Open Source Waste Plastic Granulator

Abstract

1. Introduction

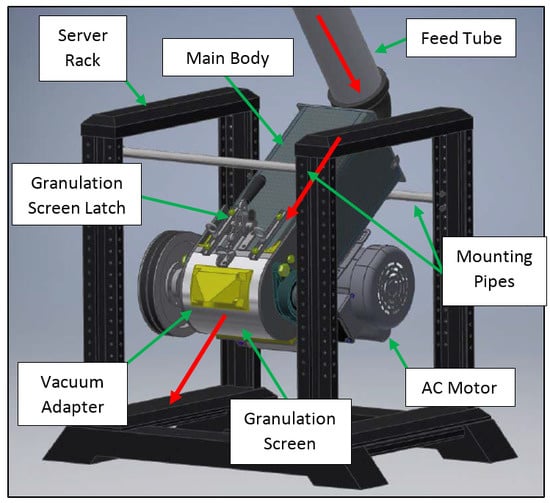

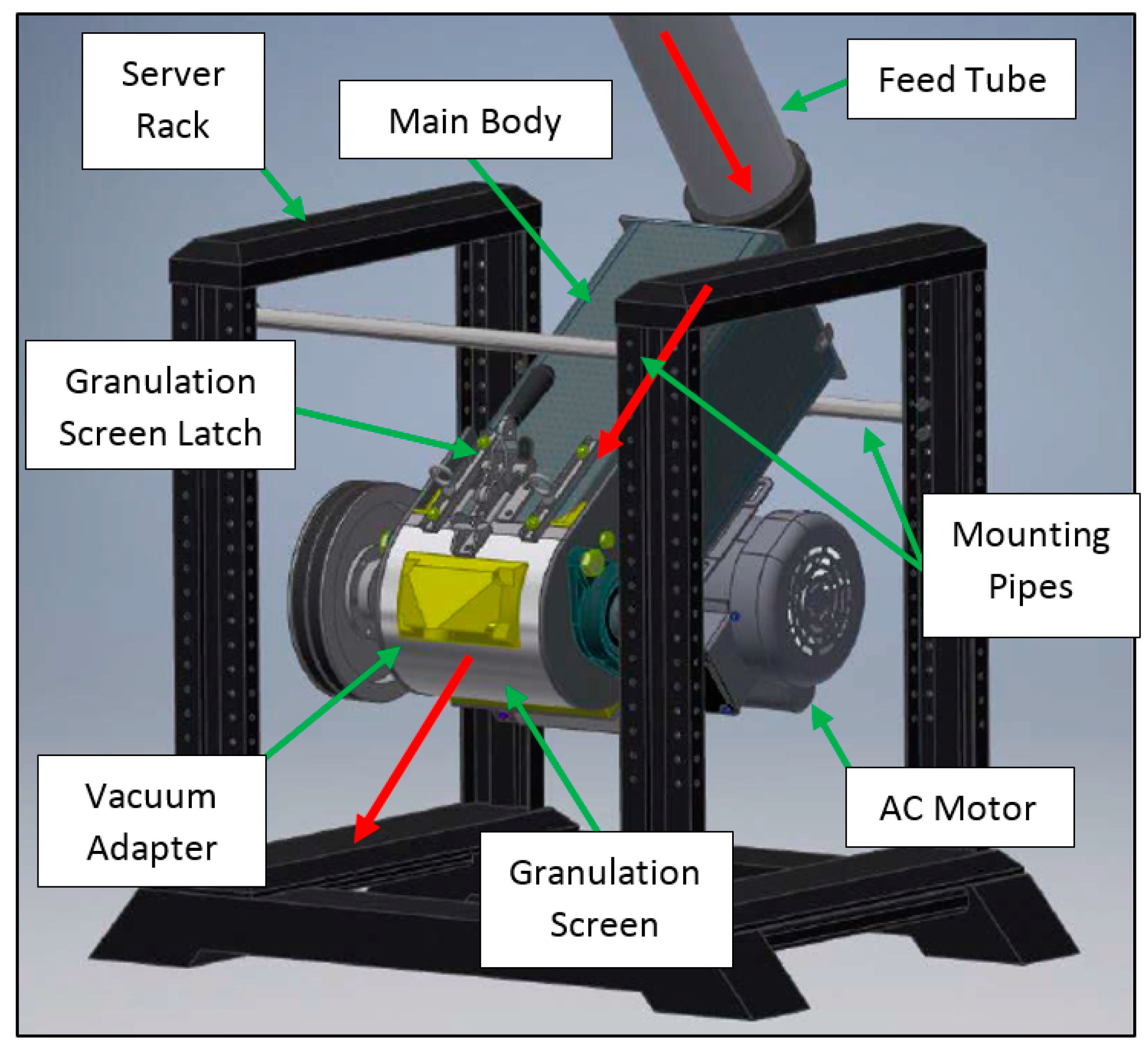

2. Design Concept

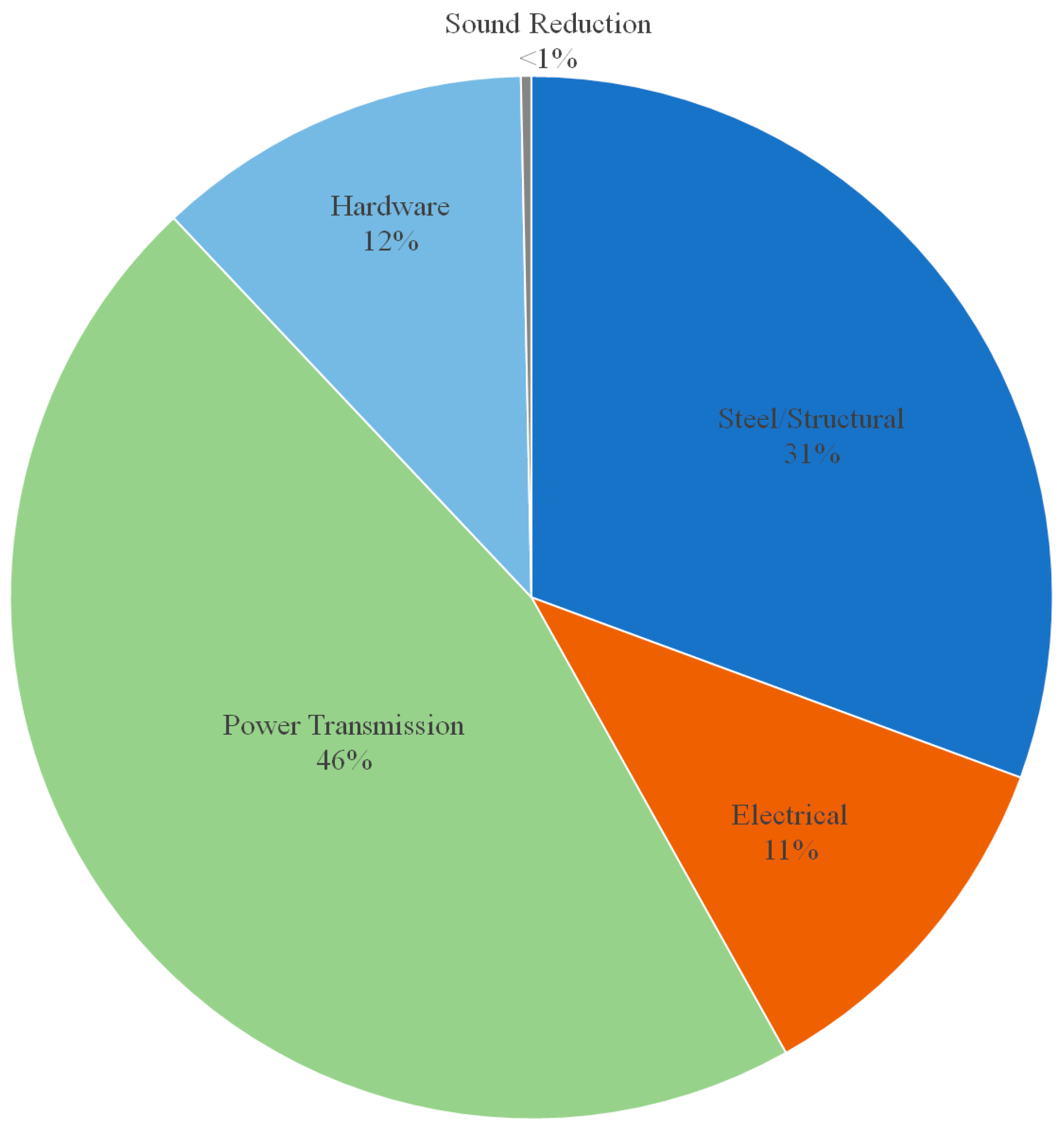

- Power Transmission: This system encompasses all machine parts needed to convert the electrical energy being input to the system into mechanical energy, as well as transmit that mechanical energy to the plastic cutting/granulation system.

