5.1. Flow Field Isosurface

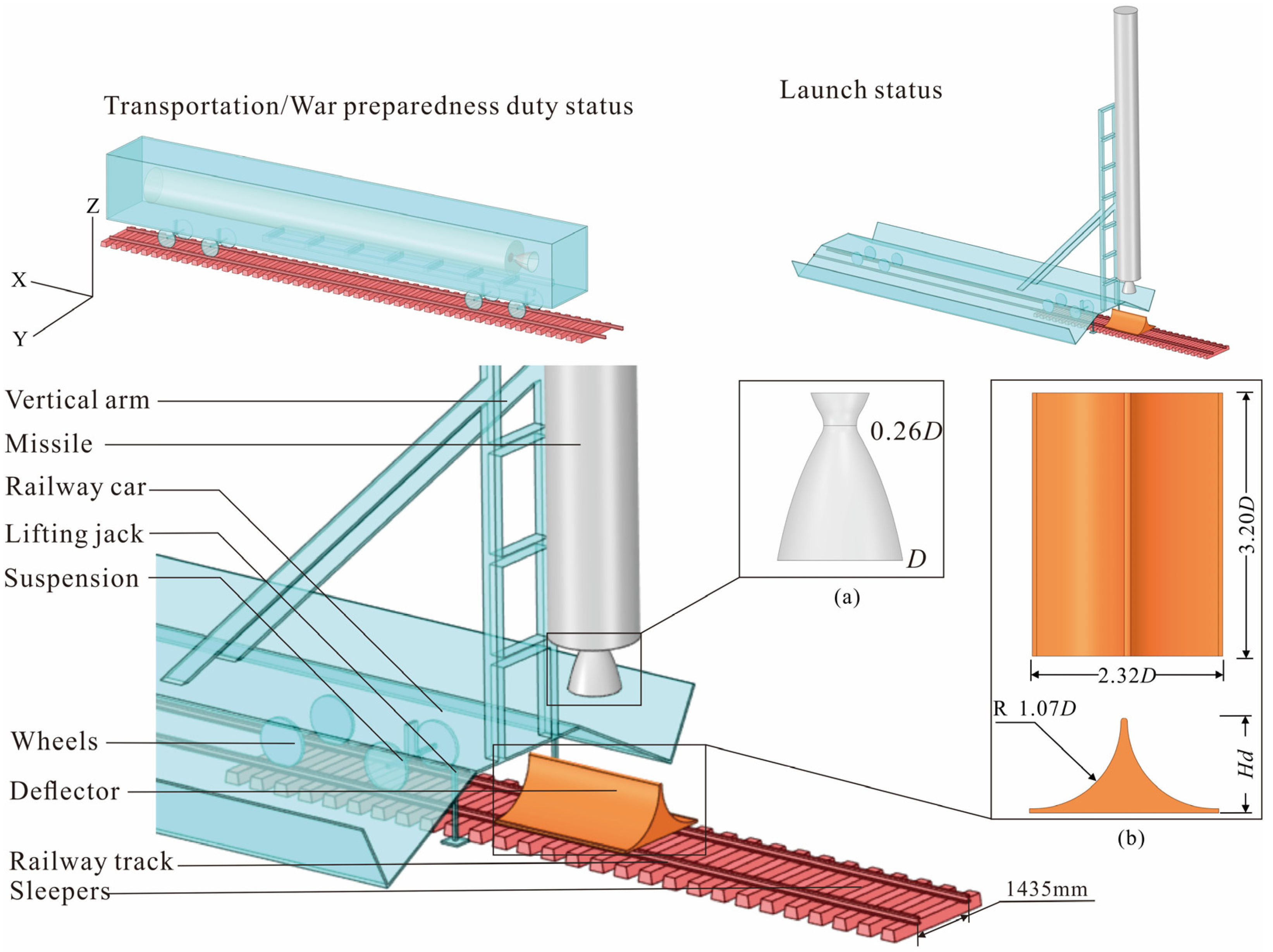

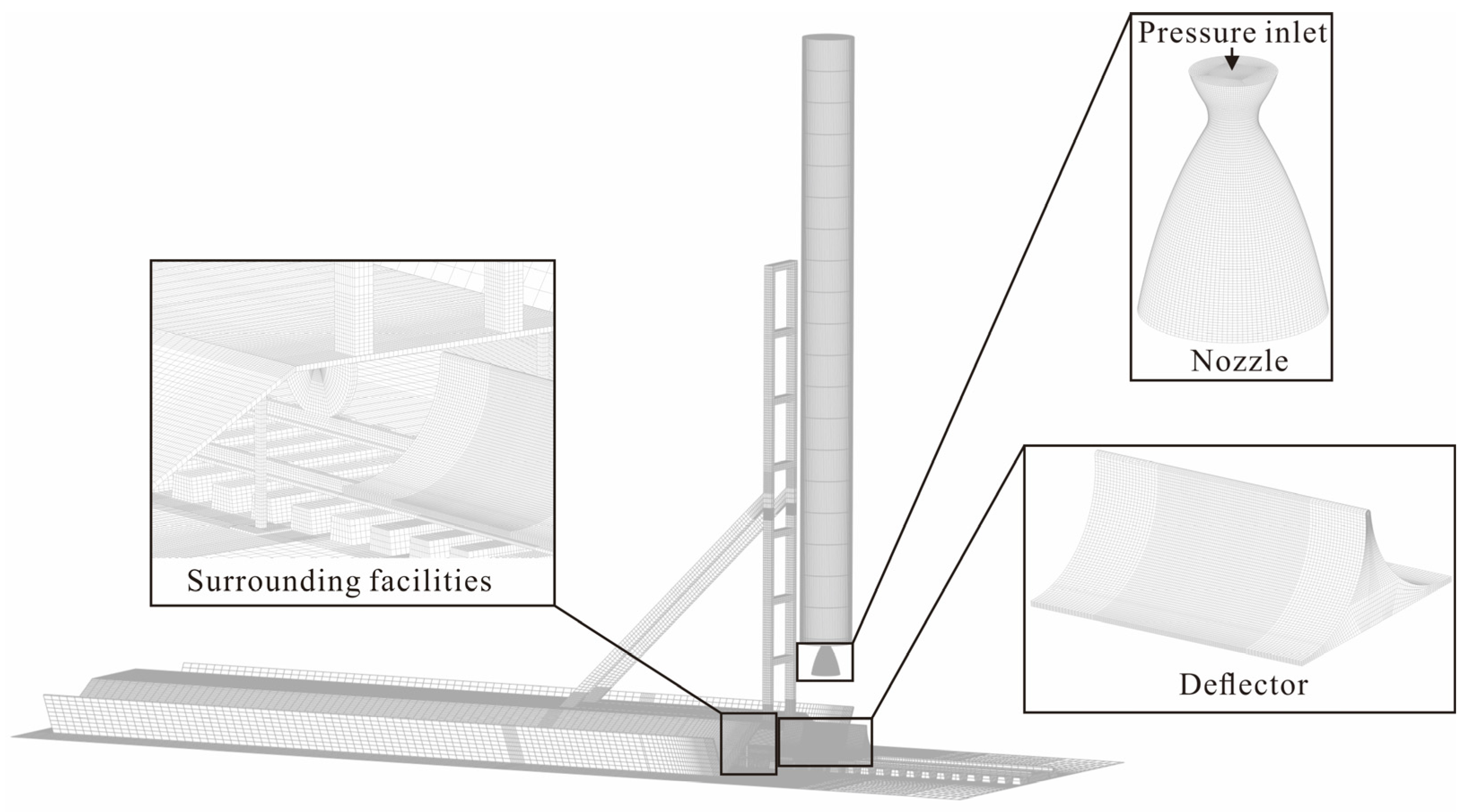

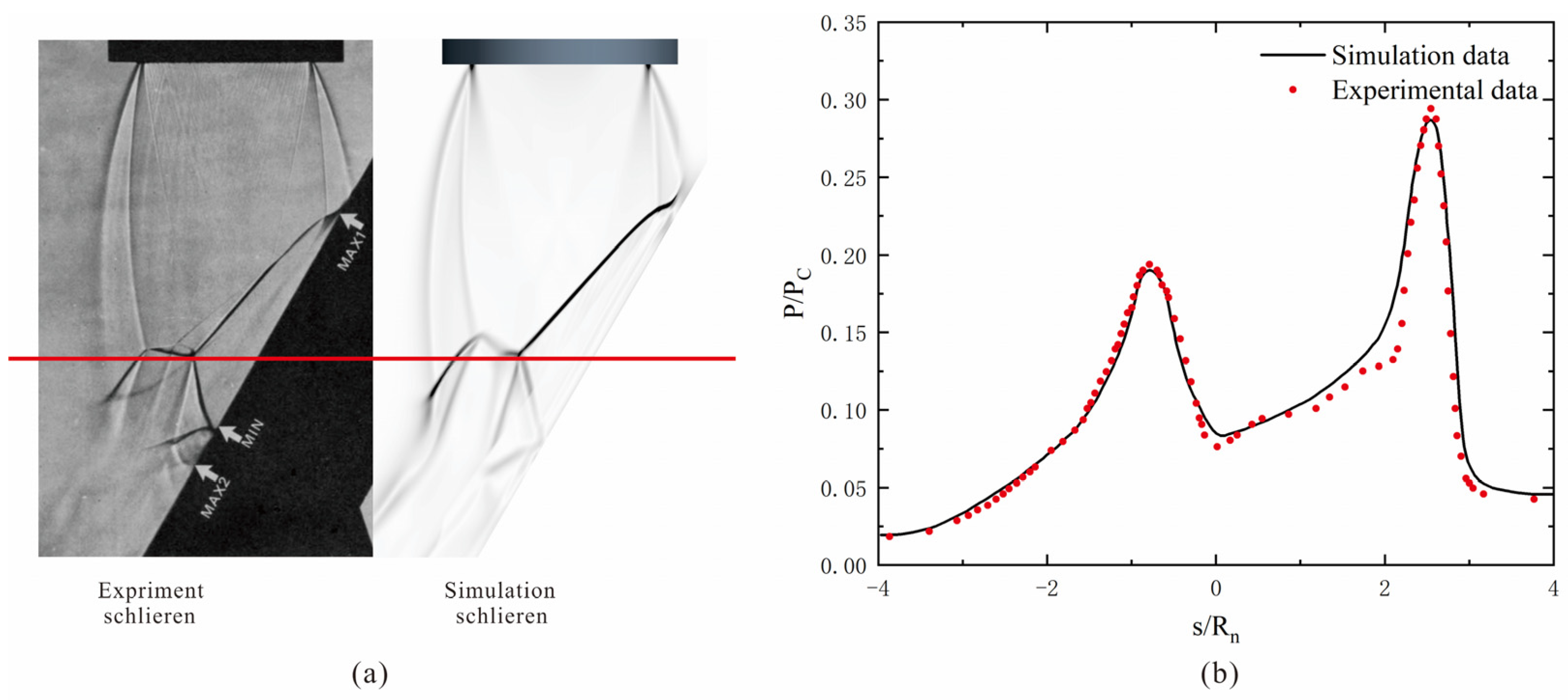

To accurately understand the flow field characteristics of the railway launch system during operation, the flow field results at different missile flight altitudes (

H) under

Hd = 1.2

D are first extracted and analyzed. The Mach number is an important dimensionless quantity that can reflect the flow state of the high-speed gas ejected from the missile engine. The isosurface Mach number contours and temperature contours in the YOZ direction and XOZ direction at various flight altitudes of the missile are shown in

Figure 5a,b, respectively. Parts such as the train carriage and thevertical arm are made transparent to intuitively show the interaction area between the missile engine wake and the train carriage. The gas flow from the missile engine is discharged through the laval nozzle, generating a series of clear wave system structures and plume boundary waveforms. When

H is relatively large, the gas flow expands sufficiently, forming more than 5 distinct shock cells, which impinge on the deflector, stagnate, and diffuse to the surrounding area. The interaction position between the missile gas wake and the launch system changes with the increase in the missile flight altitude. When

H = 0 m, the YOZ isosurface of the Mach number contour shows that the high-speed gas flow moves to both sides of the deflector, while the XOZ isosurface is orthogonal to the direction of the deflector, resulting in an insignificant diffusion trend of the high-speed gas flow on this isosurface. Therefore, it is necessary to further analyze in combination with the temperature distribution on the isosurfaces. The YOZ isosurface shows that in the core region of the high-speed gas flow, the temperature contour is basically opposite to the Mach number contour in the core region of the jet: the higher the gas flow velocity, the lower the temperature, this phenomenon is related to the ideal gas law and the conservation of internal energy. The gas flow stagnates and heats up when moving to the deflector. The XOZ isosurface shows that after impacting the deflector, the gas flow passes through the bottom of the train carriage, leading to a sharp increase in the gas temperature at the bottom of the carriage. A comparison of this phenomenon with the Mach number contour indicates that although the bottom of the carriage is not directly impacted by the gas flow and the change in gas velocity here is insignificant, the temperature here is relatively high. The side walls and bottom of the train carriage in the launch state together form a relatively enclosed environment, which hinders the flow of air and exacerbates the deterioration of the thermal environment at the bottom of the carriage. At

