1. Introduction

The term ‘industrial revolution’ is not new to the society, and it has been around for more than 200 years. The first industrial revolution (Industry 1.0) began in England during the late 18th century (

Mohajan, 2019). It was a period of global transition from human and animal labour into the use of steam-powered machinery to improve production efficiency (

X. Xu et al., 2021). Since then, there have been a series of industrial development, such as the second industrial revolution (Industry 2.0) dated between the late 19th century to early 20th century, which saw the development of modern production lines to enhance mass production due to the discovery of electricity (

Jevons, 1931), and the third industrial revolution (Industry 3.0) started around the 1970s due to the invention of computing and communication technologies to automate production (

Taalbi, 2019). In the 21st century, we are now in the midst of the fourth industrial revolution (Industry 4.0) which is characterised by a fusion of technologies from artificial intelligence (AI), spatial computing, advanced robotics, nanotechnology to gene editing (

M. Xu et al., 2018). One issue with Industry 4.0 is that it focuses more on automation and robotisation for flexibility of production, and it often fails to consider the importance of the human factor (

Kinzel, 2017). To address this issue, some scholars and industrialists have started discussions to bring humans back in the equation in the next phase of industrial revolution (the fifth industrial revolution, Industry 5.0) (

Raja Santhi & Muthuswamy, 2023). Industry 5.0 will be an era of augmentation, where humans and smart machines work collaboratively and in symbiosis (

Adel, 2023;

Longo et al., 2020), often seen by many as the key to reconciliation between humans and smart machines. In particular, Industry 5.0 will see the utilisation of human lateral thinking (critical thinking, creative and innovative thinking) and cognitive perfection of smart machines in research and innovation (

Pizoń & Gola, 2023) to drive long-term sustainability and resilience (

Aheleroff et al., 2022).

With each industrial revolution, there comes a need for new skills and knowledge due to the creation of new jobs. The educational system, as the fundamental pillar in fostering these new skills and competencies to meet the changing demands of industries, has also changed dramatically since Industry 1.0.

Prior to Industry 1.0, education was provided at home and the family was responsible to educate and train its young ones. Education was limited to social rules, family traditions and domestic skills. With the invention of machinery in Industry 1.0, factories began to sprout up and professional schools started to establish (

Fomunyam, 2019). Education for Industry 1.0 employed an authoritarian teaching system, where teacher was the sole source of knowledge and student was a passive recipient in a physical classroom.

During Industry 2.0, there were severe shortages of skilled workers because of the mass advancements in manufacturing, production, and transportation (

Fomunyam, 2019). Education was then shifted from theory-based learning in a physical classroom to a more interactive technical education with hands-on practical training at factories, leading to a prestige growth of engineering education (

Sakhapov & Absalyamova, 2018).

The digitalisation in Industry 3.0 has caused another reform in education, in particular, the specialised education and training of working specialties in Industries 1.0 and 2.0 were eliminated due to the integration and globalisation of education. For engineering education, the focus was placed on interdisciplinary curriculum with interpersonal skills training and the use of computing and communication technologies in teaching (

Sakhapov & Absalyamova, 2018). For instance, the use of televisions and radios to share learning materials or the use of projectors to display teaching slides to assist students’ learning process. However, some countries were slower in adopting Industry 3.0 than others, and this led to different educational frameworks across the world. In some countries, traditional teacher-centred teaching was still heavily relied upon, and students focused on memorising information rather than understanding the information to achieve pre-determined learning outcomes. Other countries, however, started to embrace constructivism over instructivism. Students became active learners, constructing their own knowledge through exploring problems, collaborating with peers and creating solutions, rather than passively taking in information. Meanwhile, teachers became the guide and mentor to facilitate class activities using technologies (

Tan et al., 2018).

Today, in the era of Industry 4.0, the presence of online platforms, such as Learning Management Systems (LMSs), social networking sites, open education resources enable students to pursue learning on their own terms. Students self-determine their own learning objectives and outcomes by deciding what, when and how they learn. While students act as creators of knowledge, teachers remain as facilitator (

Tan et al., 2018). With advanced technologies booming unprecedentedly, the global educational system now focuses on building students’ digital and technology literacies (

Kazimirov, 2018). This is what makes education for Industry 4.0 different from previous eras, but at the same time creating a new problem. One major issue of letting students take ownership of their learning while placing emphasis on digital and technological skills is the insufficient training of students in soft skills, especially ethics, integrity and critical thinking skills as reported by many studies from different countries (

Bajaj, 2022;

Noah & Abdul Aziz, 2020;

Noorbhai & Ojo, 2023). This has led to an alarming increase in academic misconduct. A common example is students misusing AI tools like ChatGPT to complete assignments.

The authors’ vision of future education, especially teaching engineering for Industry 5.0 should focus on developing students’ soft skills to complement students’ digital and technological skills. For example, students can utilise ChatGPT for fact-checking, interpretation, and critical evaluation. Since ChatGPT may occasionally generate factually incorrect or misleading information, it can serve as a valuable learning tool that encourages students to question, verify, and analyse its responses. This process helps students practise identifying inaccuracies, interpreting content in context, and critically assessing the credibility of information. These are high-order thinking skills. If the current education for Industry 4.0 is to foster students’ ability to create new knowledge, then the future education for Industry 5.0 should foster students’ ability to design and develop applications of new knowledge (creative and innovative skills). The authors’ vision is also aligned with the objectives of Industry 5.0 to bring back focus on human skills (

Adel, 2022;

Alves et al., 2023;

Poláková et al., 2023), as well as with the Australian Council of Engineering Deans’ focus on nurturing T-shaped graduate attributes to address the growing emphasis on the human dimensions of engineering work (

Crosthwaite, 2021).

