Bridging the Gap between Academia and Practice: Project-Based Class for Prestressed Concrete Applications

Abstract

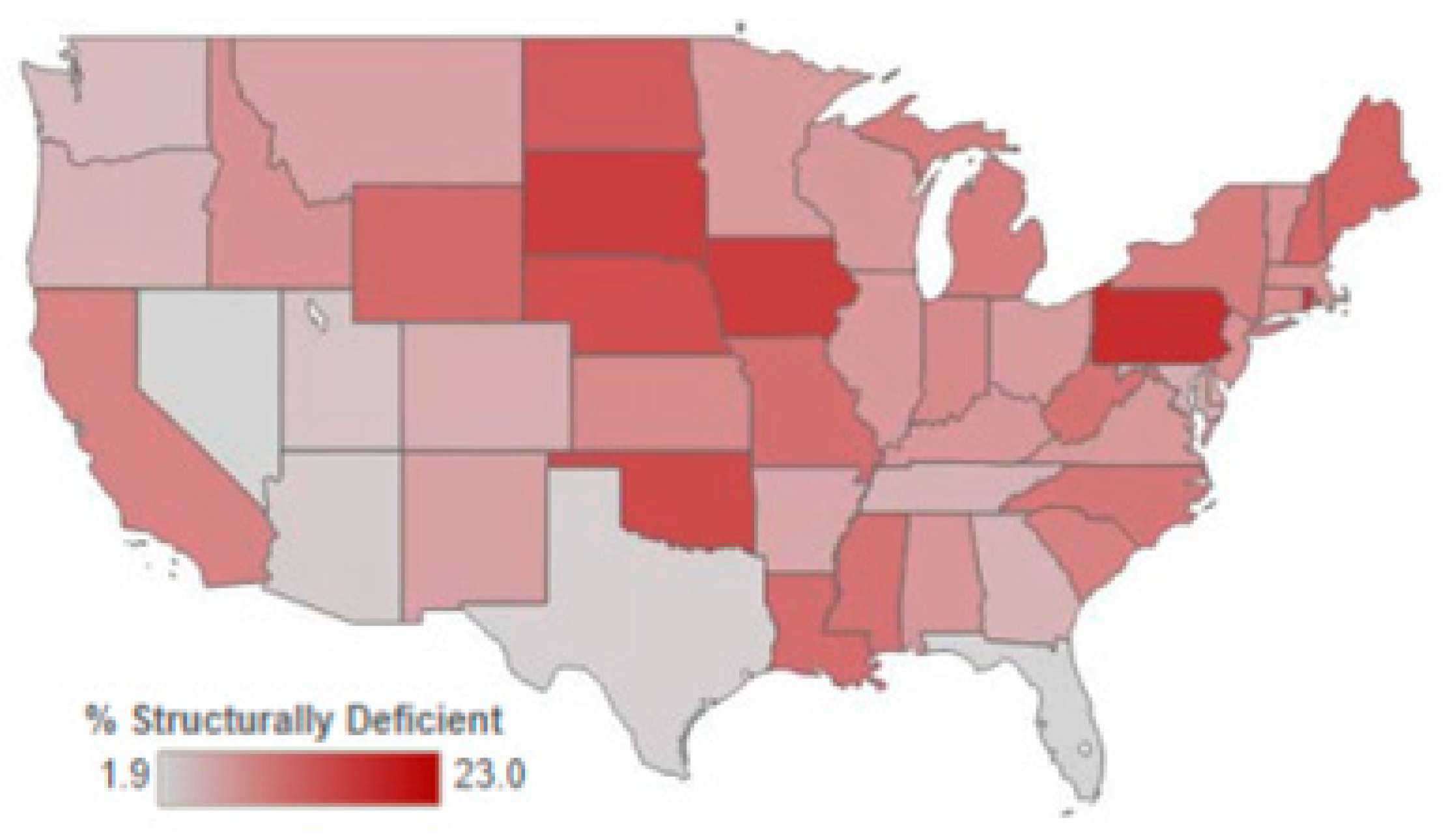

:1. Introduction

2. Literature Review on Problem-Based Learning

3. Project Methodology

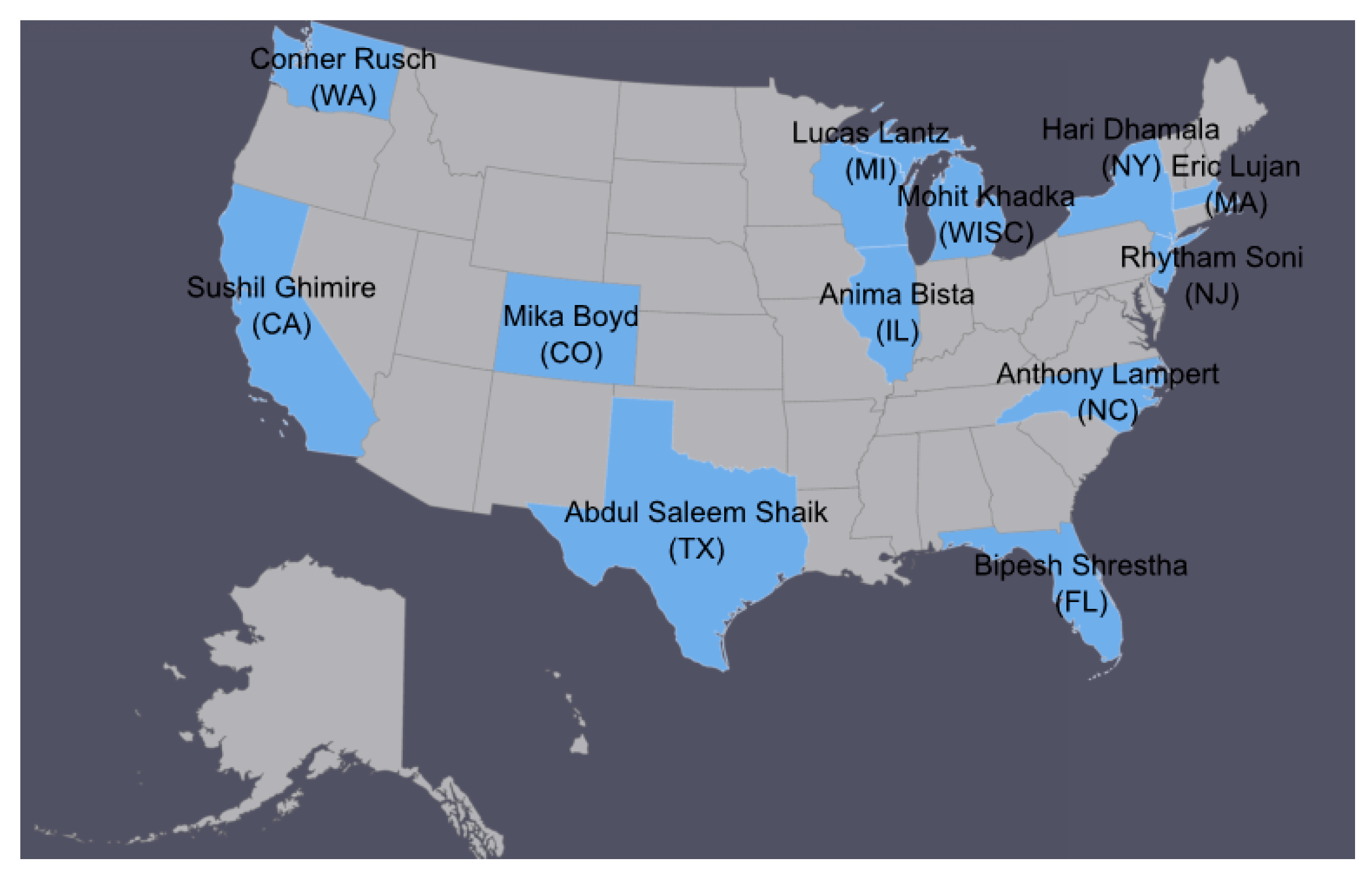

3.1. Class Layout

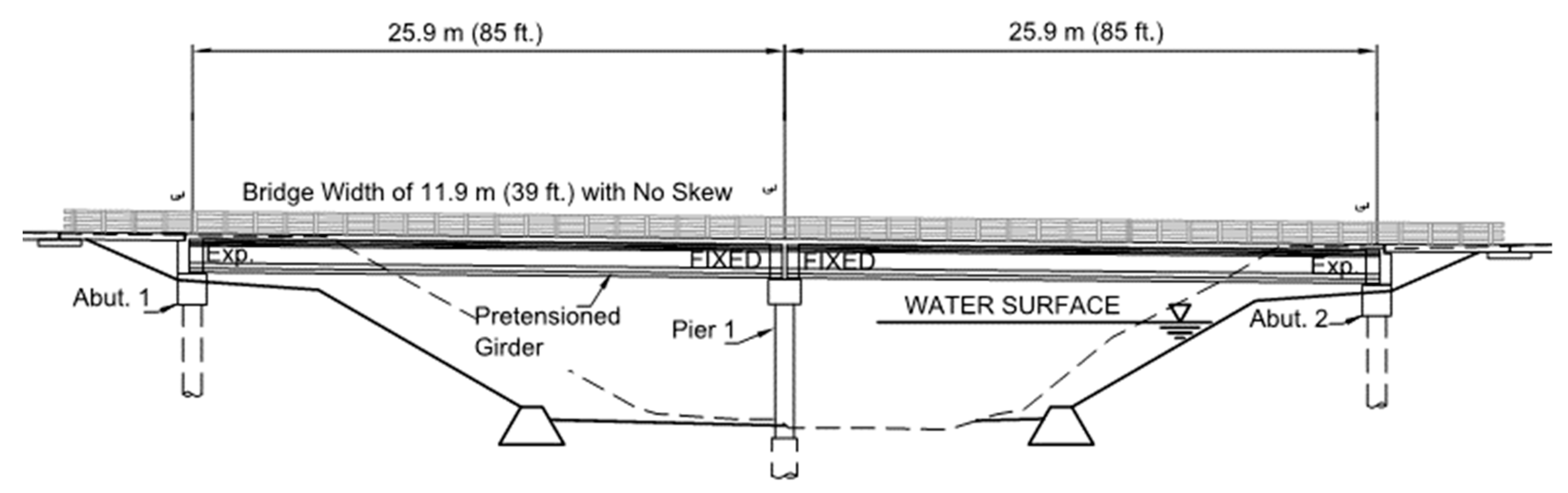

3.2. Project Objectives and Description

- Educate students on commercial software widely used in designing prestressed girders in the state departments of transportation.

- Educate student on bridge design manuals of the state departments of transportation to identify the difference between manuals and AASHTO LRFD 2014 [4].

- Educate students on the backcheck process needed to identify mistakes in modelling, using commercial software to enhance the confidence in modelling results.

- Prepare structural engineers of tomorrow in terms of practical knowledge, critical thinking, and engineering judgment.

- Pre-design phase: literature review of the selected U.S. State’s bridge manual during the semester to contrast the difference between state practice and AASHTO-LRFD 2014 [4], including all additional design requirements. The outcome of this literature review is highlighted in Section 4.1.

- Design phase, which entailed sizing the pretensioned girders according to the standard sizes per each state bridge manual, calculating the amount of prestressed steel (known as the number of prestressing strands) to satisfy stresses, flexural, shear and deflection requirements, and providing structural drawings for the pretensioned girder and its reinforcement.

