4.1. Analysis of Flow Field

In the hover condition simulation, three types of airflow are considered as follows: hot exhaust flow, main rotor downwash, and tail rotor flow. In the forward flight simulation, an additional airflow component—the forward-flight stream—is introduced, resulting in four interacting flows.

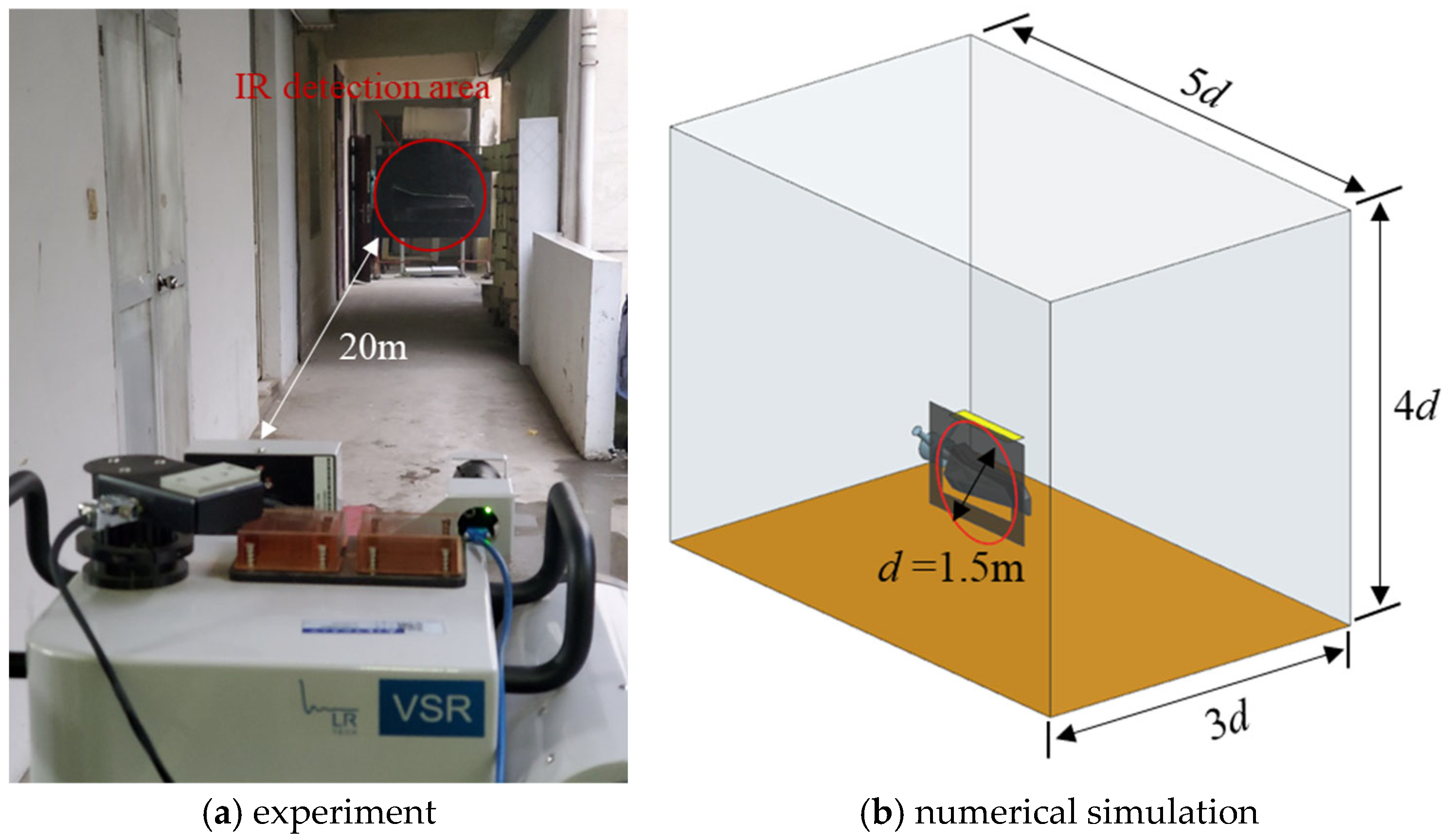

Under hover conditions, as shown in

Figure 14, the development of the exhaust plume is significantly influenced by the downward force exerted by the rotor downwash. Due to the tangential component of the induced velocity from the rotor, the streamlines of the exhaust jet from the right nozzle become asymmetric relative to those from the left nozzle. This asymmetry is caused by the clockwise rotation of the main rotor, which induces a swirling motion in the exhaust plume that follows the direction of rotor rotation.

The tail rotor flow is also disturbed by the downwash. After propagating a short distance, it is deflected downward by the rotor wash and directed toward the ground.

Under cruising conditions (flight speed of 90 m/s), as shown in

Figure 15, the influence of rotor downwash on the exhaust plume weakens noticeably. The exhaust flow is increasingly aligned with the forward-flight stream. The interaction between the forward flight airflow and the rotor downwash results in more complex plume behavior. As the forward airflow moves past the helicopter fuselage, a low-pressure region forms behind it. When the exhaust plume reaches this region, it is entrained into the low-pressure zone. Because the exhaust outlet of Model R is positioned closer to the tail, a larger portion of its plume is drawn into this region, leading to a more significant deflection in exhaust flow compared to Model W.

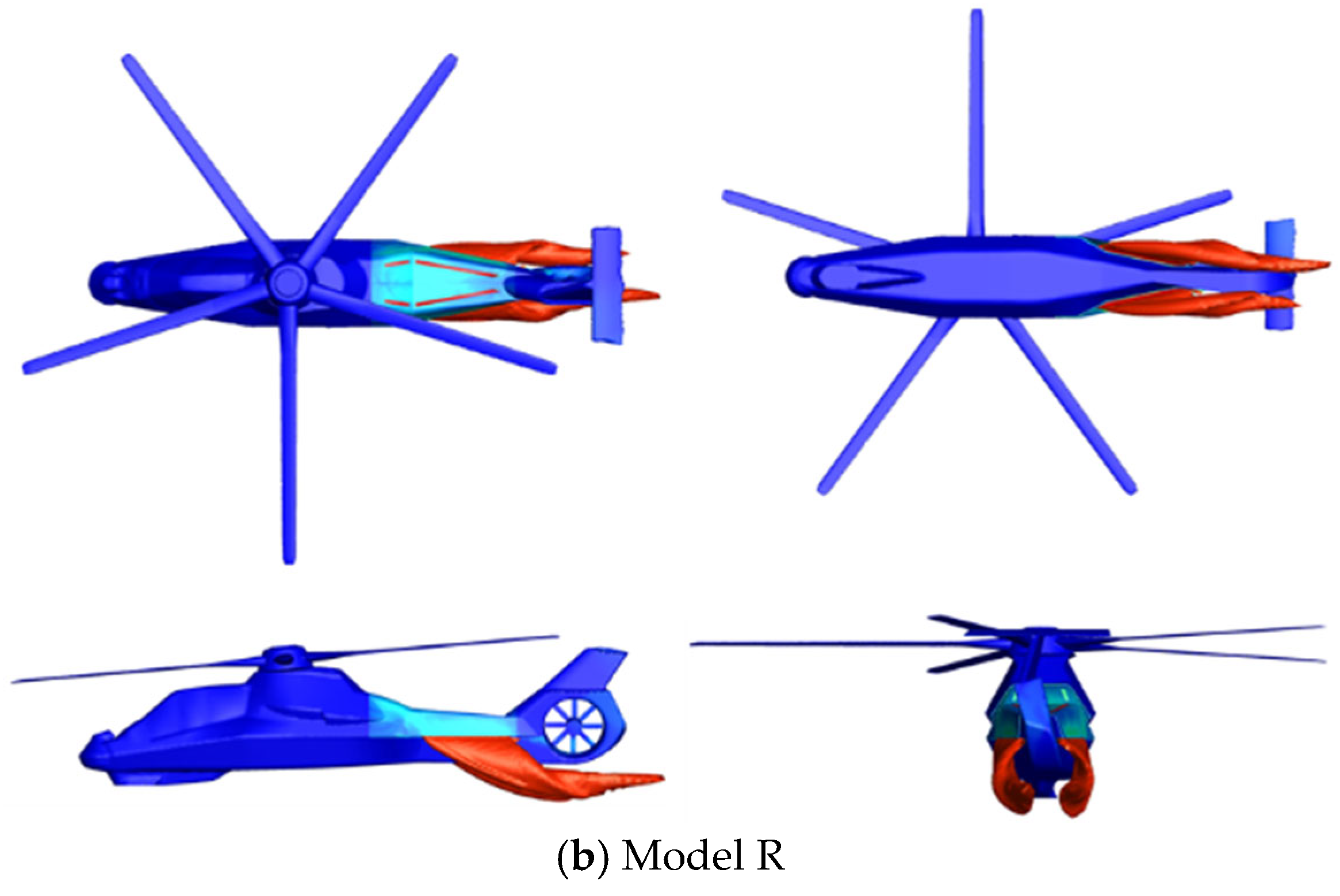

In this study, the mixing duct of the conventional helicopter (Model W) features a circular exhaust outlet, while that of the helicopter equipped with an integrated infrared suppressor (Model R) adopts a slit-shaped exhaust outlet. The different nozzle geometries result in varying levels of flow resistance within the duct. Given that the inlet and outlet areas, inlet mass flow rates, and ambient pressures are the same for both helicopter models, the flow resistance in the mixing duct can be characterized by the pressure difference ∆

P. This is defined as the difference between the total pressure

at the duct inlet and the static pressure

P∞ at the exhaust outlet, expressed as

The ejector coefficient of the mixing duct

Pc is defined as the ratio of the entrained mass flow

to the main inlet mass flow

, and is expressed as

Table 3 shows the calculated pressure loss and ejector coefficient of the mixing ducts for the two helicopter models. As shown in the table, during hover, the pressure loss of Model R is about 400–500 Pa higher than that of Model W, and about 700–800 Pa higher during cruise, indicating lower exhaust flow resistance in Model W’s mixing duct. Furthermore, the ejector coefficient of Model R is approximately 50–60% lower than that of Model W during hover, and 30–40% lower during cruise. These results suggest that the slit-type exhaust design of the helicopter equipped with an integrated infrared suppressor has a negative impact on both the flow and ejection performance of the mixing duct.

