Vapor Compression Refrigeration System for Aircrafts: Current Status, Large-Temperature-Range Challenges and Emerging Auto-Cascade Refrigeration Technologies

Abstract

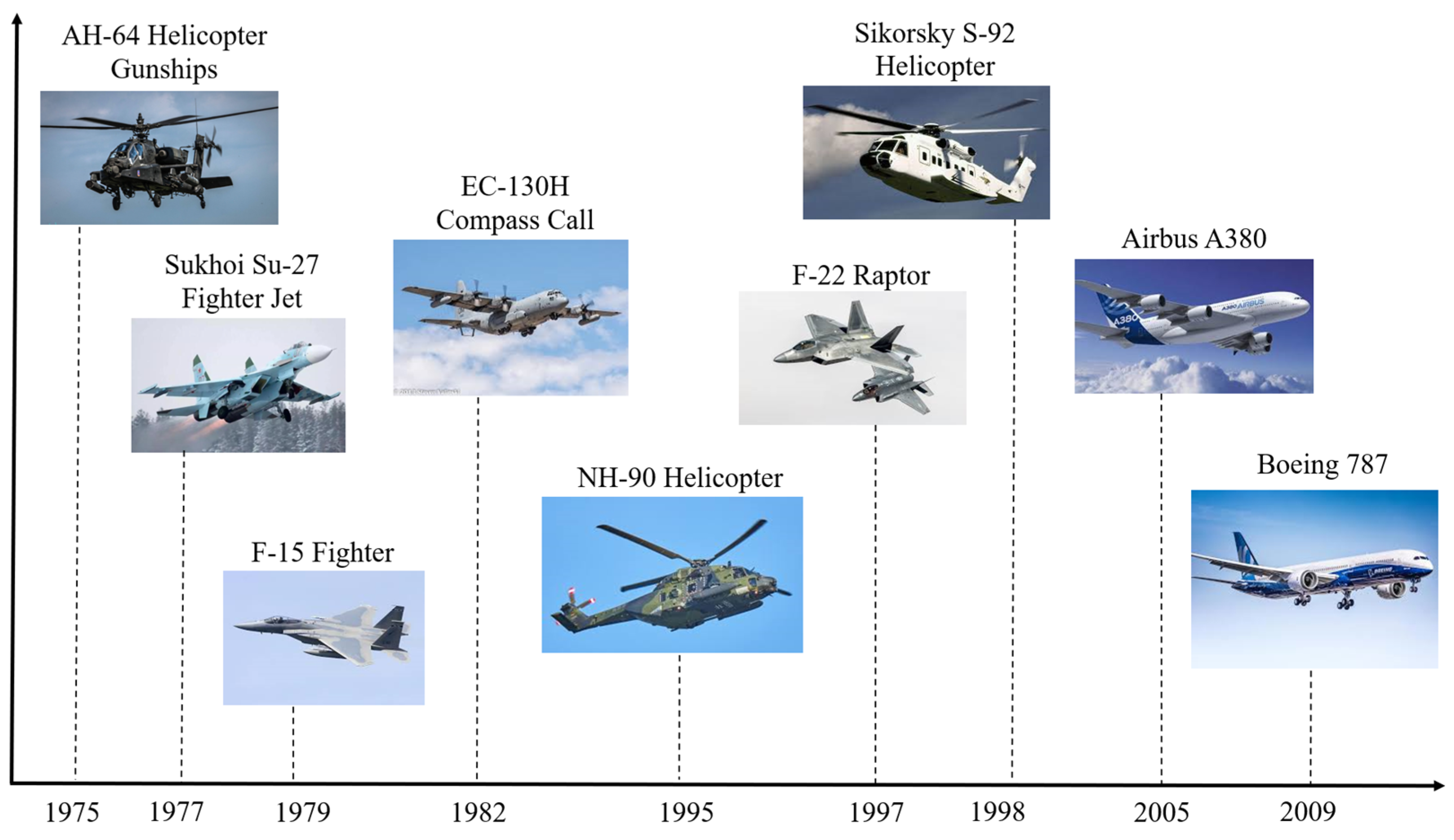

1. Introduction

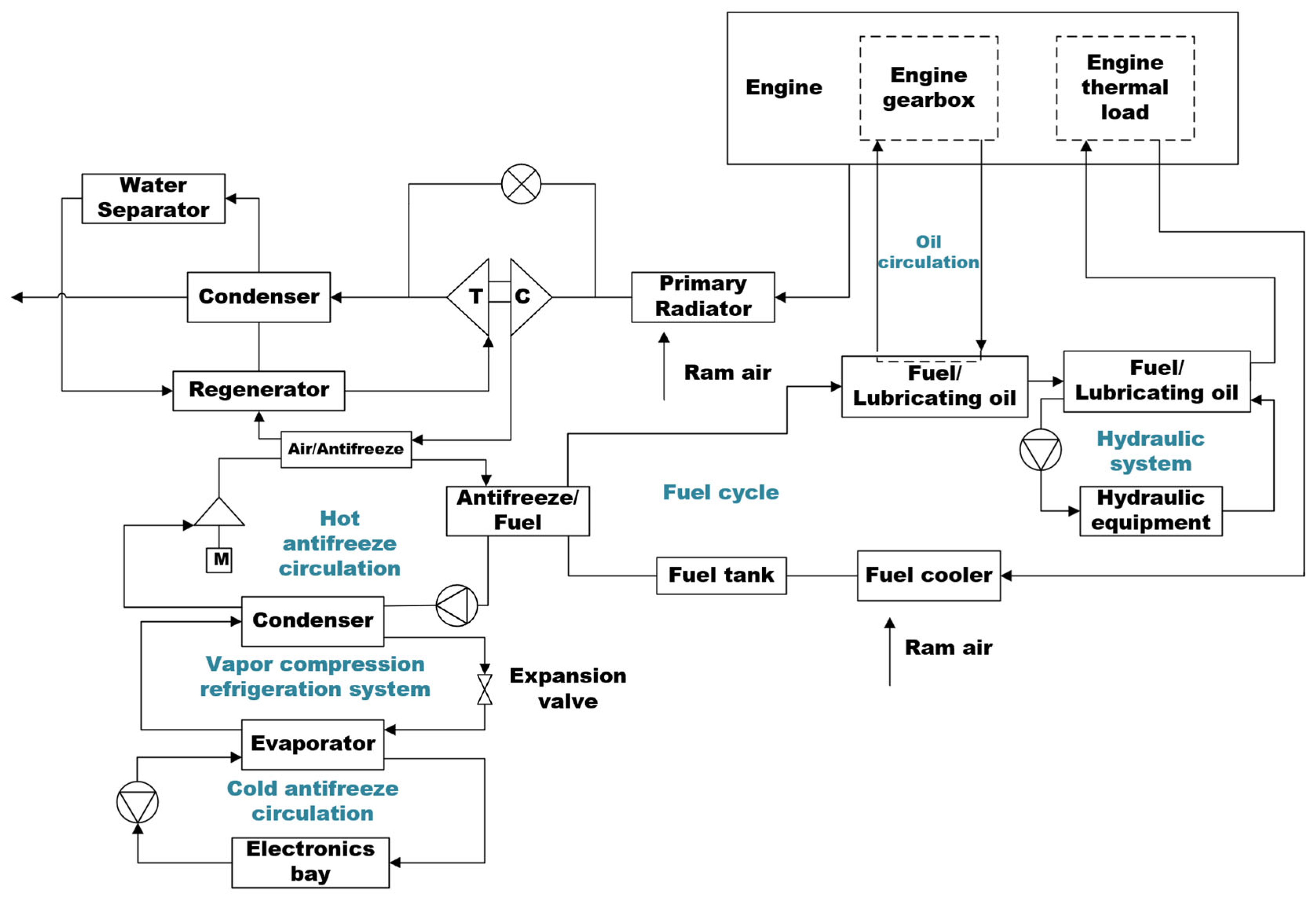

2. Research Progress

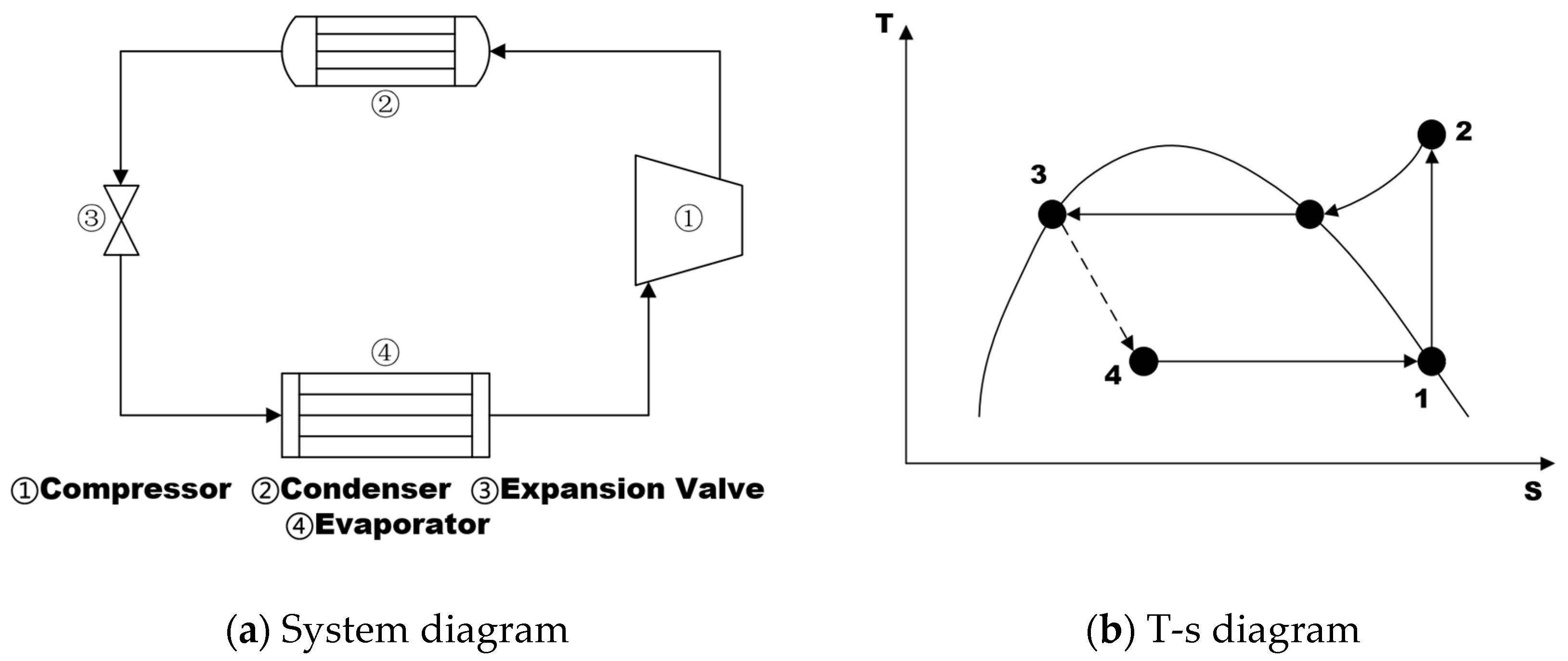

2.1. Experimental Research

2.2. Simulation Research

3. Current Application

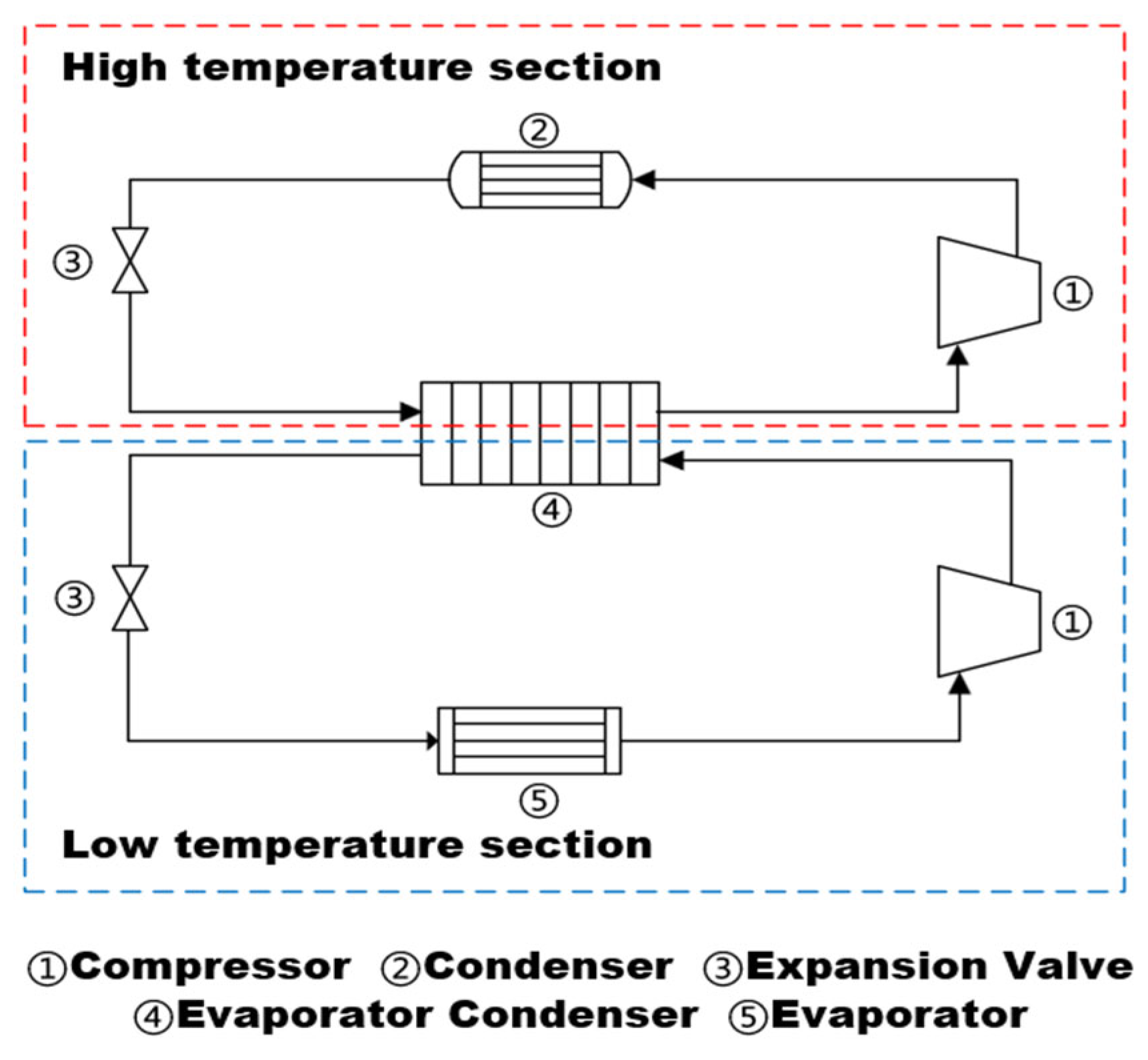

4. New Challenges Under Large-Temperature-Range Refrigeration Demand

5. Conclusions

Funding

Conflicts of Interest

Abbreviations

| AC | Alternating current |

| ACS | Air cycle system |

| ACU | Air conditioning unit |

| BP | Backpropagation |

| COP | Coefficient of performance |

| CRU | Cooling and refrigeration unit |

| DC | Direct current |

| ECS | Environmental control system |

| EEV | Electronic expansion valve |

| eva | Evaporator |

| FMEA | Failure mode and effects analysis |

| GA-PCA | Genetic Algorithm-Principal Component Analysis |

| LOVCS | Vapor compression system and a lubrication system |

| LQG | Linear quadratic Gaussian |

| MBSE | Model-based system engineering |

| P | Pressure |

| PSO-SVM | Particle swarm optimization-support vector machine |

| s | Entropy |

| set | Set value |

| SROT | Secondary refrigerant outlet temperature |

| TMS | Thermal management system |

| T | Temperature |

| VSC | Variable speed compressor |

| VG | Time-varying gravity |

