1. Introduction

Pulse Detonation Engines (PDEs) are a promising propulsion plant option for some aerospace applications. The reasons might be twofold: (a) the concept has relatively low engineering complexity and (b) its thermodynamics cycle approaches the high-efficiency constant-volume heat addition limit. Significant developments have been reported during the past few years that involve flight testing, i.e., Buyakofu et al. [

1] and Buyakofu et al. [

2], and experimental testing, i.e., Bogoi et al. [

3], and Oh et al. [

4], among others. In this context, where practical applications are being addressed, engineering questions arise that focus on the improvement in PDE performance. Among many others, the most straightforward way of improving this performance could, possibly, be the implementation of an optimized nozzle. Another question that needs to be considered for flying platforms is to correlate the actual weight of the engine to its propulsive performance parameters.

A seminal experimental study in the field of nozzle optimization for PDE was the one published by Allgood et al. [

5]. In this work, the authors studied different convergent (Con) and divergent (Di) bell-shaped nozzle geometries and provided guidelines regarding engine performance as a function of fill fraction and area ratio. The length (L) of their PDE was 1.88 m. Two diameters (D) were considered: 0.025 m and 0.051 m. Then, L/D = 1.4% to 2.8%. Nozzle length varied from 2% to 3% of the total length. The experiments of Yan et al. [

6] addressed nine convergent–divergent (Con-Di) bell-shaped geometries with different contraction and expansion area ratios. The tube length and radius were 0.920 m and 0.030 m, respectively (L/D = 3.3%). Nozzle length varied between 65 mm and 107 mm. Within this space of design parameters, the authors identified the one that provided the maximum thrust augmentation (21%). Chen et al. [

7] considered a 2.050 m long tube with a diameter equal to 0.136 m (L/D = 6.6%) equipped with Con, Di, and Con-Di nozzles. Their length varied between 188 mm and 210 mm. The experimental results showed that the performance of Con nozzles was worse than Di and Con-Di nozzles. Measured thrust augmentation ranged from 20% to 40%. Zhang et al. [

8] considered 2 tubes and 21 nozzles with different shapes. The tube length varied between 0.660 m and 0.780 m. The diameter varied between 0.024 m and 0.030 m (L/D ~ 3.8%). The length of the convergent parts ranged from 0.010 m to 0.031 m. The length of the divergent parts was in the span from 0.024 m to 0.076 m. Their experimental tests showed that (a) most Con nozzles provided thrust augmentation when the fill fraction was larger than one, and (b) Di nozzles were better suited for fill fractions smaller than one. In one case, thrust augmentation was 25%. Ornano et al. [

9] addressed the multi-fidelity geometry optimization (Con, Di, and Con-Di nozzles) of detonation combustors. Nozzle shapes were made up of five control points, Bezier curves. The parameter to be optimized was the nozzle exit force. The authors considered two types of optimization approaches. In the first case, they prescribed constant total pressure and temperature at the nozzle inlet section (i.e, no tube was considered), so the simulations had a steady character. In the second case, inlet profiles were time-dependent, so the simulations were unsteady. Two main conclusions were drawn from the study: (a) the optimum solution was the divergent nozzle, and (b) the inherent unsteadiness of PDT operation leads to optimum designs different from those obtained via the classical rocket engine approach. Zhang et al. [

10] have explored the possibility of using fluidic solutions (Nitrogen injection) to adjust the effective area ratios. The authors reported thrust increments of the order of 100% in their experiments. A different type of nozzle configuration study has been reported recently by Kang et al. [

11]. In this case, the objective was to study the acoustic characteristics of the PDE for different nozzle geometries.

The objective of the present study was to perform a systematic multi-design variables multi-objective nozzle optimization for a rocket-type PDE. Tube length and tube cross-sectional area were kept constant. A convergent–divergent nozzle was attached to its end. In all cases, the initial fresh mixture of reactants filled the tube only. The optimization involved five design variables: the equivalence ratio of the reactants, nozzle throat area, divergent exit area, length of the convergent section, and length of the divergent section. Optimum solutions were sought, accounting for different combinations of three global parameters of the PDE: total impulse, fuel-based specific impulse, and surface area of the nozzle (directly related to nozzle weight).

