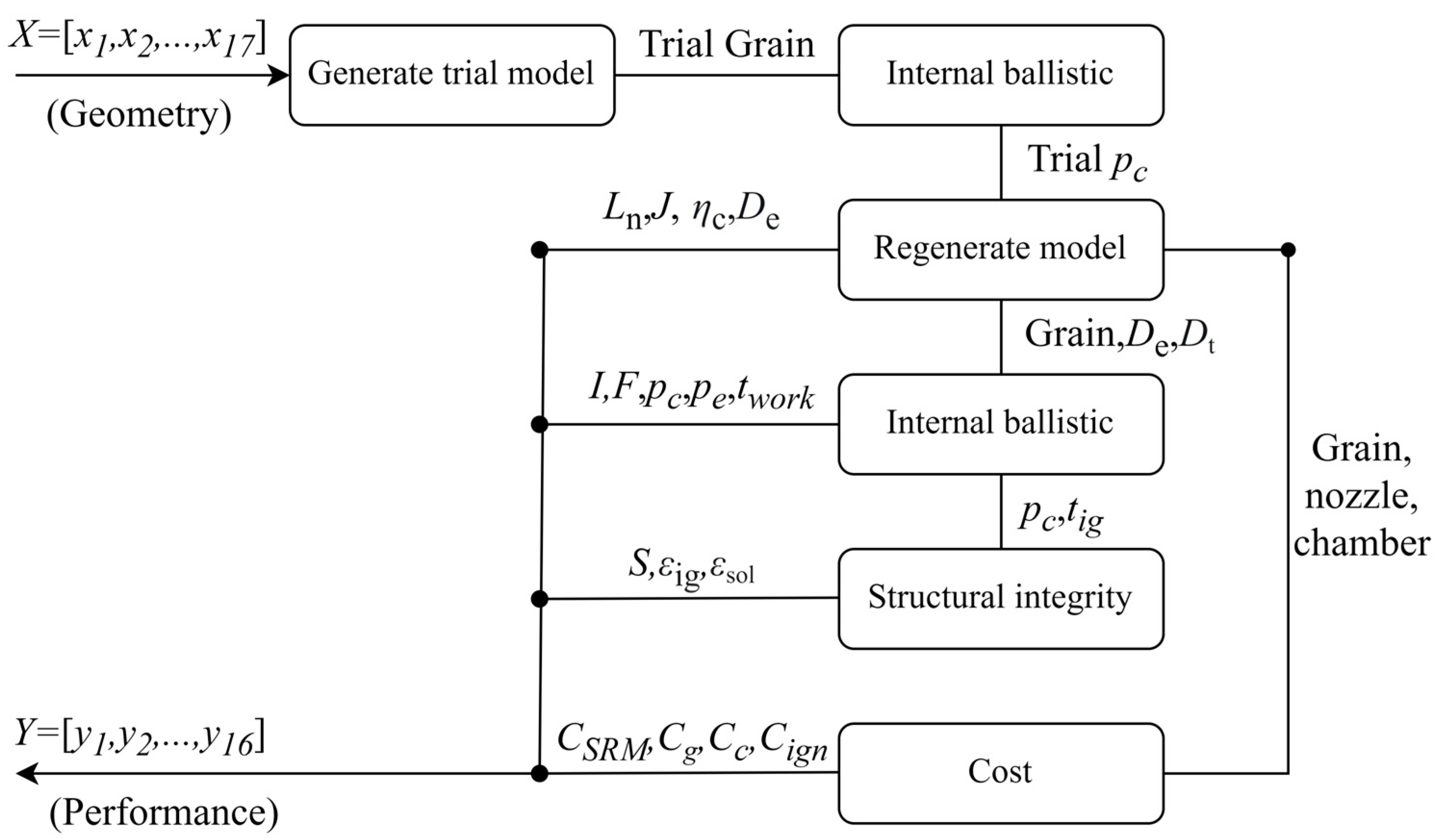

4.1. Overview of the Methodology

The overarching methodology for multi-objective optimization is illustrated in

Figure 5. The process comprises three principal stages: (i) dataset construction, (ii) surrogate model development, and (iii) optimization algorithm enhancement.

Dataset Construction (

Section 4.2). This work is founded on a comprehensive parametric analysis framework, built upon the motor performance simulation methods detailed in

Section 3. The framework systematically integrates design variables with their corresponding performance and structural metrics, enabling the automated generation of a large-scale dataset.