In addition, it is worth noting that due to the clockwise rotation of the helicopter’s main rotor, an asymmetry arises in the ejector performance of the left and right mixing ducts. Preliminary analysis reveals that the left duct consistently exhibits slightly higher ejector coefficients (e.g., 0.993 compared to 0.909 in hover conditions), suggesting that rotor-induced airflow could potentially be leveraged to optimize the mixing duct geometry. Future studies may exploit this asymmetric flow phenomenon by tailoring duct designs individually for each side, thereby minimizing aerodynamic penalties while maintaining balanced infrared and acoustic suppression effectiveness.

4.2. Analysis of Infrared Radiation

The intensity of infrared radiation is primarily influenced by the hot exhaust flow. Therefore, it is essential to first examine the thermal exhaust flow characteristics of the helicopter.

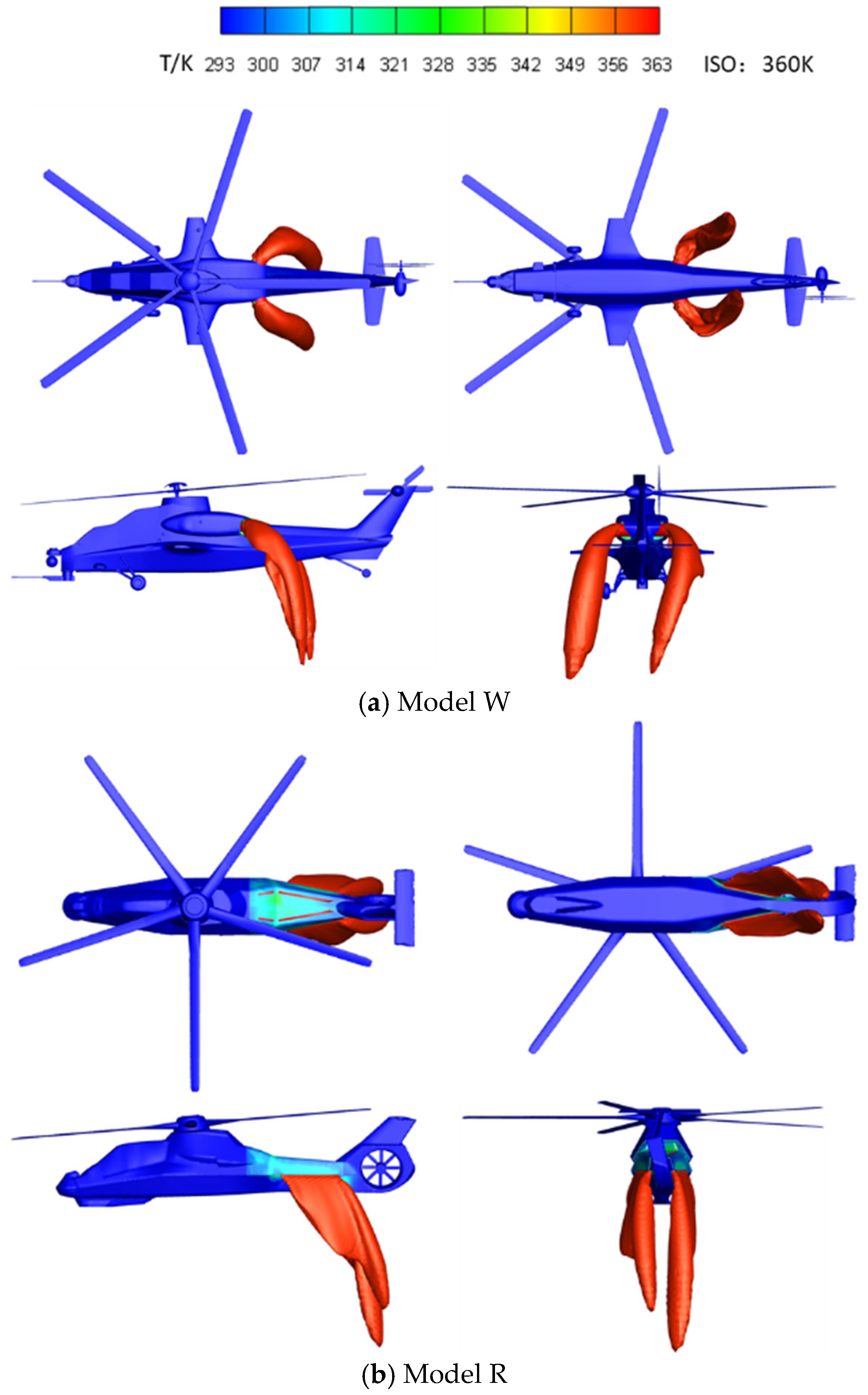

Figure 16 illustrates the 360 K isothermal surface of the exhaust jet during hover. Due to the differences in exhaust direction and nozzle geometry between the two helicopter models, the exhaust jets exhibit distinct shapes. Under the influence of the rotor downwash, the exhaust jets are deflected downward toward the lower part of the fuselage. Additionally, the rotational characteristics of the downwash induce a slight leftward deviation of the exhaust plume, which is more pronounced in Model W. Compared to Model R, the exhaust flow in Model W is farther from the fuselage and exhibits a more concentrated jet shape. In contrast, Model R, equipped with a slit-type nozzle, produces a sheet-like exhaust plume. This geometry promotes increased interaction with the surrounding airflow, enhancing mixing and cooling efficiency. The skin temperature of Model W is close to the ambient temperature, while in Model R, the exhaust system is embedded within the rear fuselage compartment, causing the rear fuselage skin to be heated by thermal radiation. Previous studies have assessed infrared suppression strategies for embedded exhaust configurations to mitigate fuselage skin heating [

33].

Figure 17 shows the 360 K isothermal surface of the exhaust jet during helicopter cruise. Compared to the hovering condition, the exhaust jet during cruise is influenced not only by the rotor downwash but also by the forward flight airflow. Since the forward flight airflow is significantly stronger than the rotor downwash during cruise, the “downward pressing” effect of the rotor downwash on the exhaust jet is diminished, and the exhaust flow is more heavily influenced by the forward flight airflow. As illustrated in

Figure 17, the exhaust jet is compelled to align with the direction of the forward flight stream. The rear fuselage skin of Model R still shows a temperature rise due to thermal radiation from the exhaust nozzle, but it is lower compared to the hovering condition.

