Mathematical Modelling and Optimization Methods in Geomechanically Informed Blast Design: A Systematic Literature Review

Abstract

1. Introduction

1.1. From Empirical Formulations to Geomechanically Enriched Models

1.2. High-Fidelity Multiphysics Simulation

1.3. Machine Learning and Multi-Objective Optimization

1.4. Research Gaps and Objectives

- There is no unified framework for evaluating the accuracy of geomechanically enriched empirical equations.

- Uncertainties persist regarding the fidelity–time trade-off in multiphysics simulations.

- The robustness of machine learning models when changing lithology needs to be assessed.

- Specific objectives.

- O1.

- Classify and analyse the spectrum of mathematical and computational models for blast design, with emphasis on the integration of geomechanical properties.

- O2.

- Synergistically evaluate traditional mathematical engineering and modern machine learning methods in different operational contexts.

- O3.

- Identify challenges and future directions towards digital twins that combine physics-informed and data-driven models to holistically optimize this industrial application.

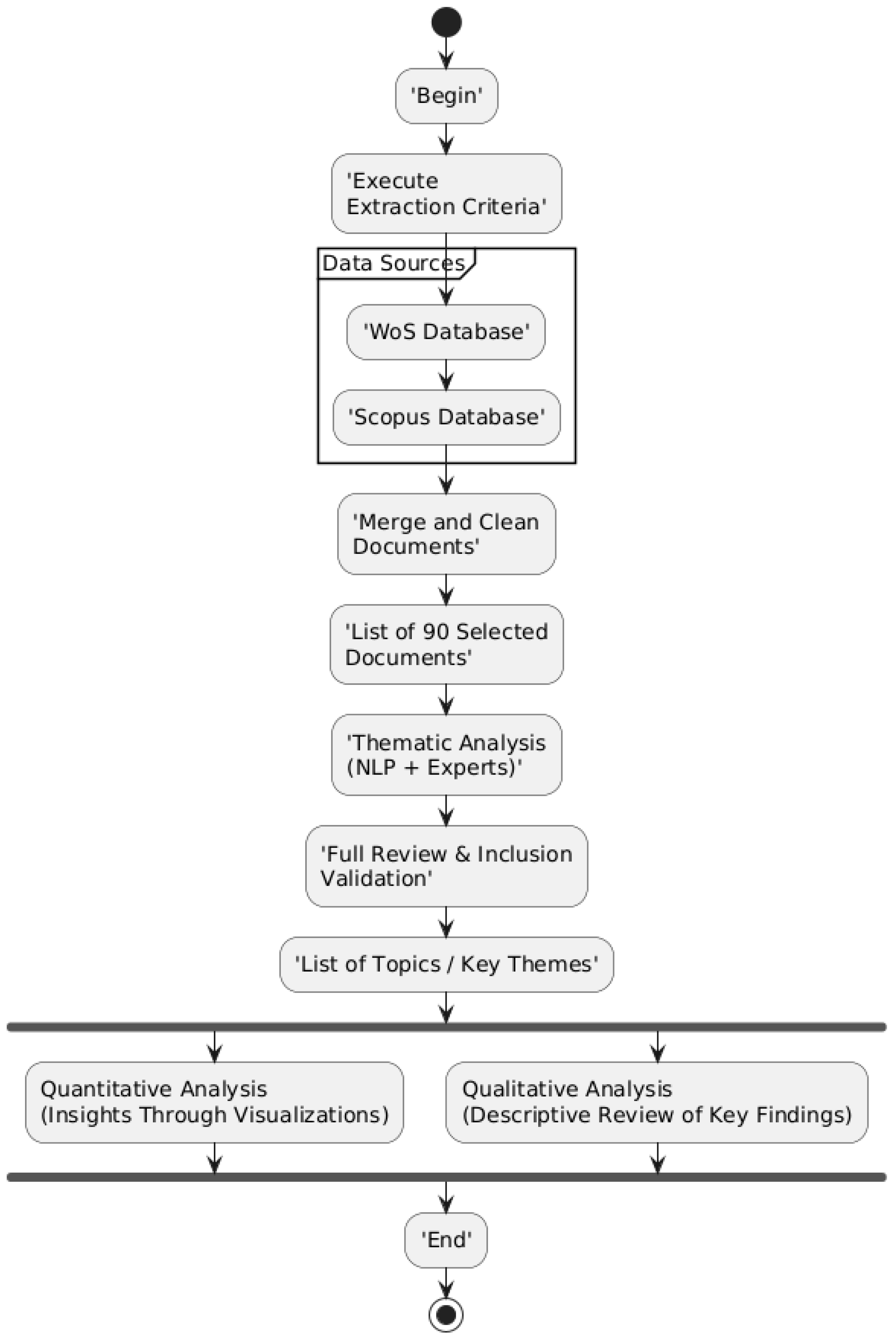

2. Systematic Analysis Methodology

2.1. Document Retrieval and Search Criteria

| Main query: | |

| Document types: | Research articles, reviews, conference proceedings, and indexed book chapters. |

| Time span: | 2000–2025, with emphasis on recent and high-impact contributions. |

2.2. Metadata Merging and Cleaning

- Inclusion criteria:

- Full text available and validated.

- Publications in English or Spanish, indexed (at least Q3).

- Five or more citations or a clear methodological contribution.

- Direct relation to blast design, geomechanical integration, or dynamic impact control.

- Exclusion criteria:

- Records without abstracts or with incomplete metadata.

- Publications in other languages without an official translation.

- Persistent duplicates or restricted access.

- Conference abstracts without peer-reviewed full texts.

