Optimization Framework for Early Conceptual Design of Helicopters

Abstract

1. Introduction

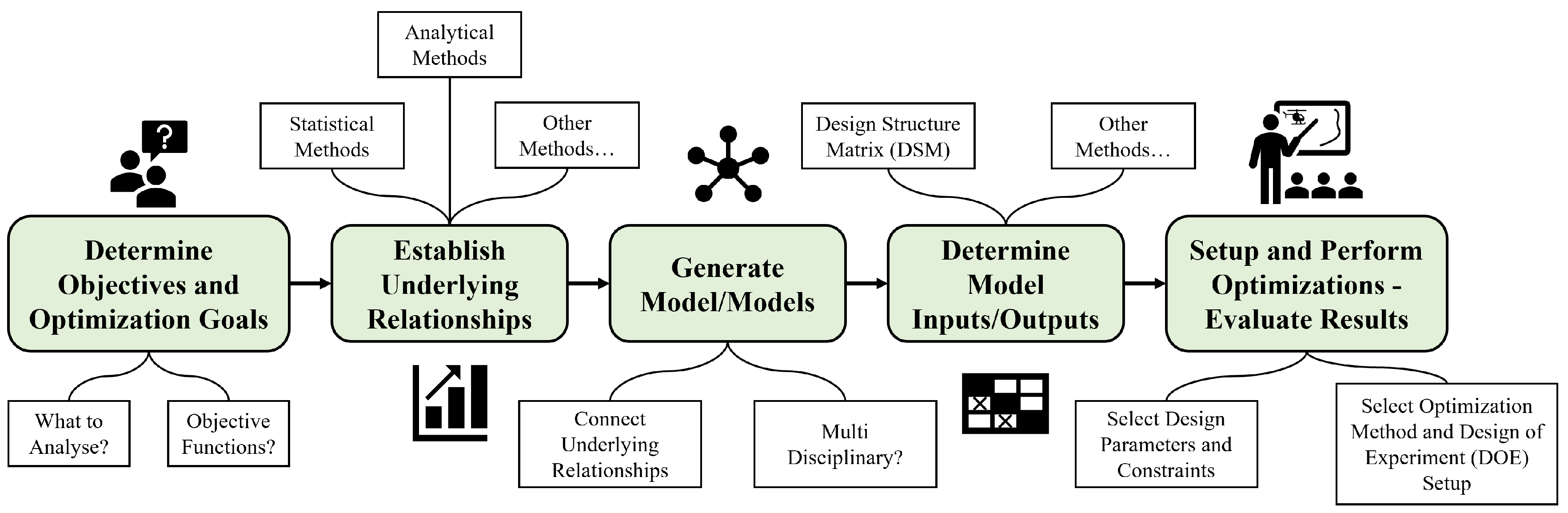

2. Approaches and Design Methodologies

2.1. Helicopter Equations and Relationships

2.2. Statistical Regression