- Plastic Cutting/Granulation: This system is the one that directly interacts with the plastic in order to cut it into small chunks. It is responsible for cutting plastic as well as ejecting granules after they have reached a uniform size.

- Material Guidance/Structural: This system involves any parts that keep the plastic feedstock inside of the proper cutting area during operation or guide the feedstock during its journey. It includes the hopper chute, the hopper lip, the granulation chamber lip, any mechanism used to hold the hopper to the granulation chamber, and the upper surfaces of the granulation chamber.

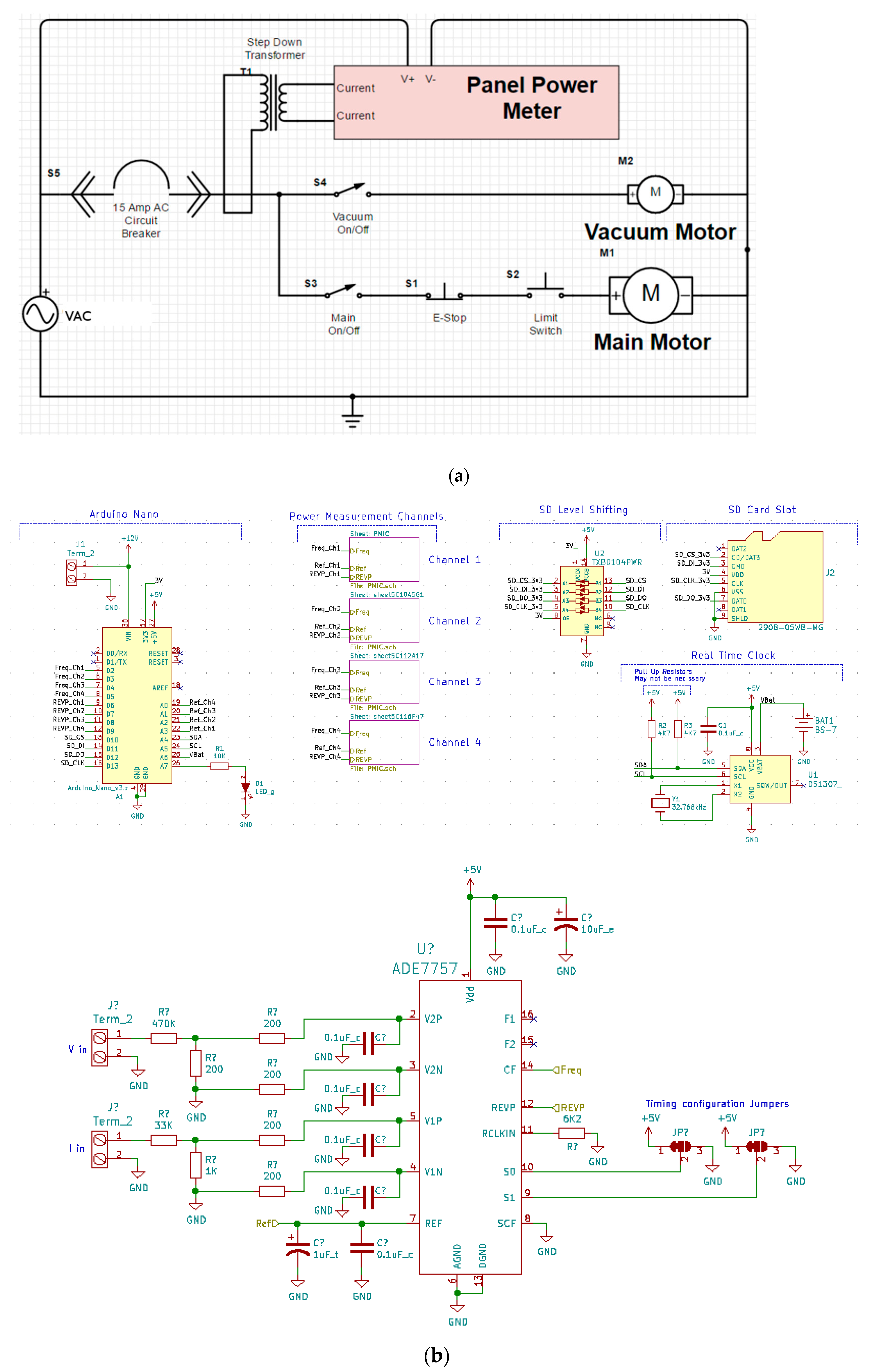

- Electrical: This system encompasses all of the components required to convert electrical energy from electrical grid power into rotational energy, as well as any other electrical peripherals present on the machine. This includes the electrical box, safety switches, circuit board, motor, and a microcontroller.

