Tool Wear Characteristics and Strengthening Method of the Disc Cutter for Nomex Honeycomb Composites Machining with Ultrasonic Assistance

Abstract

1. Introduction

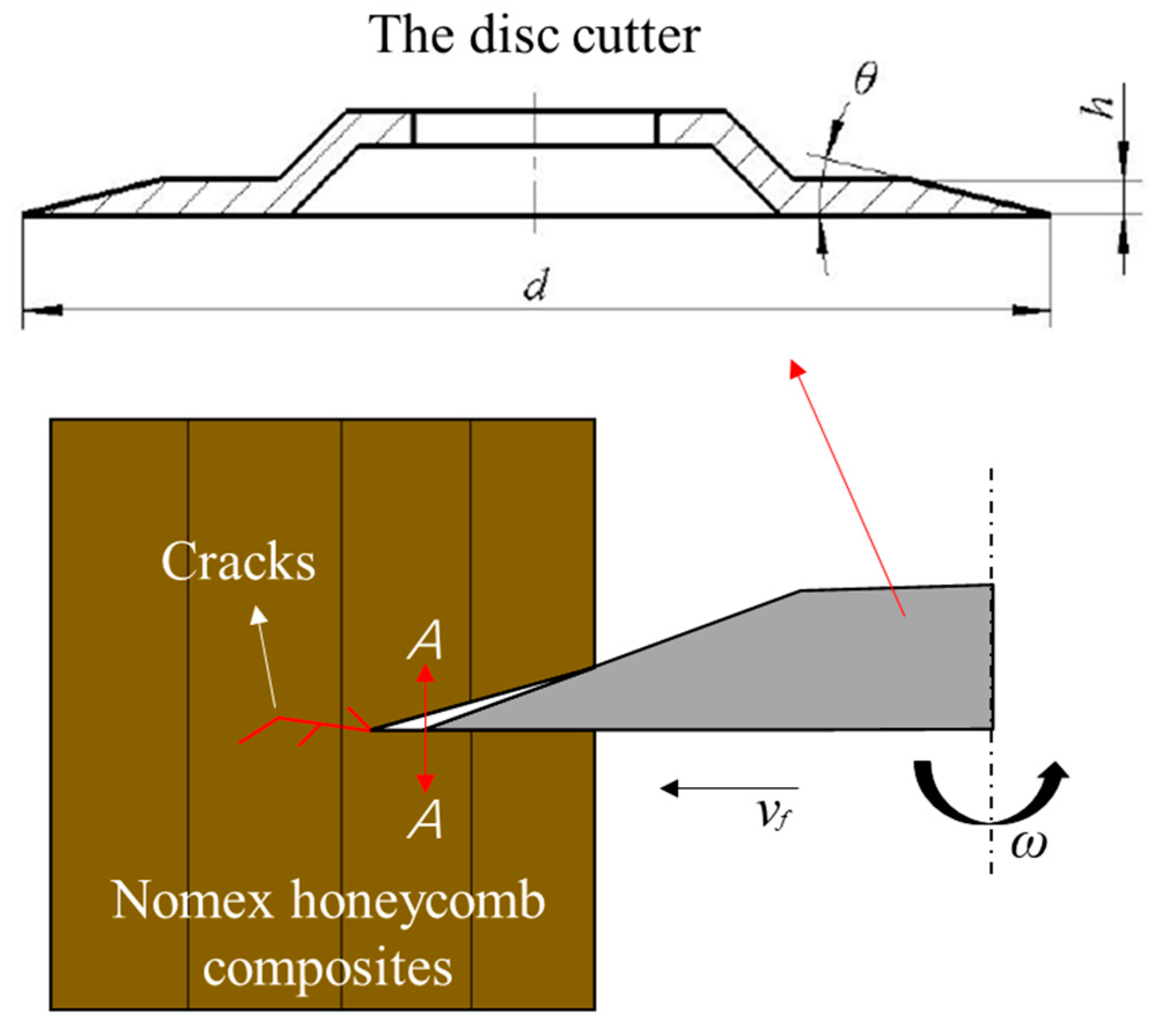

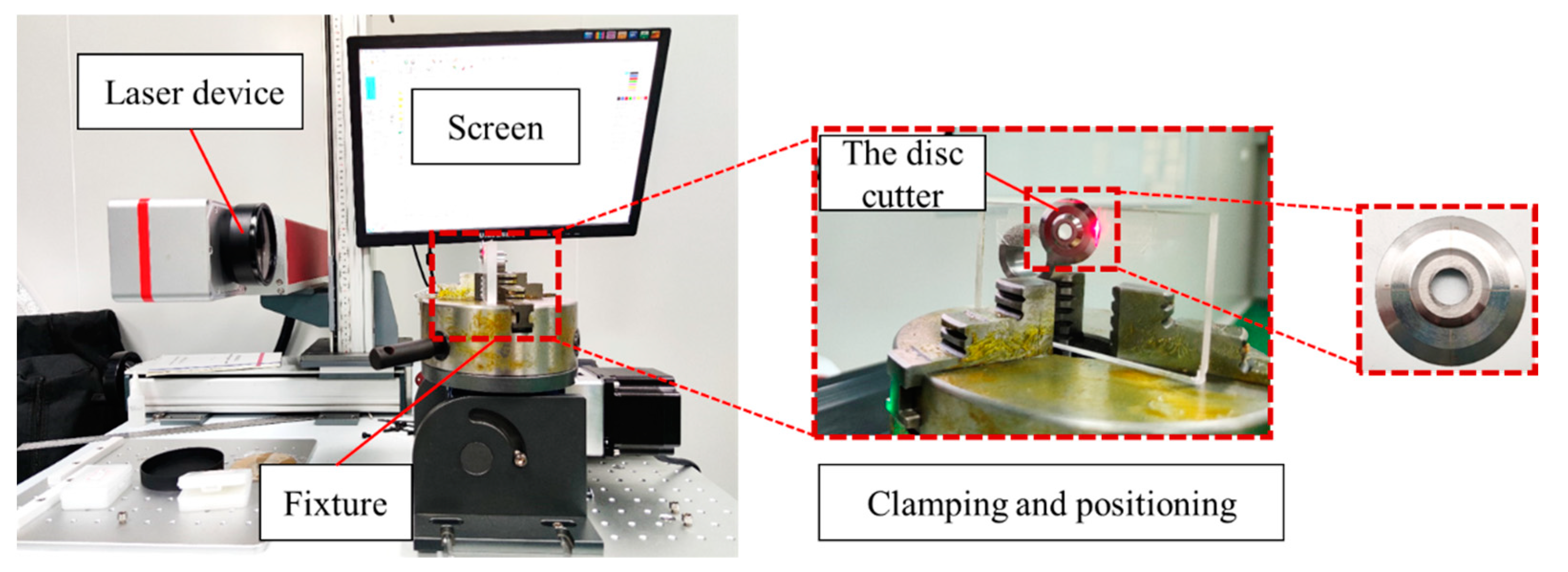

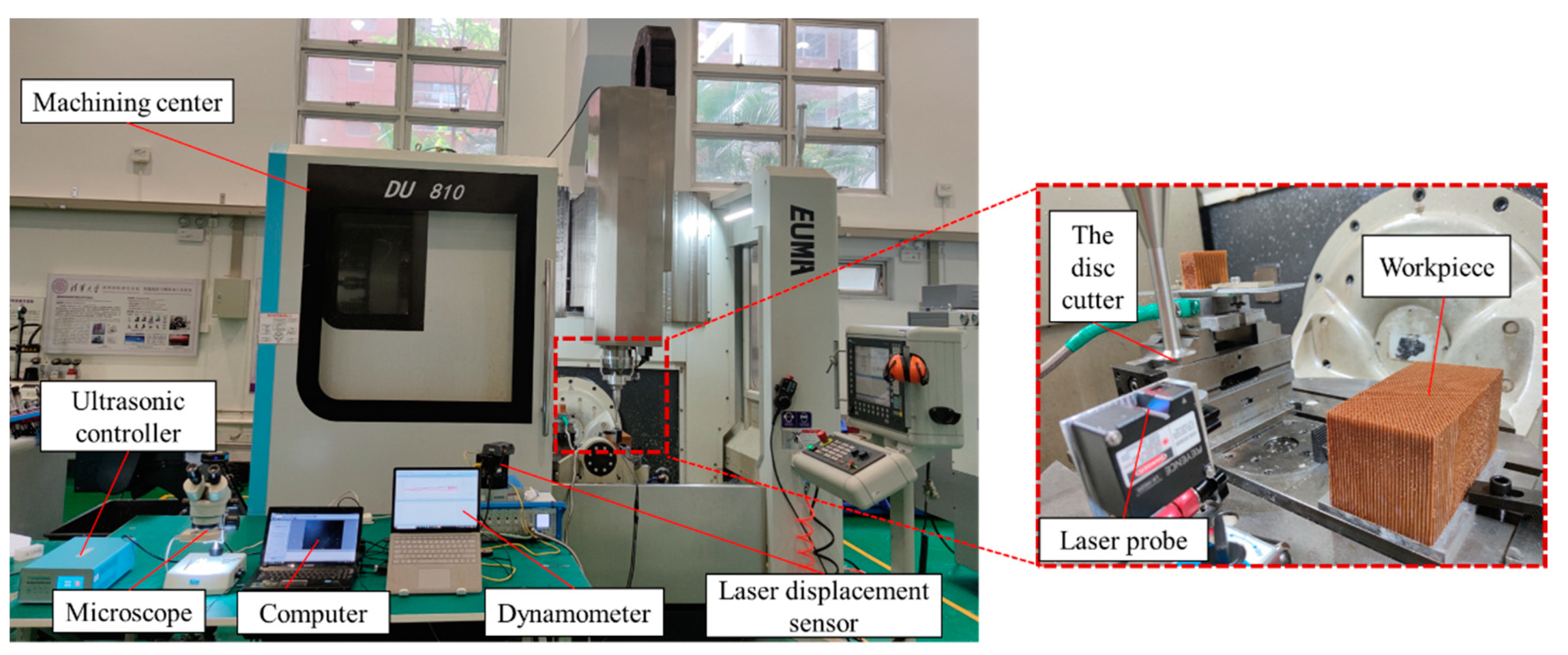

2. Experimental Details