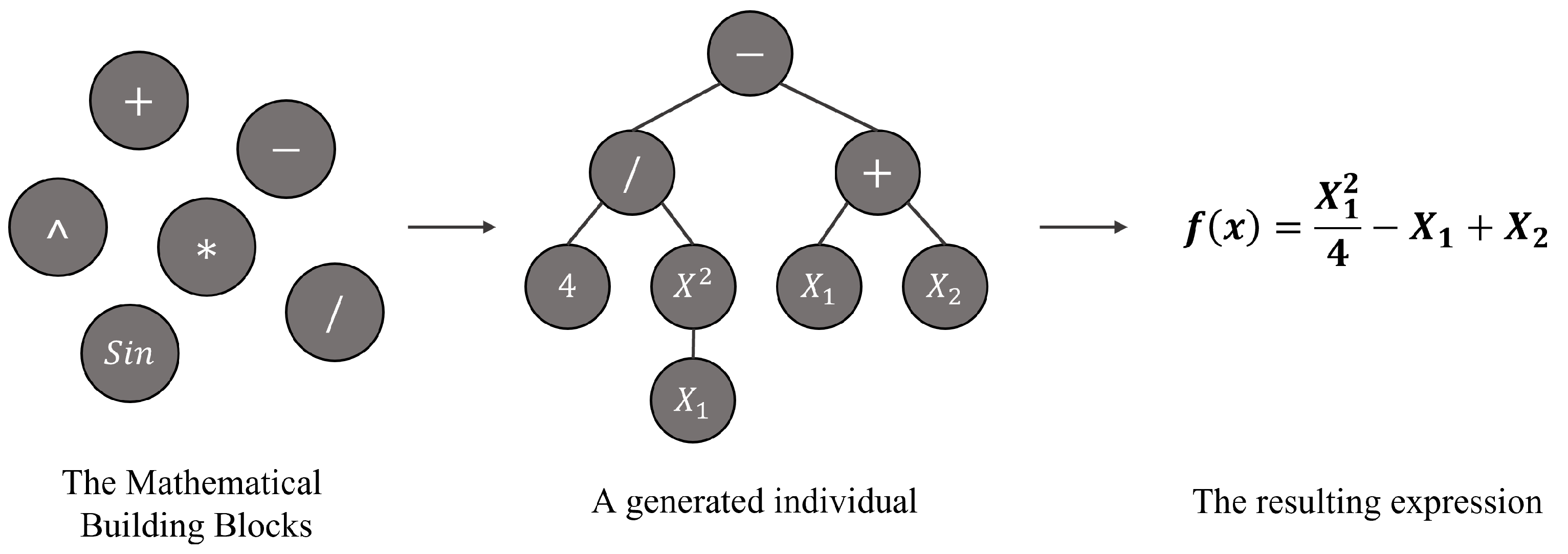

Symbolic Regression

2.3. Optimization

2.4. Conceptual Helicopter Design Initiatives

3. Method

4. Case Study and Implementation

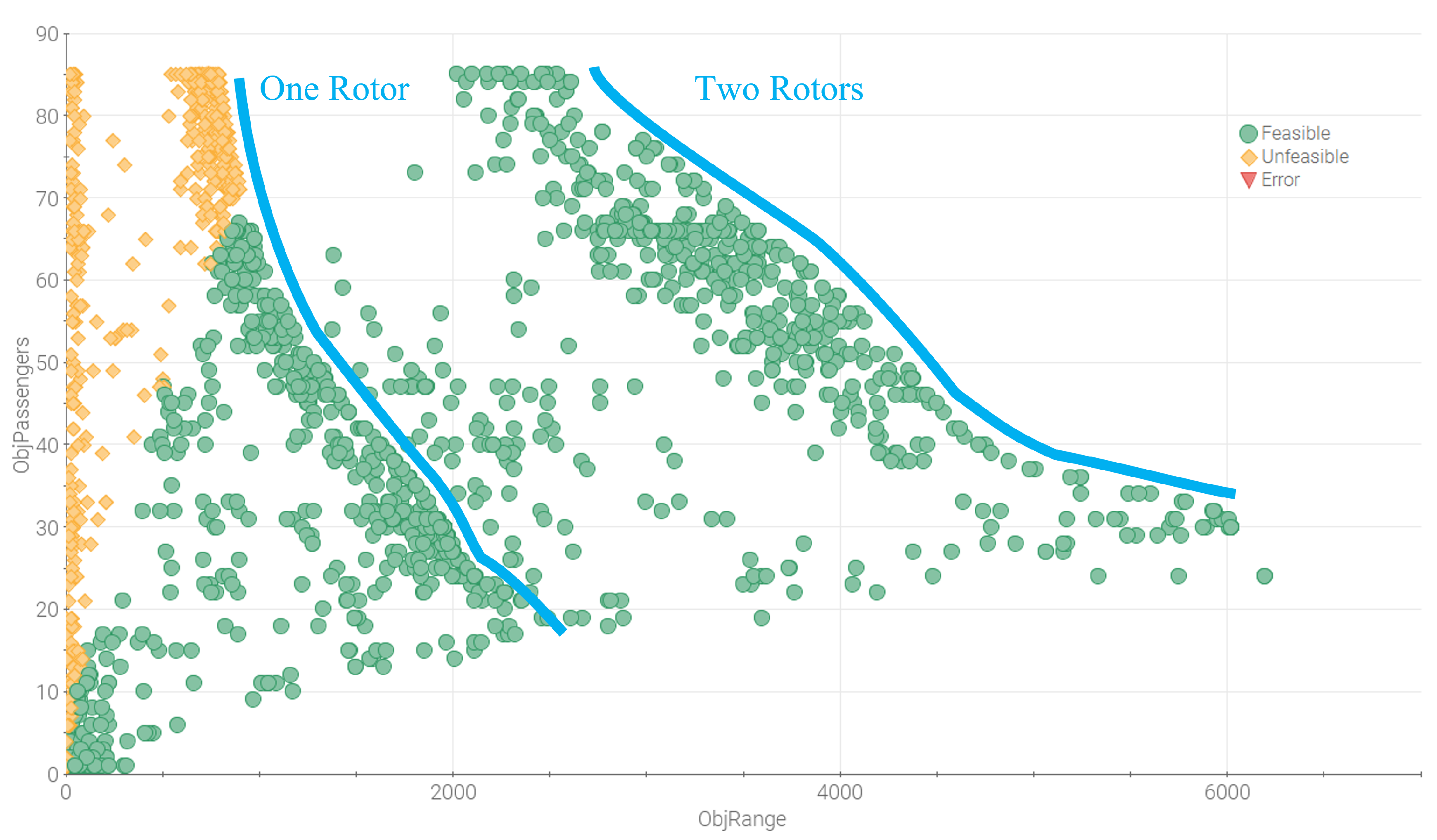

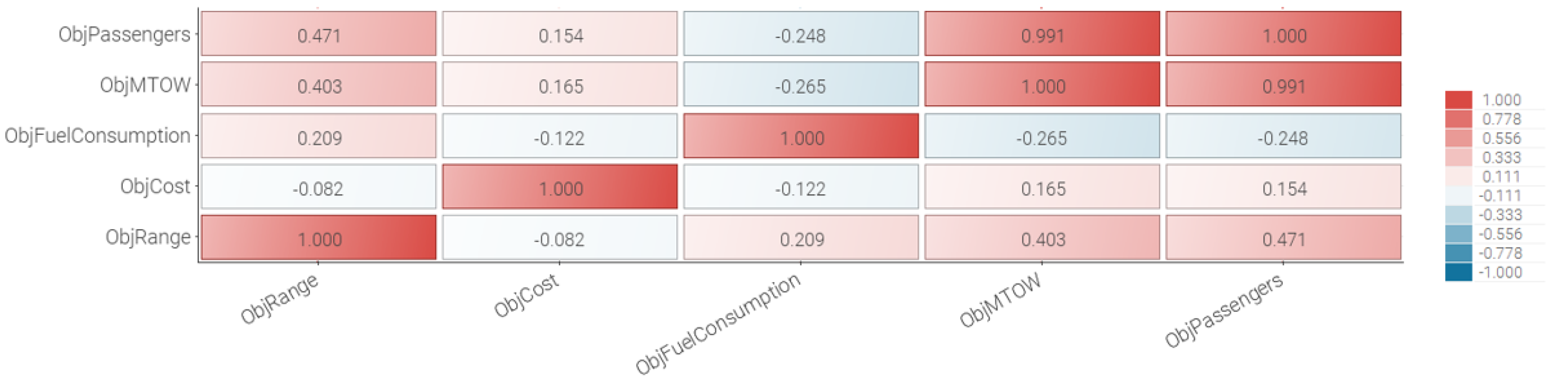