This study aims to examine the in-demand skills for Industry 5.0, while simultaneously investigating the pedagogical approaches that can foster these skills in engineering students. The three research questions (RQ) for this study are:

- RQ1:

What are the in-demand skills for the future workplace in Industry 5.0?

- RQ2:

What approaches can be used within a universal teaching model to foster Industry 5.0 skills in engineering students?

- RQ3:

How can the teaching model proposed in RQ2 be integrated into the engineering curriculum?

The structure of this paper is organised as follows.

Section 2,

Section 3 and

Section 4 address RQs 1, 2 and 3, respectively, while

Section 5 concludes the paper and discusses future works. The novelty of this paper is the proposal of an innovative teaching model termed EPIC principles to address RQ2. This is because the authors could not find a universal teaching model from existing pedagogies which can impart all the Industry 5.0 skills holistically at once. EPIC is a synthesis of Experiential, Paired, Inquiry-based and Collective learning. It has been experimented in a broad range of engineering courses at the authors’ university and has been recognised with multiple teaching awards. EPIC holds promising potential in aiding educators to cultivate and equip engineering students with the necessary skills to thrive in the forthcoming Industry 5.0 revolution.

2. In-Demand Skills for Industry 5.0

After 10 years into Industry 4.0, the European Commission formally announced the concept of Industry 5.0 with a report titled “Industry 5.0: Towards a Sustainable, Human-centric, and Resilient European Industry” on the 4th of January 2021 (

Breque et al., 2021). The report states that Industry 5.0 is not an alternative model to replace Industry 4.0. Instead, it complements and extends the existing Industry 4.0 by combining technology, research and innovation to drive the transition towards a sustainable, human-centric and resilient industry. Unlike Industry 4.0 which focuses solely on technology-driven productivity (economic value) (

X. Xu et al., 2021), Industry 5.0 will extend the focus to include the wellbeing of industrial workers and environment (societal value) (

Breque et al., 2021).

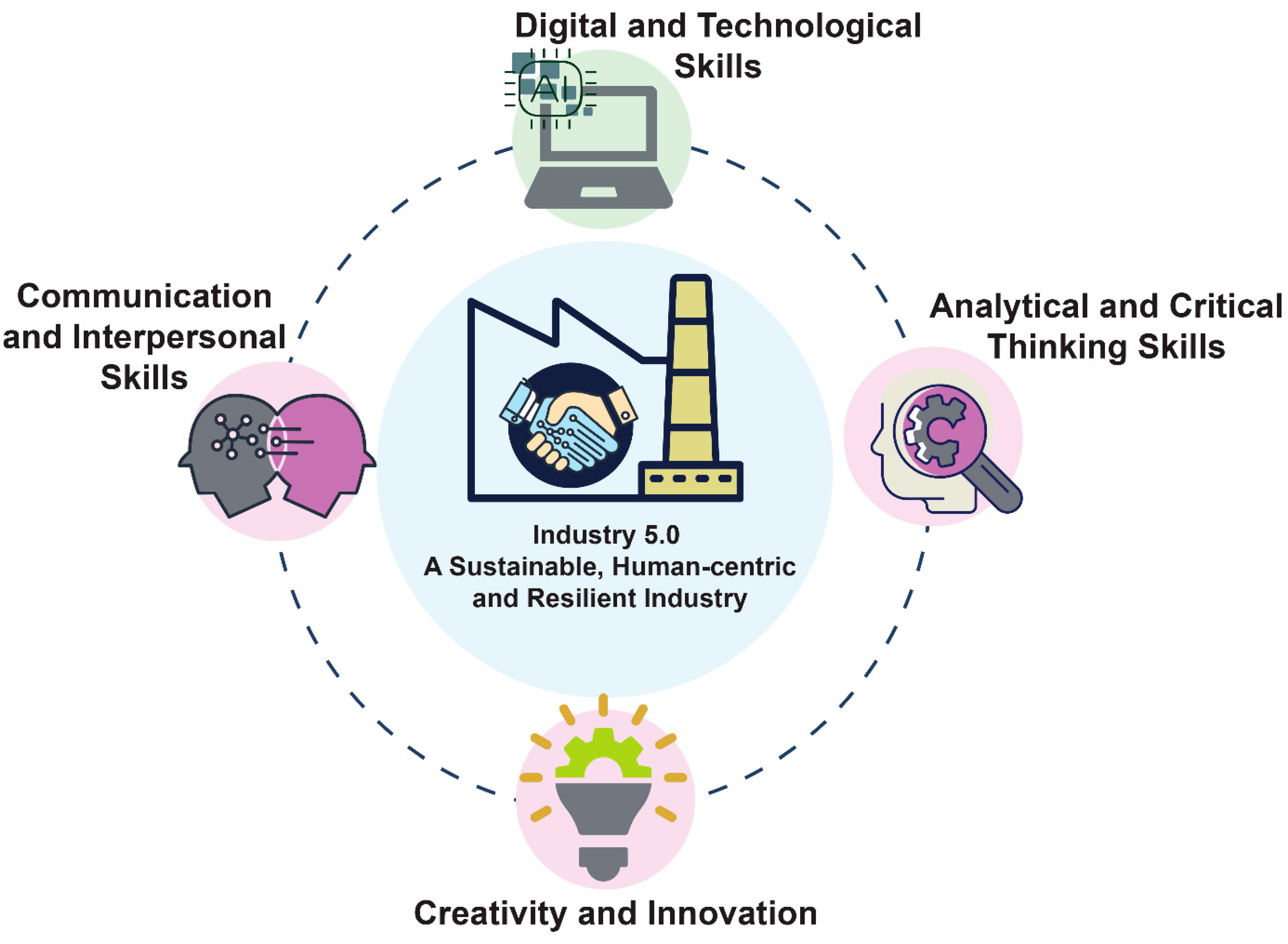

In parallel to the above development, one question that often slips into media debates and discussions is: What are the in-demand skills for the future workplace in Industry 5.0? To answer this question, the authors searched for literature with the keywords “Industry 5.0 skills”, “Future engineering skills” and “Future in-demand skills” in several databases including Google Scholar, Scopus and Web of Science databases. These databases were chosen due to two reasons. Firstly, these databases provide an extensive coverage of publications relating to Industry 5.0. Secondly, previous studies related to Industry 5.0 have also used these databases (

Alvarez-Aros & Bernal-Torres, 2021;

Poláková et al., 2023). After a detailed literature review, the authors classified the in-demand skills for future engineers in the Industry 5.0 era into four distinct categories, as shown in

Figure 1.

