Shielding Gas Effect on Dendrite-Reinforced Composite Bronze Coatings via WAAM Cladding: Minimizing Defects and Intergranular Bronze Penetration into 09G2S Steel

Abstract

1. Introduction

2. Experimental

2.1. Materials

2.2. WAAM Cladding Parameters

2.2.1. Justification of Process Parameters and Experimental Control

2.2.2. Rationale for Specific Parameter Values

2.3. X-Ray Diffraction

2.4. Optical and Scanning Electron Microscopy

2.5. Mechanical Behavior

3. Results and Discussion

3.1. Microstructure, Phase and Chemical Composition

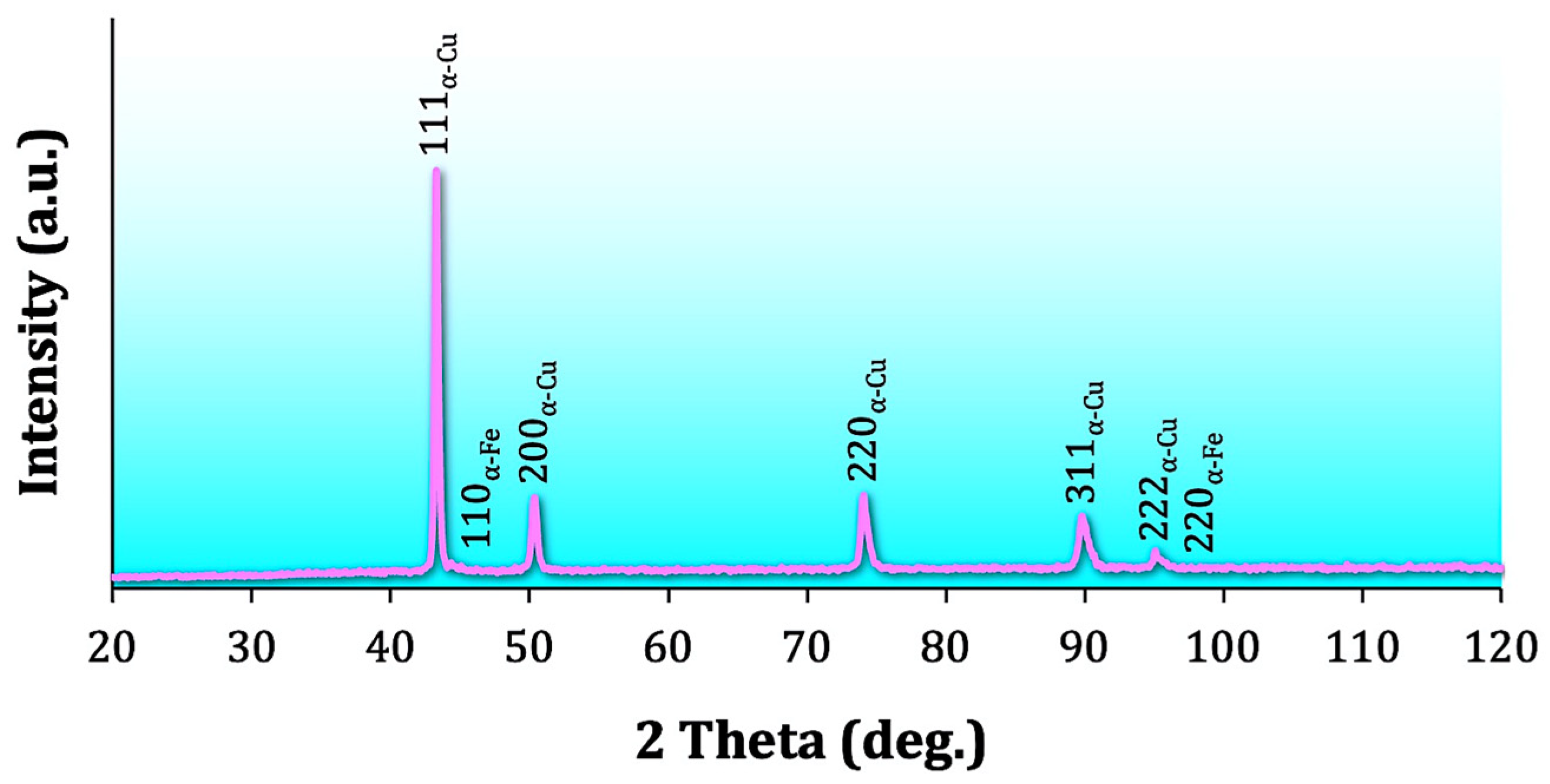

3.1.1. X-Ray Diffraction Analysis

3.1.2. Metallographic Analysis

- Bronze 1 (No Shielding Gas)