- Post-design phase: head-to-head presentation by pairing students to contrast the differences in their design due to the use of two different states’ design manuals. This presentation was used as the project final exam to evaluate the final design for each student.

- Computational bridge layout and design.

- Analysis, design, and load rating for post-tensioned and reinforced concrete box girder, T-beam, and slab bridges.

- Analysis, design, and load rating for simple and multi-span precast and prestressed concrete bridges.

- Analysis and design of reinforced concrete abutments, piers, and foundations.

- Analysis and design of spliced precast/prestressed bridge girders.

4. Project Results

4.1. Literature Review on State Bridge Manuals

- Expanding the knowledge of different bridge design manuals (11 design manuals for each student) outside the assigned bridge design manual.

- Helping students to identify the differences between AASHTO-LRFD 2014 [4] and state bridge design manuals for the later use of commercial software.

- Knowledge exchange between students and instructor, where both sides learn from each other through discussions.

4.1.1. California

- Among many standard girders, the I-girder is most commonly used and has been in use in California for nearly 60 years, with bridge span lengths normally ranging from 15.25 m to 38.1 m (50 ft. to 125 ft.). The bulb-tee girder is targeted for bridge spans up to from 24.4 m to 45.7 m (80 ft. to 150 ft.).

- For economic reasons, prestressed concrete (PC) girders commonly use 15.24 mm (0.6 in.) diameter, 1860 MPa (270 ksi), low relaxation strands. Using 12.7 mm (0.5 in.) diameter strands is less common because the 15.24 mm (0.6 in.) diameter strands provide a significantly higher efficiency due to a 42% increase in capacity.

- Live loads are based on the HL-93 design truck defined in AASHTO-LRFD 2014 [4] and permit truck P-13.

- Zero-tension stress is permitted at service condition under dead load only.

4.1.2. Colorado

- Colorado use standard BT (Bulb T) girders.

- The prestressing strand shall be 15.24 mm (0.6 in.) diameter, low-relaxation strand, with a design ultimate tensile strength of 1860 Mpa (270 ksi).

- Live loads are based on the HL-93 design truck defined in AASHTO-LRFD 2014 [4].

4.1.3. Florida

- The Florida-I Beams and the AASHTO Type II Beam are the Department’s standard prestressed concrete I-shaped beams and are used in the design of all new bridges and bridge widenings, with I-shaped beams as applicable.

- All pretensioning strands shall follow ASTM A416, 1860 MPa (270 ksi), low-relaxation, prestressing strands for the design of prestressed beams. The use of stress-relieved strands is prohibited. The use of straight-strand configurations is preferred over draped strand configurations.

- Live loads are based on the HL-93 design truck defined in AASHTO-LRFD 2014 [4].

4.1.4. Illinois

- High-Performance Concrete shall be the standard concrete for prestressed bridge elements. The minimum concrete strength (f’c) for prestressed concrete bridge beams shall be 48.25 MPa (7 ksi). The concrete strength at transfer (f’ci) can be taken as 0.6 f’c unless the designer determines a higher transfer strength is necessary.

