Effects of Seat Belts and Shock Absorbers on the Safety of Racing Car Drivers

Abstract

1. Introduction

2. Models and Method

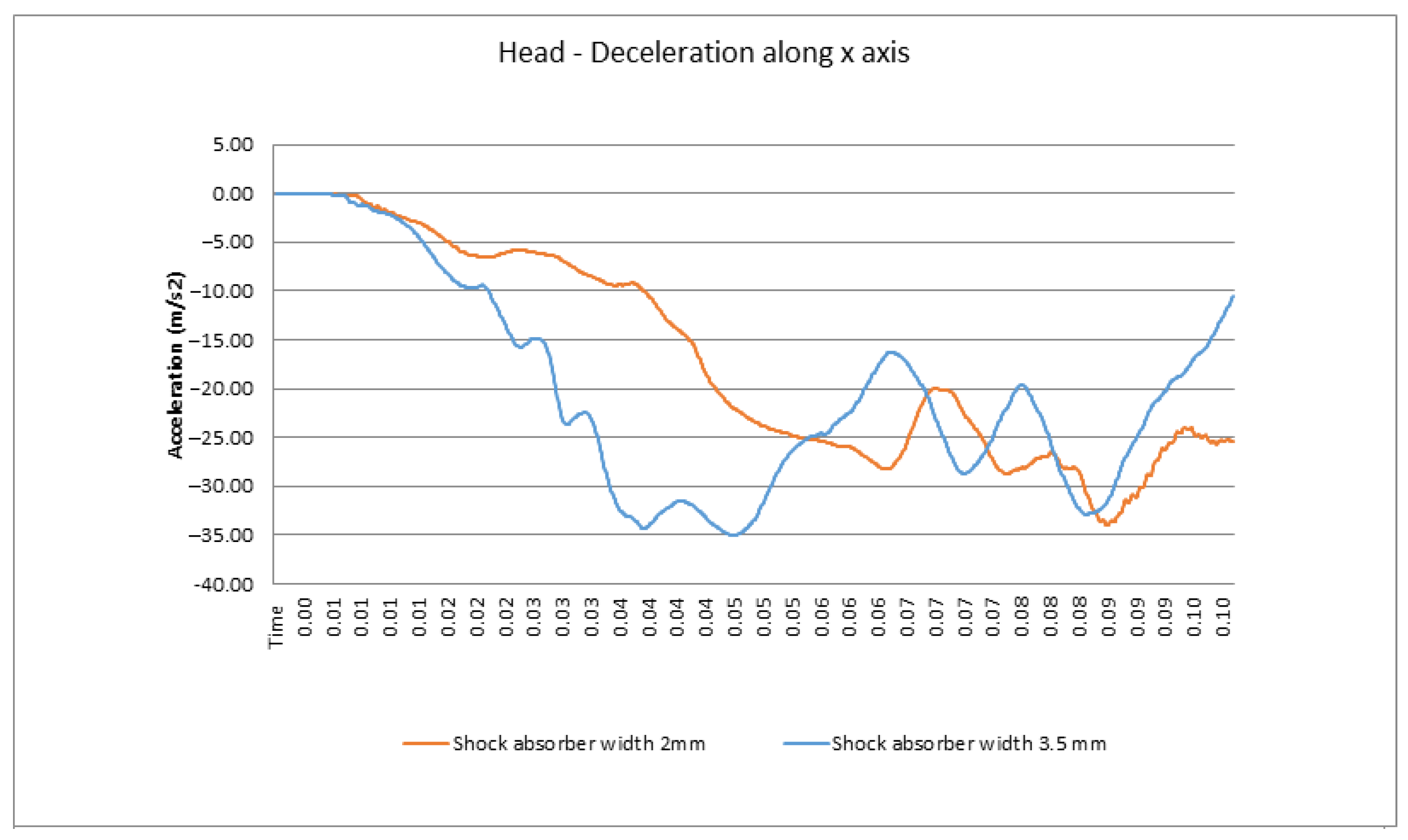

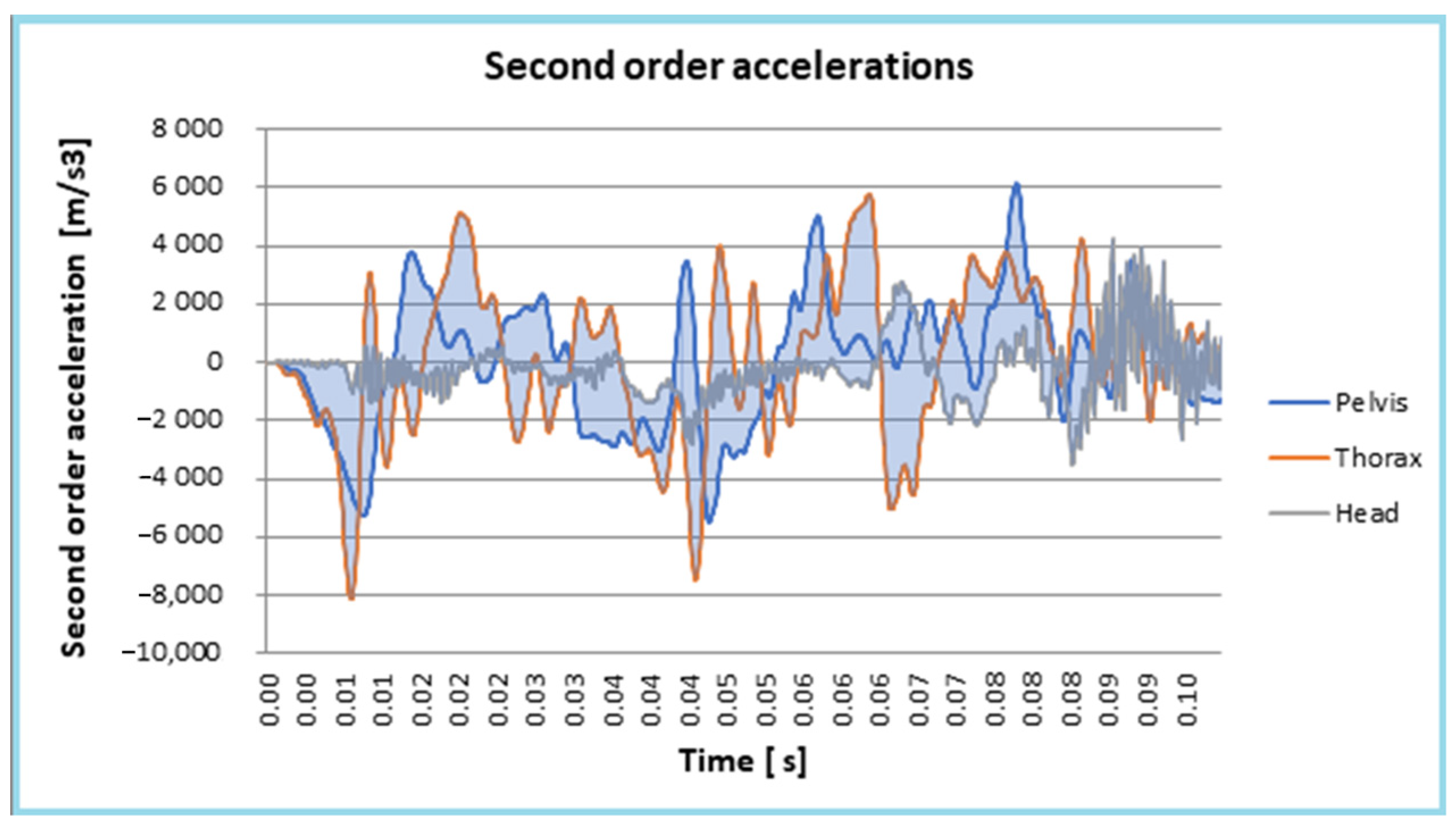

2.1. Second-Order Acceleration and Energy of Acceleration

2.2. Gibbs–Appell Formalism

- is the part of the energy of acceleration that includes only quadratic terms:

- is the part that includes linear terms:

- is the part of the energy of acceleration without terms.

