Investigation of the Effect of the Voltage Drop and Cable Length on the Success of Starting the Line-Start Permanent Magnet Motor in the Drive of a Centrifugal Pump Unit

Abstract

1. Introduction

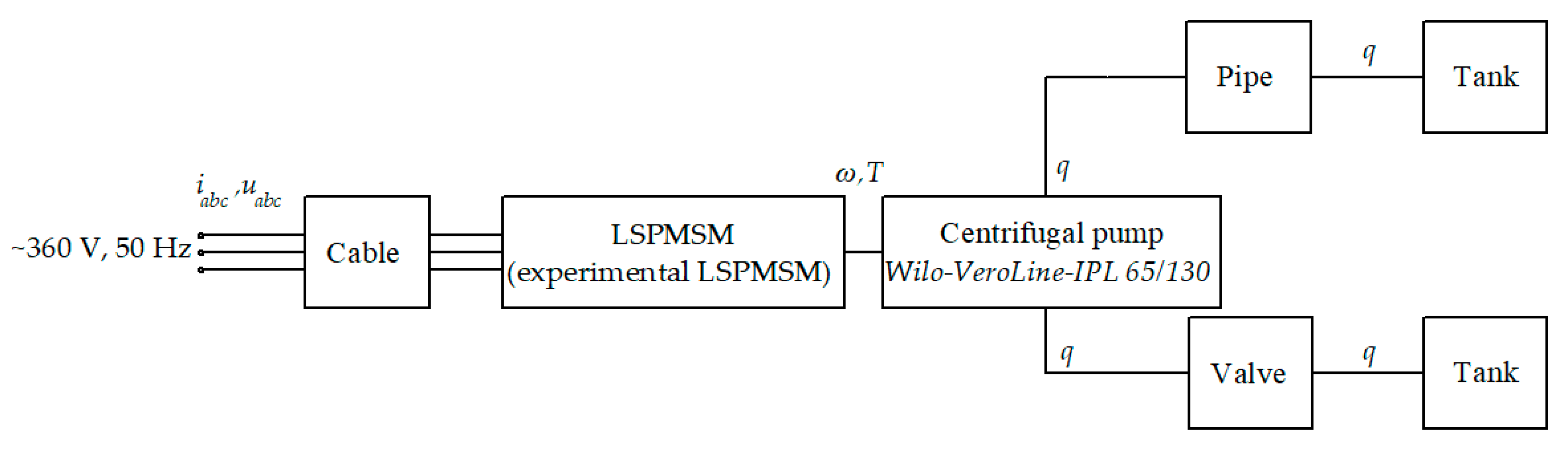

2. Problem Statement

- The fluid is incompressible;

- Only one pump unit operates in the pipeline;

- All hydraulic resistances (such as couplings, filters, etc.), except for the valve resistance, are reduced to one hydraulic diameter and to one pipeline;