Previous studies performed by other authors (see previous paragraphs) have provided a large wealth of insight into the problem of nozzle optimization for PDE. These studies have tended to focus on single optimization objectives and considered a limited number of different design variables. Then, it is not easy to compare their conclusions. In this context, the novelty of the present study is to formulate and solve a problem that encompasses, albeit in an idealized way, different approaches proposed by previous authors, including, additionally, the issue of PDE weight. The goal is to address the problem of nozzle optimization in a multi-design parameter, multi-objective context that allows for the generalization of the results obtained within the frame of PDE design.

Regarding the organization of the manuscript, the sections are the following:

Section 2: problem description,

Section 3: flow simulation method,

Section 4: optimization method,

Section 5: results and discussion, and

Section 6: conclusions.

3. Flow Simulation Method

The flow was described by a quasi-1D unsteady compressible reactive Euler equations, (Morris [

12]).

where

is the vector of conservative variables (density of the gas mixture,

, linear momentum,

, total energy,

and species densities,

) and

stands for the

-dependent cross-sectional area of the tube and attached nozzle. Therefore, all conservative variables were the averaged values across the area

.

stands for the mass fraction of each species

in the mixture. For N species in the mixture,

mass fractions were solved. Thus, the number of equations to be considered was

. The specific total energy

was defined as

The sensible enthalpy

functional dependence with temperature was

where

is the molecular weight of species

. Molar constant pressure heat capacities

were taken from Stull and Prophet [

13] (JANAF polynomials).

Two sets of

constant values for each species k were considered. The first set is valid in the temperature range from 200 K up to 1000 K and the second from 1000 K up to 5000 K. Relation between pressure and density in the mixture of

ideal gases was modelled by the state equation as

where

is the universal gas constant. Flux vector

and sources term

in Equation (1) were defined as

The source term of the energy equation was given by

where

and

are the production/consumption rates of each specie and its formation enthalpy, respectively. The standard molar heat of formation for the species was obtained, also, from the JANAF polynomials, as follows:

Combustion of

in air was considered. A generic mechanism involving

species could be described by

elementary reactions of the following form:

where

is the concentration of each species

. The arrows in Equation (11) represent, respectively, the forward

and backward

reactions, with

and

being the corresponding forward and backward rates constants. Then, each consumption/production rate of the specie

related to reaction

could be written as

Finally, the total consumption/production rate of the species

in all involved reactions is written as

In this work, a simplified chemical kinetic model with

4 species (

,

,

,

) described by the following one-step (

) irreversible global reaction was chosen, as follows:

The irreversible Arrhenius reaction rate was

with pre-exponential factor and activation temperature equal to

and

respectively, see McGough [

14], Towery et al. [

15], and Rai et al. [

16].