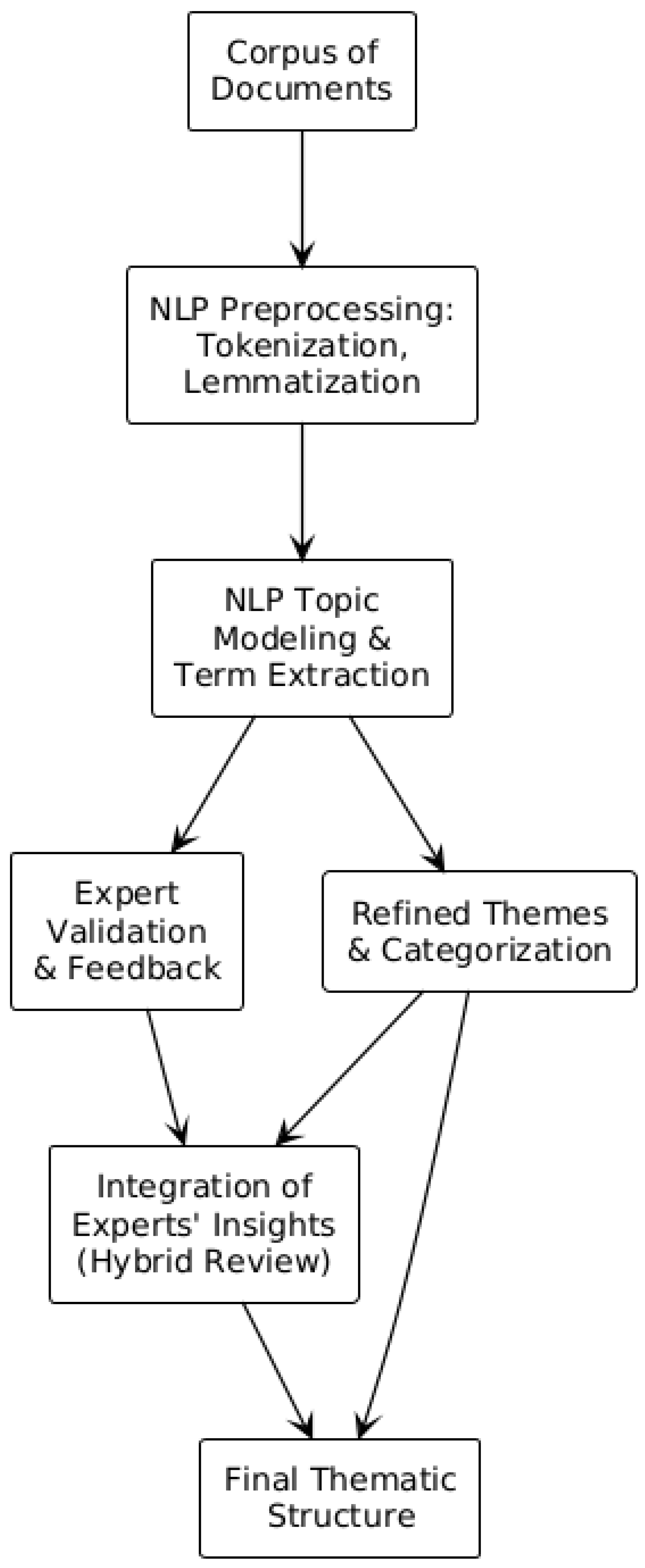

2.3. Thematic Analysis: NLP + Expert Validation

2.4. Publication Bias and Semantic Reinforcement

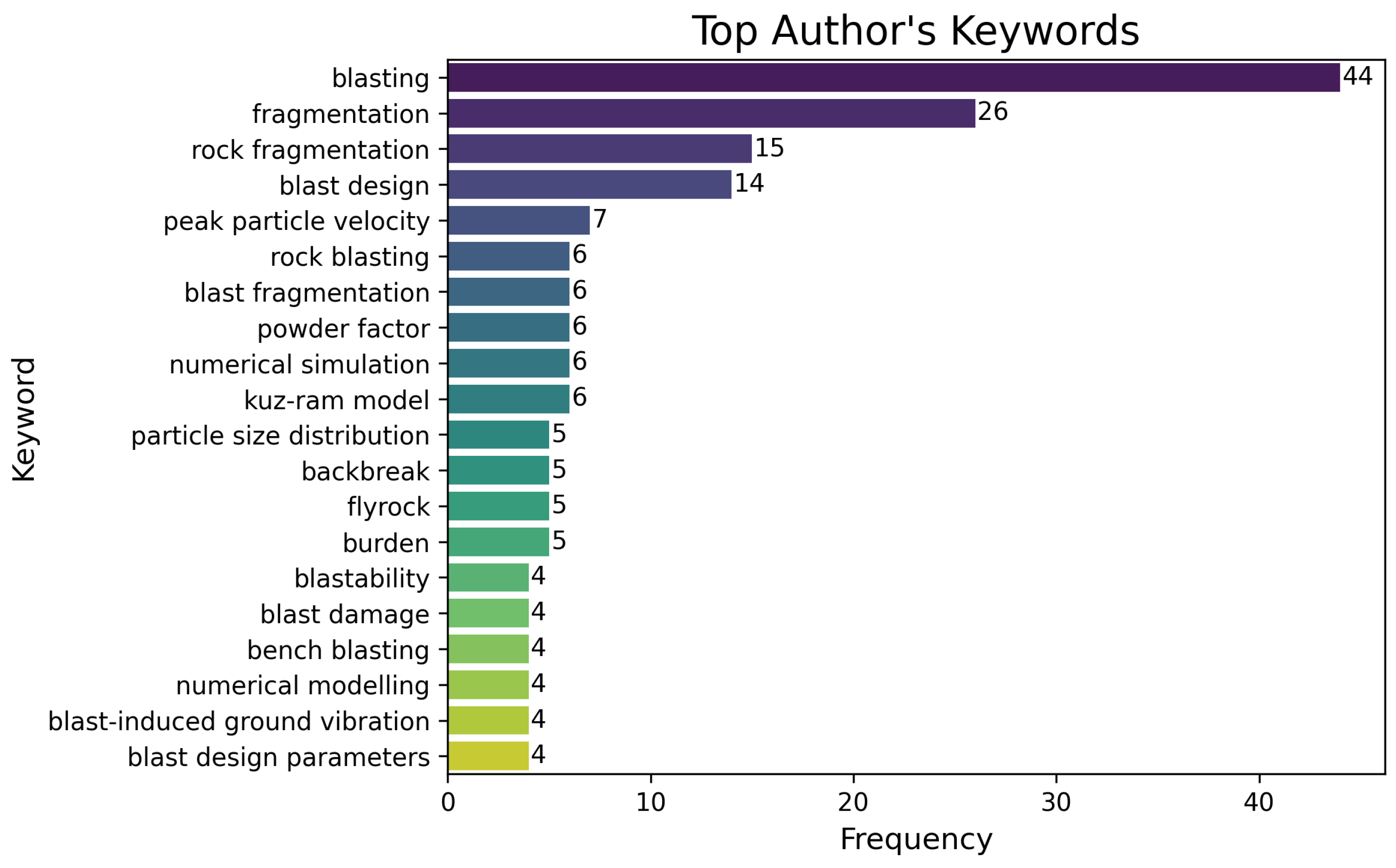

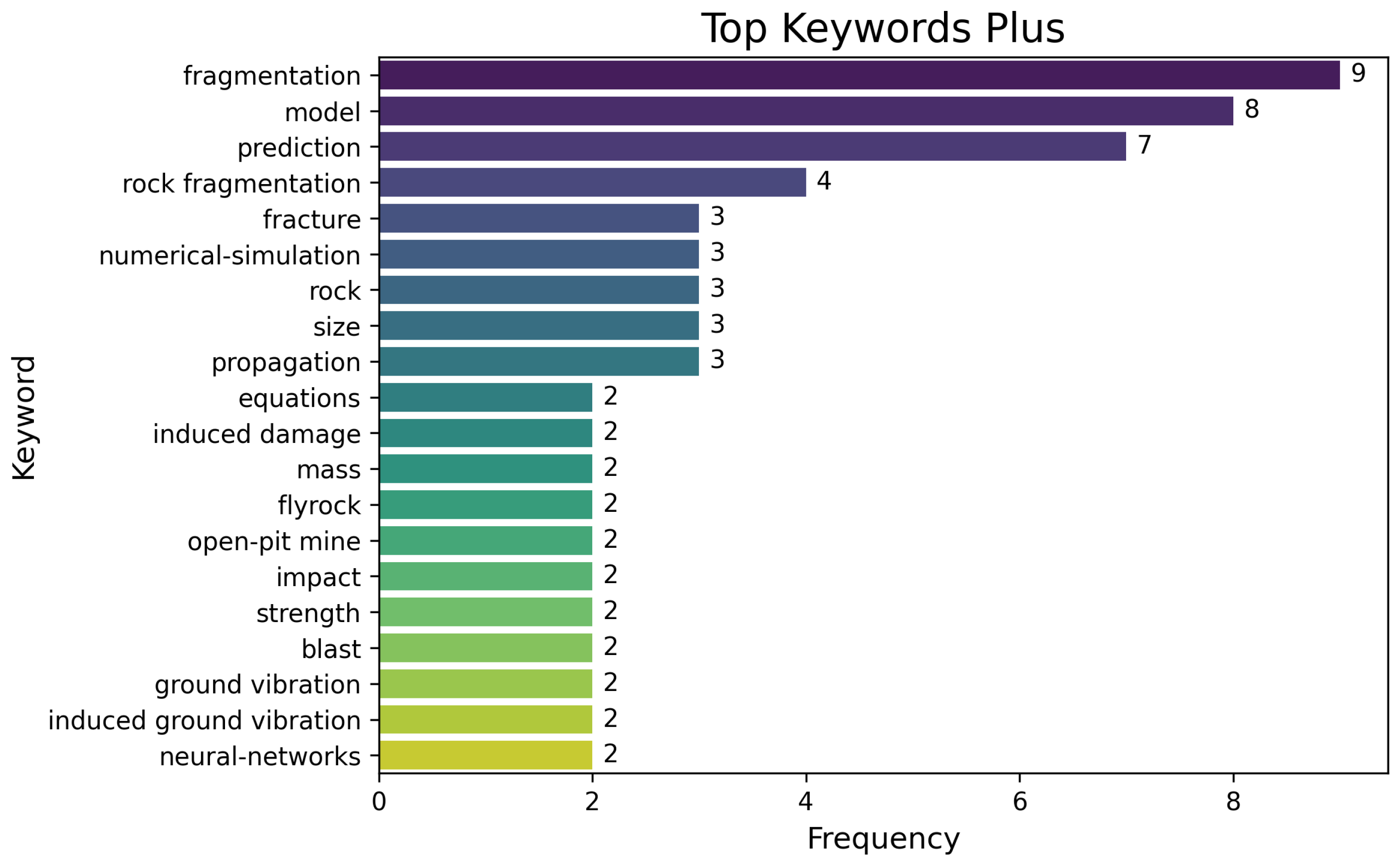

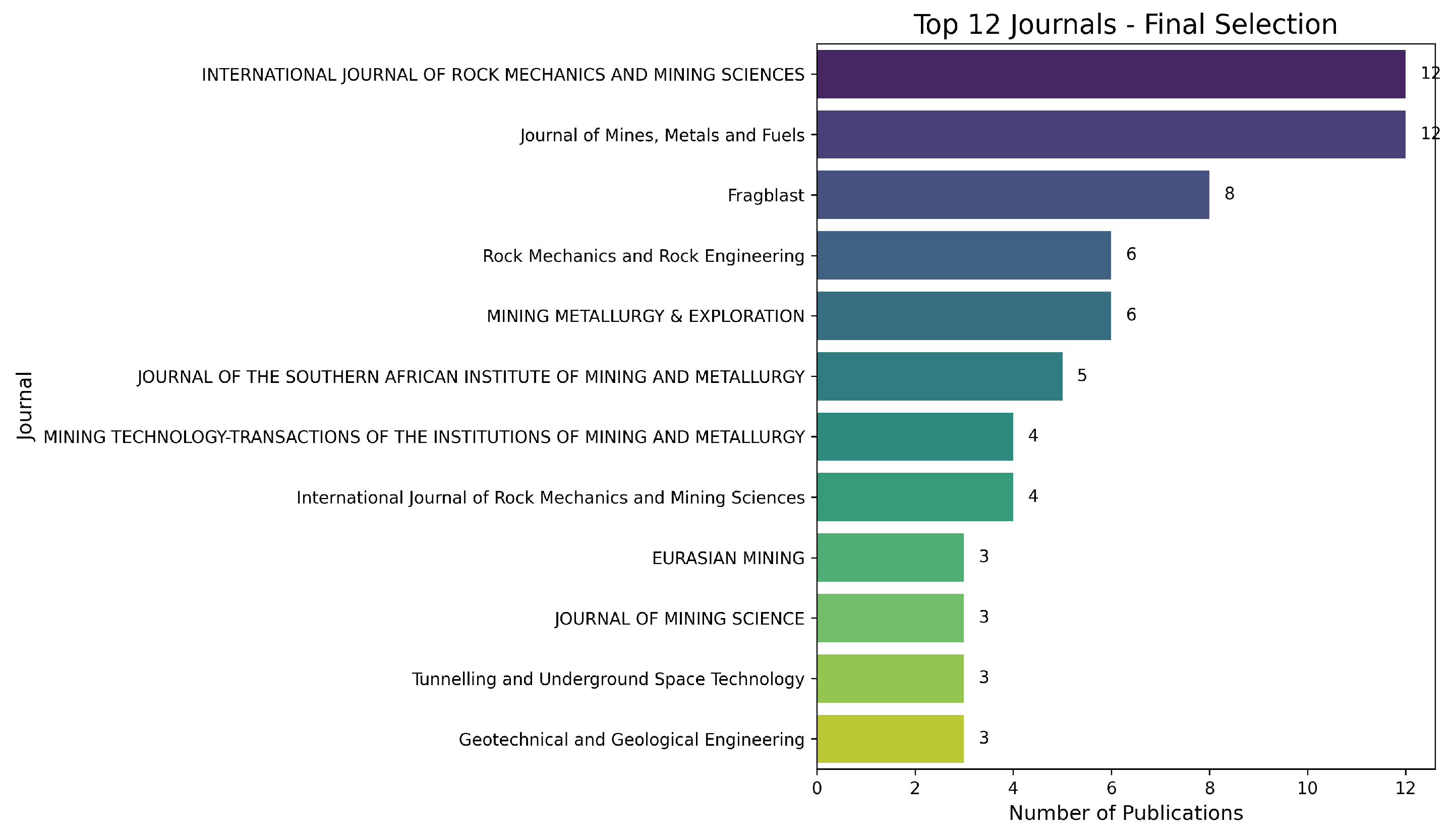

2.5. Preliminary Bibliometric Overview

2.6. Cross-Study Heterogeneity and Synthesis Rationale

2.7. Methodological Summary

2.8. Critical Appraisal of the Evidence

- Methodology

- Tool used. The Mixed Methods Appraisal Tool (MMAT, version 2018 [24]) was selected due to its suitability for reviews that combine quantitative, qualitative, and modelling-based evidence.

- Assessment process. Two independent reviewers (FL and LR) evaluated each study across the five MMAT domains. Disagreements were resolved through consensus with a senior third reviewer (JG).

- Inter-rater consistency. Cohen’s coefficient reached , indicating substantial agreement.

- Overall results

- Out of the 97 studies, 87 (89.7%) were rated as high quality (MMAT ⩾ 4/5).

- The remaining 10 studies (10.3%) were classified as moderate quality (MMAT = 3/5). While these showed specific methodological limitations (e.g., lack of data triangulation or small sample sizes), they were retained because they contribute the following:

- (a)

- Unique empirical data on under-represented lithologies (e.g., shale, karstified limestones);

- (b)

- Field validation of vibration-control techniques in deep tunnels, not found elsewhere in the 2000–2025 literature;

- (c)

- Early studies on the integration of MWD and UAV systems that support the digital twins agenda.

- Impact on the synthesis

- Appendix B, Table A1, has been added to report each study’s MMAT score and overall appraisal (either high or moderate).

- In Section 3, each quantitative claim (e.g., “48% PPV reduction”) explicitly states the proportion of high-quality studies supporting it. repeated the synthesis excluding moderate-quality studies; the main conclusions remained unchanged, confirming the robustness of the evidence.

- Summary

3. Synthesis of Findings

- Cluster 1: Numerical modeling and optimized blasting design in tunnels and underground works. This cluster focuses on studies employing Finite Element and Discrete Element Methods (FEM/DEM), FDM–GPU, ALE, and hybrid gas–solid models to predict fracture, fragmentation, and the excavation damage zone (EDZ), along with specialized software developments and critical comparisons with classical empirical models.

- Cluster 2: Empirical–probabilistic models, AI, and multi-criteria analysis for fragmentation and energy efficiency. This group gathers contributions that extend or modify the Kuz–Ram and fan size–energy paradigms, including applications of ML/AI (GPR, XGBoost, Random Forest), Monte Carlo simulations, multi-objective optimizations, and impact assessments on comminution circuits—all with a strong focus on geomechanical characterization of the rock mass.

- Cluster 3: Dynamic Control, Operational Safety, and Sustainable Blasting Design. Unlike Clusters I and II, which focus, respectively, on high-fidelity numerical simulation and empirical–probabilistic reformulations supported by AI, Cluster III groups studies whose central theme is the integrated mitigation of undesired dynamic impacts—vibration, fly-rock, overbreak, increased permeability, and structural damage—in parallel with the optimization of fragmentation and energy efficiency. Its distinctive methodological feature is the explicit incorporation of quantifiable geomechanical variables (fracture indices, dynamic modulus, in situ stress regime, anisotropy) into statistical, numerical, and AI models. This integration enables the ranking and comparison of blasting design indices from a truly holistic mine–structure–environment perspective, providing objective criteria to balance productivity, sustainability, and operational safety.

- Predict fragment size distribution and productivity indices (muckpile, SSE, throughput).

- Optimize explosive energy, charge factor, delays, and drill patterns under constraints such as vibration, overbreak, and stability.

- Quantify the propagation of collateral damage to structures and the environment (EDZ, PPV, fly-rock).