H = 2 m, the Mach number contour shows that the jet produces a complete shock cell; the YOZ isosurface of the temperature contour indicates that the high-temperature gas, which has not yet contacted the sleeper, tends to spread toward the sleeper, while the XOZ isosurface shows that the gas temperature at the bottom of the train carriage remains relatively high at this time. At

H = 10 m, the Mach number contour shows that the jet forms 4 clear and complete shock cells, and the influence range of the tail of the high-speed jet expands slightly; however, the flow velocity near the bottom facilities decreases. The temperature contour indicates that due to the increase in the missile flight altitude, the thermal environment at the bottom of the carriage is only slightly alleviated at this time, without a significant decrease. This is because although the residual energy of the gas flow from the missile engine becomes smaller with the increase in the missile flight altitude, the flow velocity of the gas flow here further decreases, and the kinetic energy of the gas flow is converted into internal energy, so the thermal load is not significantly improved. However, as the missile flight altitude increases, the impact range of the gas flow becomes larger than the size of the deflector, which in turn affects the rails and sleepers not covered by the deflector. Moreover, at this time, the high-temperature gas begins to affect the upper surface of the train and the lower area of the vertical arm. When the missile continues to rise to

H = 20 m, the Mach number contour shows that the gas flow expands sufficiently, generating 5 clear shock cells, and the high-speed core region of the jet begins to move away from the deflector. The temperature contour indicates that the affected area of high-temperature gas does not decrease with the departure of the high-speed core region; instead, it increases. Nearly half of the upper surface of the train carriage and the vertical arm are affected by the high-temperature gas, and the temperature of the rails and sleepers far from the train also rises. There is still a phenomenon where the gas flow stagnates and heats up at the deflector, but the gas temperature at the bottom of the train carriage starts to drop. When the missile flies to

H = 30 m, the Mach number contour shows that the core region of the gas flow is almost completely separated from the lower deflector and is in full contact with thevertical arm, with the high-speed core region of the jet completely leaving the deflector. The temperature contour indicates that there are no longer high-temperature areas (marked in red) on the deflector and surrounding facilities, and the heating area at the bottom of the train carriage also becomes smaller. However, the affected area on the upper surface of the train carriage, the vertical arm, and the surrounding rails and sleepers further expands. The above analysis indicates that although the deflector will withstand enormous impact and the temperature of the airflow on its surface is extremely high, for the train launch system, the thermal loads on the train roof, train bottom, nearby rails, and sleepers will all be relatively large. Therefore, further analysis of these facilities is required.

5.2. Gas Temperature Distribution on the Deflector Surface

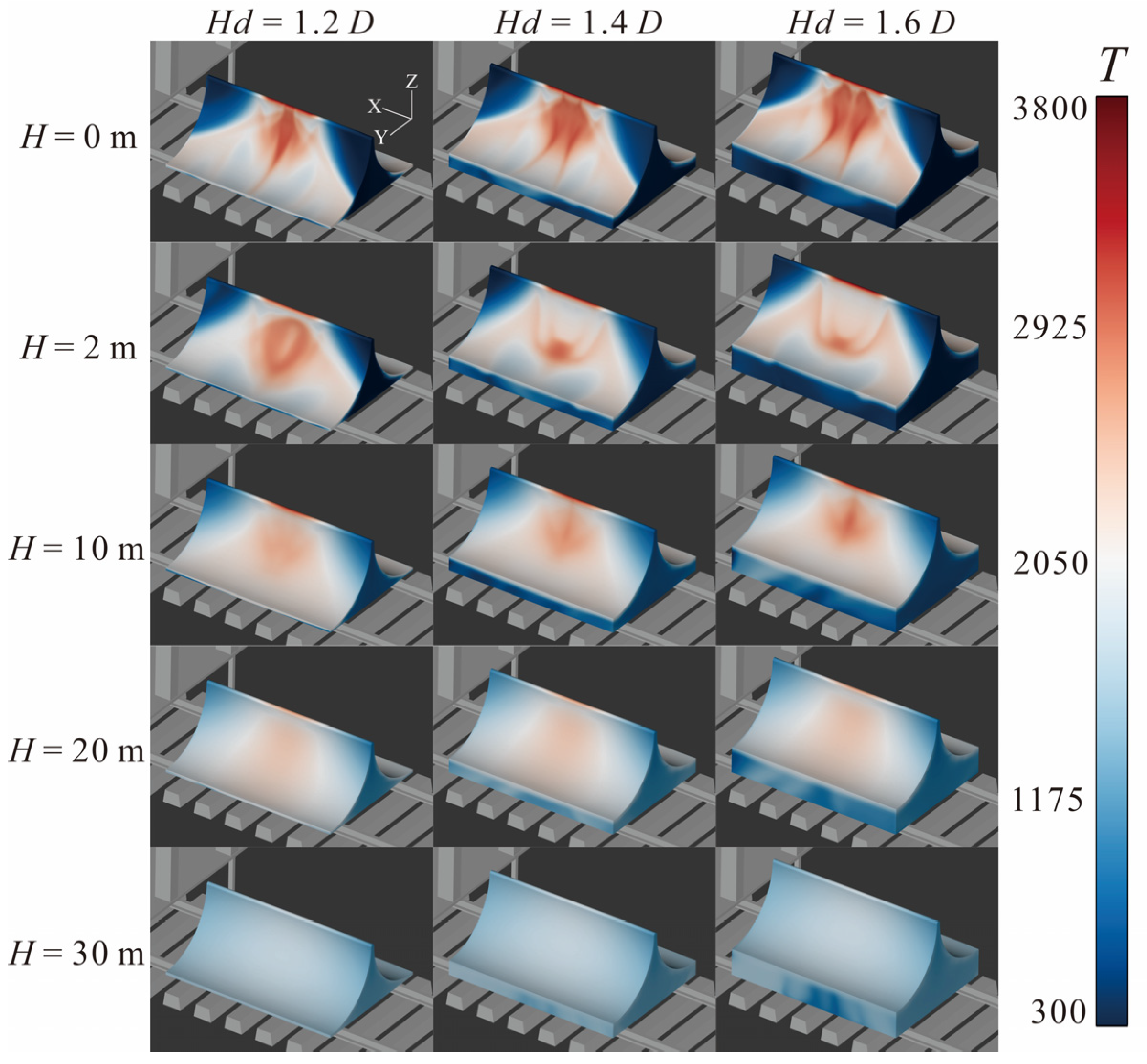

Based on the previous analysis, the thermal environment in the area of the deflector directly impacted by the high-temperature and high-speed gas flow is the most severe. Therefore, the temperature distribution contour on the surface of the deflector is extracted for further analysis.