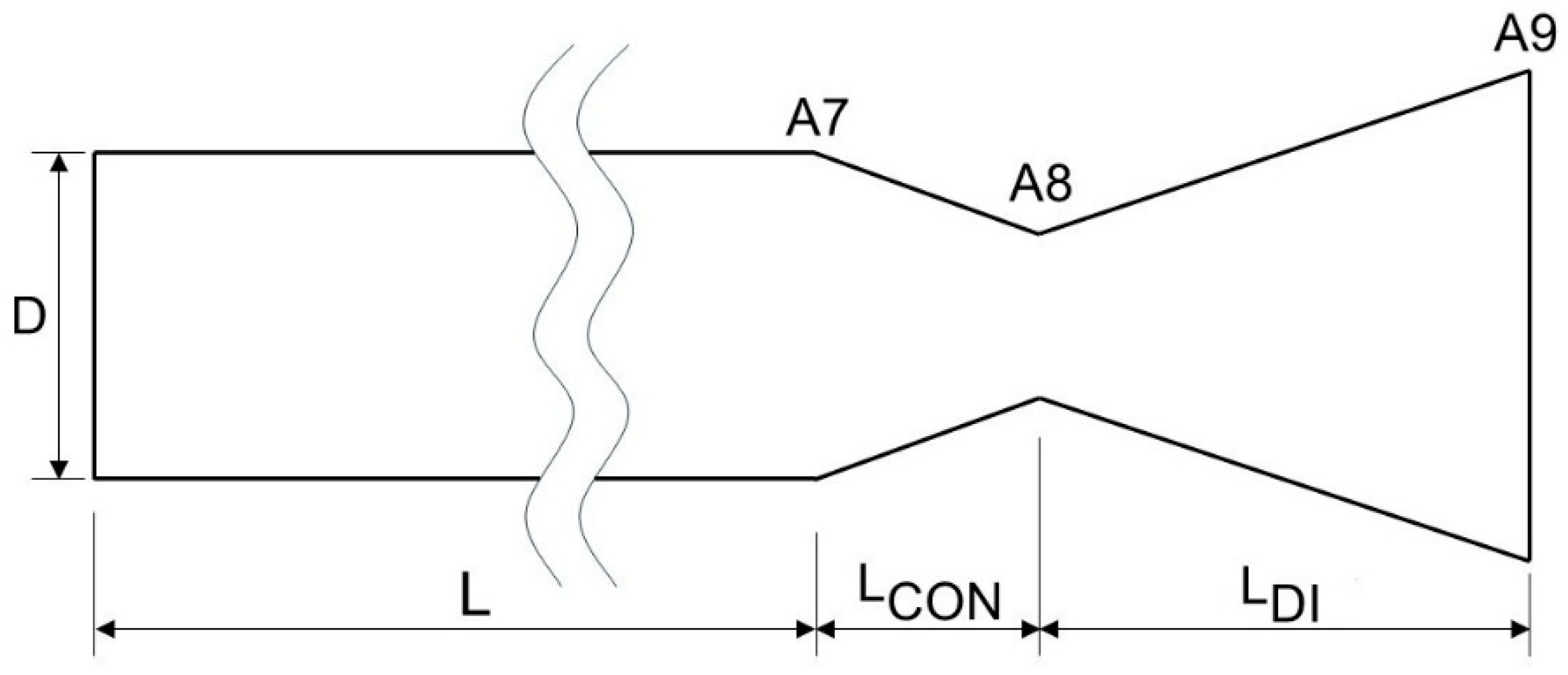

Regarding the geometry,

Figure 2 shows a sketch of the cross-section distribution of

. It could be observed that the domain had three sections: (1) tube (

), (2) nozzle (

), and (3) discharge region (

, and

). The discharge region shape had a parabolic profile, ensuring a continuous derivative at the nozzle exit to prevent numerical instabilities.

The computational domain was initially at uniform pressure and temperature

and

. The tube was initially filled with a fresh uniform mixture of

and air (

) of equivalence ratio

. The fresh mixture was assumed to initially be at rest. Detonations were numerically triggered by setting, i.e., initially, a small ignition region at

. Its length was equal to a single finite volume. The ignition pressure and temperature were

and

, respectively. The two assumptions of zero velocity for the initial fresh mixture and the setting of an initial small region to trigger ignition have been discussed previously by Sanchez de Leon et al. [

17]. Initially, the nozzle and discharge section were filled with air. Zero velocity and zero gradient for the other variables were prescribed at the tube closed end,

. Ambient pressure, 1 bar, and zero gradients for velocity and temperature were prescribed at the discharge outlet section.

As for numerical implementation, the open-source framework OpenFOAM

® was used. This software uses Finite Volume Methods (FVMs) to solve the conservation equations of mass, linear momentum, energy, and mass species at every cell volume. The finite-volume density-based solver “rhoReactingCentralFoam” (a version of the standard OpenFOAM solver “rhoCentralFoam” that incorporates chemical reactions), developed to solve high-speed reactive flows, including detonations, McGough [

14], was modified to implement the quasi-1D approach described in Equation (1).