- Maximize range and rescue/passenger capacity.

- Minimize fuel consumption, weight, and cost per hour.

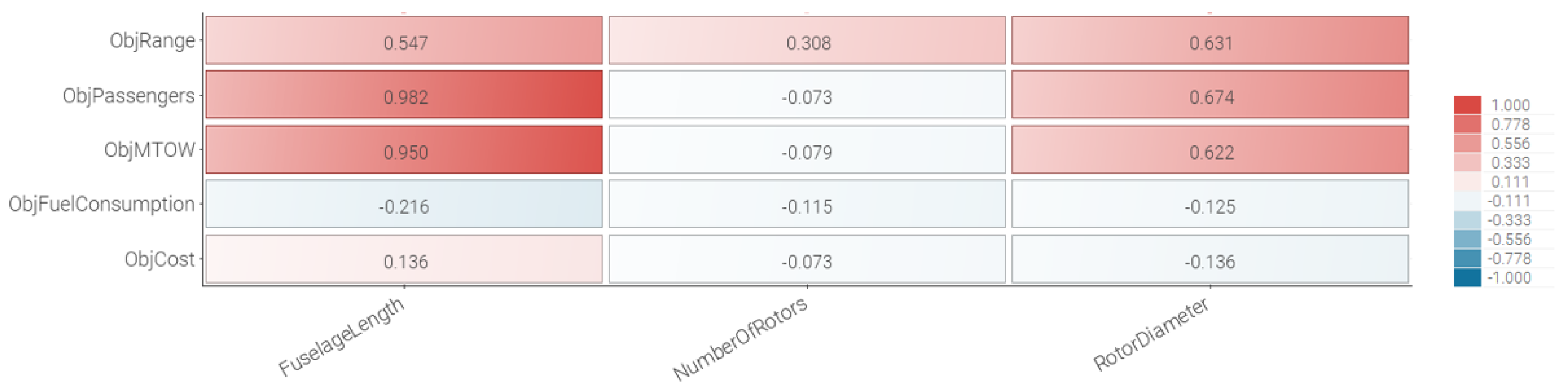

- Fuselage length (≈helicopter size).

- Helicopter rotor diameter.

- Number of rotors.

