Motion Synchronization Control for a Large Civil Aircraft’s Hybrid Actuation System Using Fuzzy Logic-Based Control Techniques

Abstract

1. Introduction

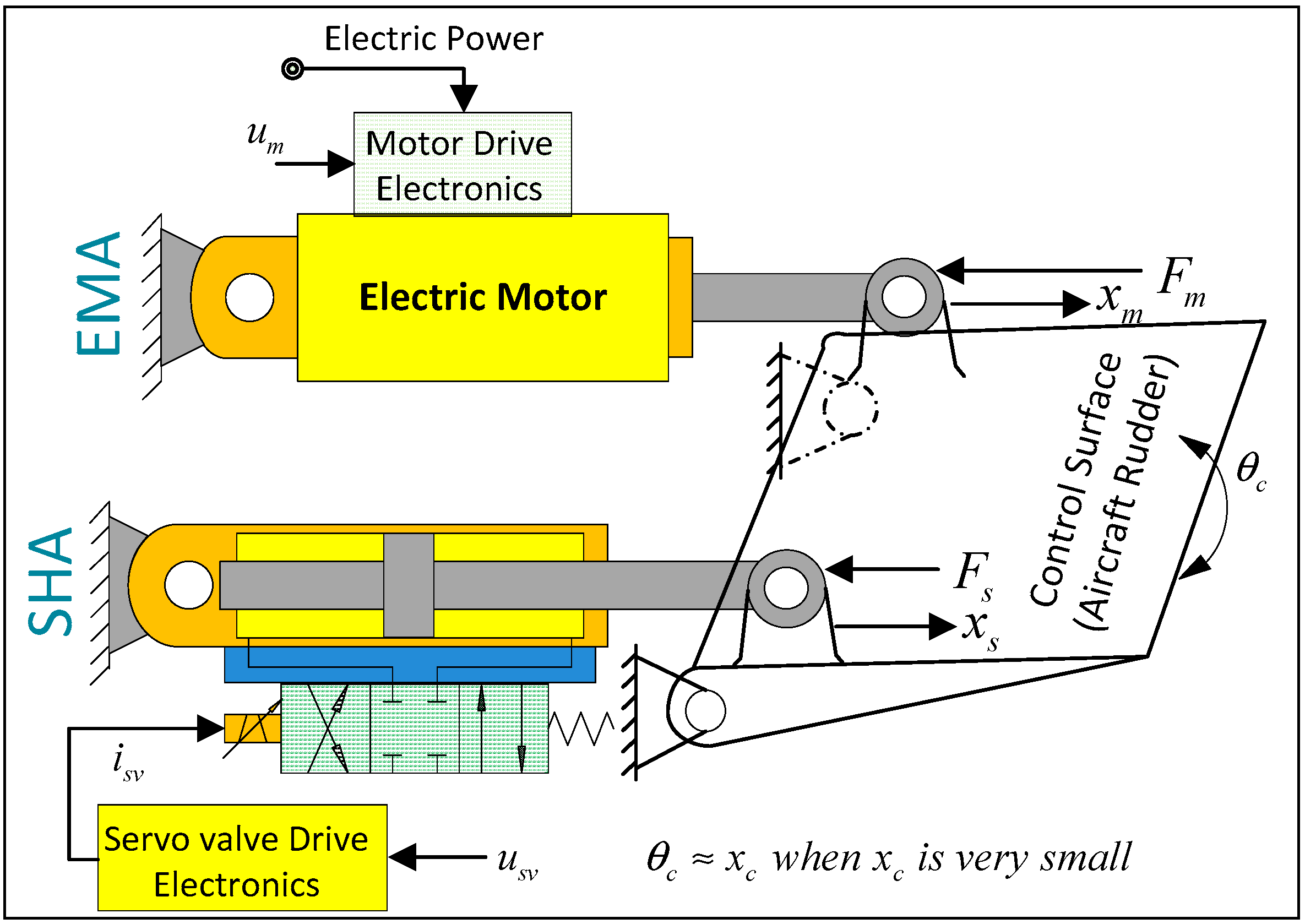

2. Problem Description

3. Mathematical Model of Hybrid Actuation System (HAS)

3.1. Modelling of Aircraft’s Control Surface

3.2. Mathematical Model of SHA

3.3. Mathematical Model of EMA

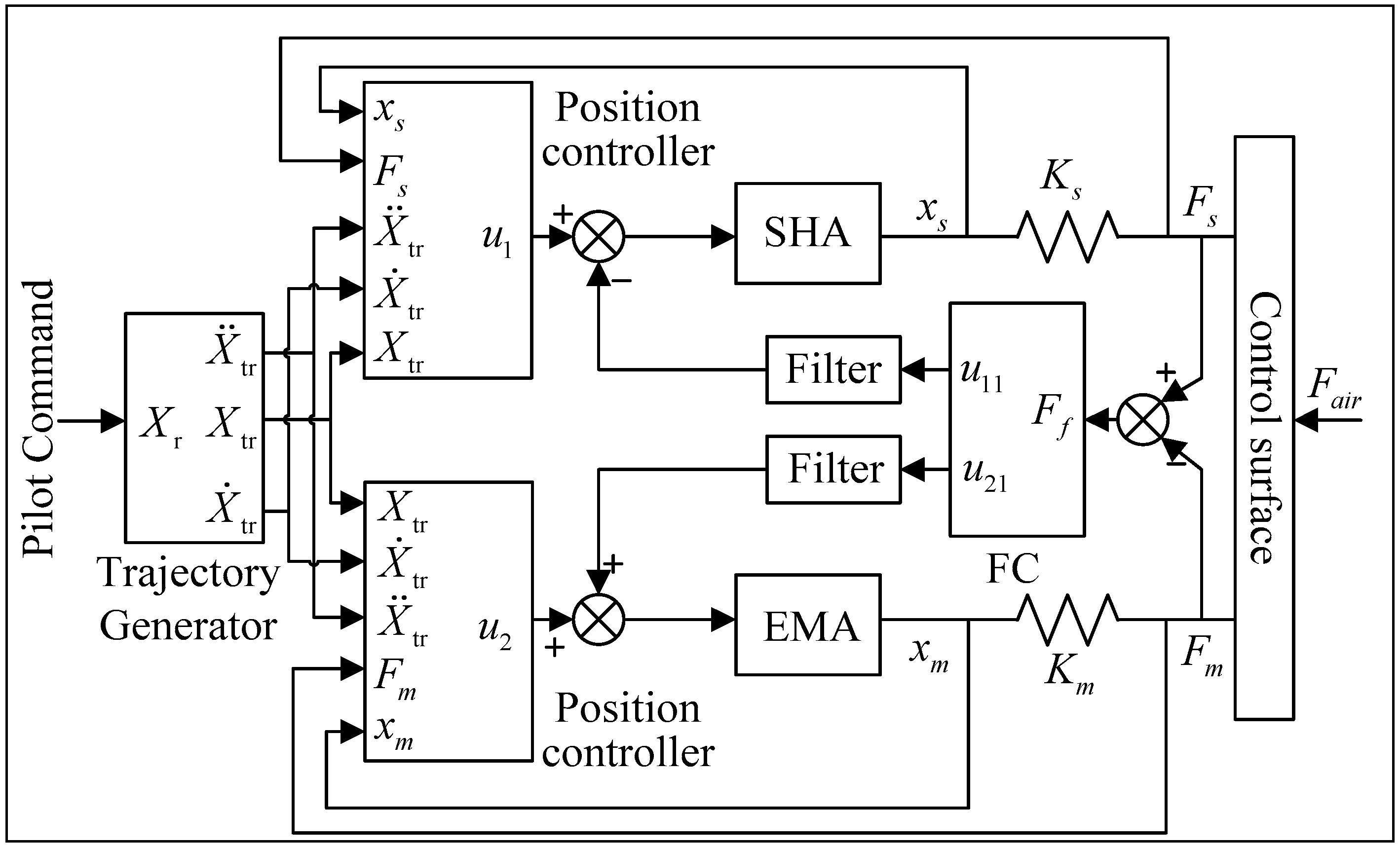

4. Nested-Loop Intelligent Control Strategy

4.1. Trajectory Generator

- = Reference natural frequency

- = Reference damping factor

- = Reference input signal

4.2. Position Controller

4.3. Force Controller

5. Result and Discussion

5.1. Results with Step Signal as Input Command

5.2. Results with Dynamic Signal as Input Command

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Benchaita, H.; Ladaci, S. Fractional adaptive SMC fault tolerant control against actuator failures for wing rock supervision. Aerosp. Sci. Technol. 2021, 114, 106745. [Google Scholar] [CrossRef]

- Ynineb, A.R.; Ladaci, S. MRAC adaptive control design for an F15 aircraft pitch angular motion using Dynamics Inversion and fractional-order filtering. Int. J. Robot. Control Syst. 2022, 2, 240–252. [Google Scholar] [CrossRef]