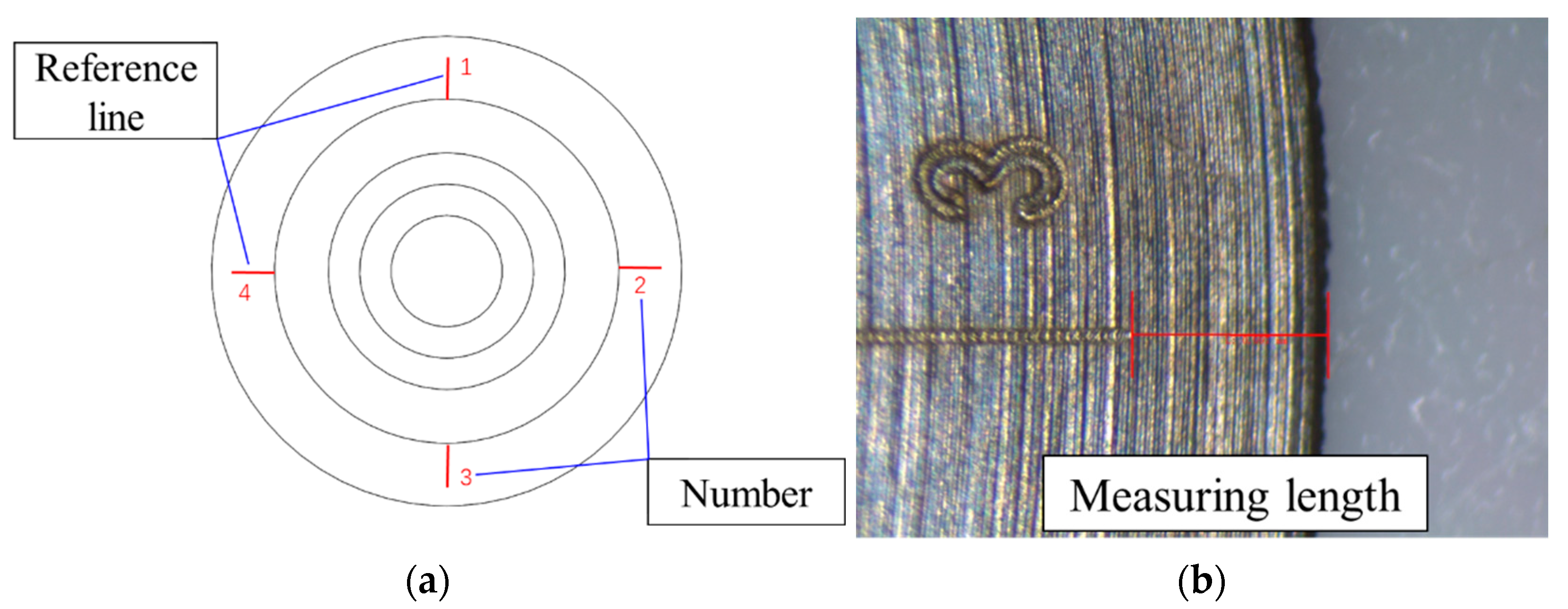

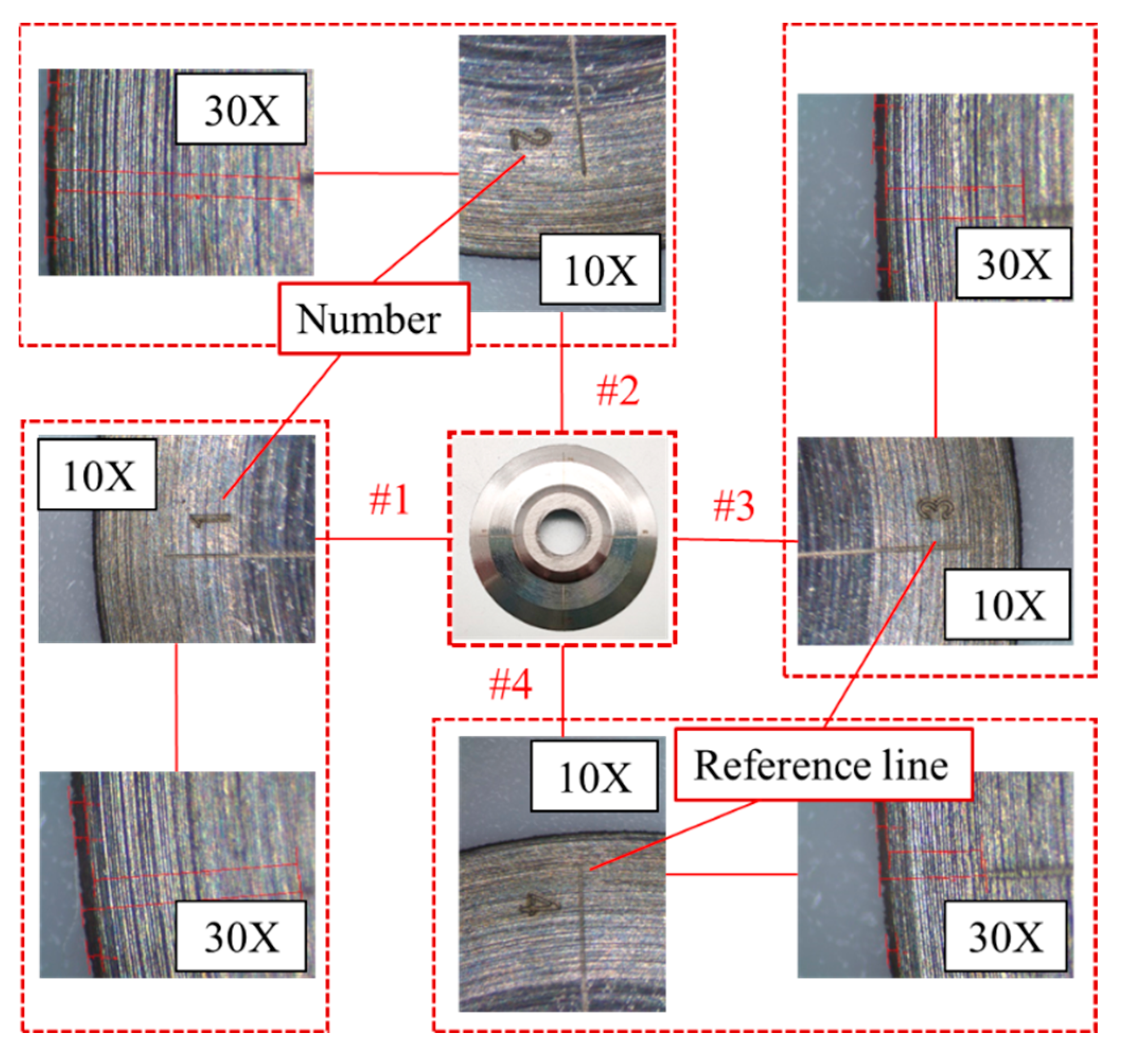

2.1. Evaluation Method for Tool Wear Characteristics

2.2. Tool Strengthening Method

2.3. Experimental Setup

3. Results and Discussion

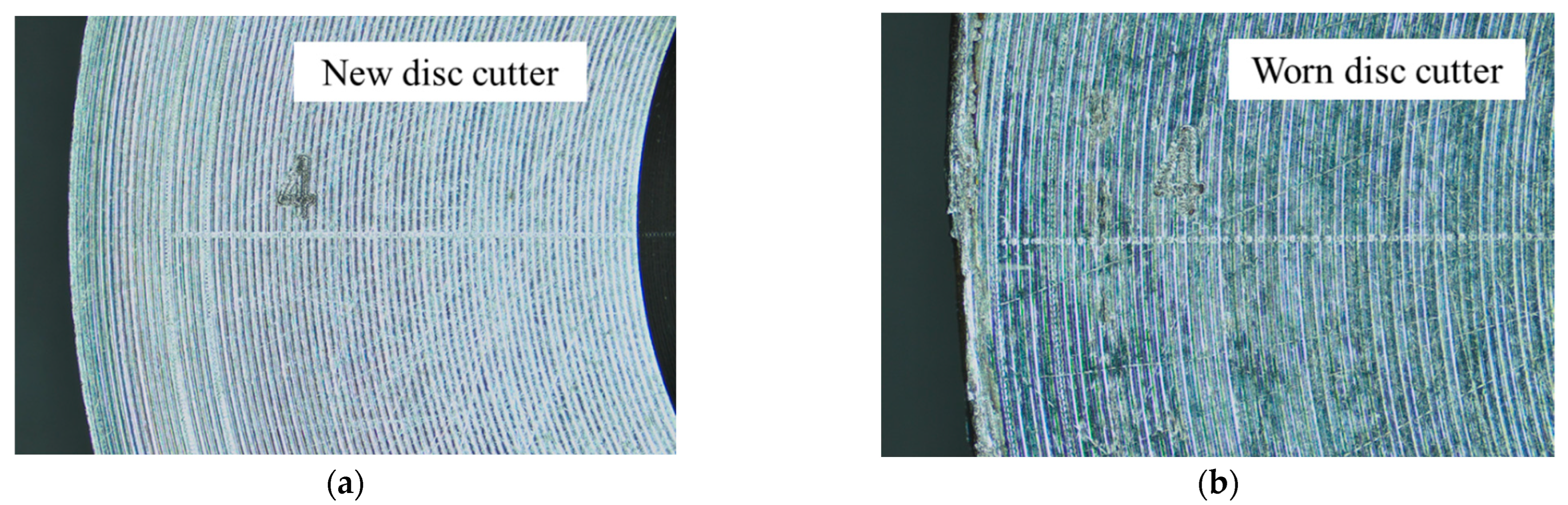

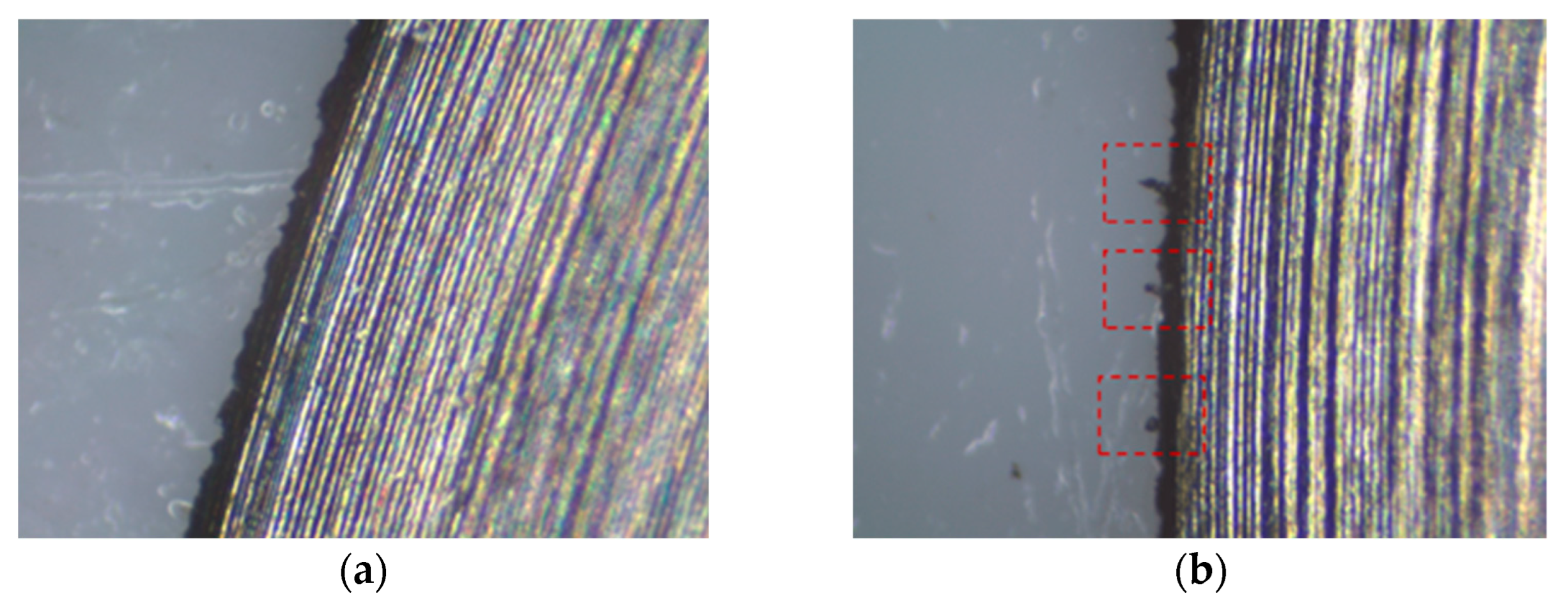