| VCS | Vapor compression system |

References

- Coutinho, M.; Bento, D.; Souza, A.; Cruz, R.; Afonso, F.; Lau, F.; Suleman, A.; Barbosa, F.R.; Gandolfi, R.; Affonso, W.; et al. A Review on the Recent Developments in Thermal Management Systems for Hybrid-Electric Aircraft. Appl. Therm. Eng. 2023, 227, 120427. [Google Scholar] [CrossRef]

- Xu, J.; Tan, H.; Wu, J.; Han, J.; Su, S.; Lyu, H. Optimization Method of Heat Transfer Architecture for Aircraft Fuel Thermal Management Systems. Chin. J. Aeronaut. 2025, 38, 103452. [Google Scholar] [CrossRef]

- Wang, R.; Dong, S.; Jiang, H.; Li, P.; Zhang, H. Parameter-Matching Algorithm and Optimization of Integrated Thermal Management System of Aircraft. Aerospace 2022, 9, 104. [Google Scholar] [CrossRef]

- Tu, M.; Yuan, G.; Xue, F.; Wang, X. Application of Integrated Thermal Management in the Development of Advanced Fighter Systems. Acta Aeronaut. Astronaut. Sin. 2020, 41, 136–146. (In Chinese) [Google Scholar]

- Zhu, X.; Zhu, W.; Zhu, L.; Huang, Z.; Wen, J.; He, X.; Meng, X.; Dai, N.; Xiong, G. Research the effects of high +Gz exposure on the kidney tissue and function of pilots. J. Hunan Norm. Univ. (Med. Ed.) 2021, 18, 93–95. (In Chinese) [Google Scholar]

- Bao, W. Research on Fighter Dynamics Modeling and Maneuver Decision Making for Aerial Threat Targets. Master’s Thesis, Huazhong University of Science and Technology, Wuhan, China, 2021. (In Chinese). [Google Scholar]