Surrogate Model Development (

Section 4.3). A network of surrogate models is trained using the constructed dataset, mapping a 17-dimensional input vector of design variables,

, to a 9-dimensional output vector of performance and structural parameters,

. A hybrid modeling strategy is adopted: for each output metric, the fitting accuracy of various model types is evaluated, and the optimal model is selected. This approach produces a high-fidelity ensemble surrogate for the entire motor analysis. Furthermore, the surrogate models facilitate sensitivity analysis, quantifying the importance of each design variable and revealing key heuristic design principles for this class of SRMs.

Optimization Algorithm Enhancement (

Section 4.4). The optimization phase employs an enhanced NSGA-III algorithm incorporating a novel phased hybrid crossover operator. The surrogate models developed in the previous stage serve as computationally inexpensive objective functions for the multi-objective, multi-constraint optimization. Finally, as presented in

Section 4.5, the process generates the Pareto front representing the trade-off between total impulse and cost, from which a solution of practical engineering value is selected for further analysis.

4.3. Selection and Evaluation of Surrogate Models

Several established surrogate modeling techniques are evaluated to approximate the performance functions of the solid rocket motor. These techniques include Support Vector Regression (SVR), Radial Basis Function (RBF) networks, Kriging models, and second-order Response Surface Models (RSM). The models are trained using the dataset generated from the parametric analysis framework, which captures the relationship between 17 input design variables and 9 output performance metrics.

The predictive performance of each surrogate model is quantified using the coefficient of determination (

), a metric that assesses the model’s goodness-of-fit. The coefficient of determination is defined as follows:

Here,

denotes the number of data points,

is the actual value obtained from the simulation,

is the value predicted by the surrogate model, and

is the mean of the actual values.

To ensure robust evaluation, the dataset was partitioned into a training set, containing 90% of the data, and a hold-out test set, comprising the remaining 10%. A comparative summary of the predictive accuracy for each model type, evaluated on the test set, is presented in

Table 5.

As shown in

Table 5, the comparative analysis highlights distinct performance characteristics among the surrogate models. In the table, values corresponding to the best performance among the four models on either the training or test set are indicated in bold. The second-order RSM model, although exhibiting exceptionally high fitting accuracy on the training set, displays substantial degradation in predictive performance on the test set, indicating a clear tendency toward overfitting. The SVM model provides reasonable predictions for certain metrics, such as

, but its overall goodness-of-fit on the training set is comparatively low, suggesting sensitivity to sample distribution and inconsistent generalization capability. In contrast, both the Kriging and RBF models demonstrate excellent consistency across the training and test sets, reflecting superior generalization ability. A closer examination shows that the Kriging model consistently achieves slightly higher evaluation metrics than the RBF model on both datasets. Therefore, considering the trade-off between predictive accuracy and robustness, the Kriging model was selected as the unified surrogate modeling methodology for all performance metrics.

To further validate the global accuracy of the Kriging surrogates, an independent validation set comprising 50 randomly sampled data points was employed. The design parameters from this set were input into the trained Kriging models, and the resulting predictions were compared against the ground-truth values from the high-fidelity simulations. As illustrated in

Figure 7, the relative error between the predicted and ground-truth values for all performance metrics remains within ±5%.

To identify the key driving factors in the optimization process and elucidate the trade-offs among performance metrics, this study employs the constructed high-fidelity surrogate model. The surrogate provides an explicit mapping between the design variables and motor performance, thereby enabling effective characterization of the global response across the entire design space.

Figure 8 presents the results of a global sensitivity analysis based on the SHapley Additive exPlanations (SHAP) method, which quantifies the relative importance of each design variable with respect to the performance metrics. The influence of each variable is shown in bar plots, with color indicating the direction of impact. The variables are ranked by global importance, computed as the mean of the absolute SHAP values across all samples.

The sensitivity analysis shows that motor cost, , is primarily driven by, and negatively correlated with, the grain aft port radius , nozzle divergence half-angle , and expansion ratio . Ballistic performance is strongly influenced by both the forward and aft port radius. While thrust is negatively correlated with both parameters, total impulse exhibits opposing correlations, being positive with and negative with , which highlights a critical trade-off. The safety factor is subject to complex, coupled effects from a broad set of geometric parameters , , , , and . Working time is governed primarily by and, to a lesser extent, by the grain segment lengths , , and .

