Influence of Postprocessing on Wear Resistance of Aerospace Steel Parts Produced by Laser Powder Bed Fusion

Abstract

1. Introduction

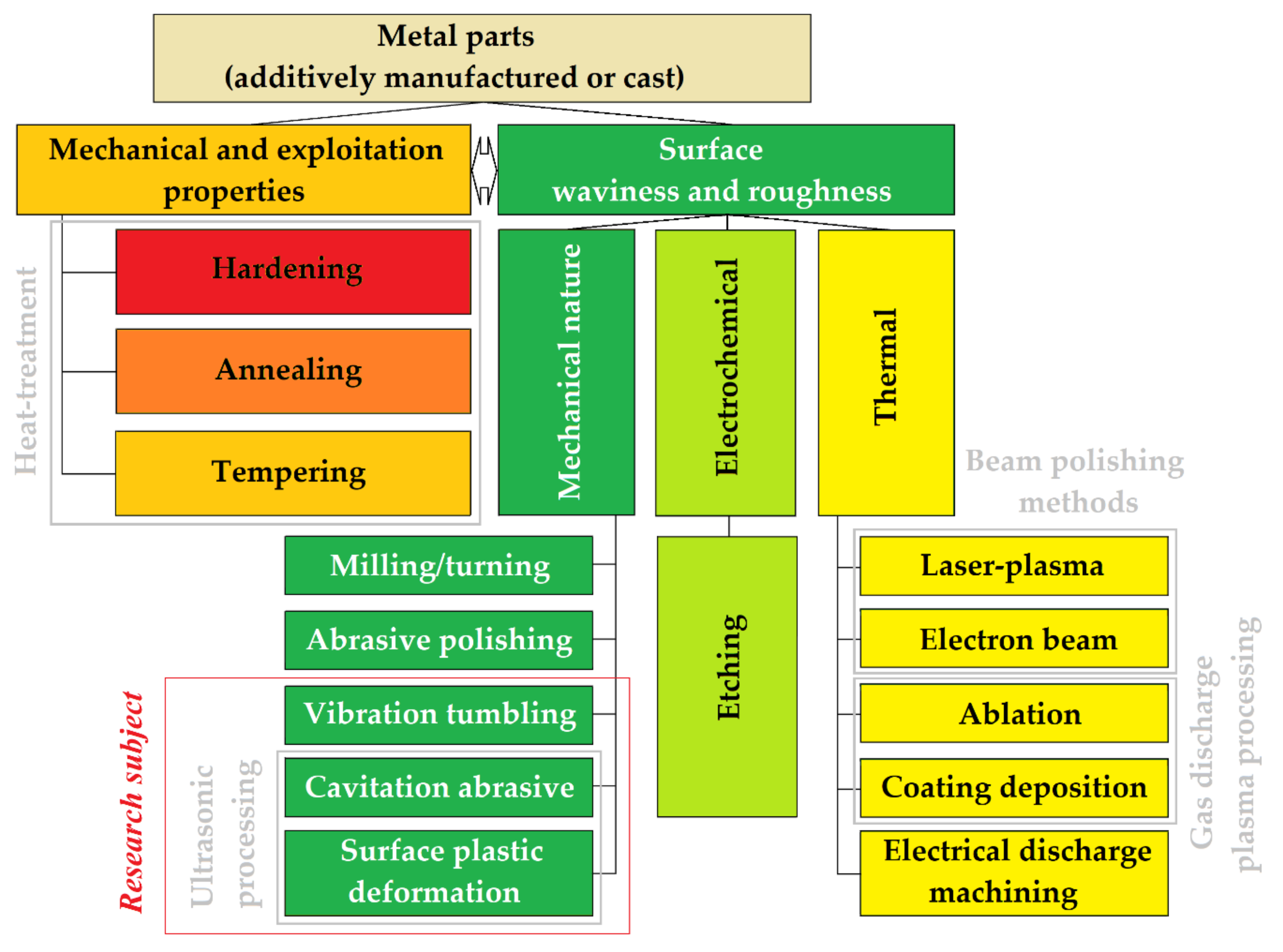

- research of the parts for which the operation steps by traditional production are complicated and involve extensive rebasing for a different type of equipment or complex assembly steps;

- analyses of the surface quality of the parts after production in comparison with the requirements;

- applying three different postprocessing methods to these parts based on their characteristics and requirements;

- research of the obtained surfaces—topology and submicron roughness;

- research on the influence of the obtained morphology on the resistance to abrasive wear in the friction pair.