Digital and Technological. Building on Industry 4.0, Industry 5.0 will continue to be driven by advanced digital technologies, such as improved AI with cognitive intelligence (cognitive AI), adaptive robots (evolved from collaborative robots), digital twins, blockchain, the Internet of Everything (IoE) (next stage of Internet of Things, IoT), 6G systems and others (

Adel, 2022;

Ghobakhloo et al., 2023;

Raja Santhi & Muthuswamy, 2023). It was mentioned by (

Czeczot et al., 2023) that the lack of knowledge and planning to manage these fast-evolving technologies in Industry 4.0 has caused enterprises to consume huge resources, creating an unsatisfactory pace of change. To welcome Industry 5.0, future engineers must not only have the capability to interact easily and confidently with these new and emerging technologies, but also have the capability to predict technological trends and their associated repercussions. In Industry 5.0, digital and technological skills are not limited to developing a deep understanding of these technologies like in Industry 4.0, but also including cybersecurity awareness, such as IoE attacks, malware, online privacy and data protection (

Czeczot et al., 2023;

Salam et al., 2023). These are currently lacking in Industry 4.0. The proliferation of interconnected devices and systems in Industry 5.0 will open new avenues for cyberattacks and engineers must possess the knowledge to identify threats and take pre-emptive measures before they occur. However, a 2021 report by the American Society of Mechanical Engineers (

Gonzalez, 2021) and several online articles (

Asaram, 2023) have shown that current engineers lack these digital and technological skills and this could jeopardise the global digital transformation journey towards Industry 5.0.

Analytical and Critical Thinking (Soft Skills). With smart machines and technologies booming, all engineering sectors are expected to generate massive amounts of data in Industry 5.0 (

Z. Xu & Saleh, 2021). Engineers, working alongside these smart machines and technologies, need to constantly break down complex machine data into useful information (analytical thinking), and evaluate this information to make informed decisions (critical thinking). To give an example, a shop floor engineer would evaluate and interpret the operational data generated by AI technologies to anticipate customer behaviour or detect abnormalities in the production processes in real time. Another example, a biomedical engineer would use patients’ data from wearable technologies to analyse, design and create personalised implants specific to individual patients (

Iyengar et al., 2022). These are just two examples to show the importance of developing high-order thinking skills in future engineers for Industry 5.0, also supported by these studies (

Broo et al., 2022;

Hartmann et al., 2023;

Poláková et al., 2023;

Ungureanu, 2020).

Creativity and Innovation (Soft Skills). Technological innovations alone cannot achieve Industry 5.0’s objective of being sustainable and resilient. Humans, as part of Industry 5.0, are to be paired with these technological innovations to create new opportunities and innovate solutions (

Mitchell & Guile, 2021). For example, in manufacturing and healthcare sectors, engineers’ creative and innovative skills can leverage the potential of flexible production technology (

Gandhi et al., 2014) to drive mass personalisation by catering to customers’ distinct needs and preferences. This will be an improvement from Industry 4.0 which is currently mass producing identical goods (or standardised implants in healthcare) with the automation system (

Adel, 2022;

Kolade & Owoseni, 2022). In supply chain management, engineers can apply creativity and innovation to integrate eco-friendly practices into smart technologies to develop a more sustainable operation that optimises energy consumption, reduces wastages, recycle resources and minimises environmental impacts (

Adel, 2022;

Masoomi et al., 2023). All these emerging trends share a renewed focusing on creativity and innovation in the engineering sectors.

Communication and Interpersonal (Soft Skills). The future of engineering in Industry 5.0 will also see a rapid increase in cross-disciplinary collaboration and interaction across different industries, as mentioned by many existing publications (

Broo et al., 2022;

Mitchell & Guile, 2021;

Poláková et al., 2023;

Taboada & Espiritu, 2012) and collaborative outcomes reports from the Australian Council of Engineering Deans, Australian Learning and Teaching Council, Engineers Australia, Australasian Association for Engineering Education, and the Australian Academy of Technological Sciences and Engineering (

Crosthwaite, 2019;

King, 2008). Engineers must develop ability to convey complex engineering terminology and ideas clearly and effectively to a larger audience (communication skill) and at the same time, work collaboratively with smart technologies and people outside of engineering (interpersonal skill). For example, a materials engineer might work with a product designer to identify potential defects and material abnormalities (

Ang, 2015,

2016;

Barakathulla & Ang, 2023) while a geotechnical engineer might consult with architects and builders to ensure suitable ground conditions for building structures.

It appears that soft skills (3 out of the 4 in-demand skills are soft skills) have increasing importance in the future workplace in Industry 5.0. This is because certain tasks that require complex decision-making, intuition, interpersonal interactions are not easily replaceable by smart machines and technologies. However, soft skills are often neglected in the current era of Industry 4.0, of which technical skills are the primary focus due to its emphasis on digital transformation. The Future of Jobs Report by World Economic Forum estimated that at least 50 percent of existing engineers will need reskilling by 2025 (

The Future of Jobs Report, 2020), indicating the need to reshape today’s engineering education.