Collectively, these results on varied and interdependent sensitivities provide a quantitative foundation for effective multi-objective optimization.

4.4. The NSGA-III-PHE Algorithm

In multi-objective optimization, the quality of a solution is typically evaluated using the concept of Pareto dominance. A solution

is said to dominate another solution

if and only if it is no worse than

in all objectives and strictly better in at least one objective. This relationship is formally defined as:

If these conditions are satisfied, solution is regarded as the superior solution. A solution that is not dominated by any other solution in the search space is termed a Pareto-optimal solution. The collection of all such solutions forms the Pareto front.

Compared with its predecessor NSGA-II, the NSGA-III algorithm achieves improved population diversity, primarily through the introduction of a reference-point mechanism. However, its performance is often constrained by a conventional reliance on the SBX operator, which exhibits limited recombination capability and search range. Although SBX provides strong exploitation ability, enabling fine-grained exploration near current solutions, its restricted scope hinders effective global search. As a result, the population may converge prematurely, becoming trapped in local optima and thereby reducing overall performance. In contrast, the Differential Evolution (DE) crossover operator has a stronger global search capacity, making it advantageous in the early stages of optimization for expanding the search space and enhancing solution diversity. To address these issues, this study proposes a Phased Hybrid Crossover (PHE) strategy, which dynamically employs DE and SBX operators at different evolutionary stages to balance global exploration and local exploitation effectively.

The division of the evolutionary process into distinct phases is determined by the relationship between the change in population entropy across consecutive generations,

and a predefined threshold

[

27]. When

, the algorithm is in the exploratory phase, emphasizing a broad search of the solution space to preserve population diversity. Conversely, when

, the algorithm shifts to the refinement phase, progressively focusing the search around the Pareto front to improve the precision and stability of the solutions. The iteration terminates when

for 50 consecutive generations, or when the number of iterations exceeds the maximum generation limit

. The population entropy

and the threshold

are defined as follows:

Here,

and

denote the interquartile range and the standardized median difference in the population, respectively;

is the dimensionality of the decision space, and

is the population size.

During the initial exploratory phase of evolution, the DE crossover operator is applied. Its vector differential mechanism introduces substantial structural perturbations, which facilitates a more comprehensive exploration of the solution space. The DE operator is formulated as follows:

Simultaneously, to mitigate the known sensitivity of the DE operator to the initial population distribution, a specialized initialization procedure is employed. The population is generated 50 times using the sampling process, and the instance with the maximum mean nearest-neighbor distance is selected to initiate the optimization.

Here,

is the mean nearest-neighbor distance of the trial set,

is the Euclidean distance from the

i-th sample point to its nearest neighbor, and

is the number of initial sample points.

Conversely, during the later refinement phase of evolution, the SBX operator is applied. SBX enhances solution refinement and accelerates convergence by effectively exploiting the local information contained within the parent solutions. The SBX operator is defined as:

Here,

denotes the iteration number,

is the variable index, and

is a dynamic random variable determined by a distribution index for crossover,

.

To validate the effectiveness of the proposed NSGA-III-PHE algorithm, experiments were conducted on standard benchmark functions from the DTLZ test suite. The Inverted Generational Distance (IGD) was used as the primary metric for evaluating algorithm performance. As defined in Equation (37), IGD quantifies both the convergence and diversity of a solution set, with lower values indicating a closer approximation to the true Pareto front.

Here,

denotes the set of solutions on the obtained Pareto front,

is a reference set of points uniformly sampled from the true Pareto front, and dis

quantifies the Euclidean distance between a point

and a point

.

To ensure a fair comparison, the following parameters were applied to all test problems: population size

, total number of generations

, crossover probability

, mutation probability

, crossover distribution index

, and mutation distribution index

. The dimensionalities of the decision and objective spaces are denoted by

and

, respectively. Both the standard NSGA-III and the proposed NSGA-III-PHE algorithms were executed independently 50 times on each test function. The results, summarized in

Table 6, are presented as mean (variance) of IGD values over the 50 independent runs. The significance level is set at 5%, with ‘+’ indicating that NSGA-III-PHE is significantly superior to NSGA-III, and ‘≈’ indicating no significant difference.