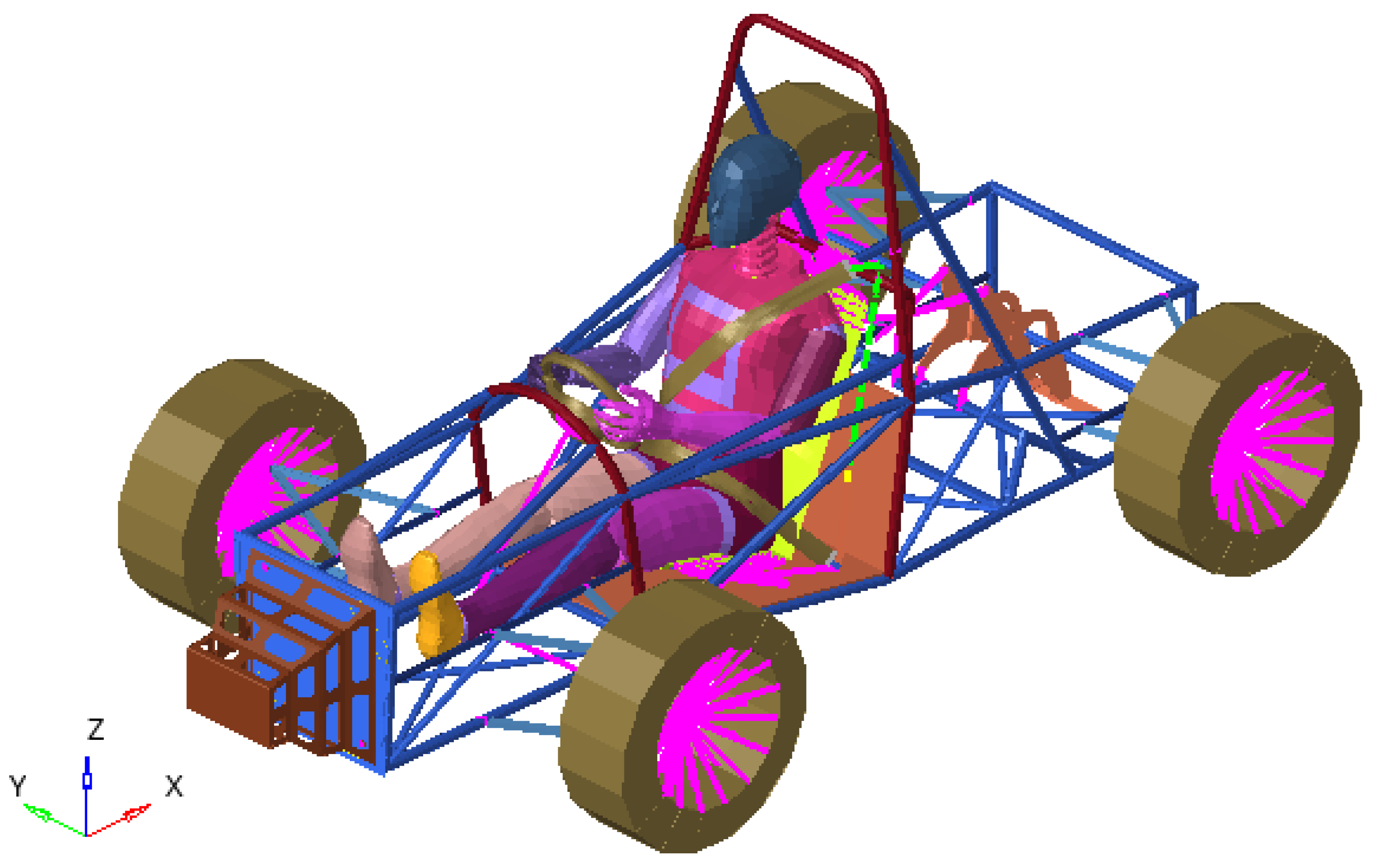

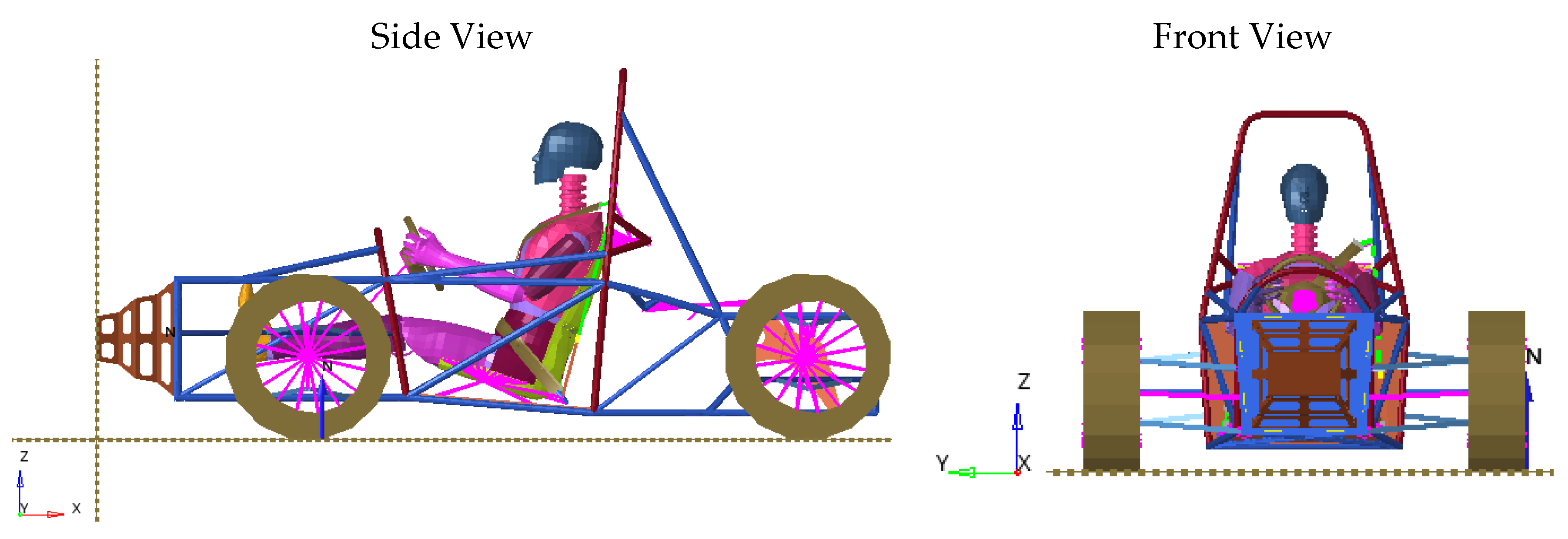

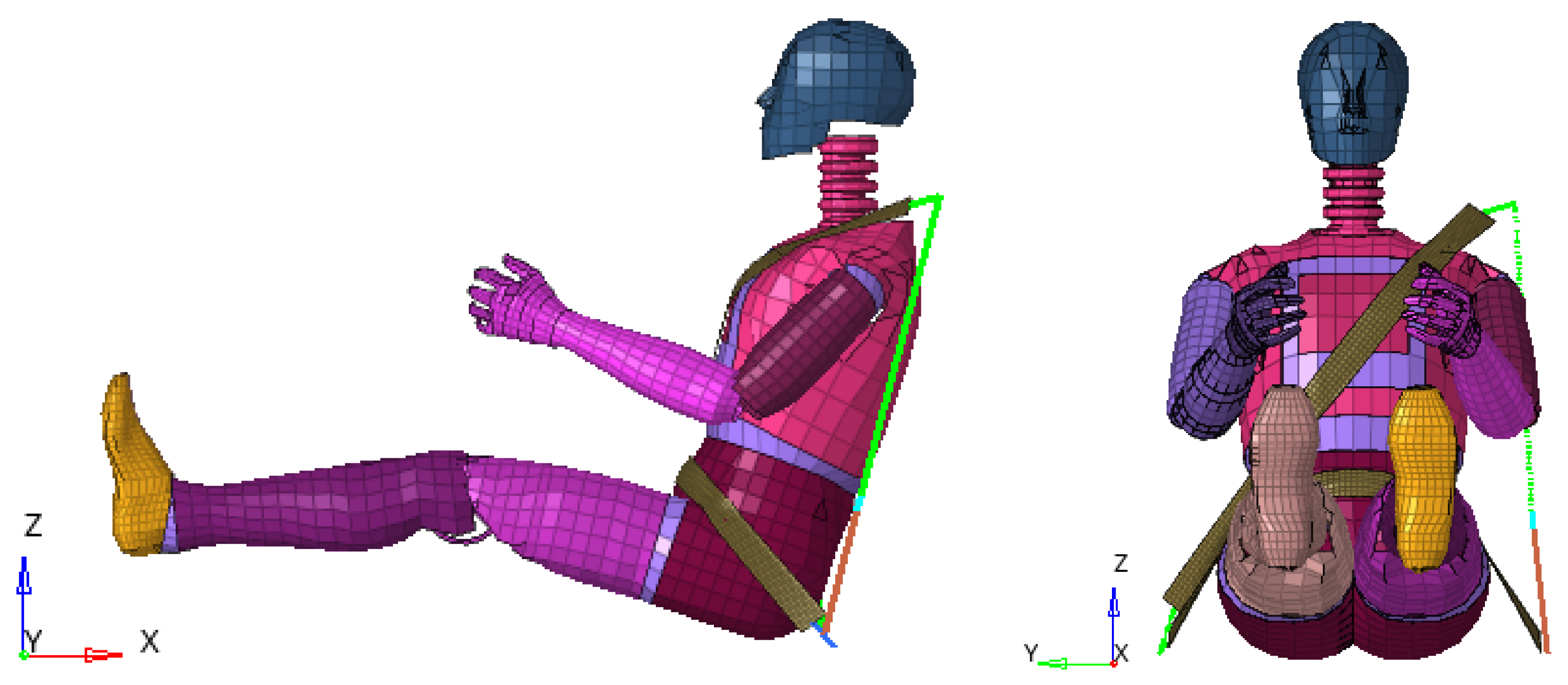

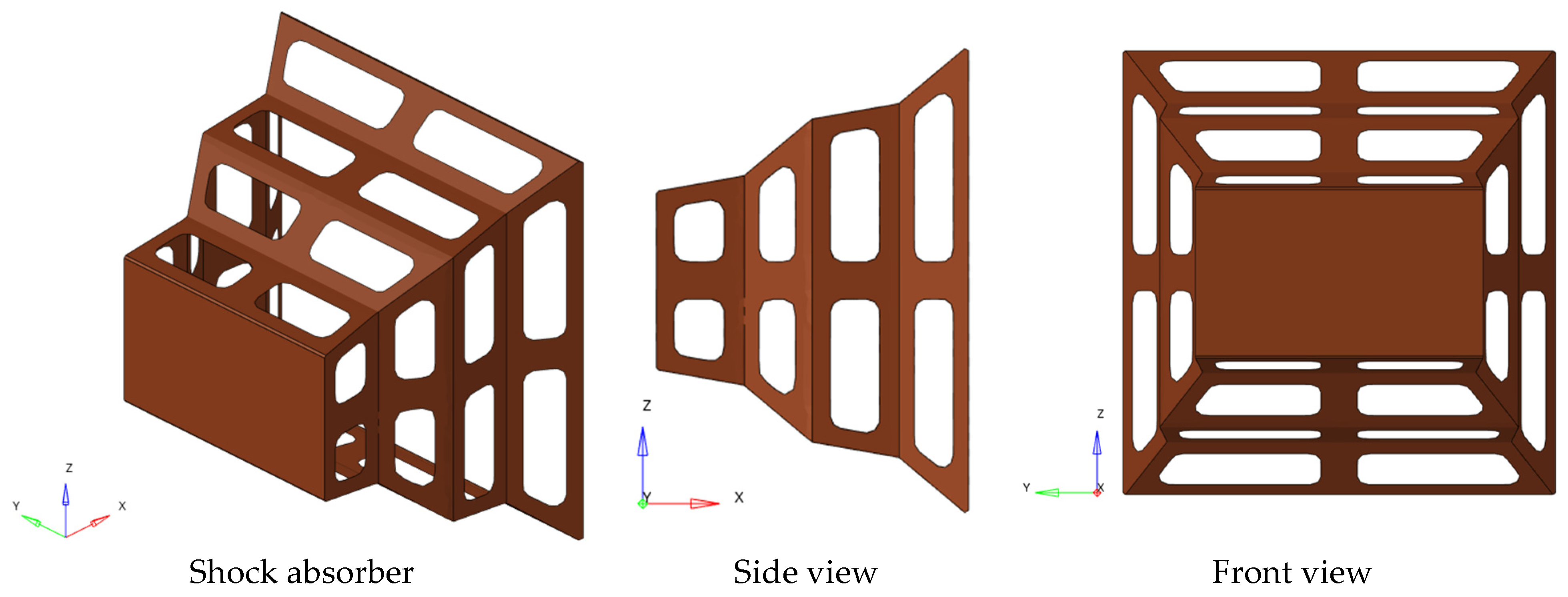

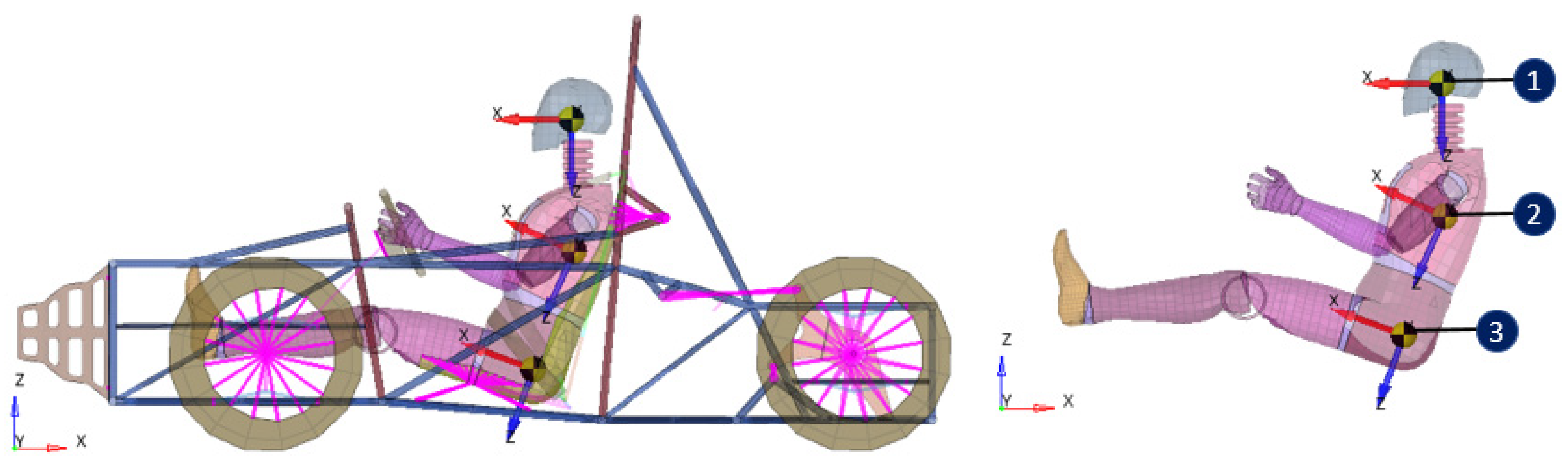

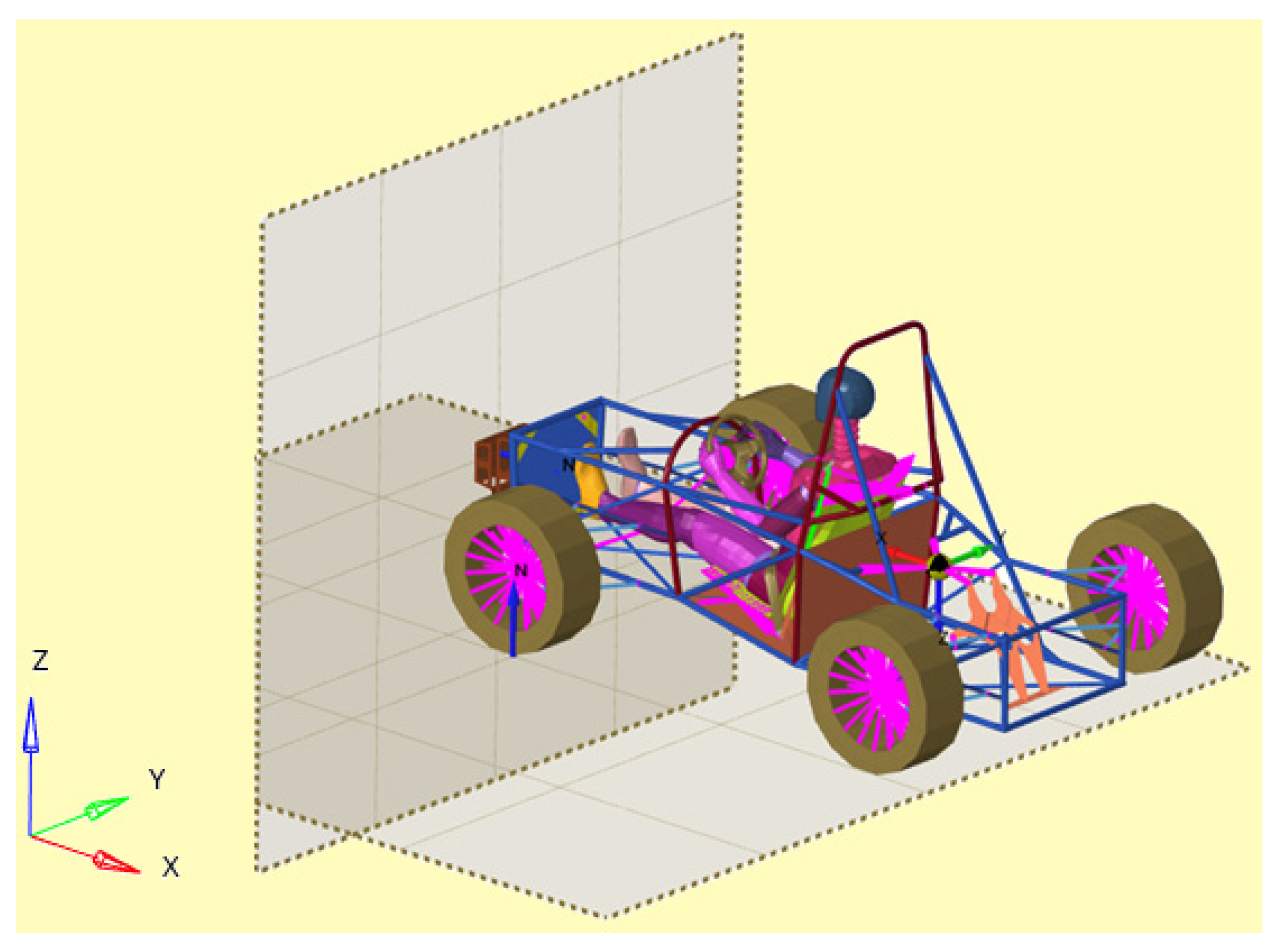

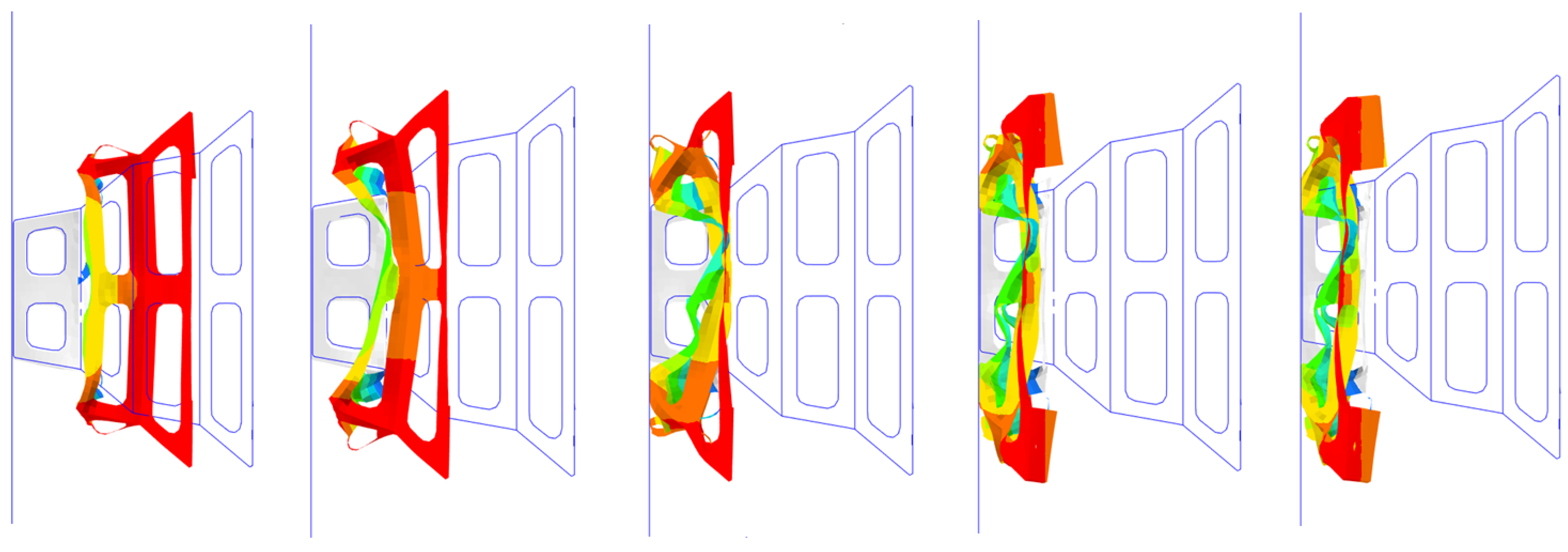

3. Numerical Model of a Race Car

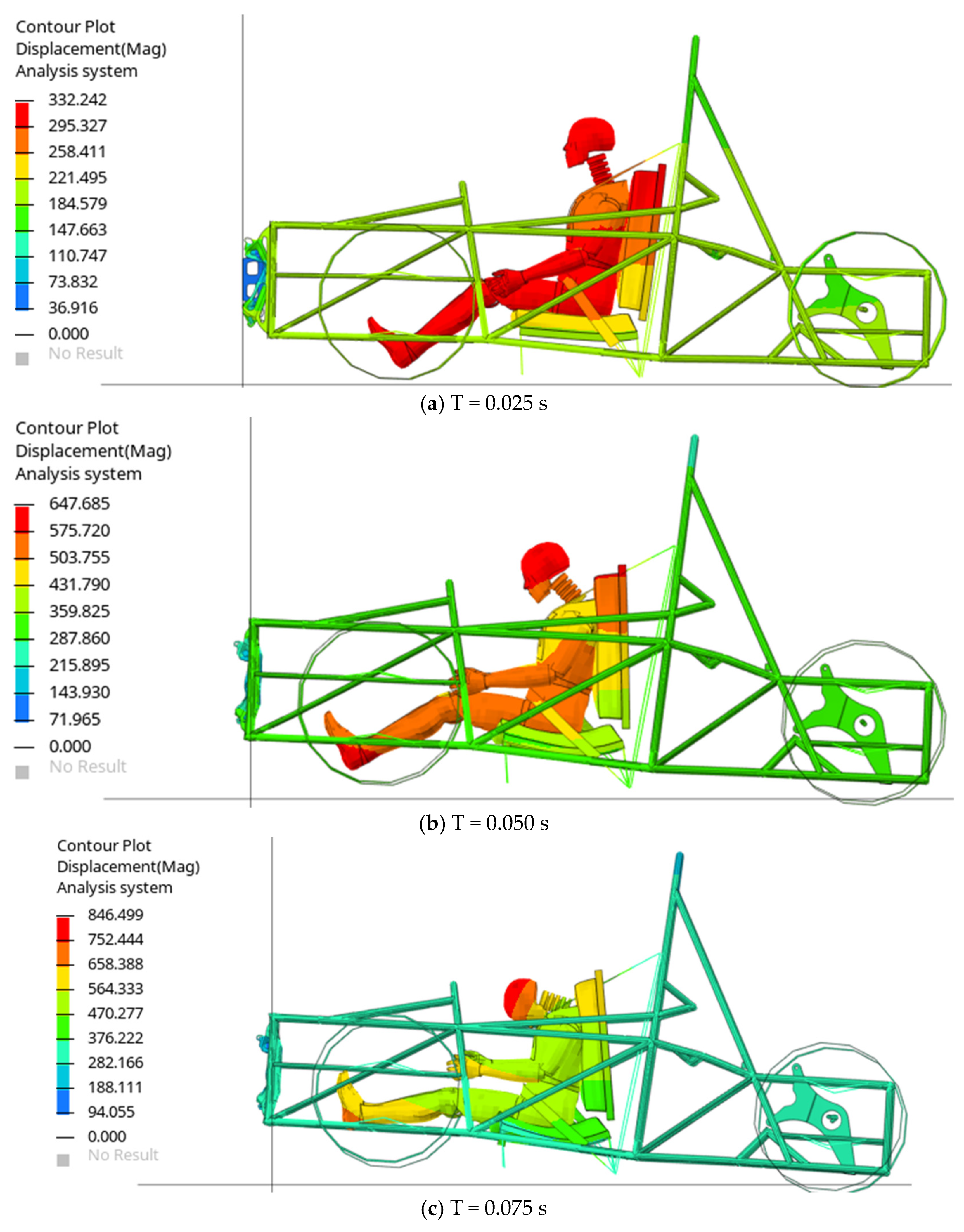

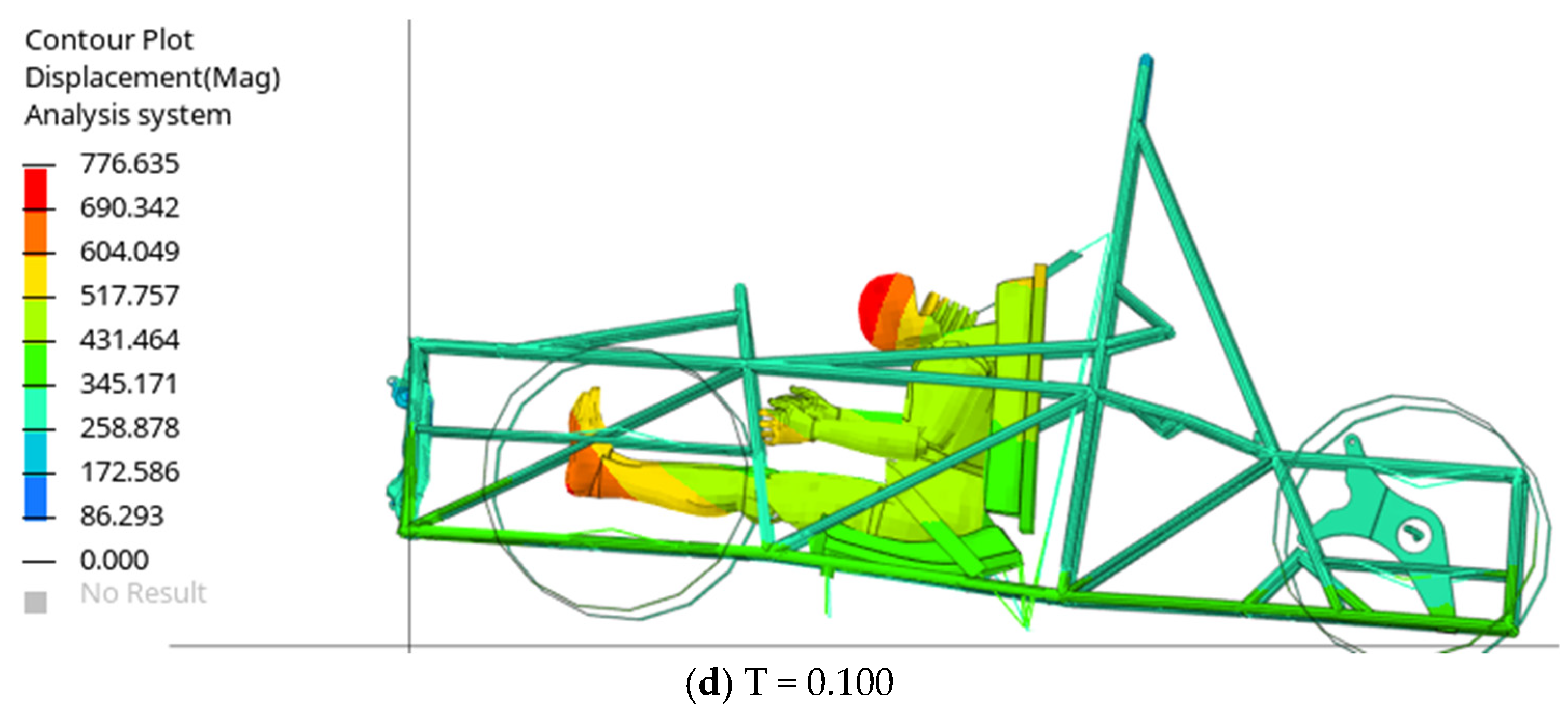

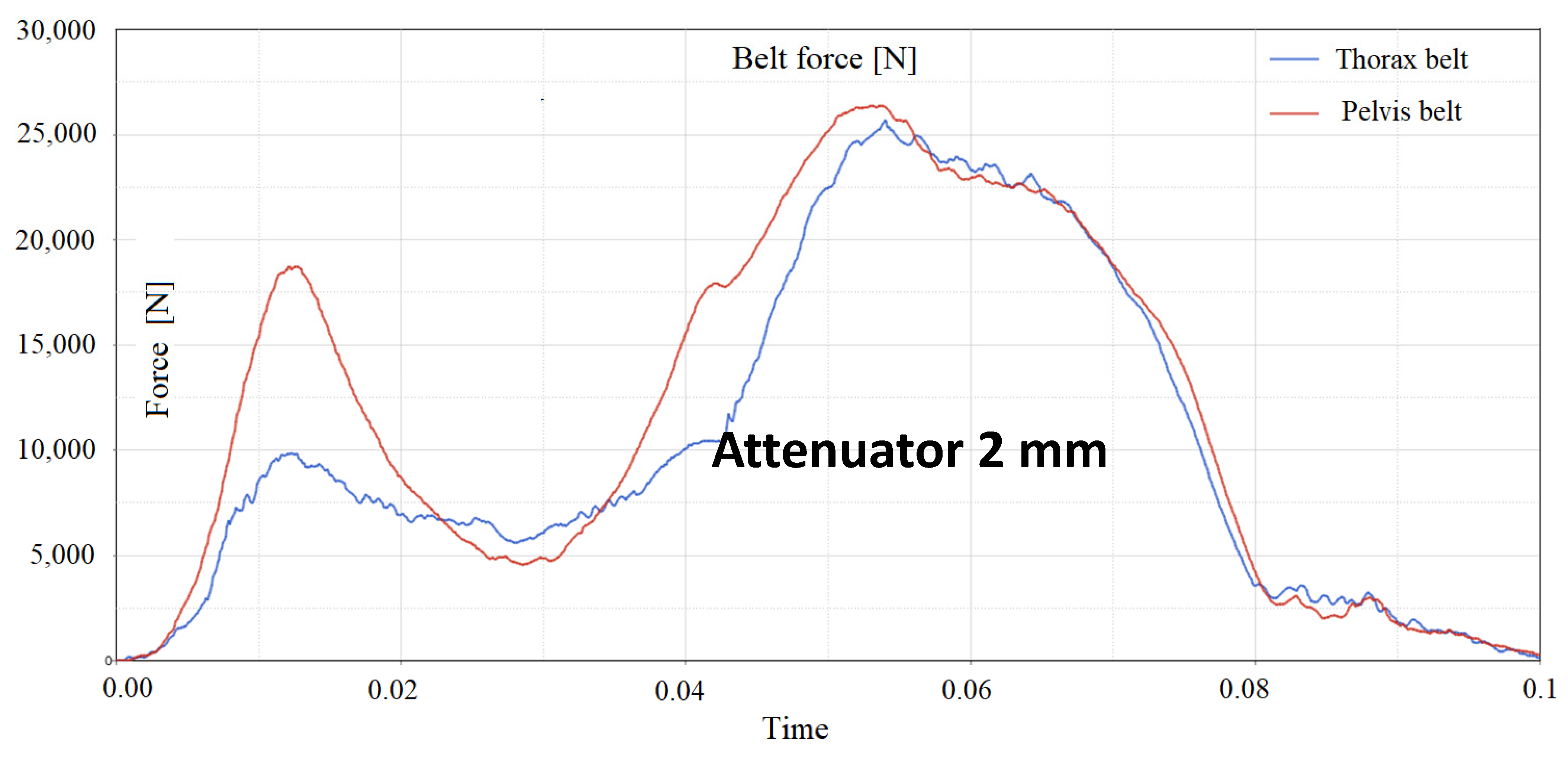

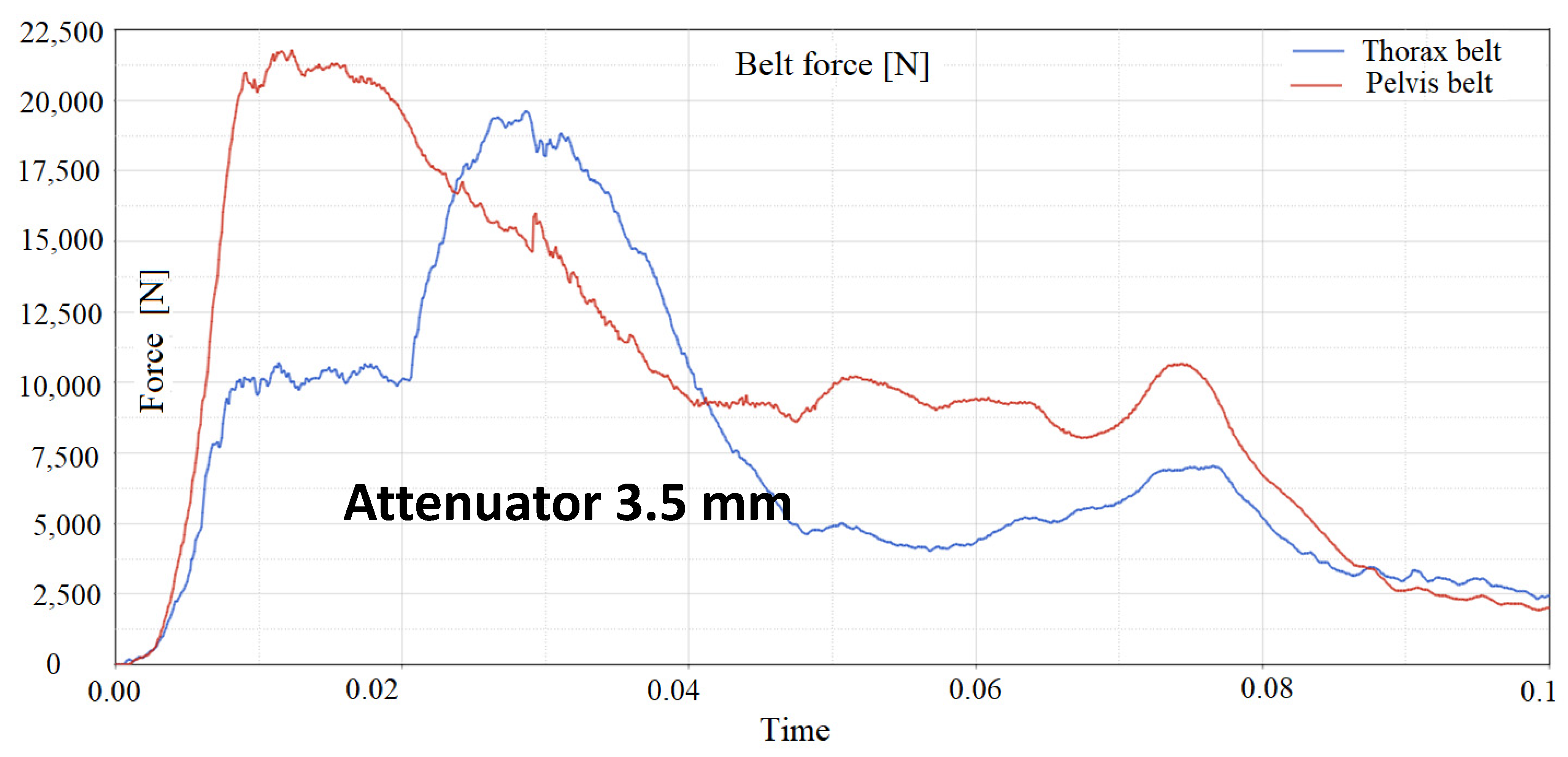

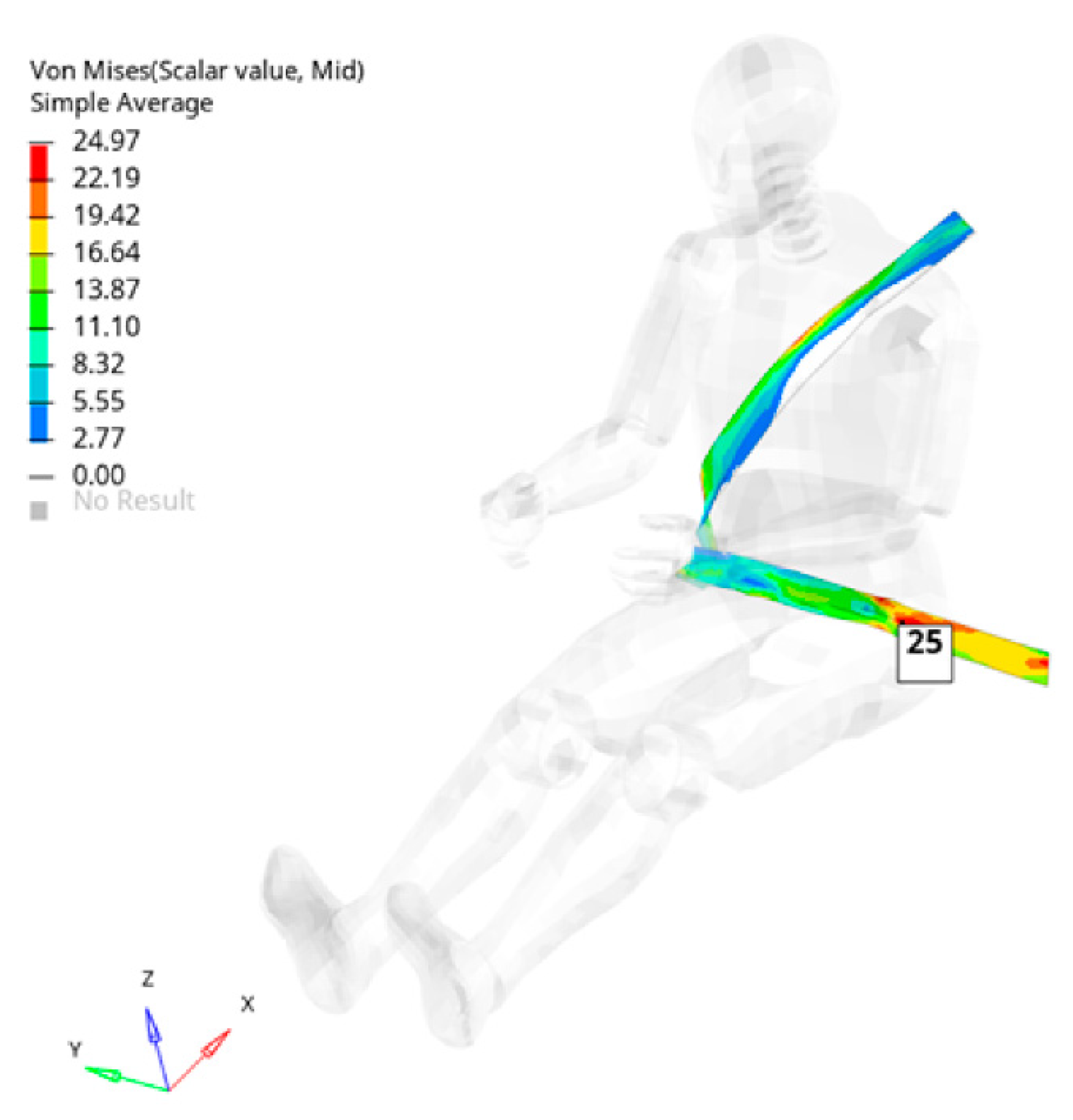

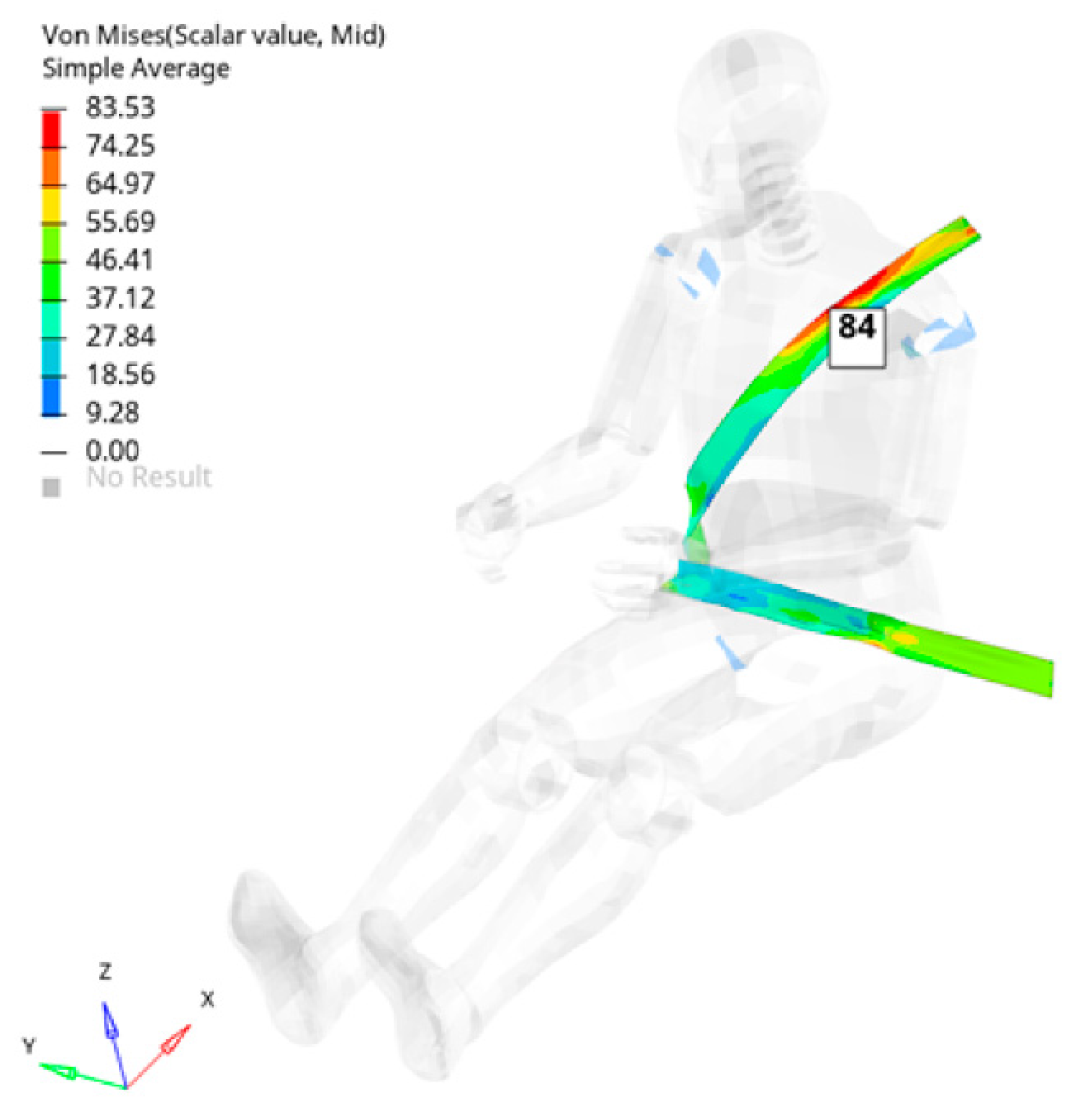

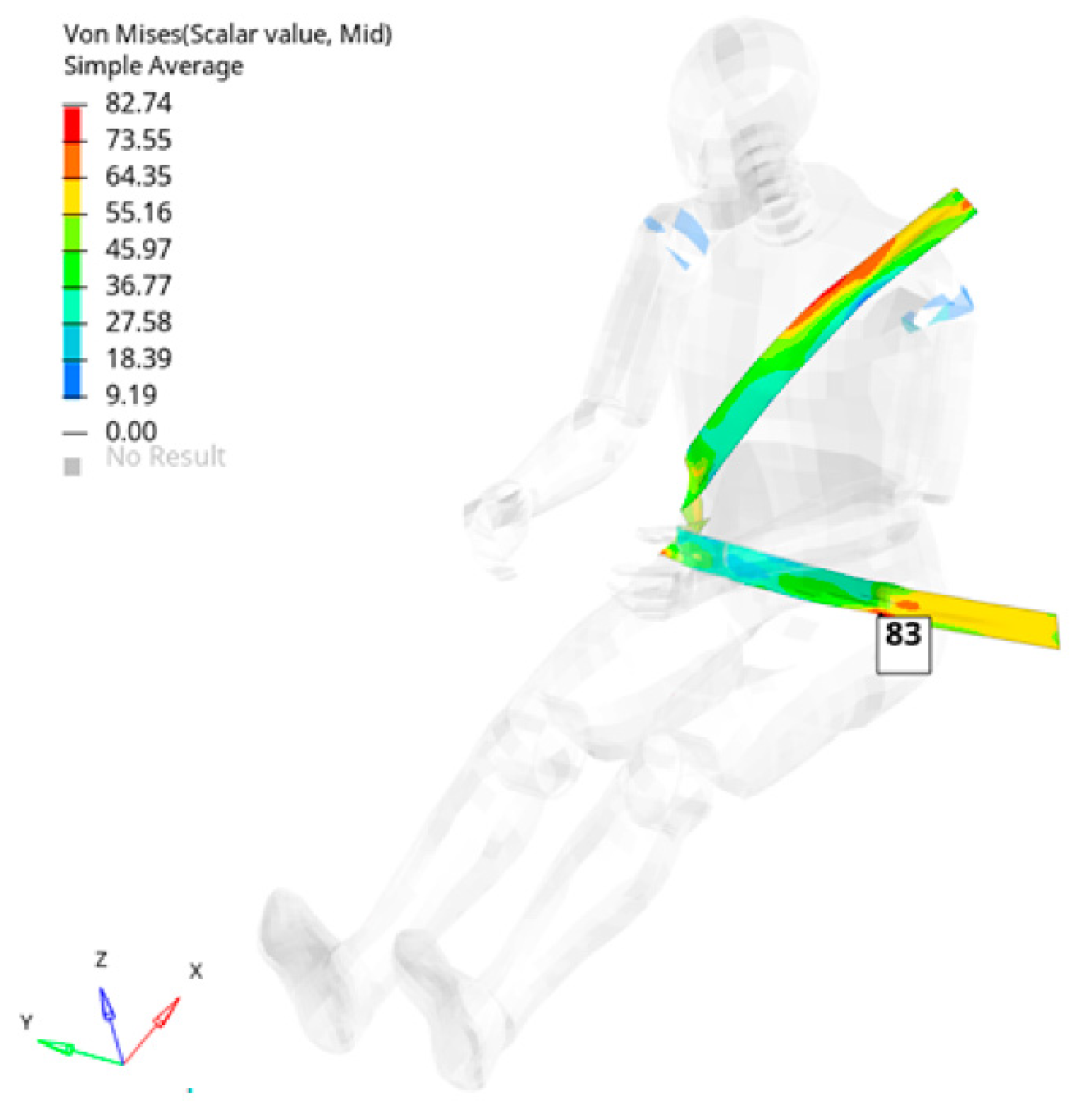

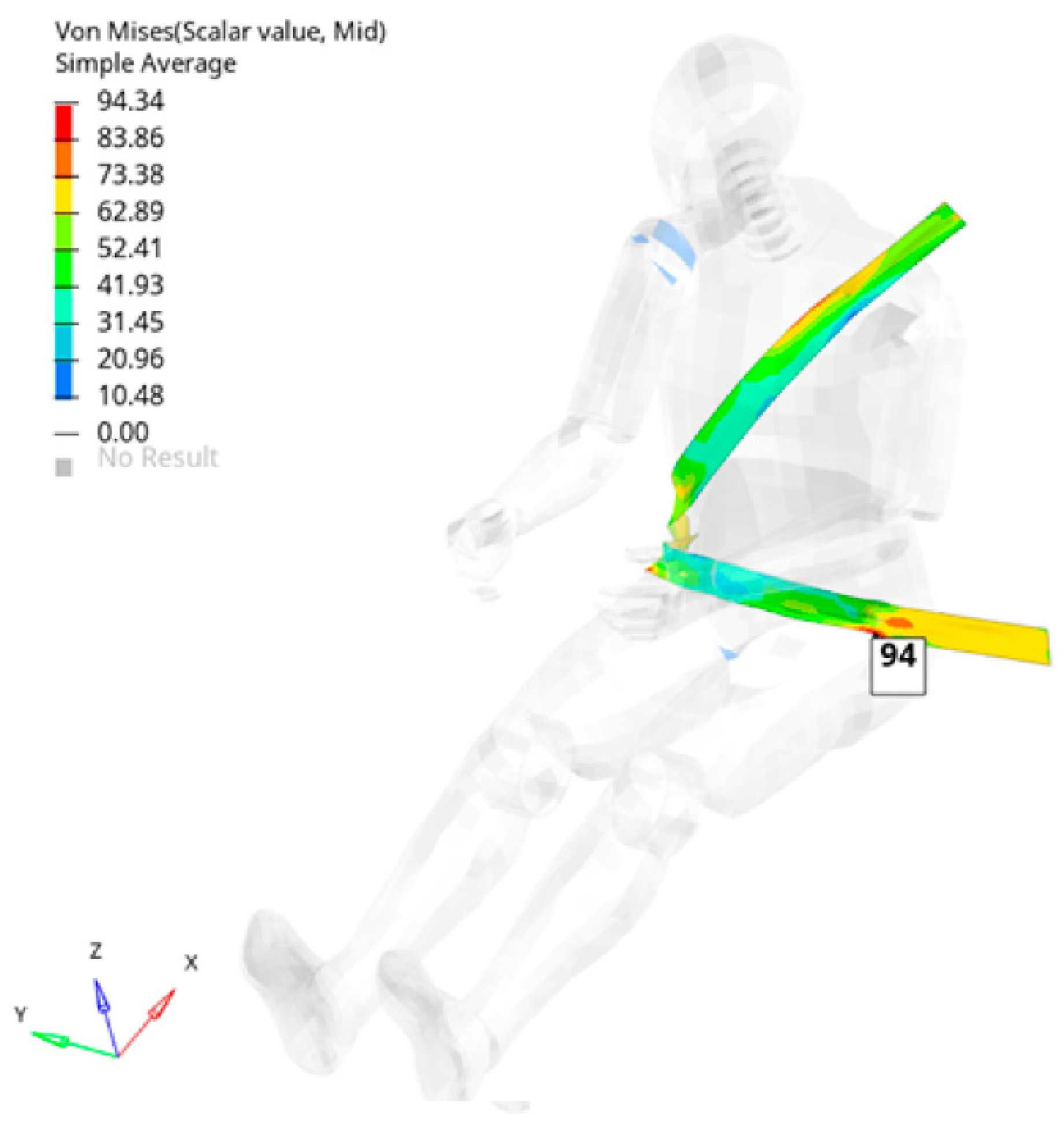

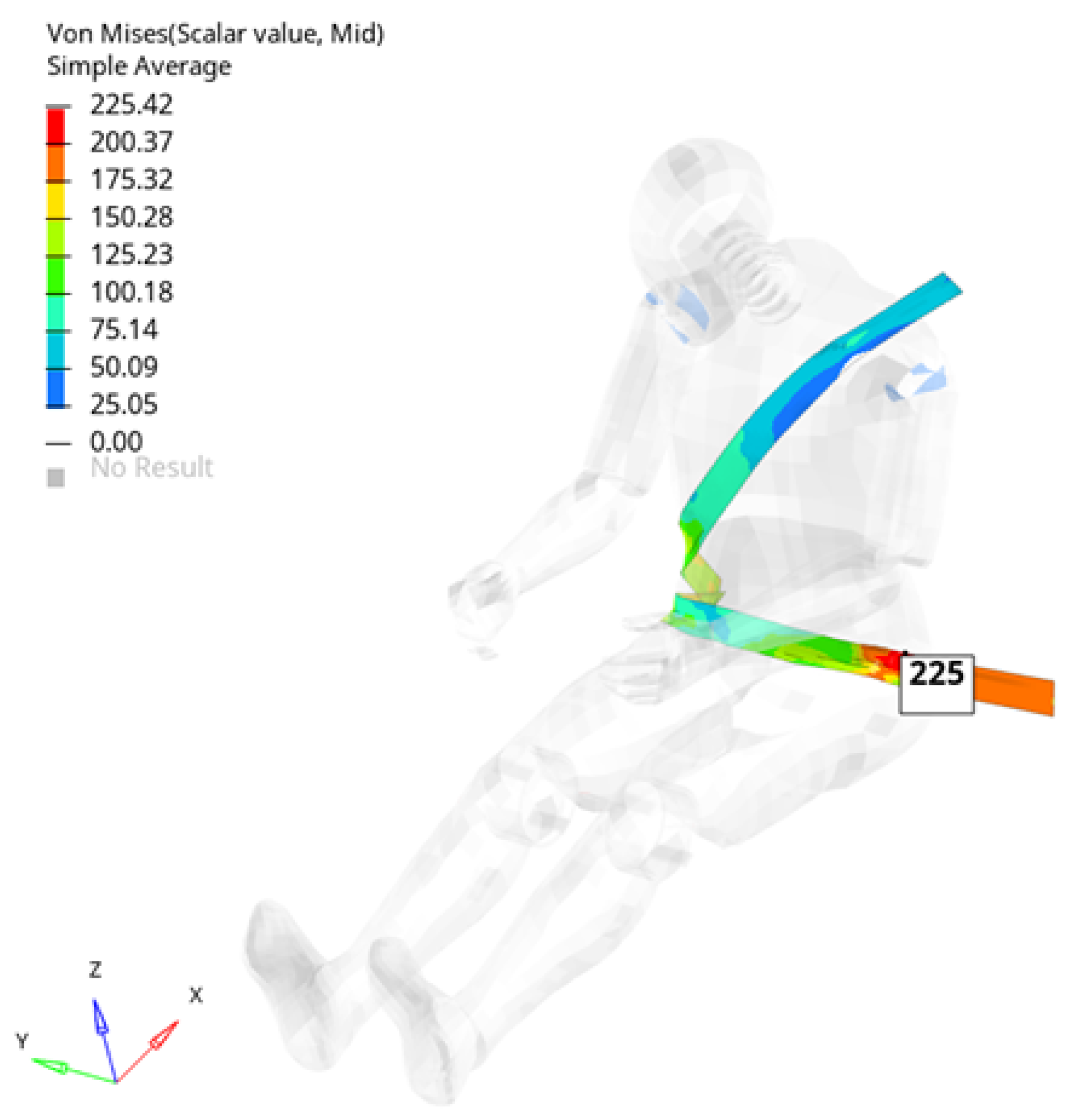

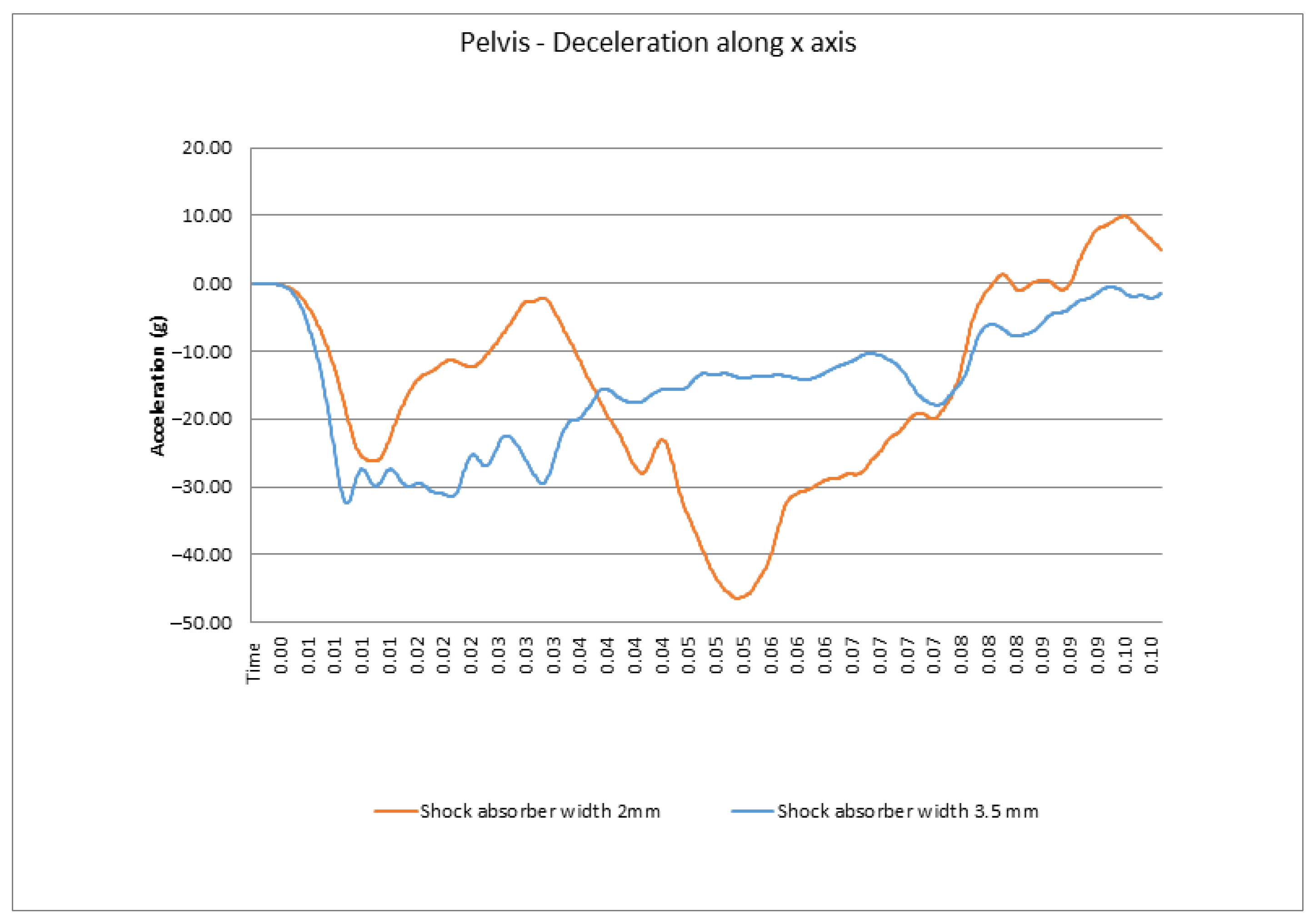

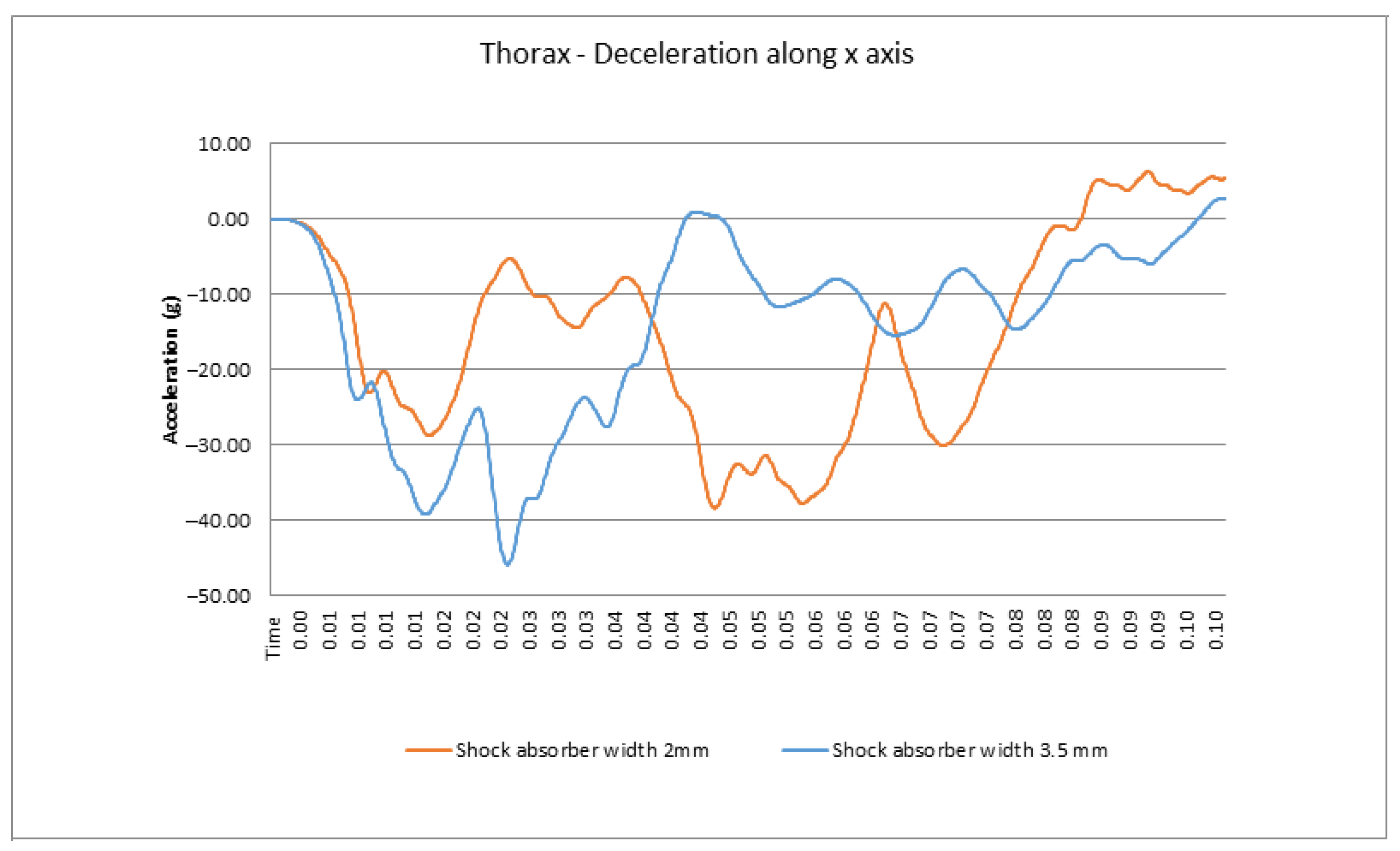

4. Results

5. Discussion and Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ashley, S. Mechanical Seat-Belt Tensioner. Mech. Eng. 1992, 114, 24. [Google Scholar]

- DeGaspari, J. ‘Smarter’ seat belt fiber. Mech. Eng. 2002, 124, 22–30. [Google Scholar]