3. EPIC Principles

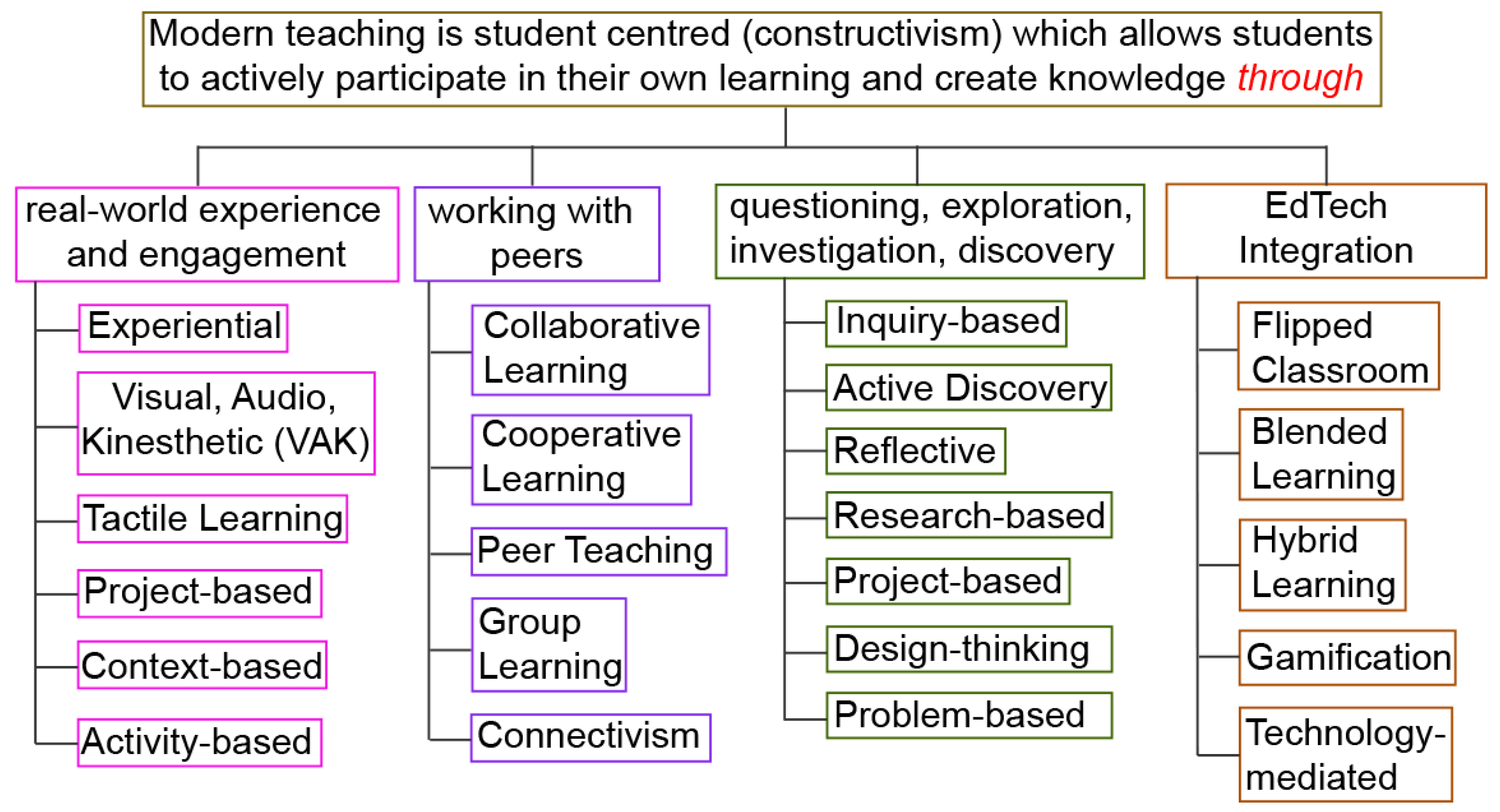

To answer RQ 2 “What approaches can be used within a universal teaching model to foster Industry 5.0 skills in engineering students?”, the authors conducted an exploratory literature review. The search was first performed using a combination of keywords such as “modern pedagogy” and “engineering education” in different databases, such as Google Scholar, Scopus and Web of Science. The initial search identified 177 articles published between 2010 and 2025. Abstracts were then reviewed for relevance to teaching approaches aimed at fostering skills relevant to Industry 5.0. Articles were included if they: (a) focused on pedagogical strategies or teaching models within engineering, and (b) discussed skill development aligned with the core pillars of Industry 5.0: human-centricity, sustainability, and resilience. Articles were excluded if they fell outside the scope of engineering education, focused solely on Industry 4.0 without considering Industry 5.0-related skills, or lacked sufficient discussion of pedagogical outcomes. Through this process, it became evident that modern pedagogy, at its core, is student-centred, allowing students to actively participate and manage their own learning (

Agumba & Haupt, 2014;

McCabe & O’Connor, 2014). This is what makes modern pedagogy different from the traditional didactic, teacher-centred pedagogy. However, the scope of modern pedagogy is broad, covering a variety of approaches. Some of these modern teaching approaches share similar characteristics while some are contradictory. In an attempt to make a more meaningful comparison, the authors grouped these modern teaching approaches into four clusters, as shown in

Figure 2. These four clusters form the basis of the proposed EPIC principles.