3.1. Cluster 1: Numerical Modelling and Optimized Blasting Design in Tunnels: Geomechanical Integration and Damage Control

3.2. Numerical Simulation and Coupled Modelling

3.3. Blasting Design in Tunnels and Deep Excavations

3.4. Structural Safety, Geomechanical Parameters, and Emerging Trends

3.5. Emerging Topics and Implications

- Greater integration of geomechanical variables in blast modelling. Most investigations [8,13,14,32,40,42,54] emphasize the importance of properly parameterizing rock mass properties (stress states, geomechanical classification, orientation of discontinuities) to realistically estimate both fragmentation and damage zones.

- Combined applications of 3D simulation and specialized software. There is a growing demand for numerical codes capable of handling large domains and highly heterogeneous materials [15,32,53]. The use of ALE, FDEM, and fluid–solid coupling methodologies offers more accurate projections of explosive–rock interaction but requires significant computational resources.

- Adaptive drilling and charging designs. Improvements are being pursued in borehole layout, initiation sequences, and explosive types (emulsions, decoupled charges, etc.) to minimize energy overuse and collateral damage [35,37,38,43]. The choice of detonator position and the use of pre-split techniques are emerging as particularly relevant practices.

3.6. Cluster 2: Advances in Empirical Methods, Artificial Intelligence, and Geomechanical Factors

3.7. Refinement of Empirical and Semi-Empirical Models Based on Kuz–Ram

- A is a constant dependent on the explosive type, powder factor, or other boundary conditions.

- Q is the energy or explosive mass (in kilograms or TNT equivalent).

- is a scale reference.

- represents a rock strength index (e.g., Rock Destruction Index) or other geomechanical characterization.

- and are empirical exponents determined through field correlation.

3.8. Optimization and AI Tools

3.9. Energy Models, Geomechanical Factors, and Specialized Designs

3.10. Damage Control Methodologies and Risk Assessment

3.11. Mixed Applications: Numerical Simulations, Statistical Analyses, and Field Experiments

3.12. Main Findings of Cluster 2

- Refinement of the Kuz–Ram and related models. Variables such as discontinuities, rock properties, and detonation delays have been incorporated to enhance the accuracy of the baseline model [7,9,10,11,55]. This refinement integrates probabilistic factors (Monte Carlo) and dimensional analysis to capture geomechanical variability.

3.13. Cluster 3: Dynamic Control, Operational Safety, and Sustainability in Blast Design

3.13.1. Vibratory Response and Multivariate Control Models

3.13.2. Prevention of Flyrock, Backbreak, and Overbreak

3.13.3. Damage Zone, Permeability, and Slope Stability

3.13.4. Energy Management and Containment Technologies

3.13.5. Mining–Civil Engineering Interface and Structural Resilience

3.13.6. Incorporation of Drilling Data and Operational Monitoring

3.13.7. Emerging Trends and Frontiers

3.13.8. Synthesis

4. Discussion

4.1. Contributions from Numerical Simulation and Multi-Physics Modeling

4.2. Reformulation of Empirical Methods and Their Integration with Geomechanics

4.3. AI, Multivariable Statistics, and Multi-Objective Optimization

4.4. Convergence and Future Implications

- (i)

- (ii)

- (iii)

4.5. Limitations and Research Directions

4.6. Modelling Challenges in Geomechanically Informed Blast Design

- Empirical and semi-empirical models: Classical fragmentation correlations (Rosin–Rammler, Kuz–Ram, Swebrec, etc.) rely on simplified assumptions (e.g., uniform rock, continuous breakage) and a small set of input parameters. They require site-specific calibration and often neglect key geomechanical details (e.g., joint sets, heterogeneity). Consequently, these models carry large uncertainties and limited transferability across different mines or rock types. For instance, recent studies note that traditional equations “apply only to specific mines,” highlighting their lack of robustness outside the training domain. Improving these models thus demands incorporating more geological variables and rigorous uncertainty quantification, but doing so exacerbates data needs that are rarely met in practice [94].

