Abstract

Industry 4.0 is originally a future vision described in the high-tech strategy of the German government that is conceived upon information and communication technologies like Cyber-Physical Systems, Internet of Things, Physical Internet, and Internet of Services to achieve a high degree of flexibility in production (individualized mass production), higher productivity rates through real-time monitoring and diagnosis, and a lower wastage rate of material in production. An important part of the tasks in the preparation for Industry 4.0 is the adaption of the higher education to the requirements of this vision, in particular the engineering education. In this work, we introduce a road map consisting of three pillars describing the changes/enhancements to be conducted in the areas of curriculum development, lab concept, and student club activities. We also report our current application of this road map at the Turkish German University, Istanbul.

1. Introduction

Digitalization is one mega trend of the century and holds the potential to drastically transform various industries and production techniques [1]. Based on this trend, the term “Industry 4.0” has emerged, which is defined as digitization of the manufacturing sector, with embedded sensors in virtually all product components and manufacturing equipment, ubiquitous cyber-physical systems, and analysis of all relevant data [2]. Industry 4.0 is originally a future vision described in the high-tech strategy of the German government that is conceived upon the information and communication technologies including initiatives such as the Industrial Internet, Factories of The Future, Internet of Things, Physical Internet, Internet of Services, and Cyber-Physical Systems, to achieve a high degree of flexibility in production, higher productivity rates through real-time monitoring and diagnosis, and a lower wastage rate of material in production. Cyber-connected manufacturing systems improve efficiency and optimize operations, but also have the potential to change the way manufacturers and industrial companies run their business.

Industry 4.0 took up a pioneering role in industrial IT, which is currently revolutionizing the manufacturing engineering. Many industrialized countries also have already begun with adapting their industrial infrastructure to meet the requirements of the Industry 4.0 vision. An important part of the tasks in the preparation for Industry 4.0 is the adaption of the higher education to the requirements of this vision, in particular the engineering education. As Turkish German University (TGU) within this changing industry environment, our ultimate aim is to educate outstanding engineers who will contribute and grow with the digitalized world of the future. In this work, we introduce a road map consisting of three pillars describing the changes/enhancements to be conducted in the areas of curriculum development, laboratory concept, and student club activities. We also report our current application of this road map at the Turkish German University, Istanbul. According to this, first pillar is the implementation of the Industry 4.0 concept in the curriculum of various engineering and science departments, which reveals synergistic benefits of different expertise areas and helps the application and improvement of Industry 4.0 concept in numerous areas. Second, a Laboratory (Lego-Lab) is to be realized, where the students work on Industrial Lego Designs using Lego Mindstorms and understand the application of the Industry 4.0 concept by simulating real production lines. Additionally, Kolb’s Experiential Learning Theory is integrated into this part in order to improve student learning experience in Lego-Lab. This theory is designed around four phases: (i) Concrete experience, (ii) reflective observation, (iii) abstract conceptualization, and (iv) active experimentation. The final and complementary pillar is the establishment of a student club, where students work on different aspects of Industry 4.0. In addition, this club serves as an intermedium for various student and research projects, organization of conferences, and events to introduce and disseminate the Industry 4.0 vision.

The goal of this work is to present a generic road map to adapt engineering education to the requirements of Industry 4.0 by specifying needed changes to the curriculum, laboratories, and student club activities.

The rest of the article is organized as follows. Section 2 gives an account of the recent research on the education in the Industry 4.0 context. Section 3 presents a generic method that was used to transform engineering education at the Turkish German University according to the requirements of future Industry 4.0 production environments. Finally, in Section 4, we discuss our conclusions.

2. Related Work

This work is an extended version of the conference paper [3]. The paper was improved mainly by details about the curriculum, initial lab projects, and related works. We also discuss our choice of theoretical framework and methods more extensively.

In the recent few years, a great number of works has been published on the subject of the education in the context of Industry 4.0. Some of the works focus on the new qualification requirements, while some others emphasize particular subject areas to be included in curricula to adapt them to Industry 4.0. Another group of papers concentrate also on the transformation of the education itself in a similar manner to Industry 4.0 while teaching about it (Academia 4.0, Education 4.0). Lastly, a series of works demonstrate new lab concepts to enable students to experience Industry 4.0-like production environments.

Following works discuss new qualification requirements in the Industry 4.0 era. Ref. [4] reports about new requirements: Interdisciplinary thinking, decision and problem solving, cultural and intercultural competency, and lifelong learning. They define the main challenge as enabling employees to implement cyber physical systems successfully. Ref. [5] examines the requirements of the Industry 4.0 era for the engineering education from the perspective of Slovakian higher education system. They stress the increased need for flexibility (interdisciplinary collaboration, soft skills), university-industry cooperation, and open learning systems such as online learning platforms and free access courses at “open” universities.