- Karpenko, M. Landing gear failures connected with high-pressure hoses and analysis of trends in aircraft technical problems. Aviation 2022, 26, 145–152. [Google Scholar] [CrossRef]

- Haitao, Q.; Yongling, F.; Xiaoye, Q.; Yan, L. Architecture optimization of more electric aircraft actuation system. Chin. J. Aeronaut. 2011, 24, 506–513. [Google Scholar]

- Goupil, P. AIRBUS state of the art and practices on FDI and FTC in flight control system. Control Eng. Pract. 2011, 19, 524–539. [Google Scholar] [CrossRef]

- Van Den Bossche, D. The A380 flight control electrohydrostatic actuators, achievements and lessons learnt. In Proceedings of the 25th International Congress of the Aeronautical Sciences, Hamburg, Germany, 3–8 September 2006; pp. 1–8. [Google Scholar]

- Shi, C.; Wang, X.; Wang, S.; Wang, J.; Tomovic, M.M. Adaptive decoupling synchronous control of dissimilar redundant actuation system for large civil aircraft. Aerosp. Sci. Technol. 2015, 47, 114–124. [Google Scholar] [CrossRef]

- Cochoy, O.; Hanke, S.; Carl, U.B. Concepts for position and load control for hybrid actuation in primary flight controls. Aerosp. Sci. Technol. 2007, 11, 194–201. [Google Scholar] [CrossRef]

- Fu, J.; Maré, J.-C.; Fu, Y. Modelling and simulation of flight control electromechanical actuators with special focus on model architecting, multidisciplinary effects and power flows. Chin. J. Aeronaut. 2017, 30, 47–65. [Google Scholar] [CrossRef]