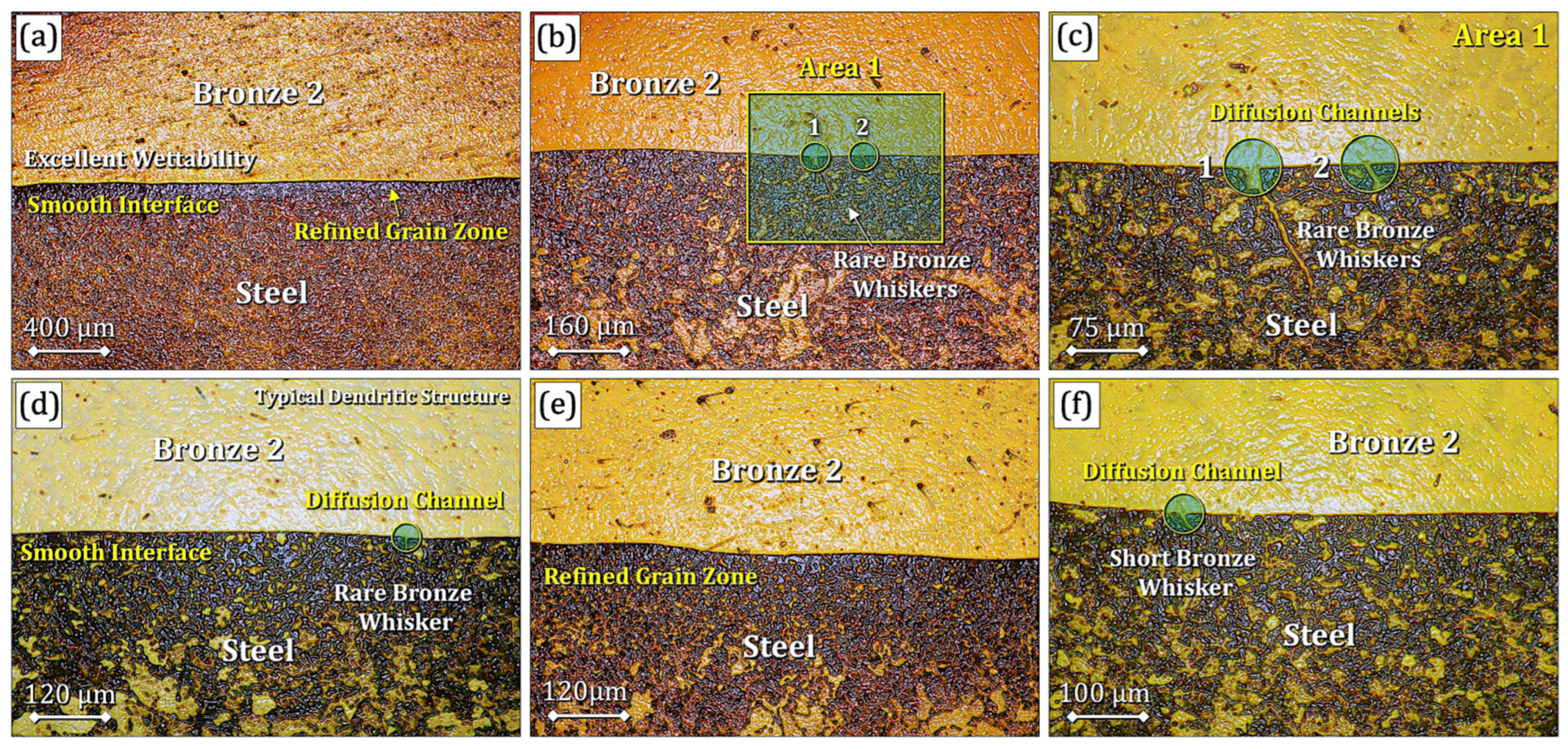

- Bronze 2 (Pure Argon)

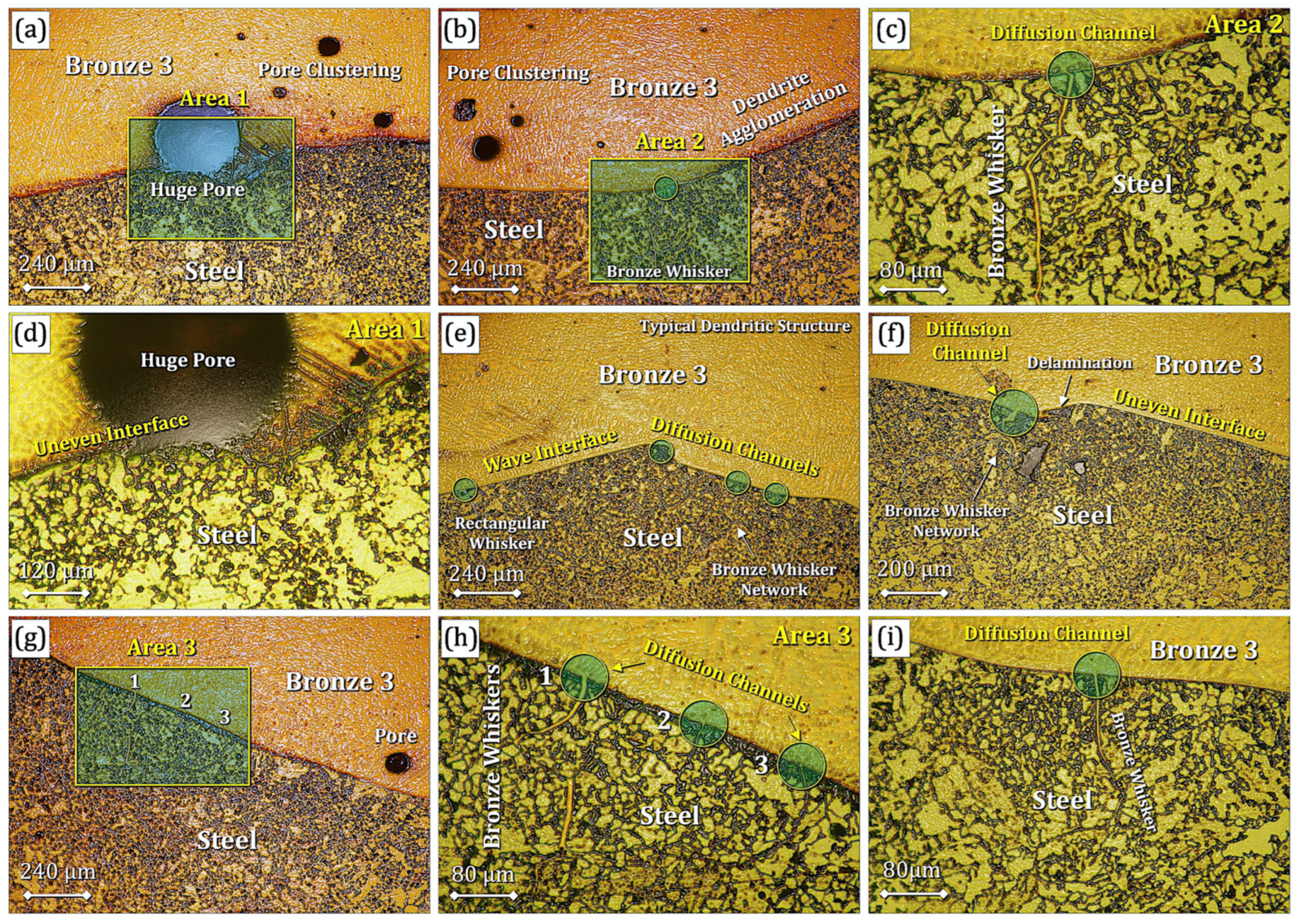

- Bronze 3 (82% Ar + 18% CO2)