- Prestressing steel for all new prestressed-precast girder construction shall be uncoated 7-wire, low-relaxation (low-lax) strands with a nominal diameter of 12.7 mm (0.5 in.) and ultimate strength of 1860 MPa (270 ksi). Strands with a nominal diameter of 15.24 mm (0.6 in.). are not permitted. Stress-relieved strands are not permitted for the new construction of precast pestressed concrete (PPC) girders.

4.1.5. Texas

- Texas uses pretensioned concrete I-girders, U-beams, slab beams, spread slab beams, decked slab Beams, double-tee beams, box beams, spread box beams (X-beams), straight plate girders, and curved plate girders.

- Live loads are based on the HL-93 design truck defined in AASHTO-LRFD 2014 [4].

4.1.6. Massachusetts

- Massachusetts, along with five other New England states, Connecticut, Maine, New Hampshire, Rhode Island, and Vermont, joined together to design the New England Bulb Tee girder (NEBT). The former New England standard was the AASHTO I-girder, but this particular girder began to suffer limitations in its range of applicability in New England. The New England bulb tee was designed with the federal metrication in mind and developed on hard metric units.

- All pretensioning strands shall be 15.24 mm (0.6 in.), uncoated 7-wire, low relaxation steel strands and shall conform to AASHTO M 203. The nominal tensile strength of the pretensioning strands shall be 1860 MPa (270 ksi). The minimum 28-day compressive strength shall be 45 Mpa (6.5 ksi).

- Live loads are based on the HL-93 design truck defined in AASHTO-LRFD 2014 [4].

4.1.7. Michigan

- MDOT uses AASHTO Types 1–4, with concrete strengths of 34.5 MPa–55 m MPa (5 ksi–8 ksi) concrete allowed if the span is less than or equal to 34.75 m (114 ft.), in the Upper Peninsula, Wisconsin type I beams (1780 mm or 70 in. deep) can be used for spans up to 36.6 m (120 ft.) with a concrete strength of 34.5 MPa–55 m MPa (5 ksi–8 ksi), and in the Lower Peninsula, Michigan 1800 Girder (1800 mm or 70.9 in. deep) at strengths of 34.5 MPa–55 m MPa (5 ksi–8 ksi) concrete can be used for spans up to 44.2 m (145 ft.).

- Live loads are based on 125% of the HL93 design truck defined in AASHTO-LRFD 2014 [4].

4.1.8. North Carolina

- Girders can be AASHTO Type II, Type IV, Type V, Type VI, 63 in. or 72 in. Modified Bulb Tee.

- The two acceptable strand diameters are 12.7 mm (0.5 in.) and 15.24 mm (0.6 in.), both at 1860 MPa (270 ksi). When using draped strands, if a straight strand design can be used by adding up to six straight strands, then detail using the straight strands. If it takes more than six straight strands, then keep the draped design. The slope of draped strands shall not exceed 12.5%.

- Live loads are based on the HL-93 design truck defined in AASHTO-LRFD 2014 [4].

4.1.9. New Jersey

- Uncoated 7-wire prestressing steel low relaxation strands, conforming to ASTM A416 (AAHSTO M 203), 1860 MPa (270 ksi), shall be used.

- Live loads are based on the HL-93 design truck defined in AASHTO-LRFD 2014 [4].

4.1.10. New York

- The preferred I-Girder shape is the Bulb-Tee. High-Performance Concrete shall be the standard concrete for prestressed bridge elements. The minimum concrete strength (f’c) for prestressed concrete bridge beams shall be 69 MPa (10 ksi). The concrete strength at transfer (f’ci) can be taken as 0.7 f’c, unless the designer determines a higher transfer strength is necessary.

- Only 1860 MPa (270 ksi), Low-Relaxation Prestressing Steel Strand shall be used. The standard diameter used by NYSDOT is 15.24 mm (0.6 in.).

- Live loads are based on the HL-93 defined design truck in AASHTO-LRFD 2014 [4].

4.1.11. Washington

- WSDOT differs from AASHTO girders as it uses all of its own type of girders. Every girder has similar cross sections but varies based on the depth needed. The girders start at 1067 mm (42 in.) depth and go all the way to 2540 mm (100 in.) depth.

- The typical strand is AASHTO M 203 of 1860 MPa (270 ksi), low relaxation or stress-relieved. Reinforcing bars are AASHTO M 275 Type II. The parallel wires are AASHTO M 204 Type WA.

- The design truck used by WSDOT is a HL-93 defined design, which means the use of the design truck HS-20 and the use of a design lane load. This is the same as AASHTO.

- A very conservative assumption of zero-tension under service load along with the requirement of lifting and hauling analyses.

4.1.12. Wisconsin

- WisDOT employs two prestressed I-girder section families. One I section family follows the AASHTO standard section, while the other section family follows a wide flange bulb-tee.

- Low relaxation strand diameters currently used in prestressed I-girders are 12.7 mm (0.5 in.) and 15.24 mm (0.6 in.).