- Takimizu, Y. Retraction performance of motor vehicle seat belt. J. Jpn. Soc. Tribol. 1997, 42, 625–630. [Google Scholar]

- Sances, A.; Kumaresan, S.; Herbst, B.; Meyer, S.; Hock, D. Biomechanics of seat belt restraint system. In Proceedings of the 41st Annual Rocky Mountain Bioengineering Symposium/41st International ISA Biomedical Sciences Instrumentation Symposium, Ft Collins, CO, USA, 23–25 April 2004; Volume 449, pp. 377–380. [Google Scholar]

- Shi, P.C.; Xu, Z.W. Analysis of Seat. In Proceedings of the 5th Annual International Conference on Material Science and Environmental Engineering (MSEE 2017), Xiamen, China, 15–17 October 2017; Volume 301, p. 012127. [Google Scholar] [CrossRef]

- Huston, R.L. A Review of the effectiveness of seat belt systems: Design and safety considerations. Int. J. Crashworthiness 2001, 6, 243–252. [Google Scholar] [CrossRef]

- Zhao, F.; Jiao, H.Y. Topography Optimization of Automobile Seat Belt Bracket. the 2017 International Conference on Mechanical, Electronic, Control and Automation Engineering (MECAE 2017), Beijing, China, 25–26 March 2017; Volume 61, pp. 10–14. [Google Scholar]