4.1. Helicopter Statistics and Regressions

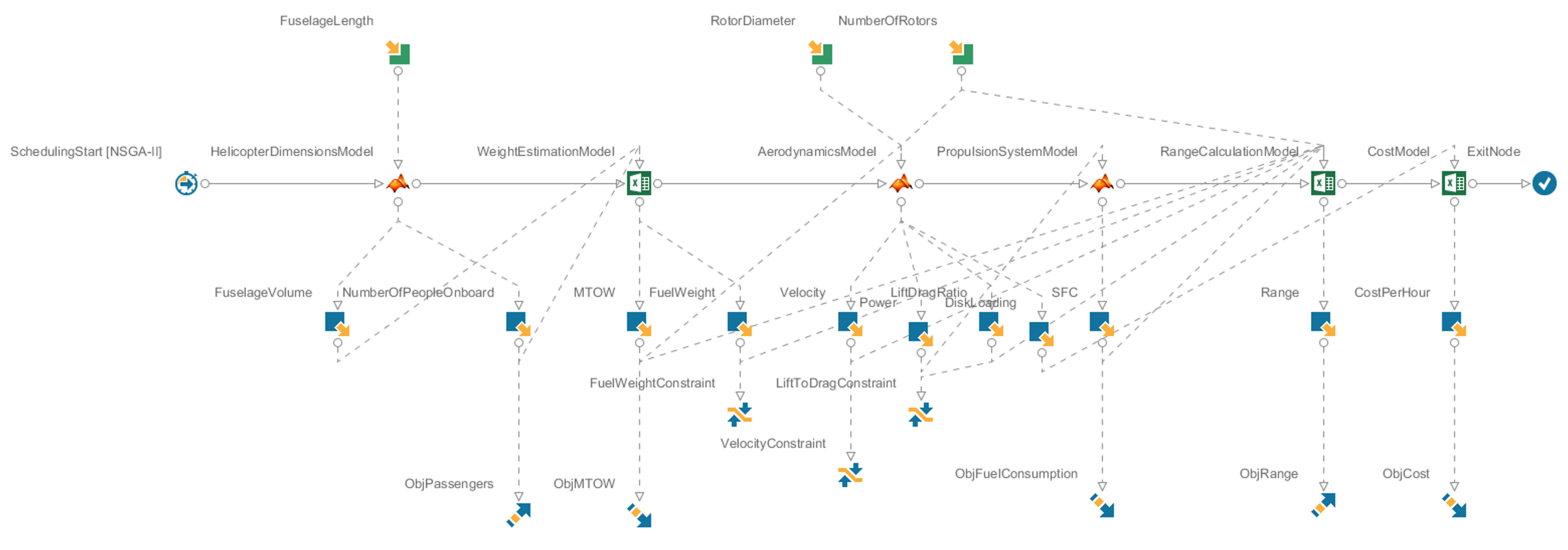

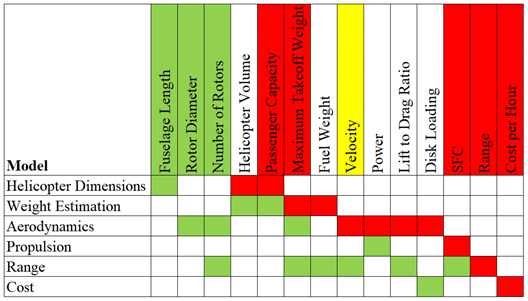

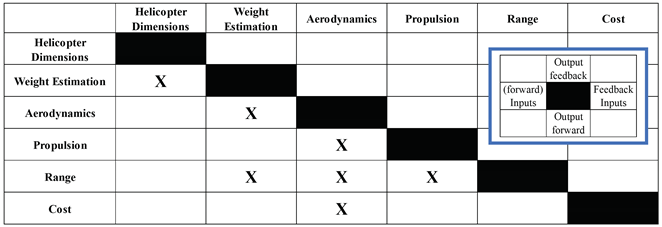

4.2. Optimization Framework

- Helicopter Dimensions Model (Matlab).

- Weight Estimation Model (Excel).

- Aerodynamics Model (Matlab).

- Propulsion Model (Matlab).

- Range Model (Excel).

- Cost Model (Excel).