2.1. Power Transmission System

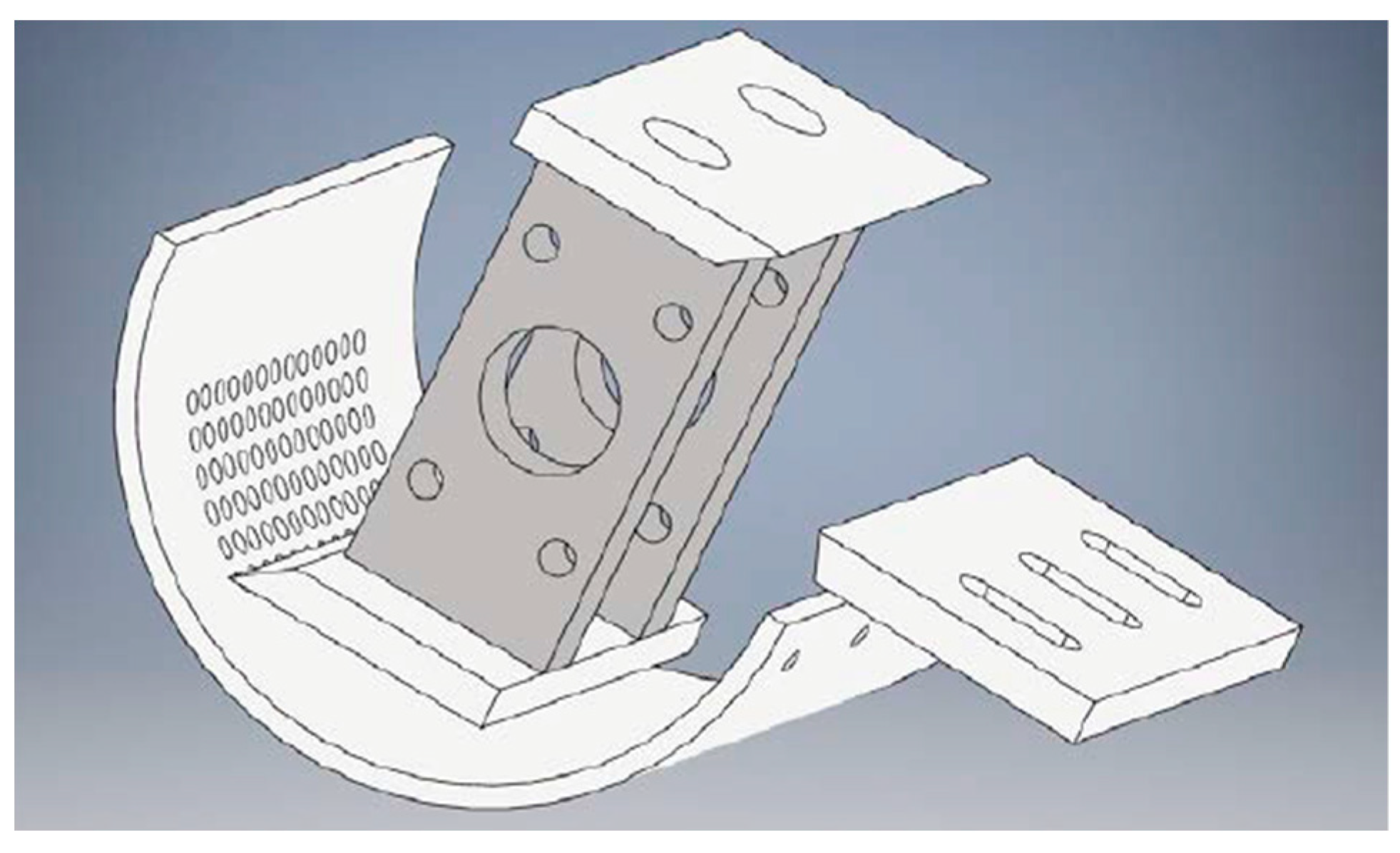

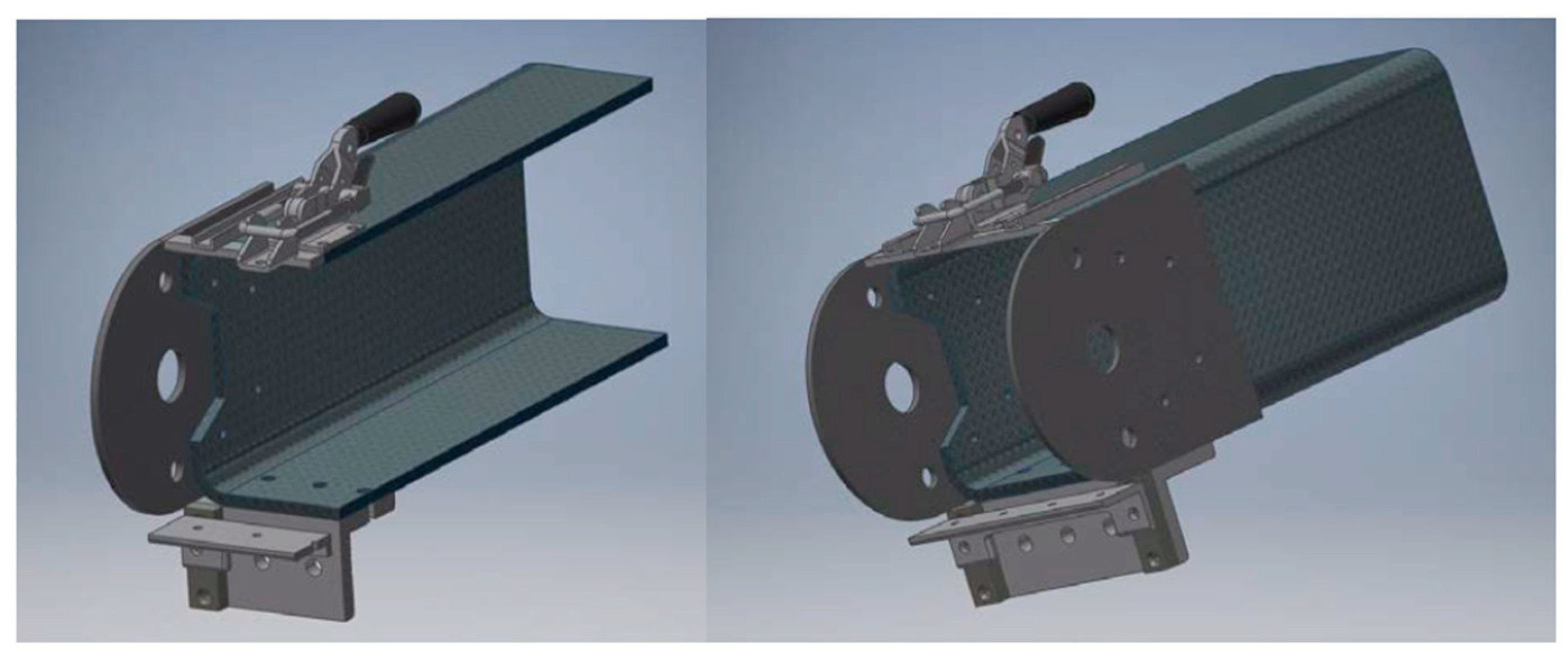

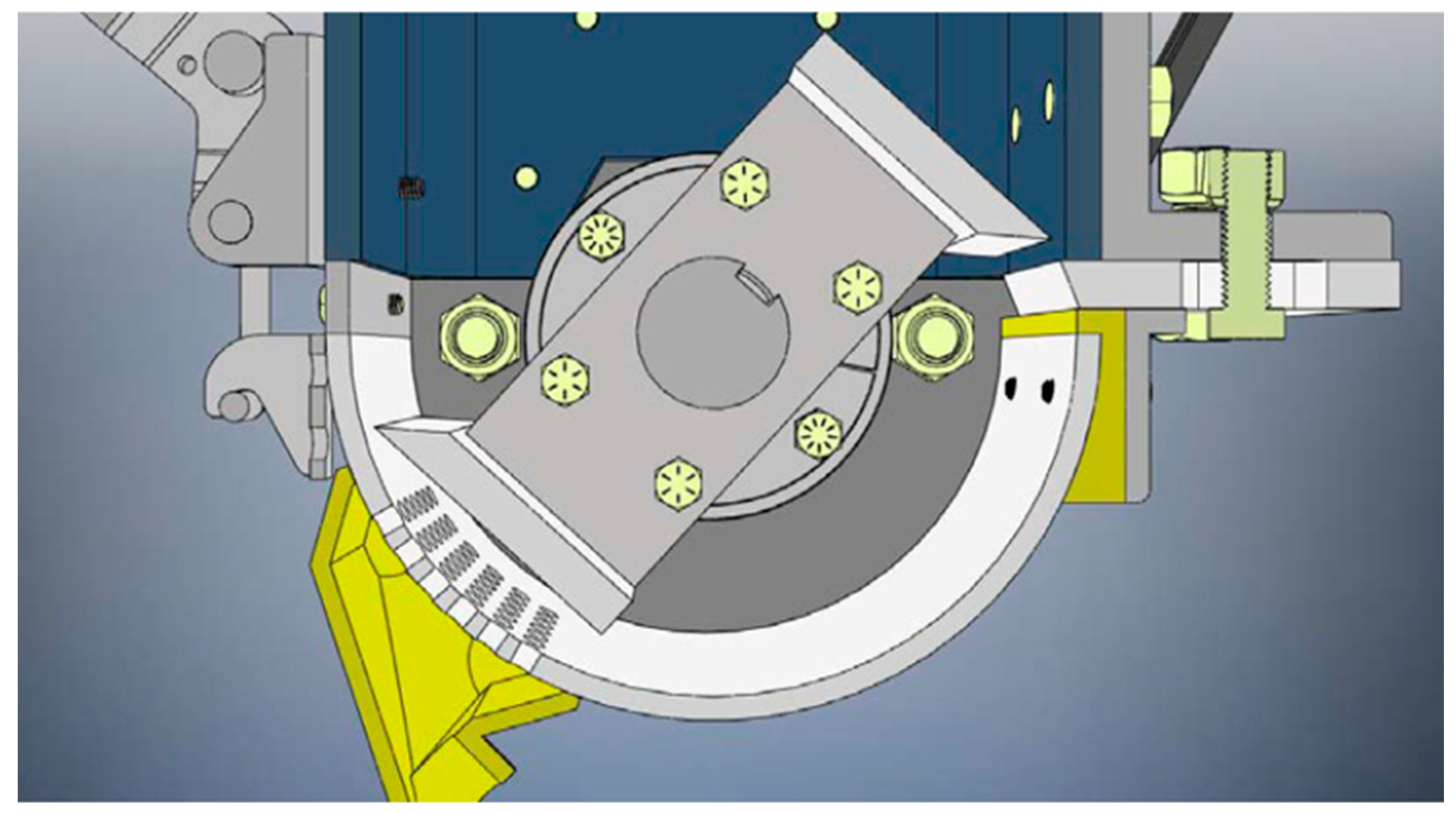

2.2. Plastic Cutting System

2.3. Material Guidance

2.4. Electrical

2.5. Peripheral Parts Assembly

2.6. Cutting Force Design Analysis

3. Material and Methods

3.1. Technical Specifications: Power Consumption and Particle Size

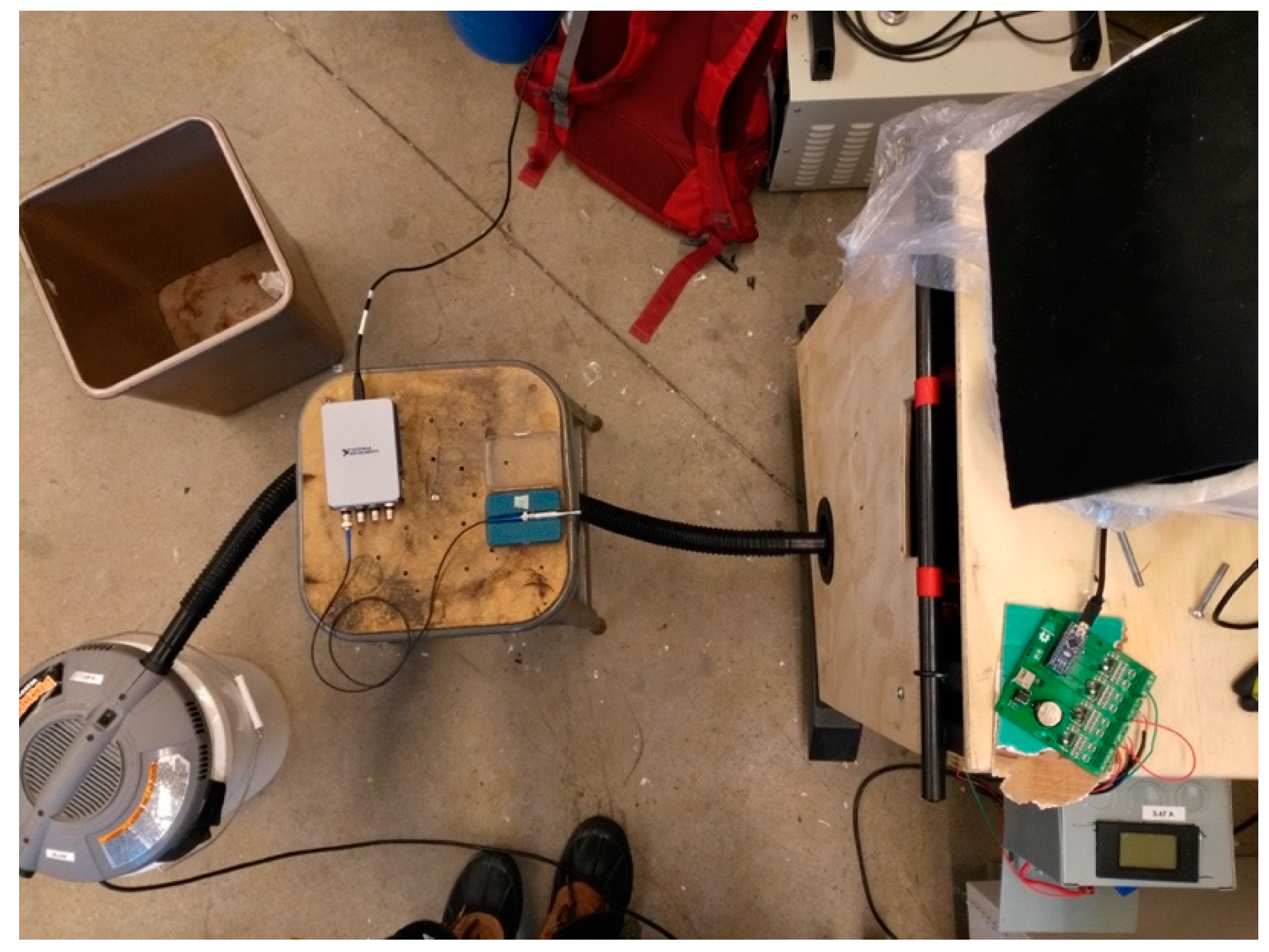

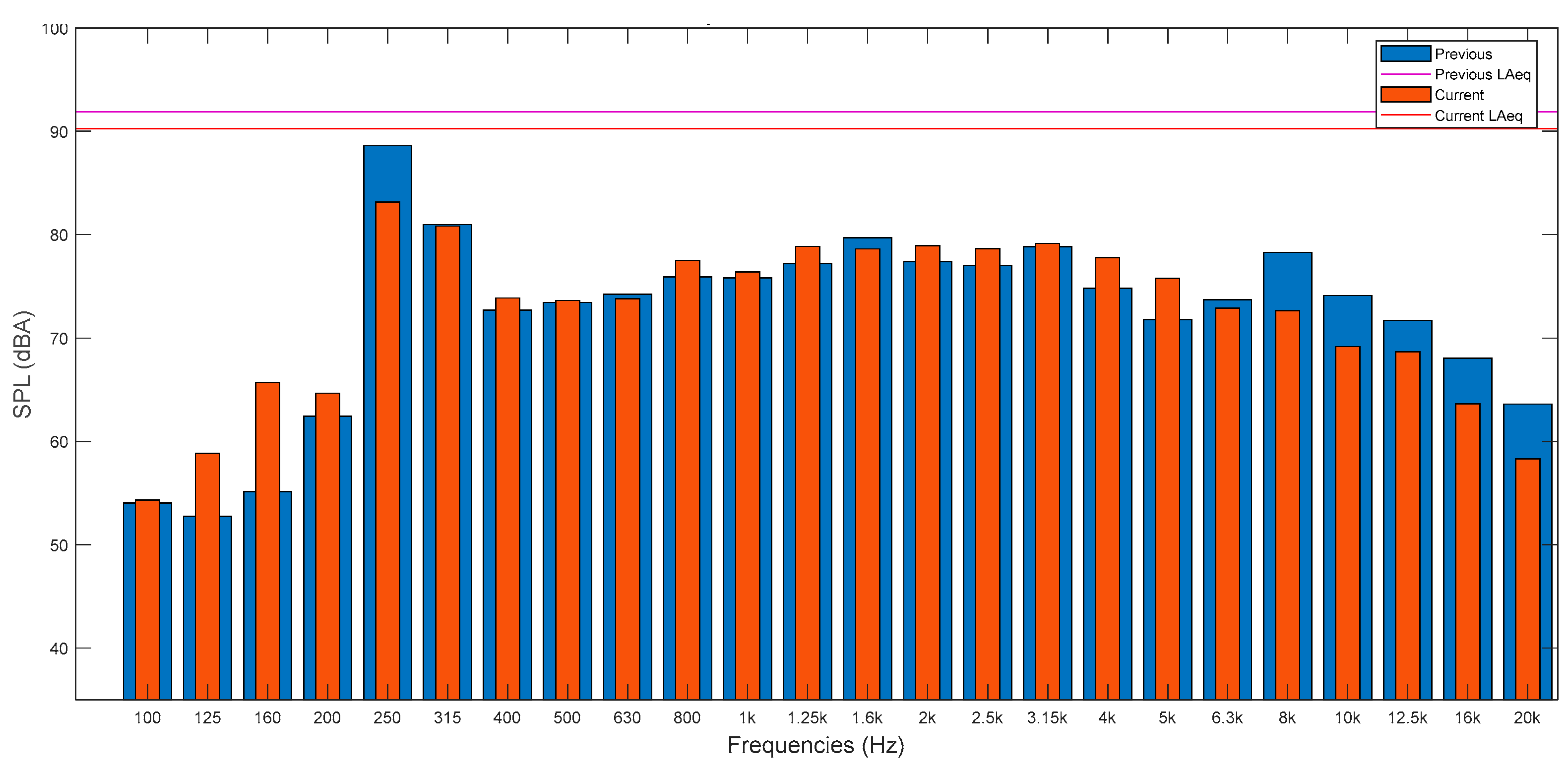

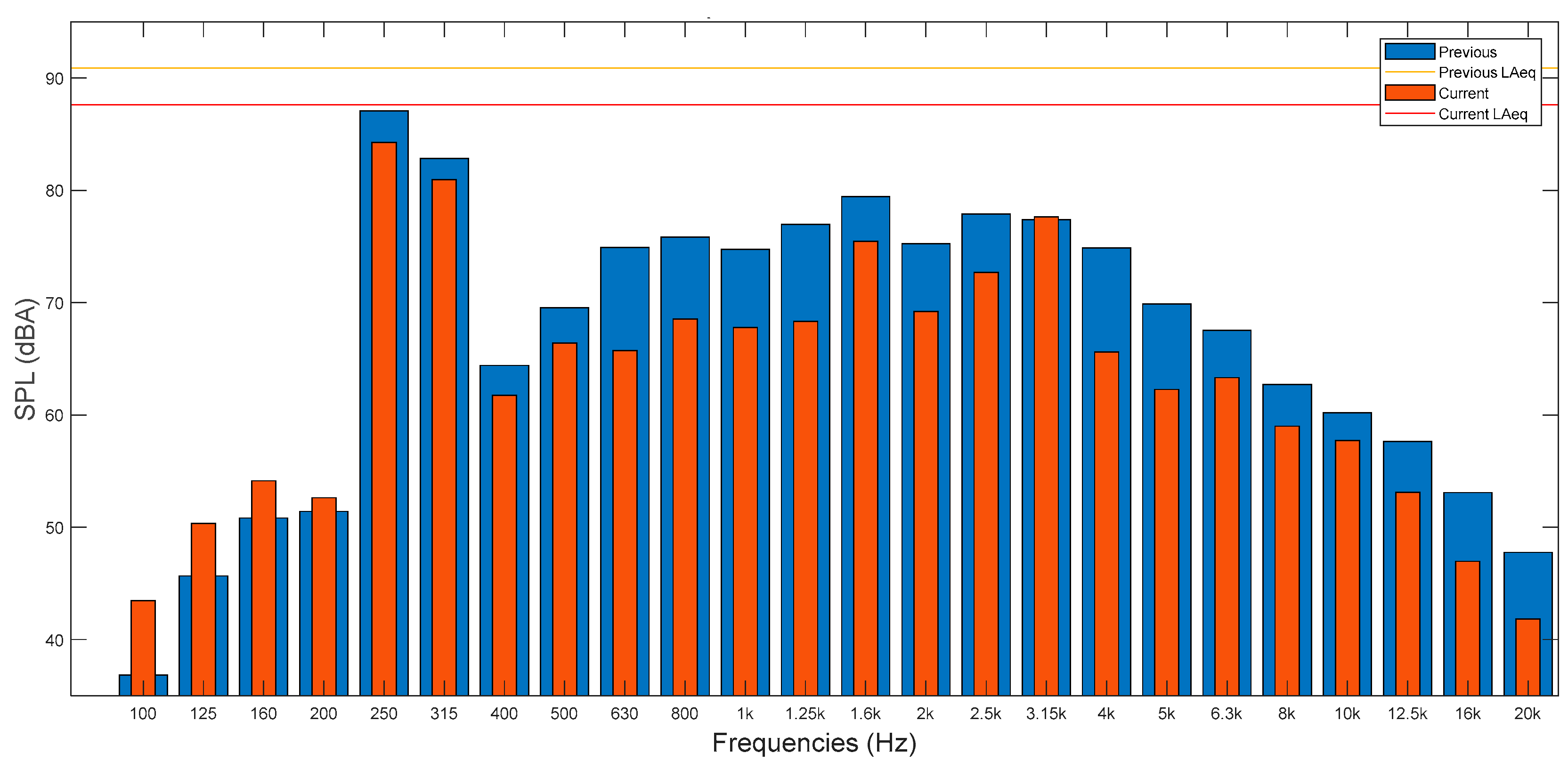

3.2. Noise Reduction

4. Results

4.1. Technical Specifications for Particle Size and Energy Use

4.2. Noise Reduction Results

5. Discussion

5.1. Technical Specifications for Particle Size, Throughput, and Energy Use

5.2. Noise Reduction

5.3. Future Work

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Sells, E.; Bailard, S.; Smith, Z.; Bowyer, A.; Olliver, V. RepRap: The Replicating Rapid Prototyper-Maximizing Customizability by Breeding the Means of Production. In Proceedings of the World Conference on Mass Customization and Personalization, Cambridge, MA, USA, 7–10 October 2007. [Google Scholar]

- Jones, R.; Haufe, P.; Sells, E.; Iravani, P.; Olliver, V.; Palmer, C.; Bowyer, A. RepRap-the Replicating Rapid Prototyper. Robotica 2011, 29, 177–191. [Google Scholar] [CrossRef]

- Bowyer, A. 3D Printing and Humanity’s First Imperfect Replicator. 3d Print. Addit. Manuf. 2014, 1, 4–5. [Google Scholar] [CrossRef]

- Rundle, G. A Revolution in the Making: 3D Printing. Robots and the Future; Affirm Press: South Melbourne, Australia, 2014. [Google Scholar]