- Dubois, D.; Gross, P.; Tramecon, A.; Markiewicz, E. Finite element analysis of seat belt bunching phenomena. Int. J. Crashworthiness 2006, 11, 519–528. [Google Scholar] [CrossRef]

- Kang, S.J.; Chun, B.K. Strength analysis of automotive seat belt anchorage. Int. J. Veh. Des. 2001, 26, 496–508. [Google Scholar] [CrossRef]

- Roberts, A.; Partain, M.; Batzer, S.; Renfroe, D. Failure analysis of seat belt buckle inertial release. Eng. Fail. Anal. 2007, 14, 1135–1143. [Google Scholar] [CrossRef]

- Dubois, D.; Zellmer, H.; Markiewicz, E. Experimental and numerical analysis of seat belt bunching phenomenon. Int. J. Impact Eng. 2009, 36, 763–774. [Google Scholar] [CrossRef]

- Cao, L.G.; Feng, H. Torque performance measurement system for spring in seat belt. In Proceedings of the 3rd International Conference on Advances in Materials Manufacturing (ICAMMP 2012), Beihai, China, 22–23 December 2012; Volume 655–657, pp. 1149–1152. [Google Scholar] [CrossRef]

- Tang, Y.M.; Lv, N.; Xue, Q.; Wang, T.; Tan, W.F. Experiment Simulation of Seat Belt and ISOFIX Anchorage for a Commercial Vehicle. In Proceedings of the 8th International Conference on Measuring Technology and Mechatronics Automation (ICMTMA), Macau, China, 11–12 March 2016; pp. 282–285. [Google Scholar] [CrossRef]

- Jung, S.P.; Park, T.W.; Park, C.S. Dynamic analysis and design optimisation of the seat belt pretensioner. Veh. Syst. Dyn. 2010, 48, 65–78. [Google Scholar] [CrossRef]

- Meyer, S.E.; Hock, D.; Forrest, S.; Herbst, B. Motor vehicle seat belt restraint system analysis during rollover. In Proceedings of the 40th Annual Rocky Mountain Bioengineering Symposium/40th International ISA Biomedical Sciences Instrumentation Symposium, Biloxi, MS, USA, 10–13 April 2003; Volume 39, pp. 229–240. [Google Scholar]

- Karishma, P.; Venugopal, K.V.; Raju, I.R.K. Optimization and Impact Analysis of a Roll Cage Model. Int. Res. J. Eng. Technol. (IRJET) 2018, 5, 526–543. [Google Scholar]