In the following works, subject areas of great importance for Industry 4.0 are highlighted. Ref. [6] emphasize the important role of artificial intelligence as an enabler for Industry 4.0. Ref. [7] examines the challenges of digitization and value creation process in the age of Industry 4.0. In parts of the work, the importance of MINT (mathematics, IT, natural sciences, and technology) subjects is stressed. Furthermore, interdisciplinary platforms for collaboration between research communities and the industry are proposed and elaborated with successfully applied examples. Ref. [8] examines the knowledge and skill-set requirements of Industry 4.0 for industrial engineers and their impact on the industrial engineering curricula in South Africa. They stress the need for competences like big data analytics and novel human-machine interfaces.

Another work relevant for the curriculum development is [9]. They present a methodology for evaluating study programs according to the Reference Architecture Model Industry 4.0. They also use this methodology to assess two study programs of the Faculty of Technology of the University of Applied Sciences Emden/Leer and show the usability of the methodology.

A number of works examine ways to transform the education itself according to the principles of Industry 4.0, while simultaneously teaching about it. Ref. [10] focuses on transforming higher education in a similar manner to the Industry 4.0 vision. They propose a list of measures to individualize education experience of students efficiently. Ref. [11] reports about the acceptance of digital education technologies especially in the vocational education. They emphasize the role of digital media as a means to individualize education in a manner similar to Industry 4.0. In our opinion, their findings can be transferred to engineering education in a considerable extent. Ref. [12] discusses how the technical education can be adapted according to requirements of the Industry 4.0. They created a model of condition variables for Education 4.0, which is comprised of changing technologies and processes, changing teaching and learning, changing economic interests and models, and socio-professional discourse. Intelligent machines, machine to machine communication (M2M), data security, big data, support systems like mixed-reality systems are areas they emphasize in changing technologies. In changing teaching and learning, they consider individualization of learning, learning on demand, cloud learning, and innovative learning environments like mixed-reality simulation, augmented reality, and remote laboratories. Ref. [13] discusses and analyzes the effects of Industry 4.0 mainly on the vocational education. They come to the interesting conclusion that the adoption of Industry 4.0 could result in decreasing the share of vocational education in favor of higher education if necessary measures are not taken to transform vocational education fundamentally. In the context of our work, this could be interpreted in the way that the engineering education in the era of Industry 4.0 cannot be imagined without its relation to the practice and hands-on work, since there is the risk of lacking adequate technical support sourcing from vocational education. Ref. [14] examines the use of mixed-reality systems and virtual teaching and learning systems especially for the vocational education in the context of Industry 4.0. In our opinion, their approach could also be transferred to the practical parts of the engineering curricula.

A hot spot in the research about the adaptation of education to the Industry 4.0 vision has been new lab concepts in recent years. We observe virtual, decentralized, realtime, and immersive laboratories emerging. A very early example of a virtual automation lab for engineering students was reported in [15]. They had developed an integrated learning environment for computer science and automation engineering students, where they could access and control a variety of devices via the Internet. Ref. [16] presents a concept to teach Industry 4.0 vision to students coming from non-IT fields (such as mechanical or industrial engineering) using a simulation game. They created a method to modify the conventional simulation games to impart key aspects of Industry 4.0 to students. By involving real industrial technologies like an ERP system and barcodes/RFID chips, they could create a near-Industry 4.0 environment. Ref. [17] elaborates concepts related to Industry 4.0 and delineates them in comparison to each other. Furthermore, they define four design principles to identify and evaluate Industry 4.0 design principles, namely; technical assistance (virtual/physical), decentralized decisions, interconnection (collaboration, standards, security), and information transparency (data analytics, information provision). They also apply these principles to an Industry 4.0 scenario in a case study. We find the results interesting, since these principles could potentially be transferred to laboratory scenarios in engineering education as well. Refs. [18,19] emphasize the role of hybrid teams consisting of humans and machines that work together in virtual and decentralized (or international) Industry 4.0 production environments. Having this perspective, they derive requirements for the engineering education of future, e.g., collaboration and problem solving in virtual environments and human-robot teams. They also design and implement an empirical study to investigate influences on the task performance of human-robot teams. In addition to other important results, they show why intercultural soft skills will gain importance. We see this as a confirmation of our intrinsically intercultural engineering education at the Turkish German University. Ref. [20] addresses the problems faced by SMEs adopting technologies related to Industry 4.0 because of lacking skills and proposes a lab concept for universities of applied sciences to educate needed highly skilled human resources for the local SMEs. They design and implement an Industry 4.0 learning factory as their lab concept, where the processes at the shop floor level and the top floor level (ERP level) are integrated transparently. Ref. [21] proposes immersive virtual learning environments in the manner of Industry 4.0, which enable international teams to collaborate remotely. They emphasize the advantages of the use of such learning environments as hazard-free, explorative learning, visualization of invisible processes, the slow-motion of fast processes, and the immersion on virtual worlds on the basis of natural user interfaces. Ref. [22] focuses on the use of mobile learning applications in the vocational and engineering education in the Industry 4.0 context in contrast to e-Learning. They propose the use of competence snippets that are available through QR-Codes, NFC, or process data instead of comprehensive material. Ref. [23] presents how industrial networks are thought at the School of Engineering Technology at McMaster University in the context of Industry 4.0. They discuss teaching methods of industrial networks and their applications within manufacturing plant and electrical grid. Several works discuss and show, how Industry 4.0 concepts and competencies can be integrated in engineering education using learning factories [24,25,26,27].