Discretization of the convective terms was performed via a second order central-upwind scheme, Kurganov et al. [

18]. Temporal discretization was carried out via an implicit Euler scheme. Equation (5) for temperature, which had an implicit character, was solved using a Newton–Raphson iterative approach. The stiff reaction terms were solved using a time-splitting method, which alternated between solving the homogeneous conservation laws without source terms (the fluid flow) and solving the conservation laws without convection (the chemistry). A fourth order Runge–Kutta scheme was selected as the time advancing algorithm for the chemistry model. An adaptative time step was set with a maximum Courant number of 0.1. The mesh size and the maximum Courant number were selected after a sensitivity analysis. The typical time step was

. This time step was adjusted to ensure that the maximum Courant number did not exceed 0.1. Simulations were run up to the time when the static pressure at the tube closed end

reached the initial pressure

. This condition defined the end time,

, of the simulation. The computation of each simulation case required an average of 40 min on a single core of an AMD Ryzen

TM 9 9900X processor.

Thrust,

, total impulse, I

T, and specific impulse based on fuel, I

SPF, were computed as follows:

where

is the initial mass of fuel inside the PDE and

.

Regarding validation, the results were compared first, see

Table 4, with reference data at the Chapman–Jouguet (CJ) point obtained from NASA’s Chemical Equilibrium with Applications (CEA) program, Gordon and McBride [

19], for a stoichiometric mixture. It could be observed that pressure and wave speed are predicted with discrepancies smaller than 3%. Temperature deviations are larger (10%). The reason could be that the present simplified model lacks intermediate reactions and heat-absorbing species. Then, energy release is overestimated.

Second, the I

SPF for different equivalence ratios was compared to the experimental results of Shauer et al. [

20] and the numerical results of Sanchez de Leon et al. [

17], see

Figure 3.

Third, the case presented by Ornano et al. [

9], computed via the Method of Characteristics, was simulated. The steady-state force predicted by the present model was 5865 N, while Ornano et al. [

9] reported a value of 5960 N (2% deviation).

Fourth, the work of Owens and Hanson [

21] was simulated. The authors considered the combustion of ethylene in oxygen with a stoichiometric ratio in a PDE with a divergent nozzle. For the present model, the following single irreversible reaction was

. The reaction constants, taken from Xu and Konnov [

22], were as follows:

and

, see Equation (15). The results are summarized in

Table 5. They are maximum nozzle force, wave detonation time (time for the detonation wave to reach the nozzle), and blowdown time.

With regard to numerical sensitivity,

Table 6 presents the sensitivity of the results obtained to mesh size and maximum Courant number allowed in the simulation, C

MAX, for a representative case with

(see

Table 2). Variables to be compared were I

T, I

SPF, wave speed, and t

end.

varied between 260 μm and 1300 μm. The number of cells varied between 1000 and 5000. C

MAX varied between 0.01 and 0.5.

The case with = 260 μm, 5000 cells, and CMAX = 0. One was taken as the reference case (highlighted in bold in the upper part of the table) for sensitivity on cell size (number of cells). It could be observed that all cases with ( had discrepancies (ε) equal or smaller than 0.2%. The case with = 433 μm, 3000 cells, and CMAX = 0.01 was taken as the reference case (highlighted in bold in the lower part of the table) for sensitivity on CMAX. The case with CMAX = 0.05 yielded the same results as the reference case. The case with CMAX = 0.1 presented discrepancies of 0.1%. The case with CMAX = 0.5 had an unacceptable discrepancy in tend. Then, it could be considered that the results were converged whenever CMAX ≤ 0.1. Accordingly, the parameters that were selected for the computations that represent a compromise between accuracy and computational load were , number of cells = 3000, and CMAX = 0.1.

4. Optimization Method

Selection of the optimization method was driven by two factors: (1) computation of each simulation case required an average of 40 min, and (2) the problem being addressed involved five design variables.

As will be shown below, each optimization case required 20,300 computations of the objective function (20,300 simulations of the PDE). Since five different optimizations were considered, a total of 101,500 different cases had to be computed. Using a Ryzen 9 9900X processor with 24 cores, this would require a computational load of 93 days that was unfeasible for the authors. Then, a different approach, based on data tensor decomposition, was implemented to reduce the computational load. It came down, finally, to 15 days, which is an acceptable figure. This type of optimization methodology has been used previously by the authors, see Sastre et al. [

23] and Sanchez de Leon et al. [

17]. Then, the optimization method was organized into four steps, as follows:

Step (1) Generation of the coarse data tensors;

Step (2) Generation of the surrogate (densified) models of the data tensors;

Step (3) Definition of the objective function;

Step (4) Optimization algorithm.