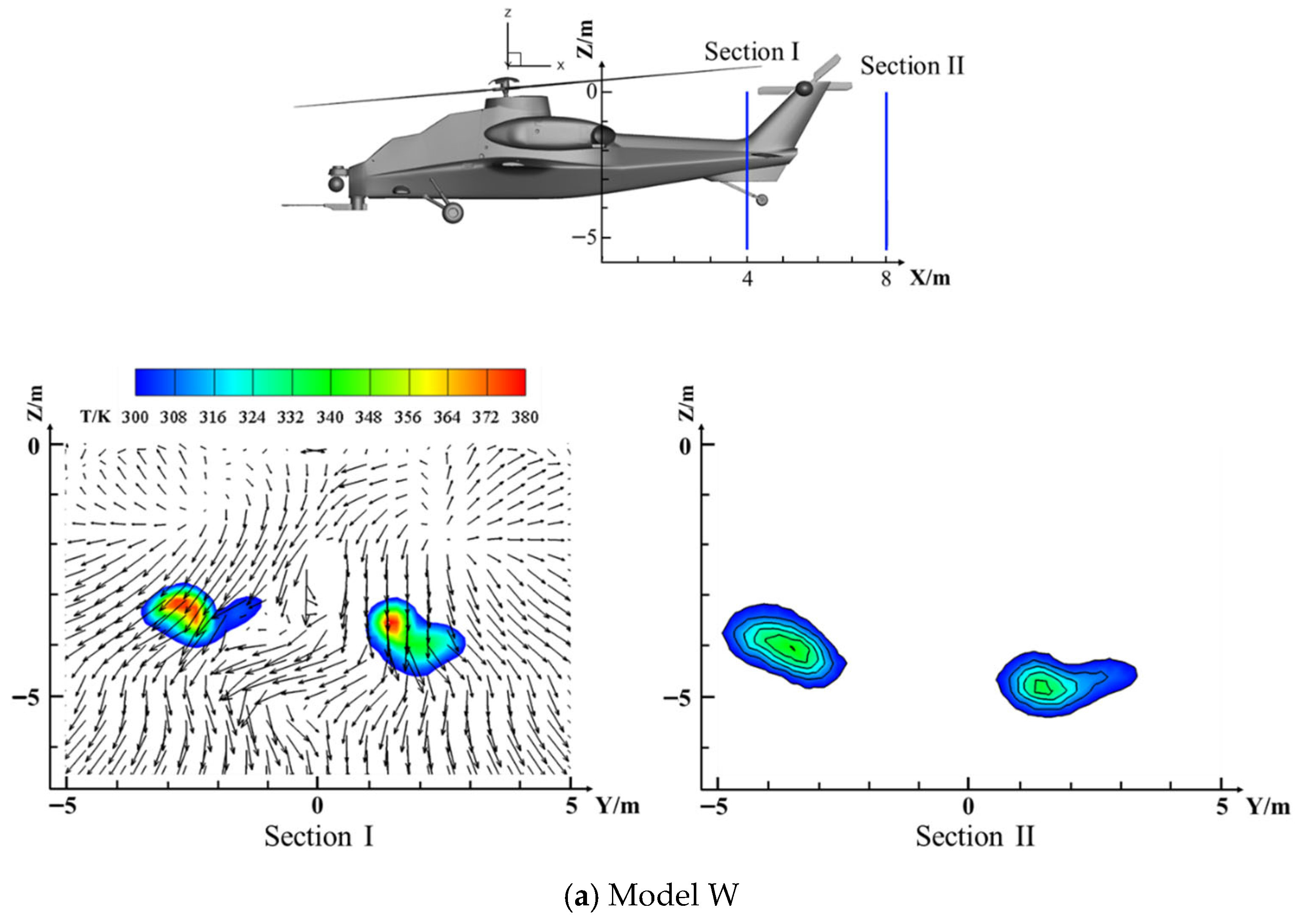

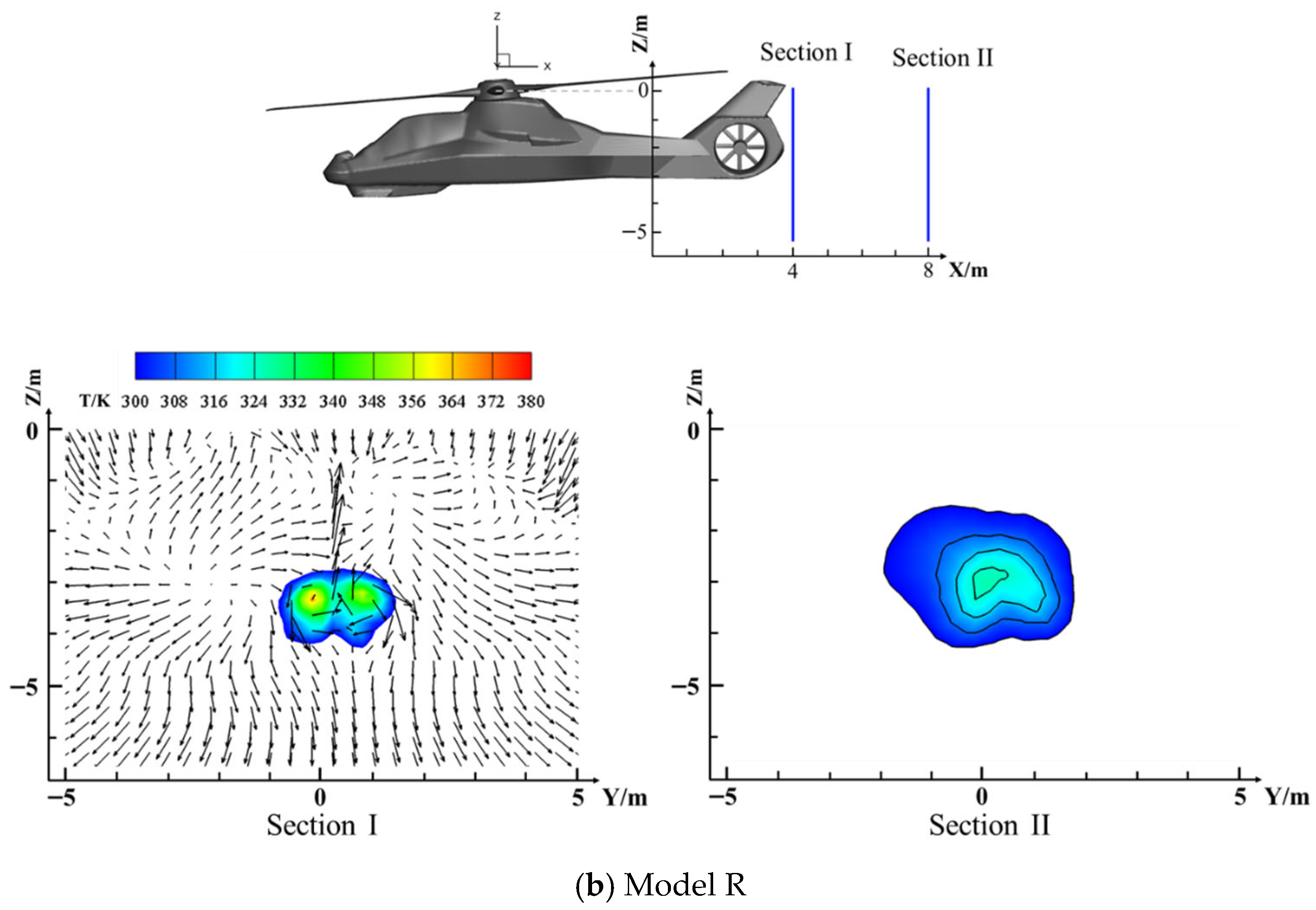

Figure 18 shows the temperature and flow field distributions at two specific cross-sectional locations during cruise, primarily to observe the downstream distribution of the hot exhaust flow. The first cross-section is located 4 m downstream from the exhaust nozzle in the direction of the forward flight airflow, and the second is 8 m downstream in the same direction. According to the analysis in

Table 3, the Model W nozzle exhibits a higher entrainment flow rate and a lower exhaust temperature at the nozzle. However, the results in

Figure 18 indicate that its downstream temperature is significantly higher. This suggests that the Model W nozzle has a lower thermal dissipation efficiency. A likely reason is the circular nozzle design, which results in slower heat exchange with the surrounding air. In contrast, the slit-shaped nozzle used in the Model R design facilitates more effective mixing with the ambient airflow, thereby enhancing the rate of exhaust temperature dissipation.