4.2.1. Helicopter Dimensions Model

4.2.2. Weight Estimation Model

4.2.3. Aerodynamics Model

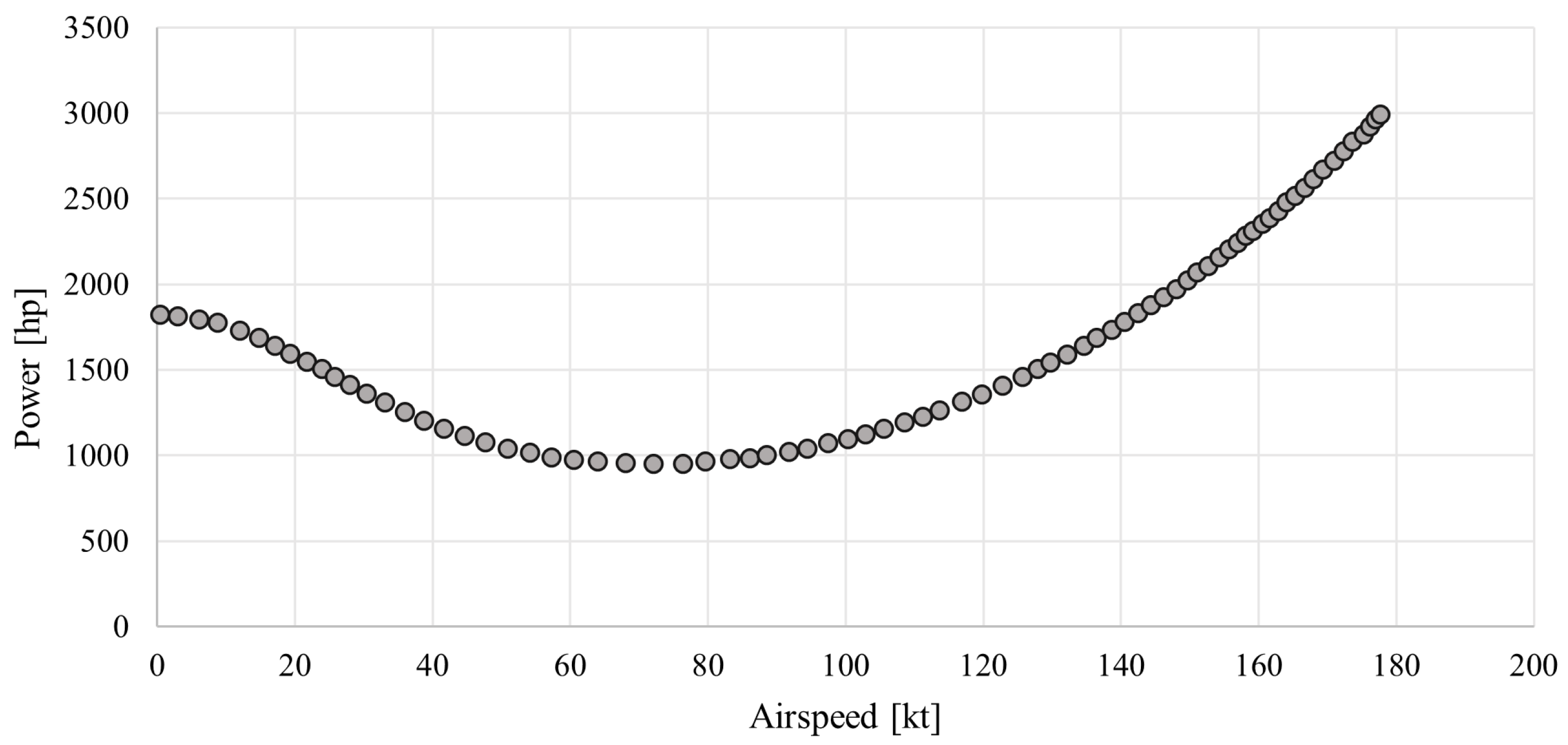

4.2.4. Propulsion, Range, and Cost Models

4.2.5. Implementation

4.2.6. Optimization Setup

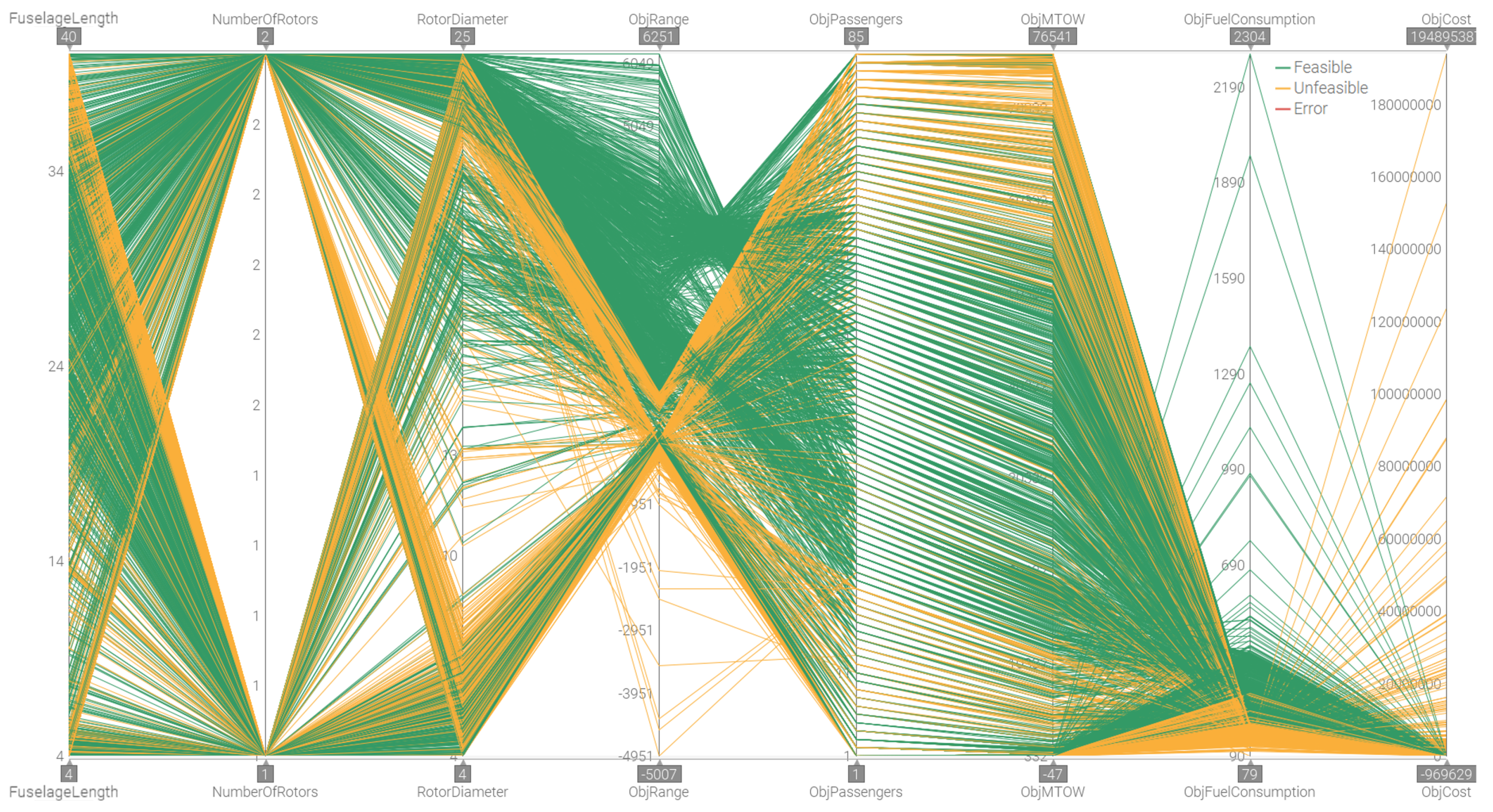

4.3. Results

5. Discussion and Future Work

Outlook

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| CFD | Computational fluid dynamics |

| DOE | Design of experiments |

| DSM | Design structure matrix |

| MDO | Multidisciplinary design optimization |

| MOO | Multiobjective optimization |

| MTOW | Maximum takeoff weight |

| SAR | Search and rescue |

| SFC | Specific fuel consumption |

| VA | Visual analytics |

References

- Khalid, A.; Schrage, D.P. Helicopter Design Cost Minimization using Multidisciplinary Design Optimization. In Proceedings of the American Helicopter Society 63rd Annual Forum, Virginia Beach, VA, USA, 1–3 May 2007; American Helicopter Society: Virginia Beach, VA, USA, 2007. Available online: https://perma.cc/QXE2-BEY7 (accessed on 6 October 2022).

- Zadeh, P.M.; Shirazi, M.A.S. 5—Multidisciplinary Design and Optimization Methods. In Metaheuristic Applications in Structures and Infrastructures; Gandomi, A.H., Yang, X.S., Talatahari, S., Alavi, A.H., Eds.; Elsevier: Oxford, UK, 2013; pp. 103–127. [Google Scholar] [CrossRef]