Step (1) Generation of the coarse data tensors

First, the 13,860 cases defined in

Table 2 were computed. Output parameters I

SPF and I

T were stored in two 5D tensors. The process did not apply to A

N because the nozzle surface area could be computed at any time at a negligible computational cost. The axes of the tensors were the following five design variables: ϕ, λ

1, λ

2, λ

3, and λ

4. Both the design variables (

and the output parameters (

were rendered dimensionless and normalized so that the optimization algorithm was well conditioned, as follows:

where

and

were minimum and maximum values of design variable

, and

,

, and

were the mean, maximum, and minimum value of output

, respectively. With this normalization, design variables varied between 0 and 1, and output parameters vaired between −0.5 and 0.5.

Step (2) Generation of the surrogate (densified) model of the data tensor.

The coarse data tensors were decomposed via High Order Singular Value Decomposition, Tucker [

24] and Lathauwer et al. [

25,

26]. The decomposition has the form

where

,

, and

are the original coarse tensor

, the core tensor, and the eigenmode matrices that correspond to the five design variables. Once decomposition (21) was completed, third order splines were fitted to the eigenmodes, effectively generating a continuous surrogate-densified version of the original coarse data tensor. The optimization algorithm acted upon this surrogate data tensor.

To test the accuracy of the approach, 1400 test cases were computed via the surrogate model, and the results were compared to those obtained via direct simulation. These 1400 test cases were generated at random inside the space of design variables and neither of them belonged to the set of 13,860 cases used to generate the coarse data tensors. The results obtained were as follows:

The distribution of errors is shown in

Figure 4. It could be observed that 66% of cases had an error smaller than 0.5%, 95% of cases smaller than 1%, and 99% of cases smaller than 2%.

Step (3) Definition of the objective function

The objective function,

, (formulated for minimization) contained the three following terms:

where

and

represent the maximum values of the specific impulse and total impulse in the surrogate tensors, and

is the surface area of the nozzle with a maximum surface area.

,

, and

were the weight factors to adjust the type of optimization. The coding of cases presented in

Table 3 and weight factors were related as follows:

Case #1. ;

Case #2: ;

Case #3: ;

Case #4: ;

Case #5:

Step (4) Optimization algorithm

The optimization algorithm involved the sequential application of a Genetic Algorithm (GA) plus a Gradient Method (GM). The objective function for both methods was obtained from the surrogate data tensor. The GA function of Matlab was used for the first step. The number of individuals in the population and the number of generations were 1000 and 20, respectively. The second step consisted of applying the Gradient Method-based FMINCON of Matlab to the leading individual obtained from the GA step. A maximum of 300 computations of the objective function was allowed to the GM. Accordingly, the number of steps was of the order of 20 (computing the Jacobian matrix in a 5D space requires the simulation of 10 points for each step, and the Hessian matrix needs to be computed, additionally, at some steps). In all cases, convergence (defined as a threshold for variation in the objective function) was achieved before the 300 computations were completed.

5. Results and Discussion

As detailed in

Section 4, the optimization process was performed via a combined Genetic Algorithm plus a Gradient Method acting on the surrogate space of design variables. Given the heuristic nature of the Genetic Algorithm, it is recommended to repeat the optimization process many times to ensure that the best individual in the space of design variables is recovered. Then, each of the optimization cases #1 to #5 was repeated 1000 times. This was possible because, as explained in

Section 4, the computational load is small due to the use of a surrogate space of design variables. As a matter of illustration, a histogram of the 1000 computations of case #5 is presented in

Figure 5. It could be observed that the objective function values of 0.484, 0.481, and 0.480 were obtained 882 times, 15 times, and 103 times, respectively. Accordingly, the value of 0.484 was taken as the optimum.

The results obtained for the five optimization cases #1 to #5 defined in

Table 3 are presented in

Table 7 below.