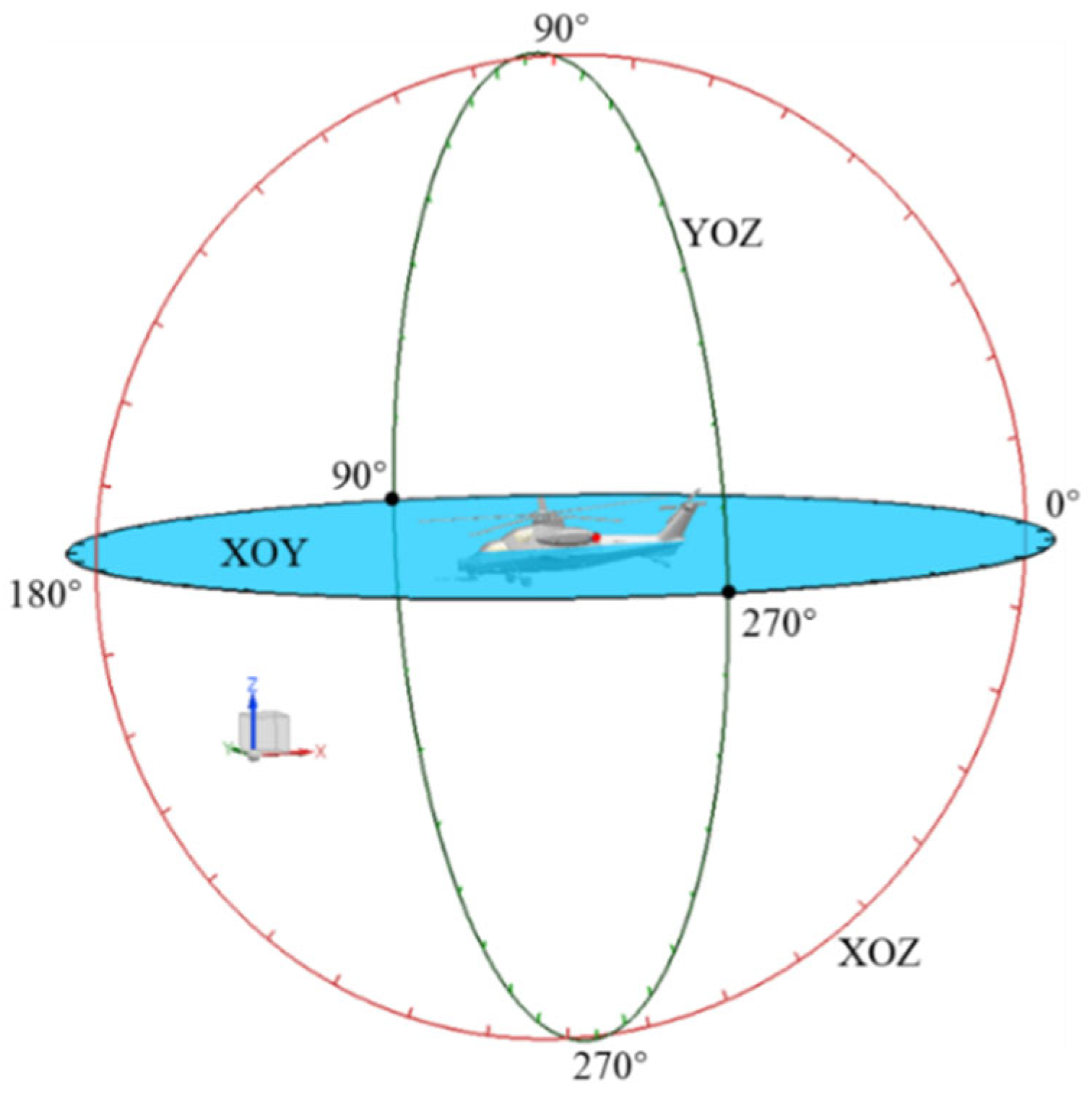

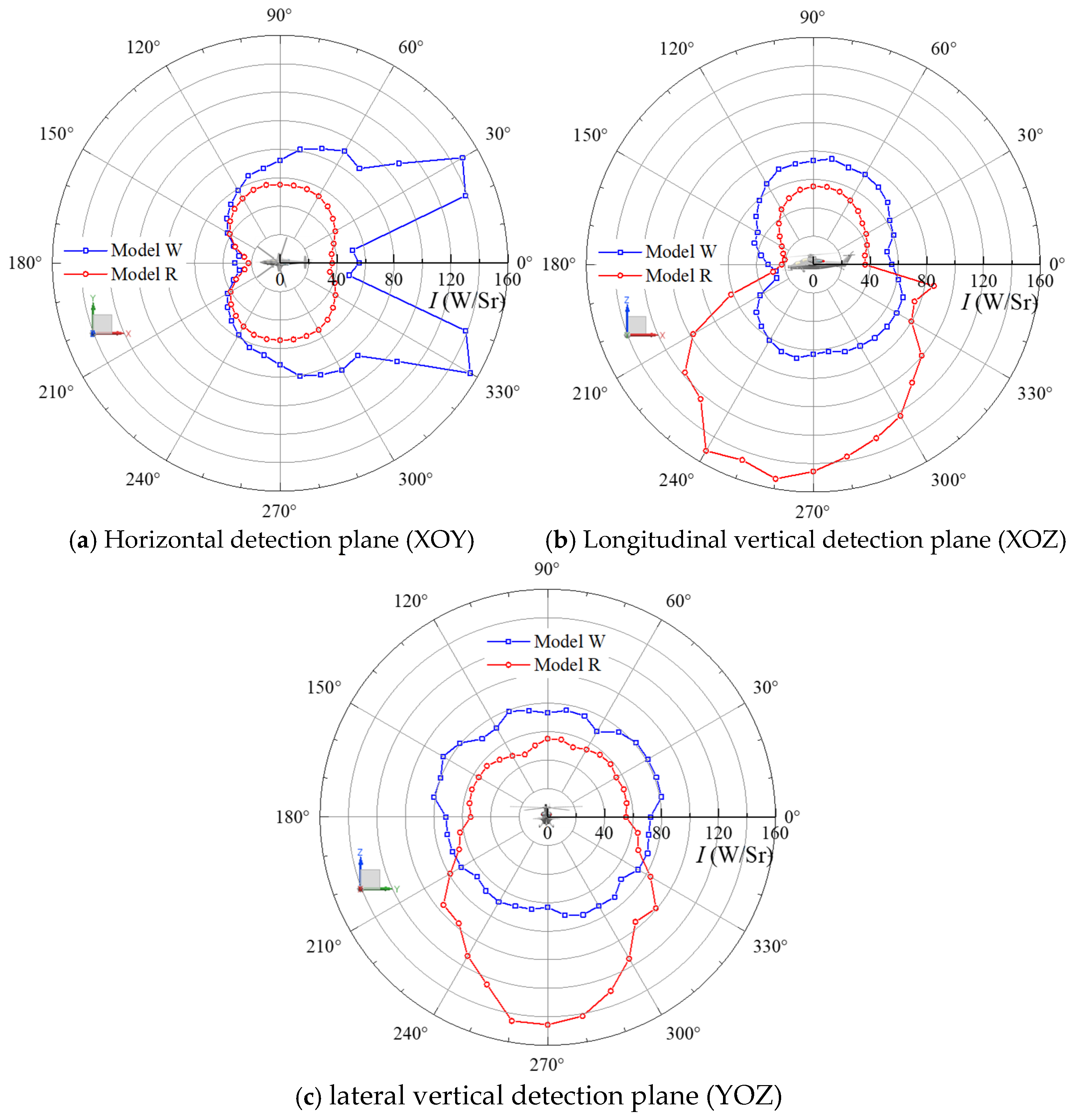

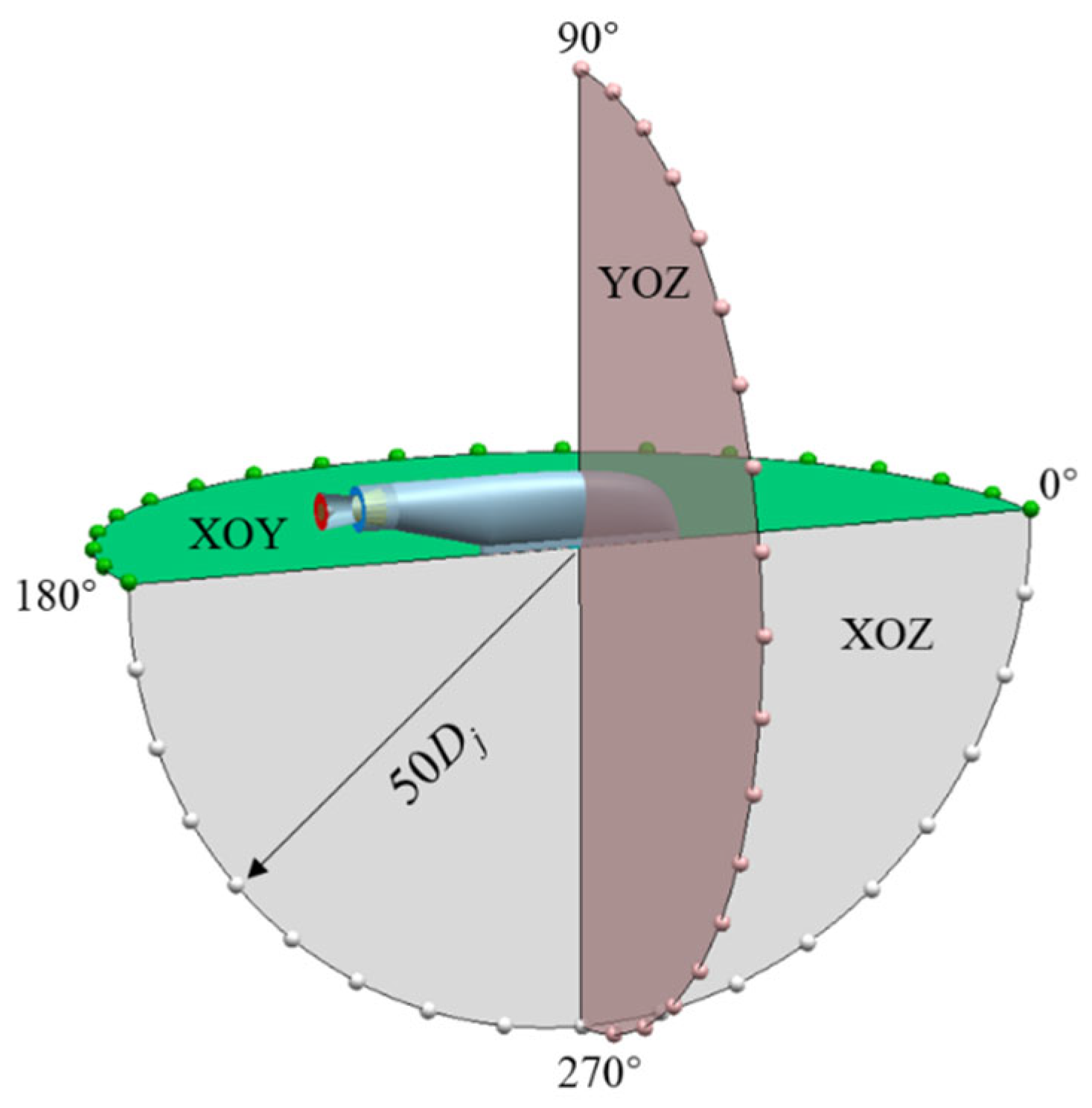

The infrared radiation calculation utilizes the forward and inverse ray tracing methods, without accounting for infrared radiation energy loss during atmospheric transmission. In this study, three representative detection planes are considered as follows: the horizontal detection plane (XOY), the longitudinal vertical detection plane (XOZ), and the transverse vertical detection plane (YOZ), as schematically shown in

Figure 19. The detection points are uniformly distributed in the circumferential direction on each plane, with an angular interval of 10 degrees.

Figure 20 presents the infrared radiation intensity distributions in the 3~5 μm band for the conventional armed helicopter (Model W) and the helicopter equipped with an integrated infrared suppressor (Model R) during hover. In the infrared radiation intensity calculations, the emissivity of the helicopter surface was set to 0.8. Since infrared radiation in the 3~5 μm band primarily originates from high-temperature components and hot exhaust flows, the distribution of infrared radiation intensity in this band is closely related to the exhaust direction. Peak radiation intensity occurs at specific locations where the mixing duct exhaust outlet is directly visible.