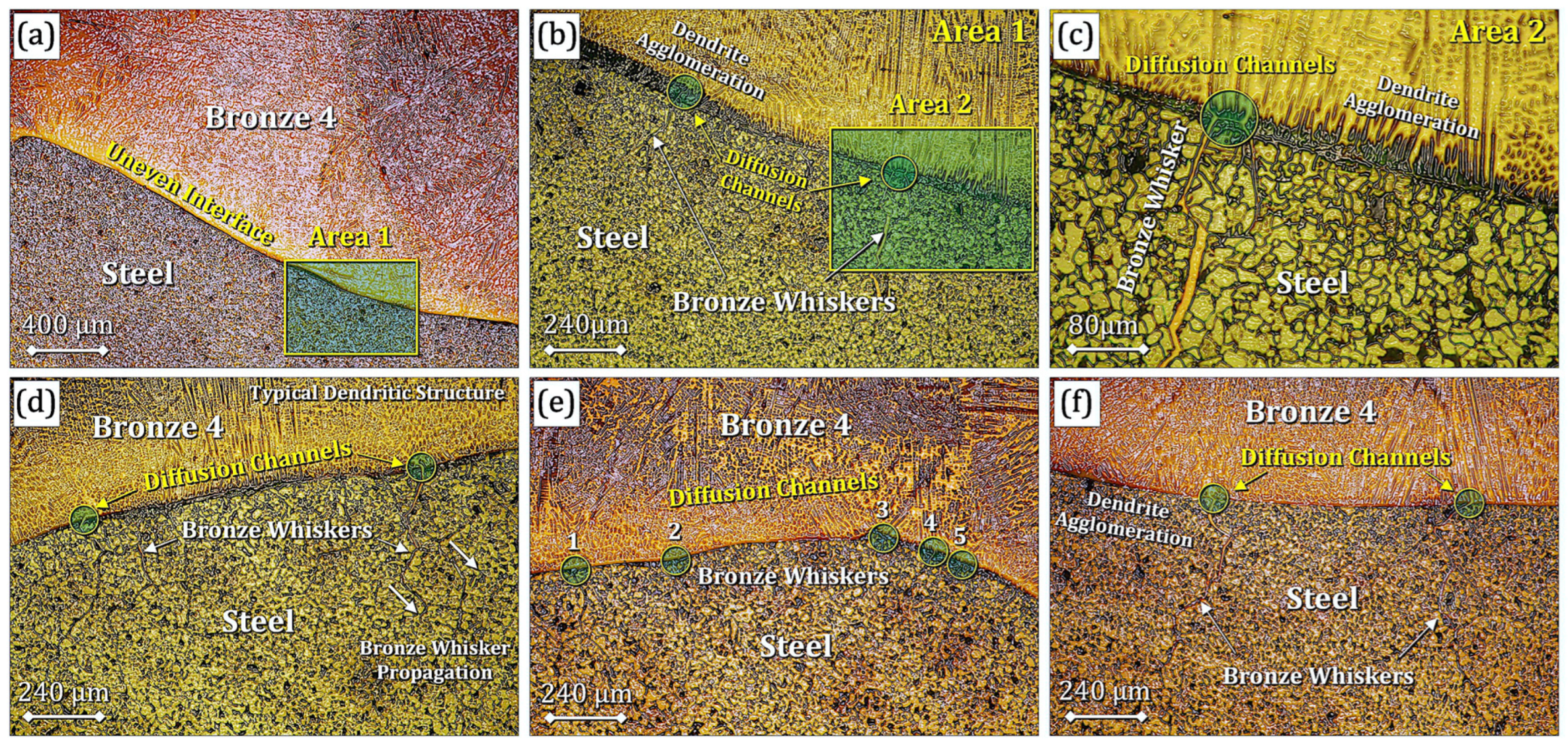

- Bronze 4 (Pure CO2)

3.1.3. SEM/EDS Characterization

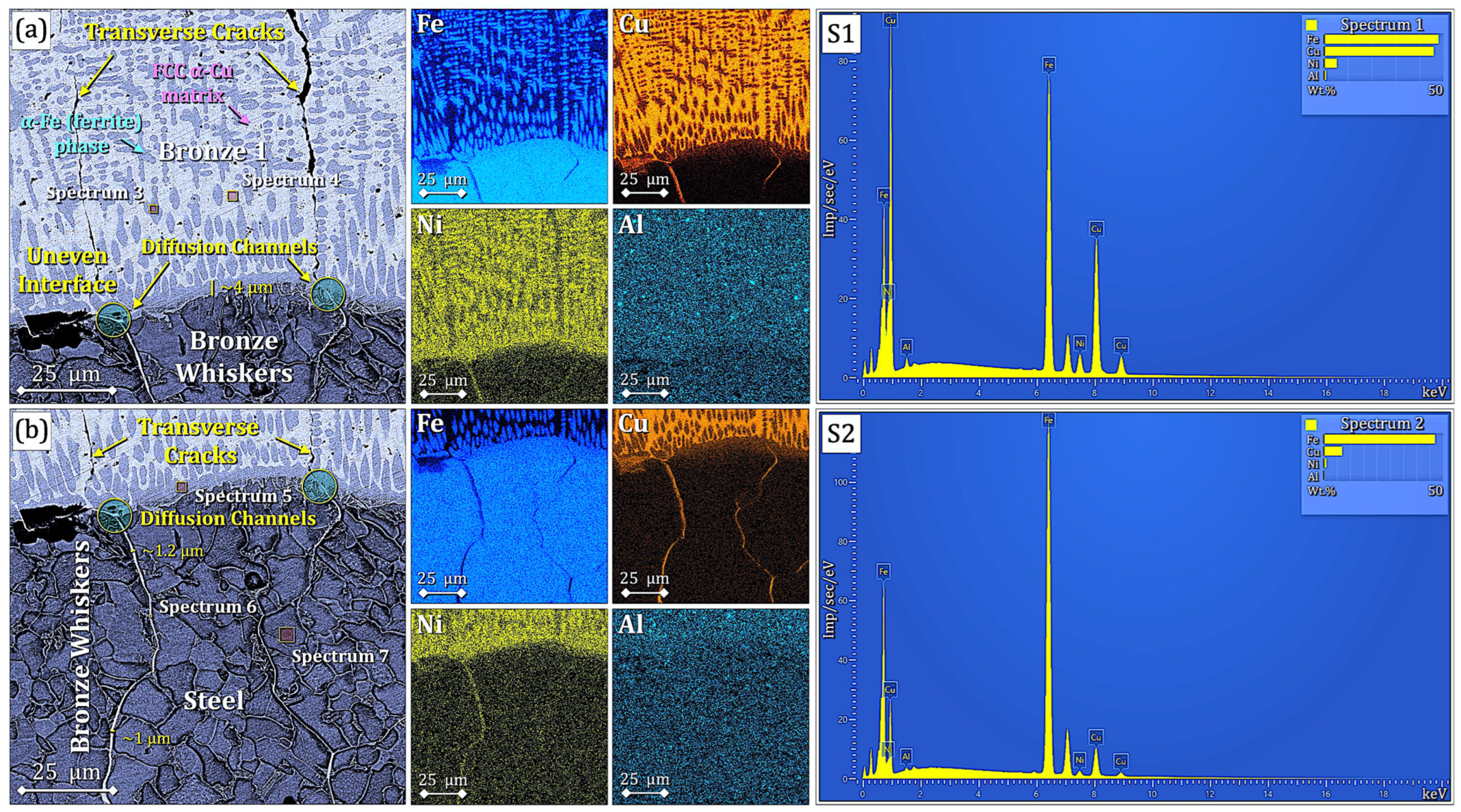

- Bronze 1 (No Shielding Gas)