- Cochoy, O.; Carl, U.B.; Thielecke, F. Integration and control of electromechanical and electrohydraulic actuators in a hybrid primary flight control architecture. In Proceedings of the International Conference on Recent Advances in Aerospace Actuation Systems and Components, Insa Toulouse, France, 13–15 June 2007; pp. 1–8. [Google Scholar]

- Emadi, K.; Ehsani, M. Aircraft power systems: Technology, state of the art, and future trends. IEEE Aerosp. Electron. Syst. Mag. 2000, 15, 28–32. [Google Scholar] [CrossRef]

- Naayagi, R. A review of more electric aircraft technology. In Proceedings of the 2013 International Conference on Energy Efficient Technologies for Sustainability, Nagercoil, India, 10–12 April 2013; pp. 750–753. [Google Scholar]

- Rosero, J.; Ortega, J.; Aldabas, E.; Romeral, L. Moving towards a more electric aircraft. IEEE Aerosp. Electron. Syst. Mag. 2007, 22, 3–9. [Google Scholar] [CrossRef]

- Wang, L.; Mare, J.-C. A force equalization controller for active/active redundant actuation system involving servo-hydraulic and electro-mechanical technologies. Proc. Inst. Mech. Eng. Part G J. Aerosp. Eng. 2014, 228, 1768–1787. [Google Scholar] [CrossRef]