On the horizontal detection plane, the peak infrared radiation intensity of Model W in the 3~5 μm band is approximately 150 W/Sr, nearly four times that of Model R. On the longitudinal and transverse detection planes, Model R exhibits significantly higher infrared radiation intensity than Model W within the 190~350° detection range, with a peak value around 150 W/Sr, compared to only about 70 W/Sr for Model W. Conversely, within the 0~180° detection range, Model R has a lower infrared radiation intensity than Model W, with a difference of approximately 20 W/Sr between the two models.

Figure 21 shows the infrared radiation intensity distribution in the 8~14 μm band for Model W and Model R during hover. As shown in the figure, except for certain detection directions at the bottom of the fuselage (210~290° on the longitudinal detection plane and 260~270° on the transverse detection plane), the infrared radiation intensity of Model W in the 8~14 μm band is generally higher than that of Model R. Infrared radiation in the 8~14 μm band is primarily emitted by the solid surfaces of the helicopter fuselage. Influencing factors include the surface area of the fuselage skin and its radiation temperature, while the contribution from gases to infrared radiation in this wavelength band is minimal.

As shown in

Table 1, Model W has a slightly larger fuselage size than Model R. Therefore, when the infrared radiation intensity of Model W in the 8~14 μm band is higher than that of Model R, it is difficult to determine whether this is due to a larger radiating surface area or a higher surface radiation temperature. To clarify this, the projected areas of both helicopter models along the three principal axes were measured, as shown in

Table 4.

The infrared radiation intensities in the 8~14 μm band along each axis direction are listed in

Table 5. Each axis includes both positive and negative directions, with the positive directions defined as shown in

Figure 19. Based on the data from

Table 4 and

Table 5, and by applying the blackbody radiation function, the equivalent radiation temperatures of each model along the three axes were inferred, as summarized in

Table 6.

As presented in

Table 6, the equivalent radiation temperatures of Model R are consistently lower than those of Model W in all directions except along the negative

Z-axis. Quantitatively, the integrated suppressor yields reductions of approximately 12 K in the X direction and about 3 K in both the Y and Z directions. While

Figure 16 and

Figure 17 indicate localized high-temperature zones on the aft fuselage surface of Model R, the overall equivalent radiation temperature of Model W remains higher despite its fuselage skin being generally closer to ambient conditions. This suggests that the unshielded, high-temperature exhaust outlet of Model W plays a dominant role in infrared emissions within the 8~14 μm spectral band, underscoring the suppressor’s effectiveness in mitigating IR signatures.

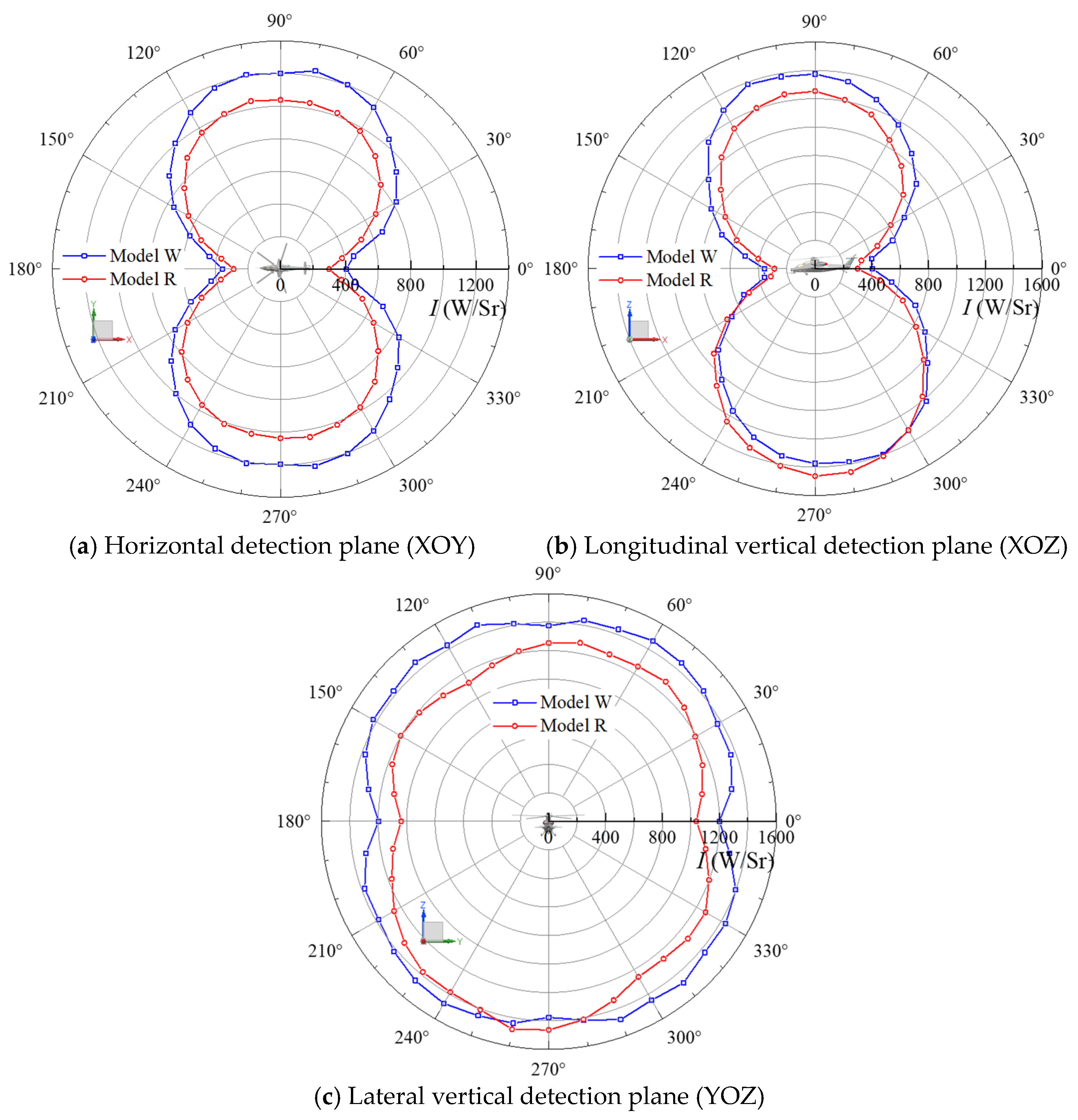

The primary threat to armed helicopters on the battlefield comes from ground-based infrared (IR) detectors and IR-guided missiles. Considering that helicopters generally cruise at a maneuvering altitude of around 300 m, and that IR detectors on the ground can have detection ranges exceeding 10 km, the position of the ground-based IR detector is almost at the same horizontal level as the helicopter being detected. Therefore, the infrared radiation distribution in the horizontal detection plane during cruise is a key focus of the study.

Figure 22 shows the infrared radiation intensity distribution in the horizontal detection plane for Model W and Model R during cruise. Comparing

Figure 20a and

Figure 22a, it can be seen that the 3~5 μm band infrared radiation of Model R during cruise decreases significantly, to about 20 W/Sr, while Model W shows no noticeable change. The reduction in 3~5 μm IR radiation intensity for Model R during cruise is mainly due to the decrease in gas-phase radiation. The slit-type exhaust nozzle of Model R produces a sheet-like exhaust jet, which increases contact with ambient air, making the exhaust more easily dispersed and cooled by the forward airflow during cruise.

In contrast, comparing

Figure 21a and

Figure 22b, it is evident that flight status has little effect on the 8~14 μm band infrared radiation intensity of the helicopter. Overall, the use of an integrated infrared suppressor on the helicopter is effective in reducing its infrared signature.

4.3. Analysis of Exhaust Acoustic

According to aeroacoustic theory, jet noise is proportional to the eighth power of the jet velocity at the nozzle, making jet velocity the most critical factor influencing jet noise. In addition, jet noise is also related to the structure of the fluid. When the jet is subsonic, the primary noise source is the turbulent mixing noise between the jet and the ambient atmosphere [

34]. Turbulent motion contains a large number of randomly generated small-scale vortices as well as large-scale quasi-organized vortex structures. Vorticity is one of the most important physical quantities used to describe vortex motion, and its mathematical expression is defined as [

35]

where

x,

y, and

z represent the three coordinate axes, and

u,

v, and

w denote the velocity components of the fluid in these directions. Among all vortex structures generated in fluid motion, streamwise vortices and transverse (orthogonal) vortices are two types that have a significant impact on the flow field. The directions of these vortices are parallel and perpendicular to the main flow direction, respectively. In this study, the streamwise and transverse vortices are defined as follows:

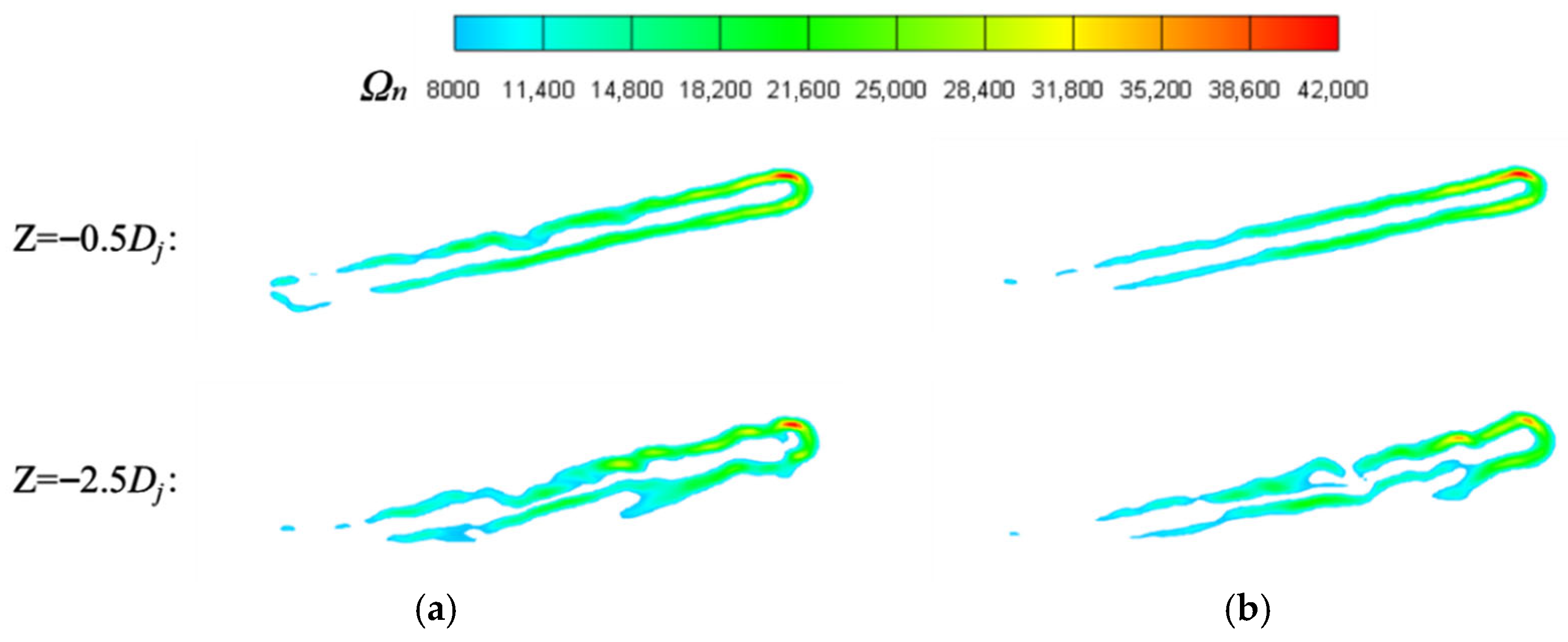

Streamwise vortices primarily occur in turbulent boundary layers and typically appear in alternating pairs of opposite rotation, extending along the direction of the main flow. Through a helical motion, they draw in ambient fluid toward the jet center. Under the influence of these vortices, the jet core spreads outward, promoting convective mixing between the core jet and the surrounding airflow. Therefore, given a fixed vorticity, stronger streamwise vortices lead to a faster decay of the main flow. Streamwise vortices are prone to compression from adjacent vortex structures and often coexist with vortices of the opposite rotation, intertwining with one another. As a result, their cross-sectional distribution is usually disordered and uneven in size.

Transverse (orthogonal) vortices are widely present in any free shear layer. During flow development, they interact with streamwise vortices. Their rotational direction is perpendicular to that of the streamwise vortices. Near the nozzle, their distribution pattern is constrained by the nozzle’s geometry and tends to exhibit a more uniform shape.

