4.1.1. Design of Experimental and Road Environment

To validate the trafficability of the controlled vehicle, four experiments were designed to simulate off-road environments like steep slopes, slippery roads, slimy muddy roads and potholes.

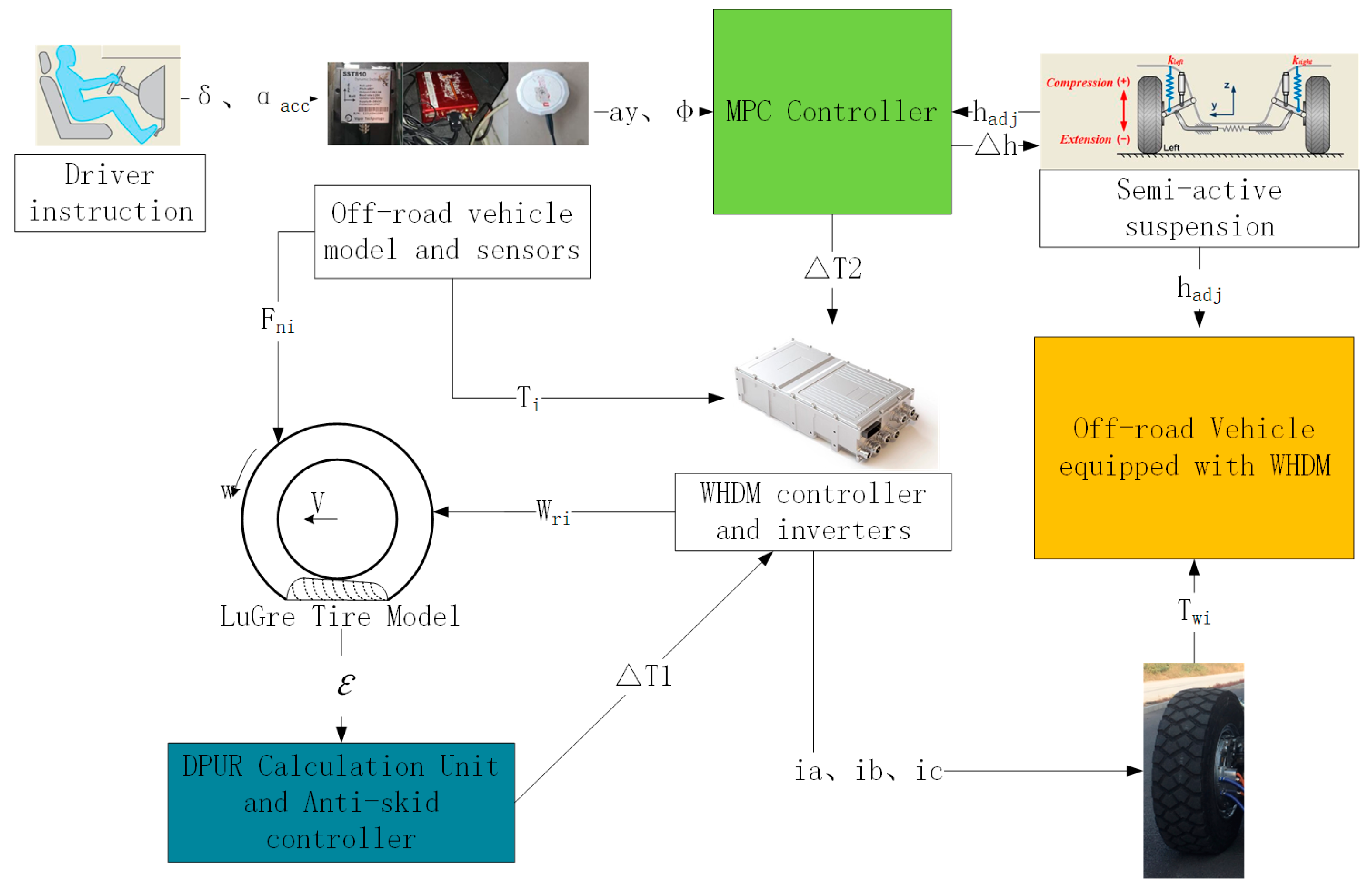

Figure 3 illustrates that a SST810 dynamic inclinometer with dynamic accuracy ±0.4% was fixed on the position of the static CG to measure the acceleration and inclination angle, and the data were optimized by a Kalman filter. The actual velocity and yaw angle were measured by a GPS.