Cluster 1 Learning through real-world experience and engagement. This practice has long been recognised in the educational system, such as the traditional proverb “I hear and I forget. I see and I remember. I do and I understand.”, presumably originated from the age of Confucius (1000–250 BC); an adage “One learns by doing a thing; for though you think you know it, you have no certainty until you try.”, from Sophocles (400 BC) (

Gentry, 1990); or in a more recent times, “Learning by doing” by (

Dewey, 1910); “Experience-based learning” by (

Wolfe & Byrne, 1975); “Experiential learning cycle” by (

Kolb, 1984); and “Kinaesthetic/Tactile learning” in the VARK model by (

Fleming, 2006), to name a few. Beneath these, there may be some subtle differences in the details. For example, Dewey’s philosophy states that students do not learn from experience but learn from reflecting on experience. Experience is only educative if it is continuous and has positive impact in students’ future (progressive) (

Dewey, 1910). Kolb refers to experience as “concrete” (

Kolb, 1984), often interpreted as learning by doing additional discrete activities. This contradicts Dewey’s idea of progressive lifelong experience if the additional activity is not continuous and connected with the return wave of consequences which flow from it (

Ord, 2012).

Lewis and Williams (

1994) reported that this practice can take many different forms, namely, role plays, case studies, context-based simulations (replicate real-life scenarios in teaching (

Lave & Wenger, 1991)) and project work activities. Although this practice has been expressed using different terms with some subtle differences in their focus, they all share the same fundamental belief: that is, education should be a process of actively engaging students in authentic experience and reflection so that students can connect theories and knowledge learned in the classroom to real-world situations.

Cluster 2 Learning through working with peers. This is another modern teaching practice which has been seen in a variety of teaching approaches with their learning activities vary across different disciplines and fields, but these approaches all share the same essence, and that is the construction of knowledge through social interaction and interpersonal communication. Two famous foundational psychologists of this practice are Jean Piaget and Lev Vygotsky. Although both Piaget’s theory of cognitive development (

Piaget, 1983) and Vygotsky’s social development theory (

Vygotsky, 1978) share a lot of resemblances on active interaction, there exists a fundamental distinction between their theories as pointed out by Lourenço (

Lourenço, 2012). Piaget focuses on the interaction of experiences and ideas in the creation of new knowledge while Vygotsky stresses the importance of collaboration and learning alongside peers in the accommodation and assimilation of knowledge (

Lourenço, 2012). From the authors’ point of view, also supported by the literature (

Boud et al., 1999;

Falchikov, 2001;

Göl & Nafalski, 2007;

O’Donnell & King, 1999;

Sumtsova et al., 2018), learning through working with peers (peer learning) can be further divided into two sub-categories: peer tutoring (also known as peer teaching) and collaborative learning (also known as cooperative learning). Peer tutoring is where a more knowledgeable individual acts as tutor to the less knowledgeable. For this to occur, there needs to be a difference in knowledge level between the two individuals. Peer tutoring does not only improve the tutee’s knowledge but also the tutor’s understanding. In cognitive science, this is known as the self-explanation effect whereby providing an explanation can help the explainers to proceduralise their declarative knowledge (

Chi et al., 1989), increasing understanding and knowledge retention. Collaborative learning whereas can occur peer-to-peer or in groups, stressing the importance of peer discussions to create knowledge and achieve learning goals. Unlike peer tutoring, collaborative learning does not necessarily exist a difference in knowledge level between the collaborating individuals.

Cluster 3 Learning through questioning and investigation. This practice emphasises the importance of critical thinking, where students actively engage in questioning, exploring, and investigating to deepen their understanding. Rooted in the constructivist learning theories, learning through questioning and investigation encourages students to formulate questions, seek out answers, and critically examine evidence. Several studies also support the effectiveness of this modern practice.

White and Frederiksen (

1998) created a cycle for this process, labelling the stages as Question, Predict, Experiment, Model, and Apply. A similar cycle was also proposed by Bybee et al. (

Bybee et al., 2006), but with stages labelled Engagement, Exploration, Explanation, Elaboration, and Evaluation (the 5E cycle). One key difference between these cycles is that the first two phases of the White and Frederiksen cycle (Question and Predict) suggest starting with a deductive approach, which is based on theory or hypotheses, while the first two phases of the 5E cycle (Engagement and Exploration) encourage starting with an inductive approach, based on gathering data and evidence. Another debate in learning through questioning and investigation is whether this should form separately (e.g., to teach students to think critically in non-school contexts) or be integrated into existing subject-matter instruction (

Ennis, 1989). In engineering education, the latter approach is often adopted, typically through research projects, problem-based and project-based learning, where students investigate real-world problems (

Doulougeri et al., 2024;

Ramírez de Dampierre et al., 2024).

Cluster 4 Learning through the integration of Educational Technology (EdTech). This modern practice primarily focuses on combining traditional face-to-face pedagogy with digital technologies to retain the benefits of in-person instruction while integrating digital tools to enhance engagement, learning, and access to resources. It gained particular prominence during the COVID-19 pandemic. However, the body of literature surrounding EdTech integration remains scattered and diverse. For example, terms such as blended learning (

Sala et al., 2024), flipped classroom (

Ngo, 2024), hybrid learning (

Festiawan et al., 2024), gamification (

Dahalan et al., 2024), technology-mediated learning, among others, can all be categorised under this practice. Additionally, a unified definition of EdTech integration remains elusive, as reported by this review (

Sala et al., 2024). For instance, Graham defines it as “combining face-to-face instruction with computer-mediated instruction” (

Graham, 2006), while

Garrison and Kanuka (

2004) describe it as “the thoughtful integration of classroom face-to-face learning experiences with online learning experiences”. While Graham’s definition focuses on instruction,

Garrison and Kanuka (

2004) emphasise learning experiences and the quality aspect of integration by using the expression “thoughtful”. This implies that the integration should aim to improve teaching and learning effectiveness by offering a wider range of learning experiences and educational opportunities, as well as enhancing course communication and management efficiency.