Before addressing the discussion of these results, it is convenient to summarize the results obtained by the other researchers referred to in

Table 1. This summary is presented in

Table 8.The spread of the experimental results shown in

Table 8 is large. This is possibly caused by the variety of experimental conditions and specificities of the test benches. For example, Allgood et al. [

5] and Zhang et al. [

8] agreed that the optimum solution was the Con nozzle when α > 1. However, for α < 1, Allgood et al. [

5] recommended the straight tube while Zhang et al. [

8] recommended the Di nozzle. In parallel, Cheng et al. [

7] found that the Con-Di nozzle, Di nozzle, and straight tube delivered better performance than the Con nozzle. These somewhat contradictory conclusions might seem confusing, but it is to be said that similar discrepancies when addressing PDE nozzle performance were already noted in the review article of Kailasanath [

27] back in 2003 (see the chapter titled “Nozzles for Pulse Detonation Engines” on page 153). More recently, Ornano et al. [

9] were very clear when stating that in both single-cycle steady and unsteady state operation, the optimum is the Di nozzle with the largest area ratio. One of the possible phenomenological reasons could be that references [

5,

6,

7,

8] were multi-cycle while reference [

9] was single cycle. This is related to the issue of single-cycle performance (neither purging nor filling) versus multi-cycle performance (sequential cycles that involve purging and filling). This problem was considered in detail by Ma et al. [

28]. The authors modelled performance losses at high operation frequencies and concluded that above some frequency threshold, differences between single-cycle and multi-cycle analysis might have to be considered.

Another reason for the discrepancies could be that references [

5,

6,

7,

8] are experimental, while reference [

9] is numerical. Obviously, from the methodological viewpoint, the numerical approach is cleaner in the sense that different physical effects could be isolated. However, in an actual test bench, real effects interact with each other, and the practical outcome is affected by these complex interactions. For example, two reasons of Allgood et al. [

5] to propose the Con nozzle were back-pressurization and control the frequency of the engine. Also, Allgood et al. [

5] suggested that purging and filling may not have a negligible effect on thrust performance. All this suggests that PDE performance is very sensitive to practical operating conditions.

Now, coming back to the present results shown in

Table 7, the following aspects could be observed:

In all cases, the optimum nozzle was divergent except in one case where the optimum solution was the straight tube;

Optimizing in view of ISPF and IT separately with no regard for nozzle area (cases #1 and #2) led, basically, to the same nozzle geometry: largest allowable length and nearly the same diverging ratio D9/D (less than 2% discrepancy). The difference was on the equivalence ratio: 0.8 for ISPF optimization and 1 for IT optimization, respectively. ISPF in case #1 was 10% larger than in case #2. IT in case #2 was 10% larger than in case #1;

In all cases with the divergent nozzle, the diverging ratio was small: D9/D < 1.12;

Introduction of nozzle surface area (related to total PDE weight) in the optimization process substantially modified the optimum solution. In cases #3 and #4, the solution was the straight tube (the actual solution of case #4 was a very short divergent nozzle that yielded a PDE surface area that differed by a factor of 2% only from the straight tube);

The comparison of cases #1 and #3 suggests that if the design team is willing to sacrifice 10% of ISPF or 12% of IT, the surface area of the PDE could be reduced by a factor of 17%. A similar conclusion could be drawn when comparing cases #2 and #4;

Simultaneous optimization of ISPF, IT, and AN (case #5) reverts to the solution of case #1 (optimization of ISPF only). In cases #1 and #5, the relative importance of AN in the optimization function is 0 and 33%, respectively, and this led to the same optimum nozzle. If the relative importance of AN in the optimization function is increased to 50% (case #3), the optimum solution changes dramatically to the straight tube. This suggests that the topological space of optimum solutions depends sharply on the importance assigned to AN in the optimization function;

The results presented in

Table 7 suggest that different options are possible depending on the terms present in the optimization function and on their relative importance. Also, although the divergent nozzle seems to be preferable in general terms, the simple solution of the straight tube has its own advantages and, accordingly, should not be discarded.

A way to visualize the behaviour of I

SPF and I

T as a function of the input parameters for the divergent nozzles, A

N, L

N, A

9/A

8, and ϕ, is presented in

Figure 6 and

Figure 7.