In the first test, the vehicle climbed to the tops of the ramps at certain standard gradients (40% and 60%). Here, the two slopes’ lengths were greater than 20 m, and the change rates of the slopes conformed to the road design requirements from GB/T 12539-2018 [

37].

Figure 4 shows that the test scenarios and

of slopes were nearly equal to 0.8.

imposed on the front and rear axles are estimated in the VCU based on the 14 DOF vehicle model, and

was expected to remain unanimous by adjusting the desired current of each WHDM. The significance parameters of the tested off-road vehicle and the reference values of real-vehicle test conditions were shown in

Table 2 and

Table 3, respectively.

Continuous uphill cross-axis tests simulated bumpy roads or mountainous regions in which certain wheels may be easily vacated, while the other wheels would provide sufficient

to fit the wheel resistance changing frequently and greatly. To avoid crashing the chassis, the vertical heights of the test rods were limited by

. Thus, two standard twist lanes with different approach/departure angles and maximum vertical heights selected at the national automobile quality supervision and test center (NAST) were selected. Accordingly, the wavelength of these standard test roads was nearly 7 m, and the length of the straight section was 3 m. The test procedures obeyed GB/T 12541-2023 [

38].

In terms of the slippery roads or muddy roads where were different and were great, a four-wheel-drive system (4WD) was essential in ensuring that the four wheels output appropriately and avoid slipping. The designed ASC was expected to improve both and . As the metal surface that dripped water continuously was similar to a wet basalt surface, and since the concrete pavement possessed a high adhesion limit, three groups of experiments were designed:

- (1)

was small: Accelerate on the slippery road;

- (2)

was great: Accelerate from the cement road to the slippery road;

- (3)

differed greatly: Acceleration test where the left and right wheels were on the slippery and cement road, respectively.

Three control groups were set concluding ASC for a single wheel, ASC and open differential control (ODC) for coaxial wheels and only ODC for coaxial wheels in order to appraise the performance of ASC. The velocity and stability of the controlled vehicles served as evaluation indexes. Moreover, according to the test principle, a strategy was not available if the vehicle had instability or WHDM faults occurred. The pilot always remained the same, and the number of passengers was also fixed during the tests to maintain the identical driving habit and static position of the CG.

4.1.2. Analysis of Real-Vehicle Tests

To increase the ground area and the friction force in low- velocity off-road conditions, the tire pressure should be decreased. Considering the constraint of the tire load under different pressures as well as the front axle load is less than that of the rear axle, the range of pressure adjustment should be limited to 150 kPa. To this effect, the front and rear tire pressures were decreased from the normal pressure (520 kPa) to 380 kPa and 420 kPa, respectively.

First, according to GB/T12539-2018 [

37], the climbing experiment is designed to verify whether

can be effectively constrained by ASC intervention when the CG moves significantly backward, in which the driver should control

close to stability and not more than 10 km/h during the test.

Figure 5 shows test results of the climbing experiment with a standard gradient of 60%. The vibration in the output signal is due to the fact that the data shown are the original data that were not filtered during the test in order to reflect the true state of the vehicle. As shown in

Figure 4b and

Figure 5b, in the two climbing tests with design slopes I1 and I2, the ratio

gradually decreases from 0.944 to 0.623 and 0.54. In addition, the ratio

is approximately 1 due to the small side slope and the lateral deviation of CG, and Vx is manually controlled in the range of 5–10 km/h. Based on the real-time calculation of (

), the current adjustment of WHDMs makes the speed difference between the four wheels very small, as shown in

Figure 4c and

Figure 5c.

Table 4 and

Figure 4d and

Figure 5d show that the peak slip rate

of each wheel is less than 20%, indicating that the ASC intervention can achieve coordinated optimization of the four-wheel attachment and high margin of stability of the results of the four-wheel, similar to the simulation test, and finally reach the performance index of passing a ramp of 60% at low speed.