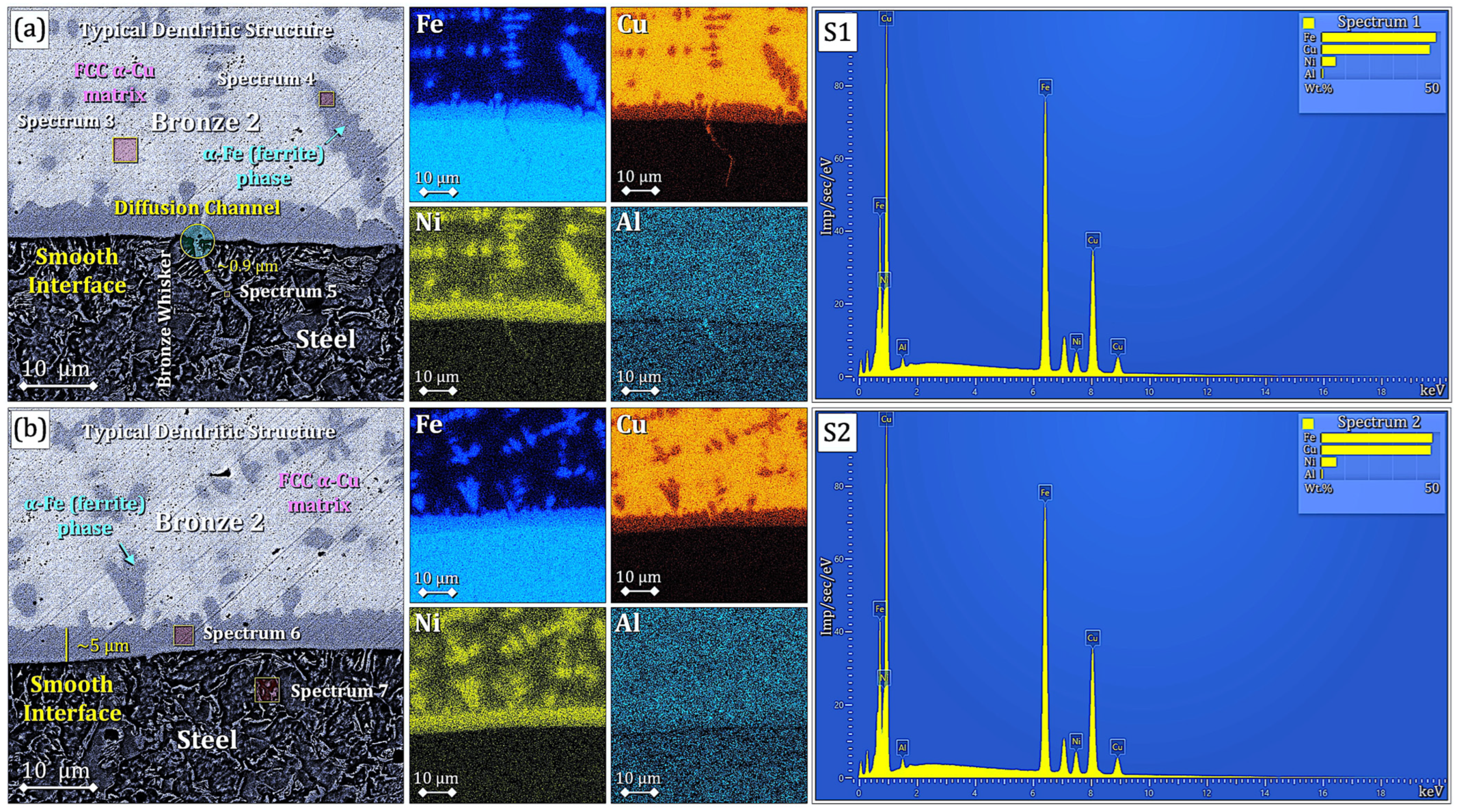

- Bronze 2 (Pure Argon)

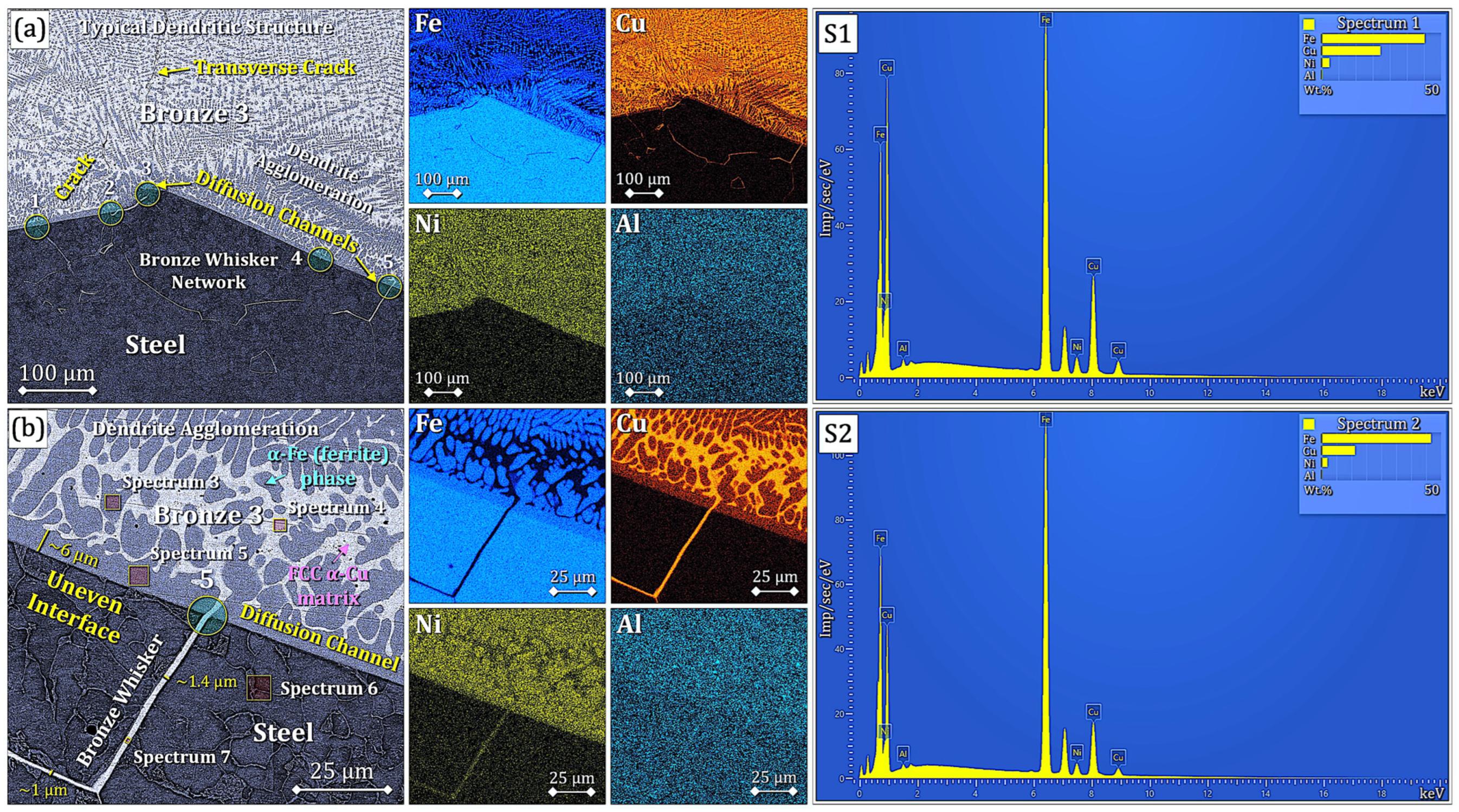

- Bronze 3 (82% Ar + 18% CO2)

