Development of Hollow Cathodes for Space Electric Propulsion at Sitael

Abstract

:1. Introduction

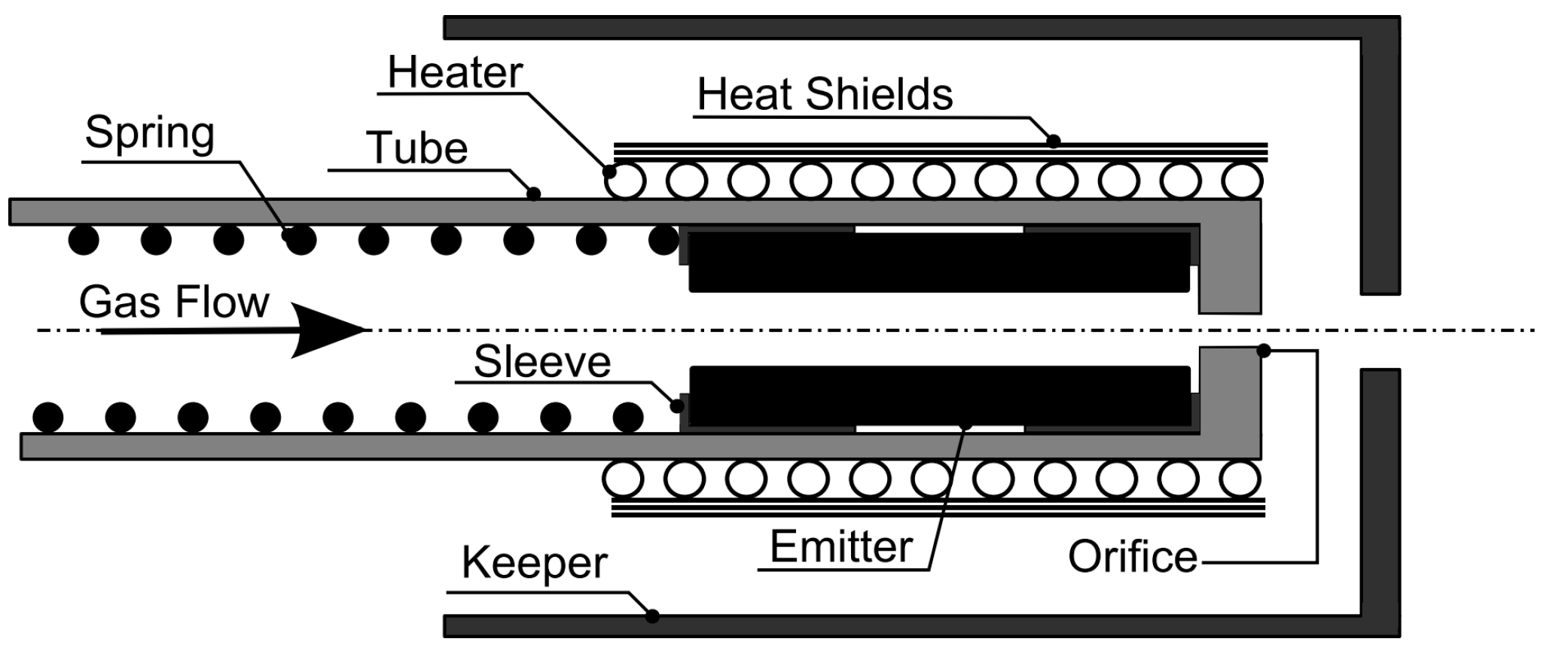

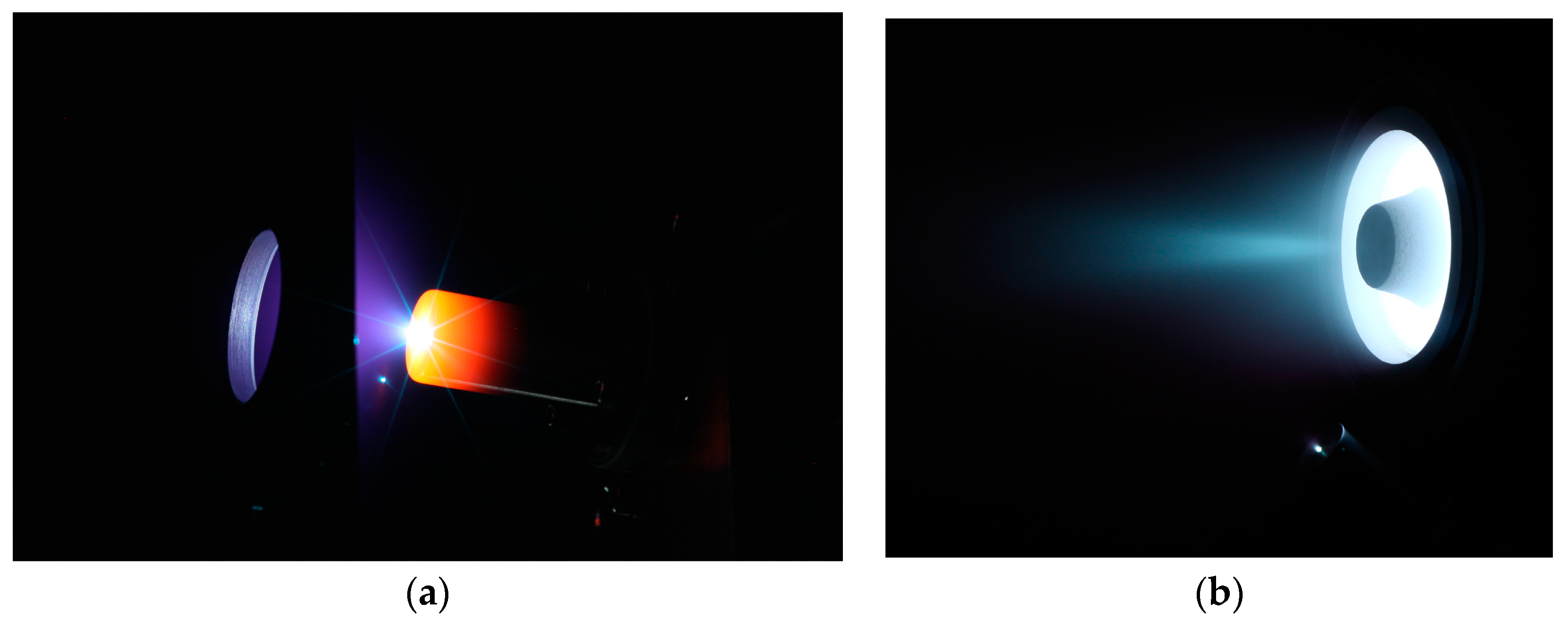

2. Cathode Design

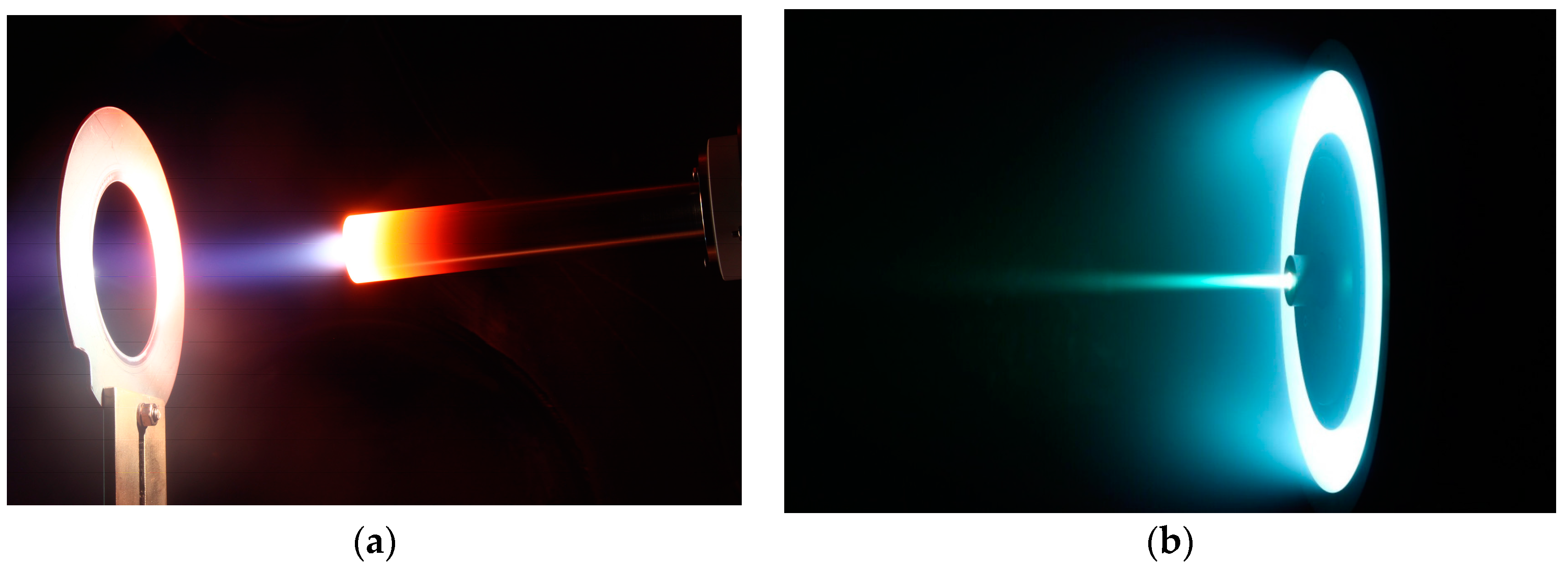

3. Low-Current Hollow Cathodes

3.1. HC1

3.1.1. Experimental Setup

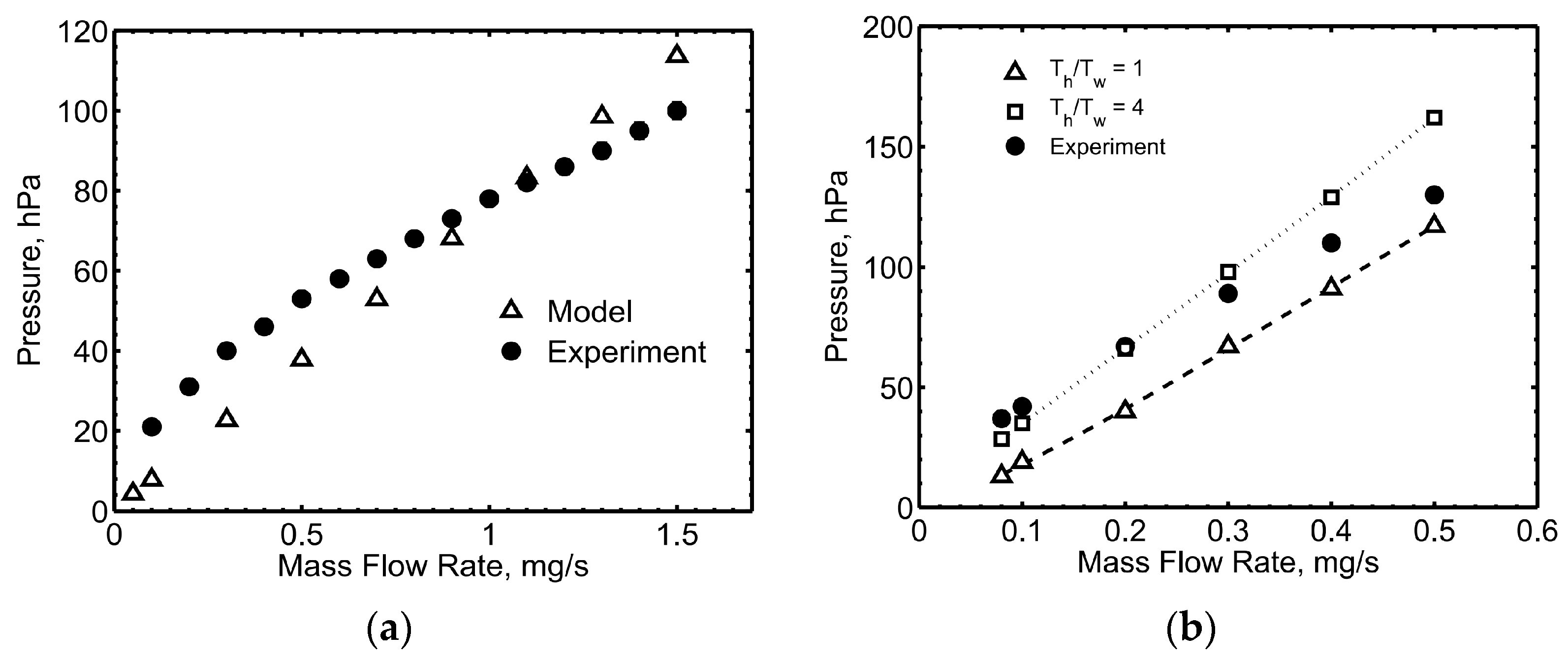

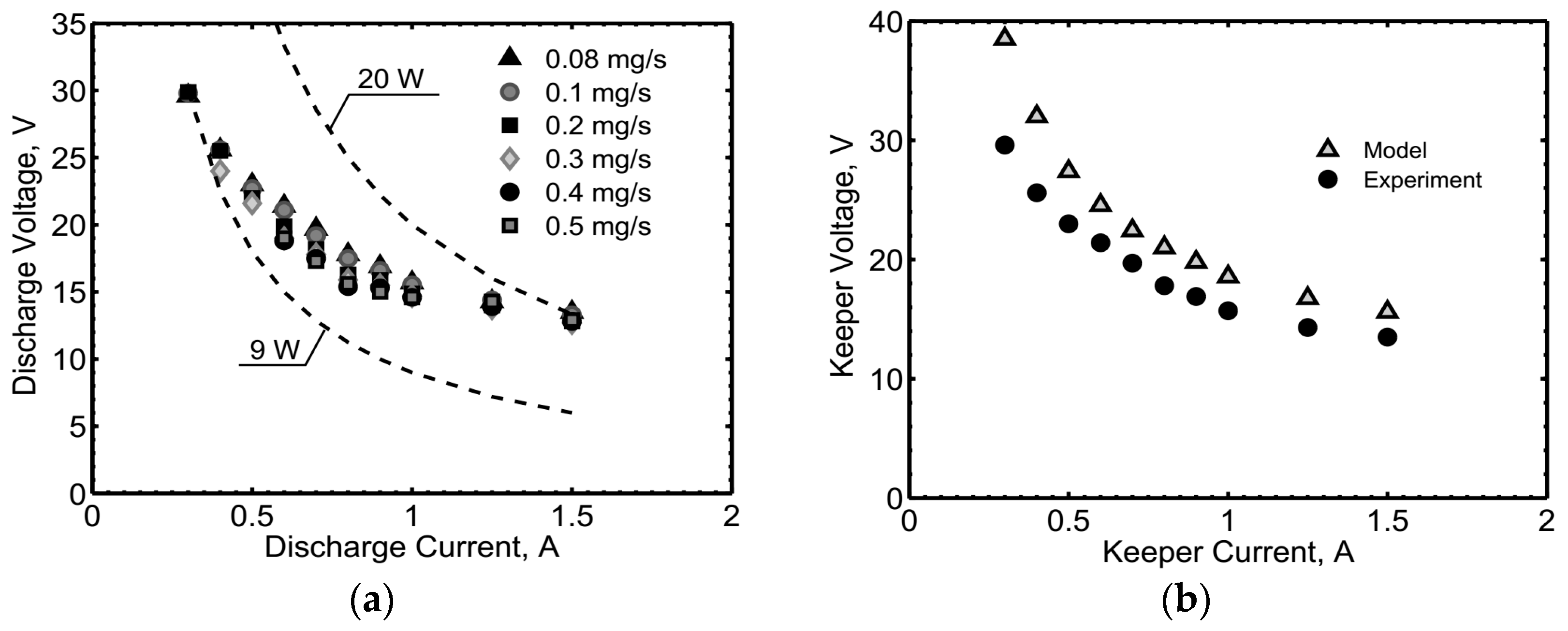

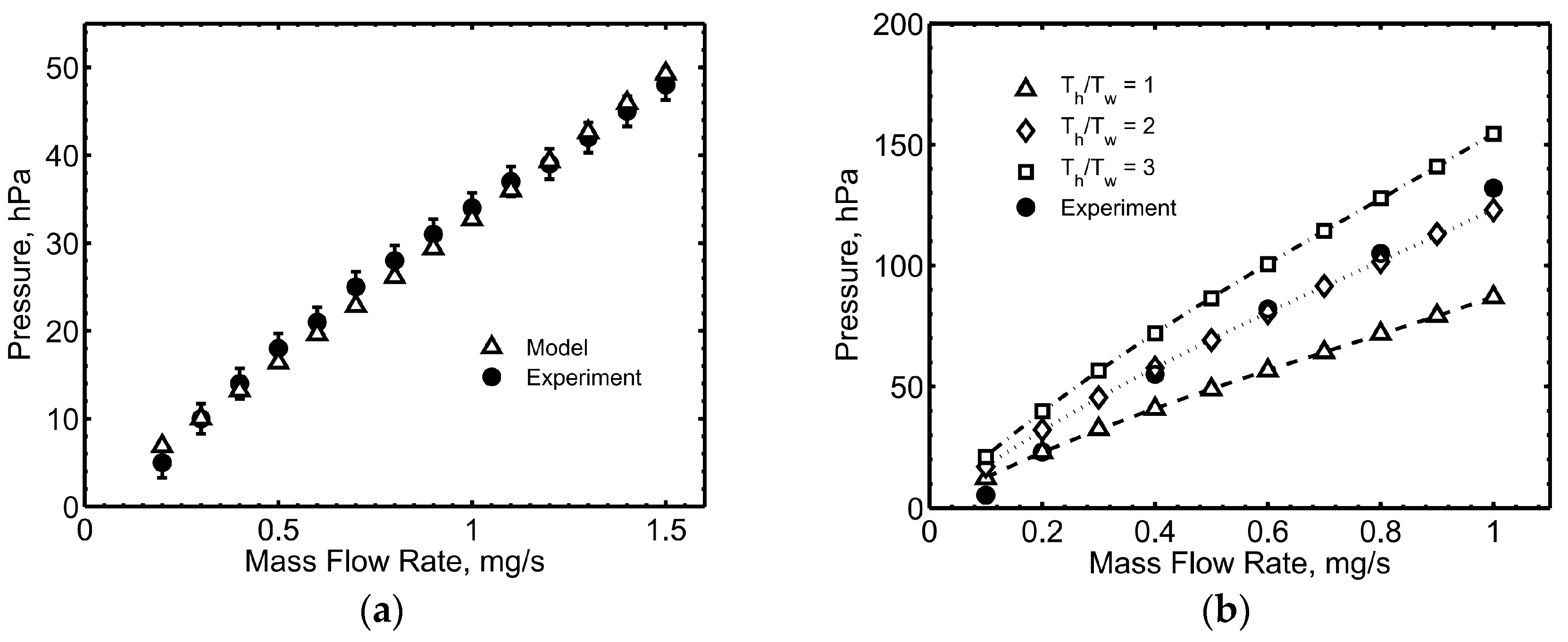

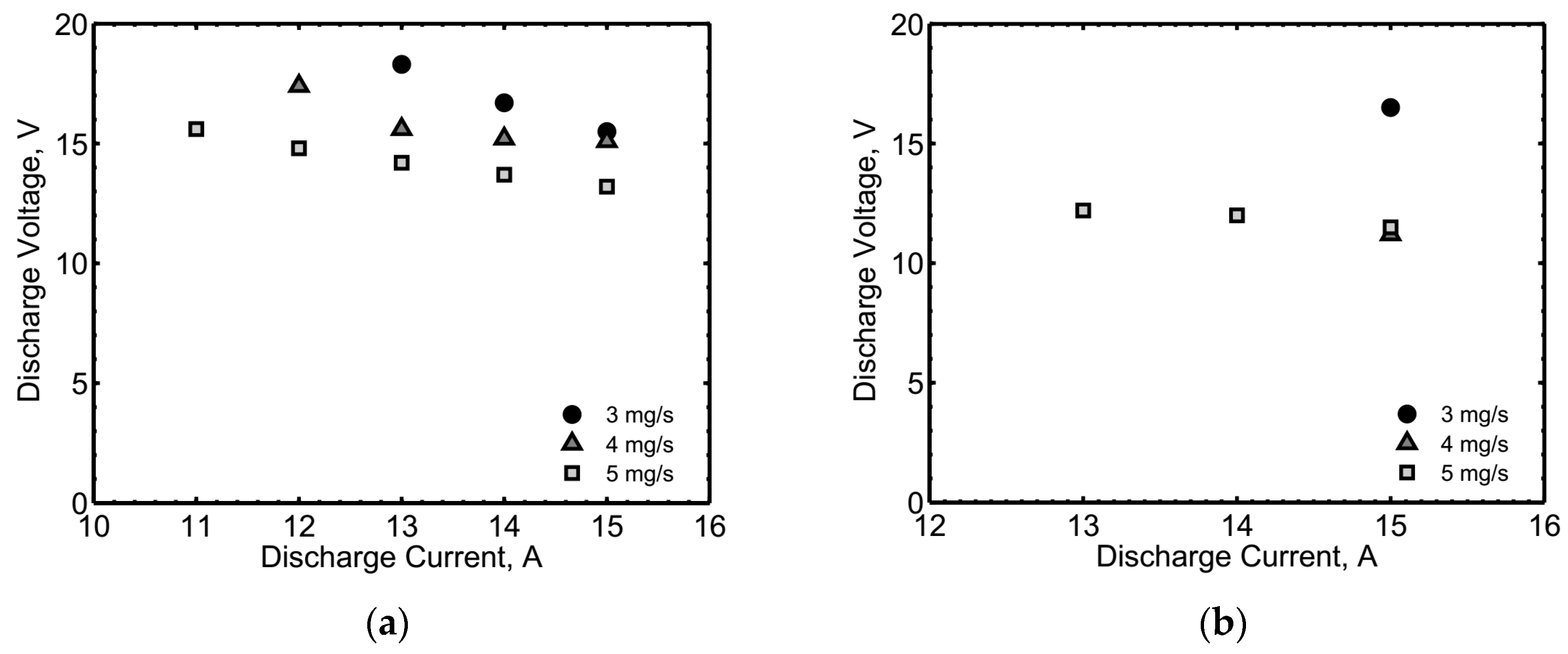

3.1.2. Cathode Performance

3.2. HC3

3.2.1. Experimental Setup

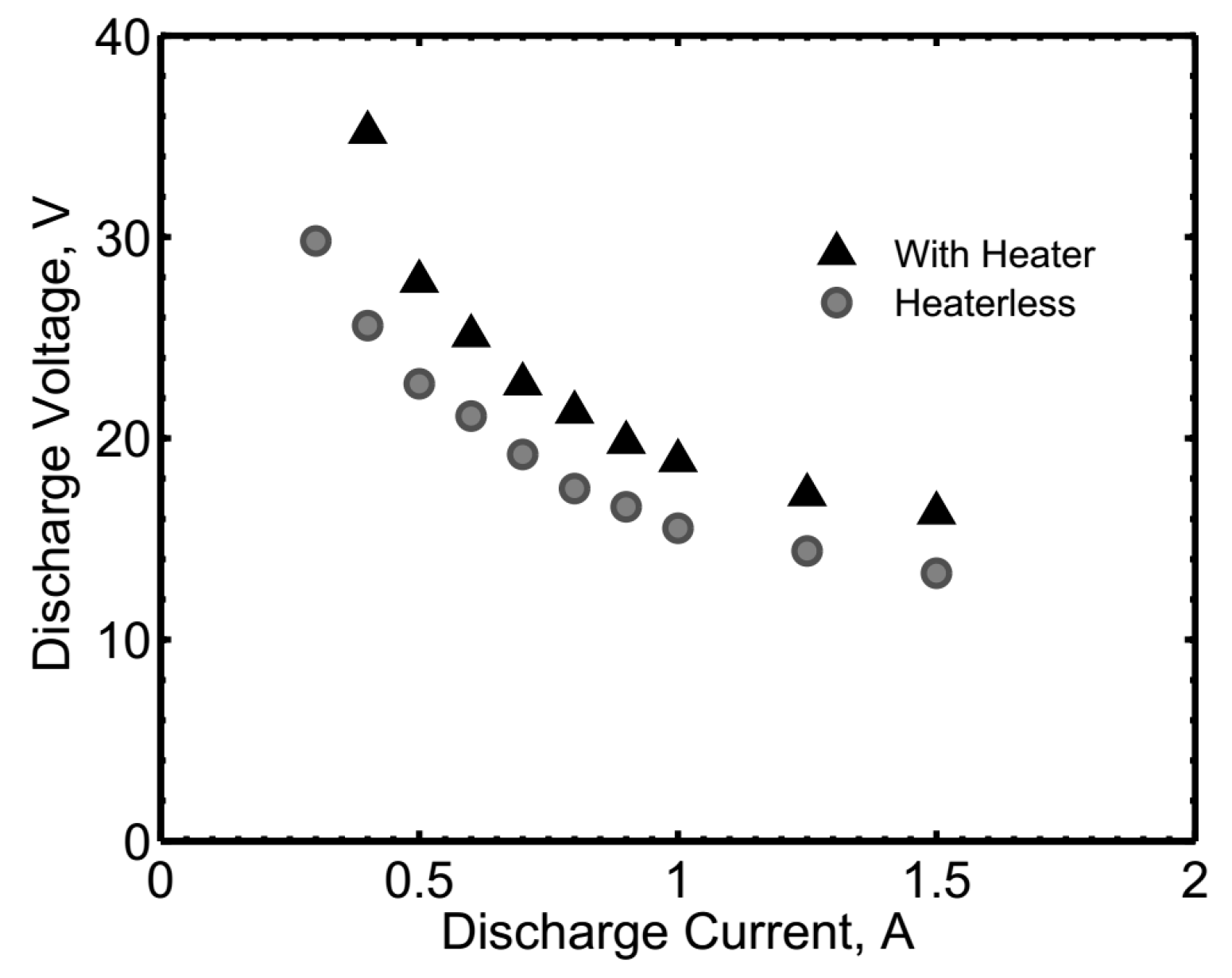

3.2.2. Cathode Performance

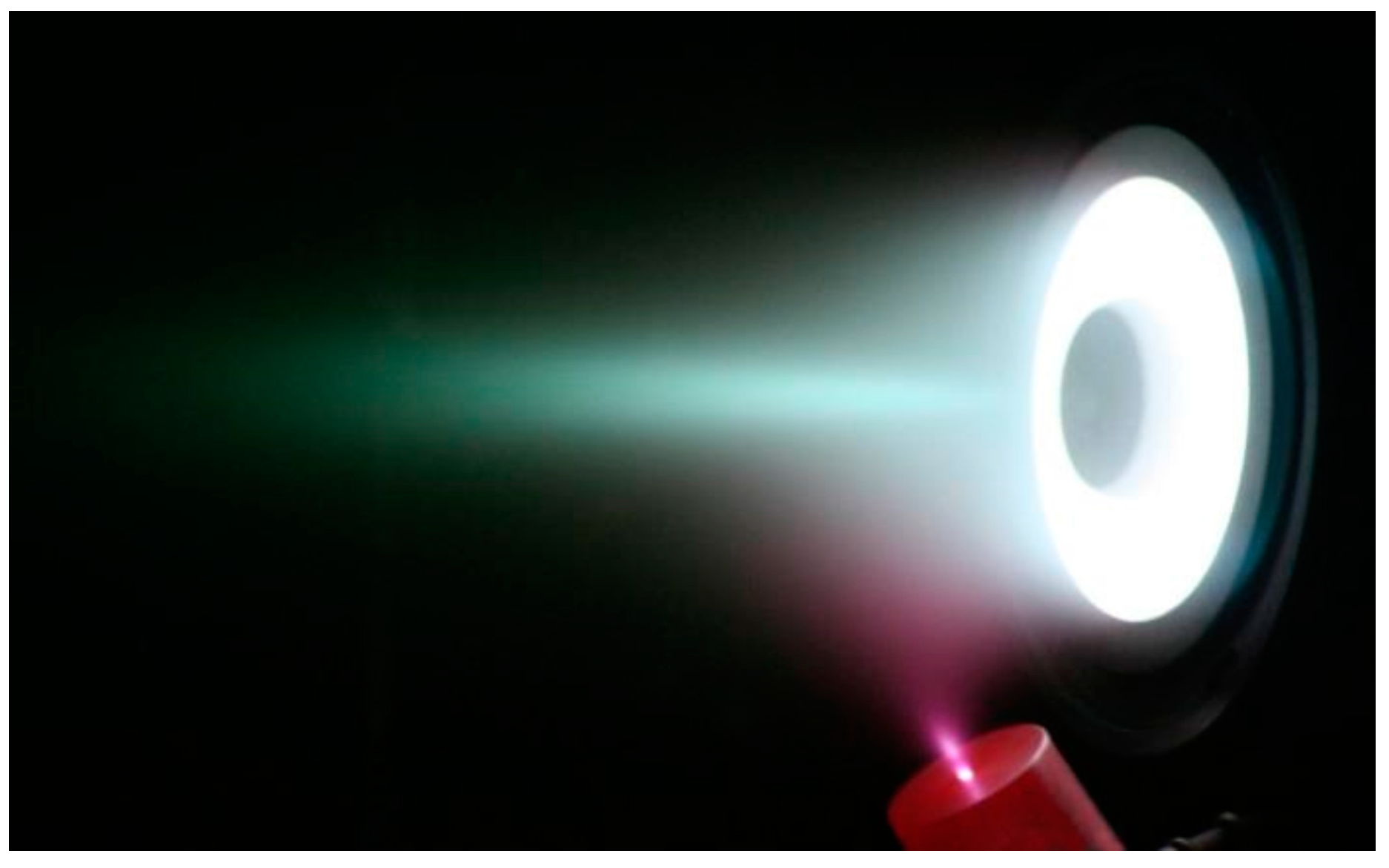

4. High-Current Hollow Cathodes

4.1. HC20

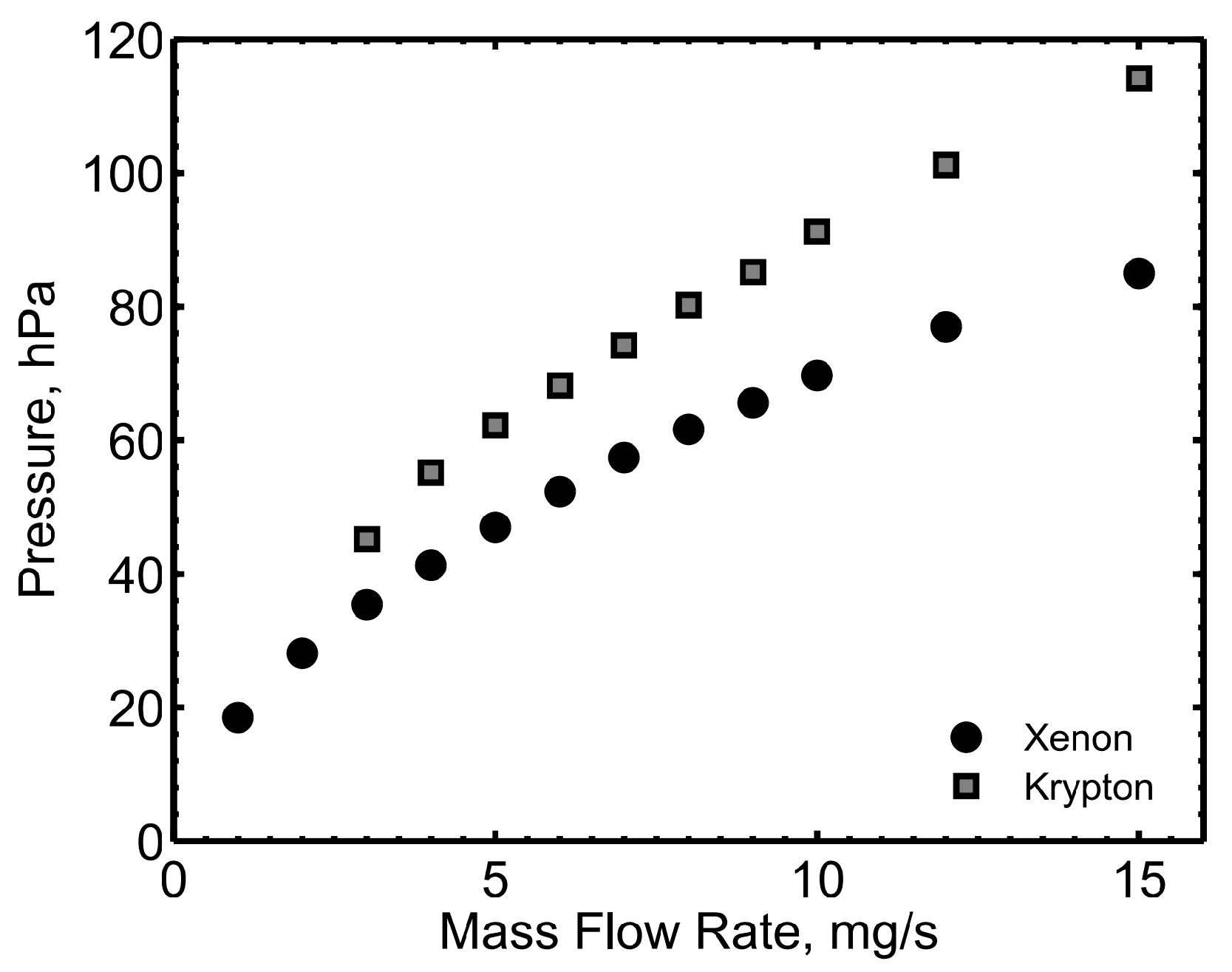

4.1.1. Experimental Setup