Justification for the EPIC principles: From the literature review and discussion of modern pedagogical practices, it is evident that “modern pedagogy” is polysemous, encompassing a variety of interpretations. Additionally, each pedagogical cluster often focuses on developing specific skills. For instance, while experiential learning can enhance students’ critical thinking abilities, it may not necessarily foster their communication skills. Similarly, peer learning can improve communication skills but may not fully develop analytical thinking. Therefore, the authors propose the

EPIC principles as a unified teaching framework designed to impart all Industry 5.0 skills (as illustrated in

Figure 1) to engineering students in a holistic manner, ensuring the development of these skills simultaneously. EPIC signifies Experiential, Paired, Inquiry-based, and Collective learning, shown in

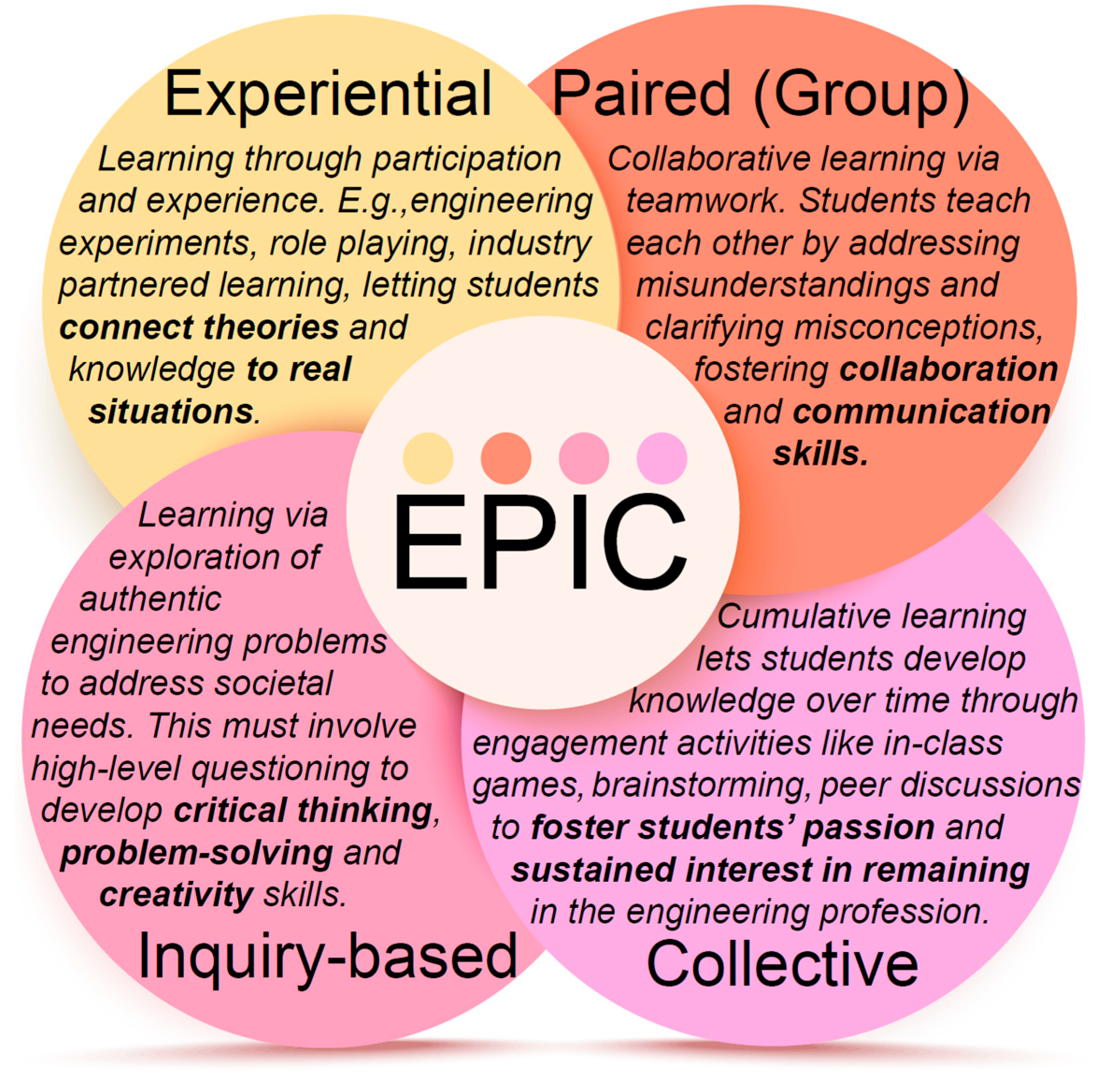

Figure 3, and is derived from a synthesis of modern pedagogical approaches (the four clusters) discussed above.

EPIC principles offer a more defined and simplified framework for designing engineering assessments, as outlined in

Section 4.

Experiential component emphasises active participation and experience through engineering experiments, role-playing, and industry-partnered learning, allowing students to connect theoretical knowledge to real-world situations. This approach aligns with Dewey’s and Kolb’s ideas but places greater emphasis on engaging students with authentic tasks and reflective learning.

Paired learning (or group learning) continues to strengthen collaboration and communication skills, but the authors argue that it should not be limited to pairing or grouping students with peers, as typically suggested in traditional peer learning. Students can also be paired or grouped with teachers or more knowledgeable individuals, such as industry partners. Furthermore, attention should be paid to group size to foster optimal student engagement. Smaller groups allow every student to have equal status and a clear role, while larger groups can result in unequal contributions, with some voices being drowned out by more outspoken participants (

Davies, 2009).