- Kanketr, T.; Phongphinnittana, E.; Patamaprohm, B. Design of a CFRP composite monocoque: Simulation approach. In Proceedings of the 9th Thai-Society-of-Mechanical-Engineers International Conference on Mechanical Engineering (TSME-ICoME), Phuket, Thailand, 11–14 December 2018; IOP Conference Series-Materials Science and Engineering. Volume 501, p. 012014. [Google Scholar] [CrossRef]

- Lufinka, A. Crash Test of the Student Racing Car Impact Attenuator. In Proceedings of the 58th International Conference of Machine Design Departments (ICMD 2017), Prague, Czech Republic, 6–8 September 2017; pp. 210–213. [Google Scholar]

- Kaul, A.; Abbas, A.; Smith, G.; Manjila, S.; Pace, J.; Steinmetz, M. A revolution in preventing fatal craniovertebral junction injuries: Lessons learned from the Head and Neck Support device in professional auto racing. J. Neurosurgey-Spine 2016, 25, 756–761. [Google Scholar] [CrossRef] [PubMed]

- Mihradi, S.; Golfianto, H.; Mahyuddin, A.I.; Dirgantara, T. Head Injury Analysis of Vehicle Occupant in Frontal Crash Simulation: Case Study of ITB’s Formula SAE Race Car. J. Eng. Technol. Sci. 2017, 49, 534–545. [Google Scholar] [CrossRef]