- Gwamuri, J.; Wittbrodt, B.; Anzalone, N.; Pearce, J. Reversing the Trend of Large Scale and Centralization in Manufacturing: The Case of Distributed Manufacturing of Customizable 3D-Printable Self-Adjustable Glasses. Chall. Sustain. 2014, 2, 30–40. [Google Scholar] [CrossRef]

- Steenhuis, H.J.; Pretorius, L. Consumer additive manufacturing or 3D printing adoption: An exploratory study. J. Manuf. Technol. Manag. 2016, 27, 990–1012. [Google Scholar] [CrossRef]

- Wittbrodt, B.; Laureto, J.; Tymrak, B.; Pearce, J. Distributed Manufacturing with 3D Printing: A Case Study of Recreational Vehicle Solar Photovoltaic Mounting Systems. J. Frugal Innov. 2015, 1, 1–7. [Google Scholar] [CrossRef]

- Woern, A.L.; Pearce, J.M. Distributed Manufacturing of Flexible Products: Technical Feasibility and Economic Viability. Technologies 2017, 5, 71. [Google Scholar] [CrossRef]

- Wittbrodt, B.T.; Glover, A.G.; Laureto, J.; Anzalone, G.C.; Oppliger, D.; Irwin, J.L.; Pearce, J.M. Life-cycle economic analysis of distributed manufacturing with open-source 3D printers. Mechatronics 2013, 23, 713–726. [Google Scholar] [CrossRef]

- Petersen, E.E.; Kidd, R.W.; Pearce, J.M. Impact of DIY Home Manufacturing with 3D Printing on the Toy and Game Market. Technologies 2017, 5, 45. [Google Scholar] [CrossRef]

- Petersen, E.E.; Pearce, J. Emergence of Home Manufacturing in the Developed World: Return on Investment for Open-Source 3D Printers. Technologies 2017, 5, 7. [Google Scholar] [CrossRef]