Figure 6 shows a comparison of the gas temperature distribution contours on the surface of the deflector under the impact of the missile at different takeoff altitudes with deflectors of different

Hd values. The high-speed gas flow stagnates and heats up when impacting the deflector. At

H = 0 m, the surface temperature of the deflector is the highest, and the shape of the heated part is bilaterally symmetric, presenting a trapezoid-like hexagon. The boundary between this region and the unheated dark blue part at the edge of the deflector is very clear. The most intensely heated region is concentrated at the center of the deflector groove, with a dimension of approximately 1.0

D in the X direction and about 1.1

D in the direction along the arc surface of the deflector within the YOZ plane. As

Hd increases, the area of the red part with intense temperature rise expands, the maximum temperature also increases from 3088 K to 3258 K, and the morphology changes—the high-temperature core regions where the gas converges on the deflector surface change from one to two. When the missile further rises to

H = 2 m, the gas temperature on the deflector surface decreases, and the boundary between the heated region and the unheated blue region is also relatively clear. However, in the case of

Hd = 1.2

D, the area of the red high-temperature region is larger than that of

Hd = 1.4

D and

Hd = 1.6

D, and there are differences in the distribution pattern, which is similar to the distribution of the red heated region when

H = 0 m. This is because changes in

Hd will cause a shift in the contact position between the deflector and the core region of the gas jet. At lower flight altitudes, the relative degree of such changes is greater, leading to variations in the contact between the gas flow and the deflector at different positions within a complete shock cell of the high-speed jet, which in turn results in differences in the distribution of the heated regions. When the missile further flies to

H = 10 m, the gas temperature on the deflector surface decreases further. Due to the increase in flight altitude, the influence range of the jet expands, and the temperature of the originally unheated parts of the deflector also rises slightly. The trapezoid-like hexagonal region mentioned earlier can still be observed, with the boundary between the red high-temperature region and the light blue slightly heated region gradually blurring. At this point, the impact caused by changes in

Hd will weaken. At

H = 20 m, the red regions fade further, the boundaries between the blue and white regions become more blurred, the impact caused by changes in

Hd almost disappears, and the calculation results under different

Hd values are basically consistent. When the missile flight altitude increases to

H = 30 m, the red regions on the deflector surface disappear, and the entire deflector presents a very uniform light blue color, indicating that the temperature of the gas flow here further decreases. At the same time, the range affected by the gas flow is highly likely to have spread to facilities such as the rails, sleepers, and train carriages around the deflector. Overall, it can be seen that the lower the missile flight altitude

H and the higher the deflector height

Hd, the greater the thermal load on the deflector. Obviously, this rule is as expected: the closer the deflector is to the missile engine nozzle, the harsher the thermal environment.

However, a comparison of the calculation results for different

Hd values at the same flight altitude

H shows that when

H is low, only the maximum temperature at the top of the deflector fully conforms to the rule that “the closer the distance, the harsher the thermal environment”. Other areas of the deflector do not fully comply with this rule.

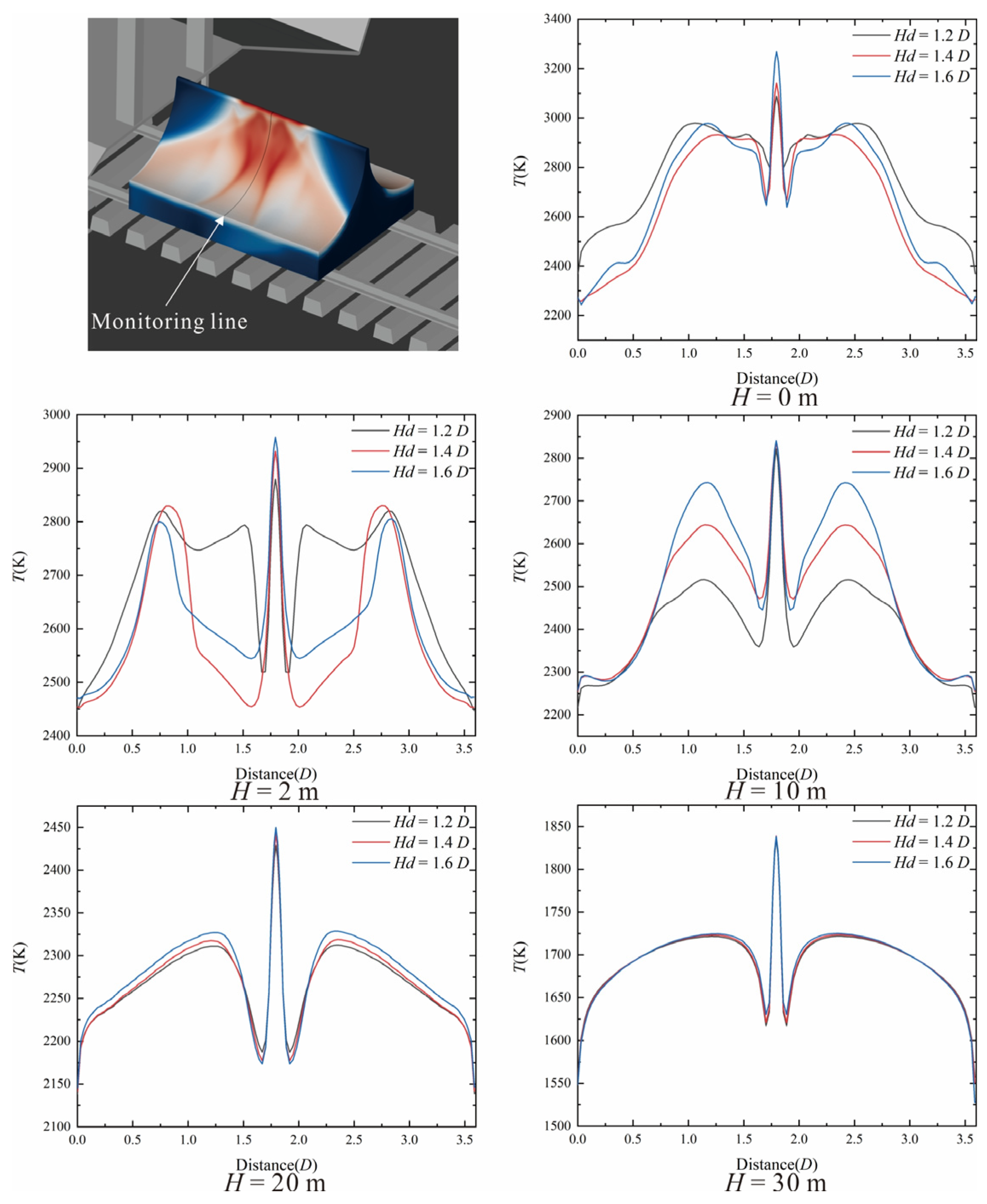

Figure 7 shows the gas temperature curves of the monitoring lines on the deflector surface under various working conditions. These curves can describe the above situation in more detail. At

