Constant Strain Aging Model of HTPB Propellant Involving Thermal–Mechanical Coupled Effects

Abstract

1. Introduction

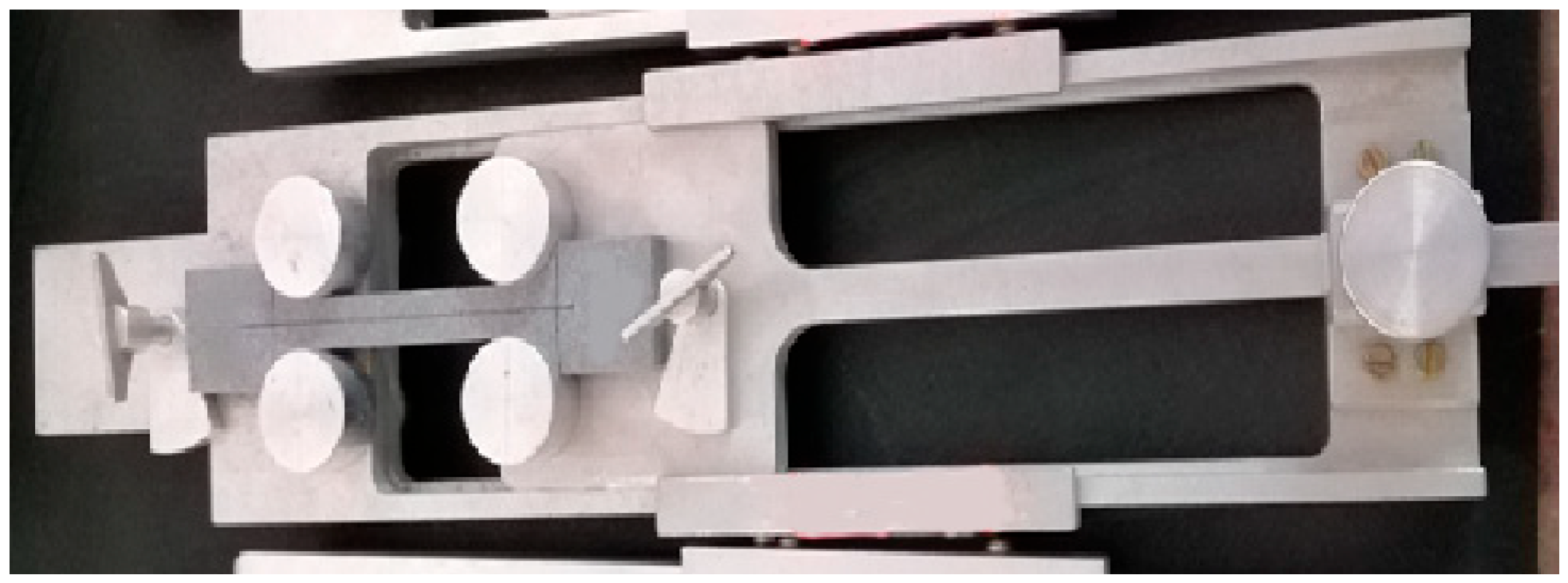

2. Experiment

2.1. Sample Preparation

2.2. Thermal Accelerated Aging Test for Propellants

- (1).

- To increase accuracy, the lowest temperature should be as near to the propellant’s typical storage temperature as feasible. However, it must not be too close, or the experiment will take too long.

- (2).

- In order to ensure safety and avoid altering the failure mechanism, the maximum value of the accelerated aging temperature should be determined. The temperature that can provide the highest acceleration effect should be chosen to the greatest extent feasible.

- (3).

- Generally speaking, three to five is the number of acceleration temperature points. A lower value will impact the statistical analysis accuracy, while a higher value will result in higher test costs.

- (1).

- Over the course of its whole life cycle, a solid rocket grain’s propellant grain can experience a maximum strain of 16.3% while being stored.

- (2).

- A safety buffer of 10% was taken into account based on the maximum strain.

- (3).

- Three intermediate strain levels, ranging from 0% to 18%, were established.