3. Methods

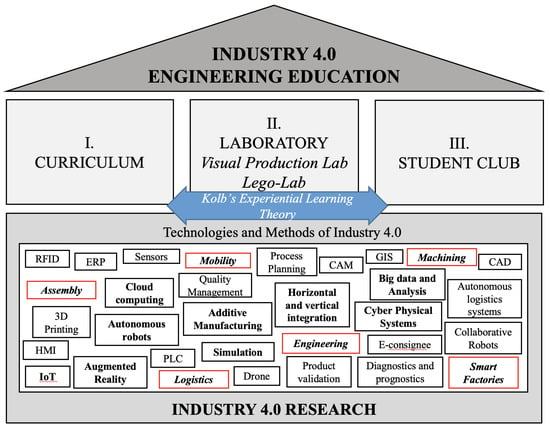

In this part, a generic framework of Industry 4.0 engineering education at Turkish German University as seen in Figure 1 is presented. The framework consists of three main stages, namely curriculum, laboratory and student club. These pillars are interrelated and even dependent on each other. Furthermore, they are surrounded by the theory of Kolb’s Experiential Learning Theory as well as Industry 4.0 technologies and methods which are conducted along with scientific research including developed ideas and prototypes, running projects at Turkish German University.

Figure 1.

Generic framework of Industry 4.0 engineering education.

3.1. Curriculum

The Industry 4.0 vision is implemented with a content of curricula into existing courses and new study modules are designed in order to adapt this vision into the engineering education. The module specifications of existing courses are explicitly documented and intersection areas to the Industry 4.0 vision are determined. Finally, the courses are connected with the practical exercises in the laboratory. Teaching materials for courses with regard to Industry 4.0 are prepared in order to train the students. Bringing together theoretical and practical units, the curriculum enables students to obtain basic knowledge of Industry 4.0 relevant themes and experience real business cases in order to provide hands-on exercises for laboratory stage. Primarily, the curricula of all manufacturing related engineering programs are to be adapted in this manner, but also programs like computer science/engineering or material science/engineering should be enhanced with elective courses or study tracks relating to Industry 4.0.

In Table 1, we list courses taught at the Turkish German University, which are related to Industry 4.0, or which are subject to change in order to be adapted to the requirements of Industry 4.0. The table comprises data about five different engineering programs at TGU, namely Computer Engineering (CE), Mechatronic Systems Engineering (MSE), Industrial Engineering (IE), Electrical and Electronic Engineering (EET), and Mechanical Engineering (MEC). We indicate with a plus sign that the course is being offered in the respective curriculum. We have not included the Civil Engineering program in the table, since we find that a separate analysis needs to be carried out, in order to define requirements for the adaptation of this discipline to the Industry 4.0 requirements. As one of the reasons of this, it can be stated that civil engineers diverge from the engineering disciplines above in their use of construction methods and their laboratory needs greatly.

Table 1.

Industry 4.0-related courses at the Turkish German University.

Even a first glance at the table shows us that more computer science/engineering courses are now part of other engineering disciplines’ curricula. The entry programming course for engineers is now not only a mere programming course, but also an introductory course into the computer science as is attended by computer engineering students. In our opinion, syllabi for programming courses in engineering faculty should be changed in a way that they introduce not only low level programming languages, but also new programming languages that are more common in artificial intelligence and data science communities like Python and R. In the following term, programming skills of engineering students are to be improved in object-oriented programming in a common course for all engineering disciplines. A software engineering project for all engineering students is conceived in order to enable the students from different engineering disciplines to define and work on the same project. As a cross-program course, this course requires the collaboration of lecturers from different engineering programs, so that the students can create project teams containing students from different disciplines. In that way, it is possible to realize projects that are much more realistic and interesting. Also, a better organization of teamwork is effectively enabled, since the division of work can now be done having team members already coming from different disciplines. This is one of the key changes to the curricula of the engineering programs to adapt them to Industry 4.0, since the projects related to Industry 4.0 virtually always need to be implemented in an interdisciplinary manner.

Other relatively common courses are Statistical Methods of Data Analysis and Database Systems. Both of these courses impart also key competences to the students in regard to Industry 4.0. The course Statistical Methods and Data Analysis lays foundations for the understanding of subjects like machine learning and artificial intelligence. In an Industry 4.0 manufacturing environment, a tremendous amount of data flow occurs between production resources and cloud systems. The sensor data coming from the production resources need to be analyzed and evaluated in a correct and efficient manner. The course Database Systems gains also importance because of the same reason. The order of magnitude of the data to be analyzed obligates the use of state of the art database systems. The syllabus of the course is also adapted to these requirements, by including subjects like big data, no-SQL databases, MapReduce, and data management in the cloud.