- Anderson, P.; Sherman, C.A. A discussion of new business models for 3D printing. Int. J. Technol. Mark. 2007, 2, 280–294. [Google Scholar] [CrossRef]

- Laplume, A.; Anzalone, G.; Pearce, J. Open-source, self-replicating 3D printer factory for small-business manufacturing. Int. J. Adv. Manuf. Technol. 2015, 85, 633–642. [Google Scholar] [CrossRef]

- Laplume, A.; Petersen, B.; Pearce, J. Global value chains from a 3D printing perspective. J. Int. Bus. Stud. 2016, 47, 595–609. [Google Scholar] [CrossRef]

- Gallup, N.; Bow, J.K.; Pearce, J.M. Economic Potential for Distributed Manufacturing of Adaptive Aids for Arthritis Patients in the U.S. Geriatrics 2018, 3, 89. [Google Scholar] [CrossRef] [PubMed]

- Pearce, J.M. Return on investment for open source scientific hardware development. Sci. Public Policy 2016, 43, 192–195. [Google Scholar] [CrossRef]

- Pearce, J. Quantifying the Value of Open Source Hardware Development. Mod. Econ. 2015, 6, 1–11. [Google Scholar] [CrossRef]

- Wohlers Associates. Wohlers Report 2018: 3D Printing and Additive Manufacturing State of the Industry; Annual Worldwide Progress Report; Associates Inc: Fort Collins, CO, USA, 2018. [Google Scholar]

- Baechler, C.; DeVuono, M.; Pearce, J.M. Distributed recycling of waste polymer into RepRap feedstock. Rapid Prototyp. J. 2013, 19, 118–125. [Google Scholar] [CrossRef]

- Kreiger, M.; Anzalone, G.C.; Mulder, M.L.; Glover, A.; Pearce, J.M. Distributed recycling of post-consumer plastic waste in rural areas. MRS Online Proc. Libr. Arch. 2013, 1492, 91–96. [Google Scholar] [CrossRef]