- High-fidelity numerical simulations (FEM/DEM/ALE): Physics-based simulations can, in principle, resolve blast-induced damage and fragmentation with high spatial and temporal resolution. FEM, DEM, coupled FDEM/ALE formulations, and hydrocodes have been used to simulate wave propagation, fracture initiation, and block motion under detailed constitutive laws. In practice, however, these methods are computationally demanding. Large-scale blast scenarios involving hundreds of holes and realistic block geometries are typically intractable, except under reduced-scale or two-dimensional approximations. Moreover, the continuum assumption in FEM breaks down under pervasive fracturing, requiring alternative formulations—such as lattice spring models, peridynamics, or adaptive meshing—to capture crack propagation accurately, further increasing the computational cost. Calibration also presents a major challenge: DEM models often require tuning of contact parameters (e.g., friction, cohesion, particle shape) based on limited laboratory or field data, typically through trial-and-error or optimization procedures. As noted in [95], achieving a balance between model fidelity and computational efficiency remains difficult, particularly when multiple parameters interact nonlinearly. In summary, high-fidelity simulations offer detailed physical insight, but at the expense of computational cost, complex parameterization, and sensitivity to uncertain geomechanical inputs.

- Machine learning models: Data-driven approaches—such as neural networks, random forests, and support vector machines—have been applied to predict fragmentation and other blast outcomes by learning nonlinear input–output relationships without relying on explicit physical models. However, ML methods introduce a distinct set of challenges. First, they require large and representative datasets of prior blasts, including design variables, rock properties, and measured outputs, which are often scarce or biased toward specific sites or lithologies. As a result, ML models are prone to overfitting and may generalize poorly outside their training domain. In many cases, a model trained on one pit or rock type fails when applied to new geological contexts unless specifically adapted. Furthermore, purely data-driven models offer limited interpretability and do not inherently enforce physical consistency, which may lead to unrealistic predictions under unseen conditions. Hyperparameter optimization is commonly performed using static strategies such as grid search or random search, which converge slowly and may become trapped in suboptimal solutions. Although ML can outperform empirical formulas in terms of fitting accuracy, its generalization capability under dynamic field conditions remains limited [94].

- Integrating physics and machine learning (hybrid models): To overcome the limitations of purely empirical or data-driven approaches, recent research has focused on hybrid models that integrate first-principle physics with ML techniques. Physics-informed neural networks (PINNs) and other hybrid frameworks embed governing equations—such as wave propagation or constitutive laws—directly into the training process. This integration helps reduce data demands while enforcing physically consistent behaviour throughout model inference. In the context of blasting, however, the strong nonlinearities associated with shock waves and fracturing pose major challenges to PINN training. Capturing such highly dynamic and discontinuous phenomena often requires specialized network architectures or custom loss formulations. An alternative hybrid strategy involves surrogate modeling, where fast approximation models (e.g., Gaussian processes or neural network surrogates) are trained on a limited set of high-fidelity simulations and subsequently coupled with optimization or uncertainty quantification routines. These surrogates can be further enhanced using transfer learning to adapt efficiently to new scenarios. Recent developments suggest that physics-constrained surrogate models and digital twins—capable of incorporating real-time sensor data from blasts—represent a promising direction for improving both predictive power and operational usability [96].

- Digital twins and real-time integration: The concept of a digital twin for blasting—defined as a continuously updated virtual replica of the rock mass and blasting process—holds significant promise but remains largely unrealized in mining applications. A fully functional digital twin would integrate in situ monitoring technologies (e.g., seismic arrays, vibration sensors, fragmentation imaging) with real-time simulations and ML models, enabling dynamic prediction and adaptive blast design. Achieving this requires robust integration of heterogeneous data streams and multiscale modeling approaches, a challenge that remains unresolved. Although general frameworks for mining digital twins have been proposed, practical implementations specific to drill-and-blast operations are still at an early proof-of-concept stage. Bridging this gap will necessitate interdisciplinary progress across geomechanics, data science, and engineering software development.

5. Conclusions

- C1.

- Numerical simulation reduces uncertainty: Multiphysics models improve the prediction of damage zones by incorporating calibrated mechanical properties and dynamic blast parameters. These simulations enhance reliability in high-stress conditions, reducing uncertainty in the spatial extent of fragmentation.

- C2.

- Hybrid empirical models remain valuable: Classical formulas such as Kuznetsov’s gain predictive power when augmented with geomechanical inputs. This integration improves accuracy and reduces error margins, reaffirming the utility of hybrid empirical–physical approaches in practice.

- C3.

- Machine learning enables flexible and adaptive inference: Advanced ML techniques can model complex nonlinear relationships among numerous variables with high predictive accuracy. Nonetheless, challenges remain regarding data availability, model generalization, and domain transferability.

- C4.

- Multi-objective optimization supports sustainable design: Optimization frameworks allow for the systematic balancing of competing goals, such as fragmentation quality, energy efficiency, and vibration control. Improvements in these metrics demonstrate the practical impact of mathematically grounded trade-off analysis.

- C5.

- Digital twins integrate models and data: The concept of a digital twin synthesizes physics-based models, data-driven inference, and real-time sensing into a unified predictive framework. This approach has already shown promise in reducing operational inefficiencies and improving energy use, bringing the field closer to closed-loop, autonomous design systems.

- Developing integrated validation frameworks that combine simulation, empirical models, and AI.

- Promoting open, standardized datasets for benchmarking ML methods in industrial contexts.

- Advancing performance metrics that jointly consider efficiency, cost, and sustainability.

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| 3D | Three-Dimensional |

| AI | Artificial Intelligence |

| ALE | Arbitrary Lagrangian–Eulerian |

| BDZ | Blast Damage Zone |

| DEM | Discrete Element Method |

| EDZ | Excavation Damage Zone |

| FDEM | Finite-Discrete Element Method |

| FEM | Finite Element Method |

| GBM | Gradient Boosting Machine |

| GPR | Gaussian Process Regression |

| GSI | Geological Strength Index |

| GPU | Graphics Processing Unit |

| HV | Hypervolume (multi-objective metric) |

| HSBM | Hybrid Stress Blasting Model |

| IA | Artificial Intelligence |

| LiDAR | Light Detection and Ranging |

| MAPE | Mean Absolute Percentage Error |

| MWD | Measurement While Drilling |

| NSGA-II | Non-Dominated Sorting Genetic Algorithm II |

| PPV | Peak Particle Velocity |

| RF | Random Forest |

| RDI | Rock Destruction Index |

| RMR | Rock Mass Rating |

| SD | Scaled Distance |

| UAV | Unmanned Aerial Vehicle |

| UCS | Uniaxial Compressive Strength |

| VOD | Velocity of Detonation |

| XGBoost | Extreme Gradient Boosting |

| Median fragment size in Kuznetsov model | |

| 80% passing size in comminution |

Appendix A. Search-Protocol Registration, Full Database Queries, and Bibliographic Exports

Appendix A.1. Complete Search Strategies (Executed 15 April 2025)

- A.

- Scopus (Elsevier)—Advanced queryTITLE-ABS-KEY ( blasting OR "rock fragmentation" )AND TITLE-ABS-KEY ( geomechan* OR joint* OR "compressive strength" )AND TITLE-ABS-KEY ( model* OR simulation OR AI OR optimization )AND PUBYEAR > 1999 AND PUBYEAR < 2026AND ( LIMIT-TO ( DOCTYPE , "ar" ) -- articlesOR LIMIT-TO ( DOCTYPE , "re" ) -- reviewsOR LIMIT-TO ( DOCTYPE , "cp" ) -- proceedings papersOR LIMIT-TO ( DOCTYPE , "ch" ) )-- book chaptersAND ( LIMIT-TO ( LANGUAGE , "English" ) ORLIMIT-TO ( LANGUAGE , "Spanish" ) )

- B.

