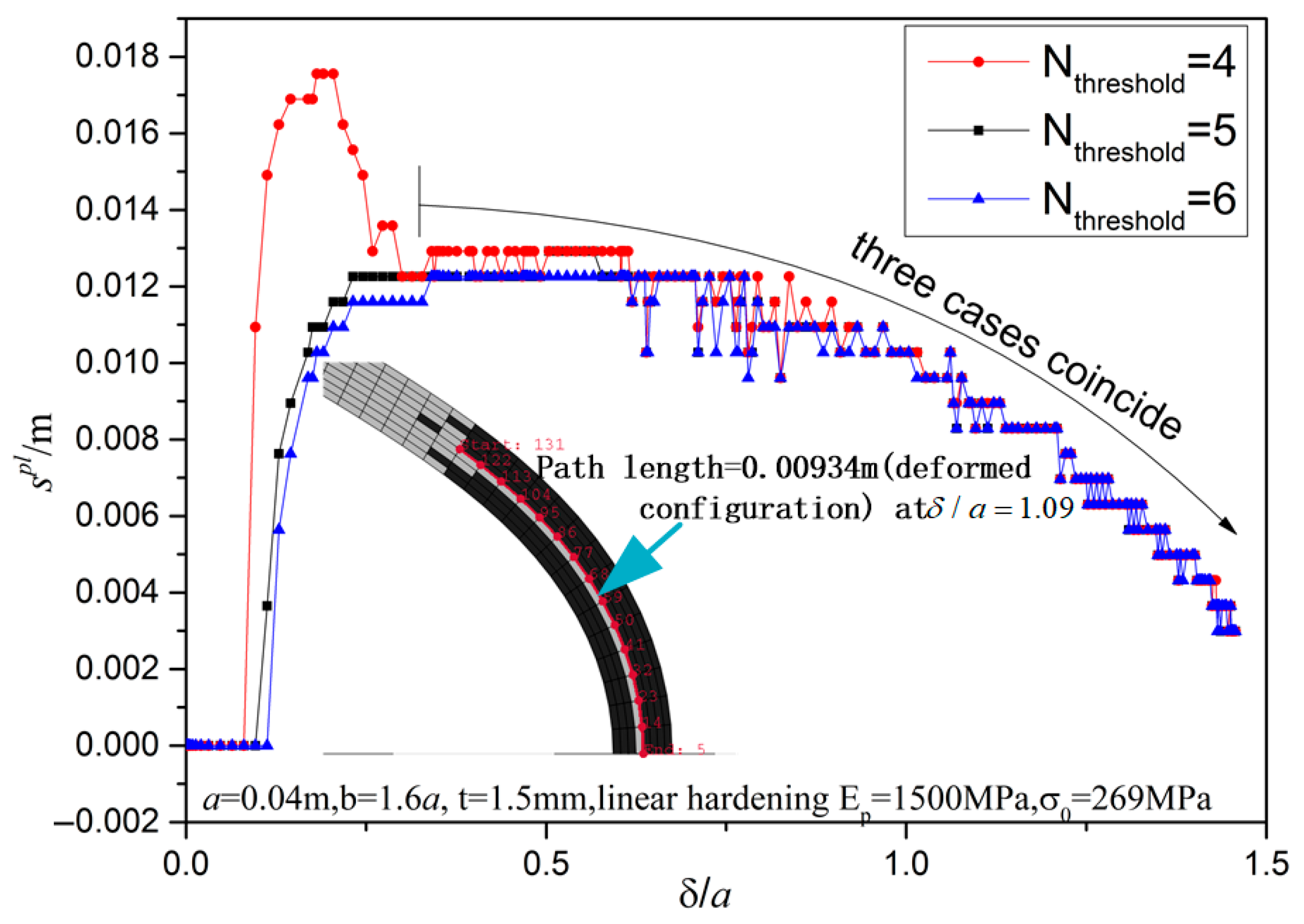

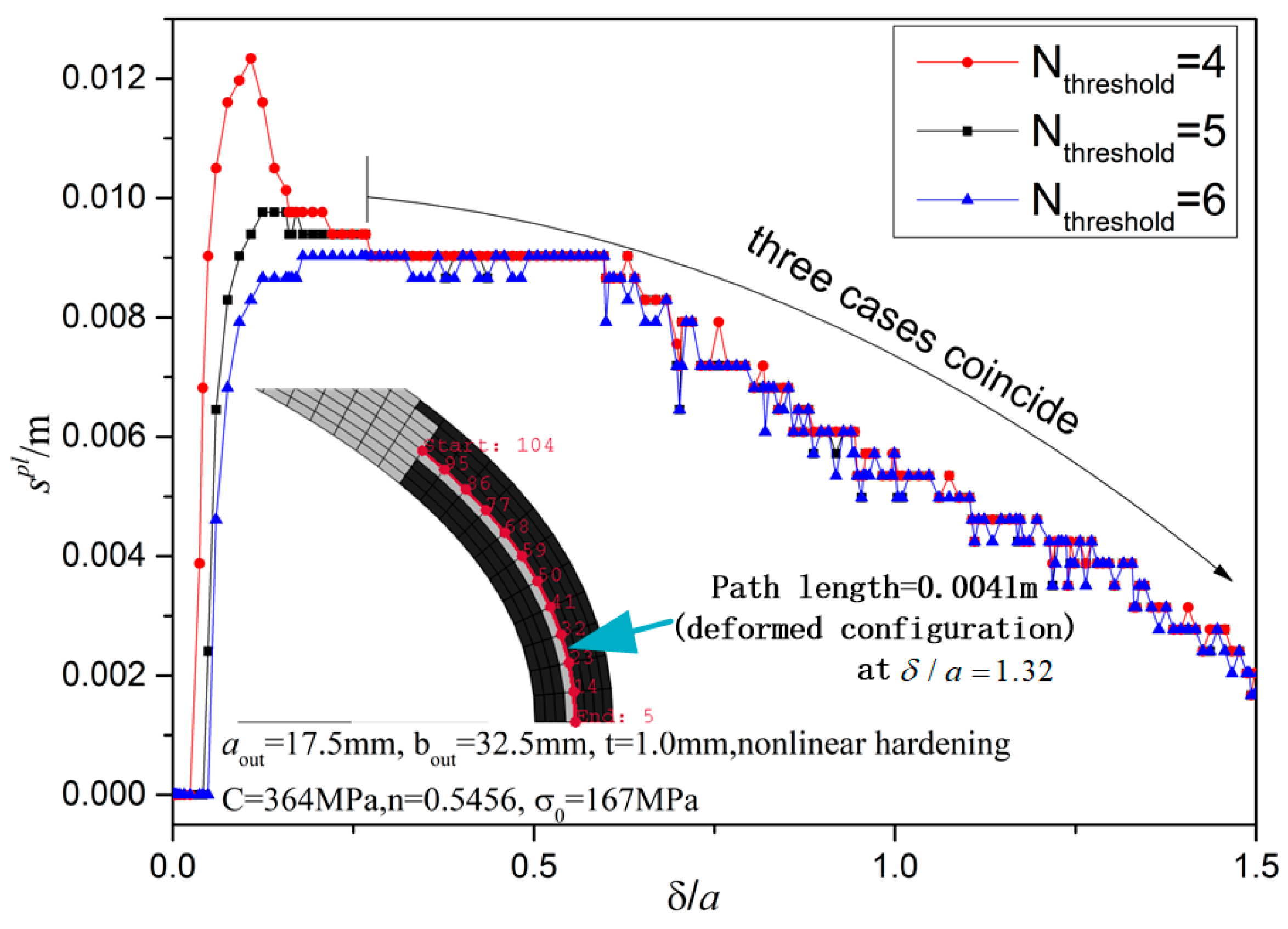

Before proceeding further, the robustness of these steps are shown in

Figure 14 for

= 4, 5, 6 with geometric parameters

a = 0.04

m,

b = 1.6

a,

t = 0.0015

m and linear hardening modulus

Ep = 1500 MPa and

σ0 = 269 MPa. For

= 4, 5, 6,

when

is small since initially the deformation is elastic and all curves almost coincide when

> 0.3. For example for

increases steeply to about 0.018 m and then decreases to about 0.012 m when

≈ 0.3 and then gradually decreases as

increases. For

= 5, 6, the curves agree very well for all

δ/

a values. Initially

only increases to 0.012 m (smaller than the value 0.018 m for

= 4). Of course, since the curvature-induced strain is small at the middle thickness points and thus theoretically in FEA the central layers in thickness direction may always remain elastic (see defined meshes in

Figure 14: one layer in thickness direction is not plastic), and thus, it is not reasonable to set

= 8. For example, at

= 1.09, the deformed configuration at the bottom region is presented as the defined meshes in

Figure 14 with black-colored actively yielding elements. Manually creating a path by connecting the middle-thickness related nodes and the path’s total length = 0.00934 m, and if the top layer is dropped, the resulting path’s total length = 0.00868 m. Thus, the averaged length is

, while the corresponding

for

, which agrees very well.

Figure 15 presents an example with the non-linear hardening model. Similarly, all three curves (

) coincide when

and initially

due to elasticity; the smaller

has a larger

when

; generally, the curves of

agree well for all

Also particularly the deformed configuration at the bottom region is presented at

and the length of the manually created path is 0.0041 m and if excluding the top layer, the length is 0.0037 m. The averaged value 0.0039 m agrees well with the automatically extracted length 0.00388 m.

Setting a smaller

compromises the condition of “fully” plastic, and setting

may not be reasonable since the middle thickness layer should be elastic (see defined meshes in

Figure 13 and

Figure 14). Thus,

is chosen throughout this paper afterwards(except in

Appendix E) and the discussion here shows the robustness of our proposed automatic extraction method of fully plastic region length.