2.3. Propellant Mechanical Property Testing

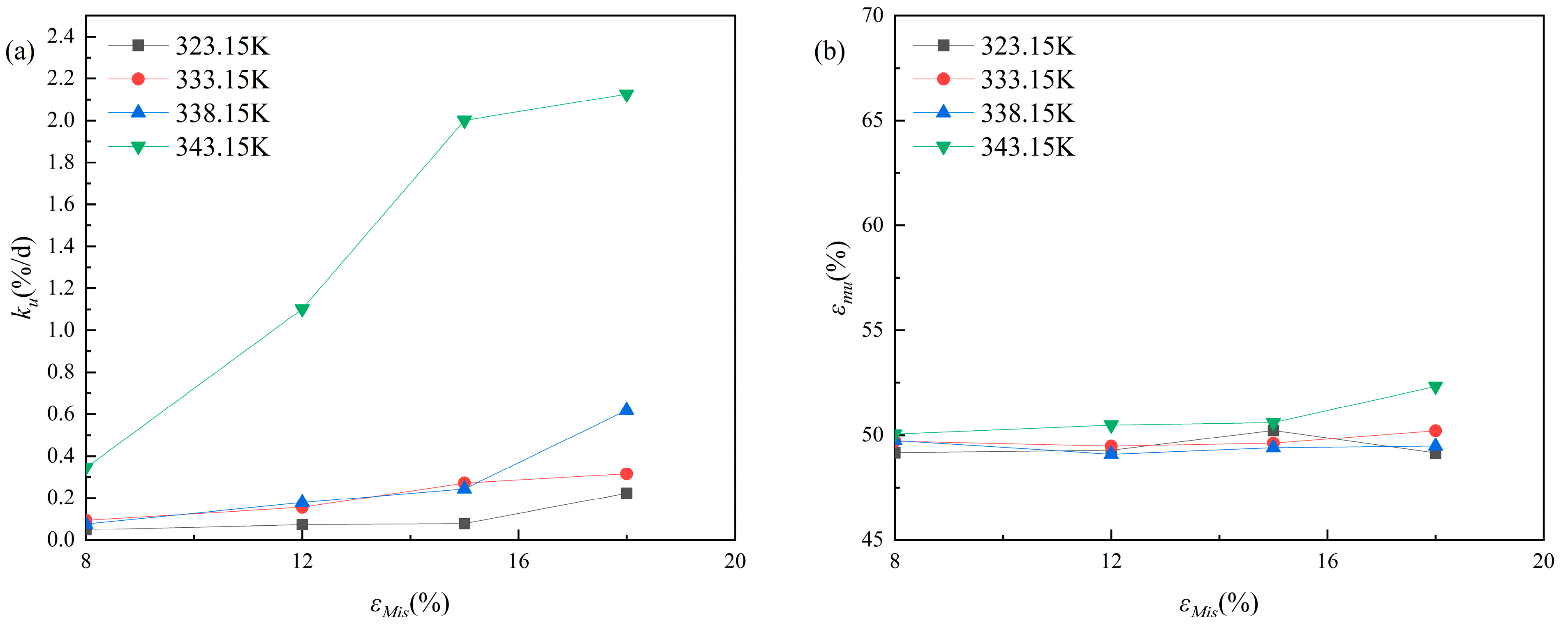

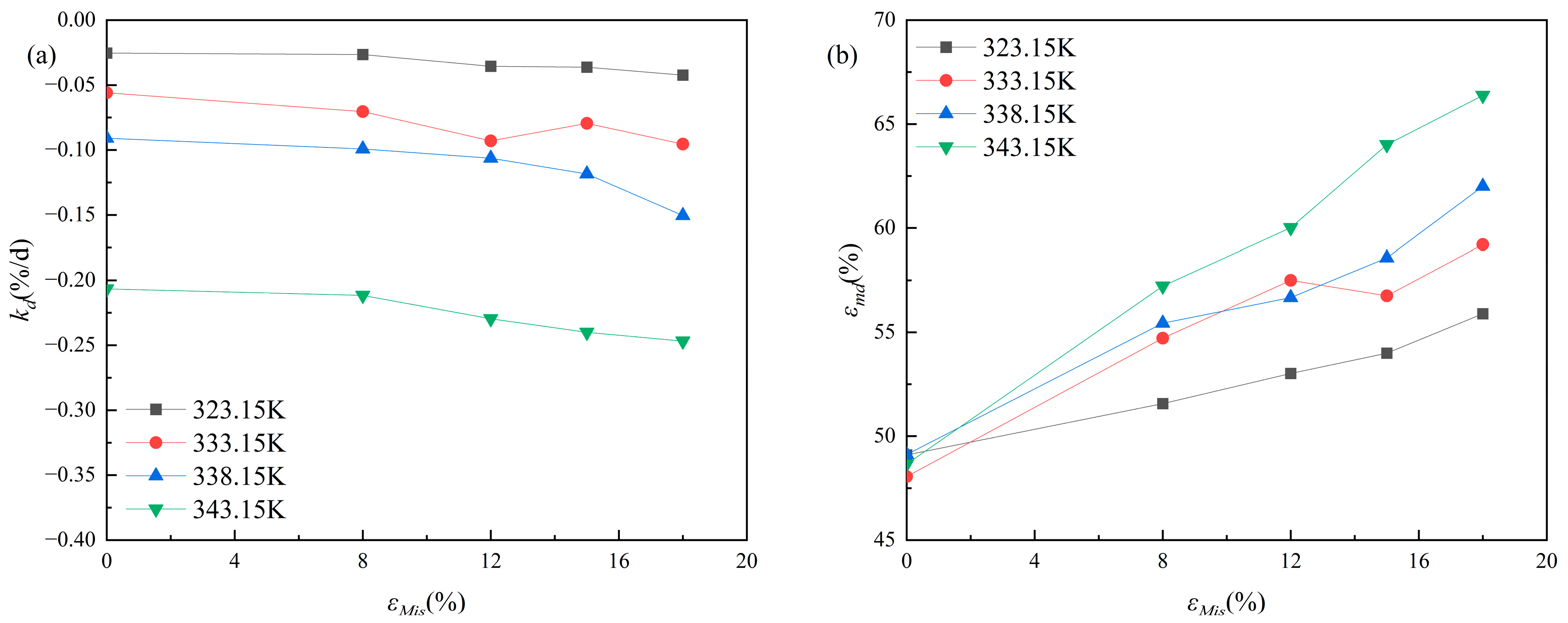

3. Test Results and Discussion

- (1).

- Two-stage aging dynamics:

- (2).