- Salman, I.; Lin, Y.; Hamayun, M.T. Fractional order modeling and control of dissimilar redundant actuating system used in large passenger aircraft. Chin. J. Aeronaut. 2018, 31, 1141–1152. [Google Scholar]

- Ijaz, S.; Yan, L.; Hamayun, M.T.; Shi, C. Active fault tolerant control scheme for aircraft with dissimilar redundant actuation system subject to hydraulic failure. J. Frankl. Inst. 2019, 356, 1302–1332. [Google Scholar] [CrossRef]

- Ijaz, S.; Hamayun, M.T.; Yan, L.; Ijaz, H.; Shi, C. Adaptive fault tolerant control of dissimilar redundant actuation system of civil aircraft based on integral sliding mode control strategy. Trans. Inst. Meas. Control 2019, 41, 3756–3768. [Google Scholar] [CrossRef]

- Ijaz, S.; Hamayun, M.T.; Anwaar, H.; Yan, L.; Li, M.K. LPV modeling and tracking control of dissimilar redundant actuation system for civil aircraft. Int. J. Control Autom. Syst. 2019, 17, 705–715. [Google Scholar] [CrossRef]

- Ijaz, S.; Yan, L.; Hamayun, M.T.; Baig, W.M.; Shi, C. An adaptive LPV integral sliding mode FTC of dissimilar redundant actuation system for civil aircraft. IEEE Access 2018, 6, 65960–65973. [Google Scholar] [CrossRef]

- Cieplok, G.; Wójcik, K. Conditions for self-synchronization of inertial vibrators of vibratory conveyors in general motion. J. Theor. Appl. Mech. 2020, 58, 513–524. [Google Scholar] [CrossRef]

- Fang, P.; Zou, M.; Peng, H.; Du, M.; Hu, G.; Hou, Y. Spatial synchronization of unbalanced rotors excited with paralleled and counterrotating motors in a far resonance system. J. Theor. Appl. Mech. 2019, 57, 723–738. [Google Scholar] [CrossRef]

- Jacazio, G.; Gastaldi, L. Equalization techniques for dual redundant electro hydraulic servo actuators for flight control systems. Fluid Power Motion Control 2008, 2008, 543–557. [Google Scholar]

- Qi, H.; Mare, J.-C.; Fu, Y. Force equalization in hybrid actuation systems. In Proceedings of the 7th International Conference on Fluid Power Transmission and Control, Hangzhou, China, 7–10 April 2009; pp. 342–347. [Google Scholar]

- Rehman, W.U.; Wang, S.; Wang, X.; Fan, L.; Shah, K.A. Motion synchronization in a dual redundant HA/EHA system by using a hybrid integrated intelligent control design. Chin. J. Aeronaut. 2016, 29, 789–798. [Google Scholar] [CrossRef]

- Waheed, U.R.; Wang, S.; Wang, X.; Kamran, A. A position synchronization control for HA/EHA system. In Proceedings of the 2015 International Conference on Fluid Power and Mechatronics (FPM), Harbin, China, 5–7 August 2015; pp. 473–482. [Google Scholar]

- Rehman, W.U.; Nawaz, H.; Wang, S.; Wang, X.; Luo, Y.; Yun, X.; Iqbal, M.N.; Zaheer, M.A.; Azhar, I.; Elahi, H. Trajectory based motion synchronization in a dissimilar redundant actuation system for a large civil aircraft. In Proceedings of the 2017 29th Chinese Control and Decision Conference (CCDC), Chongqing, China, 28–30 May 2017; pp. 5010–5015. [Google Scholar]

- Rehman, W.U.; Wang, X.; Wang, S.; Azhar, I. Motion synchronization of HA/EHA system for a large civil aircraft by using adaptive control. In Proceedings of the 2016 IEEE Chinese Guidance, Navigation and Control Conference (CGNCC), Nanjing, China, 12–14 August 2016; pp. 1486–1491. [Google Scholar]