2. Materials and Methods

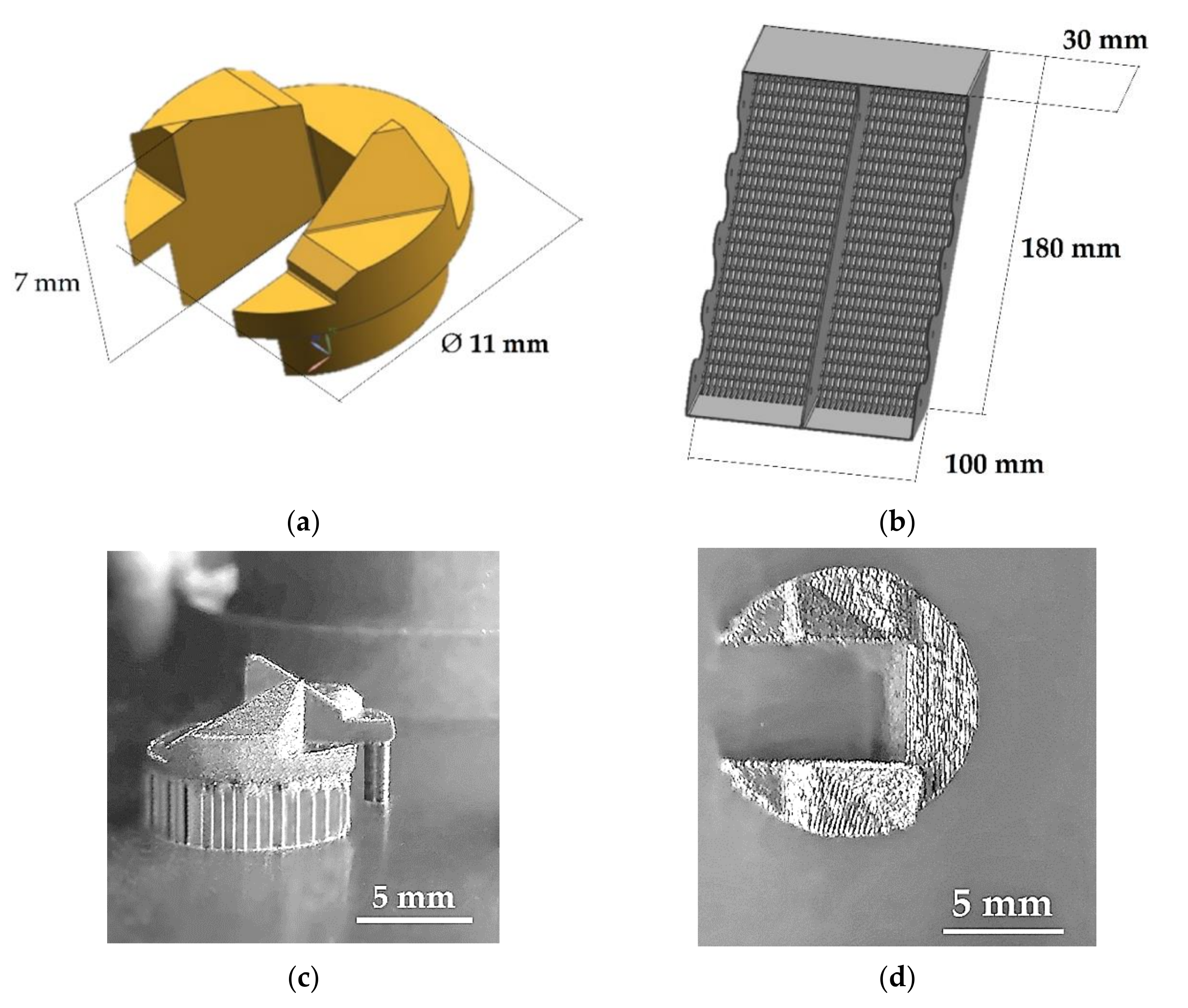

2.1. Research Object

2.2. Production Technology

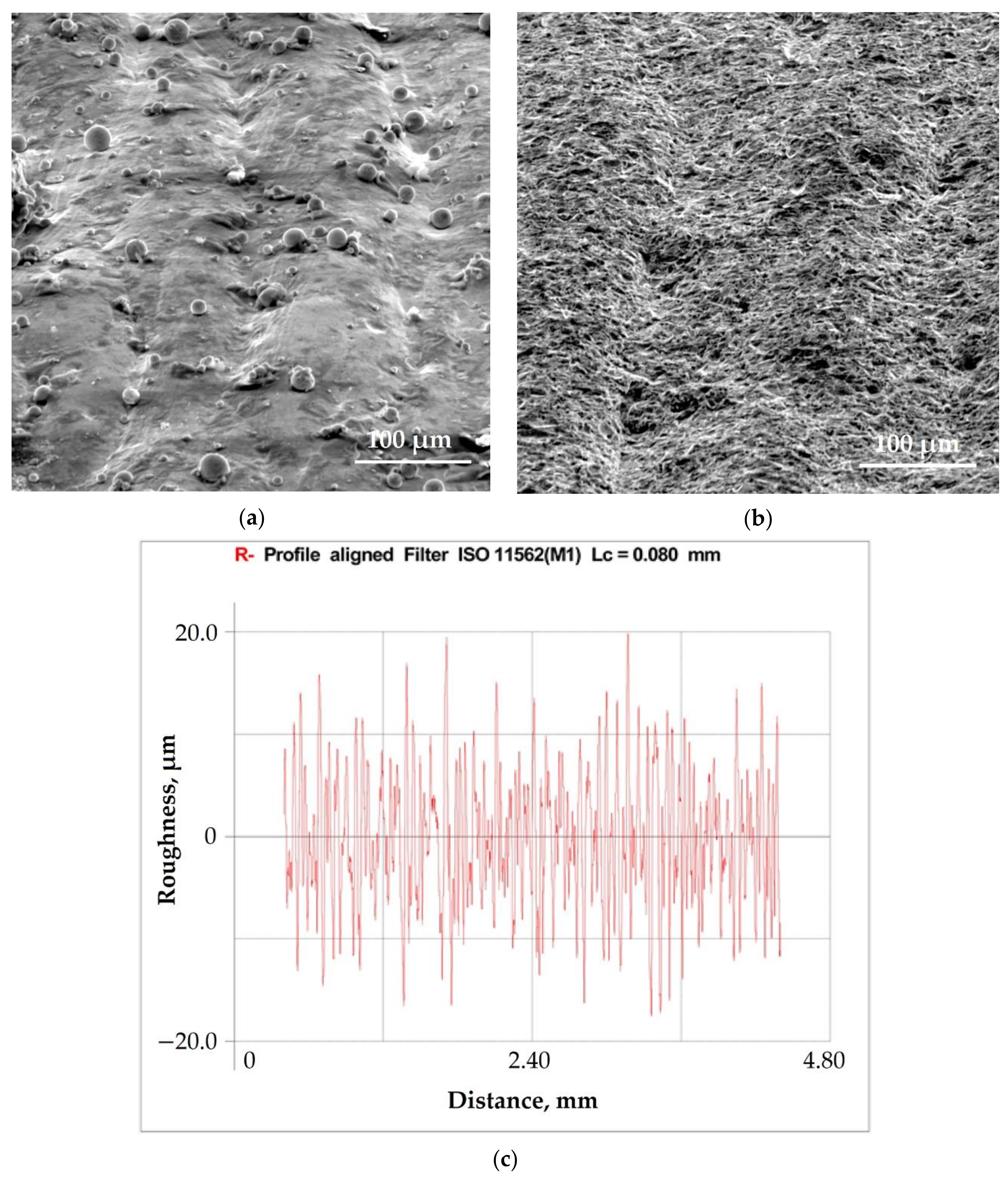

2.3. Surface Quality of the Samples

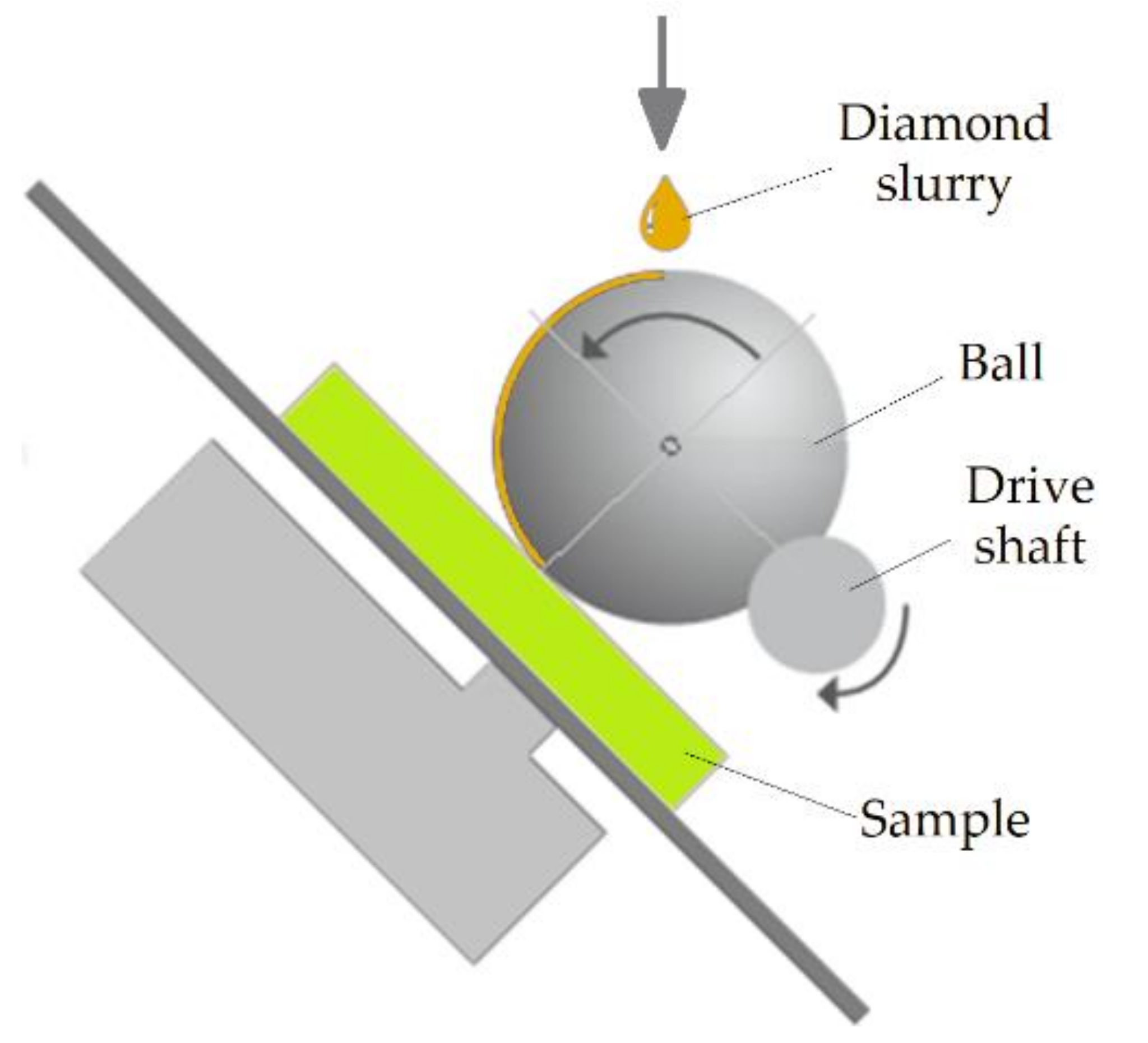

2.4. Characterization of the Samples

3. Results

3.1. Density and Porosity