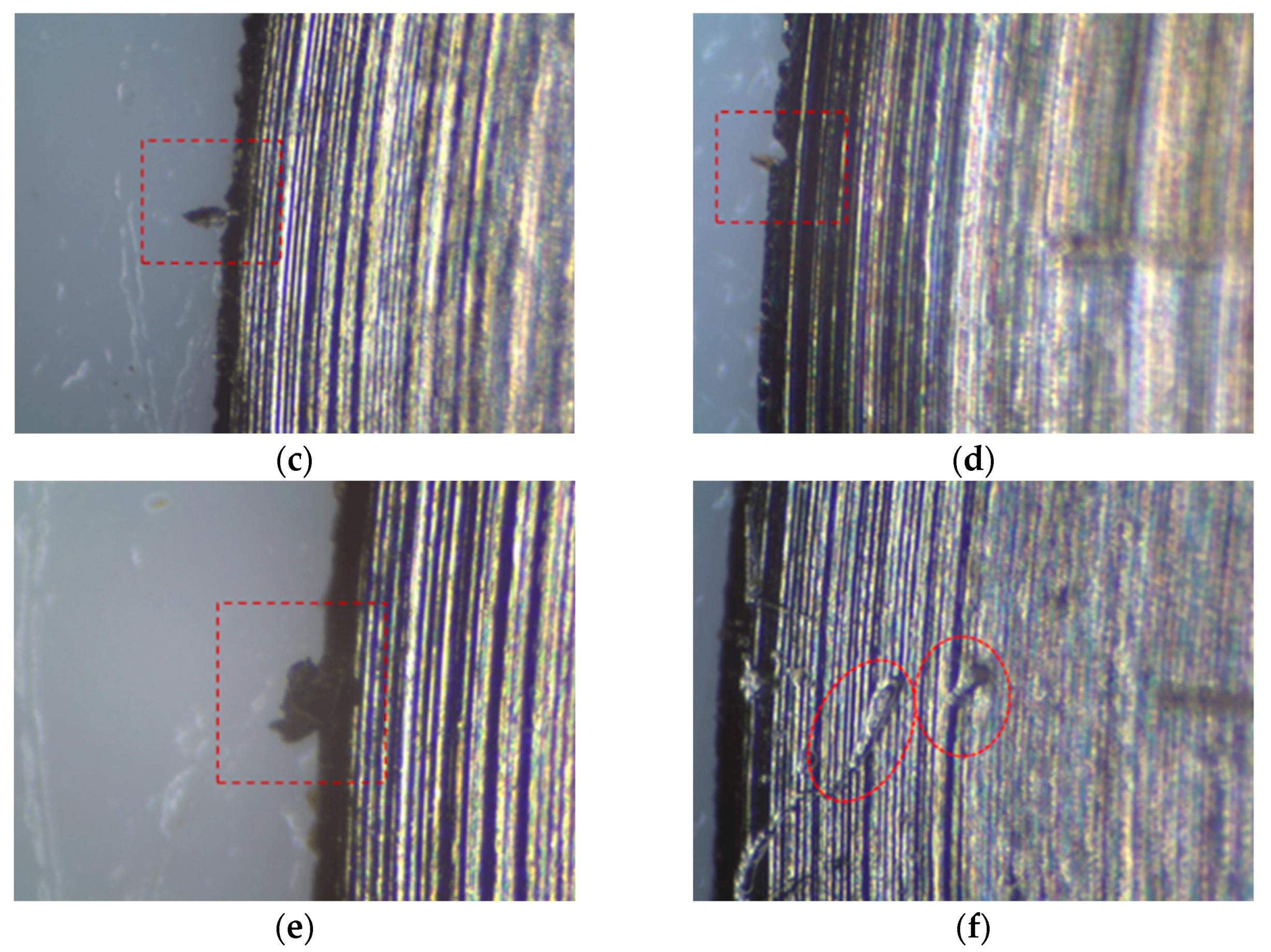

3.1. The Morphology of Tool Wear Process

3.2. The Analysis of Tool Wear

3.3. The Tool Wear of the Strengthened Disc Cutter

4. Conclusions

- (1)

- An evaluation method was proposed to evaluate the tool wear of the disc cutter quantitatively which was called the radial difference calculation method. Small tears were typical morphology of the tool wear at the beginning of the machining process. Edge chipping and curls occurred with increase of the cutting length. Furthermore, even the surface of the disc cutter was damaged at the end stage of the cutting process.

- (2)