- Sobieszczanski-Sobieski, J.; Haftka, R. Multidisciplinary aerospace design optimization-Survey of recent developments. In Proceedings of the 34th Aerospace Sciences Meeting and Exhibit, Reno, NV, USA, 15–18 January 1996; American Institute of Aeronautics and Astronautics: Reno, NV, USA, 1996. [Google Scholar] [CrossRef]

- Ali, F.; Tzanidakis, K.; Goulos, I.; Pachidis, V.; d’Ippolito, R. Conceptual Design and Optimisation of an Advanced Rotorcraft Powerplant Architecture. In Proceedings of the 41st European Rotorcraft Forum, Munich, Germany, 1–4 September 2015; The European Rotorcraft Forum: Munich, Germany, 2015. Available online: https://perma.cc/HNQ5-27QN (accessed on 6 October 2022).

- Linares, C.; Lawson, C.P.; Smith, H. Multidisciplinary Optimisation Framework for Minimum Rotorcraft Fuel and Air Pollutants at Mission Level. Aeronaut. J. 2013, 117, 749–767. [Google Scholar] [CrossRef][Green Version]

- Wang, L.; Diskin, B.; Biedron, R.; Nielsen, E.; Sonneville, V.; Bauchau, O. High-Fidelity Multidisciplinary Design Optimization Methodology with Application to Rotor Blades. J. Am. Helicopter Soc. 2019, 64, 1–11. [Google Scholar] [CrossRef]

- Kee, S.G. Guide for Conceptual Helicopter Design. Master’s Thesis, Naval Postgraduate School, Monterey, CA, USA, 1983. Available online: https://apps.dtic.mil/sti/citations/ADA128974 (accessed on 6 October 2022).

- Dalin, V.N. Helicopter Design; U.S. Army Foreign Science and Technology Center: Springfield, VA, USA, 1972; Available online: https://apps.dtic.mil/sti/citations/AD0748751 (accessed on 6 October 2022).