On the other hand, computer engineering curriculum has also been enhanced with three specialization tracks: Intelligent systems, IT security, and hardware systems (industrial applications). All of three specialization areas has been designed to prepare students for challenges of Industry 4.0. In the track of intelligent systems, there are courses like machine learning, artificial intelligence, methods of data analysis, knowledge representation and reasoning, and recommender systems. In IT security track, we have courses like security systems and protocols, cryptology, network security, data privacy and security, and security management. Hardware systems track involves courses like embedded systems, industrial automation technology, industrial robotics, and realtime systems. As the Industry 4.0 systems will mature, we will see more and more manufacturing environments that are smart and autonomous in a way that they will be able to analyze their own state and the environment and handle autonomously according to their analysis. In order to design and implement such systems, engineering students must be competent in methods of artificial intelligence and machine learning. Regarding the data flow needed for the analysis, and its confidentiality and business value, it is obvious that one of the tracks should be about IT security. This track is designed in a manner that the emphasis must be placed on the wireless communication security and cloud systems security. Differing from the conventional computer engineering tracks, the hardware systems track had to have an emphasis on the industrial automation and robotics subjects. The students must acquire hands-on experiences on industrial applications before they graduate, so that they can understand and follow problems and challenges in implementing Industry 4.0 applications while they are still studying.

3.2. Laboratory

The practical units are completed with visualization software tools or with simulators at the laboratory. The foundation of a “Visual Production Lab”, where computer-aided design and manufacturing (CAD/CAM) with enterprise resource planning (ERP) are to be carried out, Materials and Logistics determined and 3D printed factories generated, will be one of the most important pillars when adapting the engineering education to Industry 4.0. The aforementioned Lego Design Concept would also be used to optimize factory design, since it enables dynamic simulation of different production entities with moving parts and supports the static 3D printed factory model.

Lego Mindstorms systems provide programmable brick computers, modular motors and sensors, and a variety of Lego Technic elements, which can be used to simulate real production lines. Sensors like touch, light, distance, sound, and servo motor/rotation sensors and programmable brick computers provide the components needed for the development of intelligent manufacturing models and concepts that are central to the Industry 4.0 vision. With the Lego factory to be established within the scope of this study, sample production lines for different products will be set up and alternative production plans will be designed. according to the Industry 4.0 concept.

A drone will be used to investigate a real-life landscape and capture the overlapping images while in motion, images are converted to georeferenced (i.e., geographical information system-GIS) 2D data maps and 3D models via using drone-based mapping software for the foundation of a real factory. This drone-based factory inspection helps measure the stockpiles, efficiency of factory layout, performance of assembly lines, etc. As a result, all the simulation data will be compared to real data and the obtained feedback will be used to consummate the whole design. For this purpose, a 3D Printing Lab in the Visual Production Lab is to be established. Here, realistic models of digitally designed factory will repeatedly be created and the obtained feedback will be used to remedy the flaws of the design. In addition to that, production of non-standard Lego parts will be carried out and accordingly mass production scenarios specific to different demands will be realized. Moreover, a research on material properties used in 3D printing (and also 3D pen) can also be carried out. The main aim in material research should be to develop a strong, durable and low melting temperature polymer, which as a result might lead to rapid manufacturing beside rapid prototyping (RP). The rapid prototyping refers to a process used in various industries for rapidly creating a representative system or part before final release or commercialization.

Additive manufacturing (AM) is the formalized term for what used to be called rapid prototyping and what is nowadays popularly called 3D Printing. In mass customization, one of the key concepts is the capability of flexible production, i.e., production of individualized products on the same line subsequently, at the costs near that of mass production. In order to achieve that, additive manufacturing has been proposed as a flexible production model. So, the developments in 3D printing technology might lead the transformation from rapid prototyping to rapid manufacturing and ultimately to ideal mass customization. As a result, the synergetic efforts of the students and also researchers in Visual Production Lab and Lego-Lab will make a significant contribution for the adaption of the engineering education to Industry 4.0, since an ideal engineering education should contain the combination of scientific research and industrial application.

3.2.1. Implementing Kolb’s Theory to Laboratory

According to Kolb (Kolb, 1984), learning is “the process whereby knowledge is created through the transformation of experience”. Experiential and simulation learning techniques are used in a wide range of fields from quality [28] to product development [29], process re-engineering [30], and supply chain management [31]. They contribute to the creation of a learning and practicing environment that maximizes learners’ skills by learning from their own experience. The full potential for learning can be realized, moreover the costs during the learning process in case of failures can be avoided. Basically, learning comes from three principal sources: Learning from content, learning from experience and learning from feedback [32,33]:

- learning from content: The discovery of new ideas, principles and concepts;

- learning from experience: An opportunity to apply content in an experiential environment;

- learning from feedback: The results of actions taken and the relationship between the actions in the experiment and performance