6.2. Proposed Theoretical Prediction Method of Fully Plastic Region Length

The detailed procedure for the theoretical prediction of the bottom fully plastic region length is proposed here. By the theoretical method in

Section 2,

depends on crushing displacement

and thus,

is a function of

. Interestingly, representing the fully plastic region length by

(regarded as the

criterion) results in large unacceptable overestimation when FEA results are compared. We thus consider the unloading effect and propose the modified criterion as follows: at displacement level

, a point

is plastic if

where

and means cross-sectional resultant moments at displacement

respectively. This modified criterion excludes the points where its moment is smaller than the highest moment in the loading history(thus, some unloading must have occurred at this point previously).

Thus, a possible automatic algorithm for extraction of theoretical fully plastic region length is proposed as follows:

Step (1): choose larger than all possible s0 (one may just set since typically ); choose a large integer N, subdivide the interval into N many sub-intervals evenly with division points for j = 1, 2, …, N;

Step (2): For each denting displacement level

and each

j, sample

from the theoretical results (see

Section 2.2) and if

, just assign

;

Step (3): For each displacement level , increment j as j = 0, 1, 2, …, N sequentially and check whether for all : if it is true for all j, then fully plastic region length is returned as ; otherwise fully plastic region length is returned as when the first violation occurs.

6.3. Verification of the Proposed Theoretical Modified Criterion Method for Fully Plastic Region Length Prediction

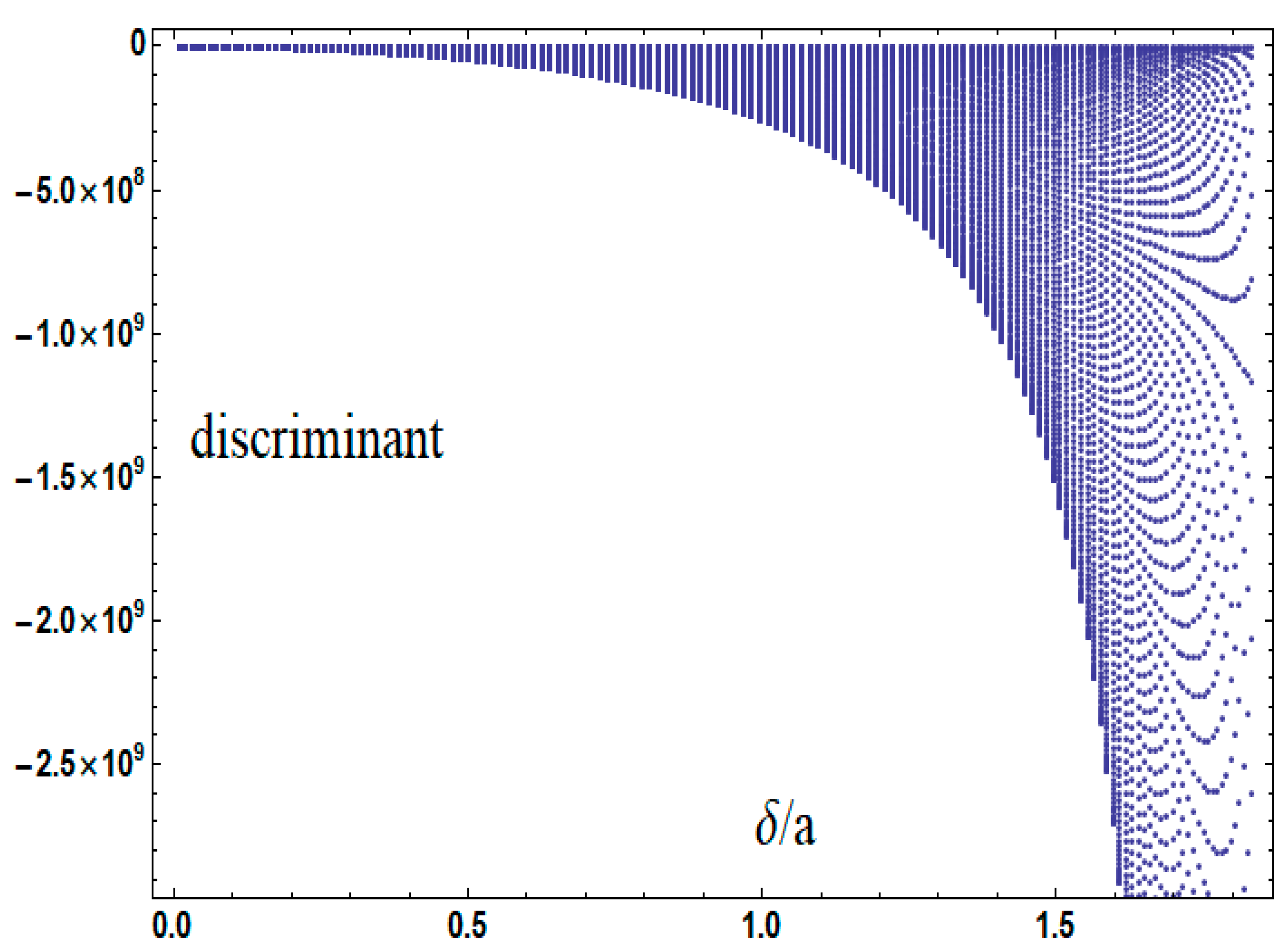

Figure 16 presents the fully plastic region length predictions for a non-linear hardening material model with four cases (circular in case 1 and elliptic in case 2, case 3, and case 4). As mentioned before

is used for automatic FEA extraction.

Taking case 1 for example, as

increases from zero, both curves of

criterion and modified criterion have normalized lengths

steeply increasing initially and coincide exactly before reaching the maximum point. After the maximum point, in modified criterion case,

suddenly decreases almost linearly (i.e., the slope of the curves changes abruptly and jumps from zero to negative values just at the maximum point). However, in conventional

criterion case, after maximum point,

smoothly decreases, where the decrease is initially quite slow until

. And an accelerated decrease is observed afterwards. The automatically extracted length from FEA has constant zero value when

is small (since FEA considers the elasticity, while the theoretical models disregard elasticity); after FEA length reaches the maximum (slightly larger than 8), it decreases almost in a linear manner and agrees well with the modified criterion curve closely. Thus the conventional

criterion is unacceptably over-estimating the lengths and this justifies the validity of our proposed modified criterion method. By connecting the maximum point and the end point

, the constructed straight line (see

Figure 16, case 1) agrees well with both modified criterion curve and FEA results which again confirms the linear decrease pattern after maximum point is passed. The same observation can be made for the other three cases obviously.

We study the theoretical moment distribution here for insights into the problem.

Figure 17 presents the moment distribution for

when crushing displacement increases where

for case 2. Obviously, at

,

(the horizontal dotted line in

Figure 17 and, of course,

varies as

increases, where at

, the curve terminates at

, while at

the curve terminates at

. One key observation is that for

,

N at

s = 0 which value is larger than

N for

at

, while when

s/

t = 3,

of

is less than

of

. Thus, physically at

, from

to 1.11, the material is still loaded with a larger moment. However, some unloading must happen at

. Thus, loading and unloading occur simultaneously when deformation is large. This is not the case when deformation is small; considering the curves of

, the moment is always increasing for any

s. We postulate that this feature is the cause of over-estimation of plastic region length by

-criterion-based curve in

Figure 16, and this motivated our proposal of a modified criterion based on the highest moment in loading history to account for the unloading effect.

The corresponding results for the linear hardening material model are presented in

Figure 18 below, where case 1 (circular,

) and case 2 (

), case 3 (

), and case 4 (

) are compared. The patterns are identical: both modified criterion and

criterion solution coincide again before maximum points and

criterion-based

is slowly decreasing after maximum points, while the modified criterion-based

abruptly decreases much faster after maximum points. The FEA results agree well with the modified criterion-based results (interestingly upper-bounding the FEA points roughly) and the conventional

curves significantly over-estimate the lengths. The straight lines connecting maximum points and end point

are plotted and it serves as tight lower bounds of the FEA points confirming once again that the fully plastic region length should decrease almost linearly when maximum points are passed. Taking

case as example, in FEA, the initial length remains constantly zero due to elasticity and then it climbs to about 6.5 and then decreases almost linearly; interestingly when

is slightly increased to

, during this 1% increment, the structure suddenly develops a global plastic region occupying a large area of the ring (see “active yielding” subfigure in

Figure 18a). This sudden appearance of the global plastic region is not observed in the elliptic counter-parts (see “active yielding” subfigures in case 2, case 3, case 4 when

respectively) and this shows that circular rings may distinctly differ from the elliptic rings in terms of plastic dissipation modes especially when

is large.

The above comparisons completely verify our proposed modified criterion method for fully plastic region length prediction. Interestingly for all considered cases the maximum

which rationalizes the choice of

in step (1) of the theoretical length computation algorithm in

Section 6.2.

Figure 19 presents moment distributions for various

in the corresponding linear hardening case for the circular ring (

Figure 18a) and the elliptic ring (

Figure 18d). The result is similar to that in the non-linear hardening case. For example, in

Figure 19b, the initial moments are monotonically increasing for all

s until

. Then, for smaller

, the moments are still monotonically increasing, while for larger

the moments are decreasing. There are two interesting features: (1) the overall moment magnitudes in

h = 1.6 case seem smaller than those in

h = 1.0 case; (2) generally, the moment curve terminates at larger

s/

t when

h = 1.6 than when

h = 1.0 case. This explains the cause of key advantages of elliptic rings in energy absorption, where longer stroke with a smaller force level.