- Joy, D.P.; Simonds, R.M. Transport Helicopter Design Analysis Methods; Technical Report 473.6; Transport Helicopter Study Group: Arlington, VA, USA, 1955; Available online: https://apps.dtic.mil/sti/citations/AD0086189 (accessed on 6 October 2022).

- Mil’, M.L.; Nekrasov, A.V.; Braverman, A.S.; Grodko, L.N.; Leykand, M.A. Helicopters Calculation and Design; Technical Translation NASA TT F-494; National Aeronautics and Space Administration: Springfield, VA, USA, 1967. Available online: https://perma.cc/7ARA-M42T (accessed on 6 October 2022).

- Raymer, D.P. Aircraft Design: A Conceptual Approach, 6th ed.; American Institute of Aeronautics and Astronautics, Inc.: Reston, VA, USA, 2018. [Google Scholar] [CrossRef]

- ESTECO: modeFRONTIER. 2022. Available online: https://engineering.esteco.com/modefrontier/ (accessed on 6 October 2022).

- Spakovszky, Z.S. 13.3 Aircraft Range: The Breguet Range Equation. In Thermodynamics and Propulsion; Spakovszky, Z.S., Ed.; Massachusetts Institute of Technology: Cambridge, MA, USA, 2008; Available online: https://perma.cc/FGD7-L35M (accessed on 6 October 2022).

- Lee, J.J.; Lukachko, S.P.; Waitz, I.A.; Schafer, A. Historical and Future Trends in Aircraft Performance, Cost, and Emissions. Annu. Rev. Energy Environ. 2001, 26, 167–200. [Google Scholar] [CrossRef]

- Yang, K.; Han, D.; Shi, Q. Study on the Lift and Propulsive Force Shares to Improve the Flight Performance of a Compound Helicopter. Chin. J. Aeronaut. 2022, 35, 365–375. [Google Scholar] [CrossRef]

- Leishman, J.G. Principles of Helicopter Aerodynamics, 2nd ed.; Cambridge University Press: Cambridge, UK, 2006; Available online: https://www.cambridge.org/se/academic/subjects/engineering/aerospace-engineering/principles-helicopter-aerodynamics-2nd-edition-1?format=HB&isbn=9781107013353 (accessed on 6 October 2022).

- Frost, J. Statistics by Jim. Curve Fitting Using Linear and Nonlinear Regression. 2022. Available online: https://perma.cc/44Z5-4FXC (accessed on 6 October 2022).

- Frost, J. Statistics by Jim. How to Interpret R-squared in Regression Analysis. 2022. Available online: https://perma.cc/AU3A-H3DQ (accessed on 6 October 2022).

- Freedman, D. Statistical Models: Theory and Practice; Cambridge University Press: Cambridge, UK, 2005. [Google Scholar] [CrossRef]

- Ford, C. Interpreting Log Transformations in a Linear Model; University of Virginia Library: Charlottesville, VA, USA, 2018; Available online: https://perma.cc/T7AK-Q6AJ (accessed on 6 October 2022).

- Ruggiero, R. Symbolic Regression: The Forgotten Machine Learning Method. Towards Data Science. 2020. Available online: https://perma.cc/7UM6-Q3D3 (accessed on 6 October 2022).

- Rothlauf, F. Optimization Methods; Springer: Berlin/Heidelberg, Germany, 2011; pp. 45–102. [Google Scholar] [CrossRef]

- Miettinen, K. Nonlinear Multiobjective Optimization; International Series in Operations Research & Management Science; Springer Science + Business Media, LLC: New York, NY, USA, 2004. [Google Scholar] [CrossRef]

- Watson, M.D.; Mesmer, B.L.; Farrington, P.A. Engineering Elegant Systems: Theory of Systems Engineering. National Aeronautics and Space Administration. NASA/TP-20205003644. 2020. Available online: https://perma.cc/R78L-RSWF (accessed on 6 October 2022).

- Wang, G.; Shan, S. Review of Metamodeling Techniques in Support of Engineering Design Optimization. J. Mech. Des. 2007, 129, 370–380. [Google Scholar] [CrossRef]

- Federal Aviation Administration. Helicopter Flying Handbook, FAA-H-8083-21B; U.S. Department of Transportation: Oklahoma City, OK, USA, 2019. Available online: https://www.faa.gov/regulations_policies/handbooks_manuals/aviation/helicopter_flying_handbook (accessed on 6 October 2022).

- Krenik, A.; Weiand, P. Aspects on Conceptual and Preliminary Helicopter Design. In Proceedings of the Deutscher Luft- und Raumfahrtkongress, Braunschweig, Germany, 13–15 September 2016; pp. 1–12. Available online: https://nbn-resolving.org/urn:nbn:de:101:1-201609303730 (accessed on 6 October 2022).

- Patterson, F.; Lamour, R.; Schrage, D. A Conceptual Design Methodology for Rotorcraft Maneuverability. In Proceedings of the 39th European Rotorcraft Forum, Moscow, Russia, 3–6 September 2013; pp. 1–11. Available online: https://hdl.handle.net/20.500.11881/617 (accessed on 6 October 2022).