H = 0 m, in the area about 0.3

D downward along both sides of the monitoring line from the top of the deflector, the temperature instead decreases as

Hd increases. In most of the subsequent regions, the temperature is instead highest under the working condition with the smallest

Hd. Comparing the three working conditions at

H = 0 m in

Figure 6, the shape of the red high-temperature region on the deflector surface changes, gradually splitting into two regions as

Hd increases, which exactly separate at the monitoring line. Therefore, in most regions at this time, the temperature curve for

Hd = 1.2

D is instead higher than those for the other two working conditions with larger

Hd values. A similar situation still exists when

H = 2 m. The curves for

H = 10 m,

H = 20 m, and

H = 30 m show that under the working conditions with higher missile flight altitudes (

H), the common-sense rule is maintained: the larger the

Hd (the closer to the missile body), the harsher the thermal environment on the entire deflector surface. Moreover, this difference gradually weakens as

H increases. In the analysis of

Figure 7, it is impossible to explain the reason why the change in Hd leads to a significant difference in the shape of the high-temperature core region where the gas flow converges on the deflector surface at lower missile flight altitudes. To address this phenomenon, a further explanation will be provided in combination with the temperature distribution of the deflector.

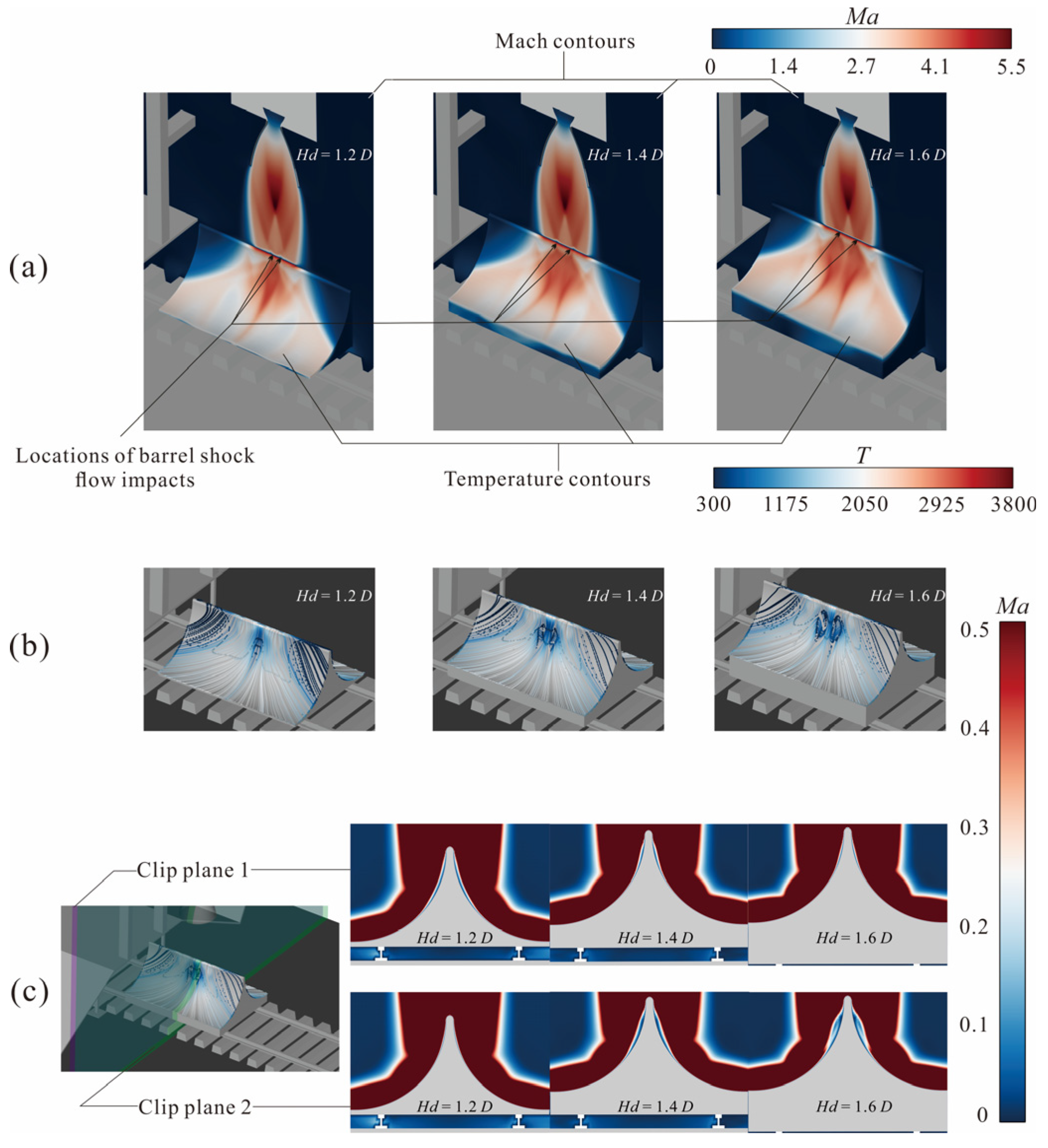

To address the aforementioned phenomenon,

Figure 8 selectively displays the flow conditions in the deflector and its adjacent local areas at

H = 0 m, in combination with the temperature distribution of the deflector. In

Figure 8a, the isosurface is the Mach number contour, and the temperature distribution is displayed on the surface of the deflector. The gas flow is accelerated through the Laval nozzle, forming the first barrel shock wave. The position where the barrel shock wave impinges on the deflector is marked in the figure. When

Hd = 1.2

D, the impingement positions of the barrel shock waves are relatively close, so the heated region is relatively concentrated. As

Hd increases, the distance between the impingement positions of the barrel shock waves increases. Until

Hd = 1.6

D, the distance between the impingement positions causes the stagnation-heated regions of the airflow on the deflector surface to separate (with an obvious white area in the center of the heated regions), forming two seemingly independent heated core regions.

Figure 8b shows the streamline diagram of the airflow on the deflector surface. To better illustrate the flow state, the streamlines are colored using the Mach number, with an upper limit set at Ma = 0.5. When

Hd = 1.2

D, the image shows that the velocity in the core heated region of the deflector is relatively low, but the streamlines are generally unobstructed. At

Hd = 1.4

D, the range of this region expands, and the streamlines in this area begin to spread along both sides of the deflector, with even a slight backflow obliquely upward. When

Hd = 1.6

D, this region further expands until a W-shaped vortex is formed.