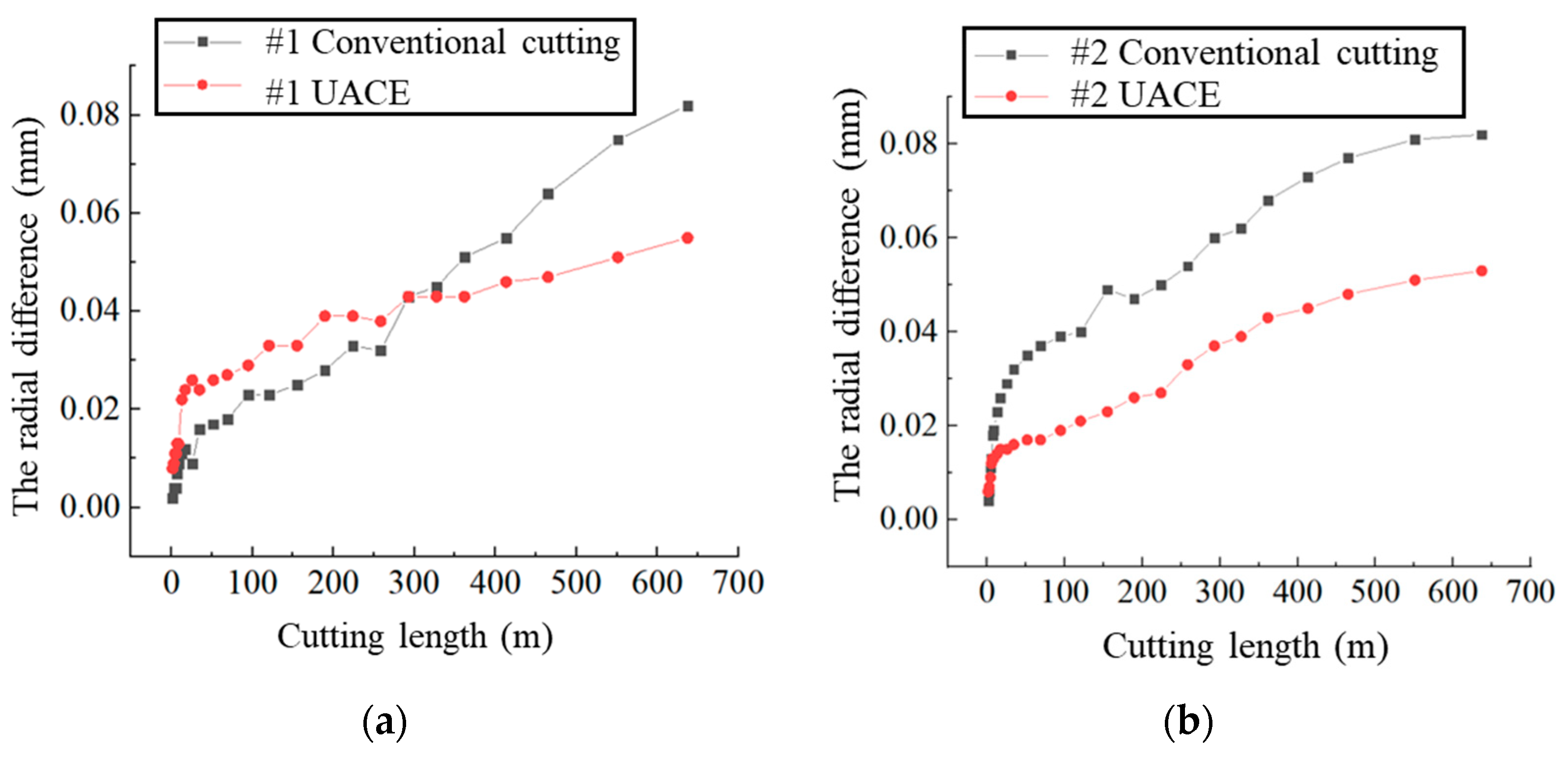

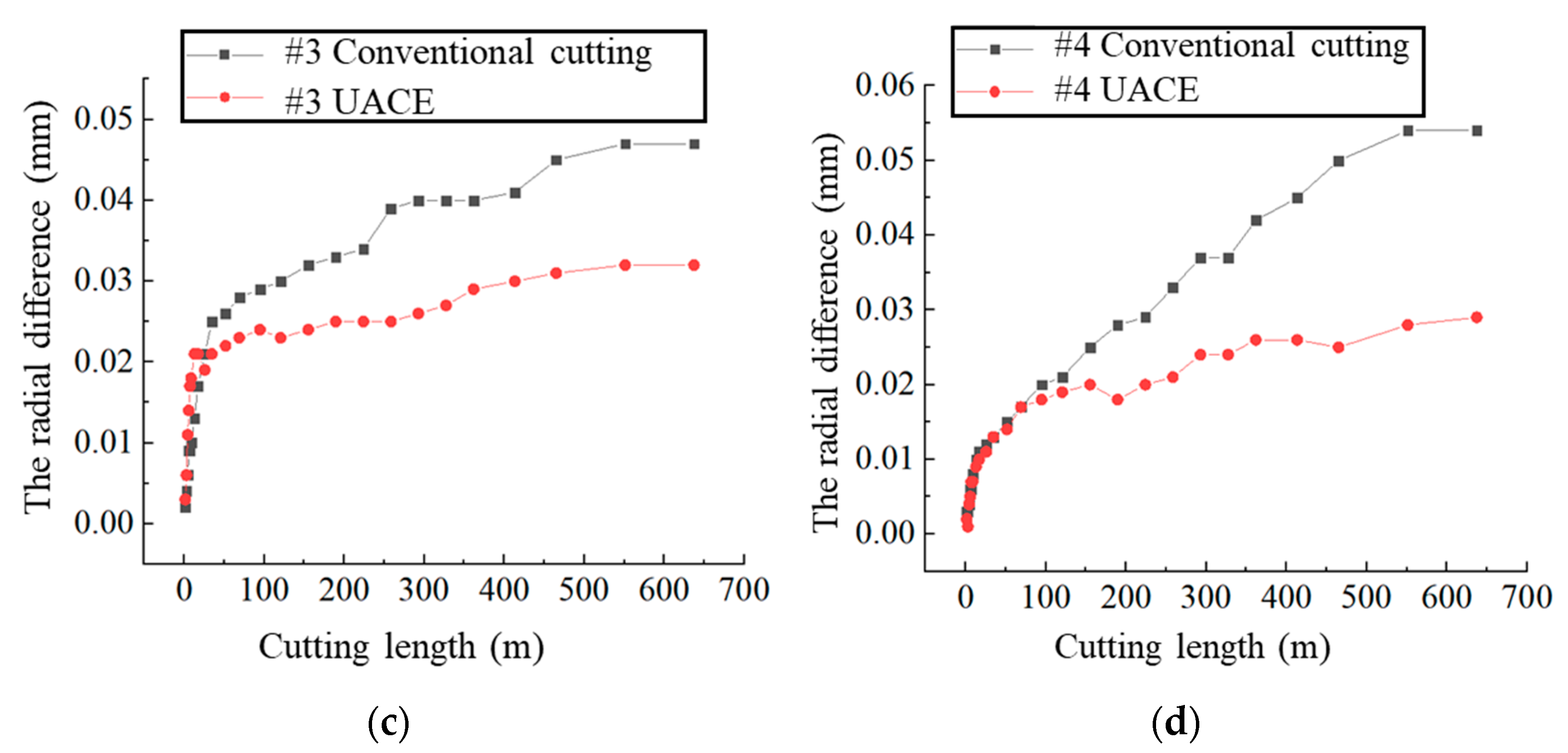

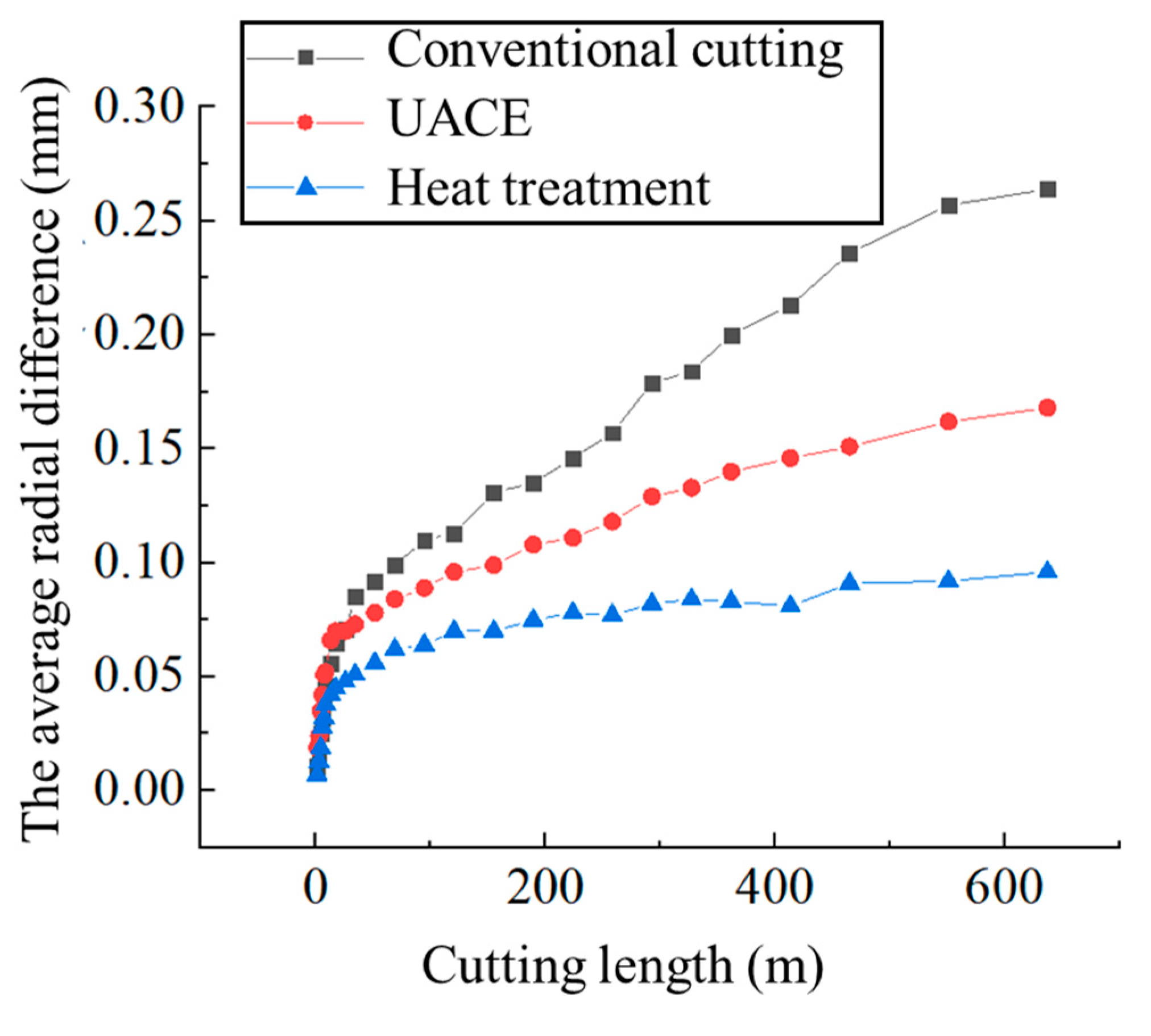

- There was a rapid wear period and a stable wear period during the tool wear process. In the stable wear period, the radial difference of the disc cutter in UACE was significantly smaller than that in conventional cutting experiments. The ultrasonic vibration could significantly reduce the tool wear of the disc cutter by up to 36% after the same machining time.

- (3)