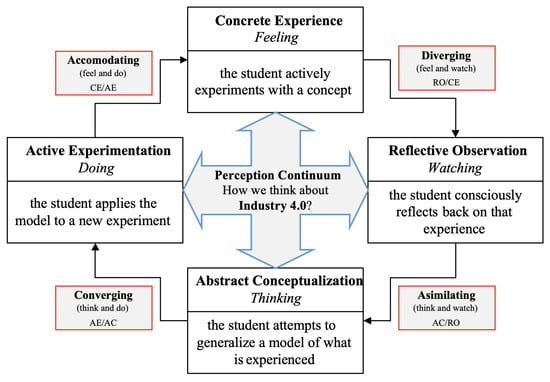

In the literature, different theories of learning are listed [34], but some learning methods are more commonly used for engineering education [35,36,37]: Kolb’s experiential learning theory [32], Felder and Silverman learning theory model [38], Honey and Mumford learning theory model [39], VARK learning theory model [40], Cognitive Theory of Multimedia Learning [41], and so on. These methods could be used as the viewing lens to better understand learning and, more so, how applicable it is to information and communication technologies within the frame of Industry 4.0 vision in the current stage of the engineering learning institutions. The experiential learning method creates an environment that requires the participant to be involved in some type of personally meaningful activity. Such an environment allows the participant to apply prior knowledge of theory and principles while developing commitment to the exercise and experiencing a real sense of personal accomplishment or failure for the results obtained [42]. In order to bring change in behavior, attitudes and knowledge, a circular four-stage experiential learning cycle model developed by Kolb [32] is used. This model is selected as a most suitable learning theory to adapt engineering education in Industry 4.0 vision. Kolb’s Experiential Learning Theory depicted in Figure 2 provides a framework for designing active, collaborative, and interactive learning experiences that support this transformational process and puts emphasis on sensory and emotional engagement in the learning activity. Effective learning is seen when a person progresses through a cycle of four stages: (i) having a concrete experience followed by (ii) observation of and reflection on that experience which leads to (iii) the formation of abstract concepts (analysis) and generalizations (conclusions) which are then (iv) used to test hypothesis in future situations, resulting in new experiences. Not only do these four stages allow students to comprehensively investigate a topic through different activities and views, they also allow for the accommodation of different learning styles [35]. According to Kolb [32], knowledge results from the interaction between theory and experience and learning can commence at any of the four stages. Learning styles are a product of two pairs of variables, doing vs. watching, and thinking vs. feeling. Each stage can be mapped to these variables [35].

Figure 2.

Kolb’s learning styles model and experiential learning theory.

At Turkish German University, the learning process at the laboratory in the frame of Industry 4.0 engineering education is provided by implementation of Kolb’s Experiential Learning Theory. Engineering students are divided into the groups at the laboratory and each group needs to get a certain task from the instructor about Industry 4.0, for example, designing an assembly line of digital car factory. The steps are listed as follows: (i) Concrete experience: Which means direct practical experience by performing a new task. In our activities, concrete experience corresponds to a set of step-by-step instructions demonstrating a new concept. Originally, all activities in Lego-Lab are designed based on this approach. In the illustrative example, students follow step-by-step instructions to learn and get a broad understanding of Industry 4.0 and its applications such as assembly line planning with mixed-model scenarios. The activity instructions are written for novice users and are very descriptive so that the students can complete the activity even though they have in previous experience in the field. (ii) Reflective observation: Which includes activities such discussion and reflective questions that require students to reflect on their hands-on experiences (hands-on exercises) that enable students to work in Industry 4.0-conform environments. Our strategy is to divide an activity into smaller sections and include reflective activities for each section. This strategy also helps the instructor phase the activity across multiple groups. In the illustrative example, after completing the first section, students are asked to analyze components of assembly line and discuss questions such as why and what kind of robotics they have to put into the assembly line. Reflective observation activities should foster student-to-student interaction in order to achieve a higher level of reflection. Group work is a particularly effective strategy to promote meaningful reflection in short classroom activities. For example, instead of asking students to analyze their own response individually, asking them to compare the responses with group members and list similarities and differences may lead to a higher level of reflection. (iii) Abstract conceptualization: Through abstract conceptualization, students are expected to create a theoretical model and generalization of what was performed. Generally, this stage could be difficult to achieve in short hands-on activities. Class or peer-to-peer discussions are helpful to connect the learning experience to the overall theory. At this stage, instructor intervention is important. In the illustrative example, students are asked to create a digitalization scenario by applying robotics technologies based on the steps that they perform. In this part, also brainstorming applications such as mind-mapping software, etc. are used. After this question, a class discussion led by the instructor may help students solidify a mental picture of robot configurations at the assembly line. Another useful strategy is the utilization of generalization questions. For example, in the illustrative example students are asked to compare what they performed in an earlier activity about robotics (i.e., kinematics) and to list the advantages and disadvantages of a type of robot (i.e., articulated robot, parallel arm robot, SCARA robot etc.). Such generalization questions can be combined with the next stage of active experimentation. (iv) active experimentation: At this stage, the student is ready to plan and try out another concrete experience. We use two strategies in this stage. The first strategy is to give students a new task, albeit similar to what was performed in the concrete experience stage, but without providing step-by-step instructions. For example, students are asked to configure a SCARA robot by applying some program comments. By this time, they should be able to achieve this task without detailed instructions. The second strategy is to combine a few related topics in the same activity such that the later topics build on the former ones.