Figure 8c shows the flow states of two cross-sections, namely clip 1 (the middle section of the deflector) and clip 2 (the section at the impingement position of the barrel shock wave). When

Hd = 1.2

D, due to the relatively close impingement points of the barrel shock waves, a thin stagnation region appears at clip 1 on the deflector, while the flow at clip 2 is relatively unobstructed. As the distance between the engine and the deflector, as well as the distance between the impingement points of the barrel shock waves, increases, at

Hd = 1.4

D, the stagnation region at clip 2 becomes larger than that at clip 1. Furthermore, when

Hd = 1.6

D, the stagnation region at clip 2 is significantly larger than that at clip 1. The above analysis indicates that when the missile takeoff altitude

H is low, the positions where the barrel shock waves formed by the engine jet impinge on the deflector determine the distribution pattern of the heated core regions. This may lead to an abnormal phenomenon where compared to the top area, the thermal environment of other regions on the deflector surface decreases as

Hd increases.

5.3. Gas Temperature Distribution on the Surface of Surrounding Facilities

Since the influence range of the gas flow will spread to the surrounding facilities under the carriage as the missile flight altitude increases, and railway tracks and sleepers are infrastructure that needs to be reused, their thermal environment also requires attention.

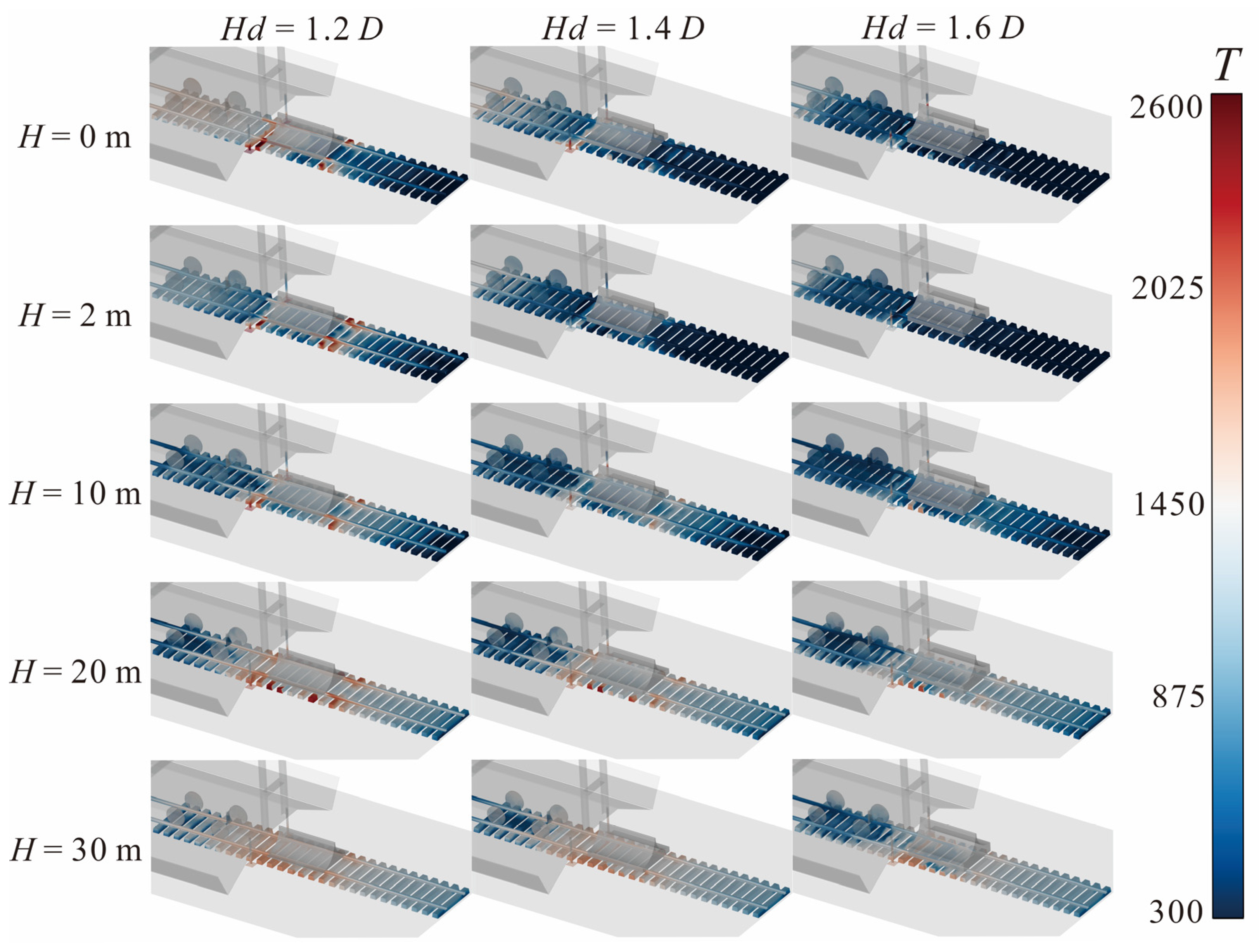

Figure 9 extracts the gas temperature distribution of surrounding facilities including rails and sleepers under different working conditions. The train carriages and deflectors are semi-transparently processed to intuitively show all the shielded parts. When

H = 0 m, an excessively small

Hd will result in the deflector failing to adequately protect the surrounding facilities under the carriage. At

Hd = 1.2

D, due to the excessively low height of the deflector, a considerable portion of the gas flow enters the undercarriage through the gap between the deflector and the train, and fails to effectively protect the surrounding rails and sleepers. Except for the 5 sleepers directly covered by the deflector, the regular structures on both sides experience significant temperature rises. Because facilities such as the train carriage block the airflow, the maximum temperature of the airflow on the surfaces of the sleepers and supporting devices here rises to 2593 K, and the sleepers and wheels at the bottom of the train also heat up. However, when

Hd = 1.4

D and

Hd = 1.6

D, the thermal environment of the surrounding facilities is greatly improved. In the former case, only the area near the bottom of the supporting device and some parts of the sleepers here have temperature rises, with the maximum temperature reaching 2017 K. In the latter case, only a small area in the middle of the supporting device has a relatively high temperature of about 1975 K, while all the surrounding sleepers are in the white medium-temperature area or blue non-heated area. When

H = 2 m, the thermal environment of the surrounding facilities is somewhat improved. However, the deflector with

Hd = 1.2

D still cannot effectively protect the surrounding facilities. There are red regions with severe temperature rises on the surfaces of the rails, sleepers, and supporting devices. Due to the increased distance from the missile engine, the gas temperature on the surfaces of these regions has decreased, but it still exceeds 2000 K. At this point, the calculation results for

Hd = 1.4

D and

Hd = 1.6

D show that there is no severe temperature rise on the rails and sleepers. As the missile continues to ascend to