- Kreiger, M.A.; Mulder, M.L.; Glover, A.G.; Pearce, J.M. Life cycle analysis of distributed recycling of post-consumer high density polyethylene for 3D printing filament. J. Clean. Prod. 2014, 70, 90–96. [Google Scholar] [CrossRef]

- Zhong, S.; Rakhe, P.; Pearce, J.M. Energy Payback Time of a Solar Photovoltaic Powered Waste Plastic Recyclebot System. Recycling 2017, 2, 10. [Google Scholar] [CrossRef]

- Unruh, G. Circular Economy, 3D Printing, and the Biosphere Rules. Calif. Manag. Rev. 2018, 60, 95–111. [Google Scholar] [CrossRef]

- Zhong, S.; Pearce, J.M. Tightening the loop on the circular economy: Coupled distributed recycling and manufacturing with recyclebot and RepRap 3D printing. Resour. Conserv. Recycl. 2018, 128, 48–58. [Google Scholar] [CrossRef]

- Shonnard, D.; Tipaldo, E.; Thompson, V.; Pearce, J.; Caneba, G.; Handler, R. Systems Analysis for PET and Olefin Polymers in a Circular Economy. Procedia CIRP 2019, 80, 602–606. [Google Scholar] [CrossRef]

- Garmulewicz, A.; Holweg, M.; Veldhuis, H.; Yang, A. Disruptive Technology as an Enabler of the Circular Economy: What Potential Does 3D Printing Hold? Calif. Manag. Rev. 2018, 60, 112–132. [Google Scholar] [CrossRef]

- Recyclebot. Appropedia. Available online: http://www.appropedia.org/Recyclebot (accessed on 8 February 2019).

- Woern, A.L.; McCaslin, J.R.; Pringle, A.M.; Pearce, J.M. RepRapable Recyclebot: Open source 3D printable extruder for converting plastic to 3D printing filament. HardwareX 2018, 4, e00026. [Google Scholar] [CrossRef]

- Cruz Sanchez, F.; Lanza, S.; Boudaoud, H.; Hoppe, S.; Camargo, M. Polymer Recycling and Additive Manufacturing in an Open Source context: Optimization of processes and methods. In Proceedings of the 2015 Annual International Solid Freeform Fabrication Symposium-An Additive Manufacturing Conference, Austin, TX, USA, 10–12 August 2015; pp. 10–12. [Google Scholar]

- Cruz Sanchez, F.A.; Boudaoud, H.; Hoppe, S.; Camargo, M. Polymer recycling in an open-source additive manufacturing context: Mechanical issues. Addit. Manuf. 2017, 17, 87–105. [Google Scholar] [CrossRef]

- Anderson, I. Mechanical Properties of Specimens 3D Printed with Virgin and Recycled Polylactic Acid. 3D Print. Addit. Manuf. 2017, 4, 110–115. [Google Scholar] [CrossRef]

- Pakkanen, J.; Manfredi, D.; Minetola, P.; Iuliano, L. About the Use of Recycled or Biodegradable Filaments for Sustainability of 3D Printing. In Sustainable Design and Manufacturing, Smart Innovation, Systems and Technologies; Springer: Cham, Switzerland, 2017; pp. 776–785. [Google Scholar]

- Mohammed, M.I.; Mohan, M.; Das, A.; Johnson, M.D.; Badwal, P.S.; McLean, D.; Gibson, I. A low carbon footprint approach to the reconstitution of plastics into 3D-printer filament for enhanced waste reduction. Knowl. E. 2017, 2, 234–241. [Google Scholar] [CrossRef]

- Mohammed, M.I.; Das, A.; Gomez-Kervin, E.; Wilson, D.; Gibson, I. EcoPrinting: Investigating the use of 100% recycled Acrylonitrile Butadiene Styrene (ABS) for Additive Manufacturing. Solid Freeform Fabrication 2017. In Proceedings of the 28th Annual International Solid Freeform Fabrication Symposium, Austin, TX, USA, 7–9 August 2017. [Google Scholar]

- Mohammed, M.I.; Wilson, D.; Gomez-Kervin, E.; Vidler, C.; Rosson, L.; Long, J. The Recycling of E-Waste ABS Plastics by Melt Extrusion and 3D Printing Using Solar Powered Devices as a Transformative Tool for Humanitarian Aid. 2018. Available online: Sffsymposium. engr. utexas. edu/sites/default/files/2018/007% 20TheRecyclingofEWasteABSPlasticsbyMeltExtr. pdf (accessed on 19 April 2019).

- Mohammed, M.; Wilson, D.; Gomez-Kervin, E.; Tang, B.; Wang, J. Investigation of closed loop manufacturing with Acrylonitrile Butadiene Styrene (ABS) over multiple generations using Additive Manufacturing. ACS Sustain. Chem. Eng. 2019, 7, 13955–13969. [Google Scholar] [CrossRef]

- Chong, S.; Pan, G.T.; Khalid, M.; Yang, T.C.K.; Hung, S.T.; Huang, C.M. Physical Characterization and Pre-assessment of Recycled High-Density Polyethylene as 3D Printing Material. J. Polym. Environ. 2017, 25, 136–145. [Google Scholar] [CrossRef]

- Pepi, M.; Zander, N.; Gillan, M. Towards Expeditionary Battlefield Manufacturing Using Recycled, Reclaimed, and Scrap Materials. JOM 2018, 70, 2359–2364. [Google Scholar] [CrossRef]

- Zander, N.E.; Gillan, M.; Lambeth, R.H. Recycled polyethylene terephthalate as a new FFF feedstock material. Addit. Manuf. 2018, 21, 174–182. [Google Scholar] [CrossRef]

- Hart, K.R.; Frketic, J.B.; Brown, J.R. Recycling meal-ready-to-eat (MRE) pouches into polymer filament for material extrusion additive manufacturing. Addit. Manuf. 2018, 21, 536–543. [Google Scholar] [CrossRef]

- Tian, X.; Liu, T.; Wang, Q.; Dilmurat, A.; Li, D.; Ziegmann, G. Recycling and remanufacturing of 3D printed continuous carbon fiber reinforced PLA composites. J. Clean. Prod. 2017, 142, 1609–1618. [Google Scholar] [CrossRef]

- Pringle, A.M.; Rudnicki, M.; Pearce, J. Wood Furniture Waste-Based Recycled 3D Printing Filament. For. Prod. J. 2018, 68, 86–95. [Google Scholar] [CrossRef]

- Zander, N.E. Recycled Polymer Feedstocks for Material Extrusion Additive Manufacturing. In Polymer-Based Additive Manufacturing: Recent Developments; ACS Symposium Series; American Chemical Society: Washington, DC, USA, 2019; Volume 1315, pp. 37–51. ISBN 978-0-8412-3426-0. [Google Scholar]

- Oblak, P.; Gonzalez-Gutierrez, J.; Zupančič, B.; Aulova, A.; Emri, I. Processability and mechanical properties of extensively recycled high density polyethylene. Polym. Degrad. Stab. 2015, 114, 133–145. [Google Scholar] [CrossRef]

- Hyung Lee, J.; Sub Lim, K.; Gyu Hahm, W.; Hun Kim, S. Properties of recycled and virgin poly(ethylene terephthalate) blend fibers. Appl. Polym. Sci. 2012, 128, 2. [Google Scholar]

- Bai, X.; Isaac, D.H.; Smith, K. Reprocessing acrylonitrile–butadiene–styrene plastics: Structure–property relationships. Polym. Eng. Sci. 2007, 47, 120–130. [Google Scholar] [CrossRef]

- Sasse, F.; Emig, G. Chemical Recycling of Polymer Materials. Chem. Eng. Technol. 1998, 21, 777–789. [Google Scholar] [CrossRef]

- Pavlo, S.; Fabio, C.; Hakim, B.; Mauricio, C. 3D-Printing Based Distributed Plastic Recycling: A Conceptual Model for Closed-Loop Supply Chain Design. In Proceedings of the 2018 IEEE International Conference on Engineering, Technology and Innovation (ICE/ITMC), Stuttgart, Germany, 17–20 June 2018; pp. 1–8. [Google Scholar]

- Volpato, N.; Kretschek, D.; Foggiatto, J.A.; da Silva Cruz, C.G. Experimental analysis of an extrusion system for additive manufacturing based on polymer pellets. Int. J. Adv. Manuf. Technol. 2015, 81, 1519–1531. [Google Scholar] [CrossRef]