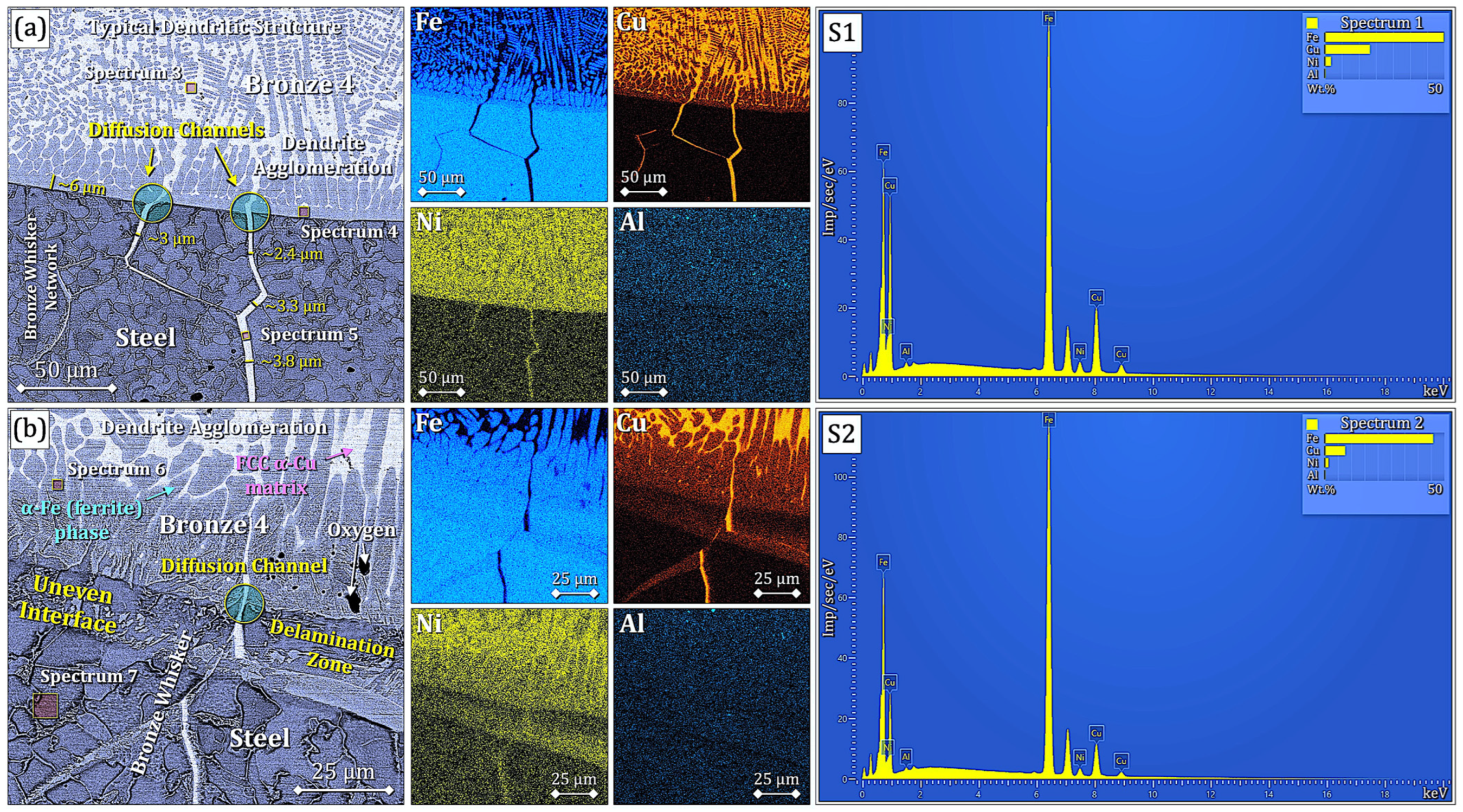

- Bronze 4 (Pure CO2)

3.2. Mechanical Characterization

4. Conclusions and Future Prospects

- Phase Composition: XRD analysis revealed the bronze coatings primarily consisted of a dominant, highly textured FCC α-Cu phase and a minor BCC α-Fe phase, with Rietveld refinement quantifying a α-Fe volume fraction of ~5%, lattice parameters of a = 0.3616 nm for α-Cu and a = 0.2869 nm for α-Fe, and a modest microstrain of 0.001.

- Microstructure and Defect Density: The pure Ar atmosphere resulted in coatings with the most favorable microstructure, exhibiting minimal porosity, absence of cracks, and effectively suppressed the bronze whisker growth. In contrast, the absence of a protective atmosphere led to significant defect formation.

- Interfacial Integrity: The Ar-shielded coating demonstrated superior wettability and interfacial adhesion with the 09G2S steel substrate, as evidenced by a uniform coating thickness and minimal irregularities at the interface. All other coatings demonstrated significant defects in the form of pores (or pore clusters), cracks and intercrystalline penetration of bronze into the substrate, often forming of bronze whisker networks.

- Microhardness Homogeneity: Microhardness measurements revealed a relatively low (~130 HV0.1) but consistent hardness profile for the Ar-shielded coating, indicative of a homogenous and structurally sound material. The other atmospheres caused greater fluctuations across the measured area as well as caused higher values up to ~203 HV0.1, indicating poor wear resistance.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Li, L.; Yang, Q. Advanced Coating Materials; John Wiley & Sons: Hoboken, NJ, USA, 2018. [Google Scholar]

- Piticescu, R.R.; Urbina, M.; Rinaldi, A.; Cuesta-Lopez, S.; Sobetkii, A. Development of Novel Material Systems and Coatings for Extreme Environments: A Brief Overview. JOM 2018, 71, 683–690. [Google Scholar] [CrossRef]

- Niu, F.; Bi, W.; Li, C.; Sun, X.; Ma, G.; Wu, D. TiC ceramic coating reinforced 304 stainless steel components fabricated by WAAM-LC integrated hybrid manufacturing. Surf. Coat. Technol. 2023, 465, 129635. [Google Scholar] [CrossRef]