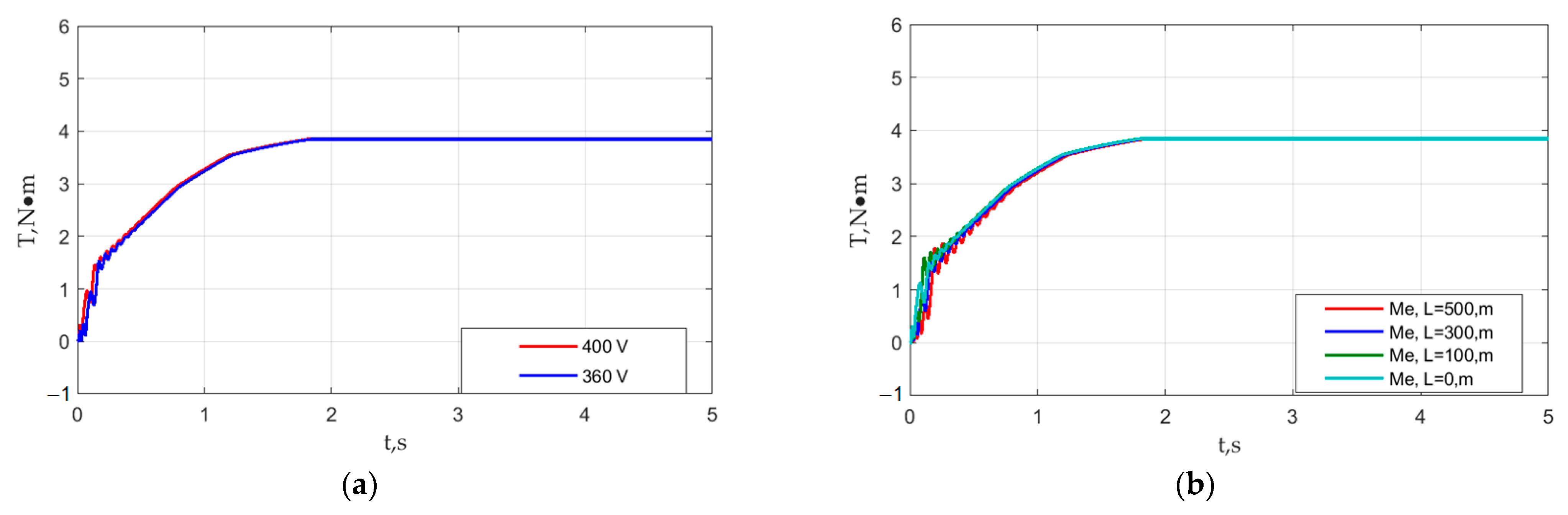

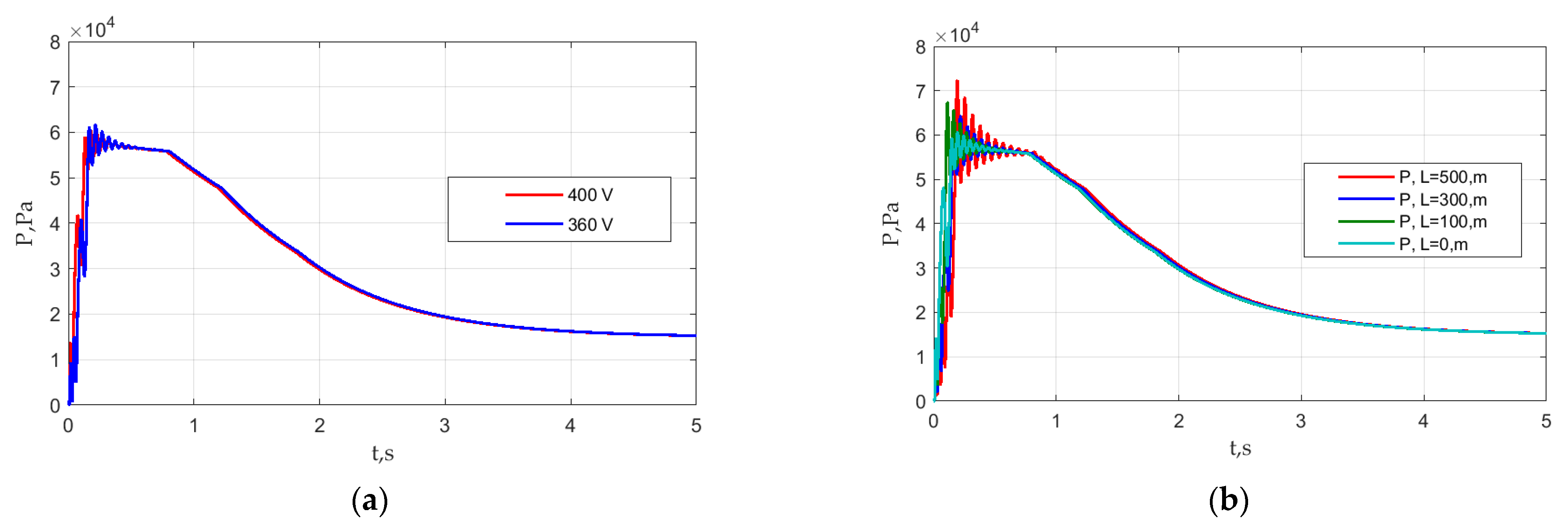

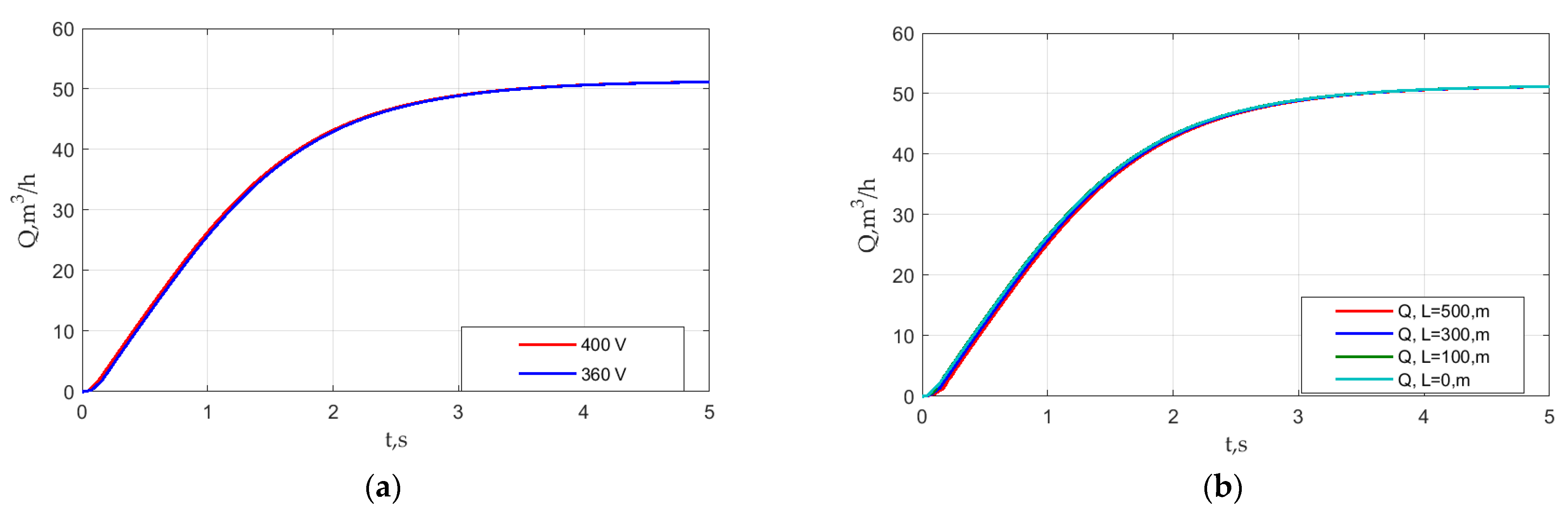

- There are no leaks in the hydraulic system.