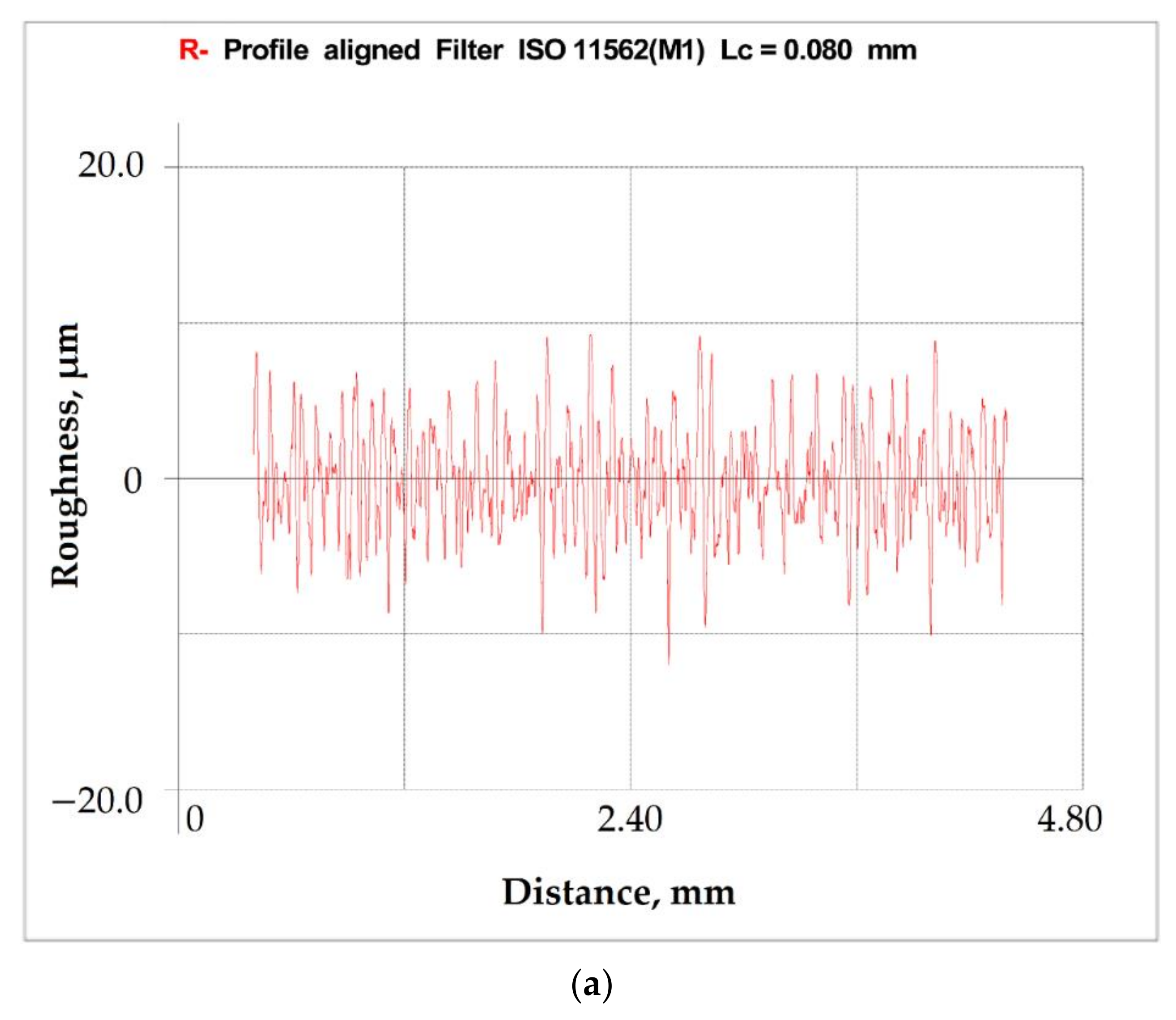

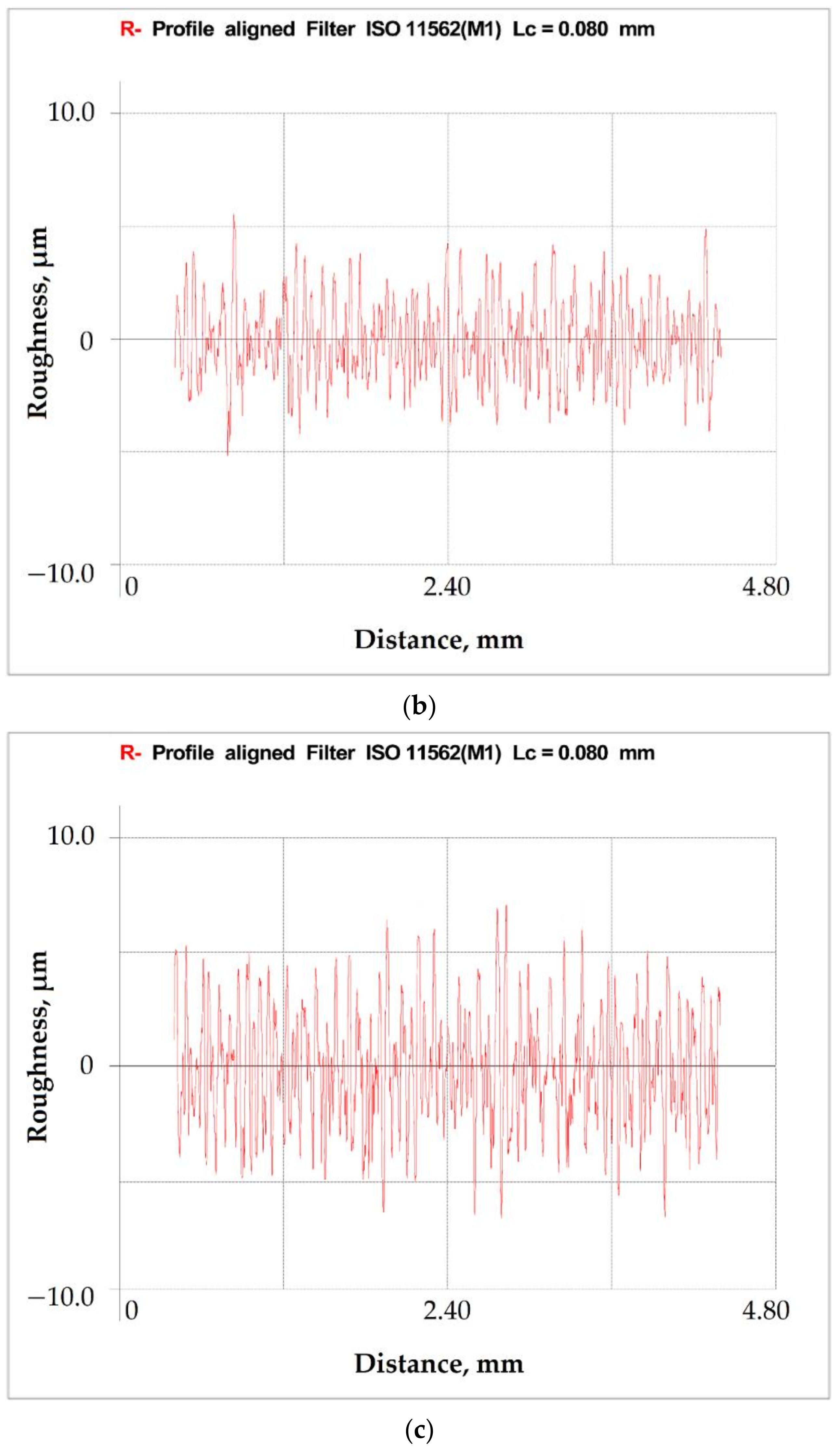

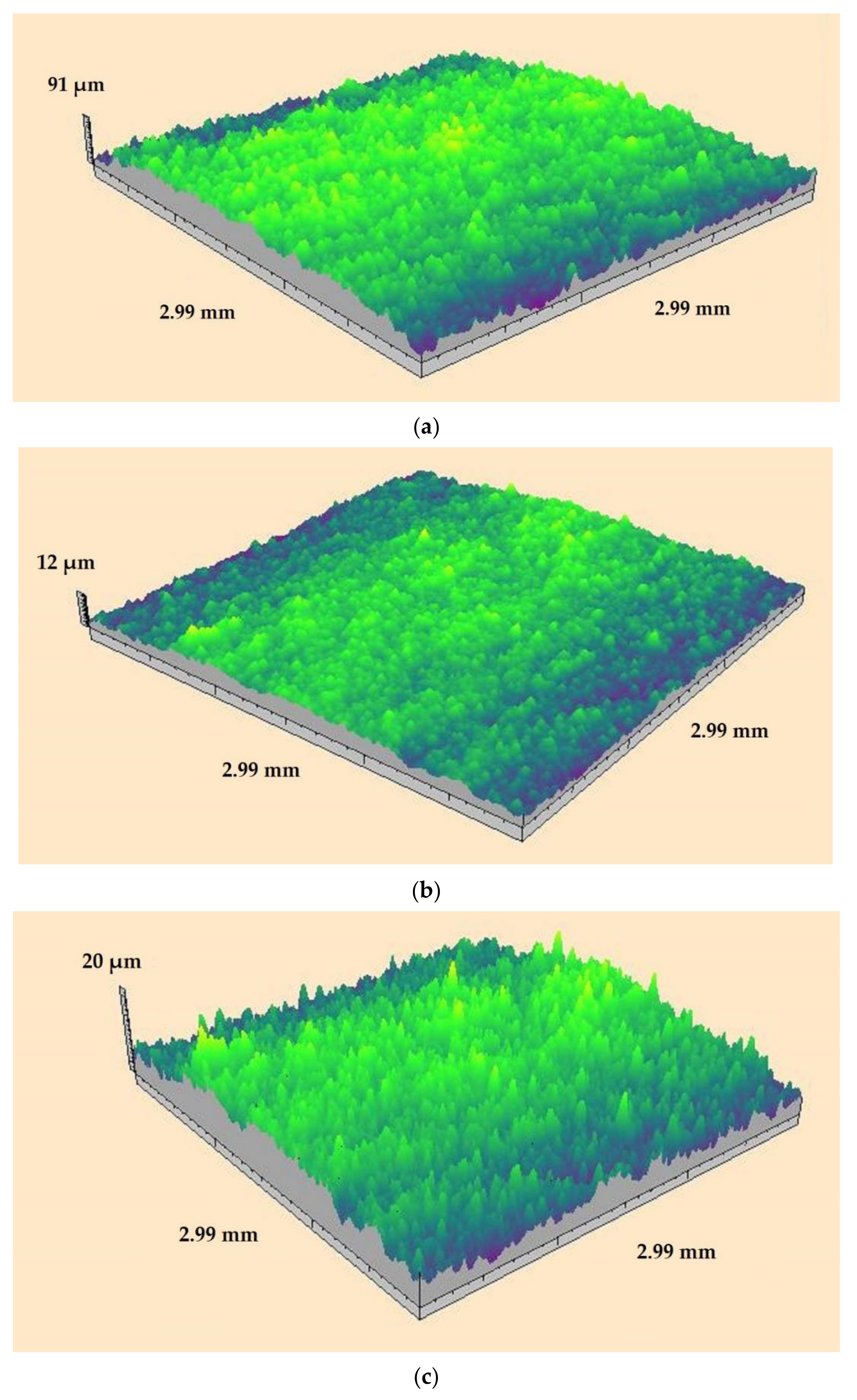

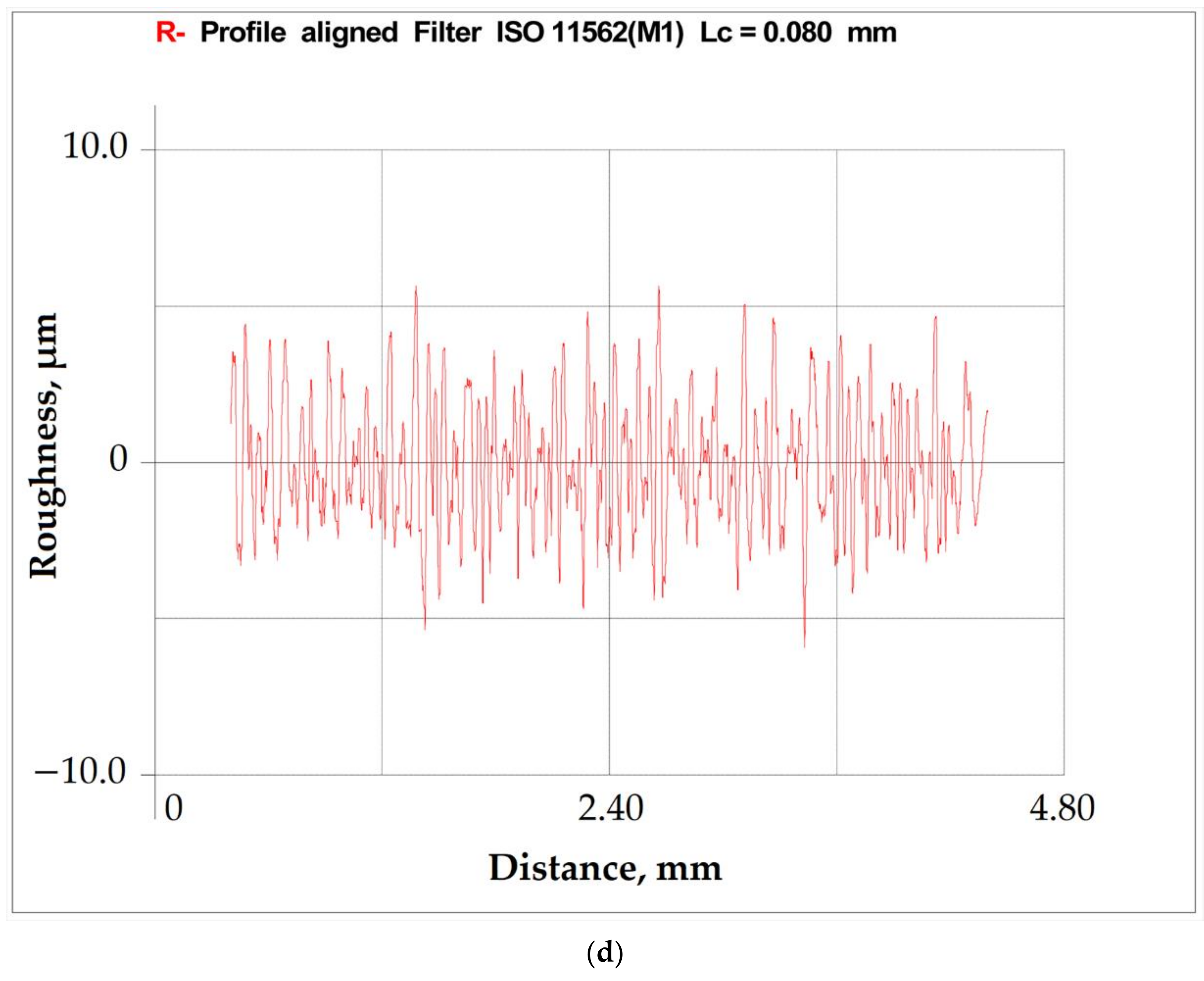

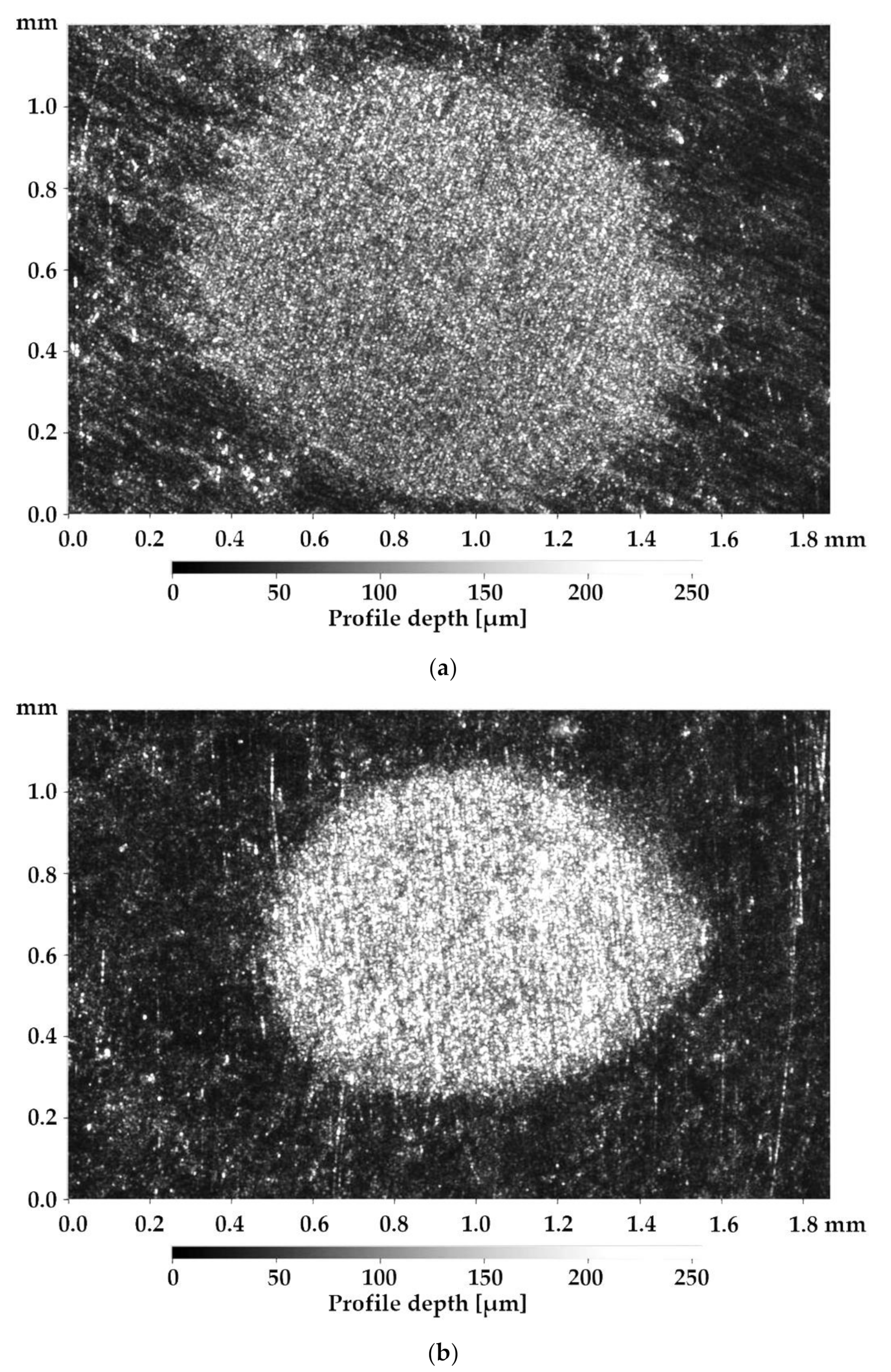

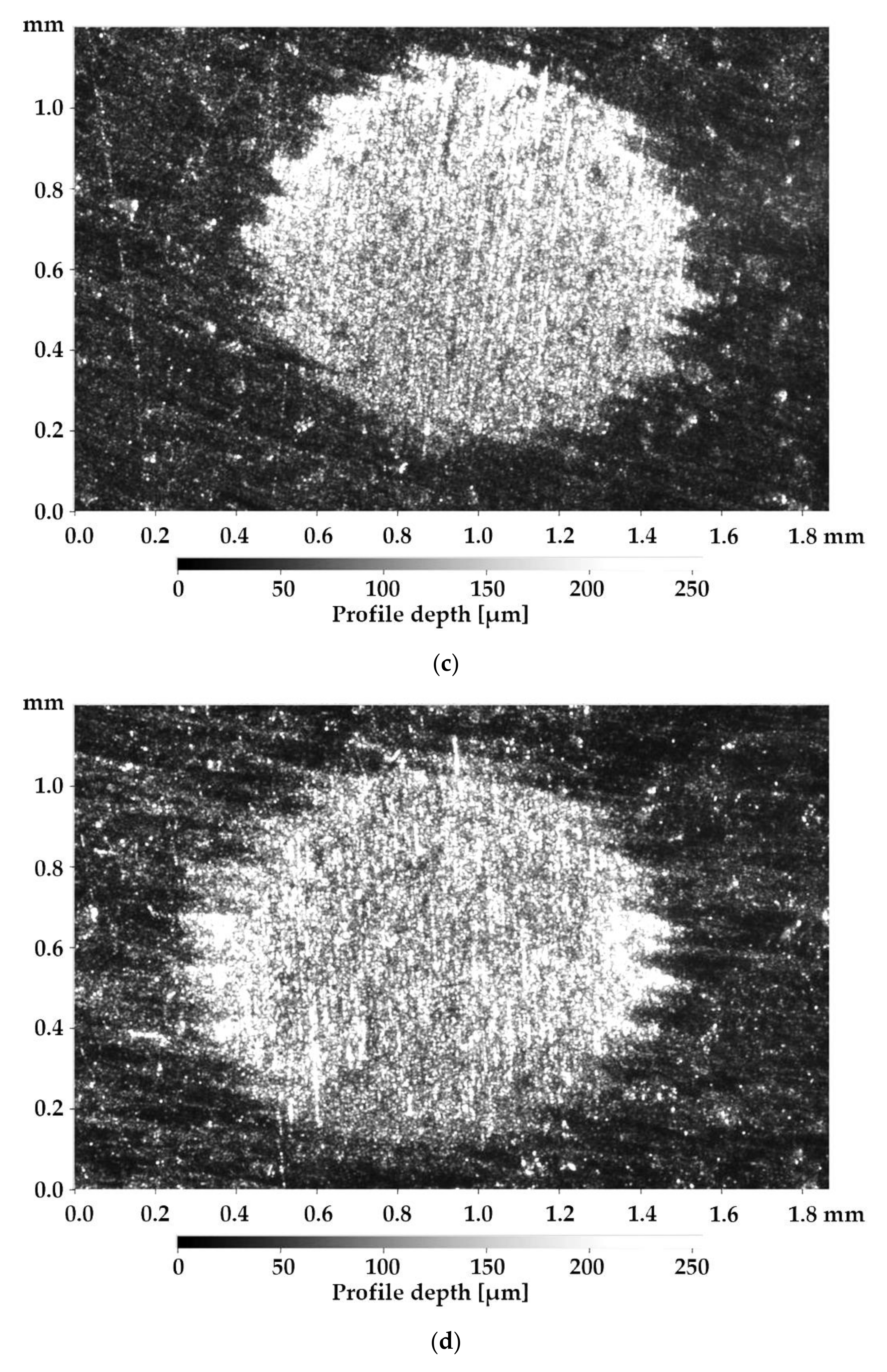

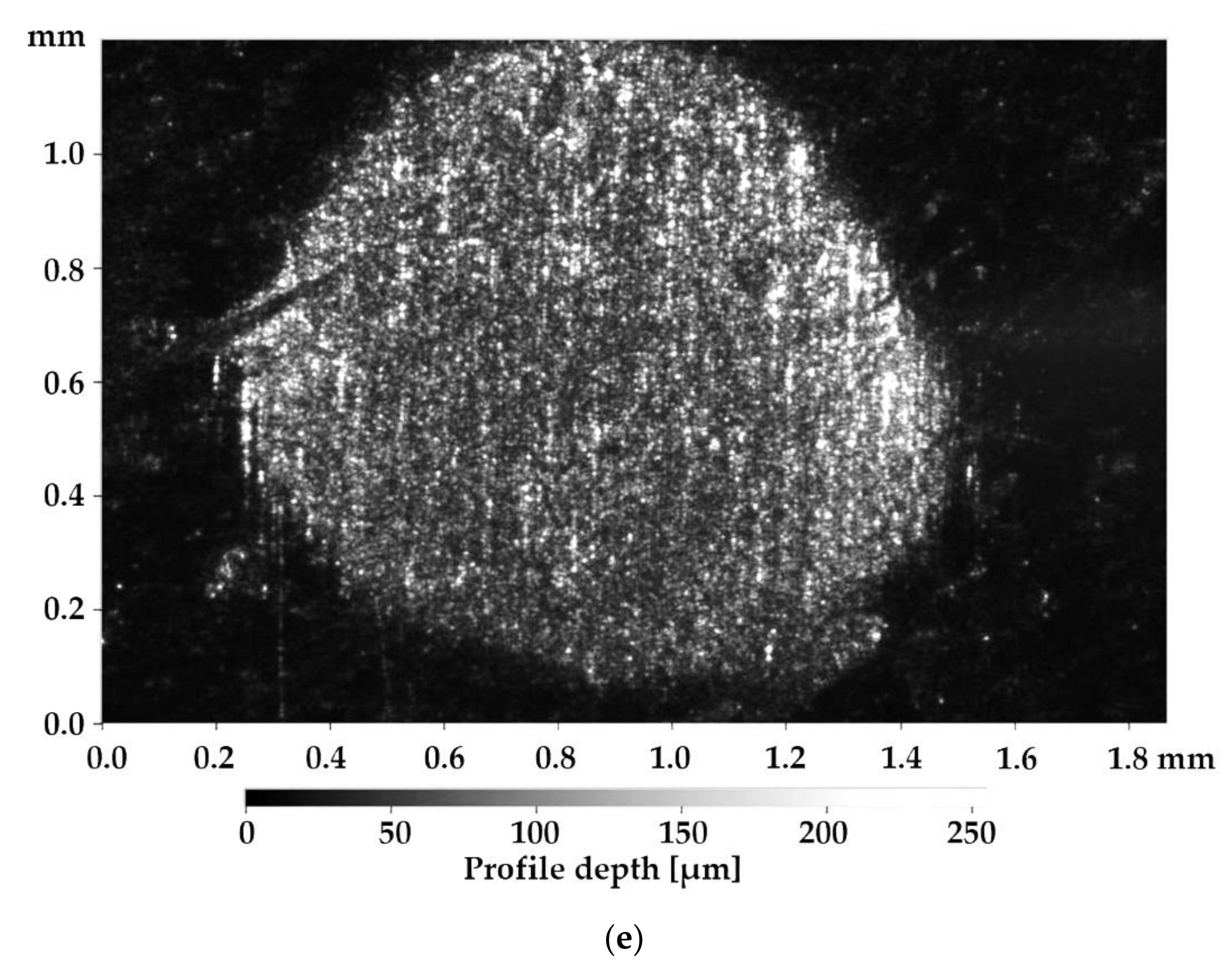

3.2. Roughness of the Samples