3.2.2. Student Club

A student club will enable the students to study the different aspects of Industry 4.0. It is considered that the activities of the club should be conducted under the roof of an Open Innovation Office or research lab, which will operate in parallel with the student club and focus on scientific developments on the topic “Industry 4.0”. The objectives of the student club will include realization of student and research projects, organization of conferences, and events to introduce and disseminate the Industry 4.0 concepts. One of the first projects that will be carried out by the club is considered to be the application of the Industry 4.0 scenarios to the production models at a Lego-Lab. The Lego-Lab will be so designed that the students can work on Industrial Lego Designs using Lego Mindstorms and understand the application of the Industry 4.0 concept by simulating real production lines.

An example application on a Lego factory model would be a scenario, where a car product variant is produced individually according to its order code, which is read by robots as it proceeds through the production line. Order codes can be encoded as color sequences that can be recognized by a standard Lego color sensor. Alternatively, a barcode/QR-code scanner could be used to read order codes. The data coming from the sensor will be then processed by a Lego intelligent brick coordinating the individual robot actions. At the end, the production line should function as fast as in the batch production but produce completely individualized cars. Similar to this example, different scenarios can be realized or simulated using the Lego Design Concept. The fact that this approach is very user-friendly and easy to understand makes it an ideal asset for students to embrace and benefit from.

The Lego-Lab will provide a production line consisting of multiple modules. Lego computer bricks that control each robot on the production line are programmable and support i.e., C/C++, Java, Python and Visual Basic. The following can be realized as first projects by the student club:

- Integration of the Lego production modules with a cloud server in order to be monitored and managed through this server [43]. In the project, data from the active sensors on the Lego production modules are transferred to the cloud server and then stored in suitable data structures for further analysis. As database technology, a No-SQL database should be used, since sensor data can accumulate very fast and high in amount, which makes a relational approach unfeasible considering the query performance.

- Printing new Lego parts using a 3D printer to enable the variant rich production of a certain product. As the first product example, transport vans can be chosen. These vehicles are especially suitable for a lab application in Industry 4.0, since they provide a very high number of variants.

- Transformation of Lego production modules from mass production model (Industry 3.0) to individualized mass production model (Industry 4.0). At the end of this project, the code on a chassis that enters the production line will be scanned by a sensor and the production order belonging to this code will be queried on the cloud server. This inquiry will be processed for each of the modules in the production line as the chassis check in. According to the response from the server, robot will decide immediately from which feeder it should take parts to continue with the montage. Thus, the production line will be working on a speed comparable to the mass production but allowing the line to put out a new vehicle configuration each time.

- Design of an optimal production line according to the product tree. Again, here transport vans can be chosen as a variant rich product. Students will analyze this product starting from the chassis taking in account different variants that can arise in the montage process using a product tree. According to the results of this analysis, they will redesign the fabric layout by rearranging modules, robots, stations and feeders optimally. The resulting new layout design will be applied on the Lego modules and production time results from the new and the old layouts will be compared.

- Addition of new Lego modules. Students will enhance the Lego production line with new Lego Mindstorm parts that will be procured and so will enable the production of new product examples.

4. Conclusions

In this work, we proposed a generic framework for Industry 4.0 education that consisted of curriculum, laboratory, and student club components to adapt engineering education to the Industry 4.0 vision. In the curriculum component, we determined new study modules to be introduced, and changes to the existing study modules. In the next step, we designed two main labs to address the changes we made on the curricula, namely the Visual Production Lab, and the Lego-Lab. While defining the relation between the course hours and hands-on laboratory units, and how these laboratory units are to be conducted, we used Kolb’s Experiential Learning Theory. In the last step, we showed how a student club can complement the changes defined in the first two steps. Students can take initiative for Industry 4.0 related projects under the roof of a student club, which in turn supports the implementation of the active experimentation stage of the Kolb’s Experiential Learning Theory. The preliminary results from our implementation of this framework at the Turkish German University showed that it was feasible to apply such a framework and the adopted underlying theory of Kolb to adapt the engineering education to Industry 4.0 vision.

Author Contributions

Conceptualization, E.G., S.C. and Y.K.; Methodology, Y.K.; Investigation, E.G., S.C. and Y.K.; Data curation, E.G.; Writing—original draft preparation, S.C., Y.K. and E.G.; Writing—review and editing, E.G., Y.K. and S.C.; Visualization, Y.K.; Funding acquisition, E.G. and Y.K.