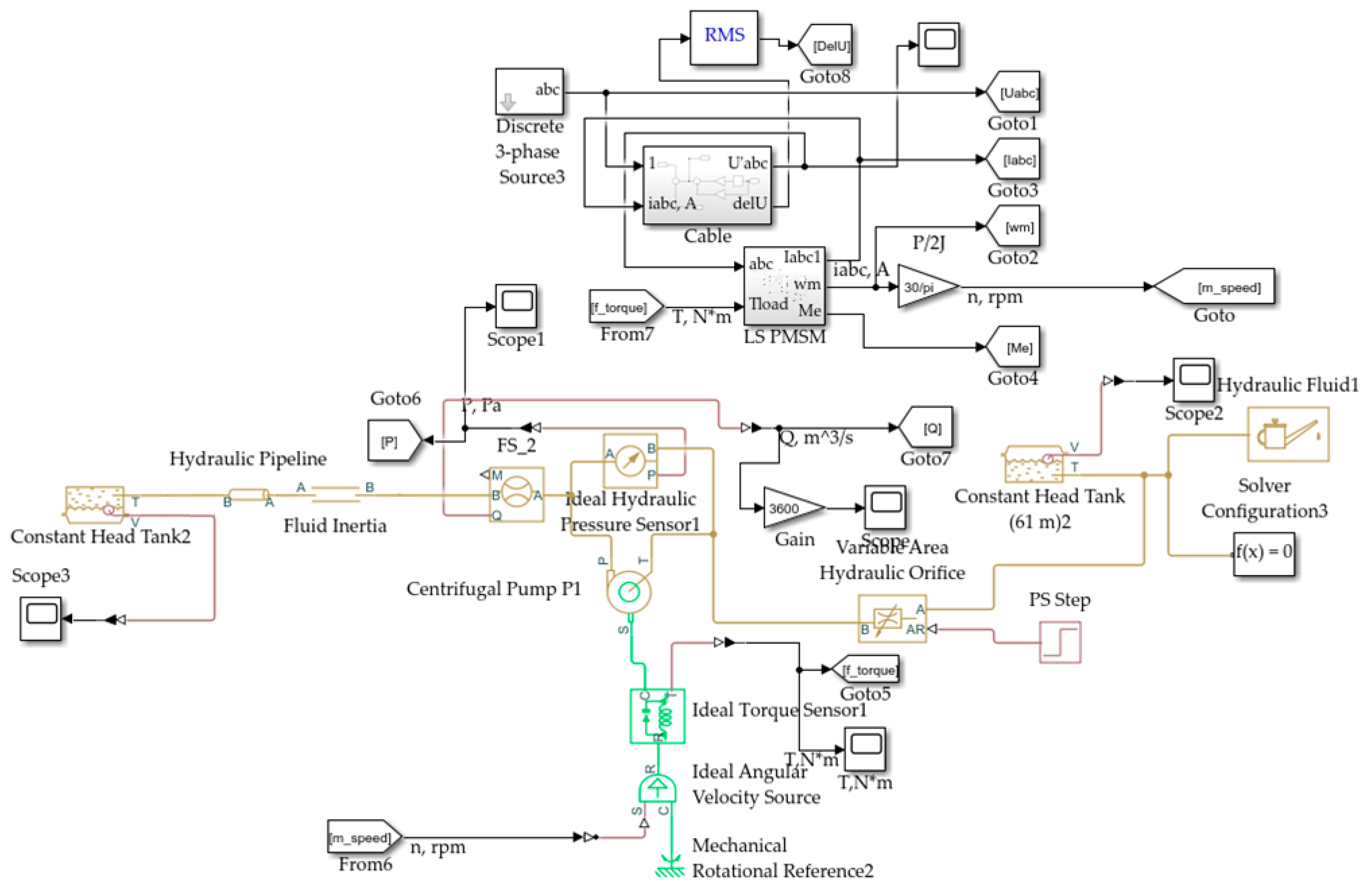

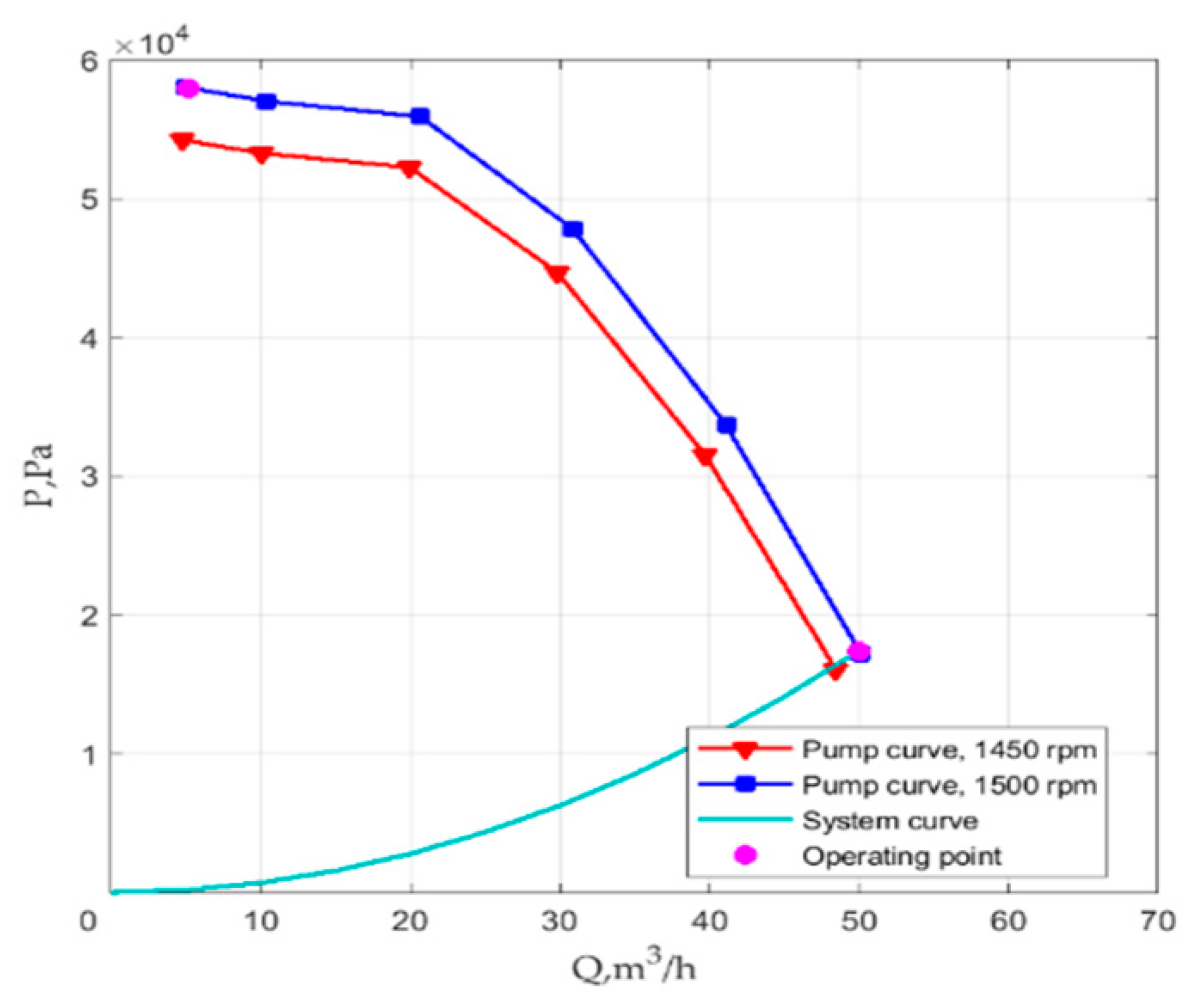

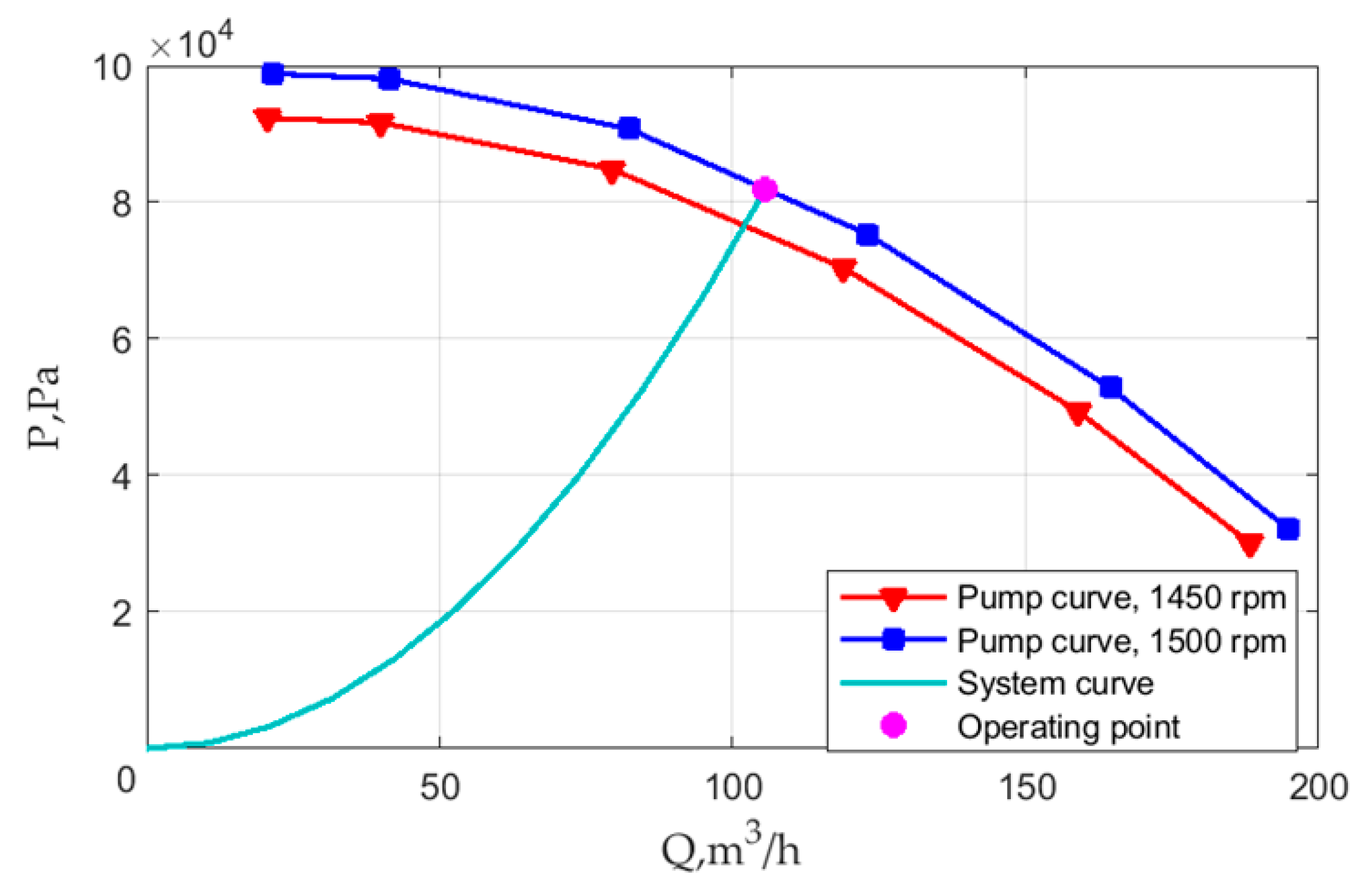

3. Hydraulic System Model

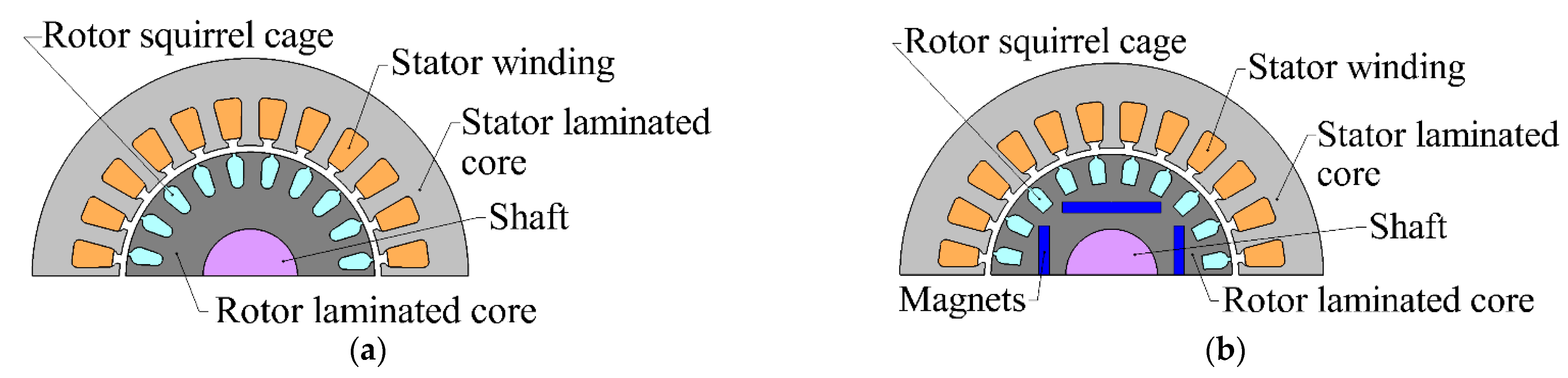

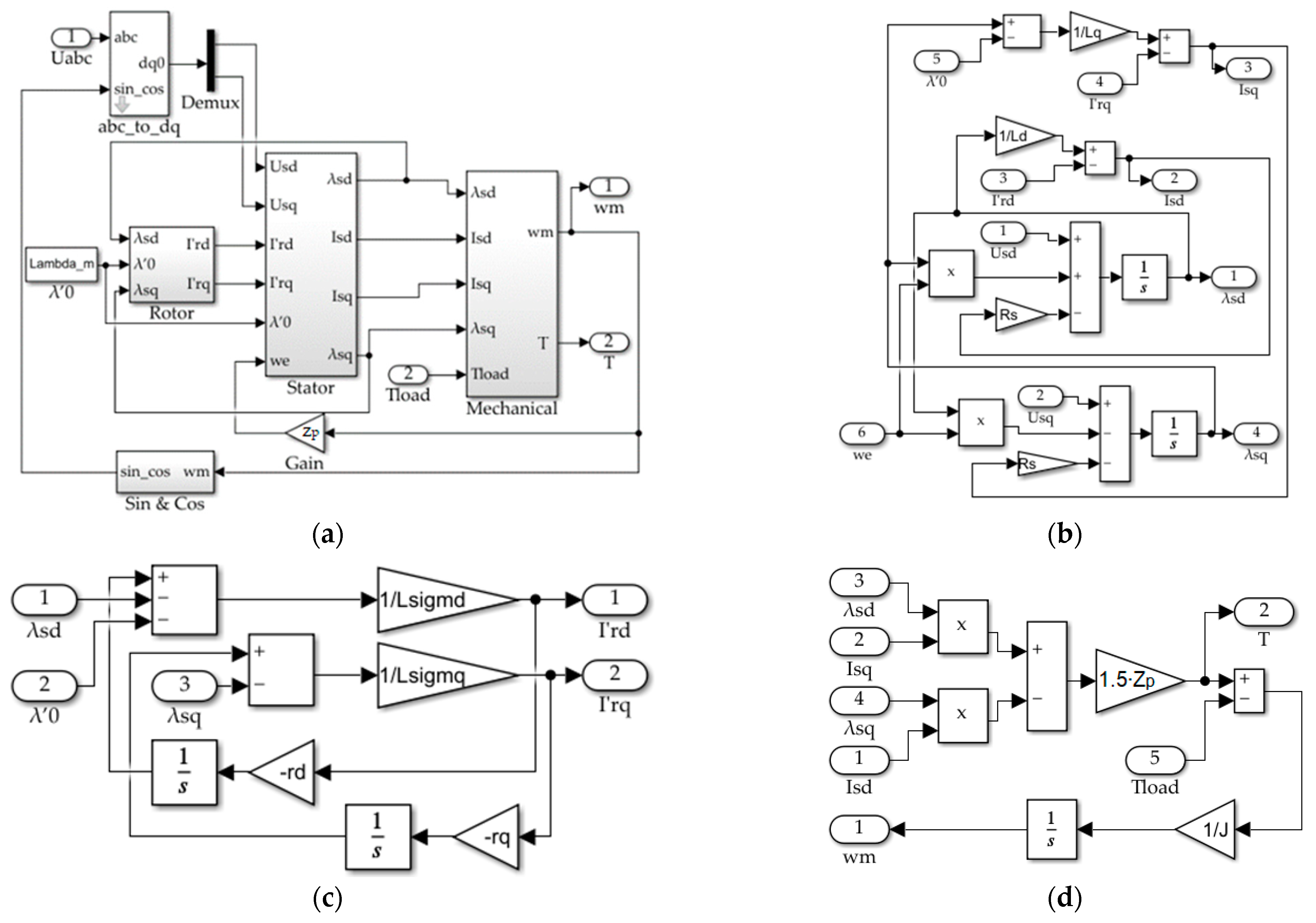

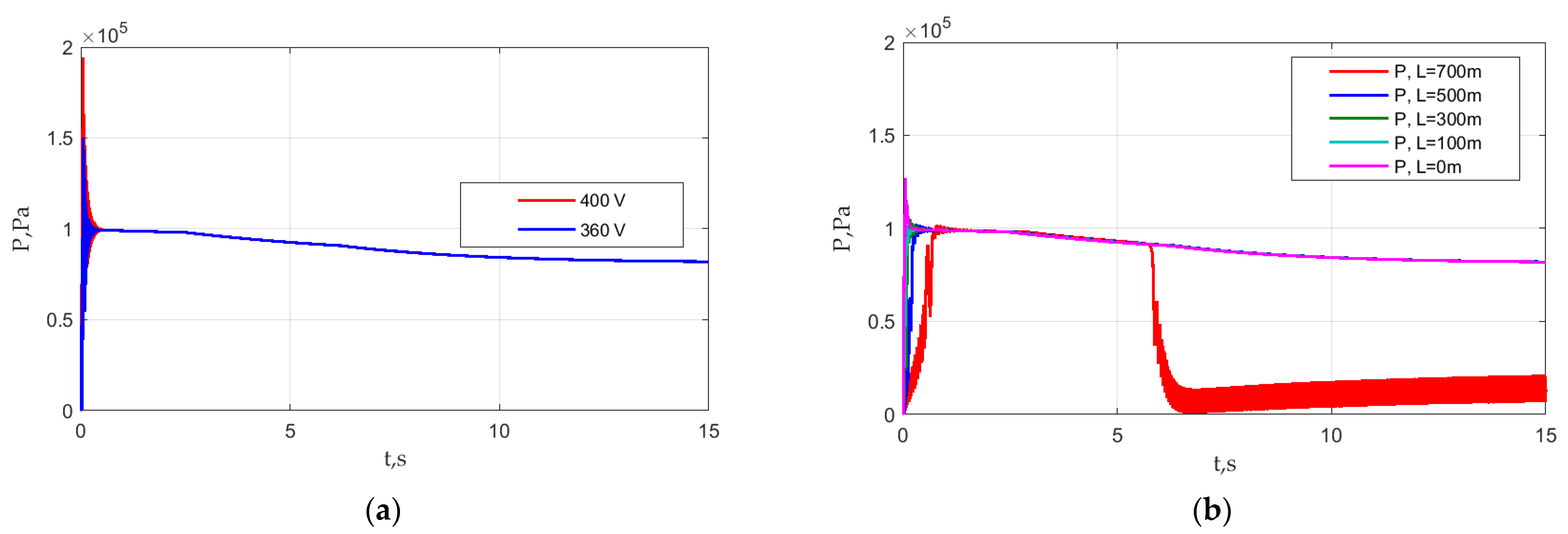

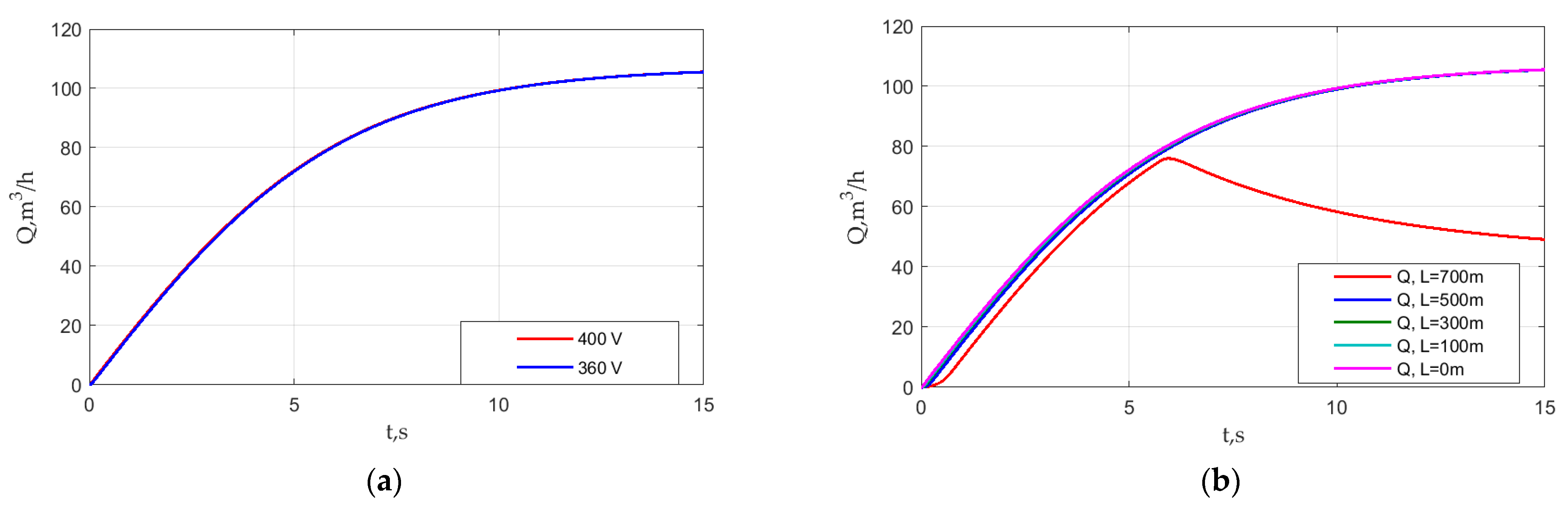

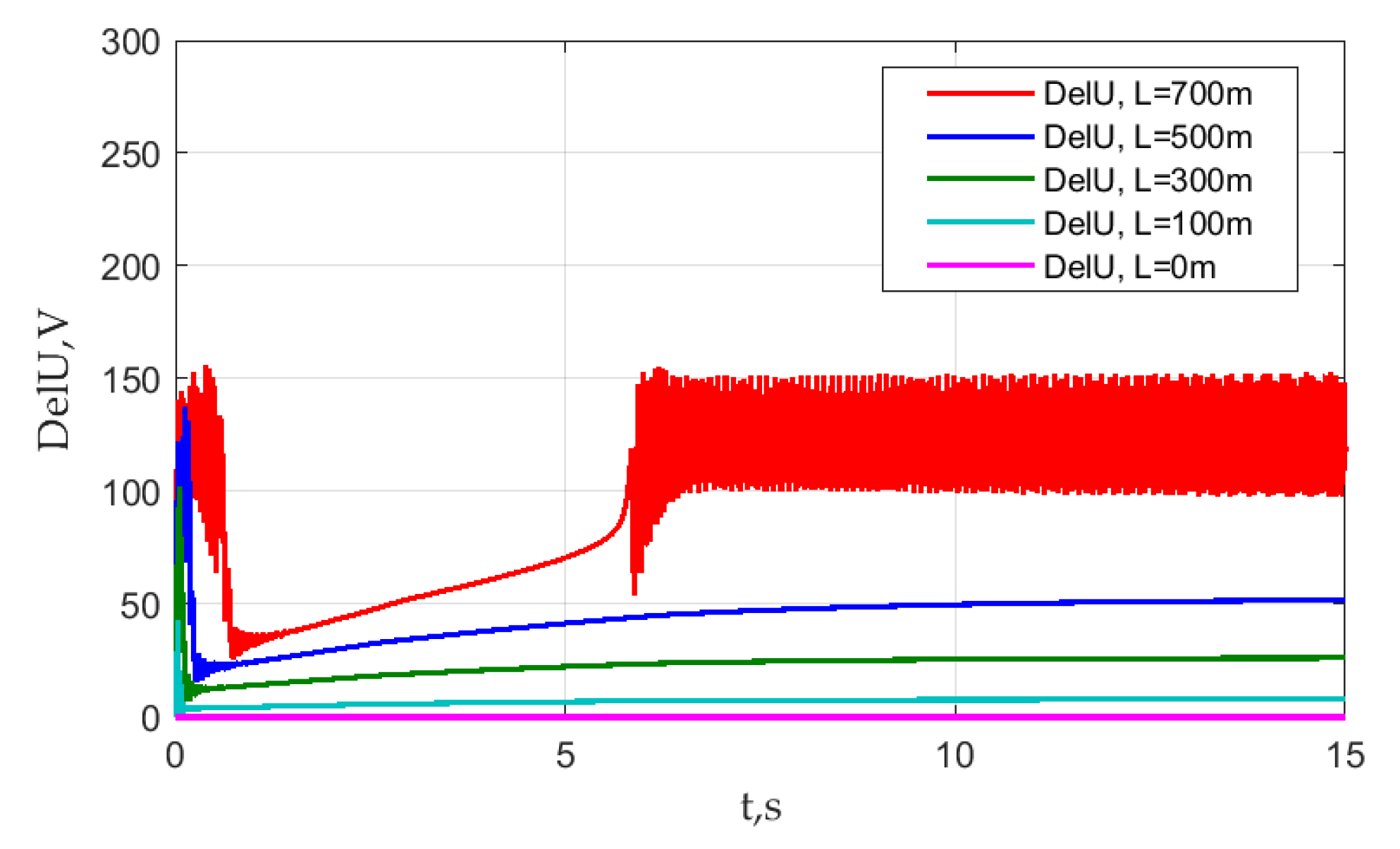

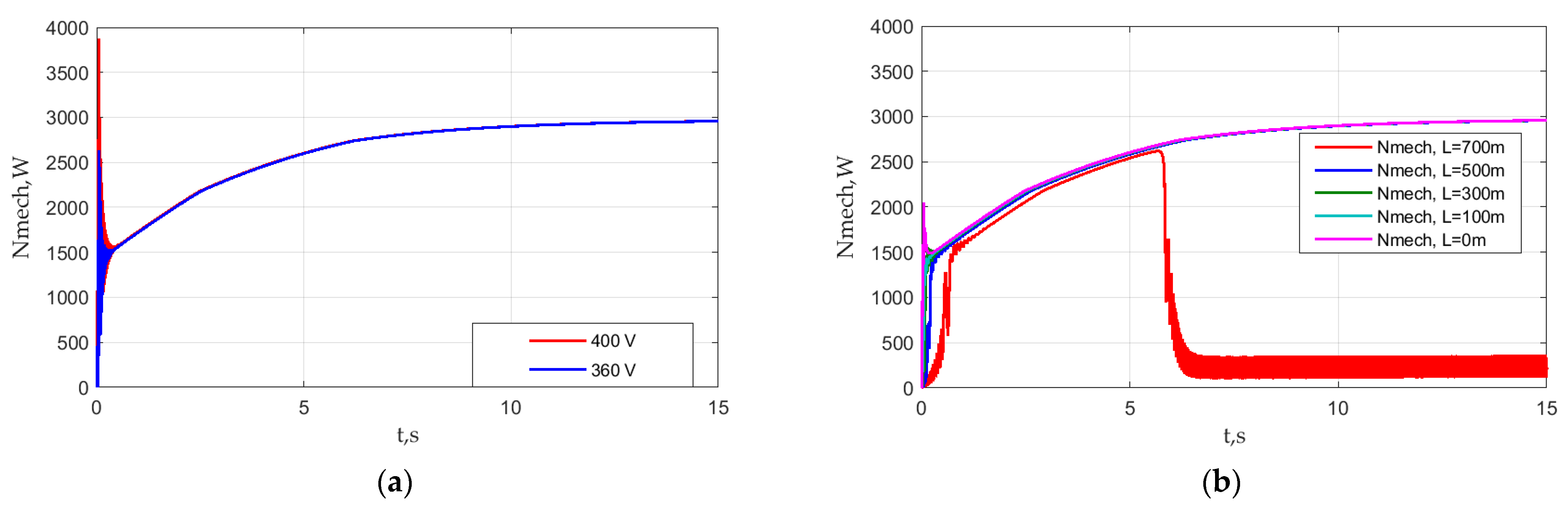

4. LSPMSM Model

- The magnetic fields generated by the stator and rotor windings have a sinusoidal spatial distribution;

- The magnetic permeability of the steel is constant;

- The stator and rotor windings are symmetrical;

- Each winding is powered by a separate source;

- The mains voltage phasor is constant throughout the entire starting process, and an increase in the motor current does not cause a decrease in its amplitude;

- Magnetic core losses are not taken into account.

dλsq/dt + Zp·λsd·dφ/dt + Rs · Isq = Usq;

dλ’rd/dt + r’d · I’rd = 0;

dλ’rq/dt + r’q · I’rq = 0;

I’rd = (λ’rd − λsd)/Lσd;

I’rq = (λ’rq − [λsq − λ’0])/Lσq;

Isd = λsd/Lsd − I’rd;

Isq = (λsq − λ’0)/Lsq − I’rq;

T = 3/2· Zp ∙ (λsd · Isq − λsq · Isd);

J ∙ d2φ /dt2 = T − Tload.