3.2.1. A Locking Washer

3.2.2. A Grille Module

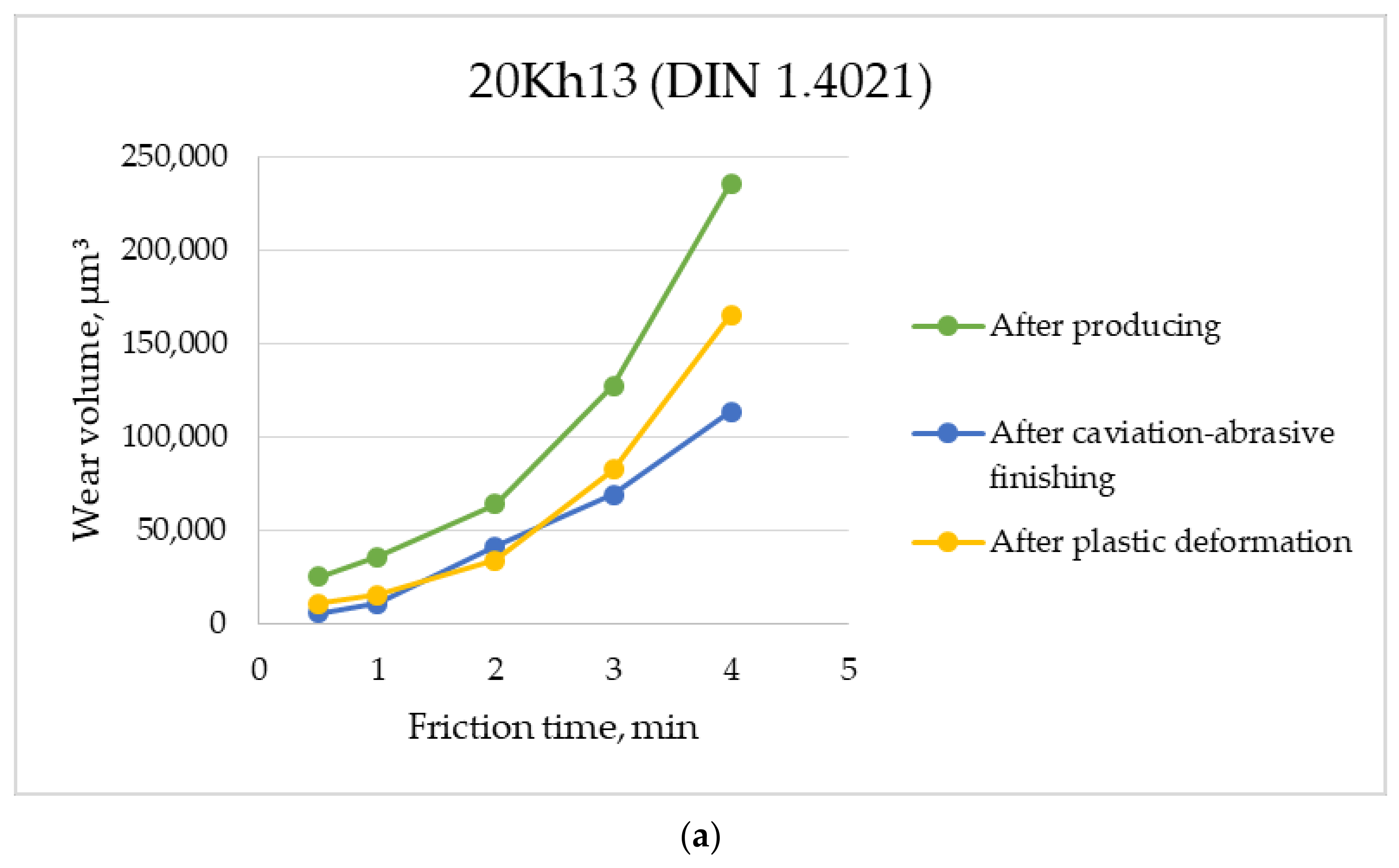

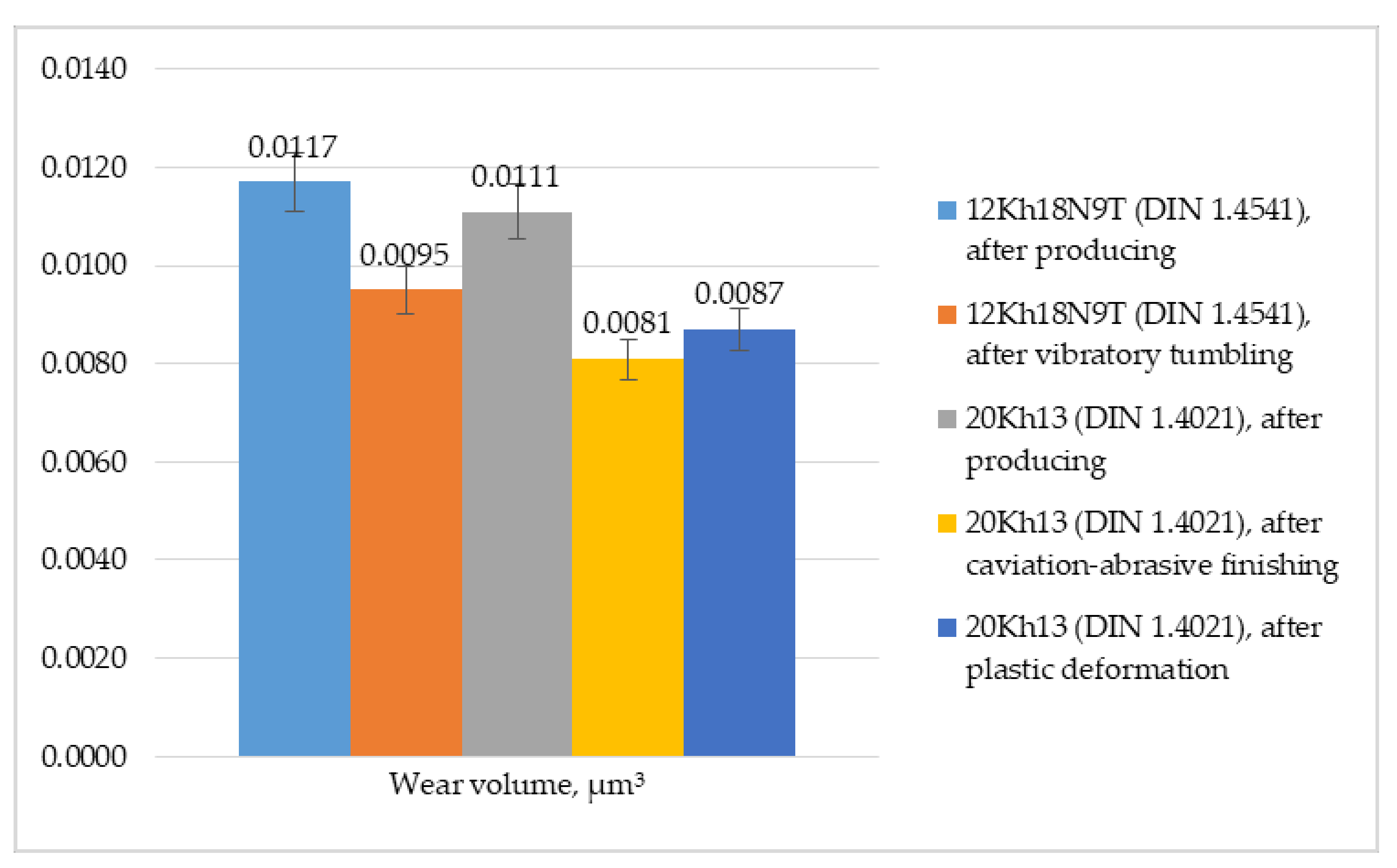

3.3. Hardness and Wear Resistance

3.4. Tests on Vibration Fatigue and Resistance to External Factors

4. Discussion

5. Conclusions

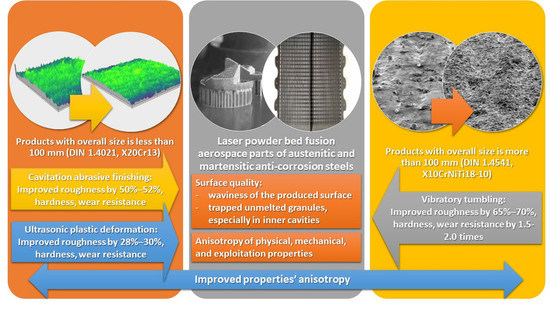

- For the locking washer of 20Kh13 (DIN 1.4021) steel, Ra of 7.24 ± 0.19 μm, which is significantly higher than the required roughness Ra of 3.2 μm;

- For the grille module of 12Kh18N9T (DIN 1.4541) steel, Ra of 8.5 ± 0.21 ÷ 14.1 ± 0.27 μm for the walls and for the grille itself instead of required Ra of 6.3 μm.