H = 10 m, for the working condition of deflector with

Hd = 1.2

D, the thermal environment of the surrounding facilities improves as the engine moves away. Compared with the calculation results at the previous two flight altitudes, the temperature of the heated regions further decreases. However, the calculation results for deflectors with

Hd = 1.4

D and

Hd = 1.6

D indicate that the thermal environment of the surrounding facilities does not improve with the increasing distance from the rocket engine; on the contrary, due to the full expansion of the gas jet, it exceeds the area covered by the deflector, eventually causing the gas temperature at the nearby rails, sleepers, and supporting devices to rise. The aforementioned cause of temperature rise in surrounding facilities becomes more pronounced when the missile flies to

H = 20 m. Although the missile is still moving away from the launch system, the calculation results under different

Hd values still show that the thermal environment of the surrounding facilities continues to deteriorate, and the affected areas also spread to the surroundings. Since the deflector with

Hd = 1.2

D has a poor shielding effect on the rails and sleepers below, the gas temperature at the sleepers even rises to 2428 K. The deflectors with

Hd = 1.4

D and

Hd = 1.6

D, due to their better shielding effect, have smaller temperature rise ranges and areas at the nearby rails and sleepers, with the maximum temperatures being 2081 K and 1907 K, respectively. As the missile reaches a flight altitude of

H = 30 m, the calculation results show that the influence range of the gas flow after expansion further expands. At this point, the number of sleepers with obvious temperature rises (turning white at least) on both sides of the deflector in the X direction continues to increase. However, since the missile is sufficiently far from the ground facilities, the energy of the gas flow has been fully attenuated when it reaches here. Even though the influence range of the gas flow has increased compared with the calculation results at the previous flight altitude, the surface temperature of various components at the bottom of the carriage has decreased. It can thus be judged that when the missile exceeds a certain altitude, its impact on the facilities around the bottom of the carriage will continue to weaken, and this altitude is between 20 m and 30 m. At this time, the rule that the larger the

Hd, the smaller the affected range of the underlying facilities still holds, but the maximum temperature of the surrounding facilities under different

Hd conditions has dropped to 1721 K. On the whole, the greater the height

Hd of the deflector, the better its protective effect on the facilities at the bottom of the train carriage. However, a continuous increase in

Hd will inevitably lead to a rise in the position where it comes into contact with the gas flow. Although this can effectively protect the facilities at the bottom of the carriage, it will bring potential safety risks to the surface of the train carriage at higher positions. Therefore, a further analysis of the relevant conditions on the upper surface of the carriage is required.

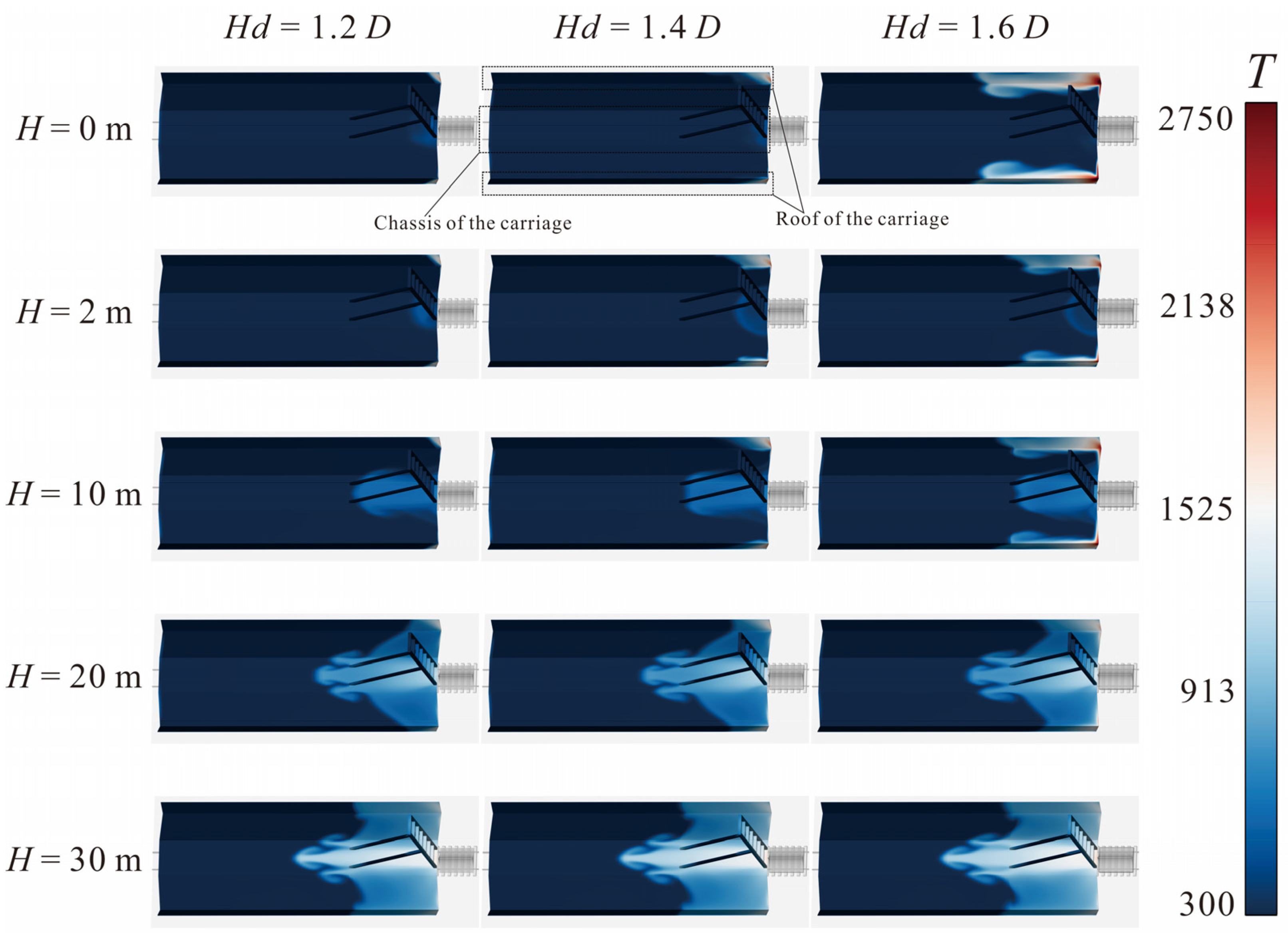

Figure 10 shows the temperature distribution of gas on the upper surface of the carriage under various operating conditions corresponding to different

Hd values at different flight altitudes

H. It is necessary to discuss the carriage chassis and the deployed roof separately here. At

H = 0 m, the calculation results for

Hd = 1.2

D show that a heated area appears at the edge of the right side (the side close to the missile) of the deployed carriage roof. The size of this area is described by the length of its distribution in the X-axis direction, which is 1.01