- Live loads are based on the HL-93 defined design truck in AASHTO-LRFD 2014 [4].

4.2. Project Outcome

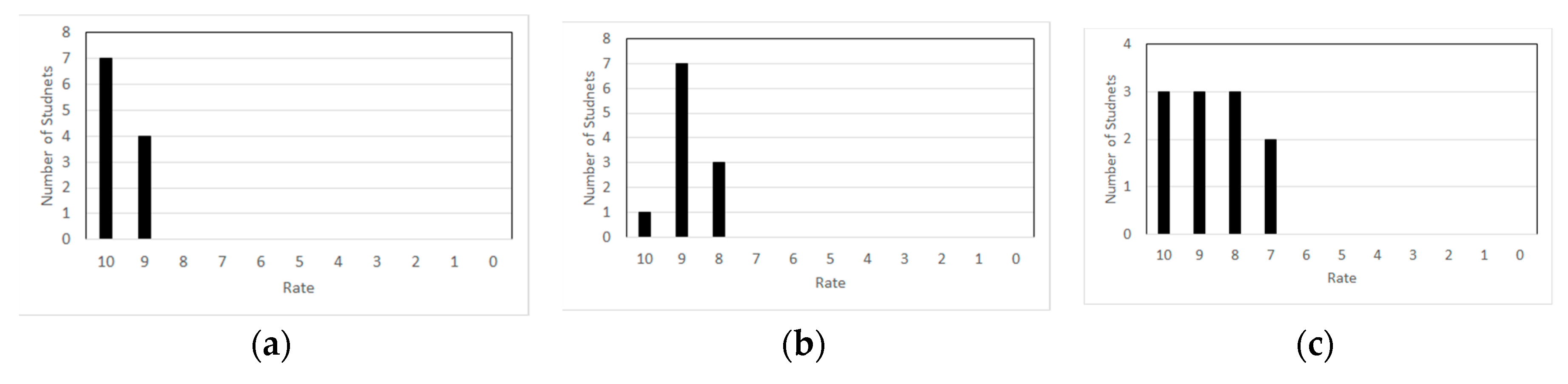

5. Project Assessment

- Students were asked to submit a full design booklet along with design drawings. The documents were then evaluated by the instructor.

- Performance of each student was evaluated throughout the entire project month including quality of work and student Q&A sessions during office hours.

- Head-to-head presentations at the end of the project were performed, where pairs of students were assigned to present at the same time to contrast the differences in their designs.

6. Student Feedback

- Rate the overall project experience.

- Rate the overall experience with commercial software.

- Rate the overall experience with the state bridge manual.

- 4.

- What are the project features that contributed the most to your learning and practical experience?

- 5.

- If you graduate, does this project foster your job search or your performance if you get a structural engineering position?

- 6.

- What did you think of the backcheck process used to check your model and the use of commercial software?

7. Discussion and Conclusions

- All students were able to complete all of the project requirements, including a literature review of the assigned bridge manual, modelling, and analysis of the bridge superstructure’s girders using one software package, backchecking the design of prestressed girders using hand calculations or spreadsheets, and performing a head-to-head presentation for their projects.

- Students’ feedback showed that conducting a literature review on the state bridge design manual was necessary to point out the differences between the state bridge design manual and AASHTO-LRFD 2014 [4].

- Students’ feedback showed that learning to use commercial software was a rewarding experience which helped them to apply the gained knowledge in a practical project.

- Students’ feedback showed that the backchecking process helped them to identify mistakes in inputs and to verify the output design results. Students agreed that the backchecking process was necessary to build confidence in their design.

- Collaboration between instructors at the university level with the leaders and developers of commercial software was necessary to accomplish a good educational environment. Commercial software leaders and developers provided great assistance throughout the project through webinars and free student versions of software packages.

- Due to the time limitation and restriction, only one month was devoted during the class to the project. It will be useful for instructors to develop a stand-alone class based on this class experience; for example, a class on prestressed concrete theory should be a prerequisite class for prestressed concrete projects and applications.

- Similar project-based classes can be developed for many courses in structural engineering, such as steel structures, concrete structures, and highway bridges.

- Several topics can be used as bases for a project-based class on prestressed concrete, such as post-tensioned slabs for buildings, prestressed beams in garages, concrete box girders in bridges, and prestressed tanks.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A

| Opinion | Answer |

|---|---|

| 1 | Fully understanding the material presented during class and applying it on a project that mimics a problem that could be encountered as an engineer is invaluable. It is also important to see each equations significance and how it applies practically. |