- Cavitation-abrasive finishing and ultrasonic plastic deformation for the small-scale part with the overall size of less than 100 mm and

- Vibration tumbling for the large-scale part with the overall size of more than 100 mm.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Terry, S.; Lu, H.; Fidan, I.; Zhang, Y.; Tantawi, K.; Guo, T.; Asiabanpour, B. The Influence of Smart Manufacturing towards Energy Conservation: A Review. Technologies 2020, 8, 31. [Google Scholar] [CrossRef]

- Acquesta, A.; Monetta, T. As-Built EBM and DMLS Ti-6Al-4V Parts: Topography–Corrosion Resistance Relationship in a Simulated Body Fluid. Metals 2020, 10, 1015. [Google Scholar] [CrossRef]

- Ghorbani, J.; Li, J.; Srivastava, A.K. Application of optimized laser surface re-melting process on selective laser melted 316L stainless steel inclined parts. J. Manuf. Processes 2020, 56, 726–734. [Google Scholar] [CrossRef]

- Salman, O.O.; Funk, A.; Waske, A.; Eckert, J.; Scudino, S. Additive Manufacturing of a 316L Steel Matrix Composite Reinforced with CeO2 Particles: Process Optimization by Adjusting the Laser Scanning Speed. Technologies 2018, 6, 25. [Google Scholar] [CrossRef]

- Doubenskaia, M.; Pavlov, M.; Grigoriev, S.; Tikhonova, E.; Smurov, I. Comprehensive Optical Monitoring of Selective Laser Melting. JLMN J. Laser Micro Nanoeng. 2012, 7, 236–243. [Google Scholar] [CrossRef]

- Manzhirov, A.V.; Murashkin, E.V.; Parshin, D.A. Modeling of Additive Manufacturing and Surface Growth Processes. In AIP Conference Proceedings, Proceedings of International Conference on Numerical Analysis and Applied Mathematics (ICNAAM), Rhodes, Greece, 13–18 September 2018; Simos, T., Tsitouras, C., Eds.; Amer Inst Physics: Melville, NY, USA, 2018; Volume 2116, p. 380011. [Google Scholar]

- Gorunov, A.I. Directional Crystallization of 316L Stainless Steel Specimens by Direct Laser Deposition. Inorg. Mater. 2019, 55, 1439–1444. [Google Scholar] [CrossRef]

- Kalashnikov, K.N.; Kalashnikova, A. Surface Morphology of Ti-alloy Samples Obtained by Electron Beam 3D-printing. In AIP Conference Proceedings, Proceedings of International Conference on Advanced Materials with Hierarchical Structure for New Technologies and Reliable Structures, Tomsk, Russia, 01–05 Oct 2019; Panin, V.E., Psakhie, S.G., Fomin, V.M., Eds.; Amer Inst Physics: Melville, NY, USA, 2019; Volume 2167, p. 020145. [Google Scholar]

- Willner, R.; Lender, S.; Ihl, A.; Wilsnack, C.; Gruber, S.; Brandao, A.; Pambaguian, L.; Riede, M.; Lopez, E.; Brueckner, F.; et al. Potential and challenges of additive manufacturing for topology optimized spacecraft structures. J. Laser Appl. 2020, 32, 032012. [Google Scholar] [CrossRef]

- Verna, E.; Genta, G.; Galetto, M.; Franceschini, F. Planning offline inspection strategies in low-volume manufacturing processes. Qual. Eng. 2020. [Google Scholar] [CrossRef]

- Saprykin, A.A.; Sharkeev, Y.P.; Saprykina, N.A.; Ibragimov, E.A. Selective Laser Melting of Magnesium. Key Eng. Mat. 2020, 839, 144–149. [Google Scholar] [CrossRef]

- Polozov, I.A.; Borisov, E.V.; Sufiiarov, V.S.; Popovich, A.A. Selective Laser Melting of Copper Alloy. Mater. Phy. Mech. 2020, 43, 65–71. [Google Scholar]

- Yadroitsev, I.; Bertrand, P.; Antonenkova, G.; Grigoriev, S.; Smurov, I. Use of track/layer morphology to develop functional parts by selectivelaser melting. J. Laser Appl. 2013, 25, 052003. [Google Scholar] [CrossRef]

- Lober, L.; Flache, C.; Petters, R.; Kuhn, U.; Eckert, J. Comparison of different post processing technologies for SLM generated 3161 steel parts. Rapid Prototyp. J. 2013, 19, 173–179. [Google Scholar] [CrossRef]

- Gatto, A.; Bassoli, E.; Denti, L.; Sola, A.; Tognoli, E.; Comin, A.; Porro, J.A.; Cordovilla, F.; Angulo, I.; Ocana, J.L. Effect of Three Different Finishing Processes on the Surface Morphology and Fatigue Life of A357.0 Parts Produced by Laser-Based Powder Bed Fusion. Adv. Eng. Mater. 2019, 21, 1801357. [Google Scholar] [CrossRef]

- Chen, Y.; Sun, H.; Li, Z.; Wu, Y.; Xiao, Y.; Chen, Z.; Zhong, S.; Wang, H. Strategy of Residual Stress Determination on Selective Laser Melted Al Alloy Using XRD. Materials 2020, 13, 451. [Google Scholar] [CrossRef]

- Wan, H.Y.; Luo, Y.W.; Zhang, B.; Song, Z.M.; Wang, L.Y.; Zhou, Z.J.; Li, C.P.; Chen, G.F.; Zhang, G.P. Effects of surface roughness and build thickness on fatigue properties of selective laser melted Inconel 718 at 650 degrees C. Int. J. Fatigue 2020, 137, 105654. [Google Scholar] [CrossRef]

- Jamshidi, P.; Aristizabal, M.; Kong, W.; Villapun, V.; Cox, S.C.; Grover, L.M.; Attallah, M.M. Selective Laser Melting of Ti-6Al-4V: The Impact of Post-processing on the Tensile, Fatigue and Biological Properties for Medical Implant Applications. Materials 2020, 13, 2813. [Google Scholar] [CrossRef]

- Cruz, N.; Martins, M.I.; Domingos Santos, J.; Gil Mur, J.; Tondela, J.P. Surface Comparison of Three Different Commercial Custom-Made Titanium Meshes Produced by SLM for Dental Applications. Materials 2020, 13, 2177. [Google Scholar] [CrossRef]

- Hollaender, A.; Cosemans, P. Surface technology for additive manufacturing. Plasma Process. Polym. 2020, 17, e1900155. [Google Scholar] [CrossRef]

- Volosova, M.A.; Grigoriev, S.N.; Ostrikov, E.A. Use of laser ablation for formation of discontinuous (discrete) wear-resistant coatings formed on solid carbide cutting tool by electron beam alloying and vacuum-arc deposition. Mech. Ind. 2016, 17, 720. [Google Scholar] [CrossRef]

- Metel, A.; Grigoriev, S.; Melnik, Y.; Panin, V.; Prudnikov, V. Cutting Tools Nitriding in Plasma Produced by a Fast Neutral Molecule Beam. Jpn. J. Appl. Phys. 2011, 50, 08JG04. [Google Scholar] [CrossRef]

- Danilov, I.; Hackert-Oschätzchen, M.; Zinecker, M.; Meichsner, G.; Edelmann, J.; Schubert, A. Process Understanding of Plasma Electrolytic Polishing through Multiphysics Simulation and Inline Metrology. Micromachines 2019, 10, 214. [Google Scholar] [CrossRef]

- Vereschaka, A.A.; Volosova, M.A.; Grigoriev, S.N.; Vereschaka, A.S. Development of wear-resistant complex for high-speed steel tool when using process of combined cathodic vacuum arc deposition. Proc. CIRP 2013, 9, 8–12. [Google Scholar] [CrossRef]

- Volosova, M.A.; Gurin, V.D. Influence of vacuum-plasma nitride coatings on contact processes and a mechanism of wear of working surfaces of high-speed steel cutting tool at interrupted cutting. J. Frict. Wear 2013, 34, 183–189. [Google Scholar] [CrossRef]

- Semenov, A.P.; Baldanov, B.B.; Ranzhurov, T.V. A Source of Nonequilibrium Argon Plasma Based on a Volume Gas Flow Discharge at Atmospheric Pressure. Instrum. Exp. Tech. 2020, 63, 284–287. [Google Scholar] [CrossRef]

- Jung, S.; Kang, E.; Park, J.; Kim, T.; Baek, S. A Study on Proposal of E-Beam Drilling Machining Criterion by Using on Vaporized Amplification Sheets in a High-Power Density Electron Beam. J. Nanosci. Nanotechnol. 2020, 20, 4231–4234. [Google Scholar] [CrossRef]

- Gavrilov, N.V.; Men’shakov, A.I. Effect of the electron beam and ion flux parameters on the rate of plasma nitriding of an austenitic stainless steel. Tech. Phys. 2012, 57, 399–404. [Google Scholar] [CrossRef]

- Fedorov, S.V.; Pavlov, M.D.; Okunkova, A.A. Effect of structural and phase transformations in alloyed subsurface layer of hard-alloy tools on their wear resistance during cutting of high-temperature alloys. J. Frict. Wear 2013, 34, 190–198. [Google Scholar] [CrossRef]

- Tan, K.L.; Yeo, S.H. Surface finishing on IN625 additively manufactured surfaces by combined ultrasonic cavitation and abrasion. Addit. Manuf. 2020, 31, 100938. [Google Scholar] [CrossRef]

- Wang, J.; Zhu, J.; Liew, P.J. Material Removal in Ultrasonic Abrasive Polishing of Additive Manufactured Components. Appl. Sci. 2019, 9, 5359. [Google Scholar] [CrossRef]

- Tan, K.L.; Yeo, S.H. Surface modification of additive manufactured components by ultrasonic cavitation abrasive finishing. Wear 2017, 378–379, 90–95. [Google Scholar] [CrossRef]

- Gou, J.; Wang, Z.; Hu, S.; Shen, J.; Tian, Y.; Zhao, G.; Chen, Y. Effects of ultrasonic peening treatment in three directions on grain refinement and anisotropy of cold metal transfer additive manufactured Ti-6Al-4V thin wall structure. J. Manuf. Process. 2020, 54, 148–157. [Google Scholar] [CrossRef]