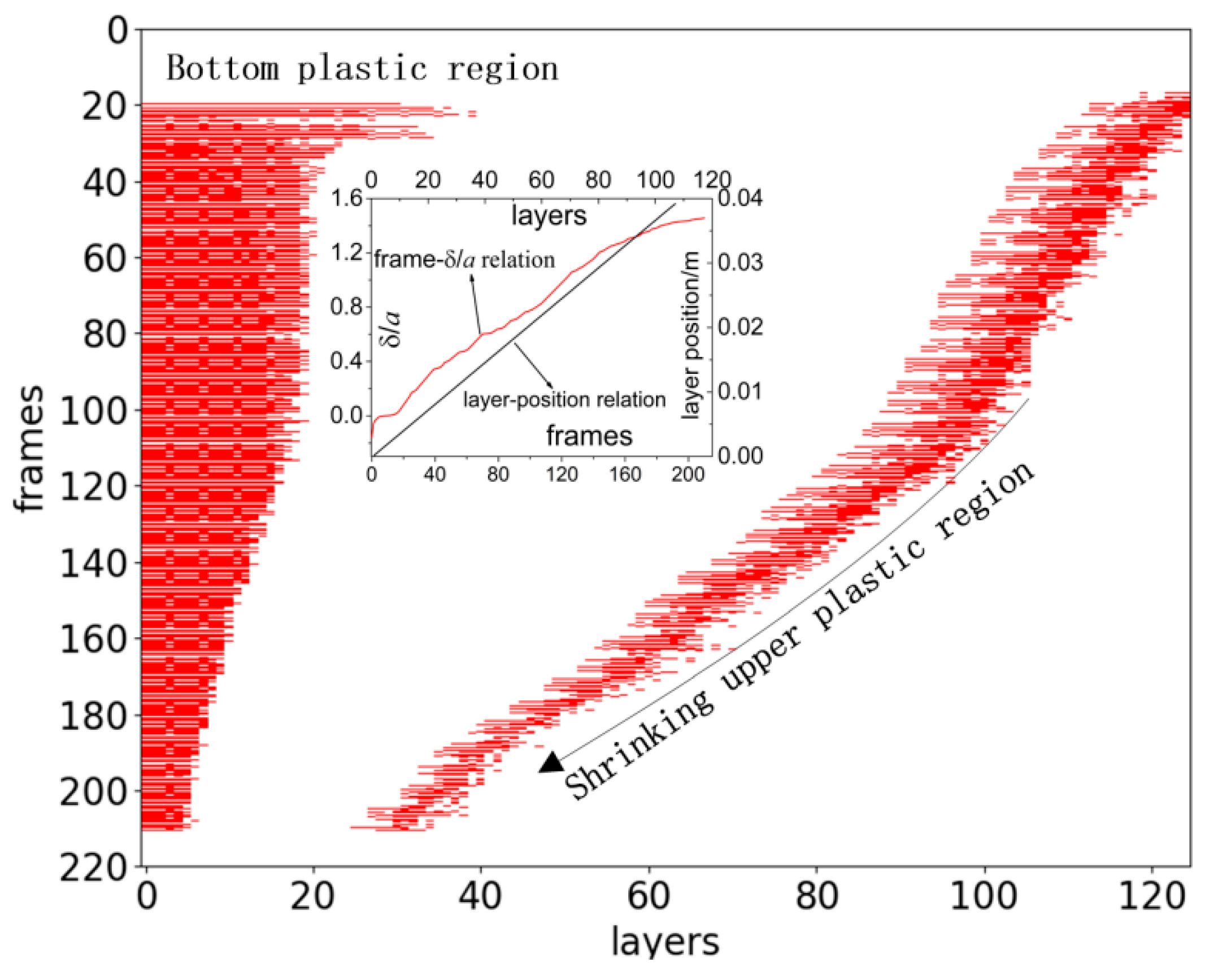

6.4. Evolution Patterns of Upper and Lower Plastic Regions in FEA

Figure 20 presents how plastic regions (actively yielding regions) evolve as

increases in FEA for the non-linear hardening model. As described in

Section 4.1 and

Section 6.1, 8 elements are generated in the thickness direction, and each circumferential layer 1, layer 2, … consists of eight elements (

Section 6.1). Thus, for each frame (i.e., each increment of the FEA crushing step (see Hibbit et al. [

28])), a matrix of row number eight and column number equal to the number of circumferential layers could be constructed by assigning entry value 1 for actively yielding elements and entry value 0 for other elements. Then all frames’ matrices (after appending a blank row to separate frames for each frame) are concatenated in the row direction to form a matrix with row number equal to nine times the frame numbers and column number equal to the number of circumferential layers. The resulting matrices are visualized in

Figure 20 and the subfigures show the correspondence between frame numbers and

values and between layer numbers and each layer’s centroid’s arc-length distance (denoted as layer position) to the end

point.

Taking

Figure 20a as an example, when the frame number initially increases from zero (frame zero means undeformed configuration), no actively yielding region exists; then the top region actively yields first (with relatively smaller area) immediately followed by a large-area active yielding region at bottom region; the actively yielding region then shrinks significantly to less than 20 layers when frame number >100 when

is just above 0.5 (see subfigure in

Figure 20a); the shrinkage of the bottom yielding region continues till the end; the upper plastic regions are translating towards the end point

and its size is much smaller than the bottom region’s size. By comparing the sizes of the upper plastic regions at frame 20 and frame 270 together, the upper region’s length becomes smaller. At the final frames, a global plastic region emerges suddenly (the deformed configurations at frame 150 and frame 270 are presented as subfigures in

Figure 20a to show the global plastic region’s appearance). This visualization also shows the difference between fully plastic region (

Section 6.1,

Section 6.2 and

Section 6.3) and the actively yielding region here: for example at frame about 20, there are about 60 layers having at least one element in thickness direction to actively yield; checking the subfigure in

Figure 20a, the total circumferential length is about 0.012 m; however, the maximum fully plastic region length from

Figure 16a is about 0.008 m much (much smaller than 0.012 m). However, we show in

Section 6.6 that, interestingly, the plastic dissipated energy is almost exclusively due to the fully plastic regions and thus, the theoretical plastic model (dealing only with fully plastic models) is meaningful, even though the actively yielding regions may be much longer than fully plastic regions.

Figure 20b presents the corresponding results for elliptic rings, and there are some distinct differences: (1) the size of the top moving/translating plastic region is shrinking significantly; and (2) no sudden appearance of the global plastic region at the final stages. The other patterns are similar to the circular counterpart: the bottom region is large around frame 20 and then its size decreases to about 25 layers (remains almost constant from frame 30 to frame 70); afterwards, its size decreases almost linearly to a small value at frame 180.

Figure 21 presents the similar plastic region evolution patterns for the linear hardening model with

h = 1.6 (case 4 in

Figure 18d). The upper plastic region is also shrinking. In the linear hardening case, the bottom plastic region covers constantly 20 layers (approximately) from frame 40 to frame 110 and then decreases almost linearly.

6.5. A Theoretical Interpretation of Why the Upper Plastic Region Significantly Shrinks in the Elliptic Ring

As previously stated in

Section 6.4, significant size shrinkage is observed for the upper moving plastic region in elliptic rings. We present a theoretical interpretation of this fact by investigating the target cross-section’s resultant moment variations as crushing displacement increases. The reader may be curious about the fact that from all deformed configurations in FEA (e.g., see

Figure 8,

Figure 9,

Figure 11 and

Figure 12) and also experiments (see

Figure 4), the upper regions are flattened into straight segments. However, in the theoretical model (see

Figure 1), arc

is assumed to be rigid and thus, arc

remains curved (i.e., not flattened) and why does the theoretical model still work well? This question could possibly be answered by visualizing the contact pressure evolution pattern from FEA (see

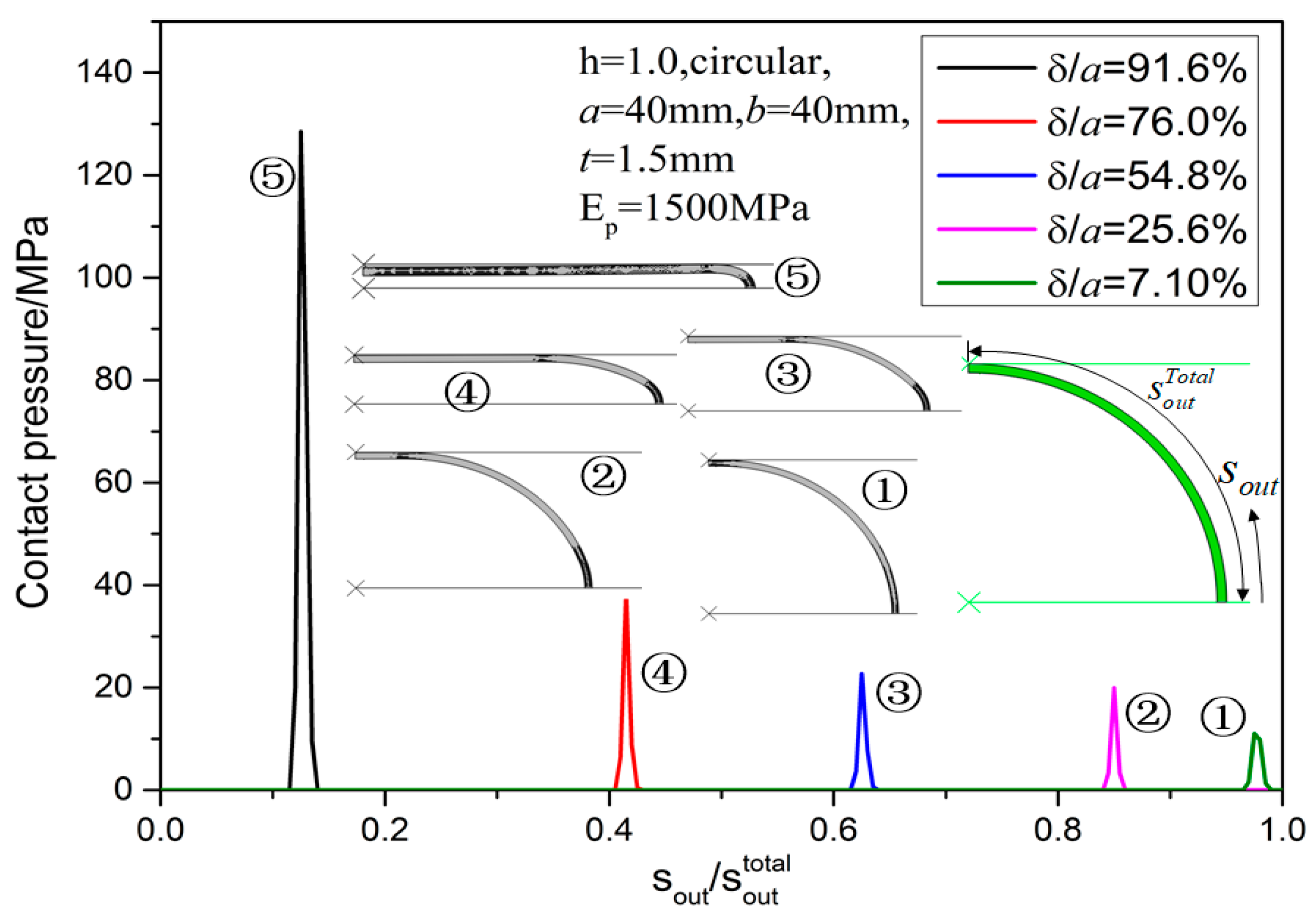

Figure 22). In

Figure 22 (also subfigures) collecting all nodes of outer edge sequentially into a path with arc-length coordinate