- Ouyang, Z.; Nikolaidis, T.; Jafari, S. Integrated Power and Thermal Management Systems for Civil Aircraft: Review, Challenges, and Future Opportunities. Appl. Sci. 2024, 14, 3689. [Google Scholar] [CrossRef]

- Pal, D.; Severson, M. Liquid Cooled System for Aircraft Power Electronics Cooling. In Proceedings of the 2017 16th IEEE Intersociety Conference on Thermal and Thermomechanical Phenomena in Electronic Systems (ITherm), Orlando, FL, USA, 30 May–2 June 2017; pp. 800–805. [Google Scholar] [CrossRef]

- Bukar, A.M.; Almerbati, A.; Shuja, S.Z.; Zubair, S.M. Enhancing Solar PV Panel Performance Through Active and Passive Cooling Techniques: A Comprehensive Review. Renew. Sustain. Energy Rev. 2025, 216, 115611. [Google Scholar] [CrossRef]

- Rashid, F.L.; Al-Obaidi, M.A.; Azziz, H.N.; Abdalrahem, M.K.; Ameen, A.; Eleiwi, M.A.; Homod, R.Z.; Kadhim, S.A.; Agyekum, E.B.; Bouabidi, A. Enhancing Heat Pipe Performance: The Influence of Nanofluids on Thermal Management Technologies—A Comprehensive Review. Int. J. Thermofluids 2025, 28, 101311. [Google Scholar] [CrossRef]

- Jain, N.; Alleyne, A.G. Thermodynamics-Based Optimization and Control of Vapor-Compression Cycle Operation: Optimization Criteria. In Proceedings of the 2011 American Control Conference, San Francisco, CA, USA, 29 June–1 July 2011; IEEE: San Francisco, CA, USA, 2011; pp. 1352–1357. [Google Scholar] [CrossRef]

- Mahindru, D.V.; Mahendru, P. Environmental Control System for Military and Civil Aircraft. Glob. J. Res. Eng. 2011, 11, 1–7. [Google Scholar]

- Pérez-Grande, I.; Leo, T.J. Optimization of a Commercial Aircraft Environmental Control System. Appl. Therm. Eng. 2002, 22, 1885–1904. [Google Scholar] [CrossRef]

- Chaturvedi, S.; Sharma, N.K.; Ranganayakulu, C. Exergy Analysis and Performance Evaluation of a Vapor Compression Refrigeration System Using R-134a, R-600a, and R-125. Int. J. Refrig. 2025, 175, 74–84. [Google Scholar] [CrossRef]

- Biru, F.; Tafesse, G.; Nigussie, S.; Zanj, A. Experimental Investigation of Phase Change Material Integrated Vapor Compression Refrigeration System. Appl. Therm. Eng. 2025, 270, 126118. [Google Scholar] [CrossRef]

- Jiang, J.; Yang, Q.; Yin, T.; Zheng, Z.; Zhao, Y.; Liu, G.; Li, L. Comparative Thermodynamic Study of CO2 Transcritical Supermarket Booster Refrigeration System Combined with Vapor Injection and Parallel Compression. Int. J. Refrig. 2025, 170, 70–84. [Google Scholar] [CrossRef]

- Salim, M.S.; Kim, M.-H. Multi-Objective Thermo-Economic Optimization of a Combined Organic Rankine Cycle and Vapour Compression Refrigeration Cycle. Energy Convers. Manag. 2019, 199, 112054. [Google Scholar] [CrossRef]

- Sheng, J.; Zhang, H.; Wu, Z.; Lei, J. Current Status of Refrigeration and Air Conditioning Technology in Aircraft Environmental Control Systems. J. Refrig. 2020, 41, 22–23. (In Chinese) [Google Scholar]

- Affonso, W.; Gandolfi, R.; Dos Reis, R.J.N.; Da Silva, C.R.I.; Rodio, N.; Kipouros, T.; Laskaridis, P.; Chekin, A.; Ravikovich, Y.; Ivanov, N.; et al. Thermal Management Challenges for HEA—FUTPRINT 50. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1024, 012075. [Google Scholar] [CrossRef]

- Affonso, W.; Tavares, R.; Barbosa, F.R.; Gandolfi, R.; Dos Reis, R.J.N.; Da Silva, C.R.I.; Kipouros, T.; Laskaridis, P.; Enalou, H.B.; Chekin, A.; et al. System Architectures for Thermal Management of Hybrid-Electric Aircraft—FutPrInt50. IOP Conf. Ser. Mater. Sci. Eng. 2022, 1226, 012062. [Google Scholar] [CrossRef]

- Van Heerden, A.S.J.; Judt, D.M.; Jafari, S.; Lawson, C.P.; Nikolaidis, T.; Bosak, D. Aircraft Thermal Management: Practices, Technology, System Architectures, Future Challenges, and Opportunities. Prog. Aerosp. Sci. 2022, 128, 100767. [Google Scholar] [CrossRef]

- Merzvinskas, M.; Bringhenti, C.; Tomita, J.T.; De Andrade, C.R. Air Conditioning Systems for Aeronautical Applications: A Review. Aeronaut. J. 2020, 124, 499–532. [Google Scholar] [CrossRef]

- Silva-Romero, J.C.; Belman-Flores, J.M.; Aceves, S.M. A Review of Small-Scale Vapor Compression Refrigeration Technologies. Appl. Sci. 2024, 14, 3069. [Google Scholar] [CrossRef]

- Alsouda, F.; Bennett, N.S.; Saha, S.C.; Salehi, F.; Islam, M.S. Vapor Compression Cycle: A State-of-the-Art Review on Cycle Improvements, Water and Other Natural Refrigerants. Clean Technol. 2023, 5, 584–608. [Google Scholar] [CrossRef]

- Asli, M.; König, P.; Sharma, D.; Pontika, E.; Huete, J.; Konda, K.R.; Mathiazhagan, A.; Xie, T.; Höschler, K.; Laskaridis, P. Thermal Management Challenges in Hybrid-Electric Propulsion Aircraft. Prog. Aerosp. Sci. 2024, 144, 100967. [Google Scholar] [CrossRef]

- Frey, A.C.; Bosak, D.; Madrid, E.; Stonham, J.; Sangan, C.M.; Pountney, O.J. Thermal Management in High Temperature Proton Exchange Membrane Fuel Cells for Aircraft Propulsion Systems. Prog. Aerosp. Sci. 2025, 153, 101052. [Google Scholar] [CrossRef]

- Homitz, J.; Scaringe, R.; Cole, G. Evaluation of a Vapor-Compression Thermal Management System for Reliability While Operating Under Thermal Transients; SAE Technical Paper 2010-01-1733; SAE: Warrendale, PA, USA, 2010. [Google Scholar] [CrossRef]

- Newman, R.W.; Dooley, M.; Lui, C. Efficient Propulsion, Power, and Thermal Management Integration. In Proceedings of the 49th AIAA/ASME/SAE/ASEE Joint Propulsion Conference, San Jose, CA, USA, 14–17 July 2013. [Google Scholar] [CrossRef]

- Lui, C.; Dooley, M. Electric Thermal Management Architectures. In Proceedings of the SAE 2013 AeroTech Congress & Exhibition, Montréal, QC, Canada, 24–26 September 2013; SAE International: Warrendale, PA, USA, 2013. [Google Scholar] [CrossRef]

- Qi, S.; Xu, Z.; Wang, J.; Xu, Y. Dynamic Characteristics of a Two-Phase Mechanically Pumped Cooling Loop for Avionics. Case Stud. Therm. Eng. 2025, 67, 105830. [Google Scholar] [CrossRef]

- Mancin, S.; Zilio, C.; Righetti, G.; Rossetto, L. Mini Vapor Cycle System for High Density Electronic Cooling Applications. Int. J. Refrig. 2013, 36, 1191–1202. [Google Scholar] [CrossRef]

- Erkinaci, T.; Coskun, F.; Cotur, A.; Onler, R.; Serincan, M.F. Experimental and Numerical Investigation of a Compact Vapor Compression Refrigeration System for Cooling of Avionics in Harsh Environments. Appl. Therm. Eng. 2024, 236, 121663. [Google Scholar] [CrossRef]

- Zhi, R.; Ma, R.; Zhang, D.; Wu, Y. Experimental Research on a Lightweight Miniature Wankel Compressor for a Vapor Compression Refrigeration System in Aerospace. Sustainability 2023, 15, 8826. [Google Scholar] [CrossRef]

- Gao, F. Experimental and Refrigerant Charge Research on Aircraft Evaporative Cycle Refrigeration System. Master’s Thesis, Nanjing University of Aeronautics and Astronautics, Nanjing, China, 2019. (In Chinese). [Google Scholar]

- Puntel, A.; Emo, S.; Michalak, T.E.; Ervin, J.; Byrd, L.; Tsao, V.; Reitz, T. Refrigerant Charge Management and Control for Next-Generation Aircraft Vapor Compression Systems; SAE International: Warrendale, PA, USA, 2013; SAE Technical Paper 2013-01-2241. [Google Scholar] [CrossRef]