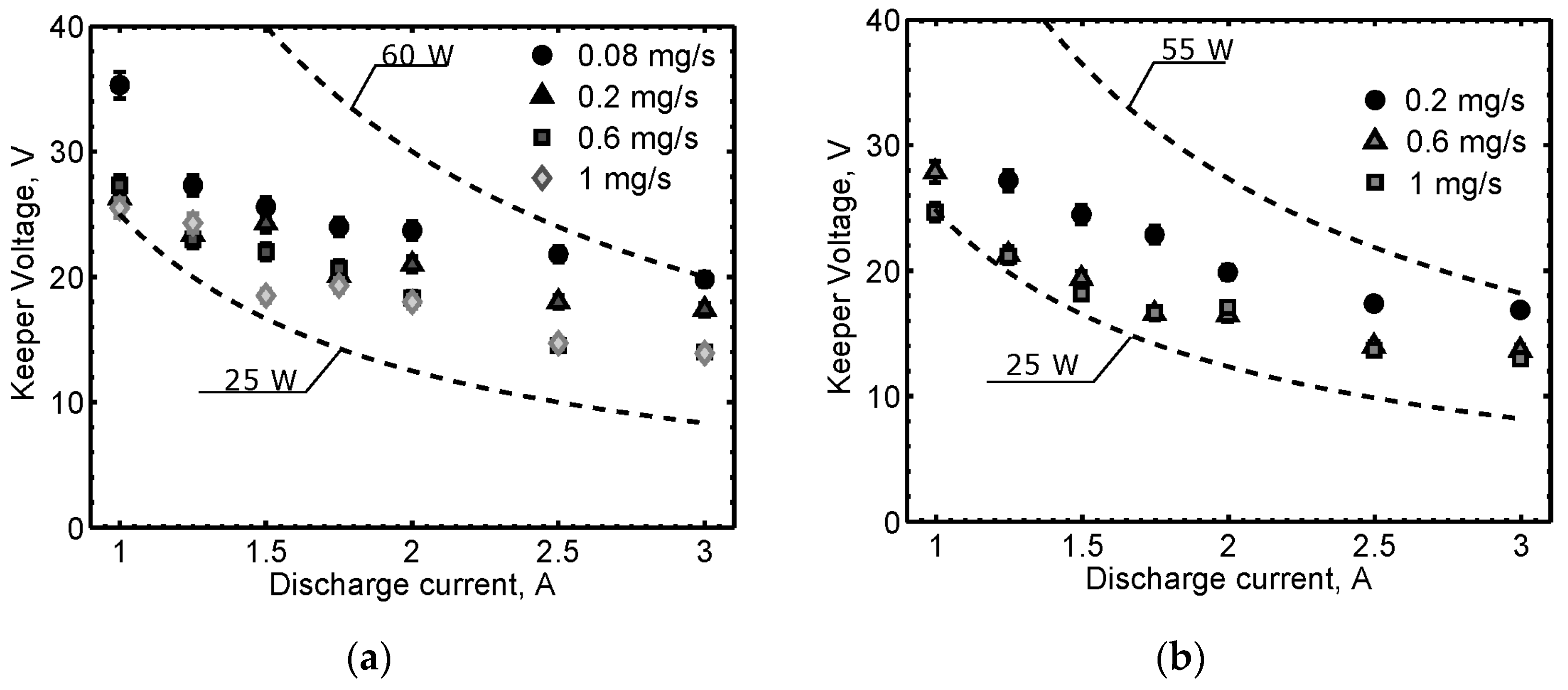

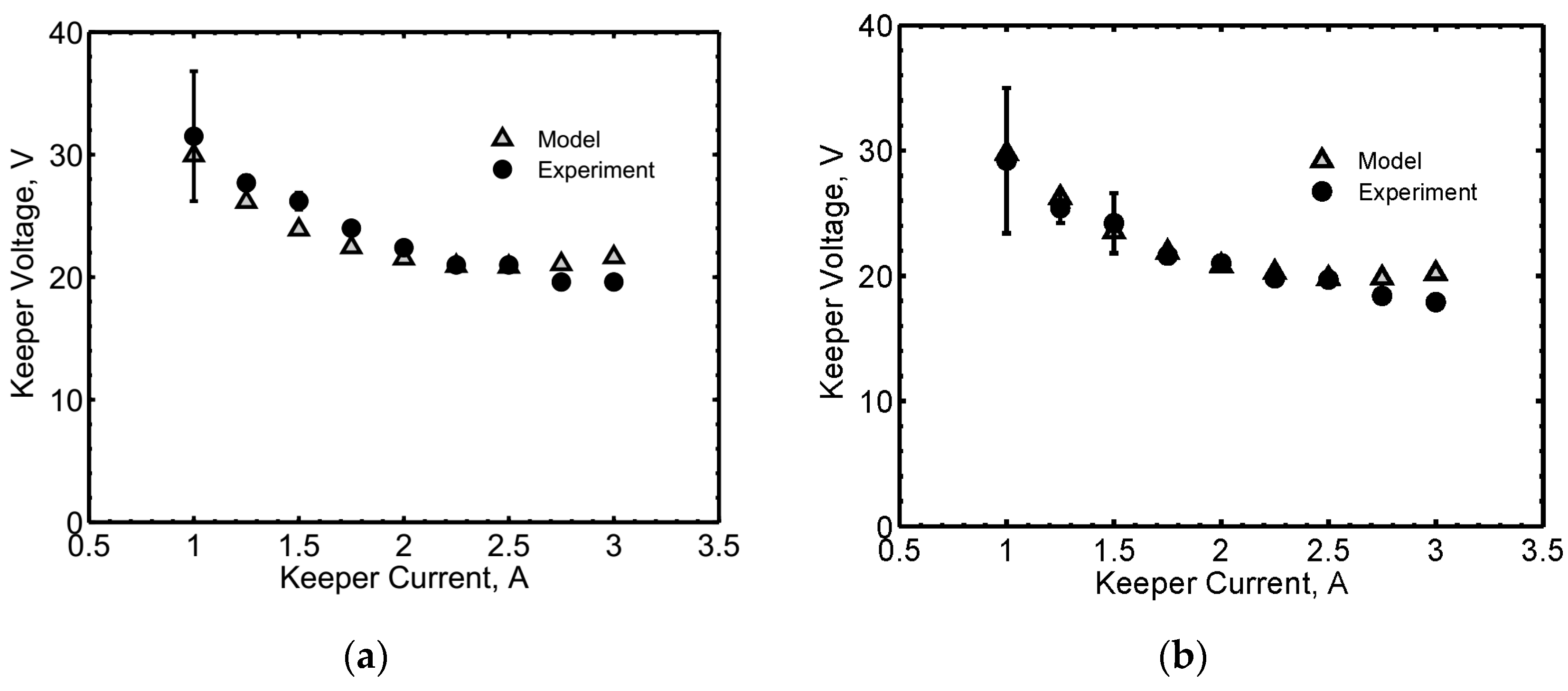

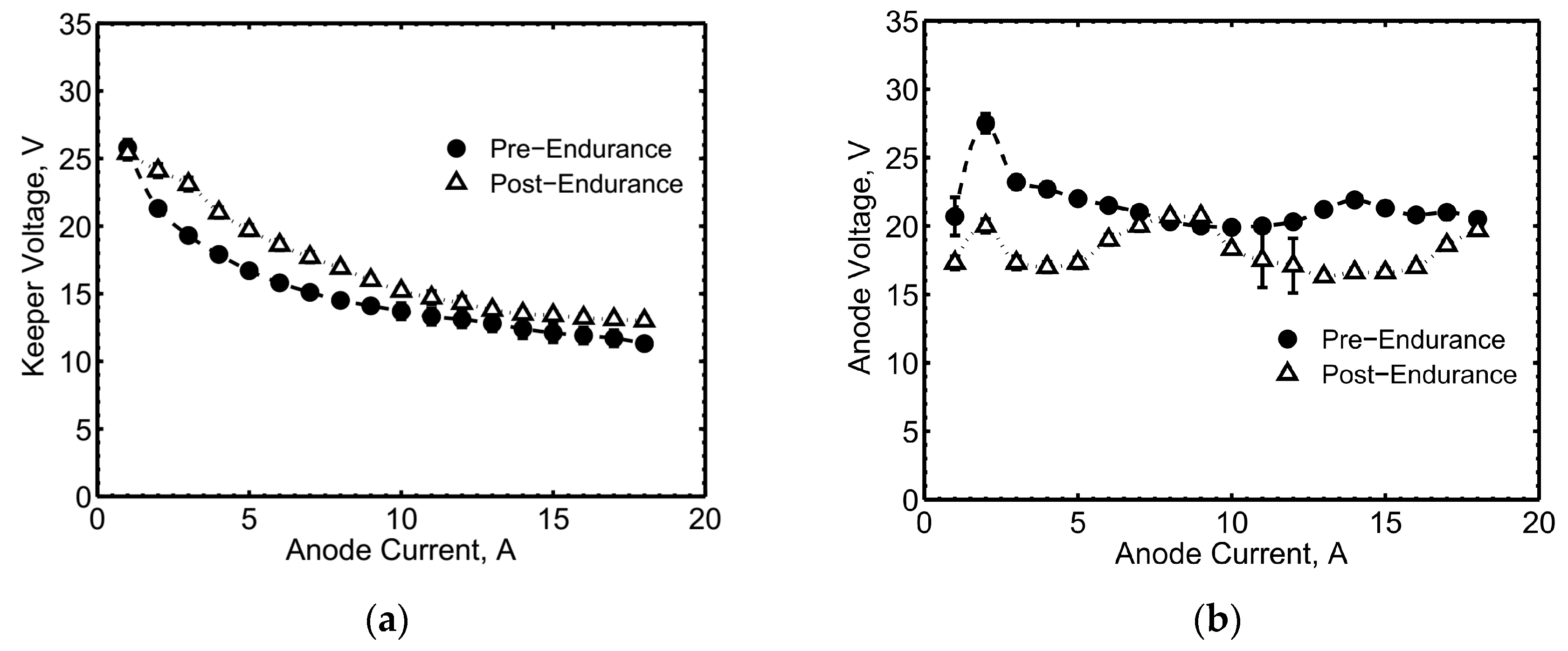

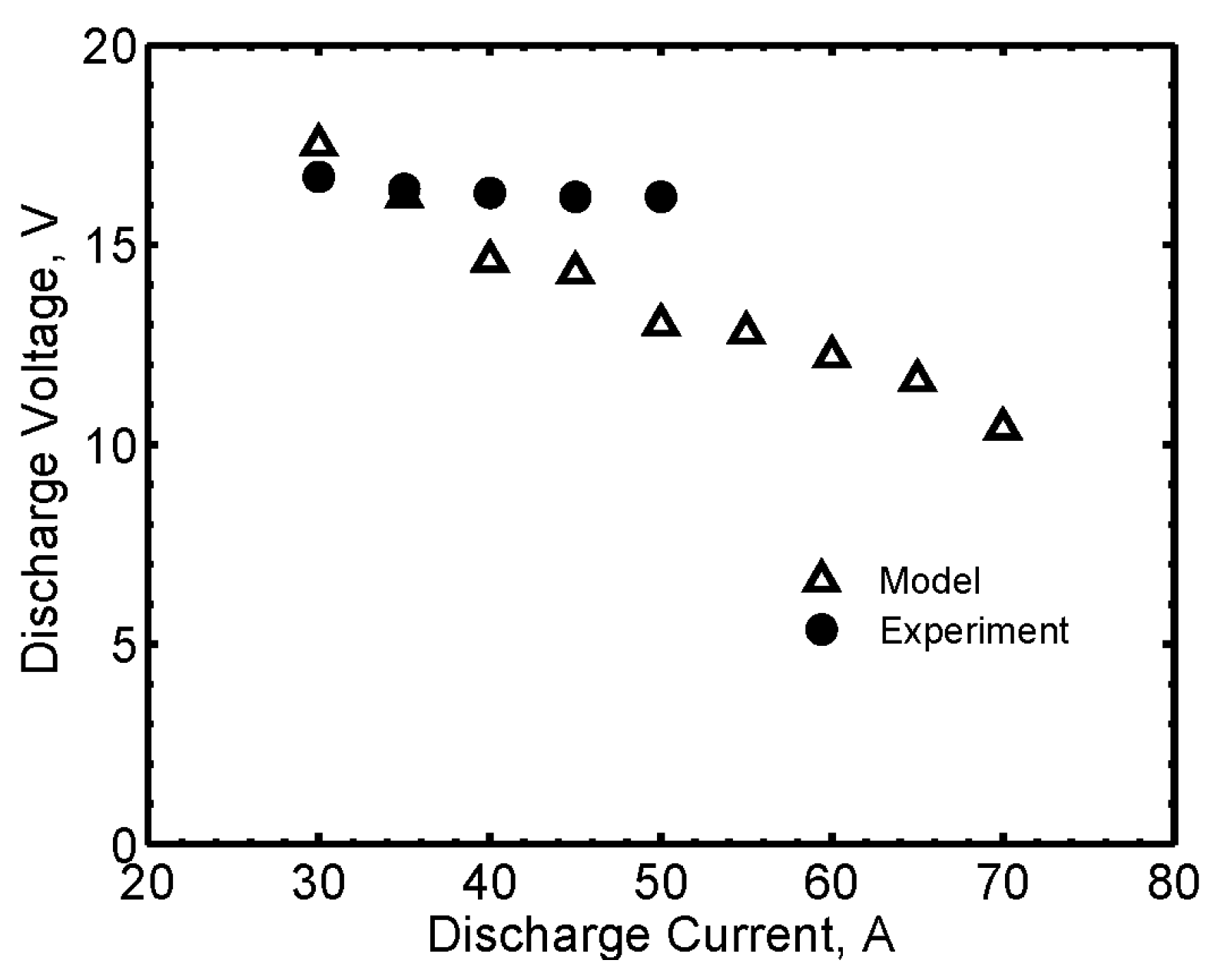

4.1.2. Cathode Performance

4.2. HC60

4.2.1. Experimental Setup

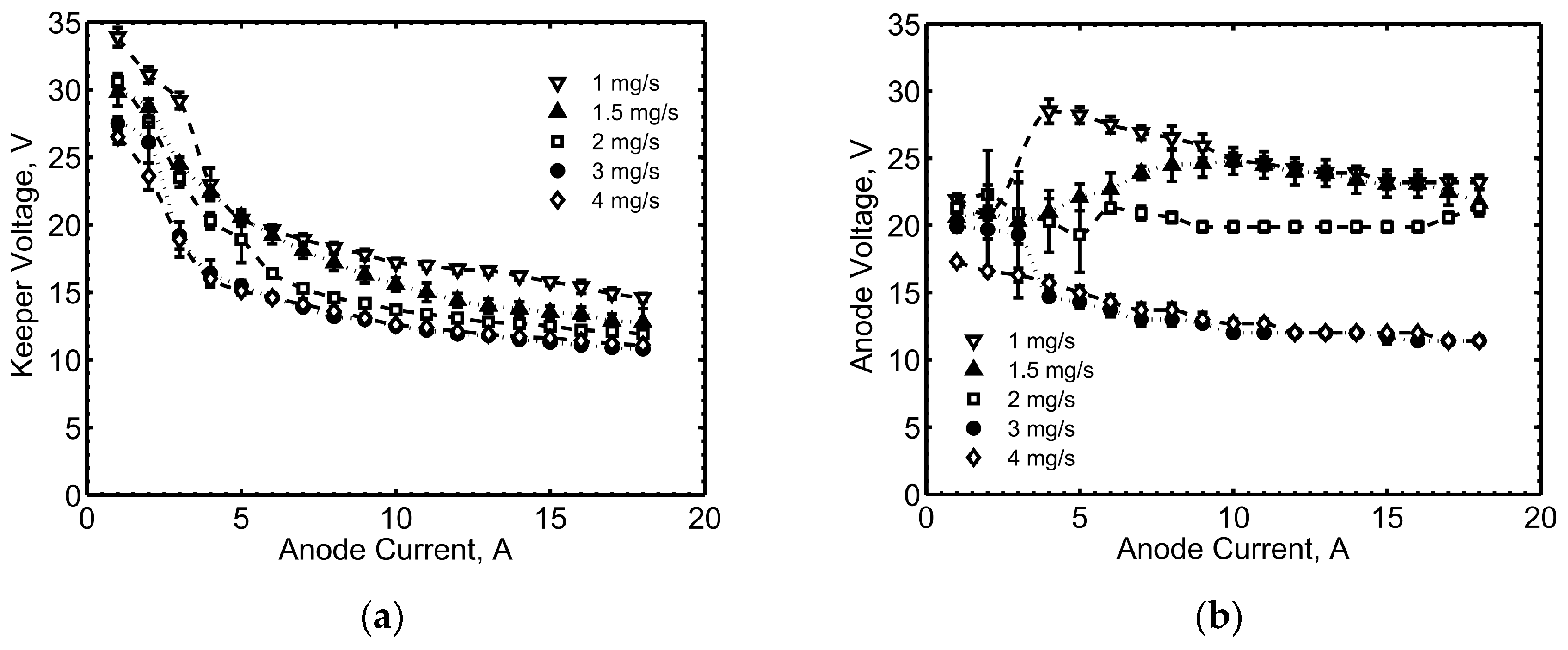

4.2.2. Cathode Performance

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Goebel, D.M.; Jameson, K.K.; Hofer, R.R. Hall Thruster Cathode Flow Impact on Coupling Voltage and Cathode Life. J. Propuls. Power 2012, 28, 355–363. [Google Scholar] [CrossRef]

- Albertoni, R.; Andrenucci, M.; Pedrini, D.; Paganucci, F. Preliminary Characterization of a LaB6 Hollow Cathode for Low-Power Hall Effect Thrusters. In Proceedings of the 33rd International Electric Propulsion Conference, Washington, DC, USA, 6–10 October 2013. [Google Scholar]