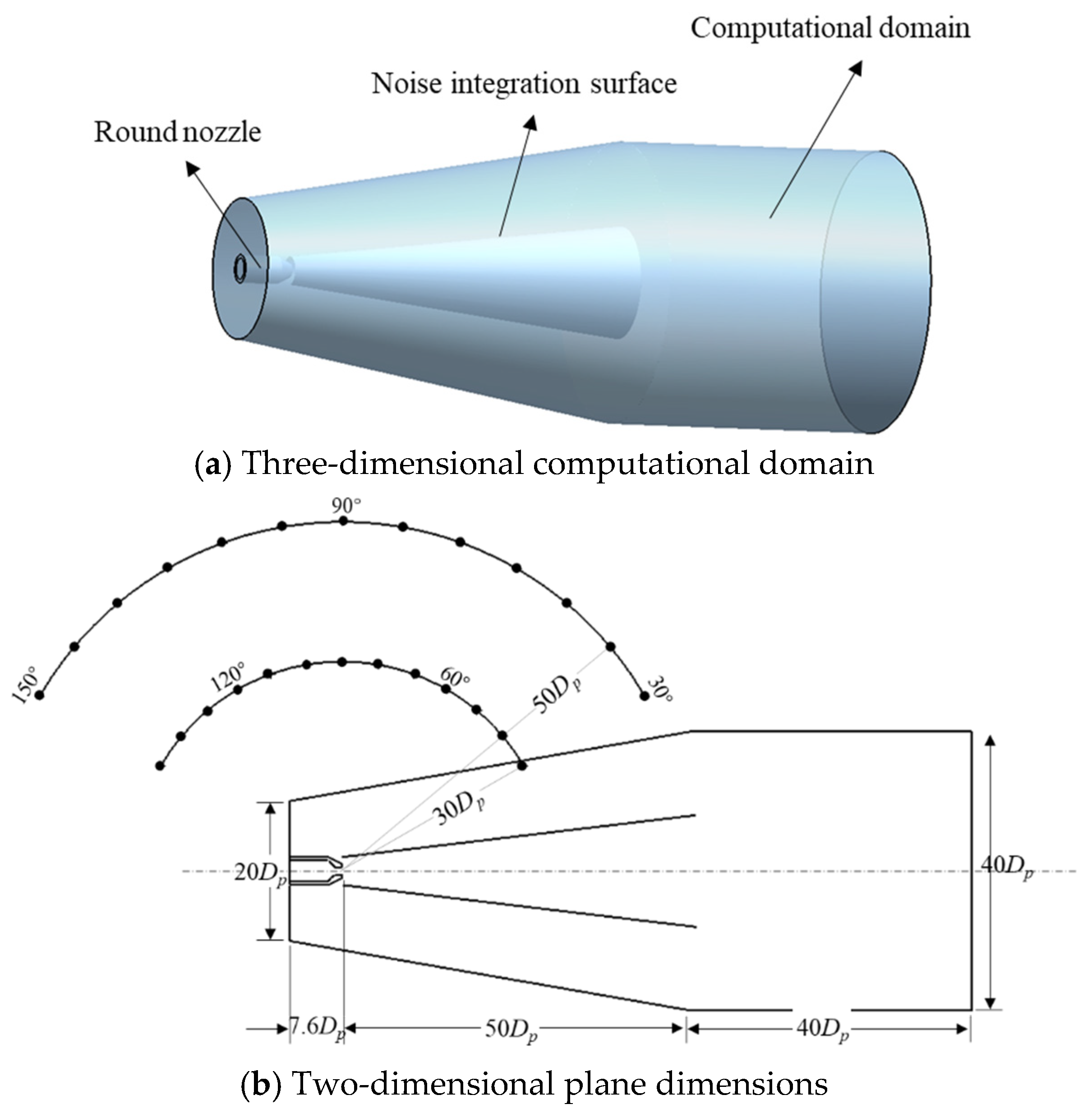

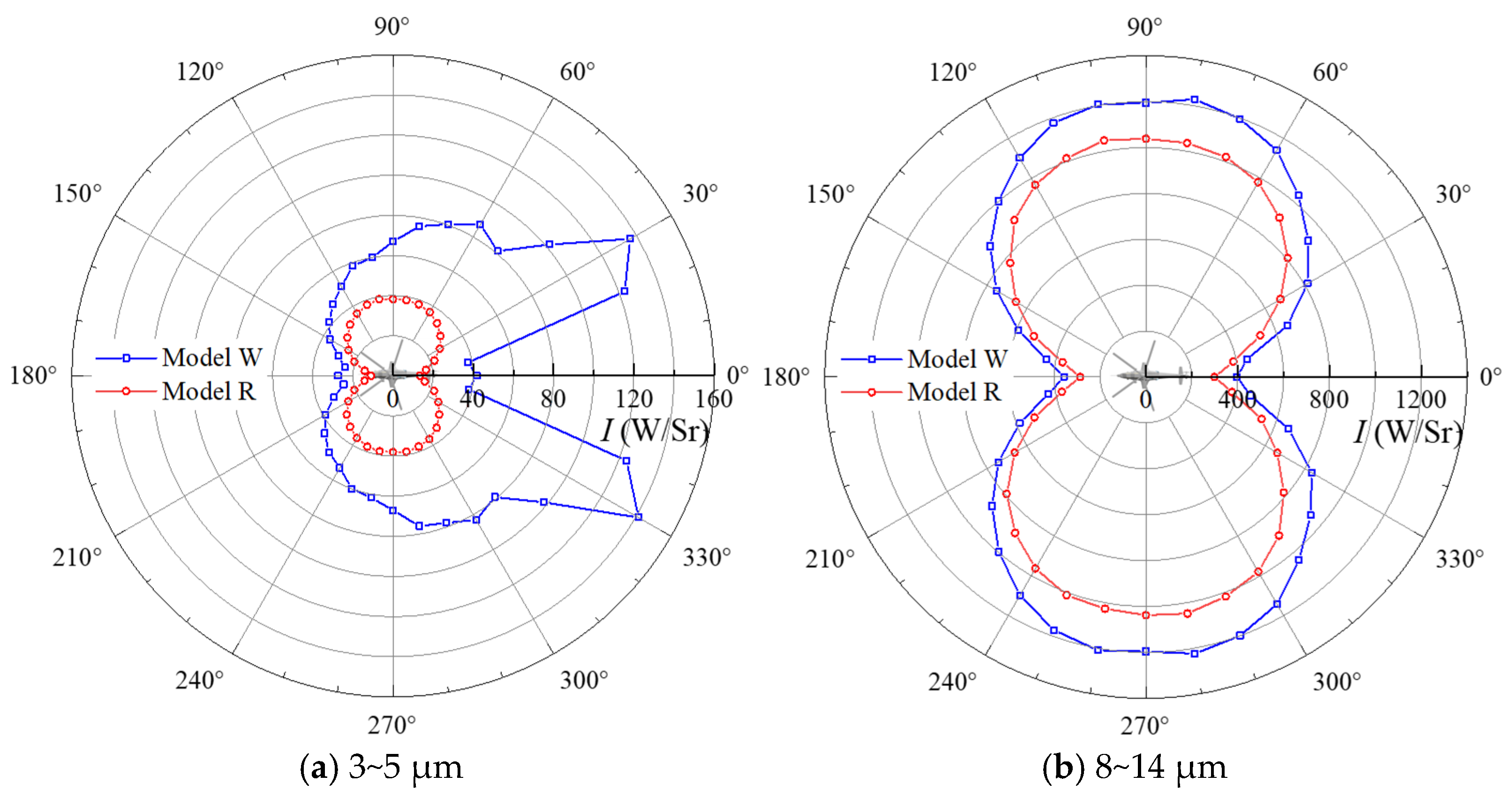

Table 7 presents the exhaust performance parameters of the Model W-0 and Model R-0. As shown in the table, the Model W-0 exhibits lower pressure loss, a higher ejector coefficient, and greater exhaust velocity. Since exhaust velocity has a significant impact on jet noise, in order to eliminate the influence of exhaust flow rate and isolate the effect of nozzle structure on jet noise, this section calculates not only the jet noise of the mixer under natural entrainment conditions, but also under non-entrainment conditions. The mixer models without entrainment are denoted with the subscript “No”.

Three typical noise monitoring planes are considered as follows: the horizontal detection plane (XOY), the longitudinal vertical detection plane (XOZ), and the lateral vertical detection plane (YOZ). Due to the left-right symmetry of the mixing duct structure, only the jet noise on one side of the symmetrical plane is monitored. On each monitoring plane, noise monitoring points are evenly distributed along the circumferential direction with an angular interval of 10 degrees and a circumferential radius of 50 times the nozzle diameter (50

Dj), as shown in

Figure 23.

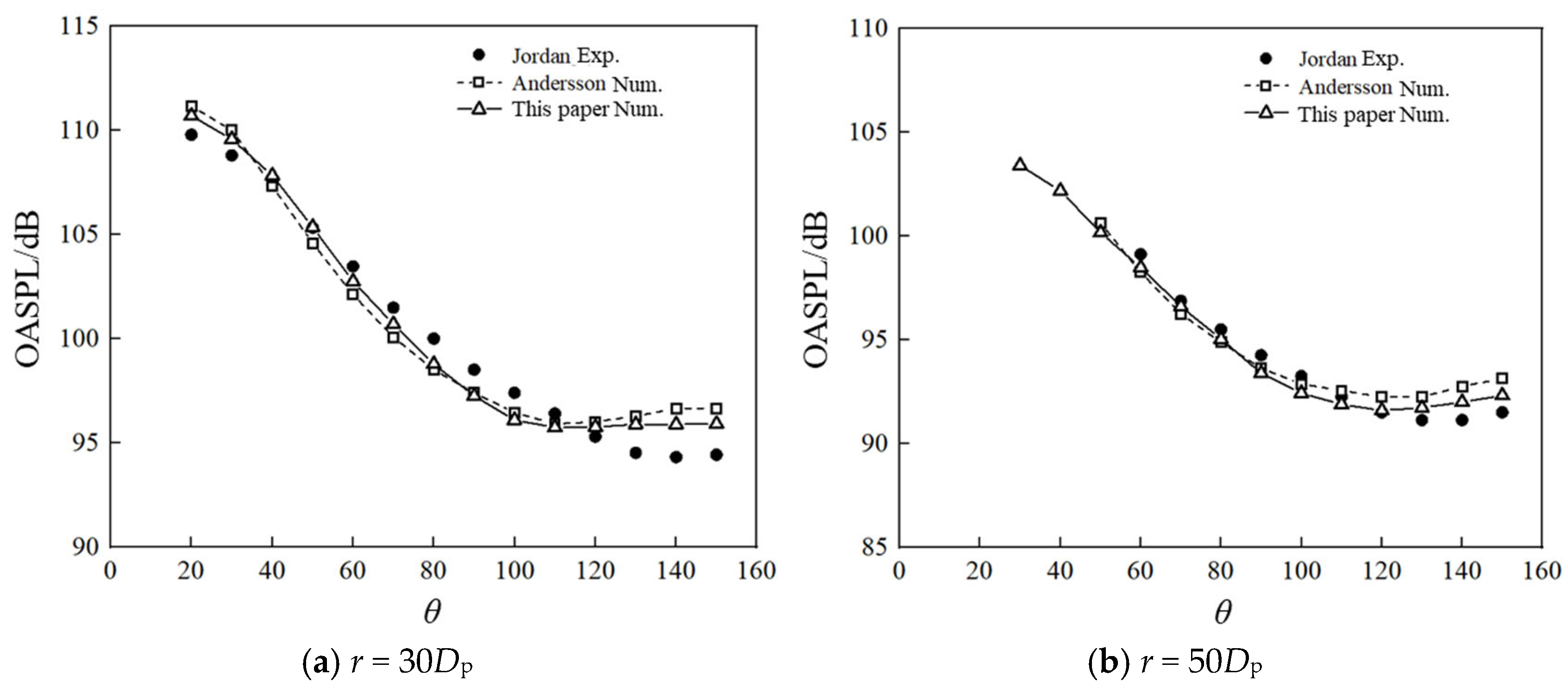

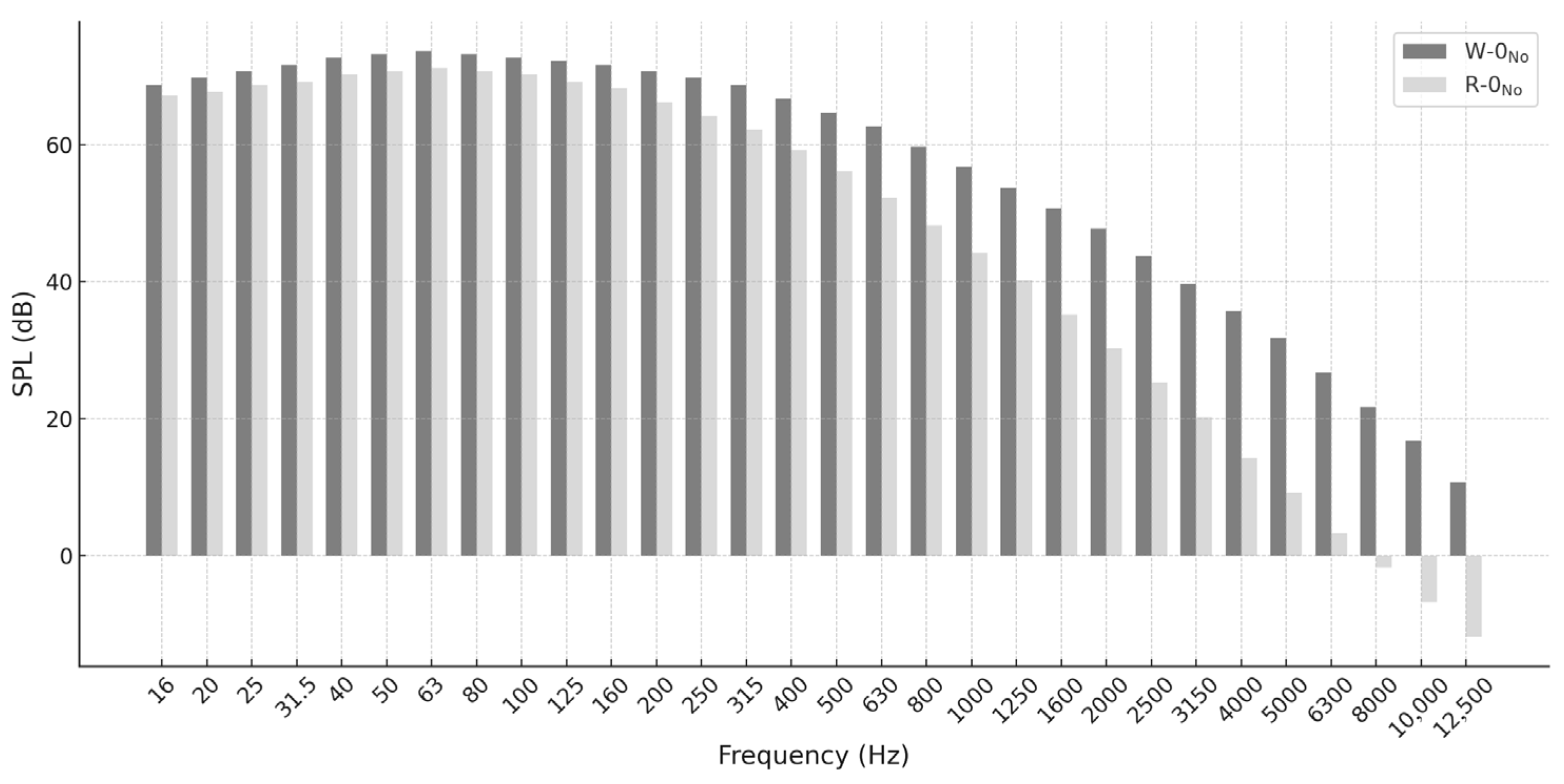

The results calculated using the F-WH acoustic module in Fluent are shown in

Figure 24. As can be seen, the noise distribution generally aligns with the jet development direction. Regardless of whether the mixing duct includes entrainment flow, the Model W-0 produces higher jet noise than the Model R-0 at all three detection circumferences. Quantitatively, the integrated suppressor reduces overall jet noise by up to 3 dB without entrainment flow and up to 5 dB when entrainment is included. These findings indicate that the large aspect ratio bent mixing duct used in the integrated infrared suppressor achieves lower jet noise levels compared to the conventional circular exhaust mixing duct.