D at this time, with a maximum temperature of 1713 K. When the deflector height increases to

Hd = 1.4

D, the length of this area increases to 2.53

D, and the temperature rises slightly. When the deflector height further increases to

Hd = 1.6

D, the length of this area increases to 11.24

D, and the maximum temperature surges to 2750 K. Due to the splashing back of high-temperature gas from the ground, rails, and sleepers when

Hd = 1.2

D, the chassis has a slight temperature rise at this time. The other two

Hd values can better play a role in guiding the flow, so the temperature rise in the chassis is not obvious. At

H = 2 m, the size of the gas-heated region on the roof surface shows no significant change when

Hd = 1.2

D; when

Hd = 1.4

D, it increases to 3.77

D, with no obvious change in the maximum temperature for either of these two cases. For

Hd = 1.6

D, the size of this heated region decreases to 8.45

D, and the maximum gas temperature also decreases to 2211 K. However, both the size and maximum temperature of this heated region are still significantly larger than the calculation results for the first two

Hd values. At this time, the size of the gas-heated region on the chassis surface increases with the increase in

Hd, and the lengths of this region in ascending order are approximately 2.45

D, 2.82

D, and 3.01

D. As the missile ascends to

H = 10 m, the distribution pattern of the gas-heated region on the roof remains essentially the same as that at

H = 2 m. However, the heated region on the right side of the chassis begins to spread to the left, and the size of this region hardly changes with variations in

Hd, all being 7.94

D, with the maximum gas temperature being lower than that on the roof, at 1023 K. When the missile further flies to

H = 20 m, the maximum gas temperature in the heated region on the roof decreases to 1556 K. Compared with the previous flight altitude, the size of the heated region increases to 2.74

D at

Hd = 1.2

D, shows no significant change at

Hd = 1.4

D, but decreases to 5.76

D at

Hd = 1.6

D. Both the size and maximum temperature of the heated region on the roof still increase slightly with the increase in

Hd, but the differences caused by changes in

Hd gradually diminish, indicating that the influence of

Hd on the size and maximum temperature of this heated region is relatively weakened. At this time, the heated region on the chassis continues to expand, increasing slightly with the increase in

Hd, being 11.67

D, 12.12

D, and 12.59

D, respectively. The maximum gas temperature rises to 1339 K, with no obvious increase or decrease as

Hd changes. When

H = 30 m, the maximum gas temperature in the heated region on the roof decreases to 1346 K, and the size of the region increases to 8.21

D, 8.51

D, and 9.07

D, respectively, increasing with the increase in

Hd. However, compared with the values at

H = 20 m (2.74

D, 3.77

D, and 5.76

D), the influence caused by the change in

Hd is further reduced. Due to the missile moving away, the gas wake expands fully, and the affected range of the chassis further increases. The maximum gas temperature in the heated region of the chassis slightly rises to 1437 K, and the size of the region increases to 13.81

D, 14.03

D, and 14.46

D, respectively. The relative influence caused by the change in

Hd continues to decrease. On the whole, a larger

Hd will lead to a worse thermal environment for the chassis. Among them,

Hd = 1.6

D will cause a sharp increase in the gas temperature and the size of the heated region on the roof when

H ≤ 10 m.

Both

Figure 5b and

Figure 9 show that although not directly impacted by the gas flow, the bottom of the carriage is still affected by the gas flow. To fully describe the thermal environment of the system,

Figure 11 presents the gas temperature distribution at the bottom of the carriage. At

H = 0 m, due to the low height of the deflector with

Hd = 1.2

D, the deflection of the gas flow occurs later, allowing a large amount of gas flow to pour into this area. As a result, the thermal environment at the entire bottom of the train is the worst, with high-temperature regions where the gas temperature exceeds 2000 K appearing on both the upper and lower sides. The maximum width of these regions in the y-direction is 2.01

D, and the maximum gas temperature reaches 2639 K. The deflector with

Hd = 1.4

D can deflect the gas flow earlier, thus reducing the amount of gas flow entering the undercarriage. The range of the high-temperature region is reduced to 1.55

D, and the maximum gas temperature drops to 2447 K. The deflector with

Hd = 1.6

D can deflect the gas flow even earlier, further reducing the range of the high-temperature region to 0.49

D, with the maximum gas temperature decreasing to 2334 K. At

H = 2 m, as the height of the missile body increases, the thermal environment at the bottom of the carriage is somewhat alleviated. For

Hd = 1.2

D, the width of the high-temperature region is 1.87

D, and the maximum gas temperature drops to 2610 K. For

Hd = 1.4

D, the width of the high-temperature region is 1.04

D, with the maximum gas temperature decreasing to 2439 K. For

Hd = 1.6

D, the high-temperature region further shrinks to 0.35

D, and the maximum gas temperature reduces to 2201 K. When the missile further moves to

H = 10 m, the thermal environment at the bottom of the carriage becomes worse than in the previous working conditions. This is because when the missile is at a lower flight altitude, although the engine is closer to the ground facilities, almost all the ejected gas flow comes into contact with the deflector and is deflected by it. However, when the missile is at a higher flight altitude, despite being farther from the ground facilities, in addition to directly impacting the deflector and being deflected, the engine gas flow will also directly impact the surrounding areas, spread, and then move toward the bottom of the carriage. At

H = 10 m, for

Hd = 1.2

D, the range of the high-temperature region instead increases to 1.92

D, and the maximum gas temperature rises back to 2502 K; for

Hd = 1.4

D, the range of the high-temperature region decreases to 1.21

D, with the maximum gas temperature dropping to 2397 K; for

Hd = 1.6

D, the range of the high-temperature region reduces to 0.79

D, and the maximum gas temperature falls to 2320 K. At higher missile flight altitudes of

H = 20 m and beyond, since the engine is sufficiently far from the ground, different deflector heights (

Hd) have little impact on the thermal environment here. There is no significant difference in the temperature distribution patterns under different

Hd conditions at

H = 20 m and

H = 30 m. At

H = 20 m, the maximum gas temperatures for

Hd = 1.2

D,

Hd = 1.4

D, and

Hd = 1.6

D are 1961 K, 1939 K, and 1874 K, respectively. At

H = 30 m, the maximum gas temperatures for

Hd = 1.2

D,

Hd = 1.4

D, and

Hd = 1.6

D are 1491 K, 1488 K, and 1476 K, respectively. Overall, a larger

Hd can improve the thermal environment at the bottom of the carriage, but after

H > 10 m, the improvement effect of increasing

Hd on the bottom thermal environment will be negligible. In addition, the calculation results at

H = 10 m indicate that because the gas flow is not completely deflected by the deflector, the thermal environment at the bottom of the carriage may become worse than that at

H = 2 m when the missile is flying around this altitude.