- Oleson, S.; Meyer, R. Launch Vehicle and Power Level Impacts on Electric GEO Insertion. In Proceedings of the 32nd Joint Propulsion Conference, Washington, DC, USA, 1–3 July 1996; pp. 1996–2978. [Google Scholar]

- Goebel, D.M.; Katz, I. Fundamentals of Electric Propulsion: Ion and Hall Thrusters; John Wiley and Sons: Hoboken, NJ, USA, 2008; pp. 243–323. [Google Scholar]

- Coletti, M.; Gabriel, S. Barium Oxide Depletion from Hollow-Cathode Inserts: Modeling and Comparison with Experiments. J. Propuls. Power 2010, 26, 364–369. [Google Scholar] [CrossRef]

- Domonkos, M.T. Evaluation of Low-Current Orificed Hollow Cathodes. Ph.D. Thesis, The University of Michigan, Ann Arbor, MI, USA, 1999. [Google Scholar]

- Pedrini, D.; Albertoni, R.; Paganucci, F.; Andrenucci, M. Theoretical Model of a Lanthanum Hexaboride Hollow Cathode. IEEE Trans. Plasma Sci. 2014, 43, 209–217. [Google Scholar] [CrossRef]

- Pedrini, D.; Cannelli, F.; Ducci, C.; Misuri, T.; Paganucci, F.; Andrenucci, M. Hollow Cathodes Development at Sitael. In Proceedings of the Space Propulsion 2016, Marriott Park Hotel, Rome, Italy, 2–6 May 2016. [Google Scholar]

- Lafferty, J.M. Boride Cathodes. J. Appl. Phys. 1951, 22, 299–309. [Google Scholar] [CrossRef]

- Yamauchi, H.; Takagi, K.; Yuito, I.; Kawabe, U. Work Function of LaB6. Appl. Phys. Lett. 1976, 29, 638–640. [Google Scholar] [CrossRef]

- Pedrini, D.; Albertoni, R.; Paganucci, F.; Andrenucci, M. Modeling of LaB6 Hollow Cathode Performance and Lifetime. Acta Astronaut. 2015, 106, 170–178. [Google Scholar] [CrossRef]