Figure 25 shows the SPL comparison of the two models without entrainment at the 300° detection point in the XOZ. The R-0

No model exhibits similar performance to the W-0

No model in the low-frequency range, but the sound pressure level decays more rapidly in the mid- to high-frequency range. This is related to the slit structure, which enhances the mixing effect between the exhaust flow and the surrounding air. The structure effectively reduces the turbulence intensity of the jet flow, thereby attenuating high-frequency noise components, resulting in a lower overall sound pressure level.

For the aft fuselage of the two helicopters, Model R-1 features two additional air intake slits on the top of the aft fuselage compared to Model W-1. These slits allow the rotor downwash airflow to enter the aft fuselage compartment to cool the mixing duct. After cooling the mixing duct, the airflow inside the aft fuselage is discharged together with the mixing duct jet through the exhaust outlet at the bottom of the aft fuselage. This creates an enveloping effect around the mixing duct exhaust flow, effectively suppressing the infrared radiation signal of the exhaust plume. However, the impact on the mixing duct jet noise requires further investigation. Measurements show that under the influence of the rotor downwash, the front intake slit on the top of the aft fuselage admits approximately 0.004 kg/s of air, while the rear intake slit admits about 0.02 kg/s. Therefore, in the noise calculations, the top aft fuselage intake slits of Model R-1 were set as mass flow inlets with corresponding flow rates to simulate the rotor downwash airflow entering the aft fuselage compartment. Additionally, a control model without the aft fuselage top intake flow was set up to explore the effect of the aft fuselage compartment airflow on the mixing duct jet noise.

Figure 26 shows the orthogonal vortex results of the aft fuselage exhaust flow. As observed, the model with the top intake airflow exhibits slightly lower orthogonal vortex intensity. This is because the airflow inside the aft fuselage, when discharged, wraps around the outer edge of the mixing duct jet, reducing the velocity gradient between the mixing duct exhaust jet and the surrounding ambient flow, which helps to reduce the jet noise.

On the other hand, when the top intake airflow is present, it lowers the pressure at the mixing duct exhaust outlet as it exits from the bottom of the aft fuselage, causing the mixing duct’s ejector coefficient to increase by 2%. This results in a higher exhaust velocity from the mixing duct, which in turn increases the jet noise.

The final calculated noise results of the two models on the horizontal detection circumference are shown in

Figure 27. Overall, the presence of the top intake airflow on the aft fuselage has little impact on the mixing duct jet noise, with the maximum noise difference between the two models not exceeding 0.5 dB. At the front end of the jet direction (330–90°), the model with the top intake airflow exhibits slightly lower noise levels than the comparison model, indicating that in this region, the noise reduction effect from the top airflow lowering the velocity gradient outweighs the noise increase caused by the higher jet velocity due to the top airflow.

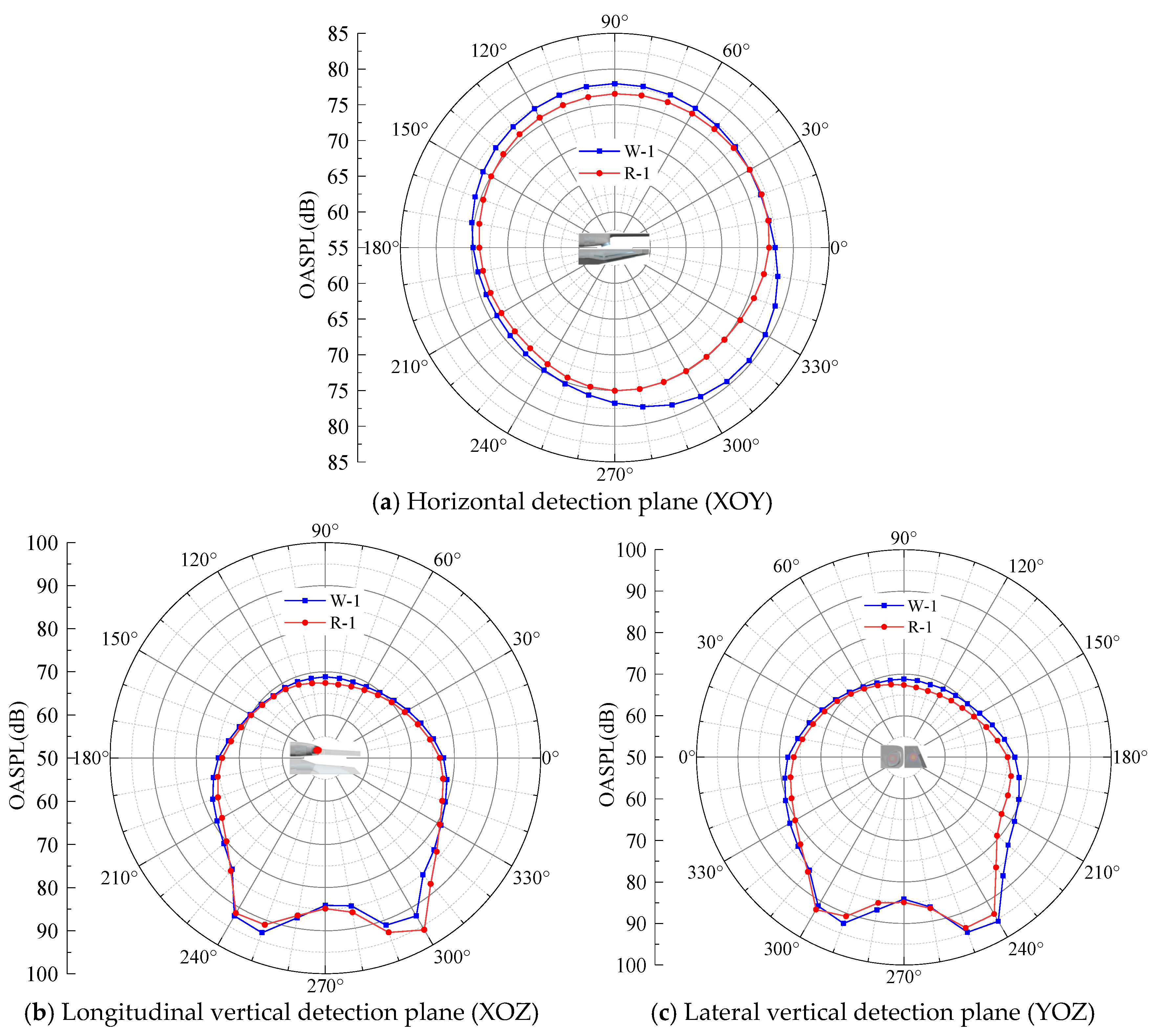

The two helicopter configurations differ in exhaust orientation, which leads to distinct aerodynamic noise distributions under the influence of rotor downwash.

Figure 28 presents the computed rotor–jet interaction noise for both aft fuselage models, with the monitoring radius set at 50 times the inlet diameter of the mixing duct.

From

Figure 28a, the noise distribution on the horizontal detection circle is approximately symmetric. Since the exhaust of Model W-1 is directed horizontally, the noise levels at positions aligned with this direction are significantly higher—up to 5 dB greater—than those of Model R-1, whose exhaust is deflected downward.

As shown in

Figure 28b, on the vertical detection circle, rotor downwash induces a distinct front–rear noise asymmetry, with downstream regions exhibiting higher sound pressure levels. Additionally, due to the radial variation in rotor speed (peaking near 0.8 times the rotor radius), the downstream noise pattern shows a dip at the center and elevated levels on either side. In this case, the downward exhaust of Model R-1 results in a local noise increase of about 3 dB around the 300° position compared to Model W-1.

In

Figure 28c, the lateral detection circle exhibits a noise distribution similar to the vertical plane. Both configurations yield comparable overall levels, but in the 180–240° range, Model W-1 demonstrates a noticeably higher noise level—up to 2 dB—due to its lateral jet exhaust orientation.

Overall, in regions not directly influenced by the exhaust jet, Model R-1 shows slightly improved aerodynamic noise performance relative to Model W-1. These results suggest that the adoption of an integrated infrared suppressor does not degrade, and may even improve, the acoustic characteristics of the helicopter in off-axis directions.