- Competing mechanisms of physical and chemical aging

4. Aging Model

4.1. Model of the Maximum Elongation of the Propellant and Aging Time

4.1.1. Model of the Maximum Elongation and Aging Time for the Propellant Under Zero Strain

4.1.2. Model of the Maximum Elongation and Aging Time for the Propellant Under Constant Strains

4.1.3. Analysis of the Model Parameters for the Maximum Elongation and Aging Time

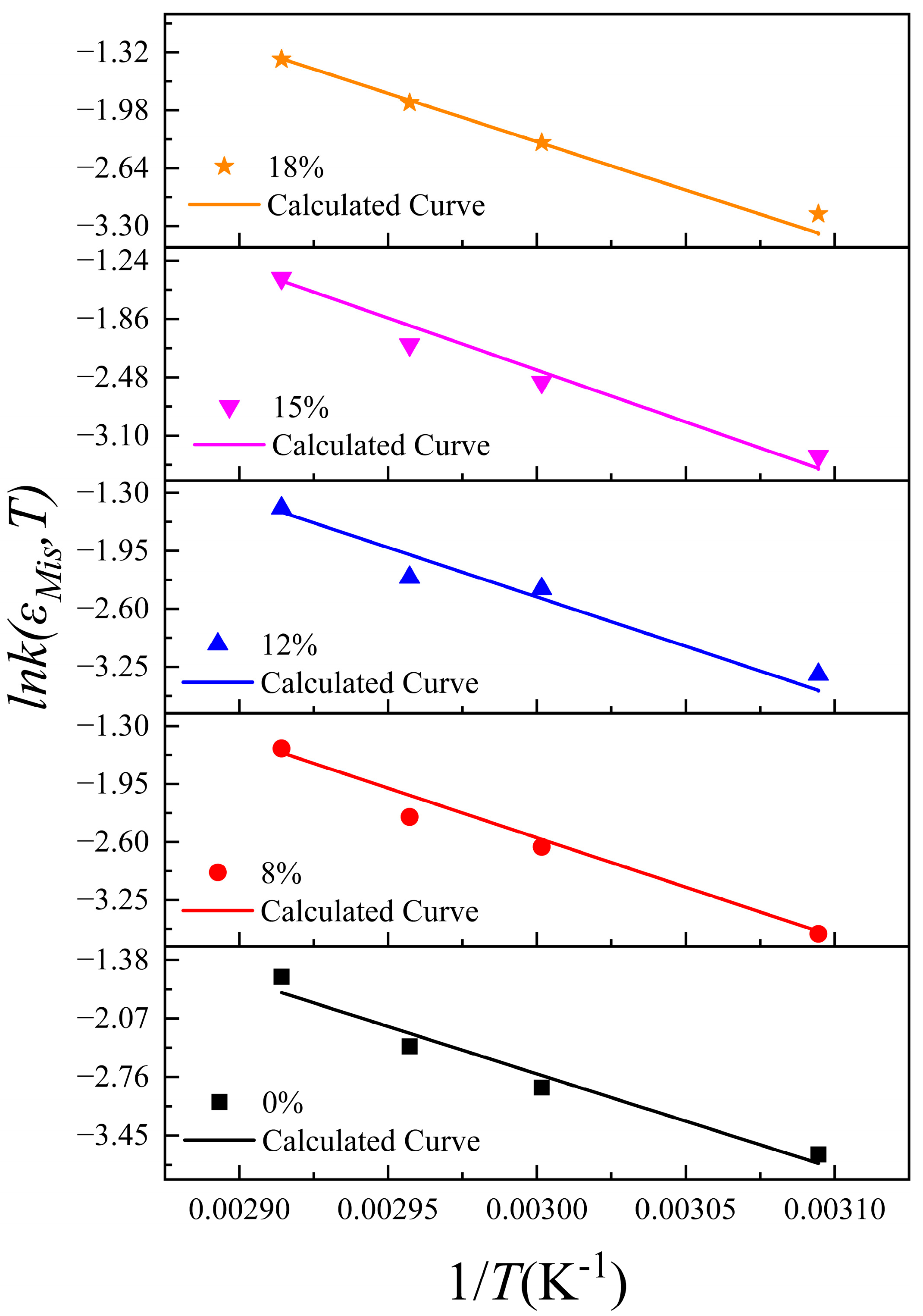

4.2. Modeling of the Aging Parameters

4.2.1. Parametric Modeling of Aging Under Zero Strain

4.2.2. Parametric Modeling of Aging Under Constant Strain

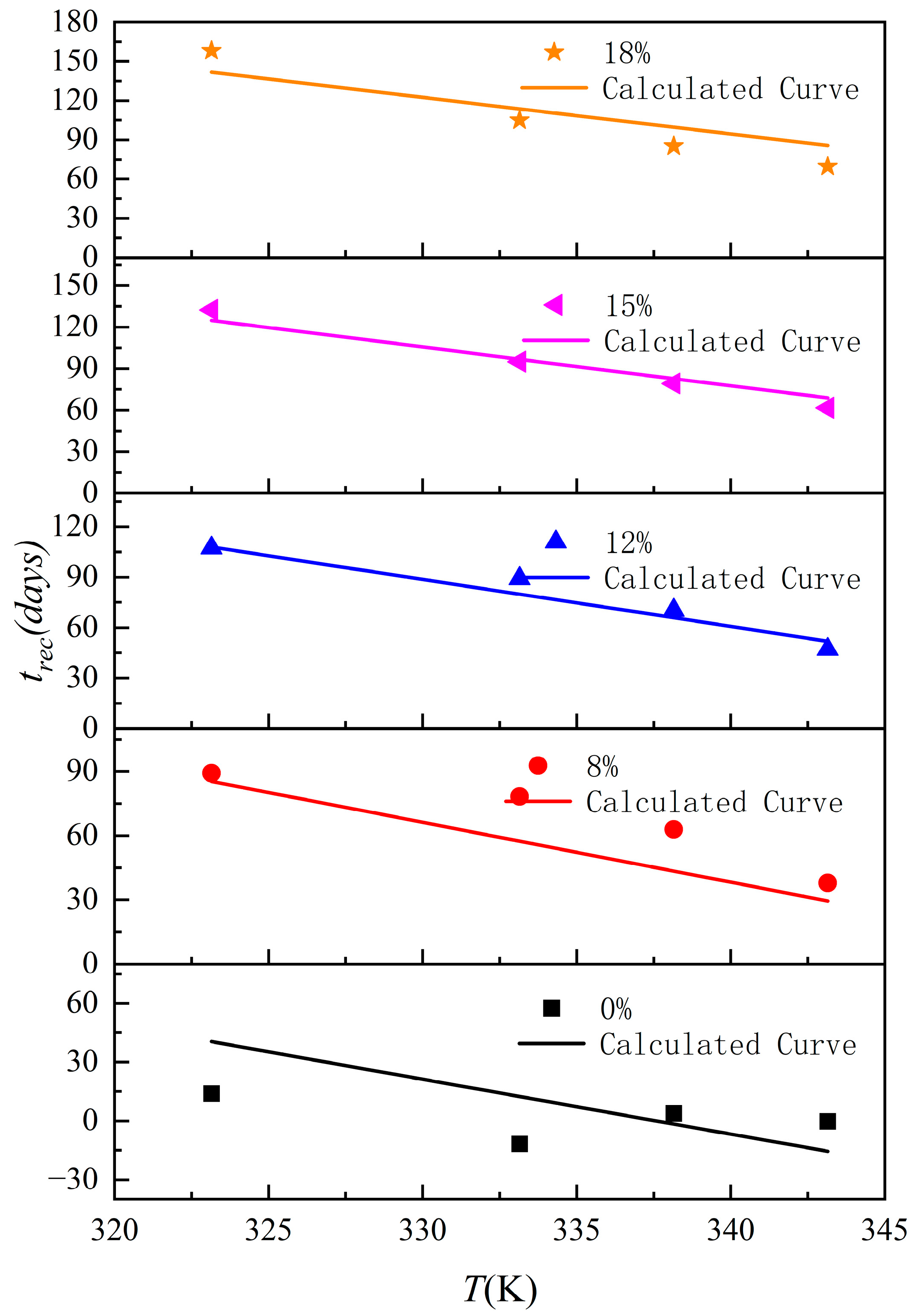

4.2.3. Elongation Recovery Time Model

5. Accelerated Aging Coefficients of Grains

5.1. Theoretical Model of Accelerated Aging

5.2. Engineering Applications of Accelerated Aging

6. Conclusions

- (1).

- Under conditions of constant strain ranging from 8% to 18%, HTPB propellant exhibits characteristic two-stage aging dynamics behavior. At first, the rearrangement in molecular chain orientation causes a brief rise in the maximum elongation. Maximum elongation steadily declines as a result of chemical aging.

- (2).

- A strain correction term is correlated with the Arrhenius equation to create an aging model under thermal–mechanical interaction. This term quantifies the synergistic impact of temperature and constant strain on the rate constant of aging.