(

is the total arc-length of outer edge), then the contact pressure field output “CPRESS” in ABAQUS [

28] is extracted along this path for

. From

Figure 22, although the upper plate seems to contact the ring at flattened segments, the contact pressure is only non-zero at moving narrow regions(after detailed checking, their length-to-thickness ratio are about 1). Thus, indeed there are no contacts at the large flattened straight segments in FEA except at the narrow contact region (of about-thickness length) at the right ends of the segments, which fact verifies the assumption of point contact at a single tangential point

C in

Figure 1 and the general validity of the theoretical model in

Figure 1. By simple force and moment balance analysis and the no contact condition above, the flattened line segments have constant resultant moments for all cross-sections in the flattened segment, excluding the contact points. Thus, the resultant moments for all such cross-sections are equal to that of the target crown cross-section (see subfigure in

Figure 23) and in ABAQUS [

28] a “free cut” technique was used to obtain the resultant moment of the target crown cross-section for various crushing displacements. The resultant moment of target crown cross-section is visualized in

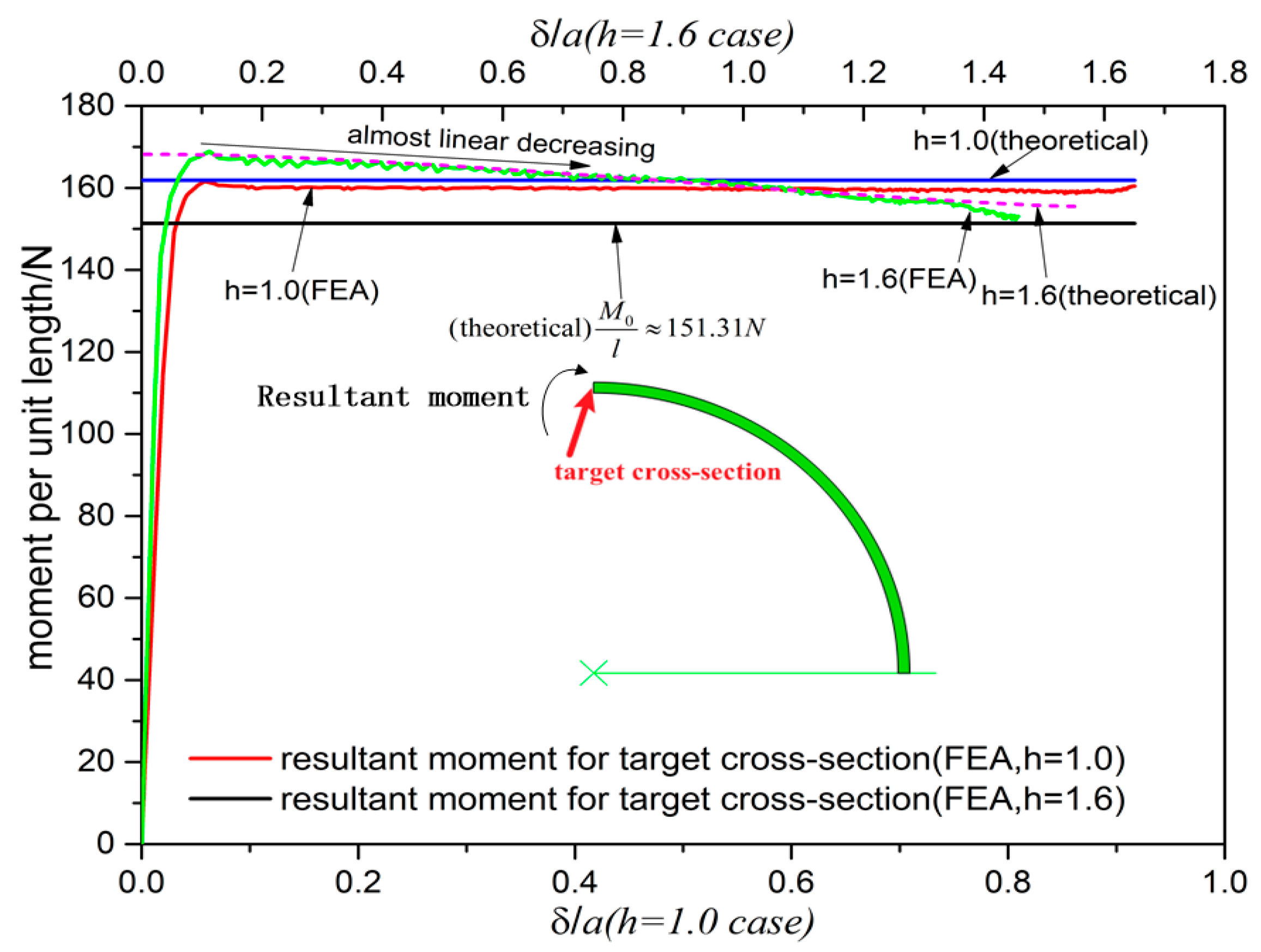

Figure 23 for circular (

, case 1 in

Figure 18a) and elliptic (

, case 4 in

Figure 18d) cases, as follows:

(1) In circular case, the resultant moment (for unit axial length) increases to about 160 N steeply when and kept almost constant;

(2) In elliptic case, the resultant moment (for unit axial length) steeply increases to about 170 N and evidently linearly decreases to about 150 N at .

Very interestingly the above resultant moment could be predicted almost exactly (see

Figure 23 for direct comparisons) by theoretical formula of moment at contact point

C (see

Figure 1):

where

(see

Appendix A for derivation) and

α is the rotation angle (see

Figure 1) of the theoretical model.

Thus, the resultant moment at the left side of the narrow contact region (equal to the value of target crown cross-section) is larger than

. Since it remains elastic (no active yielding) at the right side of the narrow contact region, there is an abrupt moment drop around the narrow contact region from

to

. Intuitively we postulate that the plastic region length should be larger when this drop is larger. This explains the significant shrinkage of moving plastic regions observed in

Figure 21. This discussion extends the previous research for circular ring by Reid and Reddy [

25] who dealt with the bottom region exclusively.

Figure 22.

Contact pressure evolution.

Figure 22.

Contact pressure evolution.

Figure 23.

Crown cross-section’s resultant moment evolution.

Figure 23.

Crown cross-section’s resultant moment evolution.

6.6. Plastic Energy Dissipation Patterns from FEA and Theoretical Models

From the previous discussions, circular and elliptic rings have upper (moving) and bottom (fixed) plastic regions.

Two rarely discussed but essential questions concerning the energy absorption properties (since the elliptic ring crushing is mainly used in energy absorption applications) include

(1) How much plastic energy is dissipated due to the moving plastic region and the bottom fixed plastic region, respectively?

(2) How much plastic energy is dissipated in the fully plastic region compared to the bottom plastic region?

The previous method in

Section 6.1 robustly identified the fully plastic region by setting

and similarly the bottom plastic region here is identified by following the same method but using

(i.e., one circumferential layer is plastic if at least one element in thickness direction is actively yielding) and all actively yielding elements excluding those in bottom plastic region are called lying in the upper plastic region in FEA. To calculate the total plastic energy dissipated, use

field output (see ABAQUS [

28]) for extracting the total plastic energy dissipated. An incremental approach is adopted for FEA: after

k-th increment (frame), identify the bottom plastic region (or fully plastic region) related elements by the just-described method and obtain the sum of

of these elements, respectively, at

k-increment (denoted as

) and

k − 1-th increment (denoted as

); then the difference

is the incremental plastic energy dissipated at

k-th increment for bottom plastic region (or fully plastic region) and the summation over all previous increments yields the plastic dissipation at bottom region

(or at fully plastic region

); also taking the history output

ALLPD (total plastic dissipation of the whole FEM, see Abaqus manual [

28], denoted as

), then subtraction yields the plastic dissipation at the upper region; the external work is obtained by integrating the crushing force-crushing displacement curves as

in FEA. The corresponding theoretical results are also presented for comparison, as follows:

(1) External work () is obtained by integrating the force-displacement curves by ;

(2) The plastic dissipated energies calculated by and .

