An Improved Moth-Flame Algorithm for Human–Robot Collaborative Parallel Disassembly Line Balancing Problem

Abstract

1. Introduction

- A human–robot collaborative parallel disassembly line balancing problem (HCPDP) is proposed. This issue aims to efficiently resolve multi-product disassembly sequences while considering task distribution to maximize profit.

- The Moth-Flame Optimization (MFO) algorithm is refined to enhance its local search capability. MFO alone is insufficient for solving the presented problem. The enhanced algorithm can effectively address this problem and achieve faster solutions and superior target values.

2. Problem Statement and Formulation

2.1. Problem Description

- The disassembly AND/OR figure of each EOL product is known.

- When each disassembly task is assigned to a workstation in the order in which it is disassembled, the priority matrix and the conflict matrix (both matrices are known) are satisfied.

- Not all EOL products can be completely disassembled.

- The cycle time of each workstation is known, and the processing time of each workstation does not exceed the cycle time.

- The complex subassemblies and hazardous subassemblies of each EOL product are known.

- The cost and energy consumption associated with workers and robots performing different disassembly tasks are known.

- The value of each sub-subassembly is known.

- Each workstation can be assigned a maximum of two disassemblers.

2.2. Description of an Example with an AND/OR Graph

2.3. Mathematical Model

3. Proposed Algorithm

3.1. Introduction of Improved MFO

3.2. Improved MFO Algorithm from MFO with Crossover Probability

| Algorithm 1: Improved Moth-Flame Optimization Algorithm |

| Input: case data, number of iterations, population size |

| Output: the best solutions |

|

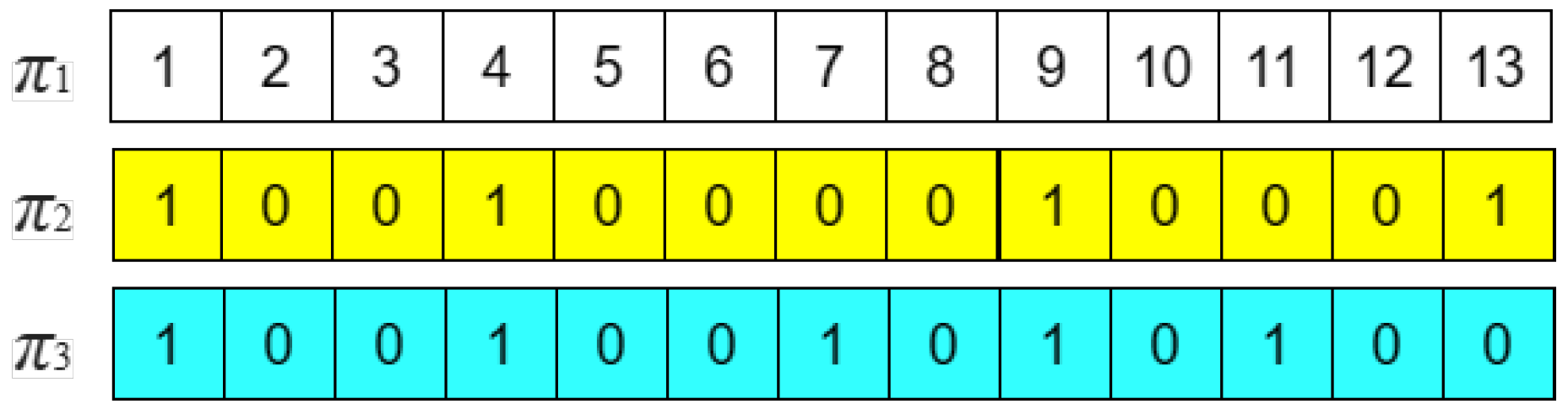

3.3. Encoding and Decoding

4. Experimental Studies

4.1. Test Instances

4.2. Performance Metrics

4.3. Instance Analysis

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhao, Z.; Zhou, M.; Liu, S. Iterated Greedy Algorithms for Flow-Shop Scheduling Problems: A Tutorial. IEEE Trans. Autom. Sci. Eng. 2021, 19, 1941–1959. [Google Scholar] [CrossRef]