- Geyer, P. Component-Oriented Decomposition for Multidisciplinary Design Optimization in Building Design. Adv. Eng. Inform. 2009, 23, 12–31. [Google Scholar] [CrossRef]

- Knöös Franzén, L. S2TEP Material. Available online: https://gitlab.liu.se/ludfr93/s2tep-ontologies-and-materials (accessed on 6 October 2022).

- MathWorks. GPTIPS—Free Open-Source Genetic Programming and Symbolic Data Mining MATLAB Toolbox. Available online: https://sites.google.com/site/gptips4matlab (accessed on 6 October 2022).

- Scaled Agile, Inc. Set-Based Design. 2021. Available online: https://perma.cc/6PGM-8N9J (accessed on 6 October 2022).

- Jändel, M.; Bivall, P.; Hammar, P.; Johansson, R.; Kamrani, F.; Quas, M.J. Visual Analytics: Perspectives on the Field of Interactive Visualization; Swedish Defence Research Agency (FOI): Stockholm, Sweden, 2016. Available online: https://perma.cc/C3QE-8ZCJ (accessed on 6 October 2022).

| Specification | Value | Unit |

|---|---|---|

| Helicopter Type | AW139 | |

| No. Crew | 2 | - |

| Passenger Capacity | 15 | - |

| No. People Onboard | 17 | - |

| Length | 16.66 | m |

| Width | 2.26 | m |

| Height | 4.98 | m |

| Helicopter Volume | 187.5 | m3 |

| Empty Weight | 3621.93 | kg |

| Max Takeoff Weight | 6400 | kg |

| Fuel Capacity | 1568 | l |

| SFC | 298 | g/(kWh) |

| No. Engines | 2 | - |

| Power (one engine) | 1142 | kW |

| Total Power | 2284 | kW |

| No. Blades | 5 | - |

| Main Rotor Diameter | 13.8 | m |

| Main Rotor Area | 149.56 | m2 |

| Total Rotor Area | 149.56 | m2 |

| No. Rotors | 1 | - |

| Disk Loading | 42.79 | kg/m2 |

| Cruise Speed | 306 | km/h |

| Never Exceed Speed | 310 | km/h |

| Range | 1061 | km |

| Endurance | 313 | min |

| Service Ceiling | 6096 | m |

| Rate of Climb | 10.9 | m/s |

| Cost per Hour | 4000 | USD |

| ID | Category | Fuselage Length [m] | Number of Rotors [-] | Rotor Diameter [m] |

|---|---|---|---|---|

| 0 | ULH | 13.678 | 2 | 20.066 |

| 1 | ULH | 39.668 | 1 | 4.835 |

| 2 | ULH | 7.581 | 1 | 13.182 |

| 3 | ULH | 37.910 | 1 | 15.783 |

| 4 | ULH | 12.680 | 1 | 5.864 |

| 5 | ULH | 19.227 | 2 | 21.868 |

| 6 | ULH | 4.470 | 2 | 8.406 |

| 7 | ULH | 28.758 | 1 | 24.122 |

| 8 | ULH | 33.890 | 2 | 12.229 |

| 9 | ULH | 16.208 | 1 | 13.831 |

| 10 | ULH | 35.622 | 2 | 10.291 |

| 11 | ULH | 30.580 | 1 | 19.087 |

| 12 | ULH | 31.198 | 2 | 15.332 |

| 13 | ULH | 27.331 | 2 | 7.275 |

| 14 | ULH | 10.134 | 2 | 6.408 |

| 15 | ULH | 24.421 | 1 | 10.590 |

| 16 | ULH | 23.584 | 1 | 21.315 |

| 17 | ULH | 8.225 | 1 | 17.664 |

| 18 | ULH | 20.228 | 2 | 17.489 |

| 19 | ULH | 18.028 | 2 | 23.204 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Knöös Franzén, L.; Staack, I.; Krus, P.; Amadori, K. Optimization Framework for Early Conceptual Design of Helicopters. Aerospace 2022, 9, 598. https://doi.org/10.3390/aerospace9100598

Knöös Franzén L, Staack I, Krus P, Amadori K. Optimization Framework for Early Conceptual Design of Helicopters. Aerospace. 2022; 9(10):598. https://doi.org/10.3390/aerospace9100598

Chicago/Turabian StyleKnöös Franzén, Ludvig, Ingo Staack, Petter Krus, and Kristian Amadori. 2022. "Optimization Framework for Early Conceptual Design of Helicopters" Aerospace 9, no. 10: 598. https://doi.org/10.3390/aerospace9100598

APA StyleKnöös Franzén, L., Staack, I., Krus, P., & Amadori, K. (2022). Optimization Framework for Early Conceptual Design of Helicopters. Aerospace, 9(10), 598. https://doi.org/10.3390/aerospace9100598