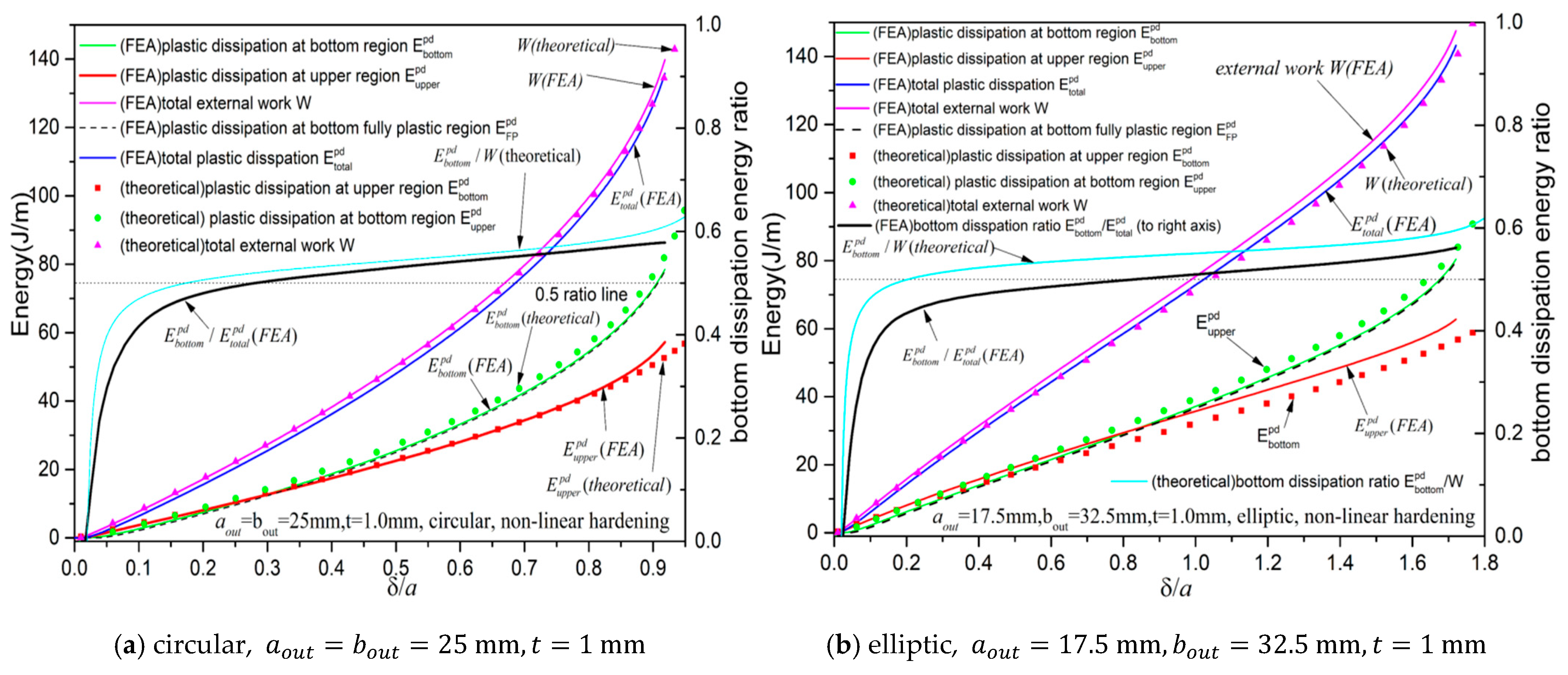

Figure 24 presents the related energies comparisons

between FEA and theoretical results for non-linear hardening material for circular case (

Figure 24a) and elliptic case (

Figure 24b). Evidently, the theoretical results agree very well with FEA results.

Taking the circular case (

Figure 24a) as an example, external works (of unit axial length)

and

increase from zero linearly and then after

accelerated increase to around 140 J/m is observed. The total plastic energy

tightly meaning stored elastic energy, is very small when plastically dissipated energy is compared verifying the neglect of elastic deformation in the theoretical model (

Section 2). The theoretical model predicts bottom plastic dissipation (

) and upper plastic dissipation (

) agreeing well with the FEA results: both

and

seemingly coincide initially and grow from zero to 20 J/m until

and when

increases further,

. However, indeed the FEA ratio

(linked to the right axis in

Figure 24a) steeply increases to 0.5 when

and monotonically increases to about 0.58 when

, indicating that the upper plastic dissipation only dominates when

is small. A similar conclusion of the theoretical ratio

could be drawn, where it steeply increases to 0.5 when

and then monotonically increases. Interestingly from FEA results,

curve almost coincides with the

curve meaning that bottom region dissipation is exclusively due to fully plastic region verifying the theoretical model again since it uses fully plastic assumption (

Section 2). The ratio (<0.6) shows that bottom region dissipation is at most 1.5 times the upper region dissipation. Similar observations are made for elliptic case (

Figure 24b), the theoretical model slightly over-estimates the bottom region dissipation (

) and under-estimates the upper region dissipation (

); the total works agree very well.

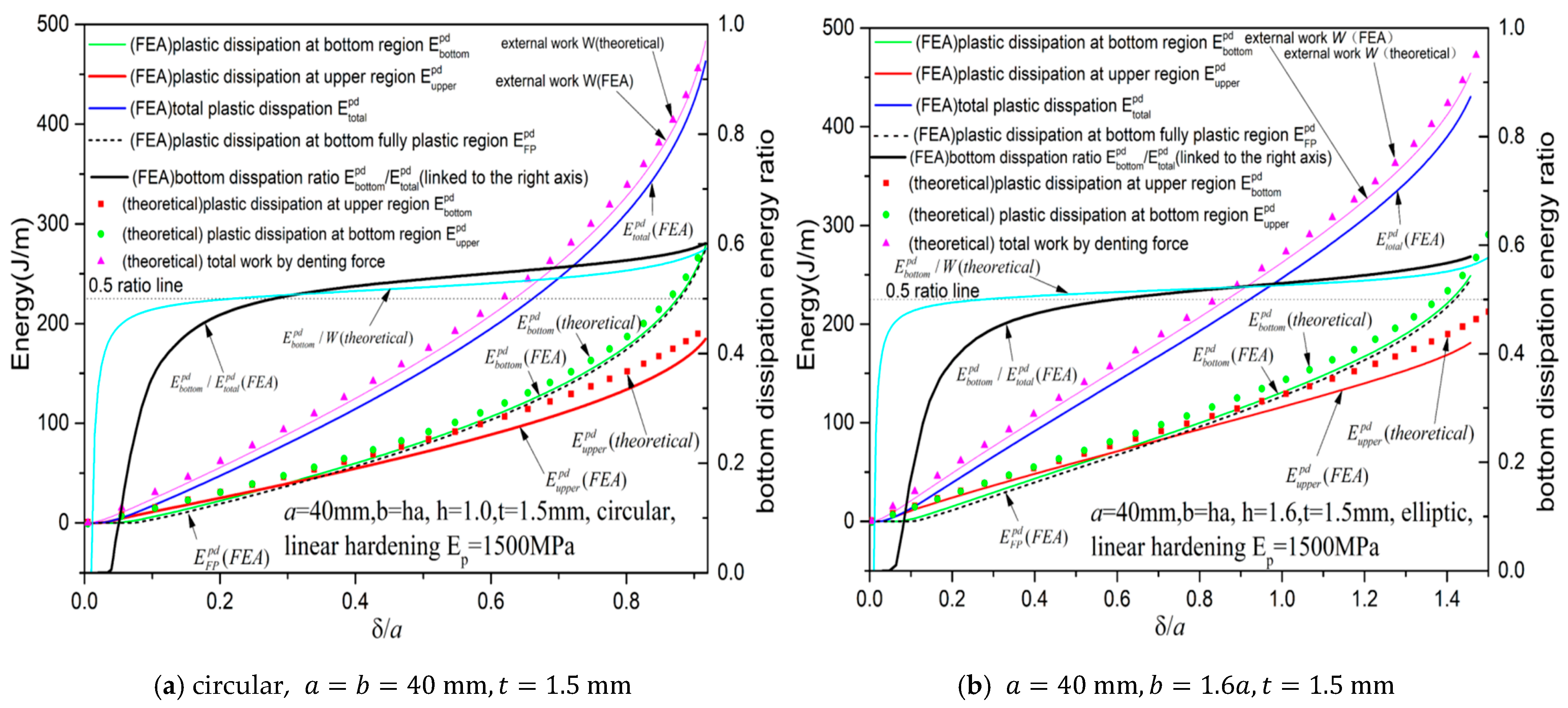

Figure 25 presents the corresponding results for the linear hardening material case for circular case (

Figure 25a) and elliptic case (

,

Figure 25b). Interestingly, in this case, when non-linear hardening cases are compared (

Figure 24), the difference between external work

(FEA) and total plastic dissipation

(FEA) is larger, meaning stored elastic energy is larger. So although theoretical model slightly over-estimates the

and

simultaneously, the

still agrees well with

tightly. Both ratios

(FEA) and

(theoretical) are above 0.5 when

, always monotonically increasing as

increases and remains smaller than 0.6. The ratio (<0.6) shows that bottom region dissipation is at most 1.5 times the upper region dissipation as in the non-linear hardening case.

7. Analytical Solution When ϕ0″ Is Neglected in Linear Hardening Model

If the linear hardening material model is adopted and

term is neglected, Equation (5a)

is reduced into a form readily solved analytically by elliptic integrals:

where

. Thus, Equation (15) is only valid if

is negligible compared to

. Equation (15) resembles the one-degree-of-freedom oscillation equation of conservative systems which is integrable by multiplying both sides by

. It yields the following:

where

D is a constant from integration determined by

where Equation (8b) is substituted for

.

Then Equation (16) is solvable by elliptic integrals by transforming into the following:

Then

s could be represented as a function of

as follows:

where

is the incomplete elliptic integral of the first kind and

H =

D/

k2. Then, the following conditions should be imposed: (1)

, (2)

and (3)

(condition (2) and (3) are identical to those in

Section 2.1). Then, there are three conditions along with three unknowns

for each specified angle

. Thus, the solution could be found by some routine zero root-finding technique. The denting displacement by Equation (11) is also expressible by elliptic integrals as follows:

In Equation (19), elliptic integrals of the first and second kind are evaluated to generate the denting displacement.