- Byrd, L.; Cole, A.; Emo, S.; Ervin, J.; Michalak, T.E.; Tsao, V. In-Situ Charge Determination for Vapor Cycle Systems in Aircraft; SAE International: Warrendale, PA, USA, 2012; SAE Technical Paper 2012-01-2187. [Google Scholar] [CrossRef]

- Kang, H.; Heo, J.; Kim, Y. Performance Characteristics of a Vapor Compression Cooling Cycle Adopting a Closed-Loop Air-Circulation System for Avionic Reconnaissance Equipment. Int. J. Refrig. 2012, 35, 785–794. [Google Scholar] [CrossRef]

- Wang, R.; Gao, Z.; Yang, H.; Hu, W.; Zhan, H. The Impact of Aircraft Refrigeration Source Parameters on the Performance of Evaporative Cycle Systems. J. Chem. Ind. Eng. 2020, 71 (Suppl. S1), 212–219. (In Chinese) [Google Scholar]

- Fan, J.; Pang, L.; Liu, D.; Zhang, H.; Zhao, M. Test Performance of Key Components in Helicopter Liquid Cooling/Evaporative Refrigeration Combined System. J. Chem. Ind. Eng. 2020, 71 (Suppl. S2), 80–84. (In Chinese) [Google Scholar]

- Sung, T.; Lee, D.; Kim, H.S.; Kim, J. Development of a Novel Meso-Scale Vapor Compression Refrigeration System (mVCRS). Appl. Therm. Eng. 2014, 66, 453–463. [Google Scholar] [CrossRef]

- Sung, T.; Kim, Y.J.; Kim, H.S.; Kim, J. Empirical Modeling and Robust Control of a Novel Meso-Scale Vapor Compression Refrigeration System (mVCRS). Int. J. Refrig. 2017, 77, 99–115. [Google Scholar] [CrossRef]

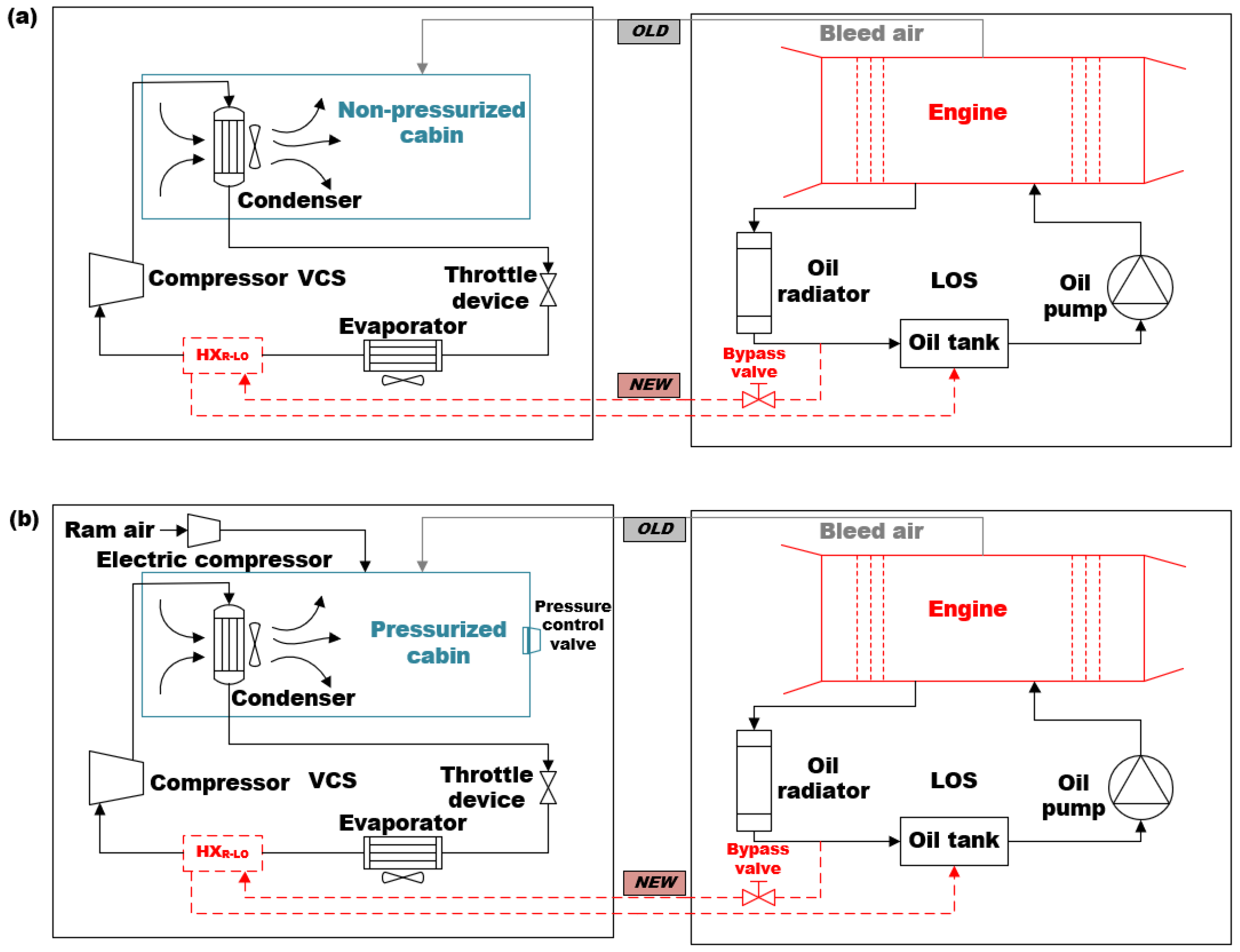

- Xu, Y.; Yan, Z.; Xia, W. A Novel System for Aircraft Cabin Heating Based on a Vapor Compression System and Heat Recovery from Engine Lubricating Oil. Appl. Therm. Eng. 2022, 212, 118544. [Google Scholar] [CrossRef]

- Zilio, C.; Righetti, G.; Mancin, S.; Hodot, R.; Sarno, C.; Pomme, V.; Truffart, B. Active and Passive Cooling Technologies for Thermal Management of Avionics in Helicopters: Loop Heat Pipes and Mini-Vapor Cycle System. Therm. Sci. Eng. Prog. 2018, 5, 107–116. [Google Scholar] [CrossRef]

- Price, D.C. Thermal Management of Military Fighter Aircraft Electro-Optics Pod: An Invited Paper. In Ninteenth Annual IEEE Semiconductor Thermal Measurement and Management Symposium; IEEE: Piscataway, NJ, USA, 2003; pp. 341–350. [Google Scholar] [CrossRef]

- Yang, G.; Xia, W.; Zhang, X. Aircraft Quasi-Two-Stage Compression Evaporative Cycle Refrigeration Technology. J. Nanjing Univ. Aeronaut. Astronaut. 2017, 49 (Suppl. S1), 35–39. (In Chinese) [Google Scholar]

- Yang, B.; Zhang, X. Optimal Design of Condenser for Aircraft Evaporative Cycle System. Henan Sci. Technol. 2021, 40, 21–23. (In Chinese) [Google Scholar]

- Wen, T.; Zhan, H.; Zhang, D.; Lu, L. Development of Evaporation Pressure-Capacity Control Strategy for Aircraft Vapor Cycle System. Int. J. Refrig. 2017, 83, 14–22. [Google Scholar] [CrossRef]

- Michalak, T.; Emo, S.; Ervin, J. Control Strategy for Aircraft Vapor Compression System Operation. Int. J. Refrig. 2014, 48, 10–18. [Google Scholar] [CrossRef]

- Byrd, L.; Cole, A.; Cranston, B.; Emo, S.; Ervin, J.; Michalak, T.E. Two Phase Thermal Energy Management System; SAE: Warrendale, PA, USA, 2011; SAE Technical Paper 2011-01-2584. [Google Scholar] [CrossRef]

- Sun, C.; Wang, H.; Jiang, Y.; Gao, Z.; Wang, J. A Hybrid Piecewise FDD Strategy for Refrigeration Charge Fault of Airborne Vapor-Compression Cycle System. Int. J. Refrig. 2022, 135, 164–173. [Google Scholar] [CrossRef]

- Sun, C. Research on Physical Integration and Health Management Technology of Aircraft Evaporative Cycle Refrigeration System. Ph.D. Thesis, Nanjing University of Aeronautics and Astronautics, Nanjing, China, 2022. (In Chinese). [Google Scholar]

- Liu, X.; Sun, C.; Jiang, Y.; Zheng, W.; Gao, Z. Research on Fault Diagnosis and Visualization Software of Aircraft Refrigeration System. Refrig. Air Cond. 2019, 33, 457–461. (In Chinese) [Google Scholar]

- Yang, B.; Zhang, X. Optimal Design of Aircraft Evaporative Cycle System Based on MBSE. China Sci. Technol. Inf. 2022, 29–30. (In Chinese) [Google Scholar] [CrossRef]