- (3).

- The elongation recovery time is correlated with aging temperature and constant strain using a binary linear relationship model. The fitted results show that the elongation recovery time lowers with the increasing temperature, while the recovery time elongates with the increasing strain.

- (4).

- Using finite element simulation and the propellant aging model under continuous strain, this work examines the acceleration coefficient of a particular solid motor grain type during accelerated aging at high temperatures (323.15 K). This corresponds to the acceleration coefficient (293.15 K) when stored at room temperature. To calculate the accelerated aging period appropriately, the high-temperature (323.15 K) accelerated test method is used.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Glossary

| Nomenclature | |

| Applied constant strain elongation amplitude, kept constant during aging | |

| Degree of freedom is (m − 1) and the confidence probability is (1 − α), the t-distribution value | |

| Gauge length of the specimen after tensile testing | |

| m | Number of samples of aging time at constant strain at each T |

| Initial gauge length of the specimen | |

| Elongation recovery time | |

| Maximum elongation of the propellant in uniaxial tensile test | |

| Strain restitution coefficient | |

| t | Aging time |

| Temperature restitution coefficient | |

| Initial maximum elongation | |

| Constant of elongation recovery time | |

| aging rate constant of | |

| p | Parameter to be fitted in the Equation (34) |

| Determination coefficient | |

| m | Total number of test groups under constant strain |

| 90% confidence probability of the determination coefficient | |

| Temperature for long-term storage | |

| Intercept of the linear regression parameters for the rising phase | |

| Maximum strain of the grains under | |

| Slope of the linear regression parameters for the rising phase | |

| Elongation recovery time under | |

| Intercept of the linear regression parameters for the decline phase | |

| Upper limit of the propellant’s aging rate constant under | |

| Slope of the linear regression parameters for the decline phase | |

| Accelerated aging temperature | |

| Aging rate constant of the propellant at a temperature T | |

| Maximum strain of the grains under | |

| Aging temperature (K) | |

| Elongation recovery time under | |

| SY | Standard deviation of |

| Upper limit of the propellant’s aging rate constant under | |

| Degree of freedom is (n − 1) and confidence probability is (1 − α), the t-distribution value | |