Funding

This study was supported by Turkish German University Scientific Research Projects Commission under the grant No: 2016BM0015. We acknowledge furthermore support by Deutsche Forschungsgemeinschaft and Open Access Publishing Fund of University of Tübingen.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Gulati, R.; Soni, T. Digitization: A strategic key to business. J. Adv. Bus. Manag. 2015, 1, 60–67. [Google Scholar] [CrossRef] [PubMed]

- Wee, D.; Kelly, R.; Cattel, J.; Breunig, M. Industry 4.0—How to Navigate Digitization of the Manufacturing Sector; McKinsey & Company: New York, NY, USA, 2015. [Google Scholar]

- Coşkun, S.; Gençay, E.; Kayıkcı, Y. Adapting Engineering Education to Industrie 4.0 Vision. In Proceedings of the 16th Production Research Symposium, Istanbul, Turkey, 12–14 October 2016; pp. 258–263. [Google Scholar]

- Luo, X.; Störmer, M. Chancen und Herausforderungen der Organisations- und Personalentwicklung im Zeitalter der Industrie 4.0–Bestandsaufnahme und Ausblick. In Kommunikation und Technik; Springer: Berlin/Heidelberg, Germany, 2018; pp. 191–209. [Google Scholar]

- Huba, M.; Kozák, Š. From E-learning to Industry 4.0. In Proceedings of the 2016 International Conference on Emerging eLearning Technologies and Applications (ICETA), Vysoke Tatry, Slovakia, 24–25 November 2016; pp. 103–108. [Google Scholar]

- Dopico, M.; Gomez, A.; De la Fuente, D.; García, N.; Rosillo, R.; Puche, J. A vision of industry 4.0 from an artificial intelligence point of view. In Proceedings of the 18th International Conference on Artificial Intelligence, Varna, Bulgaria, 25–28 July 2016; p. 407. [Google Scholar]

- Kagermann, H. Change through digitization—Value creation in the age of Industry 4.0. In Management of Permanent Change; Springer: Berlin/Heidelberg, Germany, 2015; pp. 23–45. [Google Scholar]

- Sackey, S.M.; Bester, A. Industrial engineering curriculum in Industry 4.0 in a South African context. S. Afr. J. Ind. Eng. 2016, 27, 101–114. [Google Scholar] [CrossRef]

- Götting, M.; Gosewehr, F.; Müller, M.; Wermann, J.; Zarte, M.; Colombo, A.W.; Pechmann, A.; Wings, E. Methodology and case study for investigating curricula of study programs in regard to teaching industry 4.0. In Proceedings of the 2017 IEEE 15th International Conference on Industrial Informatics (INDIN), Emden, Germany, 24–26 July 2017; pp. 533–538. [Google Scholar]

- Wallner, T.; Wagner, G.; Costa, Y.J.; Pell, A.; Lengauer, E.; Halmerbauer, G.; Seher, F.; Staberhofer, F.; Lienhardt, C.A. Academic Education 4.0. In Proceedings of the International Conference on Education and New Developments, Ljubljana, Slovenia, 12–14 June 2016; pp. 155–159. [Google Scholar]

- Eder, A. Akzeptanz von Bildungstechnologien in der gewerblich-technischen Berufsbildung vor dem Hintergrund von Industrie 4.0. J. Tech. Educ. 2015, 3, 19–44. [Google Scholar]

- Zinn, B. Bedingungsvariablen der Ausbildung 4.0—Ausbildung der Zukunft. J. Tech. Educ. 2015, 3, 10–18. [Google Scholar]

- Tenberg, R.; Pittich, D. Ausbildung 4.0 oder nur 1.2? Analyse eines technisch-betrieblichen Wandels und dessen Implikationen für die technische Berufsausbildung. J. Tech. Educ. 2017, 5, 27–45. [Google Scholar]

- Guo, Q. Learning in a Mixed Reality System in the Context of Industrie 4.0. J. Tech. Educ. 2015, 3, 92–115. [Google Scholar]

- Buhler, D.; Kuchlin, W.; Grubler, G.; Nusser, G. The Virtual Automation Lab-Web based teaching of automation engineering concepts. In Proceedings of the Seventh IEEE International Conference and Workshop on the Engineering of Computer-Based Systems (ECBS 2000), Edinburgh, UK, 3–7 April 2000; pp. 156–164. [Google Scholar]

- Zarte, M.; Pechmann, A. Concept for introducing the vision of industry 4.0 in a simulation game for non-IT students. In Proceedings of the 2017 IEEE 15th International Conference on Industrial Informatics (INDIN), Emden, Germany, 24–26 July 2017; pp. 512–517. [Google Scholar]

- Hermann, M.; Pentek, T.; Otto, B. Design principles for industrie 4.0 scenarios. In Proceedings of the 2016 49th Hawaii International Conference on System Sciences (HICSS), Koloa, HI, USA, 5–8 January 2016; pp. 3928–3937. [Google Scholar]

- Richert, A.; Shehadeh, M.; Plumanns, L.; Groß, K.; Schuster, K.; Jeschke, S. Educating engineers for industry 4.0: Virtual worlds and human-robot-teams: Empirical studies towards a new educational age. In Proceedings of the 2016 IEEE Global Engineering Education Conference (EDUCON), Abu Dhabi, UAE, 10–13 April 2016; pp. 142–149. [Google Scholar]

- Schuster, K.; Groß, K.; Vossen, R.; Richert, A.; Jeschke, S. Preparing for industry 4.0—Collaborative virtual learning environments in engineering education. In Engineering Education 4.0; Springer: Berlin/Heidelberg, Germany, 2016; pp. 477–487. [Google Scholar]