| 2 | Using the software was interesting and challenging as well |

| 3 | I would say the combination of the different bridge manual, the software, and having to do the hand calculations together contributed. The manual forced us to directly derive information from a code similar yet different from the standard AASHTO code that comes across many classes. Being able to differentiate between is likely a valuable skill since even just updates of identical codes have differences. The differences are often subtle and hard to point, so in this regard, the project had some practical application outside of just bridge design. The software and hand calculations in conjunction work together in a way to help improve the student’s knowledge of pre-stressed bridge design by allowing the user to quickly design an actual bridge but at the same time make them look at the details behind the design. It also gives an appreciation for the number of iterations done and how it would be impossible to optimize bridges in the same fashion without software. |

| 4 | This project was the direct application of study materials we covered in the class, in the practical field. Since each of us were assigned different state, we got a chance to learn about several states by consulting with each other. The head on presentation was also a good part of this project. |

| 5 | The research into the state manual helped realize the work that would go into finding the design criteria for bridge design. The software showed how much quicker designs can be completed then by hand. |

| 6 | Exposure to practical software use and industrial knowledge. |

| 7 | The project we did was based on the bridge practice that would be possible in the real world. We used all our knowledge of the course we took on Prestressed Concrete and Reinforced Concrete while working on the project. It helped us to get familiar with the real-world practice where the commercial software is used to design the engineering structures. Learning the software was helpful to get started with the first taste of how the industries work and what is going on in the engineering world of design. It gave a feeling that I was in the industry and involved in some serious design that is about to get out into the world from my desktop. |

| 8 | Backchecking the software calculations by hand contributed most as it helped me to deeply understand the concepts and equations involved. |

| 9 | The state bridge manuals are for the specific state, while the AASHTO manual is a general manual for all the states. While comparing the state of New Jersey and knowing about the differences of the state manuals with the AASHTO manual, it helped me understand the reasons why AASHTO has certain specifications while a few states have a few amendments to it based on the condition of the state like the weather, the material availability and other various reasons. This helped me in understanding how the manual is produced instead of following the manual as it is. |

| 10 | Learning commercial software along with the state bridge manual comparing with the AASTHO code which we basically followed in class was the most exciting part of this project. |

| 11 | Verifying the formulas with the software. |

| Opinion | Answer |

|---|---|

| 1 | Yes, a project like this widens the scope of jobs I would feel comfortable applying for because it closely mimics what would be expected for an engineer dealing with pre-stressed concrete design. Understanding different types of software also gives you an advantage when looking for and applying for jobs. |

| 2 | I hope so. I believe most of the companies use commercial software in their design, so having experience already with at least one of the software might give you an edge. |

| 3 | It probably would help most in an instant where I was trying to be a bridge designer, as pre-stressed steel isn’t as widespread in other applications, although having some background knowledge I’m sure can prove useful in the right instant. Likewise, it’s another design project where reading codes with a unique set of design issues, which in reality is good practice for any aspiring engineer because the goal of a degree in engineering is not to make us able to know how to design everything, but how to approach design. The project is also an instance where the students directly were involved with commercial software, which usually in the workplace regardless of what’s being designed there will be some use of computer design programs. For instance, I’ve never used Pgsuper at work, but have come across other commercial software like Enercalc or Hilti, and learning how to utilize these tools and demonstrating that you can learn them can be valuable when trying to achieve employment. |

| 4 | Sure. This project has increased my knowledge in the field of prestressed concrete. This is the first course in Prestressed concrete for me. Since the project work was the exact application of studied materials in class with the use of commercial software, this will definitely be a good point in my resume to attract employer’s attention. |

| 5 | Yes, I am currently working a designing a simple span prestressed concrete bridge in southern Colorado. I am following the steps in class we took for the final project as I work through it. I am using PGSuperTM for analysis. |

| 6 | Yes. Because this allows me to add more software to my skills. If I plan to go towards the path of a bridge engineer, it will add as a strong attribute to my profile because I can show the experience of girder design and ability to use the two software. |

| 7 | This project is a lot of help for the job search as I can now add an extra point in my resume for my skills with the software I used and the course I took to undergo this project. I already feel that I am the beginner practitioner of the software even though I had a short time to learn and get started with the software. |

| 8 | Yes, this will help me in a job search as I can put that I have some industrial design experience through a course project in my resume. |

| 9 | Yes, I plan to work in a bridge design company after I graduate, for which taking the Prestressed Concrete course was helpful as it made me understand the design of prestressed structures along with the commercial software and state manuals. |

| 10 | I am working mostly on steel design on my job after graduation. However, it might have helped very well on my experience as I did put in my resume. |

| 11 | I am sure this project experience would be of very helpful for a Structural Engineer position, right now I am working in Construction Management. |

| Opinion | Answer |

|---|---|

| 1 | It was good to be able to backcheck your calculations with the software as well as backcheck the software with your calculations. It is fast and efficient to be able to start with a base design and make numerous changes within the software program to extract answers fast, which are then backchecked with hand calculations. |

| 2 | I think it is absolutely necessary because as it is said for a software “garbage in garbage out”. You need to be sure what your getting is not garbage. |