Figure 6a and

Figure 7a demonstrate that

,

and

were within controllable ranges, however,

and

were great when

rapidly fluctuating during the cross-axis experiments. Hence, the presence of mutations on

was judged. Benefiting from large inertia and long suspension travel, the suspension system effectively conducted

to the four tires and

was enough to overcome road resistance during the first cross-axis test, thus, as shown in

Figure 6c,

is equal to 1, indicating that there is no divergence trend in the speed difference, the slip rate of each wheel.

Figure 6b illustrates several

rises (

) that occur within the first ten seconds of passing the first set of roadblocks, after which Twi remains near the minimum creep moment (150 Nm) and the vehicle passes the remaining roadblocks smoothly through inertia. As shown in

Figure 7c, when the maximum vertical height increases to

, the spring in the diagonal position is easily stretched to its limit and the corresponding

drops sharply. Since the rear of the vehicle is heavier, the CG is easily shifted to the right rear wheel or left rear wheel, so

is greater than

and the front wheel overspeed is more pronounced. The LuGre tire model detects a rapid decrease in

and

mutations to enhance

, or a rapid increase in response to driving intention, which is reflected in

Figure 7d as an alternating sudden decrease in

for both sets of diagonal wheel adhesion utilization.

Figure 7b shows that based on the transient rise or fall of

and the accurate estimation of the attachment limit of each wheel, the attachment utilization of the driving wheels can be optimized to overcome the large driving resistance, and the convergence rate of the vacated wheel slip rate is increased, which plays a role in reducing the transmission loss, and finally the performance index of continuously passing 12 large twisting roadblocks at low speed is achieved.