Inquiry-based learning must not only involve the exploration of theoretical concepts but also focus on authentic engineering problems that address societal needs. This can better promote high-level questioning and exploration, fostering analytical, critical thinking, problem-solving, and creativity skills.

Finally, Collective/Cumulative learning aligns with Dewey’s perspective that learning should be continuous. Students should be given the opportunity to develop knowledge progressively, fostering a sustained passion for and interest in the engineering profession.

While the integration of EdTech is beneficial, it should not simply replicate traditional teaching methods in blended or hybrid learning environments. Instead, students must recognise the value and advantages of using technology to enhance their learning. Therefore, in the authors’ EPIC framework, EdTech integration is not a separate principle but is embedded within the EPIC model to enrich the overall learning experience.

4. Engineering Assessments with EPIC Principles

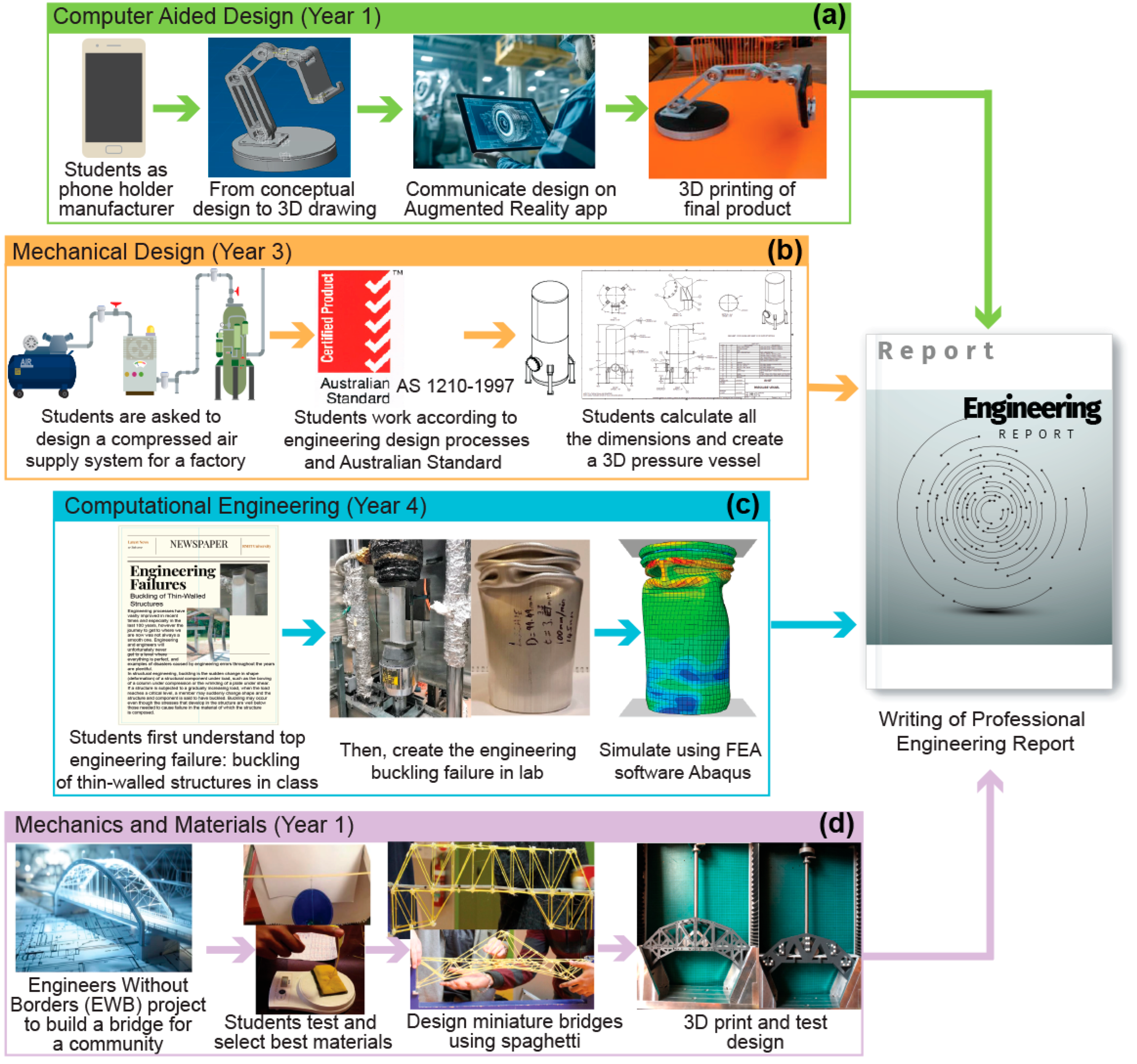

This section explains how EPIC principles can be utilised as a framework to design engineering assessments that foster engineering students’ Industry 5.0 skills, addressing RQ3. Examples of these EPIC assessments are illustrated in

Figure 4.

First, is

Experiential. These EPIC assessments integrate hands-on exercises with laboratory equipment and advanced technologies, allowing students to participate in role-playing as project managers, designers, and engineers, thereby gaining authentic engineering experience. In the Year 1 Computer-Aided Design (CAD) course (

Figure 4a), students assume the role of phone holder manufacturers, developing conceptual designs and using CATIA V5 CAD software to bring these designs to life. They also utilise novel technologies, such as augmented reality, to communicate their designs to peers and industry partners, followed by additive manufacturing (3D printing) to produce their prototypes. Drawing on Barrows’s philosophy (

Barrows, 1983) that problem-based learning involves more than just presenting problems, but requires a structured approach, in the Year 3 Mechanical Design course (

Figure 4b), the authors challenge students to design a compressed air supply system for a factory through a thoughtful, three-stage process: brainstorming solutions based on class knowledge (discussion stage), conducting self-guided research using Australian Standards (research stage), and validating their design using Simulink (evaluation and reflection stage). These processes mirror a real-world engineering workflow, integrating modern technologies. By experiencing different stages of real engineering work, students engage in high-quality, work-integrated learning that helps develop Industry 5.0 skills, including digital and technological proficiency, as well as creativity and innovation. In the Year 4 Computational Engineering course (

Figure 4c), students first study one of the most common types of structural failure—buckling—and recreate this failure in the laboratory. They then use finite element analysis to simulate the failure and explore ways to optimise the structure. By comparing experimental results with simulations, students gain a deeper understanding of the importance of a digital learning environment in achieving similar accuracy while reducing experimental costs and saving materials. Additionally, they further develop analytical and critical thinking skills when identifying and solving structural issues.