| 3 | Considering I should probably backcheck the majority of work I do with any software baring extensive use with it, it’s good practice to backcheck or at least do simple calculations that are going to give one a general idea about the computer results. It also proves that we have the knowledge to properly operate the software because we know, for the most part, what is going on behind the 50-page result list and the fancy 3D model. |

| 4 | The backcheck process is an essential part of the project. There may be some mistakes while inputting data in the software which we won’t be able to figure out unless it is checked with some hand calculations. |

| 5 | The backcheck was useful to show that calculations are the same as the program. |

| 6 | The backcheck was useful because it allowed us to check the errors and where the errors were. This way we could go back into the software and correct the errors. |

| 7 | The software is designed by human and it is there to help our jobs get done easily. However, it is always a good idea to at least check once with the skills you have in hand to see that the code is working right and there is no bug. We can always backcheck our designs and match our hand calculations with the results from the software to see if we are in the same boat. In my understanding, the backcheck increases our understanding of the process and helps us get more accurate results. |

| 8 | The backcheck process was very helpful for me to really understand every part of why the code has certain requirements for pre-stressed girders. |

| 9 | The backcheck process is always important in structural design as the software used to design cannot be always trusted. With the possibility of human error in input to the software or the software coded to design in a certain way can be different from what actually the designer wanted it to be designed. Hence the backcheck process verifies the output of the software, thus confirming the appropriate use of the designed obtained through it. |

| 10 | It is always a nice idea to compare the results from the software with our course learnings and hand calculations. Most of all results were matching between the software and my hand calculation which made me feel confident to use the commercial software if I will be involved in the prestressed concrete domain in my job in the future. |

| 11 | It builds my confidence to use the software and exposure to use the software in the future at the professional level. |

References

- SEI. A Vision for the Future of Structural Engineering and Structural Engineers: A Case for Change; A Board of Governors Task Committee Paper; Structural Engineering Institute (SEI): Reston, VA, USA, 16 October 2013. [Google Scholar]

- PCI Design Handbook, 8th ed.; Precast and Prestressed Concrete Institute: Chicago, IL, USA, 2017.

- American Concrete Institute ACI Committee 318. Building Code Requirements for Structural Concrete ACI318-17 and Commentary (ACI 318R-17); American Concrete Institute: Farmington Hills, MI, USA, 2017. [Google Scholar]

- AASHTO LRFD. Bridge Design Specifications, 7th ed.; American Association of State Highway and Transportation Officials: Washington, DC, USA, 2014. [Google Scholar]

- Federal Highway Administration (FHWA). National Bridge Inventory; U.S. Federal Highway Administration: Washington, DC, USA, 2013.

- Quinn, K.A.; Albano, L.D. Problem-based learning in structural engineering education. J. Prof. Issue Eng. Educ. Pract. 2008, 134, 329–334. [Google Scholar] [CrossRef]

- Johnson, P.A. Problem-based, cooperative learning in the engineering classroom. J. Prof. Issue Eng. Educ. Pract. 1999, 125, 8–11. [Google Scholar] [CrossRef]

- Worcester Polytechnic Institute (WPI). Undergraduate Catalog; WPI: Worcester, MA, USA, 2006; Available online: http://www.wpi.edu (accessed on 25 May 2019).

- Chinowsky, P.S.; Brown, H.; Szajnman, A.; Realph, A. Developing knowledge landscapes through project-based learning. J. Prof. Issue Eng. Educ. Pract. 2006, 132, 118–124. [Google Scholar] [CrossRef]

- Bridge Design Specifications; California Department of Transportation, Office of Structural Design: Sacramento, CA, USA, 2008.

- Bridge Design Manual; Colorado Department of Transportation: Denver, CO, USA, 2018.

- Structures Manual; Florida Department of Transportation: Tallahassee, FL, USA, 2018.

- Bridge Manual; Illinois Department of Transportation, Bureau of Bridge and Structures: Springfield, IL, USA, 2012.

- Bridge Design Manual—LRFD; Texas Department of Transportation: Austin, TX, USA, 2015.

- LRFD Bridge Manual; Massachusetts Department of Transportation: Boston, MA, USA, 2013.

- Bridge Design Manual; Michigan Department of Transportation: Lansing, MI, USA, 2018.

- Structures Design Manual; North Carolina Department of Transportation: Raleigh, NC, USA, 2007.

- Bridges and Structures Design Manual, 6th ed.; State of New Jersey Department of Transportation: Ewing Township, NJ, USA, 2016.

- Bridge Manual; New York Department of Transportation: Albany, NY, USA, 2017.

- Bridge Design Manual; Washington State Department of Transportation: Olympia, WA, USA, 2017.