5. Model of the Pump Unit in Matlab Simulink and Parameters of the 0.55 kW Pump Unit

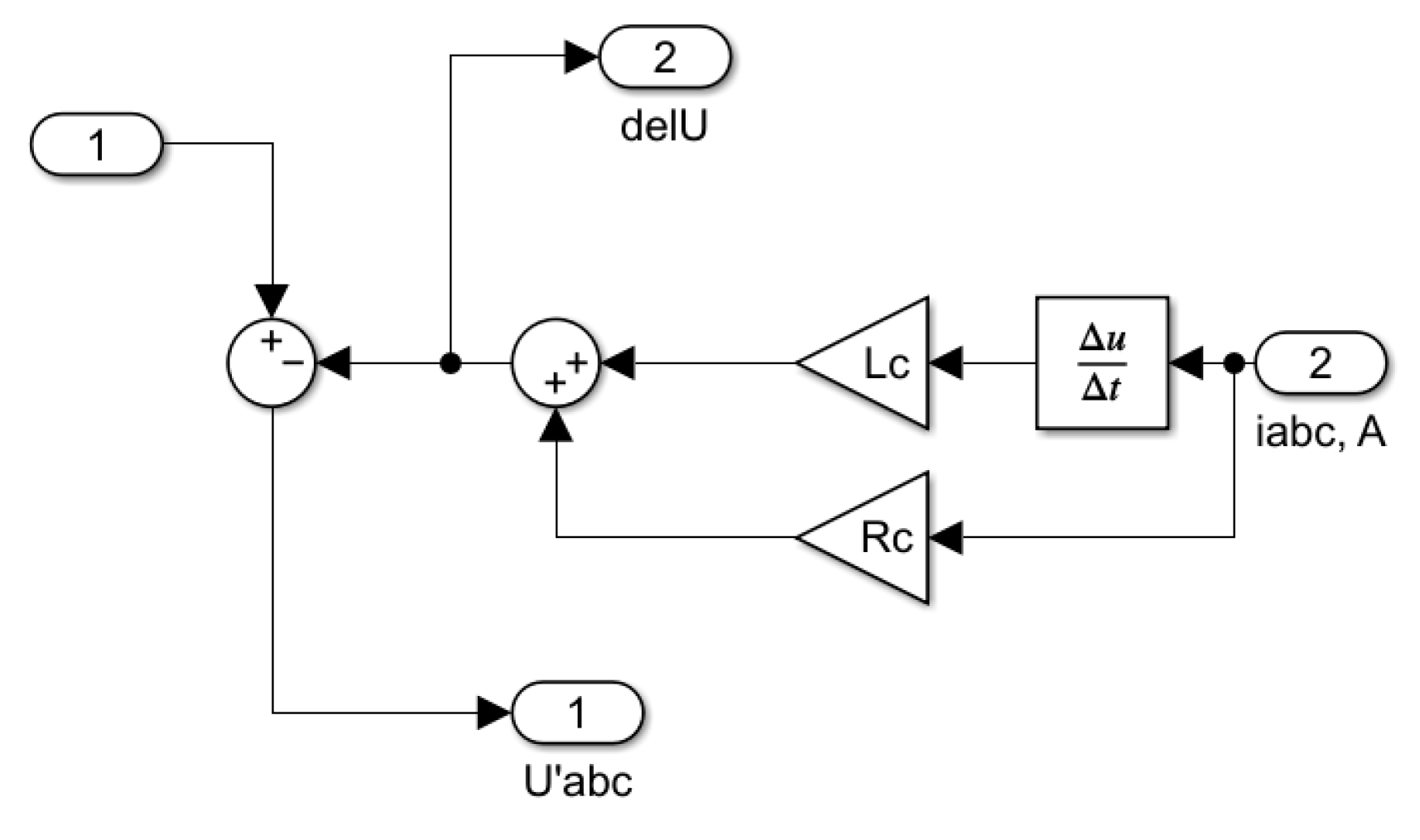

6. The Model of the Cable

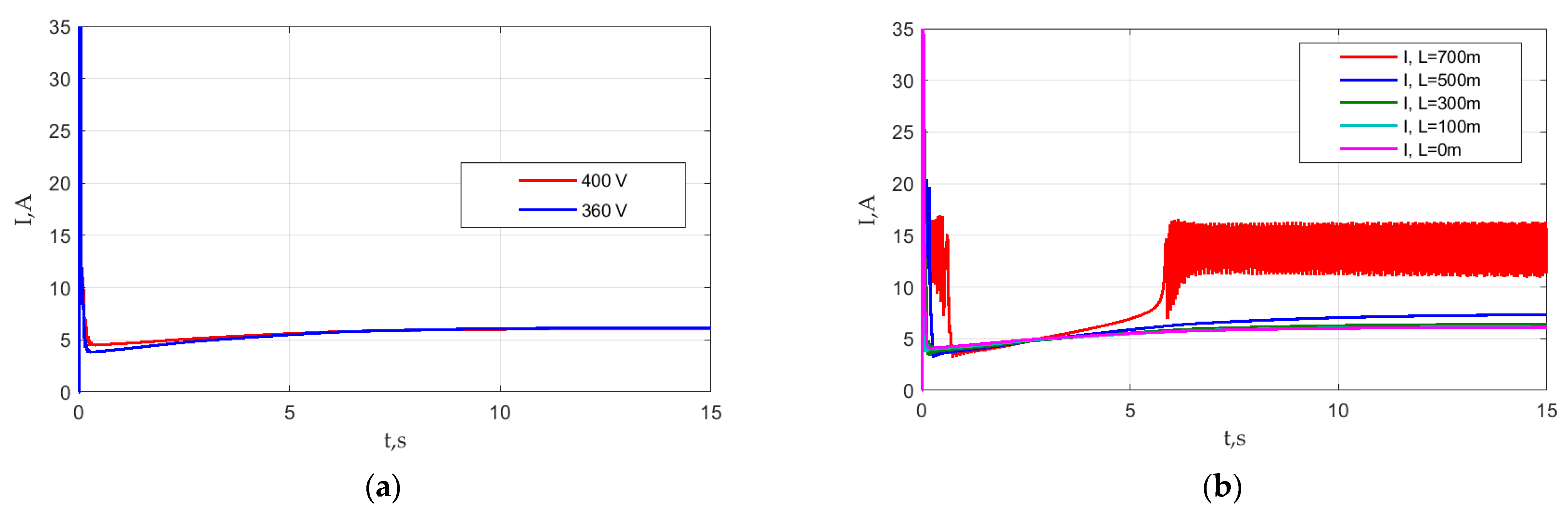

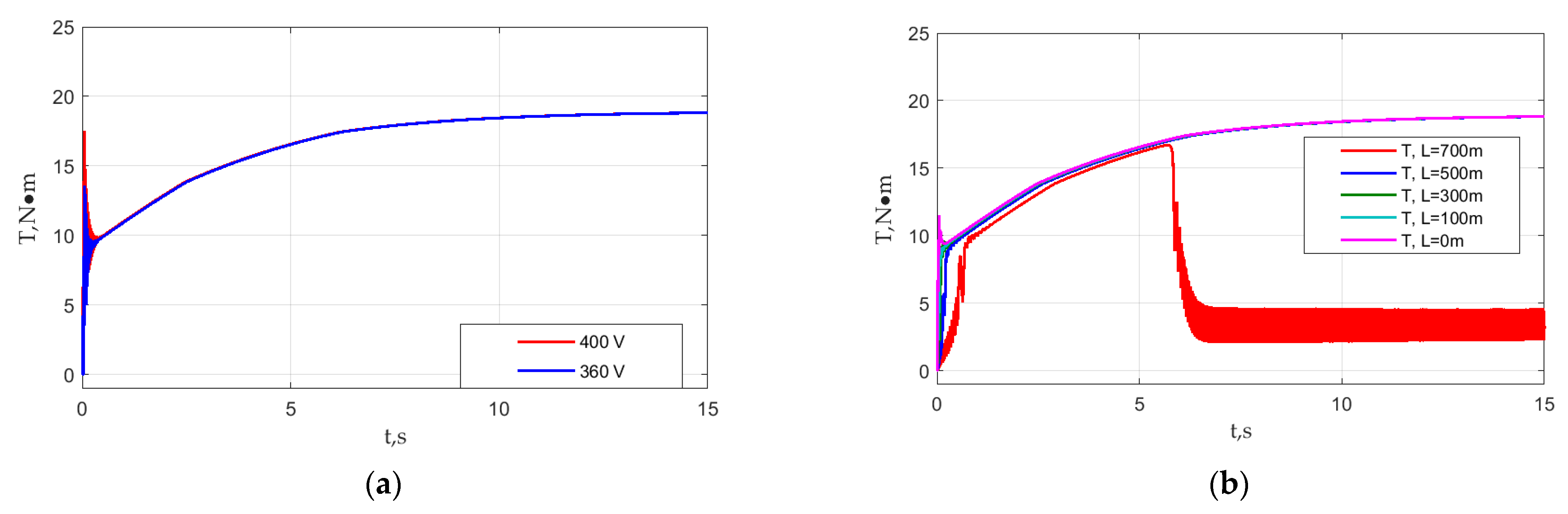

7. Simulation Results for the 0.55 kW Pump Unit

8. Parameters of the 3 kW Pump Unit

9. Simulation Results for the 3 kW Pump Unit

10. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Glossary

| List of Abbreviations | |

| EMF | Electromotive force |

| IM | Induction motor |

| LSPMSM | Linear start permanent magnet motor |

| List of Mathematical Symbols | |

| A | Cross-sectional area of the pipe, m2 |

| iabc | Mains phase currents, A |

| Isd, Isq | Stator currents, A |

| I’rd, I’rq | Rotor currents, A |

| f | Mains voltage frequency, Hz |

| J | Total moment of inertia, kg · m2 |

| Ji | Moment of inertia of the impeller, kg · m2 |

| l | Cable length, m |

| L | Length of the pipeline, m |

| Lsd, Lsq | Stator total inductances, H |

| Lc | Cable length, m |

| Lσd, Lσq | Rotor leakage inductances, H |

| N | Mechanical power consumed by the pump, W |

| Nref | Mechanical power at the rated speed of the pump, W |

| p | Differential pump pressure, Pa |

| pref | Differential pressure at the rated speed and the rated density, Pa |

| q | Flow volume, m3/s |

| qref | Volume flow rate of the pump at the rated speed according to the catalog data, m3/s |