- Suresh, R.; Basavarajappa, S.; Gaitonde, V.N.; Samuel, G.; Davim, J.P. State-of-the-art research in machinability of hardened steels. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2013, 227, 191–209. [Google Scholar] [CrossRef]

- Liu, Y.; Guo, F.; Li, J.; Liu, K.; Wang, J.; Okulov, A.; Sonar, T. Research progress on wire arc additive manufactured Al-Zn-Mg-Cu alloys: Metallurgical defects, refining grains, enhancing mechanical properties. Mater. Des. 2025, 253, 114005. [Google Scholar] [CrossRef]

- Liu, K.; Wang, H.; Li, J.; Geng, S.; Chen, Z.; Okulov, A. A Review on Factors Infuencing Solidifcation Cracking of Magnesium Alloys During Welding. Met. Mater. Int. 2024, 30, 1723–1742. [Google Scholar] [CrossRef]

- Bai, X.; Huang, C.; Wang, J.; Zou, B.; Liu, H. Fabrication and characterization of Si3N4 reinforced Al2O3-based ceramic tool materials. Ceram. Int. 2015, 41, 12798–12804. [Google Scholar] [CrossRef]

- Song, D.; Liu, K.; Li, J.; Zhu, H.; Sun, L.; Okulov, A. Mechanical tensile behavior-induced multi-level electronic transport of ultra-thin SiC NWs. Mater. Today Commun. 2023, 36, 106528. [Google Scholar] [CrossRef]

- García, J.; Ciprés, V.C.; Blomqvist, A.; Kaplan, B. Cemented carbide microstructures: A review. Int. J. Refract. Met. Hard Mater. 2019, 80, 40–68. [Google Scholar] [CrossRef]

- Heydari, L.; Lietor, P.F.; Corpas-Iglesias, F.A.; Laguna, O.H. Ti(C,N) and WC-Based Cermets: A Review of Synthesis, Properties and Applications in Additive Manufacturing. Materials 2021, 14, 6786. [Google Scholar] [CrossRef]

- Ates, S.; Aslan, O.; Tümer, M.; Arisoy, C.F. Impact sliding wear behavior of Stellite 6 and Stellite 12 hardfacings. Mater. Chem. Phys. 2024, 313, 128762. [Google Scholar] [CrossRef]

- Hardell, J.; Hernandez, S.; Mozgovoy, S.; Pelcastre, L.; Courbon, C.; Prakash, B. Effect of Oxide Layers and near Surface Trans-formations on Friction and Wear during Tool Steel and Boron Steel Interaction at High Temperatures. Wear 2015, 330–331, 223–229. [Google Scholar] [CrossRef]

- Dursun, T.; Soutis, C. Recent developments in advanced aircraft aluminium alloys. Mater. Des. 2014, 56, 862–871. [Google Scholar] [CrossRef]

- Zeng, R.C.; Jin, Z.; Huang, W.J.; Dietzel, W.; Wei, K.E. Review of studies on corrosion of magnesium alloys. Trans. Nonferrous Met. Soc. China 2006, 16, s763–s771. [Google Scholar] [CrossRef]

- Liu, C.B.; Cai, C.Y.; Xie, J.W.; Guo, W.M.; Qin, H.; Gao, P.Z.; Xiao, H.N. Effect of surface brittle-to-ductile transition on high-temperature thermal shock resistance of Al2O3 ceramics. Ceram. Int. 2022, 48, 20627–20638. [Google Scholar] [CrossRef]

- Jose, S.A.; John, M.; Menezes, P.L. Cermet Systems: Synthesis, Properties, and Applications. Ceramics 2022, 5, 210–236. [Google Scholar] [CrossRef]

- Řehoř, J.; Gombár, M.; Harničárová, M.; Kušnerová, M.; Houdková-Šimůnková, Š.; Valíček, J.; Fulemová, J.; Vagaská, A. Inves-tigation of machining of Stellite 6 alloy deposited on steel substrate. J. Adv. Manuf. Technol. 2022, 121, 889–901. [Google Scholar] [CrossRef]

- Liu, X.; Meng, L.; Zeng, X.; Zhu, B.; Wei, K.; Cao, J.; Hu, Q. Studies on High Power Laser Cladding Stellite 6 Alloy Coatings: Metallurgical Quality and Mechanical Performances. Surf. Coat. Technol. 2024, 481, 130647. [Google Scholar] [CrossRef]

- Samodurova, M.; Shaburova, N.; Samoilova, O.; Radionova, L.; Zakirov, R.; Pashkeev, K.; Myasoedov, V.; Erdakov, I.; Trofimov, E. A study of characteristics of aluminum bronze coatings applied to steel using additive technologies. Materials 2020, 13, 461. [Google Scholar] [CrossRef]

- Yang, S.; Song, K.; Zhou, Y.; Yang, R.; Yu, Y.; Liu, L.; Chen, J.; Zhou, F.; Yang, W.; Zhang, G.; et al. Research Progress on Cu–15Ni–8Sn Alloys: The Effect of Microalloying and Heat Treatment on Microstructure and Properties. Materials 2023, 16, 5913. [Google Scholar] [CrossRef]

- Wang, L.; Liu, K.; Li, J.; Geng, S. A Review on Corrosion Behavior and Surface Modification Technology of Nickel AluminumBronze Alloys: Current Research and Prospects. Adv. Eng. Mater. 2025, 27, 1779. [Google Scholar]

- Equey, S.; Houriet, A.; Mischler, S. Wear and frictional mechanisms of copper-based bearing alloys. Wear 2011, 273, 9–16. [Google Scholar] [CrossRef]

- Frost, J.; Litwin, W. Comparative Wear Test of Journal Sliding Bearings with Sintered Bronze and Babbitt Alloy Bushes Lubri-cated by Environmentally Acceptable/Adapted Lubricants (EAL). Tribol. Trans. 2023, 66, 443–452. [Google Scholar] [CrossRef]

- Gao, F.; Liu, R.; Wu, X.J. Tribaloy alloy reinforced tin–bronze composite coating for journal bearing applications. Thin Solid Films 2011, 519, 4809–4817. [Google Scholar] [CrossRef]

- Duncheva, G.; Maximov, J.; Anchev, A.; Dunchev, V.; Argirov, Y.; Kandeva-Ivanova, M. Enhancement of the wear resistance of CuAl9Fe4 sliding bearing bushings via diamond burnishing. Wear 2022, 510, 204491. [Google Scholar] [CrossRef]

- Bharatish, A.; Rajkumar, G.R.; Gurav, P.; Satheesh Babu, G.; Narasimha Murthy, H.N.; Roy, M. Optimization of Laser TextureGeometry and Resulting Functionality of Nickel Aluminium Bronze for Landing Gear Applications. Int. J. Lightweight Mater. Manuf. 2021, 4, 346–357. [Google Scholar]