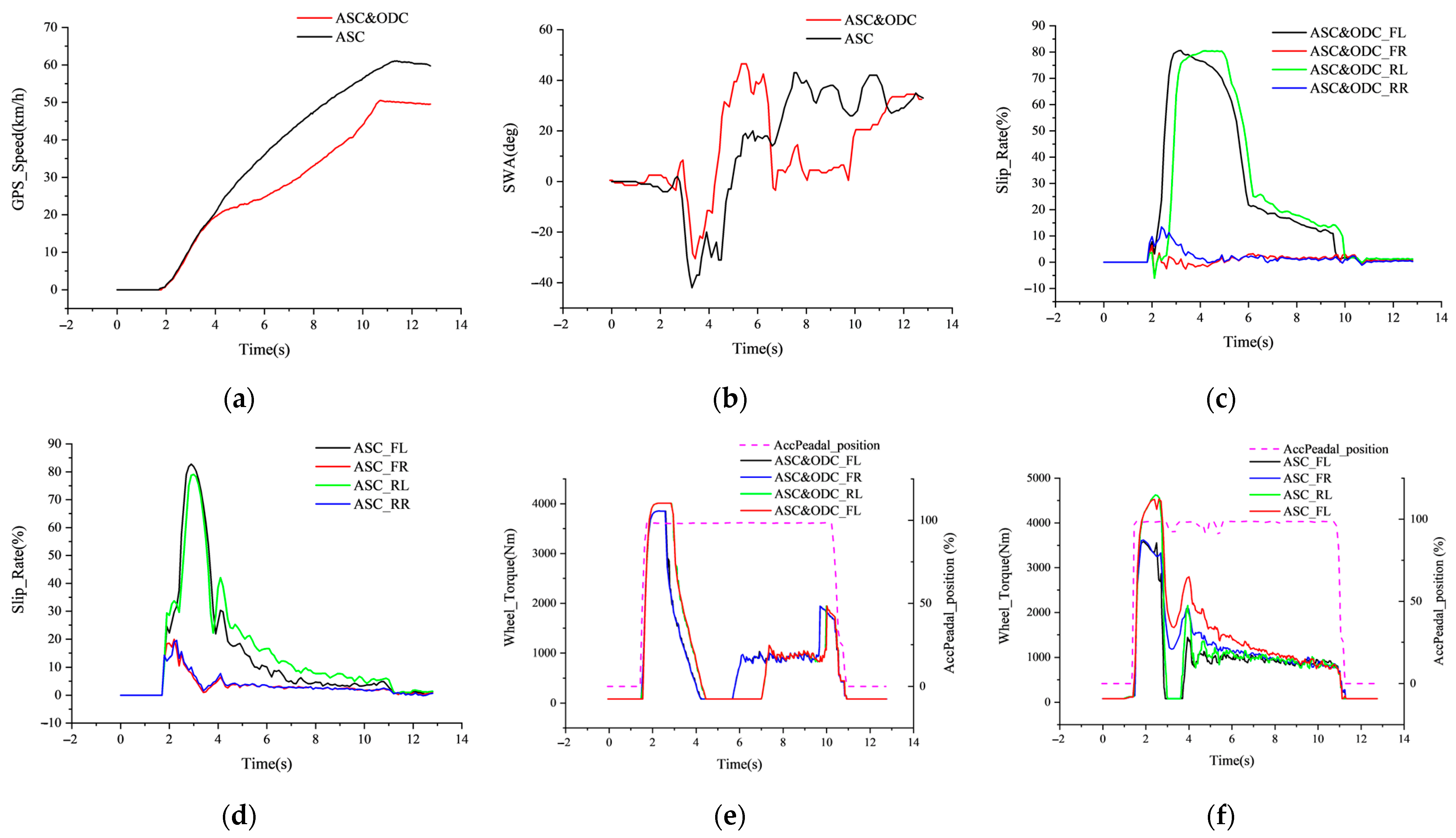

The first acceleration test simulated all four wheels being on a muddy or slippery road, so that all four wheels were all ready for overspeed.

Figure 8d shows that

cannot be effectively suppressed under the ODC of differential speed without differential torque of the coaxial wheels, and the nonlinear decrease in the longitudinal force of the low attached wheels generates additional transverse sway moments that deteriorate the handling stability, as shown in

Figure 8b, and the driver needs to apply a larger steering wheel turning angle to correct the driving trajectory; in addition, the front wheel attachment limit further decreases due to the backward shift of the droop load, making

and

in

Figure 8f triggered the overspeed protection at 3.6 s and no more torque was output, and the same failure occurred at 9.1 s for

and

. In contrast,

Figure 8e shows that SOSMC designed in this paper is enabled at the 3.4 s and the feedforward link actively suppresses the maximum output torque T

wmax after capturing the drop in the attachment limit of each wheel, so that the four-wheel slip rate in

Figure 8c drops to within 20% simultaneously in approximately 3.6 s, after which the vehicle continues to accelerate steadily. The comparison results in

Table 5 show that the average vehicle acceleration is optimized by 150% and the steering wheel correction operation is relatively mild, achieving a coordinated optimization of power and stability.

When

is large, or when only one wheel has sufficient traction,

should be assigned more to the wheel with the larger

, but the additional

caused by

should be evaluated, anticipating that the ODC can partially optimize stability. In this test, vehicle stability and trafficability were compared by ASC and ASC & ODC interventions, and the need for ODC was evaluated using the comparison.

Figure 9c,e show that under the control of ASC AND ODC, the left-side wheel moments

and

drop rapidly to within 100 Nm in 2.8 and 3 s, respectively, and correspondingly, the left-side wheel slip rates

and

drop from 80% to 20% in 1.5 s, and

and

rise rapidly and optimize acceleration after the slip rates converge, while The feedforward link limits the peak driving torque of the left low attached wheel to within 2000 Nm to avoid another longitudinal instability; in addition, the sudden increase in the left motor speed increases the power loss, which makes the right wheel torque

and

also decrease. Under the effect of ODC,

and

in

Figure 9d gradually converge to the stability domain 4 s after the test starts, and the heteroside wheel torque difference is always zero, as shown in

Figure 9f, which lowers the utilization of high attached wheel adhesion on the right and the average vehicle acceleration decreases by 23% compared to the ASC AND ODC control group. In terms of lateral stability, as shown in

Figure 9b, although the driver was forced to correct the driving trajectory due to the large transverse sway motion in the first part of acceleration, the real-time differential torque control of each wheel through ASC AND ODC improved the stability margin of each wheel in time and effectively avoided the loss of steering control caused by the nonlinear decrease in wheel lateral deflection stiffness. The comparison results in

Table 6 show that the deviation between the steering wheel angles in the two sets of tests is less than 10% and the peak value does not exceed 47 deg, indicating that the additional transverse moment is small and always within the controllable range.