- Cao, H.; Zhao, J. Steady-State Simulation of Aircraft Evaporative Refrigeration Cycle. Comput. Simul. 2007, 40–42. (In Chinese) [Google Scholar] [CrossRef]

- Li, Y.; Liu, Z.; Shi, G.; Shi, H.; Cheng, D. Simulation Study on Aircraft Evaporative Cycle Refrigeration System. World Sci. Technol. Res. Dev. 2012, 34, 398–402. (In Chinese) [Google Scholar]

- Kim, J.; Kwon, K.; Roy, S.; Garcia, E.; Mavris, D.N. Megawatt-Class Turboelectric Distributed Propulsion, Power, and Thermal Systems for Aircraft. In Proceedings of the 2018 AIAA Aerospace Sciences Meeting, Kissimmee, FL, USA, 8–12 January 2018; American Institute of Aeronautics and Astronautics: Kissimmee, FL, USA, 2018. [Google Scholar] [CrossRef]

- Shetty, J.; Lawson, C.P.; Shahneh, A.Z. Simulation for Temperature Control of a Military Aircraft Cockpit to Avoid Pilot’s Thermal Stress. CEAS Aeronaut. J. 2015, 6, 319–333. [Google Scholar] [CrossRef]

- Wang, J.; Gao, Z.; Li, S.; Wang, Q. Research on Aircraft Evaporative Cycle Refrigeration System with Economizer. Aeronaut. Sci. Technol. 2016, 27, 60–67. (In Chinese) [Google Scholar]

- Peng, X.; Feng, S.; Li, C.; Wang, C.; Liu, W. Impact of Refrigerant Type on the Performance of Aircraft Evaporative Cycle System. J. Nanjing Univ. Aeronaut. Astronaut. 2020, 52, 478–484. (In Chinese) [Google Scholar]

- Gupta, P.; Khapli, R.P.; Huliraj, R.V. Designing of Vapour Cycle Cooling System of Twin Seater Basic Trainer Aircraft. In Proceedings of the 2019 International Conference on Cutting-Edge Technologies in Engineering (ICon-CuTE), Uttar Pradesh, India, 14–16 November 2019; pp. 16–21. [Google Scholar] [CrossRef]

- Hu, H.; Sun, H.; Wu, C.; Wang, X.; Lv, Z. A Steady-State Simulation Model of Supplemental Cooling System Integrated with Vapor Compression Refrigeration Cycles for Commercial Airplane. Appl. Therm. Eng. 2020, 166, 114692. [Google Scholar] [CrossRef]

- Ablanque, N.; Torras, S.; Rigola, J.; Oliet, C. Dynamic Model of Vapor Compression Systems for Aircraft Environmental Control Systems. J. Aircr. 2024, 61, 1387–1396. [Google Scholar] [CrossRef]

- Sielemann, M.; Giese, T.; Oehler, B.; Gräber, M. Optimization of an Unconventional Environmental Control System Architecture. SAE Int. J. Aerosp. 2011, 4, 1263–1275. [Google Scholar] [CrossRef]

- Peng, X.; Jiang, H.; Li, C.; Feng, S.; Liu, W. Dynamic Simulation of Helicopter Aircraft Evaporative Cycle System Based on AMESim. J. Nav. Aeronaut. Astronaut. Univ. 2018, 33, 452–458. (In Chinese) [Google Scholar]

- Long, H.; Zhu, C. Dynamic Simulation of Aircraft Evaporative Cycle System. Aircr. Des. 2012, 32, 53–57. (In Chinese) [Google Scholar]

- Zhu, Z.; Xu, Y.; Zheng, W.; Meng, F.; Xia, W. Dynamic Characteristics of Aircraft Evaporative Cycle System in High Temperature and Humidity Environment. J. Nav. Aeronaut. Astronaut. Univ. 2020, 35, 277–284. (In Chinese) [Google Scholar]

- Wang, L.; Jiang, Y.; Sun, C. Dynamic Simulation of Aircraft Quasi-Two-Stage Compression Evaporative Refrigeration System. Refrig. Air Cond. 2018, 32, 235–241. (In Chinese) [Google Scholar]

- Li, Y.; Pan, Q.; Liu, Z.; Liu, J. Dynamic Simulation of Aircraft Evaporative Cycle Refrigeration System. J. Nanjing Univ. Sci. Technol. 2013, 37, 127–132. (In Chinese) [Google Scholar]

- Ablanque, N.; Torras, S.; Oliet, C.; Rovira, J.; Pérez-Segarra, C.D. Vapor Compression System Modelica Library for Aircraft ECS. In Proceedings of the 2018 Purdue Conferences. 17th International Refrigeration and Air-Conditioning Conference at Purdue, West Lafayette, IN, USA, 9–12 July 2018. [Google Scholar]

- Liu, H.; Jiang, H.; Dong, S.; Xue, L.; Liu, Y.; Wu, J. Simulation of an Aircraft Thermal Management System Based on Vapor Cycle Response Surface Model. Chin. J. Aeronaut. 2024, 37, 64–77. [Google Scholar] [CrossRef]

- Dexter, P.F.; Martinez, M.I.; Maxwell, G.C.; Watts, R.J. Centrifuge Test of an Aircraft Vapor Cycle Environmental Control System; SAE Technical Paper 922051; SAE: Warrendale, PA, USA, 1992. [Google Scholar]

- Watts, R.J.; Martinez, M.; Gruesbeck, W.; Skowronski, V. Test Evaluation of an Affordable Fighter Aircraft Vapor Cycle System. In Aerospace Atlantic Conference & Exposition; SAE: Warrendale, PA, USA, 1994. [Google Scholar]

- Zhou, H. Research on Intelligent Control Methods of Aircraft Evaporative Cycle Refrigeration System. Master’s Thesis, Nanjing University of Aeronautics and Astronautics, Nanjing, China, 2020. (In Chinese). [Google Scholar]

- Li, Y.; Hu, H.; Lei, R. Dynamic Modelling of Supplemental Cooling Systems with Vapor Compression Refrigeration Units in Civil Aircrafts. Appl. Therm. Eng. 2024, 248, 123285. [Google Scholar] [CrossRef]

- Drego, A.D.; Andersson, D.; Staack, I. Parameter Tuning of a Vapor Cycle System for a Surveillance Aircraft. Aerospace 2024, 11, 66. [Google Scholar] [CrossRef]

- Pollock, D.T.; Williams, M.A.; Hencey, B.M. Model Predictive Control of Temperature-Sensitive and Transient Loads in Aircraft Vapor Compression Systems. In 2016 American Control Conference (ACC); IEEE: Boston, MA, USA, 2016; pp. 575–580. [Google Scholar] [CrossRef]

- Zhao, M.; Liping, P. Dynamic Numerical Investigation of Airborne Vapor Cycle Cooling System. In Proceedings of the CSAA/IET International Conference on Aircraft Utility Systems (AUS 2018), Guiyang, China, 19–22 June 2018. [Google Scholar]

- Zhao, M.; Pang, L.; Liu, M.; Yu, S.; Mao, X. Control Strategy for Helicopter Thermal Management System Based on Liquid Cooling and Vapor Compression Refrigeration. Energies 2020, 13, 2177. [Google Scholar] [CrossRef]

- Jackson, S.D.; Palazotto, A.N.; Pachter, M.; Niedbalski, N. Control of Vapor Compression Cycles under Transient Thermal Loads. In AIAA Scitech 2019 Forum; American Institute of Aeronautics and Astronautics: San Diego, CA, USA, 2019. [Google Scholar] [CrossRef]

- Godecker, W.J.; Lentz, J.C.; Parme, C.B.; Wigmore, D.B.; Winans, K.B. Vapor Cycle System for a Fighter Aircraft—The Lantirn ECU Lessons Learned. SAE Trans. 1992, 101, 609–617. [Google Scholar]

- Wu, B.; Zhang, F.; Yang, M.; Ren, Z. Progress in the Application of Phase Change Thermal Energy Storage Technology in Thermal Management of High-Energy Aircraft Weapons. Mech. Res. Appl. 2020, 33, 197–199. (In Chinese) [Google Scholar]

- Sun, Z.; Liu, M.; Qiao, S.; Gao, Z.; Meng, F. Performance Simulation Study on Hundred Kilowatt-Level Phase Change Thermal Energy Storage Heat Exchanger for Aircraft. Aircr. Des. 2024, 44, 53–58. (In Chinese) [Google Scholar]

- Barbosa, J.R. Recent Developments in Vapor Compression Technologies for Small Scale Refrigeration Applications. In Proceedings of the ASME 2011 9th International Conference on Nanochannels, Microchannels, and Minichannels, Edmonton, AB, Canada, 19–22 June 2011; ASMEDC: Edmonton, AB, Canada, 2011; Volume 2, pp. 459–471. [Google Scholar] [CrossRef]

- Ji, S.; Liu, Z. Thermodynamic and Economic Performance Comparison Between Reverse Brayton Cycles and Cascade Refrigeration Cycles with Eco-Friendly Refrigerants. Appl. Therm. Eng. 2025, 261, 125163. [Google Scholar] [CrossRef]