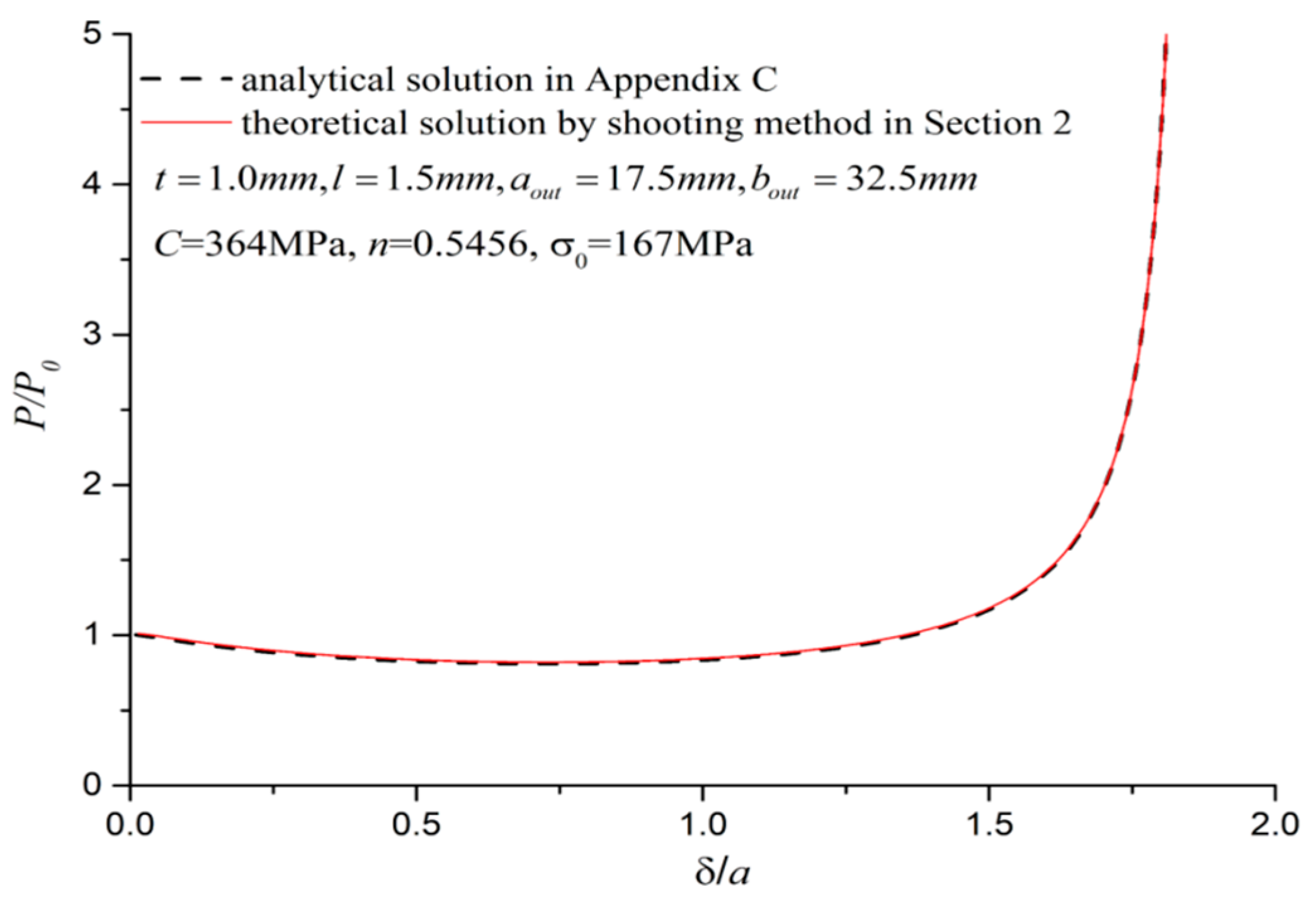

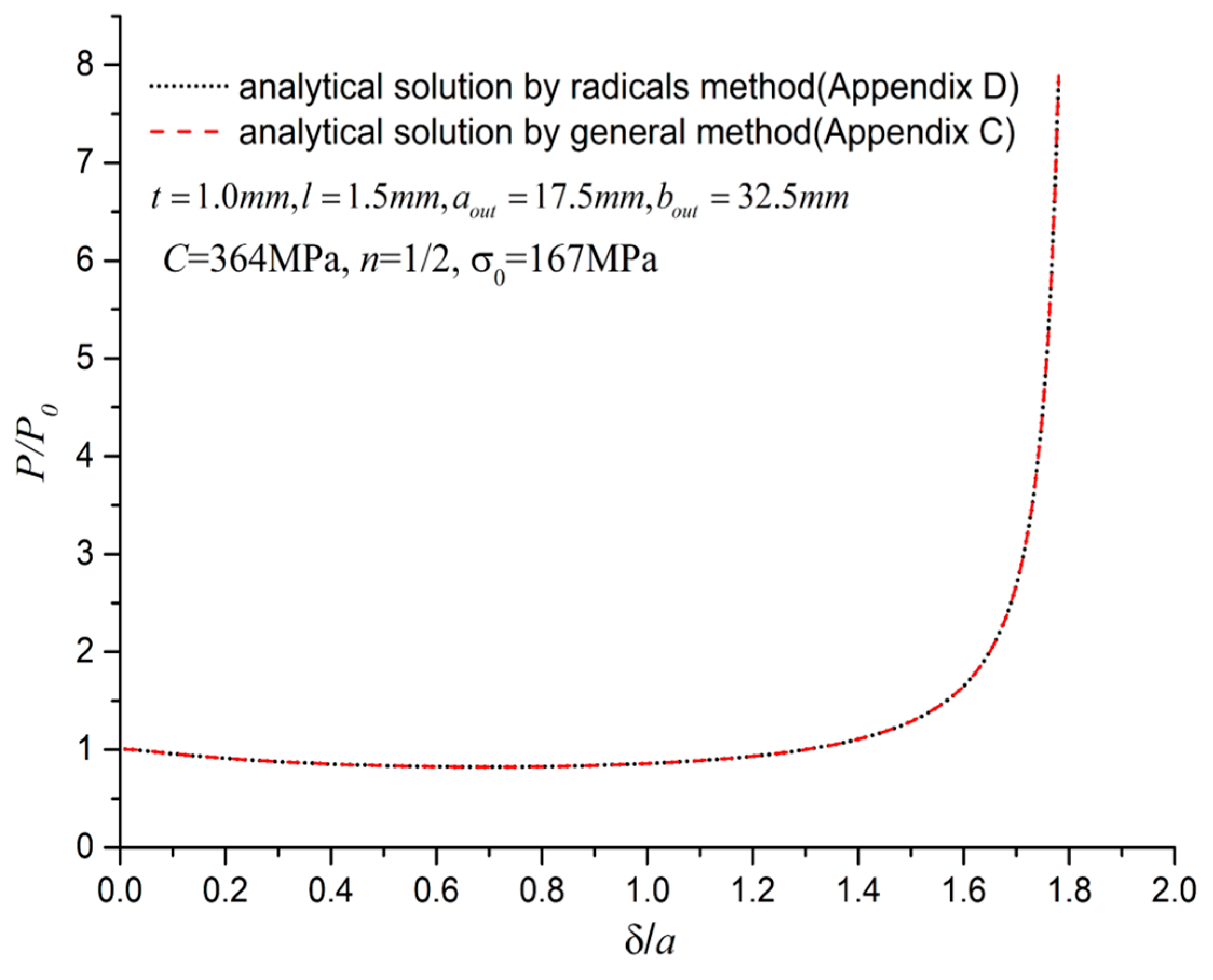

Comparisons Among FEA, Theoretical, and Analytical Solutions

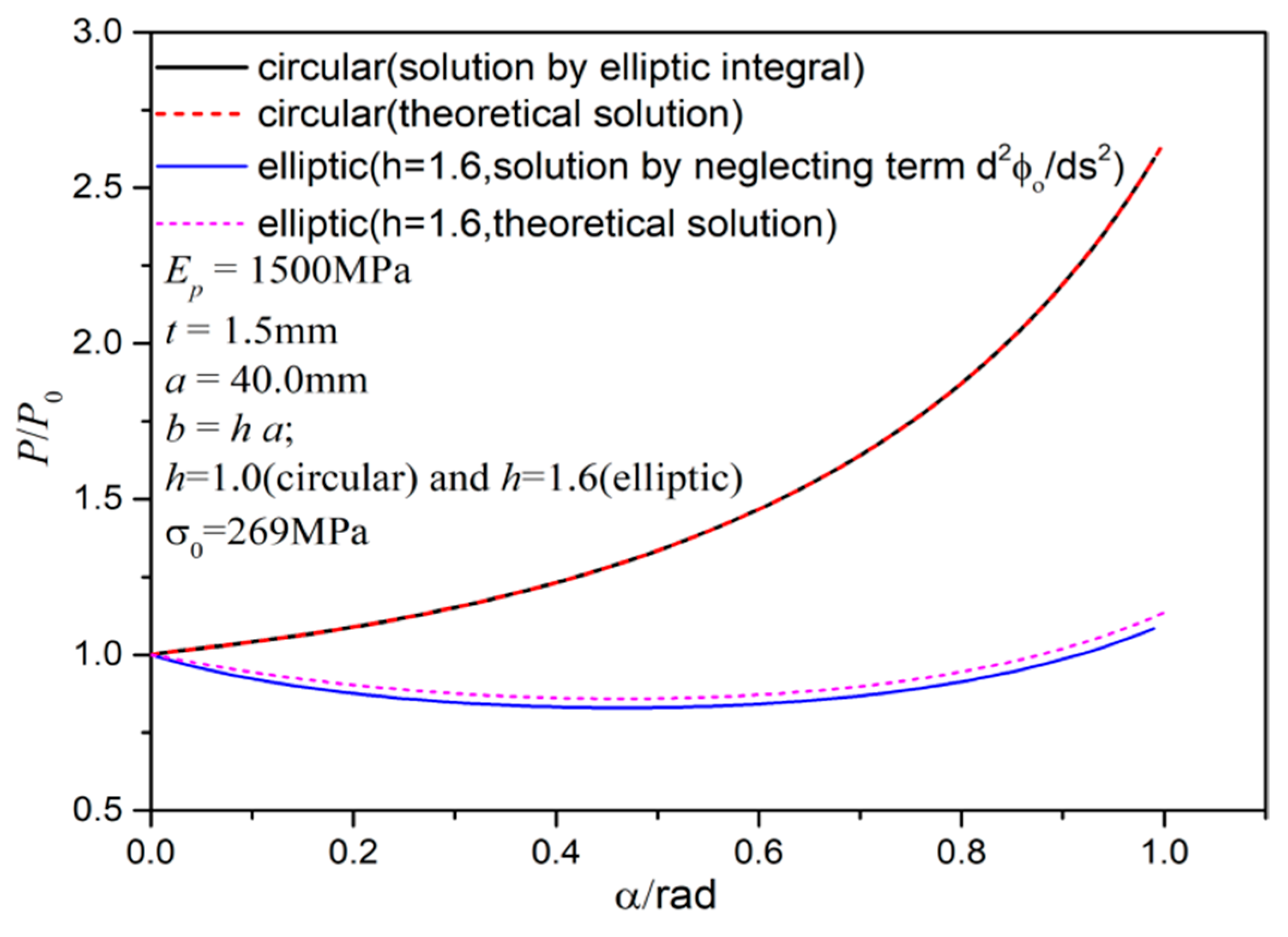

In

Figure 10, the analytical solutions in

Section 7 are verified by comparing with the theoretical solution using the method in

Section 2 and the corresponding FEA results. The validity of the neglect of

was completely unjustified in the literature [

26] and this paper fills this gap by comparing

and

. This formulation takes plastic hinge length

s0 as an unknown, while the work [

26] artificially assigned this length proportional to the rotation angle

. From discussions in

Section 6, this length is always first increasing and then decreasing. Thus, there is no any proportional relationship between

s0 and

since

is monotonically increasing during deformation.

Figure 26 presents

P/

P0 variations for various

in circular case (

h = 1.0) and elliptic case (

h = 1.6) by linear hardening parameters

. In the circular case, the analytical solution by elliptic integral is identical to the theoretical solution in

Section 2 since circular ring has

. Thus, they agree exactly in

Figure 26. While in the elliptic case (

h = 1.6) the elliptic integral solution, neglecting

slightly under-estimates

P/

P0 values. So, the neglect of

leads to only small errors.