- Web of Science Core Collection (Clarivate)—Advanced searchTS = ( blasting OR "rock fragmentation" )AND TS = ( geomechan* OR joint* OR "compressive strength" )AND TS = ( model* OR simulation OR AI OR optimization )Refined by: DOCUMENT TYPES = ( Article OR Review ORProceedings Paper OR Book Chapter )Timespan: 2000-2025Indexes: SCI-EXPANDED, SSCI, ESCI, CPCI-S, CPCI-SSH

Appendix A.2. Exported Bibliographic Files (Provided as Supplementary Material)

| Database | File Name | Format | Records † | Local Time Stamp (UTC−4) |

| Scopus | scopus.csv | Comma-separated | 1320 | 15 April 2025 14:37 |

| Web of Science | wos.xlsx | Excel (.xlsx) | 1095 | 15 April 2025 15:12 |

| † Number of raw records prior to duplicate removal. The original export files (plus the synthesis document summaries.doc) are lodged unaltered in the journal’s supplementary-material repository and in the above-mentioned OSF registration. | ||||

Appendix A.3. Reproducibility Statement

Appendix B. Detailed Critical Appraisal Matrix

Appendix B.1. MMAT Scoring Rubric

| Quality Label | Interpretation | |

| 4–5 | High | Robust design; negligible risk of bias |

| 3 | Moderate | Acceptable, but critical limitation |

| ⩽2 | Low | (none retained) Insufficient rigour |

Appendix B.2. Distribution of Quality Scores

Appendix B.3. Per-Study MMAT Matrix (Table A1)

| ID | Reference | D1 | D2 | D3 | D4 | D5 | Judgement/Key Limitation | |

|---|---|---|---|---|---|---|---|---|

| S01 | Han (2020) [14] | 1 | 1 | 1 | 1 | 1 | 5 | High |

| S02 | Onederra (2013) [13] | 1 | 1 | 1 | 1 | 1 | 5 | High |

| S03 | Gheibie (2009) [9] | 1 | 1 | 1 | 1 | 0 | 4 | High |

| S04 | Sanchidrián (2017) [10] | 1 | 1 | 1 | 1 | 0 | 4 | High |

| S88 | Chandrahas (2024) [60] | 1 | 1 | 1 | 0 | 0 | 3 | Moderate—no external validation dataset |

| S89 | Bayat (2022) [75] | 1 | 1 | 0 | 1 | 0 | 3 | Moderate—limited sample size ( blasts) |

| S90 | Budkov (2023) [82] | 1 | 0 | 1 | 1 | 0 | 3 | Moderate—permeability measured indirectly |

| S97 | Yin (2001) [86] | 1 | 1 | 0 | 1 | 0 | 3 | Moderate — dated MWD sensor resolution |

References

- Singh, P.; Roy, M.; Paswan, R.; Dubey, R.; Drebenstedt, C. Blast vibration effects in an underground mine caused by open-pit mining. Int. J. Rock Mech. Min. Sci. 2015, 80, 79–88. [Google Scholar] [CrossRef]

- Lastra, G.; Jokovic, V.; Kanchibotla, S. Understanding the impact of geotechnical ore properties and blast design on comminution circuits using simulations. Miner. Eng. 2021, 170, 107001. [Google Scholar] [CrossRef]

- Mboyo, H.; Huo, B.; Mulenga, F.; Fogang, P.; Kasongo, J. Assessing the Impact of Surface Blast Design Parameters on the Performance of a Comminution Circuit Processing a Copper-Bearing Ore. Minerals 2024, 14, 1226. [Google Scholar] [CrossRef]

- Sharma, P. Cost effectiveness of open pit hard rock ore mining depends on explosives used in terms of energy/VOD, pit-slope angle and framing strategy for fragmentation. J. Mines Met. Fuels 2013, 61, 275–281. [Google Scholar]

- Arthur, C.; Kaunda, R. A hybrid paretosearch algorithm and goal attainment method for maximizing production and reducing blast-induced ground vibration: A blast design parameter selection approach. Min. Technol. Trans. Inst. Min. Metall. 2020, 129, 151–158. [Google Scholar] [CrossRef]

- Bulushi, I.; Deressar, G.; Choudhary, B. Prediction and control of ground vibrations due to blasting activities in aggregate mines. J. Sustain. Min. 2025, 24, 267–281. [Google Scholar] [CrossRef]

- Morin, M.; Ficarazzo, F. Monte Carlo simulation as a tool to predict blasting fragmentation based on the Kuz-Ram model. Comput. Geosci. 2006, 32, 352–359. [Google Scholar] [CrossRef]

- Biswas, R.; Ghosh, A. Effect of blast design parameters on fragmentation - An application of Kuz-Ram model. J. Mines Met. Fuels 2012, 60, 206–215. [Google Scholar]

- Gheibie, S.; Aghababaei, H.; Hoseinie, S.; Pourrahimian, Y. Modified Kuz-Ram fragmentation model and its use at the Sungun Copper Mine. Int. J. Rock Mech. Min. Sci. 2009, 46, 967–973. [Google Scholar] [CrossRef]

- Sanchidrián, J.; Ouchterlony, F. A Distribution-Free Description of Fragmentation by Blasting Based on Dimensional Analysis. Rock Mech. Rock Eng. 2017, 50, 781–806. [Google Scholar] [CrossRef]

- Sanchidrián, J.; Ouchterlony, F. Blast-Fragmentation Prediction Derived From the Fragment Size-Energy Fan Concept. Rock Mech. Rock Eng. 2023, 56, 8869–8889. [Google Scholar] [CrossRef]

- Shim, H.J.; Ryu, D.W.; Chung, S.K.; Synn, J.H.; Song, J.J. Optimized blasting design for large-scale quarrying based on a 3-D spatial distribution of rock factor. Int. J. Rock Mech. Min. Sci. 2009, 46, 326–332. [Google Scholar] [CrossRef]

- Onederra, I.; Furtney, J.; Sellers, E.; Iverson, S. Modelling blast induced damage from a fully coupled explosive charge. Int. J. Rock Mech. Min. Sci. 2013, 58, 73–84. [Google Scholar] [CrossRef]

- Han, H.; Fukuda, D.; Liu, H.; Salmi, E.; Sellers, E.; Liu, T.; Chan, A. Combined finite-discrete element modelling of rock fracture and fragmentation induced by contour blasting during tunnelling with high horizontal in-situ stress. Int. J. Rock Mech. Min. Sci. 2020, 127, 104214. [Google Scholar] [CrossRef]

- Hao, Y.M.; Wei, X.D.; Li, Q.; Zhao, G.F. A feasible approach for engineering-scale 3D blasting numerical modelling incorporating explosive charges and layout design. Comput. Geotech. 2024, 170, 106253. [Google Scholar] [CrossRef]

- Monjezi, M.; Dehghani, H.; Singh, T.; Sayadi, A.; Gholinejad, A. Application of TOPSIS method for selecting the most appropriate blast design. Arab. J. Geosci. 2012, 5, 95–101. [Google Scholar] [CrossRef]

- Ohadi, B.; Sun, X.; Esmaieli, K.; Consens, M. Predicting blast-induced outcomes using random forest models of multi-year blasting data from an open pit mine. Bull. Eng. Geol. Environ. 2020, 79, 329–343. [Google Scholar] [CrossRef]

- Kinyua, E.; Jianhua, Z.; Huang, G.; Dinaniaina, R.; Kasomo, R.; Ullah, S. Application of Gaussian Process Regression for Bench Blasting Rock Fragmentation Prediction and Optimization at Wolongan Open-Pit Mine. Min. Metall. Explor. 2024, 41, 2341–2356. [Google Scholar] [CrossRef]

- Perincek, O.; Loxton, R.; Kulkarni, S.; Arthur, D. Drill Pattern Optimisation for Large Complex Blasts to Improve Fragmentation and Dig Efficiency. Math. Geosci. 2025, 57, 577–599. [Google Scholar] [CrossRef]

- Garcia, J.; Villavicencio, G.; Altimiras, F.; Crawford, B.; Soto, R.; Minatogawa, V.; Franco, M.; Martínez-Muñoz, D.; Yepes, V. Machine learning techniques applied to construction: A hybrid bibliometric analysis of advances and future directions. Autom. Constr. 2022, 142, 104532. [Google Scholar] [CrossRef]

- García, J.; Leiva-Araos, A.; Diaz-Saavedra, E.; Moraga, P.; Pinto, H.; Yepes, V. Relevance of Machine Learning Techniques in Water Infrastructure Integrity and Quality: A Review Powered by Natural Language Processing. Appl. Sci. 2023, 13, 12497. [Google Scholar] [CrossRef]

- Sánchez-Garrido, A.J.; Navarro, I.J.; García, J.; Yepes, V. A systematic literature review on modern methods of construction in building: An integrated approach using machine learning. J. Build. Eng. 2023, 73, 106725. [Google Scholar] [CrossRef]

- Cunningham, C. Concepts of blast hole pressure applied to blast design. Fragblast 2006, 10, 33–45. [Google Scholar] [CrossRef]

- Hong, Q.N.; Fàbregues, S.; Bartlett, G.; Boardman, F.; Cargo, M.; Dagenais, P.; Gagnon, M.P.; Griffiths, F.; Nicolau, B.; O’Cathain, A.; et al. The Mixed Methods Appraisal Tool (MMAT) version 2018 for information professionals and researchers. Educ. Inf. 2018, 34, 285–291. [Google Scholar] [CrossRef]

- Aben, E.; Malanchuk, Z.; Fedotenko, V.; Orynbaev, B. Improving Efficiency of Rock Breaking Using Pre-Weakening of Rock Mass. Eurasian Min. 2023, 2, 62–65. [Google Scholar] [CrossRef]