- Rehman, W.U.; Wang, S.; Wang, X.; Shi, C.; Zhang, C.; Tomovic, M. Adaptive control for motion synchronization of HA/EHA system by using modified MIT rule. In Proceedings of the 2016 IEEE 11th Conference on Industrial Electronics and Applications (ICIEA), Hefei, China, 5–7 June 2016; pp. 2196–2201. [Google Scholar]

- Wang, X.; Liao, R.; Shi, C.; Wang, S. Linear extended state observer-based motion synchronization control for hybrid actuation system of more electric aircraft. Sensors 2017, 17, 2444. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Shi, C.; Wang, S. Extended state observer-based motion synchronisation control for hybrid actuation system of large civil aircraft. Int. J. Syst. Sci. 2017, 48, 2212–2222. [Google Scholar] [CrossRef]

- Ur Rehman, W.; Wang, X.; Cheng, Y.; Chai, H.; Hameed, Z.; Wang, X.; Saleem, F.; Lodhi, E. Motion synchronization for the SHA/EMA hybrid actuation system by using an optimization algorithm. Automatika 2021, 62, 503–512. [Google Scholar] [CrossRef]

- Guo, L.L.; Yu, L.M.; Lu, Y.; Fan, D.L. Multi-mode switching control for HSA/EHA hybrid actuation system. In Applied Mechanics and Materials; Trans Tech Publications Ltd.: Bäch, Switzerland, 2014; pp. 1088–1093. [Google Scholar]

- Rehman, W.U.; Khan, W.; Ullah, N.; Chowdhury, M.S.; Techato, K.; Haneef, M. Nonlinear Control of Hydrostatic Thrust Bearing Using Multivariable Optimization. Mathematics 2021, 9, 903. [Google Scholar] [CrossRef]

- Rehman, W.U.; Wang, X.; Cheng, Y.; Chen, Y.; Shahzad, H.; Chai, H.; Abbas, K.; Ullah, Z.; Kanwal, M. Model-based design approach to improve performance characteristics of hydrostatic bearing using multivariable optimization. Mathematics 2021, 9, 388. [Google Scholar] [CrossRef]

- Wang, S.; Tomovic, M.; Liu, H. Commercial Aircraft Hydraulic Systems: Shanghai Jiao Tong University Press Aerospace Series; Academic Press: Cambridge, MA, USA, 2015. [Google Scholar]

- Wang, X.; Wang, S. Adaptive fuzzy robust control of PMSM with smooth inverse based dead-zone compensation. Int. J. Control Autom. Syst. 2016, 14, 378–388. [Google Scholar] [CrossRef]

- Wang, L.; Maré, J.-C.; Fu, Y. Investigation in the dynamic force equalization of dissimilar redundant actuation systems operating in active/active mode. In Proceedings of the 28th International Congress of the Aeronautical Sciences ICAS 2012, Brisbane, Australia, 23–28 September 2012; p. session-6.8.1. [Google Scholar]

- Wang, L.; Mare, J.-C.; Fu, Y.; Qi, H. Force equalization for redundant active/active position control system involving dissimilar technology actuators. In Proceedings of the 8th JFPS International Symposium on Fluid Power, Okinawa, Japan, 25–26 October 2011; pp. 136–143. [Google Scholar]

- Elias, N.; Yahya, N. Simulation study for controlling direct current motor position utilising fuzzy logic controller. Int. J. Automot. Mech. Eng. 2018, 15, 5989–6000. [Google Scholar] [CrossRef]

- Liu, X.; Wang, Y.; Wang, M. Speed Fluctuation Suppression Strategy of Servo System with Flexible Load Based on Pole Assignment Fuzzy Adaptive PID. Mathematics 2022, 10, 3962. [Google Scholar] [CrossRef]