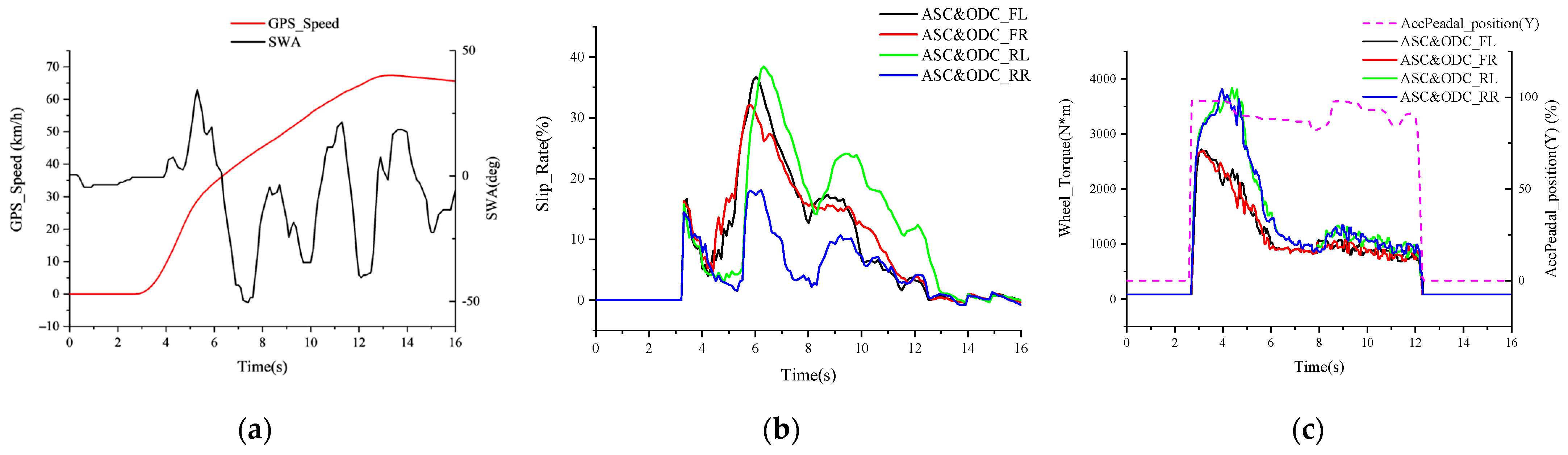

The docking road acceleration test can further verify the robustness of the ASC AND ODC distribution strategy in the face of transient perturbations. As shown in

Figure 10b,c, with the rapid increase in wheel-end drive torque, the slip rate

reaches 16% at 3.5 s and does not disperse significantly due to the high adhesion limit, while the front and rear wheels enter the low-adhesion road at 4.5 and 5.6 s, respectively, and their slip rate rises abruptly afterwards, and the estimated adhesion coefficients of the front and rear wheels decrease rapidly, and the maximum output torque of a single wheel is limited actively in the feedforward link

and the combined effect of longitudinal stability feedback control, the front and rear wheel slip rates start to converge at 5.5 and 6 s, respectively, and the response delay of ASC AND ODC is less than 0.5 s; after 6 s, ASC AND ODC takes the optimization goal of improving the adhesion utilization rate of each wheel, so that

, and carries out a continuous and stable approximate uniform acceleration motion as shown in

Figure 10a, as in

Table 7 exceeds 0.2 g, considering that the road adhesion coefficient is in the range [0.2, 0.25], indicating that the average drive power utilization exceeds 80% and max does not exceed 50 deg, achieving a coordinated optimization of dynamics and longitudinal and transverse stability.

According to the above analysis, and can be updated by the vehicle dynamic model and the LuGre tire model, respectively, in VCU. Therefore, the utilization of can be maintained as consistently as possible, and ASC can suppress with a slight lag. However, the ODC was found to be indispensable in ensuring lateral stability, and can be forced to be reduced if abruptly changes with a great .