- Bameri, A.; Seifabad, M.; Hoseinie, S. Uncertainty consideration in rock mass blastability assessment in open pit mines using Monte Carlo simulation. Eurasian Min. 2021, 35, 34–38. [Google Scholar] [CrossRef]

- Chaudhary, B.; Arora, R. Screened drill cuttings in blasthole for tamping of stemming to reduce generation of fly rock. J. Mines Met. Fuels 2017, 65, 19–23+38. [Google Scholar]

- Dey, K.; Murthy, V. Investigations on impact of blasting in tunnels. Int. J. Geotech. Earthq. Eng. 2010, 1, 59–71. [Google Scholar] [CrossRef]

- Elevli, B.; Arpaz, E. Evaluation of parameters affected on the blast induced ground vibration (BIGV) by using relation diagram method (RDM). Acta Montan. Slovaca 2010, 15, 261–268. [Google Scholar]

- Fernández, P.; Rodríguez, R.; Bascompta, M. Holistic Approach to Define the Blast Design in Quarrying. Minerals 2022, 12, 191. [Google Scholar] [CrossRef]

- Himanshu, V.; Roy, M.; Mishra, A.; Paswan, R.; Panda, D.; Singh, P. Multivariate statistical analysis approach for prediction of blast-induced ground vibration. Arab. J. Geosci. 2018, 11, 460. [Google Scholar] [CrossRef]

- Yang, P.; Xiang, J.; Chen, M.; Fang, F.; Pavlidis, D.; Latham, J.; Pain, C. The immersed-body gas-solid interaction model for blast analysis in fractured solid media. Int. J. Rock Mech. Min. Sci. 2017, 91, 119–132. [Google Scholar] [CrossRef]

- Ghosh, S.; Behera, C.; Mishra, M. Prediction of blast-induced ground vibration using multivariate statistical analysis in the opencast chromite mines of the Indian State of Odisha. Sadhana-Acad. Proc. Eng. Sci. 2024, 49, 141. [Google Scholar] [CrossRef]

- Qu, S.; Hao, S.; Chen, G.; Li, B.; Bian, G. The BLAST-CODE model—A computer-aided bench blast-design and simulation system. Fragblast 2002, 6, 85–103. [Google Scholar] [CrossRef]

- Sharma, P. Tunnel blasting-Emulsion explosives and proper blast design are the prerequisite for better efficiency. J. Mines Met. Fuels 2005, 53, 157–165. [Google Scholar]

- Onederra, I. A fragmentation modelling framework for underground ring blasting applications. Fragblast 2004, 8, 177–200. [Google Scholar] [CrossRef]

- Zare, S.; Bruland, A. Comparison of tunnel blast design models. Tunn. Undergr. Space Technol. 2006, 21, 533–541. [Google Scholar] [CrossRef]

- Dey, K.; Murthy, V. Development of a tunnel blast design software (ITBlade-1.0)—An aid for efficient blasting. J. Mines Met. Fuels 2006, 54, 402–410. [Google Scholar]

- Dotto, M.; Pourrahimian, Y.; Joseph, T.; Apel, D. Assessment of blast energy usage and induced rock damage in hard rock surface mines. CIM J. 2022, 13, 166–180. [Google Scholar] [CrossRef]

- Drover, C.; Villaescusa, E.; Onederra, I. Face destressing blast design for hard rock tunnelling at great depth. Tunn. Undergr. Space Technol. 2018, 80, 257–268. [Google Scholar] [CrossRef]

- Yilmaz, O.; Unlu, T. An application of the modified Holmberg-Persson approach for tunnel blasting design. Tunn. Undergr. Space Technol. 2014, 43, 113–122. [Google Scholar] [CrossRef]

- Liu, J.; Sun, P.; Liu, F.; Zhao, M. Design and optimization for bench blast based on Voronoi diagram. Int. J. Rock Mech. Min. Sci. 2014, 66, 30–40. [Google Scholar] [CrossRef]

- Chi, L.; Ylitalo, R.; Zhang, Z.; Bergstrom, P.; Haugen, S.; Mäki, R.; Sand, A. A Case Study of Fragmentation Improvement by Primer Placement in Kevitsa Mine. Min. Metall. Explor. 2024, 41, 1265–1278. [Google Scholar] [CrossRef]

- Adhikari, G.R. Examining blast design in India. Tunnels Tunn. Int. 2007, NOV, 25–28. [Google Scholar]

- Olmati, P.; Vamvatsikos, D.; Stewart, M. Safety factor for structural elements subjected to impulsive blast loads. Int. J. Impact Eng. 2017, 106, 249–258. [Google Scholar] [CrossRef]

- Williamson, E.; Bayrak, O.; Davis, C.; Daniel Williams, G. Performance of bridge columns subjected to blast loads. II: Results and recommendations. J. Bridge Eng. 2011, 16, 703–710. [Google Scholar] [CrossRef]

- Cortés, N.e.a. Empirical approaches for rock burst prediction: A comprehensive review and application to the new level of El Teniente Mine, Chile. Heliyon 2024, 10, 3613. [Google Scholar] [CrossRef]

- Li, B.; Huang, Z.; Lim, C. Verification of nondimensional energy spectrum-based blast design for reinforced concrete members through actual blast tests. J. Struct. Eng. 2010, 136, 627–636. [Google Scholar] [CrossRef]

- Pomasoncco-Najarro, A.; Trujillo-Valerio, C.; Arauzo-Gallardo, L.; Raymundo, C.; Quispe, G.; Dominguez, F. Pre-split blasting design to reduce costs and improve safety in underground mining. Energy Rep. 2022, 8, 1208–1225. [Google Scholar] [CrossRef]

- Sorensen, A.; McGill, W. Utilization of existing blast analysis software packages for the back-calculation of blast loads. J. Perform. Constr. Facil. 2012, 26, 544–546. [Google Scholar] [CrossRef]

- Dusenberry, D. Anticipating the post-blast condition of structures. Can. J. Civ. Eng. 2009, 36, 1340–1344. [Google Scholar] [CrossRef]

- Jensen, R.; Preece, D. Modelling explosive/rock interaction during presplitting, using ALE computational methods. J. South Afr. Inst. Min. Metall. 2000, 100, 23–26. [Google Scholar]

- Sellers, E.; Furtney, J.; Onederra, I.; Chitombo, G. Improved understanding of explosive-rock interactions using the hybrid stress blasting model. J. South. Afr. Inst. Min. Metall. 2012, 112, 721–728. [Google Scholar]

- Hosseini, M.; Khandelwal, M.; Lotfi, R.; Eslahi, M. Sensitivity analysis on blast design parameters to improve bench blasting outcomes using the Taguchi method. Geomech. Geophys. Geo-Energy Geo-Resour. 2023, 9, 9. [Google Scholar] [CrossRef]

- Shehu, S.; Yusuf, K.; Hashim, M. Comparative study of WipFrag image analysis and Kuz-Ram empirical model in granite aggregate quarry and their application for blast fragmentation rating. Geomech. Geoengin. 2022, 17, 197–205. [Google Scholar] [CrossRef]

- Sharma, A.; Mishra, A.; Choudhary, B.; Meena, R. Impact of blast design parameters on rock fragmentation in building stone quarries. Curr. Sci. 2019, 116, 1861–1867. [Google Scholar] [CrossRef]

- Shehu, S.; Mohd Hashim, M.; Kechik, N. Preliminary assessment of the effects of blast design factors on fragmentation at lafarge kanthan limestone quarry, chemor, perak. ASEAN Eng. J. 2020, 10, 58–72. [Google Scholar] [CrossRef]

- Nobahar, P.; Shirani Faradonbeh, R.; Almasi, S.; Bastami, R. Advanced AI-Powered Solutions for Predicting Blast-Induced Flyrock, Backbreak, and Rock Fragmentation. Min. Metall. Explor. 2024, 41, 2099–2118. [Google Scholar] [CrossRef]

- Shields, L.; Silva, J.; Calnan, J.; Maldonado, E.; Agioutantis, Z. Integrating Underground Blast Fragmentation Modeling for Sustainable Mine-to-Mill Optimization: A Focus on Blast Fragmentation and Energy Efficiency in Comminution Circuits. Rock Mech. Rock Eng. 2025, 58, 4497–4508. [Google Scholar] [CrossRef]

- Chandrahas, N.; Choudhary, B.; Venkataramayya, M.; Yewuhalashet, F.; Adachi, T. An Inventive Approach for Simultaneous Prediction of Mean Fragmentation Size and Peak Particle Velocity Using Futuristic Datasets Through Improved Techniques of Genetic XG Boost Algorithm. Min. Metall. Explor. 2024, 41, 2391–2405. [Google Scholar] [CrossRef]

- Sri Chandrahas, N.; Choudhary, B.; Vishnu Teja, M.; Venkataramayya, M.; Krishna Prasad, N. XG Boost Algorithm to Simultaneous Prediction of Rock Fragmentation and Induced Ground Vibration Using Unique Blast Data. Appl. Sci. 2022, 12, 5269. [Google Scholar] [CrossRef]