| Rc100 | Resistance of a cable 100 m long, Ohm |

| Rs | Stator resistance, Ohm |

| t | Time variable |

| T | Motor shaft torque, N · m |

| Tpump | Mechanical torque of the pump, N · m |

| uabc | Mains phase voltage, V |

| Usd, Usq | Stator voltages along d and q axes, V |

| Xc100 | Reactance of a cable that is 100 m long, Ohm |

| Zp | Number of motor poles |

| Δp | Pressure drop due to fluid inertia, Pa |

| λlcu | Specific cable reactance, mOhm/m |

| λ’rd, λ’rq | Rotor flux linkages, Wb |

| λsd, λsq | Stator flux linkages, Wb |

| λ’0 | Permanent magnet flux linkage, Wb |

| ρ | Density of the pumped liquid, m3/s |

| ρrcu | Specific resistance of copper, Ohm∙mm2/m |

| ρref | Rated density of the pumped liquid, m3/s |

| τsynch1 | Motor synchronization time, s |

| τhydr | Hydraulic system transient time, s |

| φ | Mechanical rotational angle, rad |

| ω | Angular frequency of the rotation of the pump shaft, rad/s |

| ωref | Rated angular frequency of the rotation of the pump shaft, rad/s |

References

- Goman, V.; Oshurbekov, S.; Kazakbaev, V.; Prakht, V.; Dmitrievskii, V. Energy Efficiency Analysis of Fixed-Speed Pump Drives with Various Types of Motors. Appl. Sci. 2019, 9, 5295. [Google Scholar] [CrossRef]

- Baka, S.; Sashidhar, S.; Fernandes, B.G. Design of an Energy Efficient Line-Start Two-Pole Ferrite Assisted Synchronous Reluctance Motor for Water Pumps. IEEE Trans. Energy Conv. 2021, 36, 961–970. [Google Scholar] [CrossRef]

- Ismagilov, F.; Vavilov, V.; Gusakov, D. Line-Start Permanent Magnet Synchronous Motor for Aerospace Application. In Proceedings of the IEEE International Conference on Electrical Systems for Aircraft, Railway, Ship Propulsion and Road Vehicles and International Transportation Electrification Conference (ESARS-ITEC 2018), Nottingham, UK, 7–9 November 2018; pp. 1–5. [Google Scholar] [CrossRef]

- Kurihara, K.; Rahman, M. High-Efficiency Line-Start Interior Permanent-Magnet Synchronous Motors. IEEE Trans. Ind. Appl. 2004, 40, 789–796. [Google Scholar] [CrossRef]

- Kazakbaev, V.; Paramonov, A.; Dmitrievskii, V.; Prakht, V.; Goman, V. Indirect Efficiency Measurement Method for Line-Start Permanent Magnet Synchronous Motors. Mathematics 2022, 10, 1056. [Google Scholar] [CrossRef]

- Rotating Electrical Machines—Part 30-2: Efficiency Classes of Variable Speed AC Motors (IE-Code). IEC 60034-30-2/IEC: 2016-12. Available online: https://webstore.iec.ch/publication/30830 (accessed on 19 December 2022).

- Quarterly Report On European Electricity Markets, Market Observatory for Energy DG Energy, 15(1), Covering First Quarter of 2022, European Commission. 2022. Available online: https://energy.ec.europa.eu/system/files/2022-07/Quarterly%20Report%20on%20European%20Electricity%20markets%20Q1%202022.pdf (accessed on 19 December 2022).

- European Commission Regulation (EC). No. 640/2009 Implementing Directive 2005/32/EC of the European Parliament and of the Council with Regard to Ecodesign Requirements for Electric Motors, (2009), Amended by Commission Regulation (EU) No 4/2014 of January 6, 2014. Document 32014R0004. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX%3A32014R0004 (accessed on 19 December 2022).

- European Council Meeting (10 and 11 December 2020)—Conclusions. EUCO 22/20 CO EUR 17 CONCL 8. Available online: https://www.consilium.europa.eu/media/47296/1011-12-20-euco-conclusions-en.pdf (accessed on 23 January 2021).

- Addendum to the Operating Instructions: AC Motors DR.71.J-DR.100.J with LSPM Technology, 21281793/EN, 09/2014, SEW Eurodrive. Available online: https://download.sew-eurodrive.com/download/pdf/21343799.pdf (accessed on 19 December 2022).

- Catalogue of Super Premium Efficiency SynchroVERT LSPM Motors. Available online: https://www.bharatbijlee.com/media/14228/synchrovert_catalogue.pdf (accessed on 19 December 2022).

- WQuattro, Super Premium Efficiency Motor, Product Catalogue, WEG Group-Motors Business Unit, Cod: 50025713, Rev: 03, Date (m/y): 07/2017. Available online: https://static.weg.net/medias/downloadcenter/h01/hfc/WEG-w22-quattro-european-market-50025713-brochure-english-web.pdf (accessed on 19 December 2022).

- KT-420-5, Operation of Bitzer Reciprocating Compressors with External Frequency Inverters, Bitzer, 01.2022. Available online: https://www.bitzer.de/shared_media/html/kt-420/Resources/pdf/279303819.pdf (accessed on 19 December 2022).

- Kazakbaev, V.; Prakht, V.; Dmitrievskii, V.; Golovanov, D. Feasibility Study of Pump Units with Various Direct-On-Line Electric Motors Considering Cable and Transformer Losses. Appl. Sci. 2020, 10, 8120. [Google Scholar] [CrossRef]

- Vasilev, B. Analysis and improvement of the efficiency of frequency converters with pulse width modulation. Int. J. Electr. Comput. Eng. 2019, 9, 2314–2320. [Google Scholar] [CrossRef]

- Churkin, A.; Churkin, B.; Savelieva, I. Improving the energy efficiency of frequency converters in networks of limited power. IOP Conf. Ser. Mater. Sci. Eng. 2019, 643, 012056. [Google Scholar] [CrossRef]

- Wang, S.-C.; Nien, Y.-C.; Huang, S.-M. Multi-Objective Optimization Design and Analysis of V-Shape Permanent Magnet Synchronous Motor. Energies 2022, 15, 3496. [Google Scholar] [CrossRef]

- Wang, D.; Wang, X.; Chen, H.; Zhang, R. Matlab/Simulink-Based Simulation of Line-start PMSM Used in Pump Jacks. In Proceedings of the 2nd IEEE Conference on Industrial Electronics and Applications, Harbin, China, 23–25 May 2007; pp. 1179–1181. [Google Scholar] [CrossRef]

- Paramonov, A.; Oshurbekov, S.; Kazakbaev, V.; Prakht, V.; Dmitrievskii, V. Study of the Effect of Throttling on the Success of Starting a Line-Start Permanent Magnet Motor Driving a Centrifugal Fan. Mathematics 2022, 10, 4324. [Google Scholar] [CrossRef]

- Sethupathi, P.; Senthilnathan, N. Comparative analysis of line-start permanent magnet synchronous motor and squirrel cage induction motor under customary power quality indices. Electr. Eng. 2020, 102, 1339–1349. [Google Scholar] [CrossRef]

- Faiz, J.; Ebrahimpour, H.; Pillay, P. Influence of unbalanced voltage on the steady-state performance of a three-phase squirrel-cage induction motor. IEEE Trans. Energy Convers. 2004, 19, 657–662. [Google Scholar] [CrossRef]

- Gnaciński, P.; Muc, A.; Pepliński, M. Influence of Voltage Subharmonics on Line Start Permanent Magnet Synchronous Motor. IEEE Access 2021, 9, 164275–164281. [Google Scholar] [CrossRef]