As shown in

Table 6, a statistical comparison at a 5% significance level reveals the following. The NSGA-III-PHE algorithm significantly outperforms the standard NSGA-III on the DTLZ1, DTLZ2, and DTLZ3 test functions [

28]. This advantage is particularly pronounced on the highly multi-modal DTLZ3 and DTLZ4 problems, where the mean IGD value achieved by NSGA-III-PHE is an order of magnitude lower. This provides strong evidence of enhanced global exploration capability, attributed to the DE operator employed during the initial evolutionary phase, which effectively enables the population to escape local optima and converge toward the true Pareto front.

Furthermore, the robustness of the proposed algorithm is improved. For test cases where NSGA-III-PHE shows a significant advantage, such as DTLZ2, the corresponding result variance (shown in parentheses) is also substantially lower than that of NSGA-III, indicating both superior performance and greater consistency across multiple runs. On the DTLZ4 and DTLZ5 test functions, which evaluate an algorithm’s ability to handle challenges such as biased or degenerate Pareto fronts, no statistically significant difference was observed. This suggests that the PHE strategy enhances global convergence without compromising other critical aspects of algorithm performance, including diversity maintenance.

Using the 2-objective, 7-variable DTLZ1 test function as an illustrative example,

Figure 9 provides a visual comparison of the results. Under the specified conditions, the Pareto front obtained by NSGA-III-PHE more closely approximates the true front than that of the standard NSGA-III, and the solutions are more uniformly distributed along the front. These observations collectively indicate an overall improvement in the performance of the NSGA-III-PHE algorithm for this problem.

4.5. Optimized Results

The NSGA-III-PHE and standard NSGA-III algorithms were applied to solve the multi-objective optimization problem for the motor, with results presented in

Figure 10. In this figure, the initial dataset (blue stars) is broadly distributed across the objective space defined by total impulse and specific cost, indicating substantial optimization potential. A comparison of the Pareto fronts generated by the two algorithms shows that the solution set obtained by NSGA-III-PHE (green triangles) completely dominates that of the standard NSGA-III (dark cyan inverted triangles), with its front boundary positioned entirely to the upper-left of the latter. This indicates that, for an equivalent cost, NSGA-III-PHE consistently yields a higher total impulse and, conversely, achieves a lower cost for an equivalent impulse, clearly demonstrating the superior optimization performance of the proposed algorithm. The median point on the NSGA-III-PHE Pareto front was selected as the preferred solution (red dot in the figure). The design parameters for this solution are listed in

Table 7, with a predicted specific cost of 23.84 × 10

4 CNY/kg and a predicted total impulse of 251.53 kN·s.

Based on the design parameters of the preferred solution, a high-fidelity solution was obtained through numerical simulation, with the calculation process illustrated in

Figure 11. The results indicate that the maximum ignition strain reaches 11.71%, whereas the maximum curing strain is 7.2%. Strain distribution is primarily concentrated in the fin slots and the central hole. The peak internal ballistic pressure is approximately 17 MPa, slightly higher than that of the initial design, and the working time ranges from 7.5 to 8.0 s.

Table 8 compares the predictions of the surrogate model with the results of this high-fidelity solution. The data show that the relative errors for all parameters are within ±3%, and, more importantly, the errors for the core performance indicators (total impulse and cost) are below 1%. Furthermore, all performance indicators satisfy the overall constraints. These findings further confirm that the constructed surrogate model exhibits excellent reliability and robustness.

Table 9 compares motor performance before and after optimization. After multi-objective optimization, the preferred design exhibits a notable improvement in overall performance: total impulse increased by 4.72%, and cost decreased by 6.73%, while all constraints were satisfied.

Based on the sensitivity analysis presented in

Section 4.3, the mechanisms underlying the optimization effects can be further examined from a design perspective. Reducing the rear port radius

increases the total impulse

while simultaneously lowering motor cost

. Conversely, increasing the front port radius

can enhance

, but it also raises costs. Increases in the expansion ratio

and the nozzle divergence angle

both contribute to reducing motor costs, while their effects on

are relatively minor. Compared with the initial design, the optimized configuration features a smaller

, a larger

, and a slightly higher

, whereas

changes only marginally due to compensating effects on

and motor cost

. Overall, the optimized design improves total impulse while reducing motor costs, demonstrating strong consistency between the optimization results and the design trends revealed by the sensitivity analysis, thereby mutually validating one another.