- Guegan, P.; Lebreton, D.; Pasco, F.; Othman, R.; Le Corre, S.; Poitou, A. Metallic energy-absorbing inserts for Formula One tyre barriers. Proceeding Inst. Mech. Eng. Part D-J. Automob. Eng. 2008, 222, 699–704. [Google Scholar] [CrossRef]

- Davies, H.C.; Bryant, M.; Hope, M.; Meiller, C. Design, development, and manufacture of an aluminium honeycomb sandwich panel monocoque chassis for Formula Student competition. Proceeding Inst. Mech. Eng. Part D-J. Automob. Eng. 2012, 226, 325–337. [Google Scholar] [CrossRef]

- Albak, E.I.; Solmaz, E.; Kaya, N.; Ozturk, F. Impact attenuator conceptual design using lightweight materials and meta-modeling technique. Mater. Test. 2019, 61, 621–626. [Google Scholar] [CrossRef]

- Switek, W.; Vallejo, R. Finite element dynamic simulation of a race car. In Proceedings of the Computer Aided Optimum Design of Structures VIII, Structures and Materials, Proceedings of the 8th International Conference on Computer Aided Optimum Design of Structures, Dearborn, MI, USA, 19–21 May 2003; WIT Press: Southampton, UK; Volume 13, pp. 115–122.