- Zhao, Z.; Liu, S.; Zhou, M.; Abusorrah, A. Dual-Objective Mixed Integer Linear Program and Memetic Algorithm for an Industrial Group Scheduling Problem. IEEE/CAA J. Autom. Sin. 2021, 8, 1199–1209. [Google Scholar] [CrossRef]

- McGovern, S.; Gupta, S. Combinatorial optimization methods for disassembly line balancing. Proc.-Spie Int. Soc. Opt. Eng. 2004, 5583, 53–66. [Google Scholar] [CrossRef]

- Gungor, A.; Gupta, S.M. A solution approach to the disassembly line balancing problem in the presence of task failures. Int. J. Prod. Res. 2001, 39, 1427–1467. [Google Scholar] [CrossRef]

- Gungor, A.; Gupta, S.M.; Pochampally, K.; Kamarthi, S.V. Complications in disassembly line balancing. SPIE 2001, 4193, 289–298. [Google Scholar] [CrossRef]

- Lu, F.; Liu, P.; Qi, L.; Qin, S.; Xu, G.; Xu, Z. Multi-objective discrete strength pareto evolutionary algorithm II for multiple-product partial U-shaped disassembly line balancing problem. J. Phys. Conf. Ser. 2021, 2024, 012058. [Google Scholar] [CrossRef]

- Liang, J.; Guo, S.; Du, B.; Li, Y.; Guo, J.; Yang, Z.; Pang, S. Minimizing energy consumption in multi-objective two-sided disassembly line balancing problem with complex execution constraints using dual-individual simulated annealing algorithm. J. Clean. Prod. 2021, 284, 125418. [Google Scholar] [CrossRef]

- Hezer, S.; Kara, Y. A network-based shortest route model for parallel disassembly line balancing problem. Int. J. Prod. Res. 2015, 53, 1849–1865. [Google Scholar] [CrossRef]

- Zhu, L.; Zhang, Z.; Guan, C. Multi-objective partial parallel disassembly line balancing problem using hybrid group neighbourhood search algorithm. J. Manuf. Syst. 2020, 56, 252–269. [Google Scholar] [CrossRef]

- Lou, S.; Zhang, Y.; Tan, R.; Lv, C. A human-cyber-physical system enabled sequential disassembly planning approach for a human-robot collaboration cell in Industry 5.0. Robot.-Comput. Manuf. 2024, 87, 102706. [Google Scholar] [CrossRef]

- Chen, Q.; Yao, B.; Pham, D.T. Sequence-Dependent Robotic Disassembly Line Balancing Problem Considering Disassembly Path. In Proceedings of the International Manufacturing Science and Engineering Conference, Online, 3 September 2020; Volume 2. [Google Scholar] [CrossRef]

- Xu, P.; Zhang, Z.; Guan, C. Modeling and Hybrid Teaching Optimization Algorithm for Parallel Disassembly Line Balance Problem of Human-machine Co-station. In Computer Integrated Manufacturing Systems; Prentice-Hall, Inc.: Upper Saddle River, NJ, USA, 2022; pp. 1–17. [Google Scholar]

- Huang, J.; Pham, D.T.; R, L. An experimental human-robot collaborative disassembly cell. Comput. Ind. Eng. 2021, 155, 20. [Google Scholar] [CrossRef]

- Guo, X.; Zhang, Z.; Qi, L.; Liu, S.; Tang, Y.; Zhao, Z. Stochastic Hybrid Discrete Grey Wolf Optimizer for Multi-objective Disassembly Sequencing and Line Balancing Planning in Disassembling Multiple Products. IEEE Trans. Autom. Sci. Eng. 2021, 19, 1744–1756. [Google Scholar] [CrossRef]