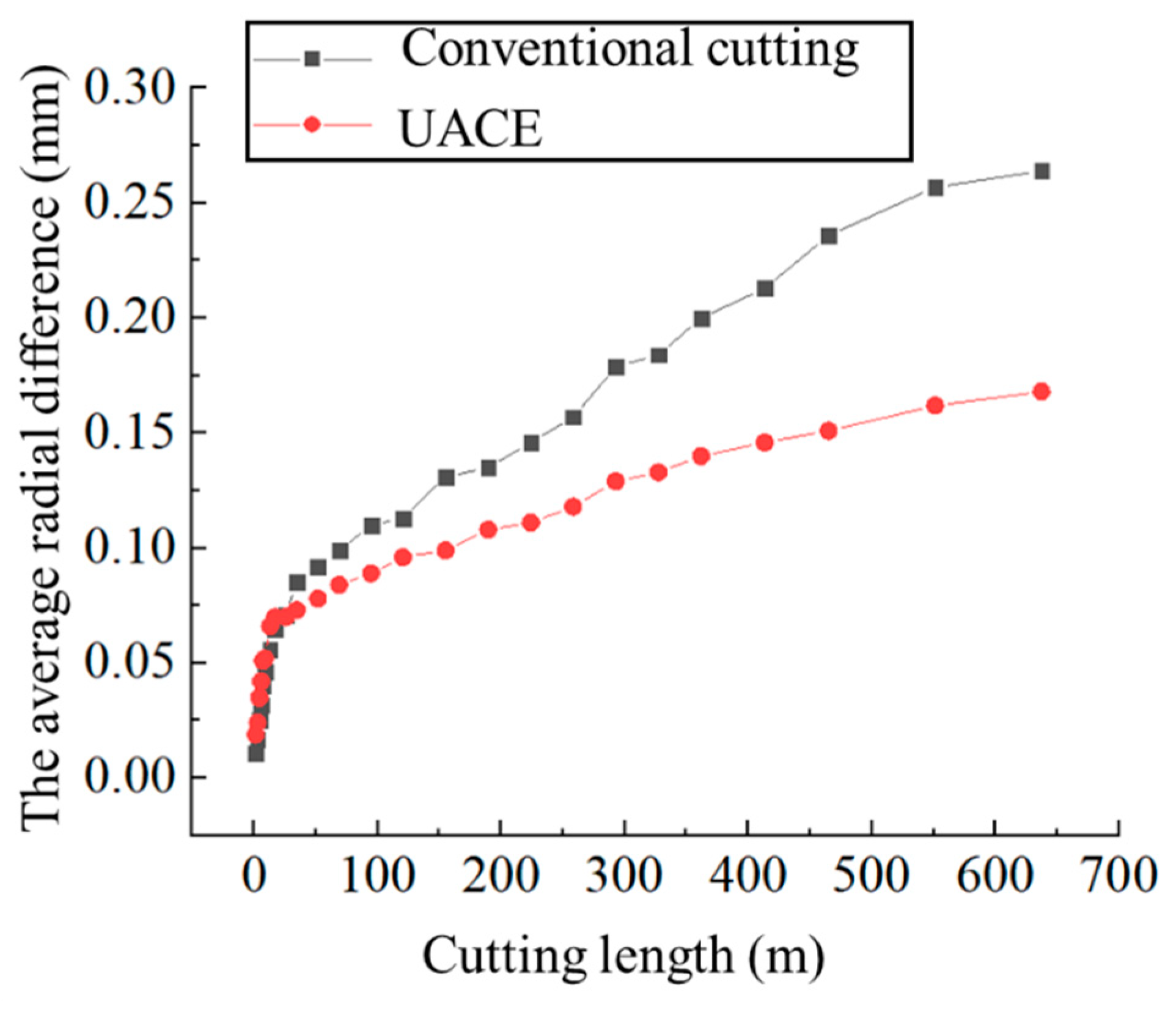

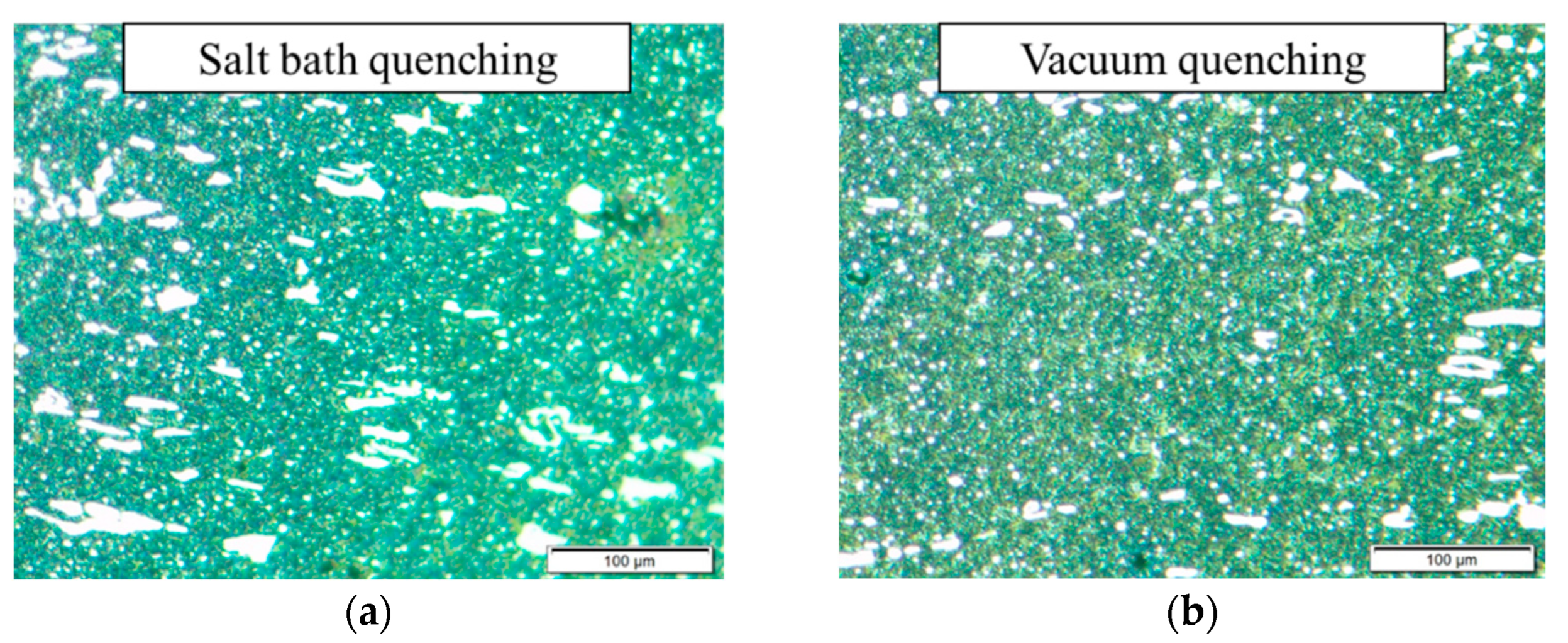

- Vacuum quenching could significantly improve the wear resistance of the disc cutter. By changing the salt bath quenching to vacuum quenching in the heat treatment process, the metallographic grains were refined and their distribution became more uniform. The tool wear of the disc cutter after vacuum quenching treatment in UACE could be reduced up to 64%, compared to conventional cutting experiments if the final value was taken as the reference.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Foo, C.C.; Chai, G.B.; Seah, L.K. Mechanical properties of Nomex material and Nomex honeycomb structure. Compos. Struct. 2007, 80, 588–594. [Google Scholar] [CrossRef]

- Roy, R.; Nguyen, K.H.; Park, Y.B.; Kweon, J.H.; Choi, J.H. Testing and modeling of Nomex™ honeycomb sandwich Panels with bolt insert. Compos. Part B Eng. 2014, 56, 762–769. [Google Scholar] [CrossRef]

- Zhou, H.; Xu, P.; Xie, S.; Feng, Z.; Wang, D. Mechanical performance and energy absorption properties of structures combining two Nomex honeycombs. Compos. Struct. 2018, 185, 524–536. [Google Scholar] [CrossRef]

- Castanie, B.; Bouvet, C.; Ginot, M. Review of composite sandwich structure in aeronautic applications. Compos. Part C Open Access 2020, 1, 100004. [Google Scholar] [CrossRef]

- Ahmad, S.; Zhang, J.; Feng, P.; Yu, D.; Wu, Z.; Ke, M. Processing technologies for Nomex honeycomb composites (NHCs): A critical review. Compos. Struct. 2020, 250, 112545. [Google Scholar] [CrossRef]

- Han, S.-W.; Kim, H.-J. Experimental Study on Shape Machining Characteristics of Composite Honeycomb Core. J. Korean Soc. Manuf. Process Eng. 2014, 13, 28–35. [Google Scholar] [CrossRef]

- Jaafar, M.; Atlati, S.; Makich, H.; Nouari, M.; Moufki, A.; Julliere, B. A 3D FE Modeling of Machining Process of Nomex® Honeycomb Core: Influence of the Cell Structure Behaviour and Specific Tool Geometry. Procedia CIRP 2017, 58, 505–510. [Google Scholar] [CrossRef]

- Singh, R.P.; Singhal, S. Rotary Ultrasonic Machining: A Review. Mater. Manuf. Process. 2016, 31, 1795–1824. [Google Scholar] [CrossRef]

- Yang, Z.; Zhu, L.; Zhang, G.; Ni, C.; Lin, B. Review of ultrasonic vibration-assisted machining in advanced materials. Int. J. Mach. Tools Manuf. 2020, 156, 103594. [Google Scholar] [CrossRef]

- Xu, W.-X.; Zhang, L.-C. Ultrasonic vibration-assisted machining: Principle, design and application. Adv. Manuf. 2015, 3, 173–192. [Google Scholar] [CrossRef]

- Ning, F.D.; Cong, W.L.; Pei, Z.J.; Treadwell, C. Rotary ultrasonic machining of CFRP: A comparison with grinding. Ultrasonics 2016, 66, 125–132. [Google Scholar] [CrossRef]

- Zha, H.; Feng, P.; Zhang, J.; Yu, D.; Wu, Z. Material removal mechanism in rotary ultrasonic machining of high-volume fraction SiCp/Al composites. Int. J. Adv. Manuf. Technol. 2018, 97, 2099–2109. [Google Scholar] [CrossRef]

- Xu, J.; Feng, P.; Feng, F.; Zha, H.; Liang, G. Subsurface damage and burr improvements of aramid fiber reinforced plastics by using longitudinal–torsional ultrasonic vibration milling. J. Mater. Process. Technol. 2021, 297, 117265. [Google Scholar] [CrossRef]

- Feng, P.; Wang, J.; Zhang, J.; Zheng, J. Drilling induced tearing defects in rotary ultrasonic machining of C/SiC composites. Ceram. Int. 2017, 43, 791–799. [Google Scholar] [CrossRef]

- Wang, Y.; Kang, R.; Dong, Z.; Wang, X.; Huo, D.; Zhang, X. A Novel Method of Blade-Inclined Ultrasonic Cutting Nomex Honeycomb Core With Straight Blade. J. Manuf. Sci. Eng. 2021, 143, 041012. [Google Scholar] [CrossRef]