- Chandrahas, N.; Choudhary, B.; Prasad, N.; Musunuri, V.; Rao, K. An investigation into the effect of rockmass properties on mean fragmentation. Arch. Min. Sci. 2021, 66, 561–578. [Google Scholar] [CrossRef]

- Garcia, J.; Rios-Colque, L.; Peña, A.; Rojas, L. Condition Monitoring and Predictive Maintenance in Industrial Equipment: An NLP-Assisted Review of Signal Processing, Hybrid Models, and Implementation Challenges. Appl. Sci. 2025, 15, 5465. [Google Scholar] [CrossRef]

- Sinha, M.; Mishra, A. Energy Factor-based Blast Design in Large Opencast Coal Mines. J. Mines Met. Fuels 2022, 70, 306–314. [Google Scholar] [CrossRef]

- Mulenga, S.; Kaunda, R. Blast Design for Improved Productivity using a Modified Available Energy Method. J. Min. Environ. 2020, 11, 643–659. [Google Scholar] [CrossRef]

- Choudhary, B.; Agrawal, A. Minimization of Blast-Induced Hazards and Efficient Utilization of Blast Energy by Implementing a Novel Stemming Plug System for Eco-Friendly Blasting in Open Pit Mines. Nat. Resour. Res. 2022, 31, 3393–3410. [Google Scholar] [CrossRef]

- Roy, M.; Mishra, A.; Agrawal, H.; Singh, P. Blast vibration dependence on total explosives weight in open-pit blasting. Arab. J. Geosci. 2020, 13, 531. [Google Scholar] [CrossRef]

- Roy, P.; Sawmliana, C.; Singh, R. Optimization of powder factor, fragmentation and oversized boulders through subsystem studies in an opencast coal mine. Int. J. Min. Geo-Eng. 2023, 57, 195–203. [Google Scholar] [CrossRef]

- Roy, M.; Singh, P.; Mishra, A.; Jawed, M. Impact of total explosive weight detonated in blasting round on blast induced ground vibration. World Min.-Undergr. 2014, 66, 177–182. [Google Scholar]

- Akbari, M.; Lashkaripour, G.; Yarahamdi Bafghi, A.; Ghafoori, M. Blastability evaluation for rock mass fragmentation in Iran central iron ore mines. Int. J. Min. Sci. Technol. 2015, 25, 59–66. [Google Scholar] [CrossRef]

- Hudaverdi, T.; Kuzu, C.; Fisne, A. Investigation of the blast fragmentation using the mean fragment size and fragmentation index. Int. J. Rock Mech. Min. Sci. 2012, 56, 136–145. [Google Scholar] [CrossRef]

- Hudaverdi, T.; Kulatilake, P.; Kuzu, C. Prediction of blast fragmentation using multivariate analysis procedures. Int. J. Numer. Anal. Methods Geomech. 2011, 35, 1318–1333. [Google Scholar] [CrossRef]

- Silva, J.; Amaya, J.; Basso, F. Development of a predictive model of fragmentation using drilling and blasting data in open pit mining. J. South Afr. Inst. Min. Metall. 2017, 117, 1089–1094. [Google Scholar] [CrossRef]

- Dumakor-Dupey, N.; Arya, S.; Jha, A. Advances in blast-induced impact prediction—A review of machine learning applications. Minerals 2021, 11, 601. [Google Scholar] [CrossRef]

- Bayat, P.; Monjezi, M.; Mehrdanesh, A.; Khandelwal, M. Blasting pattern optimization using gene expression programming and grasshopper optimization algorithm to minimise blast-induced ground vibrations. Eng. Comput. 2022, 38, 3341–3350. [Google Scholar] [CrossRef]

- Kumar, S.; Mishra, A.; Choudhary, B. Estimation Equations for Back Break and Ground Vibration Using Genetic Programming. Geotech. Geol. Eng. 2023, 41, 3139–3149. [Google Scholar] [CrossRef]

- Rojas, L.; Yepes, V.; Garcia, J. Complex Dynamics and Intelligent Control: Advances, Challenges, and Applications in Mining and Industrial Processes. Mathematics 2025, 13, 961. [Google Scholar] [CrossRef]

- Raina, A.; Murthy, V. Prediction of Flyrock Distance in Open Pit Blasting Using Surface Response Analysis. Geotech. Geol. Eng. 2016, 34, 15–28. [Google Scholar] [CrossRef]

- Raina, A. Blast fragmentation assessment and ptimization: Back to basics. J. Mines, Met. Fuels 2013, 61, 207–212. [Google Scholar]

- Sharma, M.; Agrawal, H.; Choudhary, B. Multivariate regression and genetic programming for prediction of backbreak in open-pit blasting. Neural Comput. Appl. 2022, 34, 2103–2114. [Google Scholar] [CrossRef]

- Adesida, P. Powder factor prediction in blasting operation using rock geomechanical properties and geometric parameters. Int. J. Min. Geo-Eng. 2022, 56, 25–32. [Google Scholar] [CrossRef]

- Budkov, A.; Kocharyan, G.; Kishkina, S. Assessment of Change in Rock Mass Permeability in the Vicinity of Underground Explosion from Experimental Data and Numerical Modeling. J. Min. Sci. 2023, 59, 8–16. [Google Scholar] [CrossRef]

- Zuo, J.; Shen, J. The Effects of Blast Damage Zone Thickness on Rock Slope Stability. In Hoek-Brown Failure Criterion-From Theory to Application; Springer: Singapore, 2020; pp. 201–222. [Google Scholar] [CrossRef]

- Onederra, I. Delay timing factor for empirical fragmentation models. Trans. Inst. Min. Metall. Sect. A Min. Technol. 2007, 116, 176–179. [Google Scholar] [CrossRef]

- Tao, M.; Xu, Y.; Zhao, R.; Liu, Y.; Wu, C. Energy control and block performance optimization of bench blasting. Int. J. Rock Mech. Min. Sci. 2024, 180, 105830. [Google Scholar] [CrossRef]

- Yin, K.; Liu, H. Using information extracted from drill data to improve blasting design and fragmentation. Fragblast 2001, 5, 157–179. [Google Scholar] [CrossRef]

- Segui, J.B.; Higgins, M. Blast design using measurement while drilling parameters. Fragblast 2002, 6, 287–299. [Google Scholar] [CrossRef]

- Orellana, F.; Durán, O.; Vergara, J.I.; Arata, A. Maintainability Analysis of Remotely Operated LNG Marine Loading Arms Based on UNE 151001 Standard. Machines 2024, 12, 407. [Google Scholar] [CrossRef]

- Martinez, Y.; Rojas, L.; Peña, A.; Valenzuela, M.; Garcia, J. Physics-Informed Neural Networks for the Structural Analysis and Monitoring of Railway Bridges: A Systematic Review. Mathematics 2025, 13, 1571. [Google Scholar] [CrossRef]

- Deressa, G.; Choudhary, B.; Jilo, N. Optimizing blast design and bench geometry for stability and productivity in open pit limestone mines using experimental and numerical approaches. Sci. Rep. 2025, 15, 5796. [Google Scholar] [CrossRef]

- Umarov, F.; Nasirov, U.; Zairov, S.; Nutfulloyev, G. Development of blasting designs for underground mining in the kauldy mine of almalyk mining and metallurgical company. Eurasian Min. 2024, 42, 57–61. [Google Scholar] [CrossRef]

- Yakubovskiy, M.; Sankovsky, A. Drilling and blasting design based on invariable mining parameters. J. Ind. Pollut. Control 2017, 33, 931–936. [Google Scholar]

- Salmi, E.F.; Sellers, E.J. A review of the methods to incorporate the geological and geotechnical characteristics of rock masses in blastability assessments for selective blast design. Eng. Geol. 2021, 281, 105970. [Google Scholar] [CrossRef]

- Huan, B.; Li, X.; Wang, J.; Hu, T.; Tao, Z. An interpretable deep learning model for the accurate prediction of mean fragmentation size in blasting operations. Sci. Rep. 2025, 15, 11515. [Google Scholar] [CrossRef]

- Hadi, A.; Moradi, M.; Pang, Y.; Schott, D. Adaptive AI-based surrogate modelling via transfer learning for DEM simulation of multi-component segregation. Sci. Rep. 2024, 14, 27003. [Google Scholar]

- Yuan, B.; Choo, C.S.; Yeo, L.Y.; Wang, Y.; Yang, Z.; Guan, Q.; Suryasentana, S.; Choo, J.; Shen, H.; Megia, M.; et al. Physics-informed machine learning in geotechnical engineering: A direction paper. Geomech. Geoengin. 2025, 1–32. [Google Scholar] [CrossRef]

| Methodological Component and Protocol | Tools, Metrics, and Key Outcomes |

|---|---|

| Phase I: Document retrieval and corpus extraction | |

Comprehensive search in high-impact databases to obtain an initial corpus on blasting models with geomechanical integration.