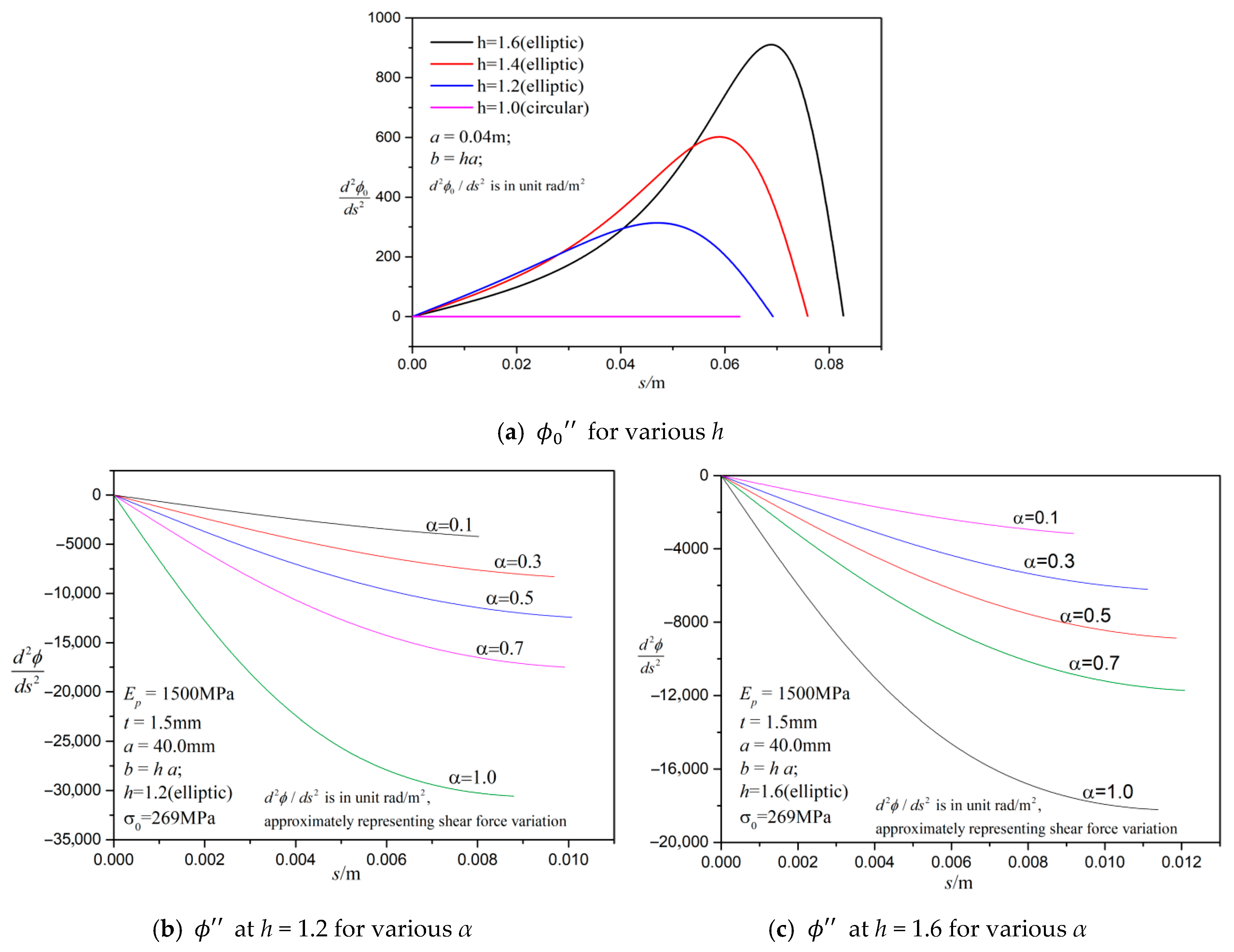

Figure 27 presents a more direct justification by comparing

and

. In

Figure 27a,

increases from zero to the maximum value and then decreases to zero when

s increases. The maximum value of

is about 900 rad/m

2. Considering the smallness of

s0 (typically ≈ 0.01 m in

Figure 27b,c),

for

is in the order of 100 rad/m

2 which is very small compared to

in

Figure 27b,c, where typically the magnitudes are in the order of 10,000 rad/m

2. Thus, the neglect of

should yield an error in the order of 1%, which in fact is consistent with observations in

Figure 26.

8. Parametric Analysis

We present a parametric analysis of the hardening parameters on the plastic region length and the force-displacement curves.

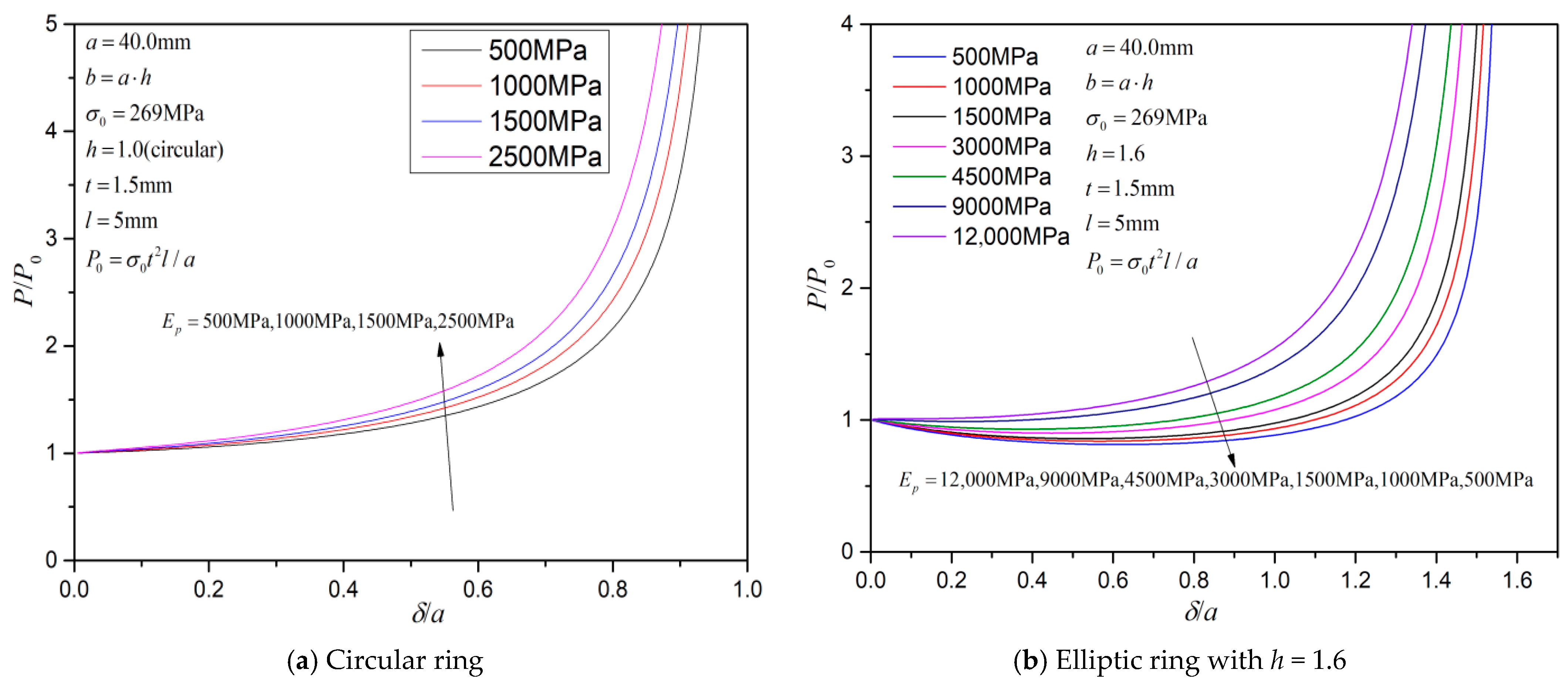

Figure 28a,b shows the effect of

Ep on crushing forces by the theoretical linear hardening model (by the method described in

Section 2) for the circular case and elliptic case, respectively. In both cases, the increase in

Ep leads to an increase in force magnitude. In

Figure 28a, the increase in force magnitude is faster at larger

Ep. Interestingly, in the elliptic case (

Figure 28b), the force is decreasing in the early phase for smaller

Ep (the softening behavior), while for larger

Ep, the force is monotonically increasing.