- Zhao, Z.; Liu, S.; Zhou, M.; You, D.; Guo, X. Heuristic Scheduling of Batch Production Processes Based on Petri Nets and Iterated Greedy Algorithms. IEEE Trans. Autom. Sci. Eng. 2022, 19, 251–261. [Google Scholar] [CrossRef]

- Cui, X.; Luo, Q.; Zhou, Y.; Deng, W.; Yin, S. Quantum-Inspired Moth-Flame Optimizer With Enhanced Local Search Strategy for Cluster Analysis. IEEE/CAA J. Autom. Sin. 2022, 5, 794–806. [Google Scholar] [CrossRef] [PubMed]

- Özceylan, E.; Kalayci, C.B.; Güngör, A.; Gupta, S.M. Disassembly line balancing problem: A review of the state of the art and future directions. Int. J. Prod. Res. 2019, 57, 4805–4827. [Google Scholar] [CrossRef]

- Kim, H.J.; Xirouchakis, P. Capacitated disassembly scheduling with random demand. Int. J. Prod. Res. 2010, 48, 7177–7194. [Google Scholar] [CrossRef]

- Xu, W.; Cui, J.; Liu, B.; Liu, J.; Yao, B.; Zhou, Z. Human-robot collaborative disassembly line balancing considering the safe strategy in remanufacturing. J. Clean. Prod. 2021, 324, 129158. [Google Scholar] [CrossRef]

- Xiang, D.; Lin, S.; Wang, X.; Liu, G. Checking Missing-Data Errors in Cyber-Physical Systems Based on the Merged Process of Petri Nets. IEEE Trans. Ind. Inform. 2023, 19, 3047–3056. [Google Scholar] [CrossRef]

- Xiang, D.; Zhao, F.; Liu, Y. DICER 2.0: A New Model Checker for Data-Flow Errors of Concurrent Software Systems. Mathematics 2021, 9, 966. [Google Scholar] [CrossRef]

- Qi, L.; Su, Y.; Zhou, M.; Abusorrah, A. A State-Equation-Based Backward Approach to a Legal Firing Sequence Existence Problem in Petri Nets. IEEE Trans. Syst. Man Cybern. Syst. 2023, 53, 4968–4979. [Google Scholar] [CrossRef]

- Zhou, J.; Wang, J.; Wang, J. A simulation engine for stochastic timed Petri nets and application to emergency healthcare systems. IEEE/CAA J. Autom. Sin. 2019, 6, 969–980. [Google Scholar] [CrossRef]

- Wang, J.; Tepfenhart, W. Formal Methods in Computer Science; John Wiley & Sons: Hoboken, NJ, USA, 2019. [Google Scholar]

- Qin, G.; Guo, X.; Zhou, M.; Liu, S.; Qi, L. Multi-Objective Discrete Migratory Bird Optimizer for Stochastic Disassembly Line Balancing Problem. In Proceedings of the 2020 IEEE International Conference on Systems, Man, and Cybernetics (SMC), Toronto, ON, Canada, 11–14 October 2020; pp. 420–425. [Google Scholar] [CrossRef]

- Seyedali, M. Moth-flame optimization algorithm: A novel nature-inspired heuristic paradigm. Knowl.-Based Syst. 2015, 89, 228–249. [Google Scholar]

- Zhang, Y.; Wang, P.; Yang, H.; Cui, Q. Optimal dispatching of microgrid based on improved moth-flame optimization algorithm based on sine mapping and Gaussian mutation. Syst. Sci. Control Eng. 2022, 10, 115–125. [Google Scholar] [CrossRef]

- Nowakowski, P. A novel, cost efficient identification method for disassembly planning of waste electrical and electronic equipment. J. Clean. Prod. 2018, 172, 2695–2707. [Google Scholar] [CrossRef]