- Bridge Manual; Wisconsin Department of Transportation: Madison, WI, USA, 2017.

| State | Software | Girder Type | No. of Girders | Strand Diameter | No. of Straight Strands | No. of Harped Strands | No. of Debonded Strands |

|---|---|---|---|---|---|---|---|

| California | LEAP | CA I42 | 6 | 15.24 mm (0.6 in) | 14 | 4 | -- |

| Colorado | LEAP | BT-54 | 5 | 15.24 mm (0.6 in) | 16 | 4 | -- |

| Florida | LEAP | FIB54 | 5 | 12.70 mm (0.5 in) | 25 | -- | 5 |

| Illinois | LEAP | AASHTO III | 5 | 15.24 mm (0.6 in) | 20 | 4 | 2 |

| Texas | PGSuper | TX 46 | 5 | 15.24 mm (0.6 in) | 24 | -- | -- |

| Massachusetts | LEAP | NEBT 1200 | 5 | 15.24 mm (0.6 in) | 16 | 4 | -- |

| Michigan | PGSuper | AASHTO IV | 6 | 15.24 mm (0.6 in) | 16 | 2 | -- |

| North Carolina | LEAP | AASHTO IV | 5 | 15.24 mm (0.6 in) | 14 | 4 | -- |

| New Jersey | LEAP | NEBT 1400 | 5 | 12.70 mm (0.5 in) | 28 | 4 | -- |

| New York | LEAP | AASHTO III | 5 | 15.24 mm (0.6 in) | 18 | 4 | -- |

| Washington | PGSuper | W58G | 5 | 15.24 mm (0.6 in) | 14 | 4 | -- |

| Wisconsin | LEAP | Wisc 45W | 5 | 15.24 mm (0.6 in) | 22 | -- | 4 |

| Question 4: What are the project features that contributed the most to your learning and practical experience? Table A1 shows the detailed answers. | |||||||||||

| Feature | Opinion | ||||||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | |

| 1- Material Understanding. | ✔ | ✔ | ✔ | ✔ | ✔ | ||||||

| 2- Learning Software. | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | |||

| 3- State Bridge Manual Knowledge. | ✔ | ✔ | ✔ | ✔ | |||||||

| 4- Backcheck Process. | ✔ | ✔ | ✔ | ||||||||

| 5- Head-to-head presentation. | ✔ | ||||||||||

| Question 5: If you graduate, does this project foster your job search and your performance if you get a structural engineer position? (If yes, explain why). Table A2 shows the detailed answers. | |||||||||||

| Answer | Opinion | ||||||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | |

| 1- Yes, I am currently working in the field. | ✔ | ✔ | |||||||||

| 2- Yes, I feel I am prepared for the job. | ✔ | ✔ | ✔ | ✔ | ✔ | ||||||

| 3- Yes, my resume is enriched. | ✔ | ✔ | ✔ | ✔ | ✔ | ||||||

| 4- No. | |||||||||||

| Question 6: What did you think of the backcheck process used to check your model and the use of commercial software? Table A3 shows the detailed answers. | |||||||||||

| Answer | Opinion | ||||||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | |

| 1- Helpful in obtaining the optimum design. | ✔ | ✔ | ✔ | ✔ | |||||||

| 2- Necessary. | ✔ | ✔ | |||||||||

| 3- Eliminates human errors in modeling. | ✔ | ✔ | ✔ | ✔ | ✔ | ||||||

| 4- Building trust in results. | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | |||||

| 5- Application of knowledge. | ✔ | ✔ | |||||||||

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mantawy, I.M.; Rusch, C.; Ghimire, S.; Lantz, L.; Dhamala, H.; Shrestha, B.; Lampert, A.; Khadka, M.; Bista, A.; Soni, R.; et al. Bridging the Gap between Academia and Practice: Project-Based Class for Prestressed Concrete Applications. Educ. Sci. 2019, 9, 176. https://doi.org/10.3390/educsci9030176

Mantawy IM, Rusch C, Ghimire S, Lantz L, Dhamala H, Shrestha B, Lampert A, Khadka M, Bista A, Soni R, et al. Bridging the Gap between Academia and Practice: Project-Based Class for Prestressed Concrete Applications. Education Sciences. 2019; 9(3):176. https://doi.org/10.3390/educsci9030176

Chicago/Turabian StyleMantawy, Islam M., Conner Rusch, Sushil Ghimire, Lucas Lantz, Hari Dhamala, Bipesh Shrestha, Anthony Lampert, Mohit Khadka, Anima Bista, Rhytham Soni, and et al. 2019. "Bridging the Gap between Academia and Practice: Project-Based Class for Prestressed Concrete Applications" Education Sciences 9, no. 3: 176. https://doi.org/10.3390/educsci9030176

APA StyleMantawy, I. M., Rusch, C., Ghimire, S., Lantz, L., Dhamala, H., Shrestha, B., Lampert, A., Khadka, M., Bista, A., Soni, R., Shaik, A. S., Lujan, E., Boyd, M., Pickings, R., & Mabrich, A. (2019). Bridging the Gap between Academia and Practice: Project-Based Class for Prestressed Concrete Applications. Education Sciences, 9(3), 176. https://doi.org/10.3390/educsci9030176