| Databases: Scopus and Web of Science (WoS). Initial metric: 2415 records retrieved. Deliverable: Primary bibliographic repository. |

| Phase II: Corpus refinement and filtering (PRISMA + NLP) | |

| Multi-stage rigorous filtering to ensure quality and relevance, combining bibliometric criteria with a semantic NLP filter. 1. Initial screening:

| Corpus reduction flow:

|

| Phase III: Hybrid thematic analysis (NLP + expert validation) | |

| Identification of research domains through a hybrid approach that combines topic modelling with expert validation. | Modelling tool: BERTopic. Process: Thematic clustering based on titles and abstracts, followed by refinement and interpretation by an expert panel. Structural result: 3 thematic clusters:

|

| Phase IV: Quality control and visualization | |

| Final quality assurance through bias assessment and semantic reinforcement, complemented by bibliometric visualizations. | Applied techniques:

|

| Reference | Numerical/Modeling Approach | Fundamental Equations | Key Findings and Applications |

|---|---|---|---|

| [14] | FDEM (Finite–Discrete Element Method) applied to tunnels under high in situ stresses. | Dynamic elasticity equation: (Equation (8)) Dynamic fracture based on a maximum stress criterion. | Demonstrates the importance of charge sequencing and burden configuration for fracture propagation. Explicitly integrates the stress state and rock–mass anisotropy, showing the need to calibrate geomechanical parameters to reduce the excavation damage zone (EDZ). |

| [15] | Large-scale three-dimensional modelling for blasthole layouts in complex geometries. | Coupled FEM/DEM formulation, treating fracture in a discrete framework and wave propagation in a continuous one. Includes an elasto-plastic constitutive law with hardening and softening. | Shows how discontinuities (faults and joints) modify shock-wave propagation and fragmentation patterns. Highlights the importance of coupling explosive dynamics with nonlinear rock response to obtain realistic predictions of damage and overbreak. |

| [13] | Model to predict damage induced by fully coupled charges, validated with field data. | Fracture-energy law (Equation (9)):

| Comparison between simulated results and in situ measurements shows agreement after rigorous calibration of fracture parameters. Emphasises the need to adjust and the actual detonation velocity to accurately predict the extent of zonal damage. |

| [23] | Analysis of blast-hole pressure from detonation velocity measurements (). | Empirical model:

| Provides a method to estimate peak borehole pressure and its relationship with fracture power. Useful for comparing explosives and determining the pressure window required according to rock strength. |

| Category | Model/Algorithm | Key Geomechanical Variables | Performance Metric | Main Finding |

|---|---|---|---|---|

| Classical empirical methods | Original Kuz–Ram and Monte Carlo | RQD, UCS, rock factor R | Mean error in | Monte Carlo simulation improves full fragment curve prediction () compared to the deterministic model [7]. |

| Modified Kuz–Ram | Empirical prefactor, joint index | in | Adjusting the prefactor to reduces prediction deviation by 23% [9]. | |

| Energy Factor (EF) | Charge density, dynamic modulus | Drill reduction (%) | EF correlates delivered energy with P80 and increases productivity by 12% in coal mines [64]. | |

| Numerical optimization | Pareto–search + Goal Attainment | Burden, spacing, allowable PPV | Multi-objective fitness function | Simultaneous maximization of production and minimization of vibration; 49% PPV reduction [5]. |

| Artificial Intelligence | Multi-year Random Forest (RF) | UCS, charge factor, delay time | MAE in PPV and P80 | RF reduces PPV MAE to 0.19 mm/s and captures rock–explosive nonlinearities [17]. |

| Gaussian Process Regression (GPR) | S-wave velocity, RMR | RMSE in P50 | GPR provides explicit uncertainty: RMSE 6.4 cm and posterior standard deviation [18]. | |

| Genetic XGBoost | Joint angle, charge factor | Dual MAE (P50, PPV) | Simultaneous prediction of fragmentation and PPV (MAE ) [60]. | |

| Gene Expression + Grasshopper | Specific power, Young’s modulus | Estimated PPV | Predicted PPV reduced by 17% compared to empirical model [75]. | |

| Sensitivity and Statistical Analysis | Taguchi–ANOVA | Stiffness ratio, UCS, burden | Significance | Stiffness ratio and UCS explain 68% of the variance in P50 [54]. |

| Advanced geomechanical factors | 3D Rock Factor Mapping | Spatial index | Drilling mesh optimization | Pattern redesign reduces overbreak by 14% [12]. |

| Delay Timing Factor | Inter-hole delay , joint density | Kuznetsov curve adjustment | Incorporates as a dimensionless coefficient; improves P80 distribution fit [84]. | |

| BDZ–Permeability Coupled Model | BDZ thickness, in situ stress | k (permeability) variation | Log-linear correlation between shear and increase in k; implications for slope stability [82,83]. |

| Model/Technique | Method Class | Mining Setting | Key Geomechanical Inputs | Primary Metric |

|---|---|---|---|---|

| Kuznetsov Cunningham Ramamurthy (Kuz–Ram) | Empirical fragmentation model | Open-pit | Rock factor R, rock destruction index (RDI) | Median size , |

| Modified Kuz–Ram (geomechanics-enriched) | Semi-empirical () | Open-pit and underground | UCS, Young’s modulus, GSI, inter-hole delay | reduction (% MAPE) |

| Swebrec + Size–Energy Fan | Empirical distribution | Open-pit | Joint spacing, burden spacing | Full size curve fit () |

| Energy-Factor (EF) Design | Energetic balance | Open-pit (coal, iron) | Bench geometry, UCS, powder factor | Explosive energy efficiency (%) |

| Pre-split/Trim blasting | Controlled blasting technique | Pit walls and tunnel perimeters | Joint orientation, in situ stress | Overbreak/backbreak (m) |

| Hybrid Stress Blasting Model (HSBM) | Hybrid numerical–empirical | Both | Rock Mass Rating (RMR) blocks, confinement | Fragmentation + damage map |

| Finite-Discrete Element Method (FDEM) | High-fidelity numerical | Underground, high stress | Constitutive tensor , fracture energy | EDZ thickness (m) |

| Arbitrary Lagrangian–Eulerian (ALE) coupling | Gas–solid CFD | Both | Detonation pressure, wave speed, stiffness gradient | Burden damage depth (m) |

| BDZ Permeability–Damage model | Coupled hydro-mechanical | Underground (deep) | Plastic strain, stress state, fracture density | k increase factor |

| PPV Scaled-Distance + rock modifiers | Vibration correlation | Surface blasts near structures | UCS, S-wave velocity | PPV prediction error (mm/s) |

| RQ | Key Finding | Supporting Evidence/Methodology | Representative Studies |

|---|---|---|---|

| RQ1 | Including discontinuities and strength improves and prediction | Monte Carlo simulation coupled to Kuz–Ram; iterations show when fracture index is added | [7] |

| Rock factor adjustment in Kuz–Ram improves accuracy in porphyry copper | Empirical recalibration (prefactor 0.073) reduces MAE by 18% compared to the base model | [9] | |

| 3D numerical models capture EDZ and reflect in situ stress conditions | FDEM–GPU analysis with adaptive mesh; correlation 0.91 with post-excavation fracture mapping | [14] | |

| Size–energy fan integrates joint spacing and detonating energy | Dimensional analysis without prior distribution; mean error 6% in limestone quarry | [11] | |

| RQ2 | ML ensemble predicts fragmentation, backbreak, and flyrock with | Random Forest–GBM fusion; 270 open-pit mining cases | [58] |

| Genetic XGBoost simultaneously estimates and PPV | 120 blasts, 14 parameters; RMSE (Frag.) m, RMSE(PPV) = 2.1 mm/s | [61] | |

| GPR + MWD data improves blast design in heterogeneous benches | 125 drill–blast records; 12% reduction in energy overuse | [18] | |

| Multivariate analysis with drilling loggers improves prediction | Stepwise regression on 38 blasts: | [72] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Leon, F.; Rojas, L.; Peña, A.; Moraga, P.; Robles, P.; Gana, B.; García, J. Mathematical Modelling and Optimization Methods in Geomechanically Informed Blast Design: A Systematic Literature Review. Mathematics 2025, 13, 2456. https://doi.org/10.3390/math13152456

Leon F, Rojas L, Peña A, Moraga P, Robles P, Gana B, García J. Mathematical Modelling and Optimization Methods in Geomechanically Informed Blast Design: A Systematic Literature Review. Mathematics. 2025; 13(15):2456. https://doi.org/10.3390/math13152456

Chicago/Turabian StyleLeon, Fabian, Luis Rojas, Alvaro Peña, Paola Moraga, Pedro Robles, Blanca Gana, and Jose García. 2025. "Mathematical Modelling and Optimization Methods in Geomechanically Informed Blast Design: A Systematic Literature Review" Mathematics 13, no. 15: 2456. https://doi.org/10.3390/math13152456

APA StyleLeon, F., Rojas, L., Peña, A., Moraga, P., Robles, P., Gana, B., & García, J. (2025). Mathematical Modelling and Optimization Methods in Geomechanically Informed Blast Design: A Systematic Literature Review. Mathematics, 13(15), 2456. https://doi.org/10.3390/math13152456