- Lev, D.R.; Emsellem, G.D.; Hallock, A.K. The Rise of the Electric Age for Satellite Propulsion. New Space 2017, 5, 4–14. [Google Scholar] [CrossRef]

- Misuri, T.; Ducci, C.; Albertoni, R.; Andrenucci, M.; Pedrini, D. Sitael Low Power Hall Effect Thrusters for Small Satellites. In Proceedings of the Joint Conference of 30th International Symposium on Space Technology and Science, 34th International Electric Propulsion Conference and 6th Nano-satellite Symposium, Hyogo-Kobe, Japan, 4–10 July 2015. [Google Scholar]

- Ducci, C.; Albertoni, R.; Andrenucci, M. HT100D Performance Evaluation and Endurance Test Results. In Proceedings of the 33rd International Electric Propulsion Conference, Washington, DC, USA, 6–10 October 2013. [Google Scholar]

- Williams, G.; Smith, T.; Domonkos, M.; Shand, K.; Gallimore, A.; Drake, R. Laser Induced Fluorescence Characterization of Ions Emitted from a Hollow Cathode. In Proceedings of the 35th AIAA/ASME/SAE/ASEE Joint Propulsion Conference and Exhibit, Los Angeles, CA, USA, 20–24 June 1999; pp. 1–16. [Google Scholar]

- Ducci, C.; Andreussi, T.; Arkhipov, A.; Passaro, A.; Andrenucci, M.; Bulit, A.; Edwards, C. Investigation of a 5 kW Class Hall-Effect Thruster Operating with Different Xenon-Krypton Mixtures. In Proceedings of the Joint Conference of 30th International Symposium on Space Technology and Science, 34th International Electric Propulsion Conference and 6th Nano-satellite Symposium, Hyogo-Kobe, Japan, 4–10 July 2015. [Google Scholar]