- Zhou, C.; Jiang, F.; Xu, D.; Guo, C.H.; Zhao, C.Z.; Wang, Z.Q.; Wang, J.D. A calculation model to predict the impact stress field and depth of plastic deformation zone of additive manufactured parts in the process of ultrasonic impact treatment. J. Mater. Process. Technol. 2020, 280, 116599. [Google Scholar] [CrossRef]

- Bankowski, D.; Spadlo, S. Vibratory Machining Effect on the Properties of the Aaluminum Alloys Surface. Arch. Foundry Eng. 2017, 17, 19–24. [Google Scholar] [CrossRef][Green Version]

- Dong, G.; Marleau-Finley, J.; Zhao, Y.F. Investigation of electrochemical post-processing procedure for Ti-6Al-4V lattice structure manufactured by direct metal laser sintering (DMLS). Int. J. Adv. Manuf. Tech. 2019, 104, 3401–3417. [Google Scholar] [CrossRef]

- Rotty, C.; Mandroyan, A.; Doche, M.-L.; Monney, S.; Hihn, J.Y.; Rouge, N. Electrochemical Superfinishing of Cast and ALM 316L Stainless Steels in Deep Eutectic Solvents: Surface Microroughness Evolution and Corrosion Resistance. J. Electrochem. Soc. 2019, 166, C468–C478. [Google Scholar] [CrossRef]

- Grigor’ev, S.N.; Fedorov, S.V.; Pavlov, M.D.; Okun’kova, A.A.; So, Y.M. Complex surface modification of carbide tool by Nb plus Hf plus Ti alloying followed by hardfacing (Ti plus Al)N. J. Frict. Wear 2013, 34, 14–18. [Google Scholar] [CrossRef]

- Volosova, M.A.; Grigor’ev, S.N.; Kuzin, V.V. Effect of titanium nitride coating on stress structural inhomogeneity in oxide-carbide ceramic. Part 4. Action of heat flow. Refract. Ind. Ceram. 2015, 56, 91–96. [Google Scholar] [CrossRef]

- Nath, S.D.; Irrinki, H.; Gupta, G.; Kearns, M.; Gulsoy, O.; Atre, S. Microstructure-property relationships of 420 stainless steel fabricated for by laser-powder bed fusion. Powder Technol. 2019, 343, 738–746. [Google Scholar] [CrossRef]

- Jamshidinia, M.; Sadek, A.; Wang, W.; Kelly, S. Additive Manufacturing of Steel Alloys Using Laser Powder-Bed Fusion. Adv. Mater. Process. 2015, 173, 20–24. [Google Scholar]

- Zhu, H.; Li, Y.; Li, B.; Zhang, Z.; Qiu, C. Effects of Low-Temperature Tempering on Microstructure and Properties of the Laser-Cladded AISI 420 Martensitic Stainless Steel Coating. Coatings 2018, 8, 451. [Google Scholar] [CrossRef]

- Khmyrov, R.; Grigoriev, S.; Okunkova, A.; Gusarov, A. On the possibility of selective laser melting of quartz glass. Phys. Procedia 2014, 56, 345–356. [Google Scholar] [CrossRef][Green Version]

- Nowotny, S.; Tarasova, T.V.; Filatova, A.A.; Dolzhikova, E.Y. Methods for Characterizing Properties of Corrosion-Resistant Steel Powders Used for Powder Bed Fusion Processes. Mater. Sci. Forum 2016, 876, 1–7. [Google Scholar] [CrossRef]

- Gavrin, V.N.; Kozlova, Y.P.; Veretenkin, E.P.; Logachev, A.V.; Logacheva, A.I.; Lednev, I.S.; Okunkova, A.A. Reactor Target from Metal Chromium for “Pure” High-Intensive Artificial Neutrino Source. Phys. Part. Nucl. Lett. 2016, 13, 267–273. [Google Scholar] [CrossRef]

- Volosova, M.A.; Okunkova, A.A.; Povolotskiy, D.E.; Podrabinnik, P.A. Study of electrical discharge machining for the parts of nuclear industry usage. Mech. Ind. 2015, 16, 706. [Google Scholar] [CrossRef]

- Sova, A.; Okunkova, A.; Grigoriev, S.; Smurov, I. Velocity of the Particles Accelerated by a Cold Spray Micronozzle: Experimental Measurements and Numerical Simulation. J. Therm. Spray Tech. 2013, 22, 75–80. [Google Scholar] [CrossRef]

- Sova, A.; Doubenskaia, M.; Grigoriev, S.; Okunkova, A.; Smurov, I. Parameters of the Gas-Powder Supersonic Jet in Cold Spraying Using a Mask. J. Therm. Spray Technol. 2013, 22, 551–556. [Google Scholar] [CrossRef]

- Breidenstein, B.; Brenne, F.; Wu, L.; Niendorf, T.; Denkena, B. Effect of Post-Process Machining on Surface Properties of Additively Manufactured H13 Tool Steel. HTM J. Heat Treat. Mater. 2018, 73, 173–186. [Google Scholar] [CrossRef]

- Crayford, A.P.; Lacan, F.; Runyon, J.; Bowen, P.J.; Balwadkar, S.; Harper, J.; Pugh, D.G. Manufacture, characterization and stability limits of an am prefilming air-blast atomizer. In Proceedings of the ASME Turbo Expo: Turbomachinery Technical Conference and Exposition, Phoenix, AZ, USA, 17–21 June 2019; Amer Soc Mechanical Engineers: New York, NY, USA, 2019; Volume 4B. [Google Scholar]

- Hunter, L.W.; Brackett, D.; Brierley, N.; Yang, J.; Attallah, M.M. Assessment of trapped powder removal and inspection strategies for powder bed fusion techniques. Int. J. Adv. Manuf. Tech. 2020, 106, 4521–4532. [Google Scholar] [CrossRef]

- Cortina, M.; Arrizubieta, J.I.; Calleja, A.; Ukar, E.; Alberdi, A. Case Study to Illustrate the Potential of Conformal Cooling Channels for Hot Stamping Dies Manufactured Using Hybrid Process of Laser Metal Deposition (LMD) and Milling. Metals 2018, 8, 102. [Google Scholar] [CrossRef]

- Zhao, Y.; Li, F.; Chen, S.; Lu, Z.Y. Unit block-based process planning strategy of WAAM for complex shell-shaped component. Int. J. Adv. Manuf. Technol. 2019, 104, 3915–3927. [Google Scholar] [CrossRef]

- Han, P. Additive Design and Manufacturing of Jet Engine Parts. Engineering 2017, 3, 648–652. [Google Scholar] [CrossRef]

- Varela, J.; Merino, J.; Pickett, C.; Abu-Issa, A.; Arrieta, E.; Murr, L.E.; Wicker, R.B.; Ahlfors, M.; Godfrey, D.; Medina, F. Performance Characterization of Laser Powder Bed Fusion Fabricated Inconel 718 Treated with Experimental Hot Isostatic Processing Cycles. J. Manuf. Mater. Process. 2020, 4, 73. [Google Scholar] [CrossRef]

- Banoth, S.; Li, C.-W.; Hiratsuka, Y.; Kakehi, K. The Effect of Recrystallization on Creep Properties of Alloy IN939 Fabricated by Selective Laser Melting Process. Metals 2020, 10, 1016. [Google Scholar] [CrossRef]

- Teixeira, Ó.; Silva, F.J.G.; Ferreira, L.P.; Atzeni, E. A Review of Heat Treatments on Improving the Quality and Residual Stresses of the Ti–6Al–4V Parts Produced by Additive Manufacturing. Metals 2020, 10, 1006. [Google Scholar] [CrossRef]

- Bunnell, D.E.; Bourell, D.L.; Beaman, J.B.; Marcus, H.L. Fundamentals of liquid phase sintering during selective laser sintering. In Processing and Fabrication of Advanced Materials IV, Proceedings of Symposium on Processing and Fabrication of Advanced Materials IV, Cleveland, USA, 29 October–2 November 1995; Srivatsan, T.S., Moore, J.J., Eds.; Minerals, Metals & Materials Soc: Warrendale, PA, USA, 1996; pp. 17–26. [Google Scholar]

- Bourell, D.L.; Marcus, H.L.; Barlow, J.W.; Beaman, J.J. Selective Laser Sintering of Metals and Ceramics. Int. J. Powder Metall. 1992, 28, 369–381. [Google Scholar]

- Grigoriev, S.; Tarasova, T.; Gusarov, A.; Khmyrov, R.; Egorov, S. Possibilities of Manufacturing Products from Cermet Compositions Using Nanoscale Powders by Additive Manufacturing Methods. Materials 2019, 12, 3425. [Google Scholar] [CrossRef]

- Gusarov, A.V.; Grigoriev, S.N.; Volosova, M.A.; Melnik, Y.A.; Laskin, A.; Kotoban, D.V.; Okunkova, A.A. On productivity of laser additive manufacturing. J. Mater. Process. Technol. 2018, 261, 213–232. [Google Scholar] [CrossRef]

- Smurov, I.; Doubenskaia, M.; Grigoriev, S.; Nazarov, A. Optical Monitoring in Laser Cladding of Ti6Al4V. J. Therm. Spray Tech. 2012, 21, 1357–1362. [Google Scholar] [CrossRef]

- Metel, A.S.; Stebulyanin, M.M.; Fedorov, S.V.; Okunkova, A.A. Power Density Distribution for Laser Additive Manufacturing (SLM): Potential, Fundamentals and Advanced Applications. Technologies 2019, 7, 5. [Google Scholar] [CrossRef]

- Liu, Z.; Huang, C.; Gao, C.; Liu, R.; Chen, J.; Xiao, Z. Characterization Of Ti6al4v Powders Produced By Different Methods For Selective Electron Beam Melting. J. Min. Met. Sect. B Met. 2019, 55, 121–128. [Google Scholar] [CrossRef]

- Gao, C.F.; Xiao, Z.Y.; Zou, H.P.; Liu, Z.Q.; Chen, J.; Li, S.K.; Zhang, D.T. Characterization of spherical AlSi10Mg powder produced by double-nozzle gas atomization using different parameters. Trans. Nonferrous Met. Soc. China 2019, 29, 374–384. [Google Scholar] [CrossRef]