- Nath, C.; Rahman, M. Effect of machining parameters in ultrasonic vibration cutting. Int. J. Mach. Tools Manuf. 2008, 48, 965–974. [Google Scholar] [CrossRef]

- Ke, M.; Jianfu, Z.; Pingfa, F.; Zhijun, W.; Dingwen, Y.; Ahmad, S. Design and implementation of a mini ultrasonic cutting system for nomex honeycomb composites. In Proceedings of the 2019 16th International Bhurban Conference on Applied Sciences and Technology (IBCAST), Islamabad, Pakistan, 8–12 January 2019; pp. 148–152. [Google Scholar]

- Xia, Y.; Zhang, J.; Wu, Z.; Feng, P.; Yu, D. Study on the design of cutting disc in ultrasonic-assisted machining of honeycomb composites. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2019; p. 012032. [Google Scholar]

- Ahmad, S.; Zhang, J.; Feng, P.; Yu, D.; Wu, Z.; Ke, M. Research on design and FE simulations of novel ultrasonic circular saw blade (UCSB) cutting tools for rotary ultrasonic machining of nomex honeycomb composites. In Proceedings of the 2019 16th International Bhurban Conference on Applied Sciences and Technology (IBCAST), Islamabad, Pakistan, 8–12 January 2019; pp. 113–119. [Google Scholar]

- Ahmad, S.; Zhang, J.; Feng, P.; Yu, D.; Wu, Z. Experimental study on rotary ultrasonic machining (RUM) characteristics of Nomex honeycomb composites (NHCs) by circular knife cutting tools. J. Manuf. Process. 2020, 58, 524–535. [Google Scholar] [CrossRef]

- Cao, W.; Zha, J.; Chen, Y. Cutting Force Prediction and Experiment Verification of Paper Honeycomb Materials by Ultrasonic Vibration-Assisted Machining. Appl. Sci. 2020, 10, 4676. [Google Scholar] [CrossRef]

- Jaafar, M.; Nouari, M.; Makich, H.; Moufki, A. 3D numerical modeling and experimental validation of machining Nomex® honeycomb materials. Int. J. Adv. Manuf. Technol. 2021, 115, 2853–2872. [Google Scholar] [CrossRef]

- Jaafar, M.; Makich, H.; Nouari, M. A new criterion to evaluate the machined surface quality of the Nomex® honeycomb materials. J. Manuf. Process. 2021, 69, 567–582. [Google Scholar] [CrossRef]

- Gill, D.D.; Yip-Hoi, D.M.; Meaker, M.; Boni, T.; Eggeman, E.L.; Brennan, A.M.; Anderson, A. Studying the mechanisms of high rates of tool wear in the machining of aramid honeycomb composites. In Proceedings of the International Manufacturing Science and Engineering Conference, Los Angeles, CA, USA, 4–8 June 2017; p. V002T003A002. [Google Scholar]

- Luthfiyah, S.; Faridh, A.; Soegijono, B. The Effect of Vacuum Quenching on Corrosion and Hardness of the Surface of SKD61 Steel. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2019; p. 012033. [Google Scholar]

- Akao, T.; Sakurai, Y.; Onda, T.; Uehara, K.; Chen, Z.-C. Surface Modification of Cold-working Die Steel by Electron Beam Irradiation—Formation of Cemented Carbide Composite Layer. Procedia Eng. 2014, 81, 1939–1944. [Google Scholar] [CrossRef]

| Preheating | Quenching | Tempering | |||

|---|---|---|---|---|---|

| Temperature /°C | Heating Coefficient /(s/mm) | Temperature /°C | Heating Coefficient /(s/mm) | Cooling Medium | Temperature /°C |

| 850 | 24 | 1180~1200 | 12~15 | 500~600 °C salt bath | 550 °C × 1 h, 3 times |

| 500~600 °C vacuum | |||||

| Conventional Cutting Experiments | Ultrasonic Assisted Cutting Experiments | |

|---|---|---|

| The size of workpiece | 205 × 105 × 100 mm | |

| The material of the disc cutter | high speed steel (W6Mo5Cr4V2) | |

| The size of the disc cutter | wedge angle: 14° outer diameter: 27 mm thickness: 0.9 mm | |

| Cutting parameters | spindle speed: 3000 r/min feed rate: 5000 mm/min cutting width: 5 mm cutting depth: 2 mm | |

| Ultrasonic parameters | / | frequency: 19,825 Hz amplitude: 20 μm |

| Observing Sequence | Cutting Layer | Cutting Length /m | Observing Sequence | Cutting Layer | Cutting Length /m |

|---|---|---|---|---|---|

| 1 | 0.33 | 1.43 | 14 | 28 | 120.54 |

| 2 | 0.67 | 2.87 | 15 | 36 | 154.98 |

| 3 | 1 | 4.31 | 16 | 44 | 189.42 |

| 4 | 1.33 | 5.74 | 17 | 52 | 223.86 |

| 5 | 1.67 | 7.17 | 18 | 60 | 258.30 |

| 6 | 2 | 8.61 | 19 | 68 | 292.74 |

| 7 | 3 | 12.92 | 20 | 76 | 327.18 |

| 8 | 4 | 17.22 | 21 | 84 | 361.62 |

| 9 | 6 | 25.83 | 22 | 96 | 413.28 |

| 10 | 8 | 34.44 | 23 | 108 | 464.94 |

| 11 | 12 | 51.66 | 24 | 128 | 551.04 |

| 12 | 16 | 68.88 | 25 | 148 | 637.14 |

| 13 | 22 | 94.71 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zha, H.; Shang, W.; Xu, J.; Feng, F.; Kong, H.; Jiang, E.; Ma, Y.; Xu, C.; Feng, P. Tool Wear Characteristics and Strengthening Method of the Disc Cutter for Nomex Honeycomb Composites Machining with Ultrasonic Assistance. Technologies 2022, 10, 132. https://doi.org/10.3390/technologies10060132

Zha H, Shang W, Xu J, Feng F, Kong H, Jiang E, Ma Y, Xu C, Feng P. Tool Wear Characteristics and Strengthening Method of the Disc Cutter for Nomex Honeycomb Composites Machining with Ultrasonic Assistance. Technologies. 2022; 10(6):132. https://doi.org/10.3390/technologies10060132

Chicago/Turabian StyleZha, Huiting, Wenjun Shang, Jie Xu, Feng Feng, Hongyun Kong, Enlai Jiang, Yuan Ma, Chao Xu, and Pingfa Feng. 2022. "Tool Wear Characteristics and Strengthening Method of the Disc Cutter for Nomex Honeycomb Composites Machining with Ultrasonic Assistance" Technologies 10, no. 6: 132. https://doi.org/10.3390/technologies10060132

APA StyleZha, H., Shang, W., Xu, J., Feng, F., Kong, H., Jiang, E., Ma, Y., Xu, C., & Feng, P. (2022). Tool Wear Characteristics and Strengthening Method of the Disc Cutter for Nomex Honeycomb Composites Machining with Ultrasonic Assistance. Technologies, 10(6), 132. https://doi.org/10.3390/technologies10060132