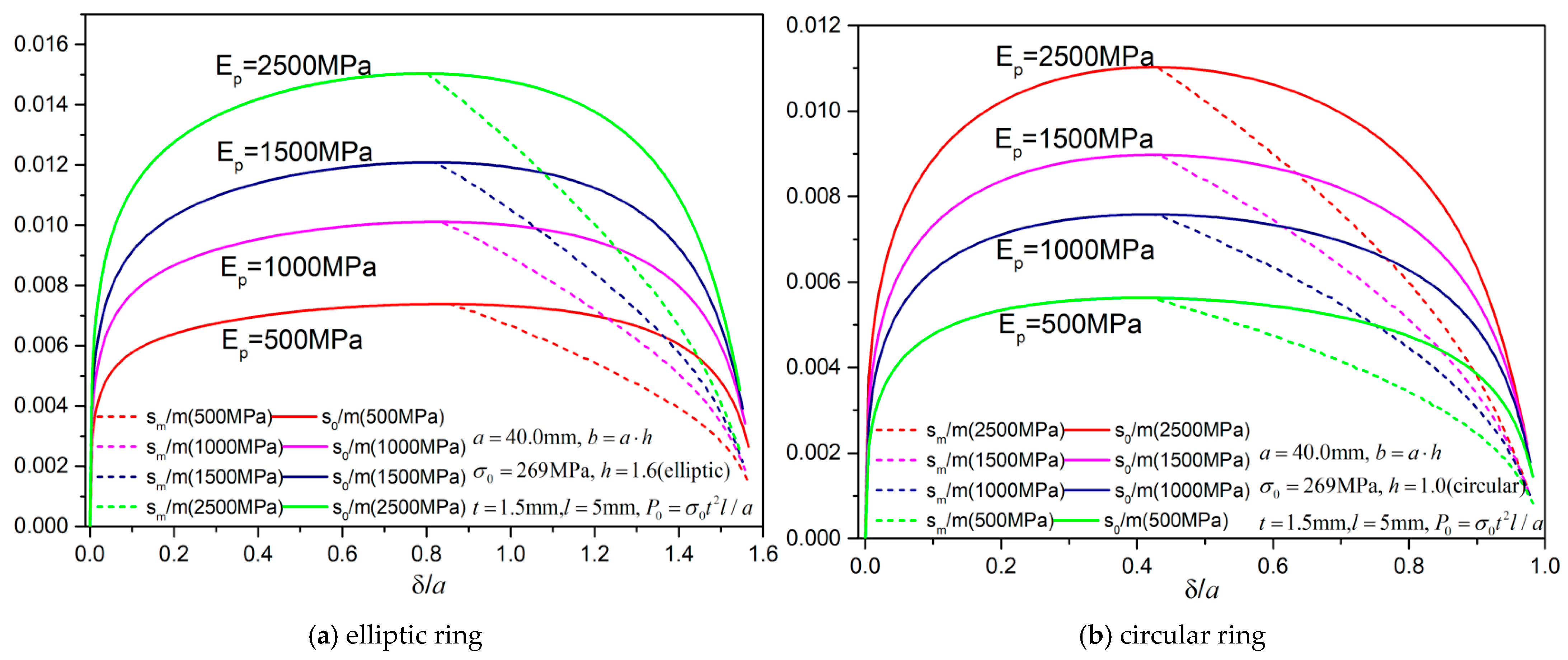

With the same parameters as in

Figure 28 and

Figure 29a,b present the corresponding theoretical plastic region lengths by linear hardening model (by methods in

Section 6) for various

Ep for the elliptic ring (

h = 1.6) and circular ring, respectively. The

s0 is the length from conventional

M0 criterion and

sm is the length from the proposed modified criterion. Evidently, for both cases,

sm is identical to

s0 before the maximum point, and afterwards

sm decreases almost linearly much faster than the decrease of

s0. Only when

is large,

sm decreases in an accelerated manner. The larger

Ep leads to larger

s0 and

sm evidently. Comparison between

Figure 29a,b indicates that the plastic region length is larger for elliptic rings and smaller for circular rings.

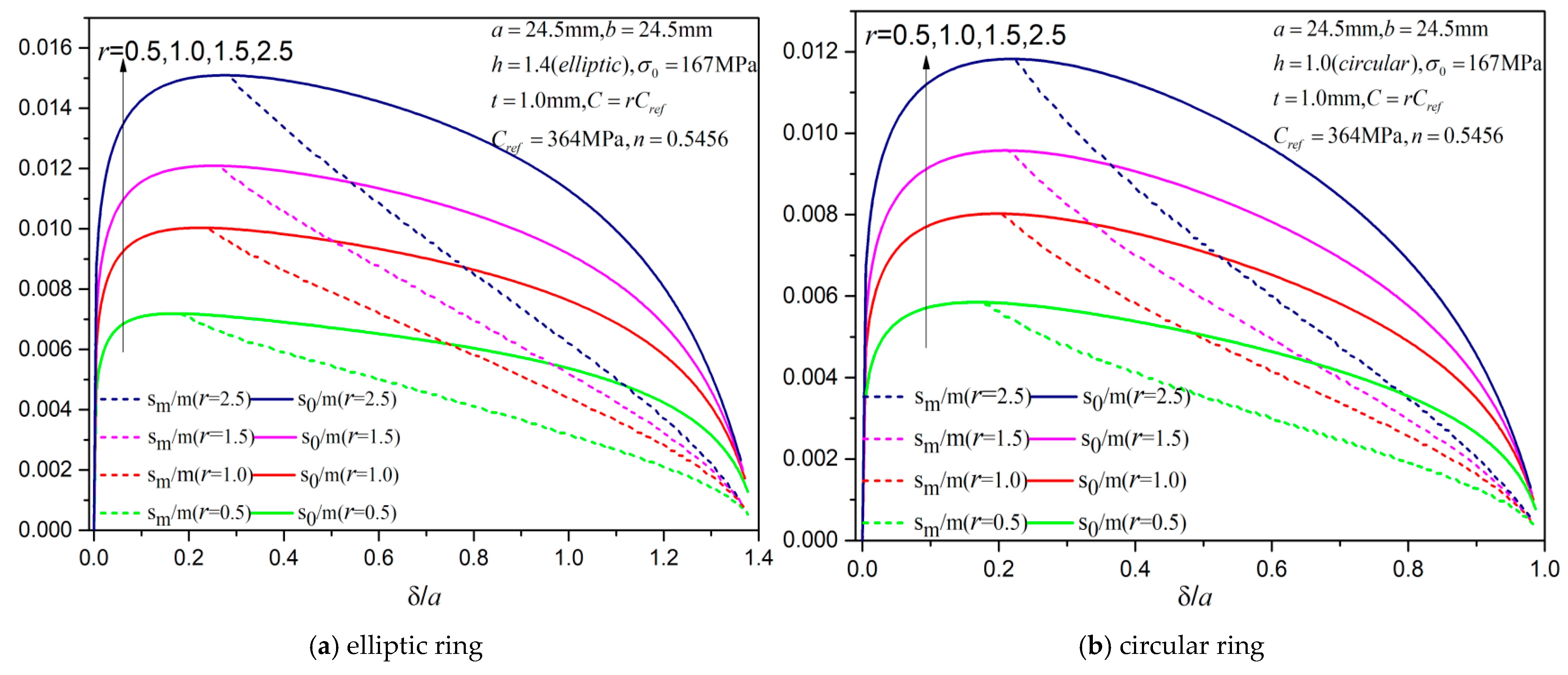

Figure 30a (elliptic) and

Figure 30b (circular) show the theoretical plastic region lengths for the power-law material model for various coefficients

C, where

C = rCref,

Cref = 364 MPa (the same as in experimental measurement in

Figure 5a) in four cases

r = 0.5, 1.0, 1.5, and 2.5. All curves share similar trends, including the lengths, which are initially increasing and then decreasing with

sm curves deviating from

s0 curves at maximum points. By comparing

Figure 30 with

Figure 29 (linear hardening case), the lengths reach a maximum at smaller

and also the initial increase is steeper, while the decrease is flatter.

Figure 31 shows the effect of material parameter

C on force-displacement curves for the elliptic ring of

h = 1.4 (by the theoretical method in

Section 2). Similarly, as in

Figure 28, a larger

C leads to a larger force magnitude. The monotonicity could be altered too, where for smaller

C at

r = 0.5 the force is initially decreasing (softening); however, for larger

C at

r = 2.5 the force is monotonically increasing without softening behavior. This discussion confirms the important role of material hardening on both crushing force and the plastic region evolution.