- Kropotkina, E.; Zykova, M.; Shein, A.; Kapustina, N. Application of roller burnishing technologies to improve the wear resistance of submerged pump parts made of powder alloys. Mech. Ind. 2018, 19, 705. [Google Scholar] [CrossRef]

- Naydenkin, E.; Mishin, I.; Khrustalyov, A.; Vorozhtsov, S.; Vorozhtsov, A. Influence of Combined Helical and Pass Rolling on Structure and Residual Porosity of an AA6082-0.2 wt% Al2O3 Composite Produced by Casting with Ultrasonic Processing. Metals 2017, 7, 544. [Google Scholar] [CrossRef]

- Badalyan, V.G.; Vorontsova, N.N.; Kazantsev, V.F.; Nazarov, A.V. Change of Copper Dislocational Structure after Action of Statical and Ultrasound Stresses. Fiz. Met. I Metalloved. 1982, 54, 1191–1193. [Google Scholar]

- Andreeva, T.A.; Berkovich, A.E.; Bykov, N.Y.; Kozyrev, S.V.; Lukin, A.Y. High-Intensity Focused Ultrasound: Heating and Destruction of Biological Tissue. Tech. Phys. 2020, 65, 1455–1466. [Google Scholar] [CrossRef]

- Grigoriev, S.N.; Metel, A.S.; Tarasova, T.V.; Filatova, A.A.; Sundukov, S.K.; Volosova, M.A.; Okunkova, A.A.; Melnik, Y.A.; Podrabinnik, P.A. Effect of cavitation erosion wear and vibration tumbling on additively manufactured parts’ surface quality. Metals 2020, 10, 1540. [Google Scholar] [CrossRef]

- Rando, R.J.; Vacek, P.M.; Glenn, R.E.; Kwon, C.W.; Parker, J.E. Retrospective Assessment of Respirable Quartz Exposure for a Silicosis Study of the Industrial Sand Industry. Ann. Work. Expo. Health 2018, 62, 1021–1032. [Google Scholar] [CrossRef]

- Hayu, R.; Sutanto, H.; Ismail, Z. Accurate density measurement of stainless steel weights by hydrostatic weighing system. Measurement 2019, 131, 120–124. [Google Scholar] [CrossRef]

- Firsov, K.N. Influence of Partial Wetting on the Results of Verification of Glass Hydrometers for Ethanol. Meas. Tech. 2017, 60, 92–95. [Google Scholar] [CrossRef]

- Rafieazad, M.; Ghaffari, M.; Nemani, A.V.; Nasiri, A. Microstructural evolution and mechanical properties of a low-carbon low-alloy steel produced by wire arc additive manufacturing. Int. J. Adv. Manuf. Technol. 2019, 105, 2121–2134. [Google Scholar] [CrossRef]

- Hung, C.H.; Sutton, A.; Li, Y.; Shen, Y.Y.; Tsai, H.L.; Leu, M.C. Enhanced mechanical properties for 304L stainless steel parts fabricated by laser-foil-printing additive manufacturing. J. Manuf. Process. 2019, 45, 438–446. [Google Scholar] [CrossRef]

- Grigoriev, S.N.; Metel, A.S.; Fedorov, S.V. Modification of the structure and properties of high-speed steel by combined vacuum-plasma treatment. Met. Sci. Heat Treat. 2012, 54, 8–12. [Google Scholar] [CrossRef]

- Tamadon, A.; Pons, D.J.; Clucas, D. AFM Characterization of Stir-Induced Micro-Flow Features within the AA6082-T6 BFSW Welds. Technologies 2019, 7, 80. [Google Scholar] [CrossRef]

- Garlea, E.; Choo, H.; Sluss, C.C.; Koehler, M.R.; Bridges, R.L.; Xiao, X.; Ren, Y.; Jared, B.H. Variation of elastic mechanical properties with texture, porosity, and defect characteristics in laser powder bed fusion 316L stainless steel. Mater. Sci. Eng. A 2019, 763, 138032. [Google Scholar] [CrossRef]

- Tan, Q.; Liu, Y.; Fan, Z.; Thiele, M.; Esen, C.; Edelmann, A.; Hellmann, R. Effect of processing parameters on the densification of an additively manufactured 2024 Al alloy. J. Mater. Sci. Technol. 2020, 58, 34–45. [Google Scholar] [CrossRef]

- Roettger, A.; Boes, J.; Theisen, W.; Thiele, M.; Esen, C.; Edelmann, A.; Hellmann, R. Microstructure and mechanical properties of 316L austenitic stainless steel processed by different SLM devices. Int. J. Adv. Manuf. Technol. 2020, 108, 769–783. [Google Scholar] [CrossRef]

- Hiratsuka, K.; Kajdas, C. Mechanochemistry as a key to understand the mechanisms of boundary lubrication, mechanolysis and gas evolution during friction. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2013, 227, 1191–1203. [Google Scholar] [CrossRef]

- Livanskiy, A.N.; Prikhodko, V.M.; Sundukov, S.K.; Fatyukhin, D.S. Research on the Influence of Ultrasonic Vibrations on Paint Coating Properties. Trans. Famena 2016, 40, 129–138. [Google Scholar]

- Sirotyuk, M.G. Resonant Electrodynamic Sound Generator for Acoustic Levitation. Sov. Phys. Acoust. USSR 1986, 32, 399–403. [Google Scholar]

- Endo, H. Thermodynamic Consideration of the Cavitation Mechanism in Homogeneous Liquids. J. Acoust. Soc. Am. 1994, 95, 2409–2415. [Google Scholar] [CrossRef]

- Wang, Q. Local energy of a bubble system and its loss due to acoustic radiation. J. Fluid Mech. 2016, 797, 201–230. [Google Scholar] [CrossRef]

- Agranat, B.A.; Khavskii, N.N. Experience in Incorporation of High-Intensity Ultrasonic Lines in Continuous Annealing Plants. Sov. Phys. Acoust. USSR 1976, 22, 80. [Google Scholar]

| Material | C | S | P | Mn | Cr | W | V | Si | Ni | Mo | Cu |

|---|---|---|---|---|---|---|---|---|---|---|---|

| PR 20Kh13 | 0.16–0.25 | ≤0.025 | ≤0.03 | ≤0.6 | 12–14 | - | - | ≤0.6 | ≤0.6 | - | - |

| PR 12Kh18N9T | ≤0.12 | ≤0.02 | ≤0.035 | ≤2.0 | 17–19 | ≤0.2 | ≤0.2 | ≤0.8 | 8–9.5 | ≤0.5 | ≤0.4 |

| Material | Layer Thickness, µm | Laser Power Pl, W | Scanning Speed Vs, mm·s−1 |

|---|---|---|---|

| 20Kh13 (DIN 1.4021) | 20 | 80 | 390 |

| 12Kh18N9T (DIN 1.4541) | 20 | 100 | 100 |

| Material | Producing Method | Density ρ, g·cm3 |

|---|---|---|

| 20Kh13 (DIN 1.4021) | Additive manufacturing | 7.709 ± 0.004 |

| Cast in combination with quenching and low or high tempering1 | 7.7 | |

| 12Kh18N9T (DIN 1.4541) | Additive manufacturing | 7.905 ± 0.004 |

| Cast in combination with quenching at 1050–1100 °C with cooling in water 1 | 7.9 |

| Method | Roughness Arithmetic Mean Deviation Ra, µm |

|---|---|

| After producing | 7.24 |

| After ultrasonic cavitation-abrasive finishing | 3.04 |

| After ultrasonic plastic deformation | 5.02 |

| Method | Roughness Arithmetic Mean Deviation Ra of the Walls, µm | Roughness Arithmetic Mean Deviation Ra of the Grille, µm |

|---|---|---|

| After producing | 14.1 | 8.5 |

| After vibratory tumbling | 5.0 | 2.5 |

| Production and Heat Treatment Methods | Rockwell Hardness HRCz 1 | Rockwell Hardness HRCxy 1 |

|---|---|---|

| Additive manufacturing without heat treatment | - | 46.25 |

| Additive manufacturing with heat treatment (tempering at 240 °C, air) | 44.2 | 46.2 |

| Cast with heat treatment (hardening at 1030 °C, oil and tempering at 240 °C, air) | 45.9 | |

| Production and Heat Treatment Methods | Rockwell Hardness HRCz 1 | Rockwell Hardness HRCxy 1 |

|---|---|---|

| Additive manufacturing without heat treatment | - | 25.7 |

| Additive manufacturing with heat treatment (tempering at 240 °C, air) | 24.35 | 25.6 |

| Cast with heat treatment (hardening at 1030 °C, oil and tempering at 240 °C, air) | 27.4 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Metel, A.S.; Grigoriev, S.N.; Tarasova, T.V.; Filatova, A.A.; Sundukov, S.K.; Volosova, M.A.; Okunkova, A.A.; Melnik, Y.A.; Podrabinnik, P.A. Influence of Postprocessing on Wear Resistance of Aerospace Steel Parts Produced by Laser Powder Bed Fusion. Technologies 2020, 8, 73. https://doi.org/10.3390/technologies8040073

Metel AS, Grigoriev SN, Tarasova TV, Filatova AA, Sundukov SK, Volosova MA, Okunkova AA, Melnik YA, Podrabinnik PA. Influence of Postprocessing on Wear Resistance of Aerospace Steel Parts Produced by Laser Powder Bed Fusion. Technologies. 2020; 8(4):73. https://doi.org/10.3390/technologies8040073

Chicago/Turabian StyleMetel, Alexander S., Sergey N. Grigoriev, Tatiana V. Tarasova, Anastasia A. Filatova, Sergey K. Sundukov, Marina A. Volosova, Anna A. Okunkova, Yury A. Melnik, and Pavel A. Podrabinnik. 2020. "Influence of Postprocessing on Wear Resistance of Aerospace Steel Parts Produced by Laser Powder Bed Fusion" Technologies 8, no. 4: 73. https://doi.org/10.3390/technologies8040073

APA StyleMetel, A. S., Grigoriev, S. N., Tarasova, T. V., Filatova, A. A., Sundukov, S. K., Volosova, M. A., Okunkova, A. A., Melnik, Y. A., & Podrabinnik, P. A. (2020). Influence of Postprocessing on Wear Resistance of Aerospace Steel Parts Produced by Laser Powder Bed Fusion. Technologies, 8(4), 73. https://doi.org/10.3390/technologies8040073