Second is Paired/Grouped. Throughout these EPIC assessments, students are immersed in a collaborative learning environment during class, such as participating in group meetings and brainstorming workshops. This simulates workplace conditions, where students take turns assuming roles like chair, presenter and note-taker. While these assessments may not always be group projects, they provide students with opportunities to engage in collaborative learning. In most cases, students are also paired with a mentor, who can be a more knowledgeable individual, such as someone who has previously completed the course or an industry partner. This paired learning approach not only helps students develop authentic engineering skills but also fosters the development of Industry 5.0 skills, particularly in communication and collaboration. By working closely with mentors and peers, students enhance their ability to work effectively in teams, solve complex problems collectively, and communicate ideas clearly in the modern, digital, and highly collaborative Industry 5.0 workplace.

Third is

Inquiry-based. These EPIC assessments are framed around real-world engineering examples involving high level of critical thinking and students must constantly self-reflect on their work as they research, solve problems, and create engineering solutions. This fits well with Knowles’ Theory of Andragogy (

Knowles, 1984) stating the importance of letting adults participate in the planning of their own learning. For example, in the Mechanics and Materials course for first-year engineering students (

Figure 4d), students partner with Engineers Without Borders (EWB) to complete a community-driven project, designing a bridge for an underserved community. Students first conduct experiments to analyse and select the best spaghetti strands (developing analytical and critical thinking skills), then use the selected spaghetti to design and construct a miniature bridge (creativity and innovation skills). Throughout the project, students predict how the bridge might fail and refine their designs accordingly (risk management and problem-solving skills). This EWB project allows students to connect theoretical knowledge to humanitarian practice while simultaneously fostering their Industry 5.0 skills. This exemplifies the authors’ perspective on inquiry-based learning, where students practise authentic engineering skills (Phase 1: experience), then see how real-life engineering situations affect their theoretical knowledge (Phase 2: outcome). This 2-phase process can lead to deeper reflections and higher-order thinking. According to

Dewey (

1910), mere activity does not create meaningful experience; it is this 2-phase process that measures the fruitfulness of educative experience.

Fourth is

Collective/Cumulative. All EPIC assessments begin with engineering problems, and students collaborate to develop solutions, documenting their findings in detailed engineering reports, as illustrated in

Figure 4. This process fosters collective problem-solving and allows students to revisit course theory and concepts throughout the semester, deepening their knowledge and enhancing their ability to apply theories in real-world contexts. It aligns with Kolb’s learning cycle (

Kolb, 1984), where each phase—concrete experience, reflective observation, abstract conceptualisation, and active experimentation—builds on the previous one, creating a continuous loop of learning that evolves with each task and interaction. Through this iterative process, students see the relevance of theory to practice and progressively build their understanding through collaboration in weekly class activities, such as mind mapping with Miro, brainstorming with Mentimeter, and participating in debate games, further enriching their learning. Utilising digital platforms such as Miro and Mentimeter allows students to experience the practical benefits of digital technologies firsthand, fostering increased engagement while simultaneously enhancing their digital proficiency. This aspect of EPIC nurtures creativity, encourages exploration of diverse perspectives, and fosters critical discussions that develop innovative thinking, as well as interpersonal skills, all of which are essential for Industry 5.0.

The EPIC framework has been adopted across engineering courses from Year 1 to Year 4 at the authors’ university, receiving favourable responses from both staff and students. In 2025, it was recognised through the National Australian Awards for University Teaching (AAUT) for its versatility and adaptability to diverse learning environments, supporting the development of future engineering skills aligned with the Industry 5.0 era.

5. Conclusions and Future Works

This study investigates the essential skills required for the future workforce in Industry 5.0 and explores how to foster these skills in engineering students through an innovative and universal EPIC teaching model. Through a comprehensive literature review, the authors identify four key in-demand skills for Industry 5.0: digital and technological skills, analytical and critical thinking, creativity and innovation, and communication and interpersonal skills. Importantly, the growing emphasis on soft skills alongside technical proficiency underscores the critical role of soft skills in the human-centric era of Industry 5.0, which requires complex decision-making, intuition, and interpersonal interaction.

The findings show that, while many modern pedagogical approaches exist, each typically focuses on developing specific skills, limiting their ability to address all four Industry 5.0 skills simultaneously. To overcome this limitation, the authors propose the EPIC principles, which combine Experiential, Paired, Inquiry-based, and Collective learning to holistically develop all the Industry 5.0 skills in engineering students. Furthermore, it is shown that EPIC can be integrated into engineering assessments across different academic levels, from Year 1 to Year 4, demonstrating its versatility and potential for wide application.

In the future, it will be crucial to investigate the long-term impact of the EPIC teaching model on students’ workplace performance, specifically how effectively they apply both soft and technical skills in real-world Industry 5.0 environments. Additionally, exploring the adaptability of EPIC across global educational settings and its scalability to disciplines beyond engineering would be valuable.