- Beaudoin, A. JMS-1704: Multihead 3D Printer. Ph.D. Thesis, Worcester Polytechnic Institute Worcester, Worcester, MA, USA, 2016. [Google Scholar]

- Whyman, S.; Arif, K.M.; Potgieter, J. Design and development of an extrusion system for 3D printing biopolymer pellets. Int. J. Adv. Manuf. Technol. 2018, 96, 3417–3428. [Google Scholar] [CrossRef]

- Giberti, H.; Sbaglia, L.; Silvestri, M. Mechatronic Design for an Extrusion-Based Additive Manufacturing Machine. Machines 2017, 5, 29. [Google Scholar] [CrossRef]

- Liu, X.; Chi, B.; Jiao, Z.; Tan, J.; Liu, F.; Yang, W. A large-scale double-stage-screw 3D printer for fused deposition of plastic pellets. J. Appl. Polym. Sci. 2017, 134, 45147. [Google Scholar] [CrossRef]

- Khondoker, M.A.H.; Sameoto, D. Direct coupling of fixed screw extruders using flexible heated hoses for FDM printing of extremely soft thermoplastic elastomers. Prog. Addit. Manuf. 2019, 4, 197–209. [Google Scholar] [CrossRef]

- Horne, R. Reprap Development and Further Adventures in DIY 3D Printing: No More Filament? -Quest for a Universal Pellet Extruder for 3D Printing. Reprap Development and Further Adventures in DIY 3D Printing 2014. Available online: https://richrap.blogspot.com/2014/12/no-more-filament-quest-for-universal.html (accessed on 9 August 2018).

- Universal Pellet Extruder. Available online: http://upe3d.blogspot.com/ (accessed on 9 August 2018).

- Braanker, G.B.; Duwel, J.E.P.; Flohil, J.J.; Tokaya, G.E. Developing a Plastics Recycling Add-on for the RepRap 3D-Printer. Available online: https://reprapdelft.wordpress.com (accessed on 9 August 2018).

- Woern, A.; Byard, D.; Oakley, R.; Fiedler, M.; Snabes, S.; Pearce, J.; Woern, A.L.; Byard, D.J.; Oakley, R.B.; Fiedler, M.J.; et al. Fused Particle Fabrication 3D Printing: Recycled Materials’ Optimization and Mechanical Properties. Materials 2018, 11, 1413. [Google Scholar] [CrossRef] [PubMed]

- Byard, D.J.; Woern, A.L.; Oakley, R.B.; Fiedler, M.J.; Snabes, S.L.; Pearce, J.M. Green Fab Lab Applications of Large-Area Waste Polymer-based Additive Manufacturing. Addit. Manuf. 2019, 27, 515–525. [Google Scholar] [CrossRef]

- Reich, M.J.; Woern, A.L.; Tanikella, N.G.; Pearce, J.M. Mechanical Properties and Applications of Recycled Polycarbonate Particle Material Extrusion-Based Additive Manufacturing. Materials 2019, 12, 1642. [Google Scholar] [CrossRef]

- Gibb, A. Building Open Source Hardware: DIY Manufacturing for Hackers and Makers; Pearson Education: London, UK, 2014; ISBN 978-0-321-90604-5. [Google Scholar]

- Oberloier, S.; Pearce, J.M. General Design Procedure for Free and Open-Source Hardware for Scientific Equipment. Designs 2017, 2, 2. [Google Scholar] [CrossRef]

- Open Source Granulator. Open Science Framework. 2018. Available online: https://osf.io/a2tk9/ (accessed on 9 August 2018).

- Juvinall, R.C.; Marshek, K.M. Fundamentals of Machine Component Design; John Wiley & Sons: Hoboken, NJ, USA, 1991. [Google Scholar]

- Vér, I.L.; Beranek, L.L. Passive Silencers. In Noise and Vibration Control Engineering: Principles and Applications, 2nd ed.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2005; ISBN 9780470172568. [Google Scholar]

- Stacey, M. The FAB LAB network: A global platform for digital invention, education and entrepreneurship. Innov. Technol. Gov. Glob. 2014, 9, 221–238. [Google Scholar] [CrossRef]

- Standardization Administration of the People’s Republic of China (SAC). GB16288, 2008. Marking of Plastics Products; Chinese Standard Publishing House: Beijing, China, 2008. [Google Scholar]

- Hunt, E.J.; Zhang, C.; Anzalone, N.; Pearce, J.M. Polymer recycling codes for distributed manufacturing with 3D printers. Resour. Conserv. Recycl. 2015, 97, 24–30. [Google Scholar] [CrossRef]

- McDonough, W.; Braungart, M. Cradle to Cradle: Remaking the Way We Make Things; Farrar, Straus and Giroux: New York, NY, USA, 2010; ISBN 978-1-4299-7384-7. [Google Scholar]

- Pearce, J.M. Expanding the Consumer Bill of Rights for material ingredients. Mater. Today 2018, 21, 197–198. [Google Scholar] [CrossRef]

- OSHE. Granulator MKII, Open Science Framework. Available online: https://osf.io/auswp/ (accessed on 10 July 2018).

| PLA (Polylactic Acid) Infill and Failed Prints | PET (Polyethylene Terephthalate) Post-Consumer Water Bottles | ABS (Acrylonitrile Butadiene Styrene) Injection Molded | |

|---|---|---|---|

| Average power | 403.6 (+/−50 W) * | 383.9 W | 460.0 W |

| Average time | 16 min | 15 min | 28 min |

| Category | Piece | Function | Price | Quantity | Component Total Cost | Group Total Cost |

|---|---|---|---|---|---|---|

| Steel/Structural | 8" Square Steel Tube 18" Length | Main Body | 85.18 | 1 | 85.18 | $ 594.88 |

| 1/2" 3" × 3" Angle Iron 8" Length | Bed Blade Mount | 10.56 | 1 | 10.56 | ||

| 3/4" × 2-1/2" Flat Stock 12" Length | Flyknife Arms | 10.43 | 1 | 10.43 | ||

| 8" OD 7.5" ID Steel Tube 8" Length | Granulation Screen | 55.2 | 1 | 55.2 | ||

| 1/4" Steel Plate 8" × 10" | Bearing Plates | 17.66 | 2 | 35.32 | ||

| 1/4" × 3/4" Steel Flat Bar 8" Length | Granulation Screen Back Spacer | 3.89 | 1 | 3.89 | ||

| 3/4" × 3/8" × 1/8" Steel Channel 6" Length | Hinge Mount Plate Connectors | 4.68 | 2 | 9.36 | ||

| 2" × 1-1/2" × 1/4" Steel Angle 8" Length | Granulation Screen Clamp | 6.32 | 1 | 6.32 | ||

| 1/2" × 1" 6061 Aluminum Flat Bar 3" Length | Granulation Screen Front Shims | 3.99 | 1 | 3.99 | ||

| Norco R4-15U Server Rack | Cart/Body Structure | 182 | 1 | 182 | ||

| 1/2" Steel Pipe 24" Length | Server Rack Mounting Interface | 5.58 | 2 | 11.16 | ||

| Polypropylene hanging strap | Support front of granulator | 7.25 | 2 | 14.5 | ||

| 8" × 12" × 1/4" Steel Flat | Motor Mount Plate | 12.95 | 1 | 12.95 | ||

| 1 3/4" × 1/4" × 8" Steel Flat | Toggle Pull Connection Plate | 2.24 | 1 | 2.24 | ||

| 8" × 8" × 1/2" Plywood Sheet | Hopper Closure | 20 | 1 | 20 | ||

| 6" PVC Elbow | Hopper Part | 20.42 | 1 | 20.42 | ||

| 6" PVC Flange | Hopper Part | 19.36 | 1 | 19.36 | ||

| 6" PVC Section | Hopper Part | 17 | 1 | 17 | ||

| Various 3D Printed Parts | Various Things | 75 | 1 | 75 | ||

| Electrical | Indoor Steel Enclosure with Knockouts | Electronics Enclosure | 12.53 | 1 | 12.53 | $ 218.96 |

| Screw-Down Cord Grip for Building Cable | Conduit Holder | 1.88 | 3 | 5.64 | ||