- Shi, R.; Bai, T.; Wan, J. Performance Analysis of a Dual-Ejector Enhanced Two-Stage Auto-Cascade Refrigeration Cycle for Ultra-Low Temperature Refrigeration. Appl. Therm. Eng. 2024, 240, 122152. [Google Scholar] [CrossRef]

- Ye, W.; Liu, Y.; Zhou, Z.; Hu, L.; Liu, Y. Performance Prediction of an Auto-Cascade Refrigeration System Using Multiple-Algorithmic Approaches. Energy 2025, 314, 134197. [Google Scholar] [CrossRef]

- Rodríguez-Jara, E.Á.; Sánchez-de-la-Flor, F.J.; Expósito-Carrillo, J.A.; Salmerón-Lissén, J.M. Thermodynamic Analysis of Auto-Cascade Refrigeration Cycles, with and without Ejector, for Ultra Low Temperature Freezing Using a Mixture of Refrigerants R600a and R1150. Appl. Therm. Eng. 2022, 200, 117598. [Google Scholar] [CrossRef]

- Karacayli, I.; Altay, L.; Hepbasli, A. Auto-Cascade Refrigeration Systems: A Key Review with Energetic and Exergetic Perspectives. Appl. Therm. Eng. 2025, 258, 124568. [Google Scholar] [CrossRef]

- Li, Y.; Jing, D.; Liu, G.; Yan, G. Study of the Migration Behavior of Mixed Refrigerants and Energy Efficiency During Actuators Action Process in Auto-Cascade Refrigeration Systems. Appl. Therm. Eng. 2025, 274, 126548. [Google Scholar] [CrossRef]

- Liu, J.; Liu, Y.; Yan, G.; Yu, J. Thermodynamic Analysis on a Modified Auto-Cascade Refrigeration Cycle with a Self-Recuperator. Int. J. Refrig. 2022, 137, 117–128. [Google Scholar] [CrossRef]

- Karacayli, I.; Altay, L.; Hepbasli, A. Comparative Analysis of a Modified Cascade Refrigeration Cycle Including an Auto-Cascade Refrigeration Cycle Using Different Zeotropic Refrigerant Mixtures for Reducing the Environmental Impact. Process Saf. Environ. Prot. 2025, 193, 976–989. [Google Scholar] [CrossRef]

- Li, Y.; Liu, G.; Chen, Q.; Yan, G. Progress of Auto-Cascade Refrigeration Systems Performance Improvement: Composition Separation, Shift and Regulation. Renew. Sustain. Energy Rev. 2023, 187, 113664. [Google Scholar] [CrossRef]

| Reference | Research Progress of VCS | Research Progress on VCS for Aircraft | Application of VCS for Aircraft | Development Trends of VCS for Aircraft Under Large-Temperature-Range Challenges |

|---|---|---|---|---|

| Coutinho et al. [1] |  |  |  |  |

| Affonso et al. [19] |  |  |  |  |

| Van Heerden et al. [21] |  |  |  |  |

| Merzvinskas et al. [22] |  |  |  |  |

| Silva-Romero et al. [23] |  |  |  |  |

| Alsouda et al. [24] |  |  |  |  |

| Asli et al. [25] |  |  |  |  |

| Frey et al. [26] |  |  |  |  |

| Current review |  |  |  |  |

—The topic was addressed in detail,

—The topic was addressed in detail,  —The topic was mentioned, but further research is needed,

—The topic was mentioned, but further research is needed,  —The topic has not been addressed.

—The topic has not been addressed.| Research Perspective | Author | Research Content | Main Results/Conclusions |

|---|---|---|---|

| Equipment Level Vapor Compression Refrigeration | Qi et al. [30] | Experimental study on VCS for aviation electronic equipment | Analyzed changes in heated wall temperature and pressure drop under variable cold source temperature conditions for both fixed and variable pump modes; Identified impacts of low-temperature startup and heat load jumps |