- Blair, T.H. 3 phase AC motor starting methods: An analysis of reduced voltage starting characteristics. In Proceedings of the IEEE SoutheastCon 2002 (Cat. No.02CH37283), Columbia, SC, USA, 5–7 April 2002; pp. 181–186. [Google Scholar] [CrossRef]

- Hsu, C.-T.; Chuang, H.-J. Power quality assessment of large motor starting and loading for the integrated steel-making cogeneration facility. In Proceedings of the Fourtieth IAS Annual Meeting. Conference Record of the 2005 Industry Applications Conference, Hong Kong, China, 2–6 October 2005; pp. 59–66. [Google Scholar] [CrossRef]

- Patil, P.; Porate, K. Starting Analysis of Induction Motor: A Computer Simulation by Etap Power Station. In Proceedings of the Second International Conference on Emerging Trends in Engineering & Technology, Nagpur, India, 16–18 December 2009; pp. 494–499. [Google Scholar] [CrossRef]

- Low Voltage Process Performance Motors 400 V 50 Hz, 460 V 60 Hz., ABB, Catalog, February 2022. Available online: https://search.abb.com/library/Download.aspx?DocumentID=9AKK105944&LanguageCode=en&DocumentPartId=&Action=Launch (accessed on 19 December 2022).

- International Standard IEC 60038, IEC Standard Voltages, Edition 7.0 2009-06. Available online: https://webstore.iec.ch/publication/153 (accessed on 19 December 2022).

- Wilo, Circulation Pumps, Catalog. 2009. Available online: http://sirkulasyonpompasi.org/sirkulasyonpompasi/wilo-katalog.pdf (accessed on 19 December 2022).

- Centrifugal Pump, Pumps and Motors. Model Description. MathWorks. Available online: https://www.mathworks.com/help/hydro/ref/centrifugalpump.html;jsessionid=9398cce96bf548d19dfefaa598e3 (accessed on 19 December 2022).

- Fluid Inertia. Model description. MathWorks. Available online: https://www.mathworks.com/help/simscape/ref/fluidinertia.html?s_tid=doc_ta (accessed on 19 December 2022).

- Improving Pumping System Performance, a Sourcebook for Industry. Prepared for the United States Department of Energy Office of Energy Efficiency and Renewable Energy Industrial Technologies Program, Second Edition, May 2006. Available online: https://www.energy.gov/sites/prod/files/2014/05/f16/pump.pdf (accessed on 19 December 2022).

- Hydraulic Pipeline. Model Description. MathWorks. Available online: https://www.mathworks.com/help/hydro/ref/hydraulicpipeline.html (accessed on 19 December 2022).

- Variable Area Hydraulic Orifice. Model Description. MathWorks. Available online: https://www.mathworks.com/help/simscape/ref/variableareahydraulicorifice.html?searchHighlight=%20hydraulic%20orifice&s_tid=srchtitle_%20hydraulic%20orifice_2 (accessed on 19 December 2022).

- Tank. Low-Pressure Blocks. Model Description. MathWorks. Available online: https://www.mathworks.com/help/hydro/ref/tank.html?s_tid=doc_ta (accessed on 19 December 2022).

- Estimation of Pump Moment of Inertia. Article. Native Dynamics. 10 September 2013. Available online: https://neutrium.net/equipment/estimation-of-pump-moment-of-inertia (accessed on 19 December 2022).

- Kirar, M.; Aginhotri, G. Cable sizing and effects of cable length on dynamic performance of induction motor. Proceedings of IEEE Fifth Power India Conference, Murthal, India, 19–22 December 2012; pp. 1–6. [Google Scholar] [CrossRef]

- IEC 60364-5-52; Electrical Installations in Buildings—Part. 5-52: Selection and Erection of Electrical Equipment—Wiring Systems, Is the IEC Standard Governing Cable Sizing. IEC: Geneva, Switzerland, 2009. Available online: https://webstore.iec.ch/publication/1878 (accessed on 19 December 2022).

| Parameter | Value |

|---|---|

| Rated power Prate, kW | 0.55 |

| Rated line-to-line voltage Urate, V | 380 |

| RMS rated stator current, A | 1.11 |

| Rated power factor | 0.85 |

| Rated frequency f, Hz | 50 |

| Pole pair number Zp | 2 |

| Stator phase resistance Rs, Ohm | 15.3 |

| Total direct inductance Ld, H | 0.26 |

| Total quadrature inductance Lq, H | 0.15 |

| Leakage direct inductance Lσd, H | 0.038 |

| Leakage quadrature inductance Lσq, H | 0.051 |

| Rotor direct resistance r’d, Ohm | 9.24 |

| Rotor quadrature resistance r’q, Ohm | 10.1 |

| Permanent magnet flux linkage λ’0, Wb | 0.76 |

| Motor inertia moment Jm, kg·m2 | 0.003 |

| Pump impeller inertia moment Ji, kg·m2 | 0.00022 |

| Flow Q, m3/h | Pressure P, Pa | Braking power Nm, W |

|---|---|---|

| 4.77 | 54,229 | 239.15 |

| 10.00 | 53,304 | 300.71 |

| 19.97 | 52,259 | 418.44 |

| 29.82 | 44,691 | 502.98 |

| 39.73 | 31,490 | 545.82 |

| 48.42 | 16,106 | 545.82 |

| Parameter | Value |

|---|---|

| Rated power Prate, kW | 3 |

| Rated line-to-line voltage Urate, V | 380 |

| RMS rated stator current, A | 5.84 |

| Rated power factor | 0.82 |

| Rated frequency f, Hz | 50 |

| Pole pair number Zp | 2 |

| Stator phase resistance Rs, Ohm | 1.281 |

| Total direct inductance Ld, H | 0.110 |

| Total quadrature inductance Lq, H | 0.0567 |

| Leakage direct inductance Lσd, H | 0.0186 |

| Leakage quadrature inductance Lσq, H | 0.0108 |

| Rotor direct resistance r’d, Ohm | 2.943 |

| Rotor quadrature resistance r’q, Ohm | 2.426 |

| Permanent magnet flux linkage λ’0, Wb | 0.6095 |

| Motor inertia moment Jm, kg·m2 | 0.010 |

| Pump impeller inertia moment Ji, kg·m2 | 0.0011 |

| Flow Q, m3/h | Pressure P, Pa | Power Nm, W |

|---|---|---|

| 20.67 | 92,337 | 1613.5 |

| 40.00 | 91,669 | 1968.5 |

| 79.51 | 84,825 | 2475.3 |

| 118.96 | 70,390 | 2819.2 |

| 158.92 | 49,404 | 3011.0 |

| 188.19 | 30,138 | 3052.1 |

| lc, m | Δu, % |

|---|---|

| 0 | 0 |

| 100 | 3.12 |

| 300 | 9.37 |

| 500 | 15.61 |

| 700 | 21.85 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Paramonov, A.; Oshurbekov, S.; Kazakbaev, V.; Prakht, V.; Dmitrievskii, V. Investigation of the Effect of the Voltage Drop and Cable Length on the Success of Starting the Line-Start Permanent Magnet Motor in the Drive of a Centrifugal Pump Unit. Mathematics 2023, 11, 646. https://doi.org/10.3390/math11030646

Paramonov A, Oshurbekov S, Kazakbaev V, Prakht V, Dmitrievskii V. Investigation of the Effect of the Voltage Drop and Cable Length on the Success of Starting the Line-Start Permanent Magnet Motor in the Drive of a Centrifugal Pump Unit. Mathematics. 2023; 11(3):646. https://doi.org/10.3390/math11030646

Chicago/Turabian StyleParamonov, Aleksey, Safarbek Oshurbekov, Vadim Kazakbaev, Vladimir Prakht, and Vladimir Dmitrievskii. 2023. "Investigation of the Effect of the Voltage Drop and Cable Length on the Success of Starting the Line-Start Permanent Magnet Motor in the Drive of a Centrifugal Pump Unit" Mathematics 11, no. 3: 646. https://doi.org/10.3390/math11030646

APA StyleParamonov, A., Oshurbekov, S., Kazakbaev, V., Prakht, V., & Dmitrievskii, V. (2023). Investigation of the Effect of the Voltage Drop and Cable Length on the Success of Starting the Line-Start Permanent Magnet Motor in the Drive of a Centrifugal Pump Unit. Mathematics, 11(3), 646. https://doi.org/10.3390/math11030646