- Li, H.; Gao, K.; Duan, P.; Li, J.; Zhang, L. An Improved Artificial Bee Colony Algorithm With Q-Learning for Solving Permutation Flow-Shop Scheduling Problems. IEEE Trans. Syst. Man Cybern. Syst. 2023, 53, 2684–2693. [Google Scholar] [CrossRef]

- Fu, Y.; Ma, X.; Gao, K.; Li, Z.; Dong, H. Multi-Objective Home Health Care Routing and Scheduling With Sharing Service via a Problem-Specific Knowledge-Based Artificial Bee Colony Algorithm. IEEE Trans. Intell. Transp. Syst. 2024, 25, 1706–1719. [Google Scholar] [CrossRef]

- Fu, Y.; Ding, J.; Wang, H.; Wang, J. Two-objective stochastic flow-shop scheduling with deteriorating and learning effect in Industry 4.0-based manufacturing system. Appl. Soft Comput. 2018, 68, 847–855. [Google Scholar] [CrossRef]

- Shao, Z.; Pi, D.; Shao, W. Hybrid enhanced discrete fruit fly optimization algorithm for scheduling blocking flow-shop in distributed environment. Expert Syst. Appl. 2020, 145, 113147. [Google Scholar] [CrossRef]

- Dao, S.D.; Abhary, K.; Marian, R.M. Maximising Performance of Genetic Algorithm Solver in Matlab. Eng. Lett. 2016, 24, EL_24_1_11. [Google Scholar]

- Ong, K.M.; Ong, P.; Sia, C.K. A carnivorous plant algorithm for solving global optimization problems. Appl. Soft Comput. 2020, 33, 106833. [Google Scholar] [CrossRef]

| Type | Complex Subassemblies | Complex Tassk | Hazardous Subassemblies | Hazardous Tasks |

|---|---|---|---|---|

| Index | 3 | 2, 6, 9, 12 | 6 | 4, 7, 11 |

| Case Num | Instance | Num of Tasks | Num of Subassemblies |

|---|---|---|---|

| I | Refrigerator and washing machine | 35 | 40 |

| II | Washing machine and copy machine | 45 | 44 |

| III | Refrigerator and copy machine | 57 | 54 |

| IV | Two copy machines and washing machine | 52 | 59 |

| V | Two refrigerators and washing machine | 82 | 79 |

| VI | Two copy machines and refrigerator | 89 | 83 |

| Index | Type | Complex Subassemblies | Complex Task | Hazardous Subassemblies | Hazardous Task |