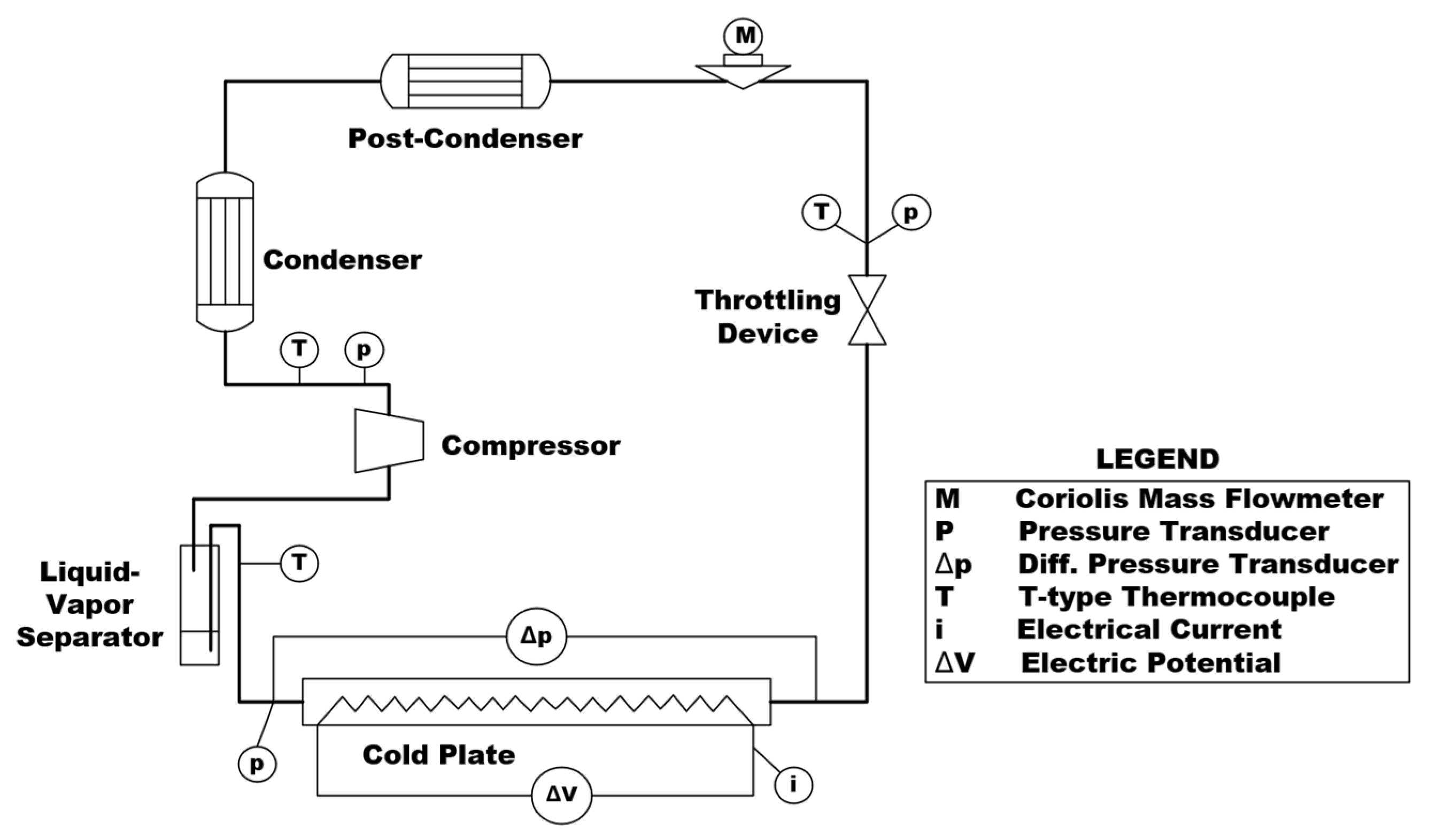

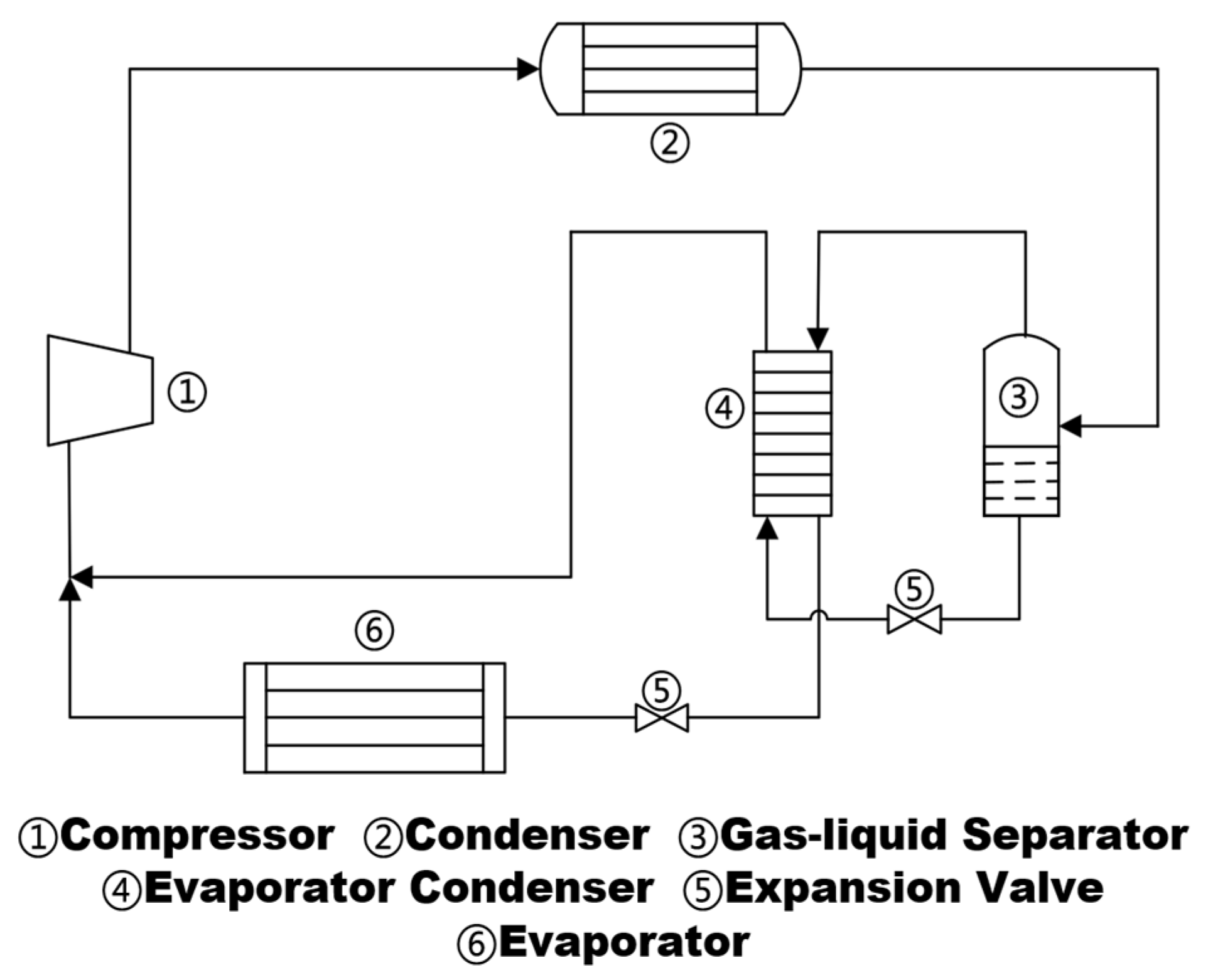

| Mancin et al. [31] | Experimental study on micro VCS for airborne electronic equipment | Obtained a system with cooling capacity of 37~374 W and COP of 1.04~5.80. System design shown in Figure 2 | |

| Erkinaci et al. [32] | Experimental study on equipment-level compact VCS | Achieved 623 W cooling capacity, COP of 2.7, maintaining component temperature below ambient temperature; Suitable for harsh thermal environments | |

| Zhi et al. [33] | Development of lightweight miniature Wankel compressor | Determined optimal charge amount as 220 g, COP reached 2.8, verified 600-h operational reliability | |

| Refrigerant Charge Amount | Gao et al. [34] | Impact of refrigerant charge amount on system performance | Determined the optimal refrigerant charge amount based on changes in COP, and verified its universality |

| Puntel et al. [35] | Control and management issues of refrigerant charge amount | Developed real-time refrigerant charge measurement technology and proposed a dynamic operating point optimization strategy | |

| Byrd et al. [36] | Method for determining appropriate refrigerant charge amount | Charge amount significantly affects system performance; Analyzed system performance under static and dynamic conditions as a function of refrigerant charge | |

| Operating Characteristics and System Form Innovation | Kang et al. [37] | Testing experiment on ACS and VCS | Measured system operating characteristics under different compressor speeds, evaporator air-side flow rates, condenser air-side flow rates, and temperatures; Optimized system performance via parameter adjustment |

| Wang et al. [38] | Characteristic test of airborne VCS based on liquid-cooled evaporator | Cold source inlet temperature significantly affects compressor superheat and heat source outlet temperature, but cold source flow rate impact is not significant | |

| Fan et al. [39] | Helicopter ECS and key component heat transfer performance test | Completed heat exchanger performance tests for evaporator and condenser, validated simulation model effectiveness, and performed parameter correction | |

| Xu et al. [42] | Ground experiment on vapor compression refrigeration and lubrication coupled system | Achieved heat recovery from lubricating oil and utilized it for cabin heating | |

| Zilio et al. [43] | Development and experiment of a novel electronic cooling system | This system couples a loop heat pipe with a micro VCS; Experiments verified its application potential in airborne scenarios | |

| Yang et al. [45] | Performance test of quasi-two-stage compression VCS | Quasi-two-stage system can reduce compressor speed and discharge temperature, extending lifespan and improving COP; Reduces power consumption and fuel consumption under the same power output | |

| Control Methods | Yang et al. [46] | Experimental optimization Experimental study on condenser two-stage parallel flow core optimization technology | Significantly reduced condenser mass and volume by adopting an optimized series structure design; Met heat exchange requirements and passed flight test assessment |

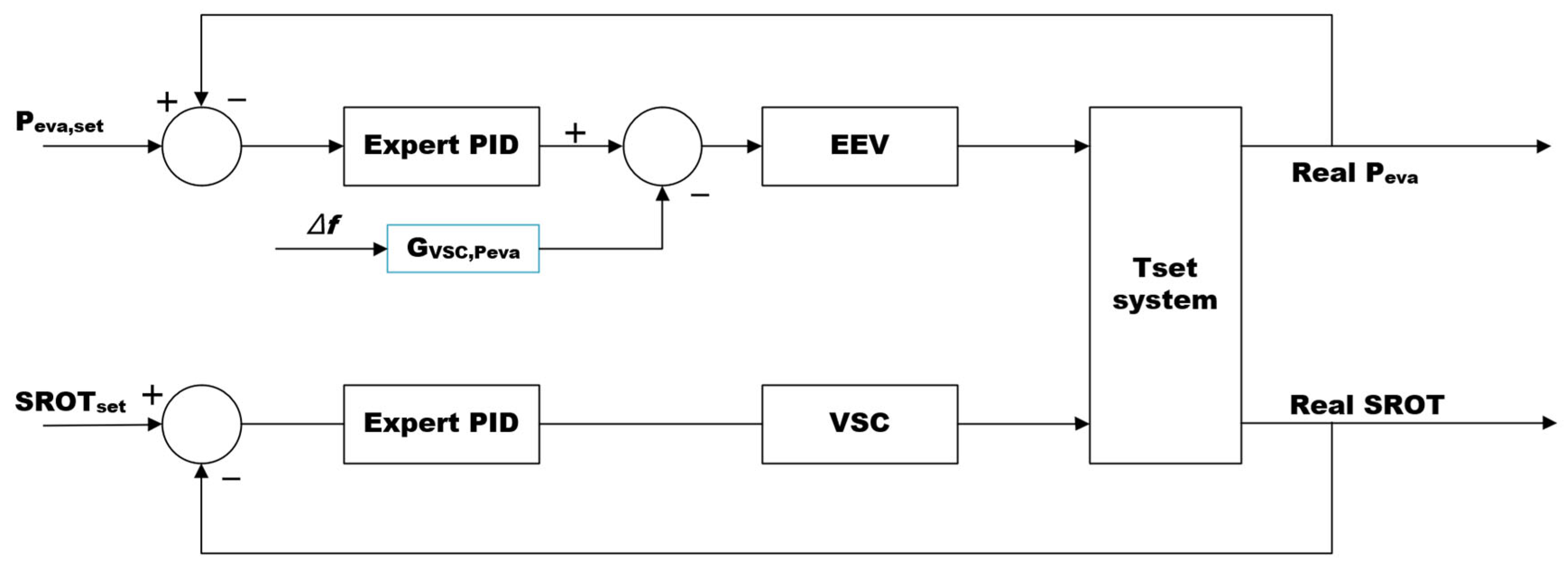

| Wen et al. [47] | Comparison and improvement of evaporation pressure control strategies | Proposed an improved control strategy that can stably control evaporation pressure (420 ± 16 kPa) and temperature (20 ± 2 °C) under severe environmental conditions | |

| Michalak et al. [48] | Experimental study on compressor control strategy based on alternating cycles | Enhanced control characteristics and COP by modulating compressor and expansion valve | |

| Byrd et al. [49] | Dynamic control of multi-evaporator VCS | Developed an optimized control strategy; System COP reached 2.39, with fast dynamic response (time constant 13 s); Supports fault detection and thermal model validation | |

| Fault Detection | Sun et al. [51] | Fault mode analysis and diagnostic model (GA-PCA-BP) development for airborne VCS | Identified main fault modes based on FMEA; Experimentally simulated 9 types of gradual faults and developed corresponding diagnostic models |