- Faller, C.; Feldmüller, D. Industry 4.0 learning factory for regional SMEs. Procedia CIRP 2015, 32, 88–91. [Google Scholar] [CrossRef]

- Anjarichert, L.P.; Gross, K.; Schuster, K.; Jeschke, S. Learning 4.0: Virtual Immersive Engineering Education. Digit. Univ. 2016, 2, 51. [Google Scholar]

- Jaschke, S. Mobile learning applications for technical vocational and engineering education: The use of competence snippets in laboratory courses and industry 4.0. In Proceedings of the 2014 International Conference on Interactive Collaborative Learning (ICL), Dubai, UAE, 3–6 December 2014; pp. 605–608. [Google Scholar]

- Singh, I.; Al-Mutawaly, N.; Wanyama, T. Teaching network technologies that support industry 4.0. Proc. Can. Eng. Educ. Assoc. 2015. [Google Scholar] [CrossRef]

- Abele, E.; Metternich, J.; Tisch, M.; Chryssolouris, G.; Sihn, W.; ElMaraghy, H.; Hummel, V.; Ranz, F. Learning factories for research, education, and training. Procedia CiRp 2015, 32, 1–6. [Google Scholar] [CrossRef]

- Baena, F.; Guarin, A.; Mora, J.; Sauza, J.; Retat, S. Learning factory: The path to industry 4.0. Procedia Manuf. 2017, 9, 73–80. [Google Scholar] [CrossRef]

- Prinz, C.; Morlock, F.; Freith, S.; Kreggenfeld, N.; Kreimeier, D.; Kuhlenkötter, B. Learning factory modules for smart factories in industrie 4.0. Procedia CiRp 2016, 54, 113–118. [Google Scholar] [CrossRef]

- Erol, S.; Jäger, A.; Hold, P.; Ott, K.; Sihn, W. Tangible Industry 4.0: A scenario-based approach to learning for the future of production. Procedia CiRp 2016, 54, 13–18. [Google Scholar] [CrossRef]

- Wang, G.G. Bringing games into the classroom in teaching quality control. Int. J. Eng. Educ. 2004, 20, 678–689. [Google Scholar]

- Holmqvist, M. Experiential learning processes of exploitation and exploration within and between organizations: An empirical study of product development. Organ. Sci. 2004, 15, 70–81. [Google Scholar] [CrossRef]

- Riis, J.O.; Smeds, R. The future of simulation games: Issues and challenges. In Experimental Learning in Production Management; Springer: Berlin/Heidelberg, Germany, 1998; pp. 157–164. [Google Scholar]

- Carbonneau, R.; Laframboise, K.; Vahidov, R. Application of machine learning techniques for supply chain demand forecasting. Eur.J. Oper. Res. 2008, 184, 1140–1154. [Google Scholar] [CrossRef]

- Kolb, D. Experiential Learning as the Science of Learning and Development; Prentice Hall: Englewood Cliffs, NJ, USA, 1984. [Google Scholar]

- Kirby, A. Games for Trainers; Gower: Aldershot, UK, 1992. [Google Scholar]

- Leonard, D.C. Learning Theories, A to Z; Greenwood Press: Westport, CT, USA, 2002. [Google Scholar]

- Konak, A.; Clark, T.K.; Nasereddin, M. Using Kolb’s Experiential Learning Cycle to improve student learning in virtual computer laboratories. Comput. Educ. 2014, 72, 11–22. [Google Scholar] [CrossRef]

- Bajaj, R.; Sharma, V. Smart Education with artificial intelligence based determination of learning styles. Procedia Comput. Sci. 2018, 132, 834–842. [Google Scholar] [CrossRef]

- Wanjogu, E. Potential Relevance of Neuroscience to Guide Consumption of Multimedia Technologies towards Enhancing Learning. Ph.D. Thesis, University of Cape Town, Cape Town, South Africa, 2016. [Google Scholar]

- Felder, R.M.; Silverman, L.K. Learning and teaching styles in engineering education. Eng. Educ. 1988, 78, 674–681. [Google Scholar]

- Honey, P.; Mumford, A. Styles of learning. Gower Handb. Manag. Dev. 1994, 101, 101–111. [Google Scholar]

- Fleming, N.D. Teach. Learn. Styles; IGI Global: Hershey, PA, USA, 2001. [Google Scholar]

- Mayer, R.E.; Heiser, J.; Lonn, S. Cognitive constraints on multimedia learning: When presenting more material results in less understanding. J. Educ. Psychol. 2001, 93, 187. [Google Scholar] [CrossRef]

- Keys, B.; Wolfe, J. The role of management games and simulations in education and research. J. Manag. 1990, 16, 307–336. [Google Scholar] [CrossRef]

- Schlechtendahl, J.; Kretschmer, F.; Lechler, A.; Verl, A. Communication mechanisms for cloud based machine controls. Procedia CiRp 2014, 17, 830–834. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).