- Yin, H.; Yi, W.; Wu, J.; Wang, K.; Guan, J. Adaptive Fuzzy Neural Network PID Algorithm for BLDCM Speed Control System. Mathematics 2021, 10, 118. [Google Scholar] [CrossRef]

| Parameters in Membership Function | Membership Function | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| NB | NS | ZE | PS | PB | NB | NS | ZE | PS | PB | S | MS | M | MB | B | |

| ar | −15 | −10 | −5 | 0 | 5 | −75 | −50 | −25 | 0 | 25 | 0.1 | 0.15 | 0.30 | 0.5 | 0.7 |

| br | −10 | −5 | 0 | 5 | 10 | −50 | −25 | 0 | 25 | 50 | 0.15 | 0.3 | 0.5 | 0.7 | 1 |

| cr | −5 | 0 | 5 | 10 | 15 | −25 | 0 | 25 | 50 | 75 | 0.3 | 0.5 | 0.7 | 1 | 1.15 |

| Parameters in Membership Function | Membership Function | |||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| NB | NS | ZE | PS | PB | NB | NS | ZE | PS | PB | S | MS | M | MB | B | S | MS | M | MB | B | |

| ar | −100 | −10 | −5 | 0 | 5 | −100 | −8 | −4 | 0 | 4 | 0.1 | 0.15 | 0.3 | 0.5 | 0.7 | 0.87 | 0.90 | 0.92 | 0.95 | 0.97 |

| br | −10 | −5 | 0 | 5 | 10 | −8 | −4 | 0 | 4 | 8 | 0.15 | 0.3 | 0.5 | 0.7 | 1 | 0.90 | 0.92 | 0.95 | 0.97 | 1 |

| cr | −5 | 0 | 5 | 10 | 100 | −4 | 0 | 4 | 8 | 100 | 0.3 | 0.5 | 0.7 | 1 | 1.15 | 0.92 | 0.95 | 0.97 | 1 | 1.15 |

| SHA/EMA Parts | Parameters | Values | Units | ||

|---|---|---|---|---|---|

| Servo-hydraulic Actuator (SHA) | Gain Coefficient | ||||

| Flow /opening gain | |||||

| Flow / pressure gain | |||||

| Area of Piston | |||||

| Cylinder chamber volume | |||||

| Mass of piston including chamber | |||||

| Damping constant | |||||

| Bulk modulus constant | |||||

| Coefficient of Leakage | |||||

| Electro-mechanical Actuator (EMA) | Bake emf constant | ||||

| Armature Inductance | |||||

| Armature resistance | |||||

| Electro-magnetic coefficient | |||||

| Total inertia of rotating parts | |||||

| Damping coefficient | |||||

| Transmission coefficient | |||||

| Transmission efficiency | |||||

| Control Surface | Connection stiffness | SHA | |||

| EMA | |||||

| Radial distance for control surface | |||||

| Moment of inertia for control surface | |||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ur Rehman, W.; Wang, X.; Hameed, Z.; Gul, M.Y. Motion Synchronization Control for a Large Civil Aircraft’s Hybrid Actuation System Using Fuzzy Logic-Based Control Techniques. Mathematics 2023, 11, 1576. https://doi.org/10.3390/math11071576

Ur Rehman W, Wang X, Hameed Z, Gul MY. Motion Synchronization Control for a Large Civil Aircraft’s Hybrid Actuation System Using Fuzzy Logic-Based Control Techniques. Mathematics. 2023; 11(7):1576. https://doi.org/10.3390/math11071576

Chicago/Turabian StyleUr Rehman, Waheed, Xingjian Wang, Zeeshan Hameed, and Muhammad Yasir Gul. 2023. "Motion Synchronization Control for a Large Civil Aircraft’s Hybrid Actuation System Using Fuzzy Logic-Based Control Techniques" Mathematics 11, no. 7: 1576. https://doi.org/10.3390/math11071576

APA StyleUr Rehman, W., Wang, X., Hameed, Z., & Gul, M. Y. (2023). Motion Synchronization Control for a Large Civil Aircraft’s Hybrid Actuation System Using Fuzzy Logic-Based Control Techniques. Mathematics, 11(7), 1576. https://doi.org/10.3390/math11071576