|---|---|---|---|---|---|

| Case | |||||

| Washing machine | 3 | 2, 6, 9, 12 | 6 | 4, 7, 11 | |

| Copy machine | 5, 6 | 1, 2, 17 | 26, 27 | 14, 22, 25, 27 | |

| Refrigerator | 12 | 9, 11 | 21 | 2, 7 | |

| Case Num | Disassembly Sequence | f | T |

|---|---|---|---|

| I | 1 → 4 → 8 → 12 → −14 | 836.2 | 4.84 s |

| II | 2 → 11 → −14 → 5 → −18 → 7 → 8 | 1306.3 | 4.798 s |

| III | 2 → 4 → −20 → 12 → −22 → −26 → 13 | 1467.9 | 5.513 s |

| IV | 2 → 5 → 8 → 9 → 11 → −25 → −33 → −35 → −44 | 1923.8 | 12.66 s |

| V | 1 → 3 → −20 → −21 → −25 → 13 → 12 | 1411.0 | 10.737 s |

| VI | – | – | 9000.00 s |

| Case Num | Disassembly Sequence | f | T |

|---|---|---|---|

| I | 1 → 4 → 8 → 12 → −14 | 836.2 | 2.865 s |

| II | 2 → 11 → −14 → 5 → −18 → 7 → 8 | 1306.3 | 2.679 s |

| III | 2 → 4 → −20 → 12 → −22 → −26 → 13 | 1467.9 | 5.782 s |

| IV | 2 → 5 → 8 → 9 → 11 → −25 → −33 → −35 → −44 | 1923.8 | 4.236 s |

| V | 1 → 3 → −20 → −21 → −25 → 13 → 12 | 1411.0 | 6.456 s |

| VI | 2 → −34 → −66 → 3 → 12 → −53 → −82 → 13 → −44 → −57 | 2450.3 | 5.836 s |

| Cases | Algorithm | Population Size | |||

|---|---|---|---|---|---|

| 300 | 400 | 500 | 600 | ||

| I | IMFO | 708.3 | 759.5 | 789.9 | 836.2 |

| DFOA | 667.2 | 735.0 | 765.9 | 789.9 | |

| EA | 688.6 | 733.0 | 746.7 | 759.5 | |

| CPA | 673.3 | 719.9 | 767.3 | 820.2 | |

| II | IMFO | 1617.9 | 1658.9 | 1687.6 | 1706.3 |

| DFOA | 1607.2 | 1622.9 | 1656.2 | 1688.9 | |

| EA | 1579.3 | 1600.3 | 1640.3 | 1669.7 | |

| CPA | 866.3 | 877.9 | 902.0 | 927.6 | |

| III | IMFO | 1184.5 | 1267.9 | 1308.2 | 1467.9 |

| DFOA | 1136.9 | 1195.4 | 1244.3 | 1288.6 | |

| EA | 1136.3 | 1344.2 | 1402.2 | 1447.8 | |

| CPA | 714.3 | 756.4 | 792.5 | 876.8 | |

| IV | IMFO | 1821.4 | 1871.6 | 1888.9 | 1923.8 |

| DFOA | 1809.5 | 1833.7 | 1853.0 | 1865.0 | |

| EA | 1827.3 | 1833.7 | 1855.4 | 1863.1 | |

| CPA | 1804.8 | 1810.5 | 1901.0 | 1916.4 | |

| V | IMFO | 1406.0 | 1408.0 | 1411.0 | 1411.0 |

| DFOA | 1399.0 | 1399.0 | 1400.0 | 1400.0 | |

| EA | 1402.3 | 1406.0 | 1410.1 | 1410.1 | |

| CPA | 1385.4 | 1388.0 | 1391.9 | 1392.3 | |

| VI | IMFO | 2434.9 | 2443.0 | 2450.3 | 2450.3 |

| DFOA | 2424.6 | 2427.3 | 2431.0 | 2432.3 | |

| EA | 2424.6 | 2417.3 | 2424.6 | 2441.0 | |

| CPA | 2426.3 | 2425.9 | 2433.7 | 2441.5 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Q.; Xu, B.; Yao, M.; Wang, J.; Guo, X.; Qin, S.; Qi, L.; Lu, F. An Improved Moth-Flame Algorithm for Human–Robot Collaborative Parallel Disassembly Line Balancing Problem. Mathematics 2024, 12, 816. https://doi.org/10.3390/math12060816

Zhang Q, Xu B, Yao M, Wang J, Guo X, Qin S, Qi L, Lu F. An Improved Moth-Flame Algorithm for Human–Robot Collaborative Parallel Disassembly Line Balancing Problem. Mathematics. 2024; 12(6):816. https://doi.org/10.3390/math12060816

Chicago/Turabian StyleZhang, Qi, Bin Xu, Man Yao, Jiacun Wang, Xiwang Guo, Shujin Qin, Liang Qi, and Fayang Lu. 2024. "An Improved Moth-Flame Algorithm for Human–Robot Collaborative Parallel Disassembly Line Balancing Problem" Mathematics 12, no. 6: 816. https://doi.org/10.3390/math12060816

APA StyleZhang, Q., Xu, B., Yao, M., Wang, J., Guo, X., Qin, S., Qi, L., & Lu, F. (2024). An Improved Moth-Flame Algorithm for Human–Robot Collaborative Parallel Disassembly Line Balancing Problem. Mathematics, 12(6), 816. https://doi.org/10.3390/math12060816