- Khaskhoussi, A.; Risitano, G.; Calabrese, L.; D’Andrea, D. Investigation of the wettability properties of different texturedlead/lead-free bronze coatings. Lubricants 2022, 10, 82. [Google Scholar] [CrossRef]

- Song, Q.N.; Xu, N.; Bao, Y.F.; Jiang, Y.F.; Gu, W.; Zheng, Y.G.; Qiao, Y.X. Corrosion and cavitation erosion behaviors of two marine propeller materials in clean and Sulfide-Polluted 3.5% NaCl solutions. Acta Metall. Sin.-Engl. Lett. 2017, 30, 712–720. [Google Scholar] [CrossRef]

- Yao, Y.L.; Cheng, J.H.; Ji, H.; Zhang, S.J.; Pang, H.Z.; Chen, Y.; Tian, Z.J. The preparation and properties of thick bronze coatingusing friction-assisted jet electrodeposition. Coatings 2024, 14, 150. [Google Scholar] [CrossRef]

- Miguel, J.; Vizcaino, S.; Lorenzana, C.; Cinca, N.; Guilemany, J. Tribological behavior of bronze composite coatings obtained by plasma thermal spraying. Tribol. Lett. 2011, 42, 263–273. [Google Scholar] [CrossRef]

- Morales, J.; Piamba, O.; Olaya, J.; Vallejo, F. Effect of Heat Treatment on the Electrochemical and Tribological Properties of Aluminum-Bronze Coatings Deposited Used the Thermal Spraying Process. Coatings 2024, 14, 423. [Google Scholar] [CrossRef]

- Okulov, A.; Korobov, Y.; Stepchenkov, A.; Makarov, A.; Iusupova, O.; Korkh, Y.; Kuznetsova, T.; Kharanzhevskiy, E.; Liu, K. Mechanical and Structural Characterization of Laser-Cladded Medium-Entropy FeNiCr-B4C Coatings. Materials 2023, 16, 5479. [Google Scholar] [CrossRef] [PubMed]

- Okulov, A.; Iusupova, O.; Liu, K.; Li, J.; Stepchenkov, A.; Zavalishin, V.; Korkh, Y.; Kuznetsova, T.; Mugada, K.K.; Moganraj, A. Micromechanical and Tribological Performance of Laser-Cladded Equiatomic FeNiCr Coatings Reinforced with TiC and NbC Particles. Materials 2024, 17, 4686. [Google Scholar] [CrossRef]

- Yin, T.; Zhang, S.; Wang, Z.; Zhang, C.; Liu, Y.; Chen, J. Effect of laser energy density on microstructural evolution and wearresistance of modified aluminum bronze coatings fabricated by laser cladding. Mater. Chem. Phys. 2022, 285, 126191. [Google Scholar] [CrossRef]

- Okulov, A.; Iusupova, O.; Stepchenkov, A.; Zavalishin, V.; Marchenkova, E.; Liu, K.; Li, J.; Sonar, T.; Makarov, A.; Korobov, Y.; et al. In Situ Ceramic Phase Reinforcement via Short-Pulsed Laser Cladding for Enhanced Tribo-Mechanical Behavior of Metal Matrix Composite FeNiCr-B4C (5 and 7 wt.%) Coatings. Technologies 2025, 13, 231. [Google Scholar] [CrossRef]

- Dharmendra, C.; Amirkhiz, B.S.; Lloyd, A.; Janaki Ram, G.D.; Mohammadi, M. Wire-arc additive manufactured nickel alumi-num bronze with enhanced mechanical properties using heat treatments cycles. Addit. Manuf. 2020, 36, 101510. [Google Scholar]

- Tao, X.P.; Zhang, S.; Zhang, C.H.; Wu, C.L.; Chen, J.; Abdullah, A.O. Effect of Fe and Ni contents on microstructure and wear resistance of aluminum bronze coatings on 316 stainless steel by laser cladding. Surf. Coat. Technol. 2018, 342, 76–84. [Google Scholar] [CrossRef]

- Chen, C.; Li, W.; Tu, F.; Qin, T. Effect of Heat Input on Tin Bronze-Induced Intergranular Cracks During Arc Cladding Pro-cess. Crystals 2024, 14, 926. [Google Scholar] [CrossRef]

- Chen, S.H.; Yu, X.H.; Huang, J.H.; Yang, J.; Lin, S.B. Interfacial ferrite band formation to suppress intergranular liquid copperpenetration of solid steel. J. Alloys Compd. 2019, 773, 719–729. [Google Scholar] [CrossRef]

- Chen, C.; Zhou, J.; Yu, J.; Ju, J.; Zhang, Y.; Wang, J.; Fan, B. Interfacial microstructures and infiltrated cracks in tin bronze/steelbimetallic materials fabricated by arc cladding. J. Mater. Sci. 2023, 58, 4679–4693. [Google Scholar] [CrossRef]

- ISO 14577-1:2015; Metallic Materials—Instrumented Indentation Test for Hardness and Materials Parameters—Part 1: Test Method. International Organization for Standardization: Geneva, Switzerland, 2015.

- Davis, J.R. Copper and Copper Alloys; ASM International: Novelty, OH, USA, 2001. [Google Scholar]

- Kucita, P.; Wang, S.; Li, W.; Cook, R.; Starink, M. The effects of substrate dilution on the microstructure and wear resistance of PTA Cu-Al-Fe aluminium bronze coatings. Wear 2019, 440, 203102. [Google Scholar] [CrossRef]

- Cai, X.; Wang, Z.; Dong, L.; Yang, M.; Zhou, J.; Xue, F. Advanced mechanical properties of nickel-aluminum bronze/steel com-posite structure prepared by wire-arc additive manufacturing. Mater. Des. 2022, 221, 110969. [Google Scholar] [CrossRef]

- Rodrigues, T.A.; Duarte, V.; Miranda, R.M.; Santos, T.G.; Oliveira, J.P. Current Status and Perspectives on Wire and Arc Additive Manu-facturing (WAAM). Materials 2019, 12, 1121. [Google Scholar] [CrossRef]

- Zhai, T.; Wilkison, A.J.; Martin, J.W. A crystallographic mechanism for fatigue crack propagation through grain bounda-ries. Acta Mater. 2000, 48, 4917–4927. [Google Scholar] [CrossRef]

- Jiao, Z.B.; Luan, J.H.; Liu, C.T. Strategies for improving ductility of ordered intermetallics. Prog. Nat. Sci. Mater. Int. 2016, 26, 1–12. [Google Scholar] [CrossRef]

- Potekhin, B.A. Novel Composite Antifriction Bronzes: Composition, Structure, Properties (A Review). Met. Sci. Heat Treat. 2023, 65, 238–246. [Google Scholar] [CrossRef]