The following aspects could be observed in the figures:

Larger equivalence ratios, ϕ~1, (blue dots) are preferable when optimizing IT. Lean mixtures (ϕ~0.8) should be used when optimizing ISPF;

For any given L

N, both I

SPF and I

T have a maximum for some specific value of the parameter A

9/A

8. The tendency is similar for different values of

ϕ. Unlike conventional rocket nozzles, where optimal performance is achieved when the exit pressure matches the ambient pressure, the present result shows that this principle does not necessarily apply to PDE. In particular, the presence of detonation waves creates a dynamic environment in which the classical nozzle optimization criterion is no longer valid. The difference arises from the fundamentally different nature of the flow in PDE, which is highly transient and nonlinear, unlike in steady or quasi-steady propulsion systems. The time-averaged outlet static pressure of all operation points plotted in

Figure 6 and

Figure 7 is presented in

Figure 8, where the optima of the A

9/A

8 curves are highlighted with pink circles. It could be observed that all these optima are far above the dashed line that marks the ambient pressure of 1 bar. This indicates that the unsteady character of the rocket-type PDE disallows the use of conventional steady-state nozzle flow theory. This was already pointed out by Ornano et al. [

9], although they reached the conclusion by other means;

Increasing A9/A8 beyond this optimum has two negative effects: it increases the nozzle surface area, and it decreases both ISPF and IT;

For very short nozzles, the curves A9/A8 are almost vertical, meaning that small variations in this parameter have a large negative impact on both ISPF and IT;

If a least squares fitting is to be performed on the I

SPF-A

N and I

T-A

N data clouds of

Figure 6 and

Figure 7, it is easy to see that a dominant near-linear behavior could be observed. Also, it would be apparent that the slope would be small. For example, changing A

N from 0.02 m

2 to 0.04 m

2 (a 100% variation) would change I

SPF from, say, 4600 m/s to 5000 m/s (a 10% variation). That is, large variations in A

N entail smaller variations in I

SPF. This implies that the objective function is more sensitive to A

N than to I

SPF (or I

T), that is, precisely, what is observed in the results of

Table 7.

6. Conclusions

When the objective function contained one performance parameter only (either specific impulse based on fuel or total impulse), the optimum solution was the divergent nozzle of the small area ratio (1.25 if the specific impulse based on fuel was considered, 1.31 if the total impulse was contemplated). In these cases, the nozzle length was the maximum allowed within the space of design variables (length equal to 20% of the tube length). If the nozzle surface area was added to the objective function (performance parameter and nozzle area having similar weights), the optimum solution switched to the straight tube. When the three criteria (specific impulse based on fuel, total impulse, and nozzle surface area) were put together in the objective function with similar weights, the optimum solution reverted to the divergent nozzle of the small area ratio (1.13). In this case, the two performance parameters had a combined weight of 2/3 in the objective function, while the weight of the nozzle surface area criterion was 1/3. These optimization results could be explained by the fact, observed in the densified data tensors, that large variations in AN, of the order of 100%, entail smaller variations in ISPF (or IT), of the order of 10%, meaning that the objective function is more sensitive to AN than to ISPF (or IT).

All this suggests that the nozzle design for rocket-type PDE is very sensitive to the criteria used for optimization. If propulsive performance is the single criterion, the divergent nozzle is the preferred solution. If, in addition, nozzle surface area (weight) is to be considered, the straight tube is the optimum solution. Broadly speaking, sacrificing 10% of the specific impulse based on fuel (or total impulse) allows for a total surface area reduction (tube plus nozzle) close to 20%. This suggests that, in a practical situation, the global architecture of a PDE might depend strongly on the type of mission. This is not surprising because it is a common feature of other propulsion plants.

Conventional steady-state nozzle flow theory should not be used for the design of Pulse Detonation Engines that present strongly unsteady behaviour. In fact, it was observed that actual performance maps present large differences, so Pulse Detonation Engine nozzles should be designed according to their unsteady character.

The practical operation of Pulse Detonation Engines depends critically on many design aspects of a very different nature. For instance, while this study and others support the convenience of the divergent nozzle, other studies propose the convergent nozzle based on control aspects of the multi-cycle operation of the engine. That is, engine optimization should be carried out, ideally accounting for both flow-related aspects and operational aspects. However, this may involve the difficult simultaneous presence of numerical and experimental approaches within the same optimization framework.