- Brophy, J.; Brinza, D.; Polk, J.; Henry, M. The DS1 Hyper-Extended Mission. In Proceedings of the 38th Joint Propulsion Conference, Indianapolis, IN, USA, 8 July 2002. [Google Scholar]

- Fearn, D.; Patterson, S. Characterisation of the High Current Hollow Cathode for the T6 Ion Thruster. In Proceedings of the 34th AIAA/ASME/SAE/ASEE Joint Propulsion Conference and Exhibit, Cleveland, OH, USA, 13–15 July 1998. [Google Scholar]

- Leporini, A.; Giannetti, V.; Andreussi, T.; Pedrini, D.; Rossodivita, A.; Piragino, A.; Andrenucci, M.; Estublier, D. Development of a 20 kW Class Hall Effect Thruster. In Proceedings of the Space Propulsion 2016, Rome, Italy, 2–6 May 2016. [Google Scholar]

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pedrini, D.; Misuri, T.; Paganucci, F.; Andrenucci, M. Development of Hollow Cathodes for Space Electric Propulsion at Sitael. Aerospace 2017, 4, 26. https://doi.org/10.3390/aerospace4020026

Pedrini D, Misuri T, Paganucci F, Andrenucci M. Development of Hollow Cathodes for Space Electric Propulsion at Sitael. Aerospace. 2017; 4(2):26. https://doi.org/10.3390/aerospace4020026

Chicago/Turabian StylePedrini, Daniela, Tommaso Misuri, Fabrizio Paganucci, and Mariano Andrenucci. 2017. "Development of Hollow Cathodes for Space Electric Propulsion at Sitael" Aerospace 4, no. 2: 26. https://doi.org/10.3390/aerospace4020026

APA StylePedrini, D., Misuri, T., Paganucci, F., & Andrenucci, M. (2017). Development of Hollow Cathodes for Space Electric Propulsion at Sitael. Aerospace, 4(2), 26. https://doi.org/10.3390/aerospace4020026