| Accelerated aging time at the accelerated aging temperature | |

| n | Number of samples of aging time at zero strain at each T |

| Grain’s elongation recovery time under | |

| Strain correction factor (J/(mol·%)) | |

| Grain’s maximum elongation accelerated aging time under | |

| Aging rate constant of at and | |

| Abbreviation | |

| HTPB | Hydroxyl-Terminated Polybutadiene |

| DOS | Dicapryl sebacate |

| NEPE | Nitrate Ester Plasticized Ether |

| TDI | Toluene diisocyanate |

| WLF | Williams–Landel–Ferry |

| MAPO | Aziridinyl phosphine oxide |

| AP | Ammonium perchlorate |

| DPPD | N,N’-Diphenyl-p-phenylenediamine |

References

- Cerri, S.; Bohn, M.A.; Menke, K.; Galfetti, L. Characterization of ADN/GAP-Based and ADN/Desmophen®-Based Propellant Formulations and Comparison with AP Analogues. Propellants Explos. Pyrotech. 2014, 39, 192–204. [Google Scholar] [CrossRef]

- DeLuca, L.T.; Galfetti, L.; Maggi, F.; Colombo, G.; Merotto, L.; Boiocchi, M.; Paravan, C.; Reina, A.; Tadini, P.; Fanton, L. Characterization of HTPB-Based Solid Fuel Formulations: Performance, Mechanical Properties, and Pollution. Acta Astronaut. 2013, 92, 150–162. [Google Scholar] [CrossRef]

- Geng, T.; Qiang, H.; Wang, Z.; Wang, X.; Zhu, Z.; Qiao, D. Biaxial Compression Mechanical Properties of HTPB Propellant under Dynamic Loading. AIP Adv. 2022, 12, 015123. [Google Scholar] [CrossRef]

- Song, S.; Shi, H.; Liu, Z.; Sha, B. Structural Analysis of Solid Rocket Motor Grain at Ignition Transient under Low Temperature. J. Solid Rocket Technol. 2018, 41, 278–283. [Google Scholar]

- Liu, Z.; Zhou, Y.; Zhang, B. Structural Integrity Analysis on Grains of Solid Rocket Motor at Low Temperature Ignition. J. Solid Rocket Technol. 2015, 38, 351–355. [Google Scholar]

- Zhang, H.; Pang, A.; Peng, S. Investigation on the Differences Between Predicted Lifetime of Propellant Carton and Actual Lifetime of Motor Propellant Grain. J. Solid Rocket Technol. 2005, 28, 53–56. [Google Scholar]

- Chang, X.; Jian, B.; Liu, C.; Wang, B.; Zhang, X.; Hu, K. Experiments on HTPB Propellant Aging Properties under Constant Strain. J. Propuls. Technol. 2010, 31, 576–580. [Google Scholar]

- Li, Y.Q.; Li, G.C.; Kong, L.Z.; Zang, H.B. Experimental Measurement and Molecular Dynamics Simulation Analysis of Thermal Aging Performance in Composite Solid Propellants. Polym. Degrad. Stab. 2024, 225, 110812. [Google Scholar] [CrossRef]

- Zeng, Y.; Huang, W.; Chen, J.X.; Xu, J.S.; Chen, X.; Wu, R.; Song, Q.X. Analysis of Thermomechanical Coupled Accelerated Aging of HTPB Propellants. Propellants Explos. Pyrotech. 2024, 49, e202300123. [Google Scholar] [CrossRef]

- Wei, X.; Li, H.; Zhao, Y.; Li, Z.; Zhao, F. Accelerated Test Method of Composite Solid Propellant with Constant Strain-Temperature Cycle. Equip. Environ. Eng. 2022, 19, 65–72. [Google Scholar]

- Dong, K.; Pei, L.; Kong, L.; Chen, S.; Zhang, C.; Xia, C. Storage Aging Performance of NEPE Propellant under Constant Strain. J. Solid Rocket Technol. 2019, 42, 403–408. [Google Scholar]

- Zhou, D.; Liu, X.; Sui, X.; Wei, Z.; Wang, N. Effect of Pre-Strain During Ageing on the Maximum Elongation of Composite Solid Propellants and Its Modelling. Polym. Test. 2016, 50, 200–207. [Google Scholar] [CrossRef]

- Zhou, D.; Liu, X.; Sui, X.; Wei, Z.; Wang, N. Elongation Aging Model of HTPB Propellant under Constant Strain. J. Propuls. Technol. 2017, 38, 207–213. [Google Scholar]