| DC 6.5-100V 0-100A LCD Display | Energy Usage Display | 20 | 1 | 20 | ||

| Heat Shrink Tubing | Cable Management Stuff | 20 | 1 | 20 | ||

| 12-3 AC Power Cable | Power Cable | 64.77 | 1 | 64.77 | ||

| SPST Switch rated for >15A | Machine On/Off Switch | 4.18 | 2 | 8.36 | ||

| Limit Switch Z-15E | Safety Switch | 17.08 | 1 | 17.08 | ||

| Emergency Stop Switch | Emergency Power Interruption | 44.93 | 1 | 44.93 | ||

| 5 gal 1.75-Peak HP Wet Dry Vac | Granule Retrieval Vacuum | 21.97 | 1 | 21.97 | ||

| 15 amp circuit breaker | replace failing fuse | 3.68 | 1 | 3.68 | ||

| Power Transmission | 1.5HP motor iron horse | Motor | 165 | 1 | 165 | $ 895.40 |

| Sliding mount | Adjustable Motor Mounting | 21.62 | 1 | |||

| 8.95" OD Double V-Belt Pulley | Shaft Pulley | 52.36 | 1 | 52.36 | ||

| 3.75" OD Double V-Belt Pulley | Motor Pulley | 27.13 | 1 | 27.13 | ||

| V-belts | To transmit power from motor to shaft | 13.38 | 2 | 26.76 | ||

| Carbon Steel 40mm Diameter Keyed Shaft | Rotor Shaft | 77.72 | 1 | 77.72 | ||

| SK Style QD Bushing 40mm Bore | Rotor Shaft Bushing (Blade Arms & Pulley) | 35 | 3 | 105 | ||

| SH Style QD Bushing 5/8" Bore | Motor Pulley Bushing | 16.73 | 1 | 16.73 | ||

| SK Style Weld-on Bushing-Bore Hub | Blade Arm Connector | 86.99 | 2 | 173.98 | ||

| 40mm Cast Flange Bearings | Rotor Shaft Bearings | 50.36 | 2 | 100.72 | ||

| Blades | Blades | 50 | 3 | 150 | ||

| Hardware | M16 Locknuts (10 Pack) | Mount Bearing to Plates | 13.15 | 1 | 13.15 | $ 227.58 |

| M16 × 45 Hex Cap Screws (5 Pack) | Mount Bearing to Plates | 11.35 | 1 | 11.35 | ||

| 1/4" - 20 × 3/4" Hex Cap Screw Grade 8 | Mount Channel Stock to Main Body Tube | 0.17 | 4 | 0.68 | ||

| 1/4" - 20 × 4/3" Flat Head Torx Drive Machine Screws | Mounting Shims to Bed Blade Angle Iron | 1.99 | 4 | 7.96 | ||

| 5/16" - 18 × 2" Hex Cap Screw Grade 8 | Cutting Rotor Hub Bolts | 0.45 | 2 | |||

| 5/16" - 18 × 2 1/2" Full ThreadHex Cap Screw Grade 8 | Cutting Rotor Hub Bolts | 0.53 | 2 | |||

| 5/16" - 18 × 1 3/8" Hex Cap Screw Grade 9 | Cutting Rotor Hub Bolts | 0.95 | 2 | |||

| 3/8" - 16 × 7/8" Hex Cap Screw Grade 8 | Mount Pull Action Toggle Clamp | 0.31 | 6 | 1.86 | ||

| 3/8" - 16 × 5/8" Hex Cap Screw Grade 8 | Various Mounting Stuff | 0.3 | 12 | 3.6 | ||

| 3/8" - 16 × 1" Hex Cap Screw Grade 8 | Motor Plate Mounting | 0.32 | 2 | 0.64 | ||

| 3/8" - 16 × 1 5/8" Hex Cap Screw Grade 8 | Granulation Screen Clamp Downs | 1.28 | 4 | 5.12 | ||

| 3/8*" - 16 Locknut Grade 8 | Various Mounting Stuff | 0.22 | 6 | 1.32 | ||

| 3/8" Nylon Washers (Pack of 25) | Standoffs for Pull Action Toggle Clamp | 2.25 | 1 | 2.25 | ||

| 1/2" -- 13 × 1-1/2" Hex Cap Screws Grade 9 Extreme Strength (Pack of 5) | Flyknife Blade Mounting | 8.77 | 1 | 8.77 | ||

| 1/2" - 20 × 7/8" Hex Cap Screws Grade 8 | Mounting Bed Blade Angle Iron to Square Tube Housing | 0.95 | 4 | 3.8 | ||

| 1/2" - 20 × 1 3/4" Hex Cap Screws Grade 8 | Bed Blade Mounting | 1.19 | 3 | 3.57 | ||

| 1/2" - 20 Locknut Grade 8 | Bed Blade Mounting | 1.14 | 3 | 3.42 | ||

| 1/4" - 20 × 3/4" Socket Screw | Granulation Screen Hardware | 0.17 | 4 | 0.68 | ||

| 1/4" - 20 × 7/8" Socket Screw | Granulation Screen Hardware | 0.18 | 4 | 0.72 | ||

| 10-24 × 3/8" Hex Cap Screw Grade 8 (25 Pack) | Hardware Mounting to Main Body Tube | 11.5 | 1 | 11.5 | ||

| 1/2" Pipe Strap Clamp | Frame Hardware | 1.43 | 2 | 2.86 | ||

| Adjustable Motor-Mounting Base | Motor Mount | 21.62 | 1 | 21.62 | ||

| Pull Action Toggle Clamp | Granulation Screen Connection | 26.87 | 1 | 26.87 | ||

| 1/2" × 20 Threaded Eye Bolts | Front Square Tube Webbing Connections | 3.01 | 2 | 6.02 | ||

| 1" Black Oxide U-Bolts | Server Rack Connection Hardware | 0.78 | 4 | 3.12 | ||

| Surface Mount Cabinet Hinge (1 pair) | Hopper Cover Hinges | 9.12 | 1 | 9.12 | ||

| 1/4" Spacers, 1/4" Height | Standoffs for Channel Stock Mounting Hardware | 0.5 | 6 | 3 | ||

| Draw Latches | Closing Mechanism for Hopper Plate | 6.77 | 2 | 13.54 | ||

| Various Wood Screws | Wood Screws for Attaching Draw Latches and Hinges to Plywood Hopper | 5 | 1 | 5 | ||

| Various Nuts/Bolts | Hardware for Attaching PVC Flange to Plywood Hopper Cover & For Attaching Draw Latch to Square Tube Housing | 10 | 1 | 10 | ||

| Bronze Flange Bearing | Drill Guide for Granulation Screen | 3.43 | 1 | 3.43 | ||

| Threadlocker—Blue | Securing Bolts | 20.38 | 1 | 20.38 | ||

| Key Stock | QD Hub Securing | 5.24 | 1 | 5.24 | ||

| 40mm Carbide Hole Cutter (2 pack) | Cutting Holes in Blade Arms & Side Plates | 16.99 | 1 | 16.99 | ||

| Sound Reduction | Fiberglass Utility Roll, 16 × 3/4 × 48-In, Frost King | Noise attenuation | 6.29 | 1 | 6.29 | $ 6.29 |

| $ 1943.11 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ravindran, A.; Scsavnicki, S.; Nelson, W.; Gorecki, P.; Franz, J.; Oberloier, S.; Meyer, T.K.; Barnard, A.R.; Pearce, J.M. Open Source Waste Plastic Granulator. Technologies 2019, 7, 74. https://doi.org/10.3390/technologies7040074

Ravindran A, Scsavnicki S, Nelson W, Gorecki P, Franz J, Oberloier S, Meyer TK, Barnard AR, Pearce JM. Open Source Waste Plastic Granulator. Technologies. 2019; 7(4):74. https://doi.org/10.3390/technologies7040074

Chicago/Turabian StyleRavindran, Arvind, Sean Scsavnicki, Walker Nelson, Peter Gorecki, Jacob Franz, Shane Oberloier, Theresa K. Meyer, Andrew R. Barnard, and Joshua M. Pearce. 2019. "Open Source Waste Plastic Granulator" Technologies 7, no. 4: 74. https://doi.org/10.3390/technologies7040074

APA StyleRavindran, A., Scsavnicki, S., Nelson, W., Gorecki, P., Franz, J., Oberloier, S., Meyer, T. K., Barnard, A. R., & Pearce, J. M. (2019). Open Source Waste Plastic Granulator. Technologies, 7(4), 74. https://doi.org/10.3390/technologies7040074