- Nguyen, H.C.; Vo-Minh, T. The use of the node-based smoothed finite element method to estimate static and seismic bearing capacities of shallow strip footings. J. Rock Mech. Geotech. Eng. 2022, 14, 180–196. [Google Scholar] [CrossRef]

- Iorio, L. Revisiting the 2PN Pericenter Precession in View of Possible Future Measurements. Universe 2020, 6, 53. [Google Scholar] [CrossRef]

- Negrean, I. Formulations about Elastodynamics in Robotics. Acta Tech. Napoc. Ser. Appl. Math. Mech. Eng. 2019, 62, 237–250. [Google Scholar]

- Hassan, M.; Bruni, S. Experimental and numerical investigation of the possibilities for the structural health monitoring of railway axles based on acceleration measurements. Struct. Health Monit. Int. J. 2019, 18, 902–919. [Google Scholar] [CrossRef]

- Xiao, M.L.; Zhang, Y.; Zhu, H.Y. The mechanism of hindering occupants’ evacuation from seismic responses of building. Nat. Hazards 2019, 96, 669–692. [Google Scholar] [CrossRef]

- Ma, S.J.; Xu, X.X.; Huang, P.T.; Hu, L.Y. The discussion on Lagrange equation containing third order derivatives. Acta Phys. Sin. 2004, 53, 3648–3651. [Google Scholar]

- Krut’ko, P.D. Energy damping problems and control algorithms of motion of dynamical systems. Nonlinear models. J. Comput. Syst. Sci. Int. 1999, 38, 841–859. [Google Scholar]

- Kim, C.J.; Kang, Y.J.; Lee, B.H. Experimental spectral damage prediction of a linear elastic system using acceleration response. Mech. Syst. Signal Processing 2011, 25, 2538–2548. [Google Scholar] [CrossRef]

- Krutko, P.D. Control of the motion of Lagrangian systems. Synthesis of algorithms by the method of the inverse problems of dynamics. J. Comput. Syst. Sci. Int. 1996, 34, 77–94. [Google Scholar]

- Berges, C.; Weber, Y.; Soufflet, P. General linearized model use for High Power Reliability Assessment test results: Conditions, procedure and case study. Microelectron. Reliab. 2015, 55, 1346–1350. [Google Scholar] [CrossRef]

- Stachiw, T.; Khouli, F.; Langlois, R.G.; Afagh, F.F. Linearization of Aircraft Landing Equations of Motion with Airframe Flexibility Effects. SAE Int. J. Aerosp. 2022, 15, 19–38. [Google Scholar] [CrossRef]

- Ledezma-Ramirez, D.F.; Guzman-Nieto, M.; Tapia-Gonzalez, P.E.; Ferguson, N.S. Shock isolation systems using non linear stiffness and damping. Proceedings of International Conference on Noise and Vibration Engineering (ISMA2014) and International Conference on Uncertainty in Structural Dynamics (USD2014), Leuven, Belgium, 15–17 September 2014; pp. 4111–4121. [Google Scholar]

- Kim, K.H.; Yoh, J. Multi-physics modeling based on combustion of energetic materials. Explosion, Shock Wave and Hypervelocity Phenomena in Materials. In Materials Science Forum; Materials II, Book Series; Trans Tech Publications Ltd.: Bäch, Switzerland, 2008; Volume 566, pp. 95–100. [Google Scholar] [CrossRef]

- Murthy, A.N.; Pfabe, M.; Xu, J.F.; Talke, F.E. Dynamic response of 1-in. form factor disk drives to external shock and vibration loads. Microsyst. Technol. 2007, 13, 1031–1038. [Google Scholar] [CrossRef]

- Clegg, R.A.; Hayhurst, C.J.; Nahme, H. Validation of an advanced material model for simulating the impact and shock response of composite materials. AIP Conf. Proc. 2002, 620, 685–688. [Google Scholar] [CrossRef]

- Hundal, M.S. Linear Shock Isolator—Response to Velocity Pulse. J. Sound Vib. 1983, 86, 293–296. [Google Scholar] [CrossRef]

- Hill, R.J.; Boratav, O.N. Next-order structure-function equations. Phys. Fluids 2001, 13, 276–283. [Google Scholar] [CrossRef]

- Alghafir, M.N.; Dunne, J.F. A NARX damper model for virtual tuning of automotive suspension systems with high-frequency loading. Veh. Syst. Dyn. 2012, 50, 167–197. [Google Scholar] [CrossRef]

- Wheaton, B.J.; Maybeck, P.S. 2nd-Order Acceleration Models for an MMAE Target Tracker. IEEE Trans. Aerosp. Electron. Syst. 1995, 31, 151–167. [Google Scholar] [CrossRef]

- Djenidi, L.; Antonia, R.A. Modeling the third-order velocity structure function in the scaling range at finite Reynolds numbers. J. Math. Phys. 2021, 62, 083102. [Google Scholar] [CrossRef]

- Owen, H.; Codina, R. A third-order velocity correction scheme obtained at the discrete level. Int. J. Numer. Methods Fluids 2012, 69, 57–72. [Google Scholar] [CrossRef]

- Filben, T.M.; Pritchard, N.S.; Oravec, C.S.; Hile, C.W.; Bercaw, J.R.; Zoch, S.R.; Miller, L.E.; Bullock, G.S.; Flashman, L.A.; Miles, C.M.; et al. Pilot characterization of head kinematics in grassroots dirt track racing traffic injury prevention. Traffic Inj. Prev. 2022, in press. [Google Scholar] [CrossRef]

- Bhat, A.; Gupta, V.; Aulakh, S.S.; Elsen, R.S. Generative design and analysis of a double-wishbone suspension assembly: A methodology for developing constraint oriented solutions for optimum material distribution. J. Eng. Des. Tecnol. 2021, in press. [Google Scholar] [CrossRef]

- Drage, T.; Lim, K.L.; Koh, J.E.H.; Gregory, D.; Brogle, C.; Braunl, T. Integrated Modular Safety System Design for Intelligent Autonomous Vehicles. In Proceedings of the 2021 IEEE Intelligent Vehicles Symposium (IV), Nagoya, Japan, 11–17 July 2021; pp. 258–265. [Google Scholar] [CrossRef]

- Vaverka, O.; Koutny, D.; Palousek, D. Topologically optimized axle carrier for Formula Student produced by selective laser melting. Rapid Prototyp. J. 2019, 25, 1545–1551. [Google Scholar] [CrossRef]

- Vlase, S.; Teodorescu, P.P. Elasto-Dynamics of a Solid with a General “RIGID” Motion using FEM Model. Part I. Theoretical Approach. Rom. J. Phys. 2013, 58, 872–881. [Google Scholar]

- Vlase, S.; Negrean, I.; Marin, M.; Scutaru, M.L. Energy of Accelerations Used to Obtain the Motion Equations of a Three-Dimensional Finite Element. Symmetry 2020, 12, 321. [Google Scholar] [CrossRef]

- Gibbs, J.W. On the fundamental formulae of dynamics. Am. J. Math. 1879, 2, 49–64. [Google Scholar] [CrossRef]

- Appell, P. Sur une forme générale des equations de la dynamique. C.R. Acad. Sci. Paris 1899, 129, 317–320. [Google Scholar]

- Mirtaheri, S.M.; Zohoor, H. The Explicit Gibbs-Appell Equations of Motion for Rigid-Body Constrained Mechanical System. In Proceedings of the RSI International Conference on Robotics and Mechatronics ICRoM, Piscataway, NJ, USA, 23–25 October 2018; pp. 304–309. [Google Scholar]

- Korayem, M.H.; Dehkordi, S.F. Motion equations of cooperative multi flexible mobile manipulator via recursive Gibbs-Appell formulation. Appl. Math. Model. 2019, 65, 443–463. [Google Scholar] [CrossRef]

- Shafei, A.M.; Shafei, H.R. A systematic method for the hybrid dynamic modeling of open kinematic chains confined in a closed environment. Multibody Syst. Dyn. 2017, 38, 21–42. [Google Scholar] [CrossRef]

- Korayem, M.H.; Dehkordi, S.F. Derivation of dynamic equation of viscoelastic manipulator with revolute-prismatic joint using recursive Gibbs-Appell formulation. Nonlinear Dyn. 2017, 89, 2041–2064. [Google Scholar] [CrossRef]

- Vlase, S.; Marin, M.; Scutaru, M.L. Maggi’s equations used in the finite element analysis of the multibody systems with elastic elements. Mathematics 2020, 8, 399. [Google Scholar] [CrossRef]

- Ursu-Fisher, N. Elements of Analytical Mechanics; House of Science Book Press: Cluj-Napoca, Romania, 2015. [Google Scholar]

- Negrean, I.; Crișan, A.-D.; Vlase, S. A New Approach in Analytical Dynamics of Mechanical Systems. Symmetry 2020, 12, 95. [Google Scholar] [CrossRef]

- Vlase, S.; Negrean, I.; Marin, M.; Nastac, S. Kane’s Method-Based Simulation and Modeling Robots with Elastic Elements, Using Finite Element Method. Mathematics 2020, 8, 805. [Google Scholar] [CrossRef]

- European New Car Assessment Programme (Euro NCAP), Frontal Impact Testing Protocol Version 6.0 August 2012. Available online: https://cdn.euroncap.com/media/1478/euro-ncap-side-protocol-version-60.pdf (accessed on 27 August 2022).

- The Biofidelity of Hybrid III Dummies, Dimitrios Kallieris, Andreas Rizzetti, Rainer Mattern, Institute of Legal Medicine University of Heidelberg. Available online: http://www.ircobi.org/wordpress/downloads/irc1995/pdf_files/1995_10.pdf (accessed on 27 August 2022).

- Injury Criteria for Side Impact Dummies, May 2004, By Shashi Kuppa National Transportation Biomechanics Research Center National Highway Traffic Safety Administration. Available online: https://www.nhtsa.gov/DOT/NHTSA/NRD/Multimedia/PDFs/Biomechanics%20&%20Trauma/MiscBio/NPRM_SID.pdf (accessed on 27 August 2022).

- Hybrid III 50th Male FE|Humanetics. Available online: humaneticsgroup.com (accessed on 25 September 2022).

- Li, X. Simulation System of Car Crash Test in C-NCAP Analysis Based on an Improved Apriori Algorithm. Phys. Procedia 2012, 25, 2066–2071. [Google Scholar] [CrossRef]

- Martinez, M.J. Artificial Neural Networks for Passive Safety Assessment. Eng. Lett. 2022, 30, 289–297. [Google Scholar]

- Untaroiu, C.D.; Shina, J.; Ivarssona, J.; Crandalla, J.R.; Subita, D.; Takahashib, Y.; Akiyamab, A.; Kikuchi, Y. A study of the pedestrian impact kinematics using finite element dummy models: The corridors and dimensional analysis scaling of upper-body trajectories. Int. J. Crashworthiness 2008, 13, 469–478. [Google Scholar] [CrossRef]

- Bhatti, M.M.; Marin, M.; Zeeshan, A.; Abdelsalam, S.I. Recent trends in computational fluid dynamics. Front. Phys. 2020, 8, 593111. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Itu, C.; Toderita, A.; Melnic, L.-V.; Vlase, S. Effects of Seat Belts and Shock Absorbers on the Safety of Racing Car Drivers. Mathematics 2022, 10, 3593. https://doi.org/10.3390/math10193593

Itu C, Toderita A, Melnic L-V, Vlase S. Effects of Seat Belts and Shock Absorbers on the Safety of Racing Car Drivers. Mathematics. 2022; 10(19):3593. https://doi.org/10.3390/math10193593

Chicago/Turabian StyleItu, Calin, Ana Toderita, Lucia-Violeta Melnic, and Sorin Vlase. 2022. "Effects of Seat Belts and Shock Absorbers on the Safety of Racing Car Drivers" Mathematics 10, no. 19: 3593. https://doi.org/10.3390/math10193593

APA StyleItu, C., Toderita, A., Melnic, L.-V., & Vlase, S. (2022). Effects of Seat Belts and Shock Absorbers on the Safety of Racing Car Drivers. Mathematics, 10(19), 3593. https://doi.org/10.3390/math10193593