- Geng, T.; Qiang, H.; Miao, H.; Wang, X.; Wang, Z.; Zhang, H. Maximum Elongation Degradation Model and Service Life Prediction for HTPB Propellant under Constant Strain and Chemical Aging Effects. Polym. Test. 2025, 143, 108711. [Google Scholar] [CrossRef]

- Zhang, H.; Peng, S.; Pang, A. Relationship Between Stress-Strain and Service Life of Solid Propellant. J. Propuls. Technol. 2006, 27, 372–375. [Google Scholar]

- Zhang, F.; Feng, S.; Sha, B.; Chi, X. Study on Equivalent Accelerated Test Method of Low Temperature Stress for Solid Propellant Charge. J. Solid Rocket Technol. 2019, 42, 409–413. [Google Scholar]

- Yıldırım, H.; Özüpek, Ş. Structural Assessment of a Solid Propellant Rocket Motor: Effects of Aging and Damage. Aerosp. Sci. Technol. 2011, 15, 635–641. [Google Scholar] [CrossRef]

- Zhao, F.; Wei, X.; Li, H.; Yin, S.; Li, Z.; Huang, W. Study on the Aging Mechanism of Polyether Propellant under Temperature Cycle and Strain. Equip. Environ. Eng. 2021, 18, 1–6. [Google Scholar]

- Zhang, G.; Wang, J.; Liu, X.; Li, M.; Chen, C.; Wang, N.; Hou, X. Correlation Between the Micro-Structure and Macroscopic Mechanical Properties of GAP-Based Propellant During Aging. Polym. Degrad. Stab. 2023, 214, 110411. [Google Scholar] [CrossRef]

- GJB 770B-2005; Committee of National Defense Science, Technology and Industry Marh 1990. Available online: https://www.doc88.com/p-4059176473593.html (accessed on 26 May 2025).

- Liu, M.; Gao, B.; Dong, X.; Gao, J. Failure Criterion of Solid Motors at Ignition Pressurization Loading. J. Solid Rocket Technol. 2018, 41, 424–427. [Google Scholar]

- Layton, L. Chemical Structural Aging Studies on an HTPB Propellant; Technical Report; Defense Technical Information Center: Fort Belvoir, VA, USA, 1975. [Google Scholar]

- Cao, R.; Zhao, C.; Peng, S.; Chi, X. Study on Mechanical Performance of HTPB Propellant under Natural Storage and High Temperature Accelerated Aging Conditions. Chem. Propellants Polym. Mater. 2017, 15, 58–62. [Google Scholar]

- Liu, J.; Tong, X.; Luo, X.; Chen, X.; Wang, T.; Xu, J. The Relaxation Behavior of Composite Double-Base Propellants with Various Stabilizer Content under Thermal Aging. Mech. Time-Depend. Mater. 2022, 27, 651–663. [Google Scholar] [CrossRef]

- Parepalli, P.; Nguyen, Y.T.; Sen, O.; Hardin, D.B.; Molek, C.D.; Welle, E.J.; Udaykumar, H.S. Multi-Scale Modeling of Shock Initiation of a Pressed Energetic Material III: Effect of Arrhenius Chemical Kinetic Rates on Macro-Scale Shock Sensitivity. J. Appl. Phys. 2024, 135, 085901. [Google Scholar] [CrossRef]

- Kaupp, G. Mechanochemistry: The Mechanical Activation of Covalent Bonds. Chem. Rev. 2005, 105, 2921–2948. [Google Scholar]

- Caruso, M.M.; Davis, D.A.; Shen, Q.; Odom, S.A.; Sottos, N.R.; White, S.R.; Moore, J.S. Mechanically-Induced Chemical Changes in Polymeric aterials. Chem. Rev. 2009, 109, 5755–5798. [Google Scholar] [CrossRef]

| Aging Temperature (K) | Aging Time (Days) | |||||||

|---|---|---|---|---|---|---|---|---|

| 323.15 | 0 | 56 | 90 | 126 | 175 | 224 | 280 | 336 |

| 333.15 | 0 | 14 | 28 | 56 | 90 | 126 | 168 | 210 |

| 338.15 | 0 | 28 | 49 | 70 | 90 | 105 | 147 | 168 |

| 343.15 | 0 | 14 | 28 | 35 | 49 | 63 | 70 | 90 |

| Aging Temperature (K) | Aging Time (Days) | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 323.15 | 0 | 7 | 14 | 21 | 28 | 42 | 56 | 70 | 91 | 126 | 154 | 196 | 224 |