- Zhao, L.; Du, B.; Yao, J.; Chen, H.; Ding, R.; Li, K. Microstructure and mechanical properties of Nickel-Aluminum Bronze coating on 17-4PH stainless steel by laser cladding. Chin. J. Mech. Eng. 2022, 35, 140. [Google Scholar] [CrossRef]

- Huang, L.; Chen, X.; Konovalov, S.; Su, C.; Fan, P.; Wang, Y.; Xiaoming, P.; Panchenko, I. A Review of Challenges for Wire and Arc Additive Manufacturing (WAAM). Trans. Indian Inst. Met. 2023, 76, 1123–1139. [Google Scholar] [CrossRef]

| Material | Cu | Fe | Ni | Al | C | Mn | Si | Cr | S | P |

|---|---|---|---|---|---|---|---|---|---|---|

| BrZhNA 12-7-1 | Bal. | 12 | 7 | 1 | - | - | - | - | - | - |

| 09G2S steel | ≤0.3 | Bal. | ≤0.3 | - | 0.09–0.12 | 1.3–1.7 | 0.5–0.8 | ≤0.3 | ≤0.035 | ≤0.035 |

| Sample | Current, A | Voltage, V | Wire Feed Rate, m/min | Welding Speed, mm/min | Flow Rate, L/min | Shielding Gas |

|---|---|---|---|---|---|---|

| Bronze 1 | 150 | 16 | 3.6 | 250 | - | - |

| Bronze 2 | 10 | Ar | ||||

| Bronze 3 | 82% Ar + 12% CO2 | |||||

| Bronze 4 | CO2 |

| Spectra | Fe | Cu | Ni | Al | C | Mn | Si |

|---|---|---|---|---|---|---|---|

| Spectrum 1 | 47.97 | 45.92 | 5.31 | 0.8 | - | - | - |

| Spectrum 2 | 83.93 | 13.79 | 1.95 | 0.33 | - | - | - |

| Spectrum 3 | 72.75 | 17.18 | 9.51 | 0.57 | - | - | - |

| Spectrum 4 | 9.25 | 85.94 | 3.93 | 0.88 | - | - | - |

| Spectrum 5 | 80.33 | 13.38 | 5.80 | 0.49 | - | - | - |

| Spectrum 6 | 24.53 | 72.28 | 2.45 | 0.74 | - | - | - |

| Spectrum 7 | 97.84 | - | - | - | 0.1 | 1.46 | 0.6 |

| Spectra | Fe | Cu | Ni | Al | C | Mn | Si |

|---|---|---|---|---|---|---|---|

| Spectrum 1 | 47.86 | 45.33 | 5.98 | 0.83 | - | - | - |

| Spectrum 2 | 46.68 | 45.97 | 6.49 | 0.87 | - | - | - |

| Spectrum 3 | 3.38 | 92.05 | 3.46 | 1.09 | - | - | - |

| Spectrum 4 | 43.67 | 33.51 | 21.62 | 1.2 | - | - | - |

| Spectrum 5 | 96.08 | 2.69 | 1.23 | - | - | - | - |

| Spectrum 6 | 63.52 | 19.03 | 16.59 | 0.86 | - | - | - |

| Spectrum 7 | 97.92 | - | - | - | 0.11 | 1.32 | 0.65 |

| Spectra | Fe | Cu | Ni | Al | C | Mn | Si |

|---|---|---|---|---|---|---|---|

| Spectrum 1 | 60.41 | 34.44 | 4.59 | 0.56 | - | - | - |

| Spectrum 2 | 73.14 | 22.48 | 3.97 | 0.41 | - | - | - |

| Spectrum 3 | 75.3 | 16.15 | 8.55 | - | - | - | - |

| Spectrum 4 | 8.92 | 87.16 | 2.97 | 0.95 | - | - | - |

| Spectrum 5 | 79.35 | 13.68 | 6.57 | 0.4 | - | - | - |

| Spectrum 6 | 97.63 | - | - | - | 0.1 | 1.54 | 0.73 |

| Spectrum 7 | 23.13 | 73.32 | 2.85 | 0.7 | - | - | - |

| Spectra | Fe | Cu | Ni | Al | C | Mn | Si |

|---|---|---|---|---|---|---|---|

| Spectrum 1 | 69.62 | 26.39 | 3.56 | 0.43 | - | - | - |

| Spectrum 2 | 81.57 | 15.29 | 2.83 | 0.31 | - | - | - |

| Spectrum 3 | 9.14 | 71.53 | 2.65 | 16.68 | - | - | - |

| Spectrum 4 | 80.93 | 13.67 | 5.07 | 0.33 | - | - | - |

| Spectrum 5 | 11.15 | 84.26 | 3.71 | 0.88 | - | - | - |

| Spectrum 6 | 74.98 | 16.67 | 7.93 | 0.42 | - | - | - |

| Spectrum 7 | 97.72 | - | - | - | 0.1 | 1.48 | 0.7 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Okulov, A.; Khlebnikova, Y.; Iusupova, O.; Egorova, L.; Suaridze, T.; Korobov, Y.; Potekhin, B.; Sholokhov, M.; Sonar, T.; Naseri, M.; et al. Shielding Gas Effect on Dendrite-Reinforced Composite Bronze Coatings via WAAM Cladding: Minimizing Defects and Intergranular Bronze Penetration into 09G2S Steel. Technologies 2025, 13, 525. https://doi.org/10.3390/technologies13110525

Okulov A, Khlebnikova Y, Iusupova O, Egorova L, Suaridze T, Korobov Y, Potekhin B, Sholokhov M, Sonar T, Naseri M, et al. Shielding Gas Effect on Dendrite-Reinforced Composite Bronze Coatings via WAAM Cladding: Minimizing Defects and Intergranular Bronze Penetration into 09G2S Steel. Technologies. 2025; 13(11):525. https://doi.org/10.3390/technologies13110525

Chicago/Turabian StyleOkulov, Artem, Yulia Khlebnikova, Olga Iusupova, Lada Egorova, Teona Suaridze, Yury Korobov, Boris Potekhin, Michael Sholokhov, Tushar Sonar, Majid Naseri, and et al. 2025. "Shielding Gas Effect on Dendrite-Reinforced Composite Bronze Coatings via WAAM Cladding: Minimizing Defects and Intergranular Bronze Penetration into 09G2S Steel" Technologies 13, no. 11: 525. https://doi.org/10.3390/technologies13110525

APA StyleOkulov, A., Khlebnikova, Y., Iusupova, O., Egorova, L., Suaridze, T., Korobov, Y., Potekhin, B., Sholokhov, M., Sonar, T., Naseri, M., He, T., & Li, Z. (2025). Shielding Gas Effect on Dendrite-Reinforced Composite Bronze Coatings via WAAM Cladding: Minimizing Defects and Intergranular Bronze Penetration into 09G2S Steel. Technologies, 13(11), 525. https://doi.org/10.3390/technologies13110525