| Liu et al. [52] | Construction of PSO-SVM fault diagnosis model and MATLAB visualization interface design | Developed the PSO-SVM model and GUI software; Verified its accuracy and reliability using multiple datasets | |

| Yang et al. [53] | Compressor startup fault analysis and communication optimization based on MBSE | Proposed a single-wire communication improvement scheme; Validated effectiveness through bench tests and flight tests; Has guiding significance for helicopter system design |

| Research Perspective | Author | Research Content | Main Results/Conclusions |

|---|---|---|---|

| Performance under Specific Flight Missions/ Onboard Environments | Cao et al. [54] | Dynamic characteristics of onboard VCS with bilateral liquid heat exchange | Refrigerant flow rate changes affect COP and superheat degree; Model effectively supports dynamic characteristic analysis |

| Li et al. [55] | Optimization of VCS with bilateral liquid heat exchange | Evaporation pressure, condensation pressure, and compressor speed are key factors affecting system cooling capacity and COP | |

| Kim et al. [56] | Analysis of megawatt-level aircraft thermal management architecture | Hybrid architecture has optimal weight but high power demand; Requires increased compressor power density (P/W) and optimized refrigerant circulation for feasible design | |

| Shetty et al. [57] | Development of simulation model for military aircraft ECS | Quantified impact of flight parameters on cockpit thermal balance; Determined required bleed air flow rate and temperature control valve modulation strategy to maintain thermal comfort index | |

| Wang et al. [58] | Steady-state calculation of quasi-two-stage compression cycle system with economizer | Flash tank pre-throttle system offers better fuel penalty compensation than single-stage system; COP improvement rate is significant under harsh conditions | |

| Peng et al. [59] | Impact of refrigerants on helicopter air conditioning system performance | R134a and R1234yf have the highest COP; Cooling capacity ranking: R32 > R410A > R407C > R134a > R1234fa | |

| Gupta et al. [60] | Simulation of VCS for two-seater trainer aircraft | Verified cabin temperature and humidity regulation capability under high temperature and high Mach number conditions (40 °C, Mach 0.4), with the actual COP of 2.26 | |

| Hu et al. [61] | Development of steady-state simulation model for civil aircraft auxiliary refrigeration system | The model can predict performance of civil aircraft vapor cycle refrigeration auxiliary system; Prediction errors for cooling capacity, temperature, and pressure are within acceptable range | |

| Ablanque et al. [62] | Development of Modelica/Dymola library for simulating onboard VCSs | Model excels in numerical stability, computational efficiency, and accuracy; Can be integrated into commercial aircraft systems | |

| System Dynamic Characteristics | Peng et al. [64] | Dynamic characteristics of helicopter air heat exchange VCS | Maximum temperature spans between environment and cabin are 23 °C and 50 °C; Dynamic simulation reveals variation patterns of system parameters with operating conditions |

| Long et al. [65] | Dynamic model establishment using lumped parameter method and moving boundary method | Temperature span between condensation temperature and evaporation temperature is approximately 45 °C; Model reliability was verified through experiments | |

| Zhu et al. [66] | Dynamic characteristics of air heat exchange helicopter system | Ambient humidity significantly affects COP; Maximum temperature span between environment and cabin is 27 °C, corresponding to temperature span between condensation temperature and evaporation temperature not exceeding approximately 55 °C | |

| Wang et al. [67] | Dynamic response to parameter changes in quasi-two-stage compression system | Parameter step changes induce dynamic response of thermodynamic parameters; The model can capture multivariable coupling effects | |

| Li et al. [68] | Analysis of step change impact on system dynamic response | Revealed dynamic response patterns of system parameters to step disturbances in compressor speed, expansion valve opening, and refrigerant flow rate | |

| Ablanque et al. [69] | Proposal of Modelica library for transient simulation of onboard vapor compression refrigeration | The model supports high-efficiency and high-precision transient simulation, suitable for complex flight mission scenarios | |

| Liu et al. [70] | Aircraft thermal management dynamic simulation tool based on response surface model | Constructed efficient VCS response surface model; Determined optimal total fuel flow balance point; Proposed adaptive allocation strategy for fuel and ram air flow | |

| Gravity Impact | Watts et al. [72] | Impact of variable gravity environment on system and corresponding control strategies | The system can withstand 4Gx/4Gy/9Gz gravity load; Digital control system is key to stable operation |

| Complex Dynamic Control | Zhou et al. [73] | Proposal of decoupling control method based on BP neural network | Neural network decoupling control significantly improves system control effectiveness; Provides theoretical basis for dynamic environmental control |

| Li et al. [74] | Establishment of dynamic model for civil aircraft auxiliary cooling system | After optimization, maximum temperature deviation decreased from 0.4004 K to 0.0019 K; Proves dynamic model can be used for control optimization | |

| Adelia et al. [75] | Design of control strategy to adapt to dynamic changes in thermal load | Speed adjustment can effectively regulate system capacity; Optimized control strategy enhances system adaptability | |

| Daniel et al. [76] | Development of linear model predictive controller | The controller successfully achieves multi-load temperature regulation and possesses predictive disturbance rejection capability | |

| Zhao et al. [77] | Design of dual control strategy to optimize subcooling and superheat degrees | Dual-control strategy effectively improves system performance and satisfies external flight condition constraints | |

| Zhao et al. [78] | Helicopter thermal management control strategy based on liquid cooling and vapor compression | This control strategy can ensure stability of helicopter TMS under extreme weather conditions | |

| Jackson et al. [79] | Design of LQG controller for vapor compression refrigeration cycle | LQG controller is significantly better than PI control under transient thermal loads; Maintains temperature constraints and avoids overshoot; Verifies robustness of model predictive control |

| Aircraft Model | VCRS & Compressor Configuration |

|---|---|

| F-22 Raptor | Employed a 50 kW refrigeration capacity system powered by 270 V high-voltage DC, featuring a hermetic two-stage centrifugal compressor |

| EC-130H Compass call | Utilized a 62 kW refrigeration capacity system powered by 115 V, 400 Hz AC, equipped with a screw compressor |

| Warfare Aircraft | Operated an average 1.8 kW refrigeration capacity system powered by 115 V, 400 Hz AC, incorporating a sliding vane compressor |

| Lantian Electronic Pod | Implemented a 35 kW refrigeration capacity system using a quasi-two-stage architecture |

| Name | Principle | Working Medium | Whether it Can Adapt to a Large-Temperature-Range | Weight | Improving Manufacturing Ease on Single-Stage Systems |

|---|---|---|---|---|---|

| Single-stage vapor compression (conventional subcritical) | Single compression | Single refrigerants | No | Small (Single Compressor) | / |

| Single-stage vapor compression refrigeration (CO2 transcritical) | Single compression | Single refrigerants | No | Large (High operating pressure) | Relatively difficult, requires redeveloping compressors and heat exchangers |

| Quasi-secondary vapor compression refrigeration | Enthalpy increase through air injection via the compressor’s air-injection port | Single refrigerants | No | Small (Single Compressor) | Relatively difficult, requires redeveloping compressors |

| Two-stage vapor compression refrigeration | Using two compressions instead of one | Single refrigerants | No | Large (two compressors) | Difficult, requiring the use of two compressors |

| Dual-circuit cascade vapor compression refrigeration | Two independent systems connected in series via a heat exchanger | Two or more refrigerants | Yes | Large (two compressors) | Difficult, requiring the use of two compressors |

| Mixed refrigerant auto-cascade vapor compression refrigeration | Utilizing the auto-cascade characteristics of non-azeotropic refrigerants | Mixing two or more refrigerants | Yes | Small (Single Compressor) | Easy, can use ordinary single-stage compressor |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, H.; Wu, Q.; Feng, S.; Dong, S.; Gao, Z. Vapor Compression Refrigeration System for Aircrafts: Current Status, Large-Temperature-Range Challenges and Emerging Auto-Cascade Refrigeration Technologies. Aerospace 2025, 12, 681. https://doi.org/10.3390/aerospace12080681

Zhang H, Wu Q, Feng S, Dong S, Gao Z. Vapor Compression Refrigeration System for Aircrafts: Current Status, Large-Temperature-Range Challenges and Emerging Auto-Cascade Refrigeration Technologies. Aerospace. 2025; 12(8):681. https://doi.org/10.3390/aerospace12080681

Chicago/Turabian StyleZhang, Hainan, Qinghao Wu, Shuo Feng, Sujun Dong, and Zanjun Gao. 2025. "Vapor Compression Refrigeration System for Aircrafts: Current Status, Large-Temperature-Range Challenges and Emerging Auto-Cascade Refrigeration Technologies" Aerospace 12, no. 8: 681. https://doi.org/10.3390/aerospace12080681

APA StyleZhang, H., Wu, Q., Feng, S., Dong, S., & Gao, Z. (2025). Vapor Compression Refrigeration System for Aircrafts: Current Status, Large-Temperature-Range Challenges and Emerging Auto-Cascade Refrigeration Technologies. Aerospace, 12(8), 681. https://doi.org/10.3390/aerospace12080681