| 333.15 | 0 | 4 | 10 | 21 | 28 | 42 | 56 | 70 | 87 | 101 | 112 | 126 | 154 |

| 338.15 | 0 | 4 | 10 | 17 | 28 | 35 | 49 | 63 | 77 | 91 | 119 | 133 | 153 |

| 343.15 | 0 | 1 | 4 | 7 | 14 | 21 | 28 | 35 | 42 | 62 | 70 | 84 | 98 |

| Aging Temperature (K) | Model Parameters | |

|---|---|---|

| 323.15 | 0.9821 | |

| 333.15 | 0.9640 | |

| 338.15 | 0.9615 | |

| 343.15 | 0.9670 |

| Aging Temperature(K) | Constant Strain Value(%) | Model Parameters | Number of Fitted | |||

|---|---|---|---|---|---|---|

| 323.15 | 8 | rising phase | 0.9603 | 6 | 0.729 | |

| decline phase | 0.9522 | 8 | 0.622 | |||

| 12 | rising phase | 0.9845 | 6 | 0.729 | ||

| decline phase | 0.9589 | 8 | 0.622 | |||

| 15 | rising phase | 0.9498 | 5 | 0.805 | ||

| decline phase | 0.9261 | 9 | 0.582 | |||

| 18 | rising phase | 0.9800 | 5 | 0.805 | ||

| decline phase | 0.9190 | 9 | 0.582 | |||

| 333.15 | 8 | rising phase | 0.8697 | 5 | 0.805 | |

| decline phase | 0.9641 | 9 | 0.582 | |||

| 12 | rising phase | 0.9887 | 5 | 0.805 | ||

| decline phase | 0.9444 | 9 | 0.582 | |||

| 15 | rising phase | 0.9728 | 4 | 0.900 | ||

| decline phase | 0.9865 | 10 | 0.549 | |||

| 18 | rising phase | 0.8848 | 4 | 0.900 | ||

| decline phase | 0.8697 | 10 | 0.549 | |||

| 338.15 | 8 | rising phase | 0.8087 | 5 | 0.805 | |

| decline phase | 0.9408 | 9 | 0.582 | |||

| 12 | rising phase | 0.9446 | 5 | 0.805 | ||

| decline phase | 0.9840 | 9 | 0.582 | |||

| 15 | rising phase | 0.9467 | 5 | 0.805 | ||

| decline phase | 0.9884 | 9 | 0.582 | |||

| 18 | rising phase | 0.9715 | 4 | 0.900 | ||

| decline phase | 0.9483 | 10 | 0.549 | |||

| 343.15 | 8 | rising phase | 0.8308 | 5 | 0.805 | |

| decline phase | 0.9895 | 9 | 0.582 | |||

| 12 | rising phase | 0.9025 | 4 | 0.900 | ||

| decline phase | 0.9922 | 10 | 0.549 | |||

| 15 | rising phase | 0.9280 | 4 | 0.900 | ||

| decline phase | 0.9835 | 10 | 0.549 | |||

| 18 | rising phase | 0.8494 | 4 | 0.900 | ||

| decline phase | 0.9649 | 10 | 0.549 | |||

| Arrhenius Model | ||

|---|---|---|

| 0.961 | 0.90 |

| Model | Number of Fitted | ||

|---|---|---|---|

| 0.963 | 20 | 0.378 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qin, P.; Zhang, X.; Jiang, K.; Cheng, J. Constant Strain Aging Model of HTPB Propellant Involving Thermal–Mechanical Coupled Effects. Aerospace 2025, 12, 589. https://doi.org/10.3390/aerospace12070589

Qin P, Zhang X, Jiang K, Cheng J. Constant Strain Aging Model of HTPB Propellant Involving Thermal–Mechanical Coupled Effects. Aerospace. 2025; 12(7):589. https://doi.org/10.3390/aerospace12070589

Chicago/Turabian StyleQin, Pengju, Xiangyu Zhang, Kai Jiang, and Jiming Cheng. 2025. "Constant Strain Aging Model of HTPB Propellant Involving Thermal–Mechanical Coupled Effects" Aerospace 12, no. 7: 589. https://doi.org/10.3390/aerospace12070589

APA StyleQin, P., Zhang, X., Jiang, K., & Cheng, J. (2025). Constant Strain Aging Model of HTPB Propellant Involving Thermal–Mechanical Coupled Effects. Aerospace, 12(7), 589. https://doi.org/10.3390/aerospace12070589