Launch Experiment of Microwave Rocket Equipped with Six-Staged Reed Valve Air-Breathing System

Abstract

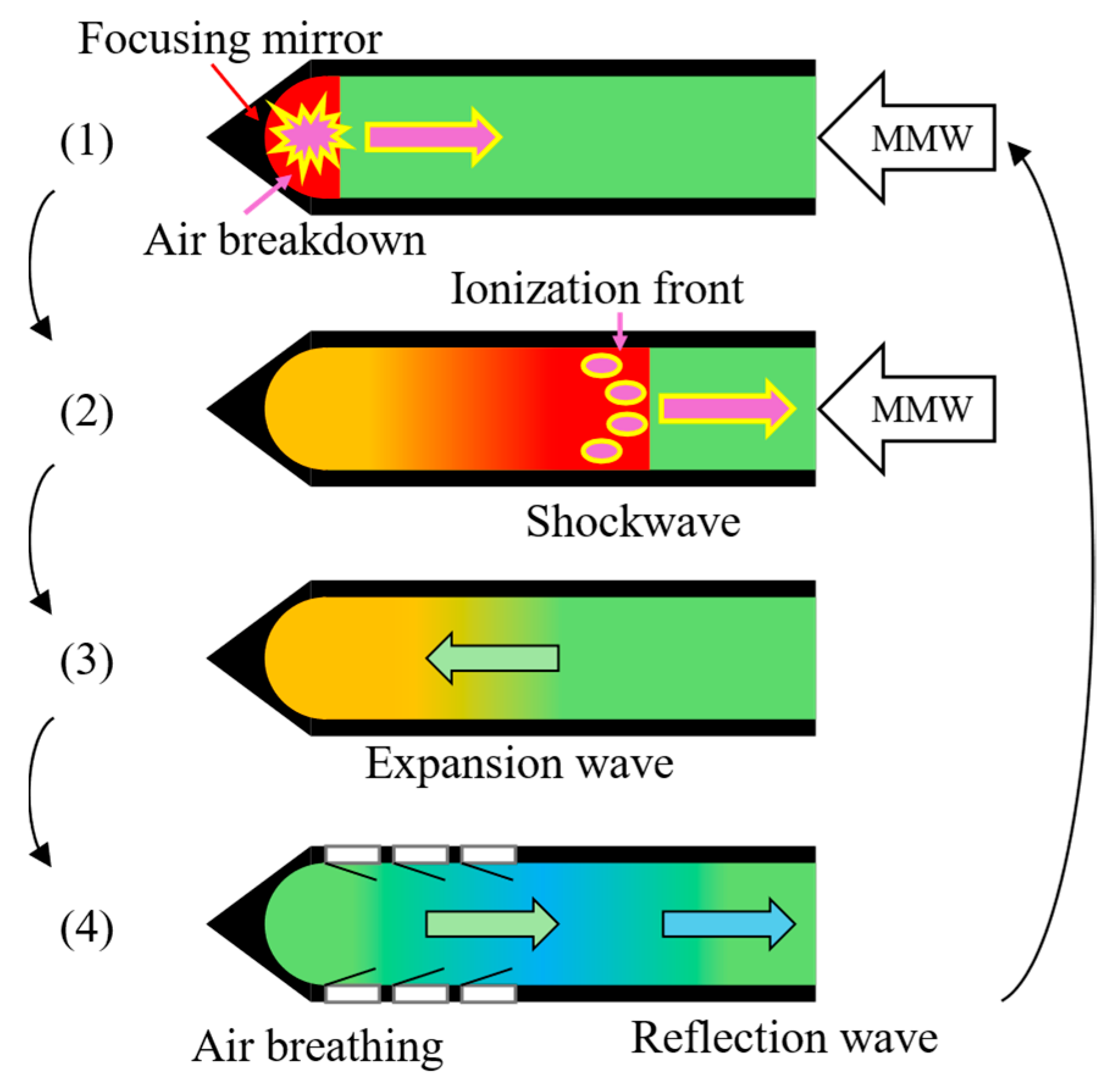

1. Introduction

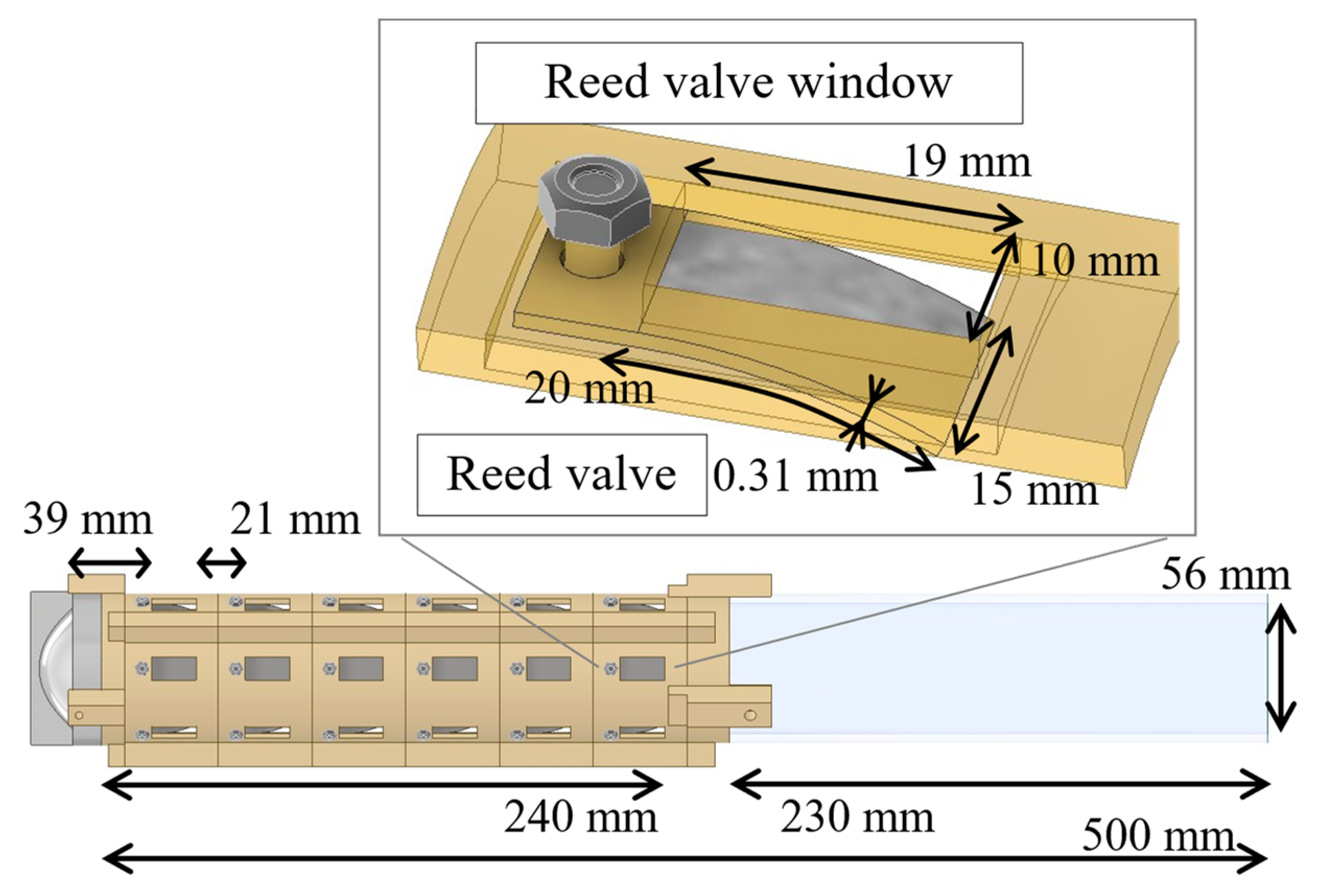

2. Reed Valve Design

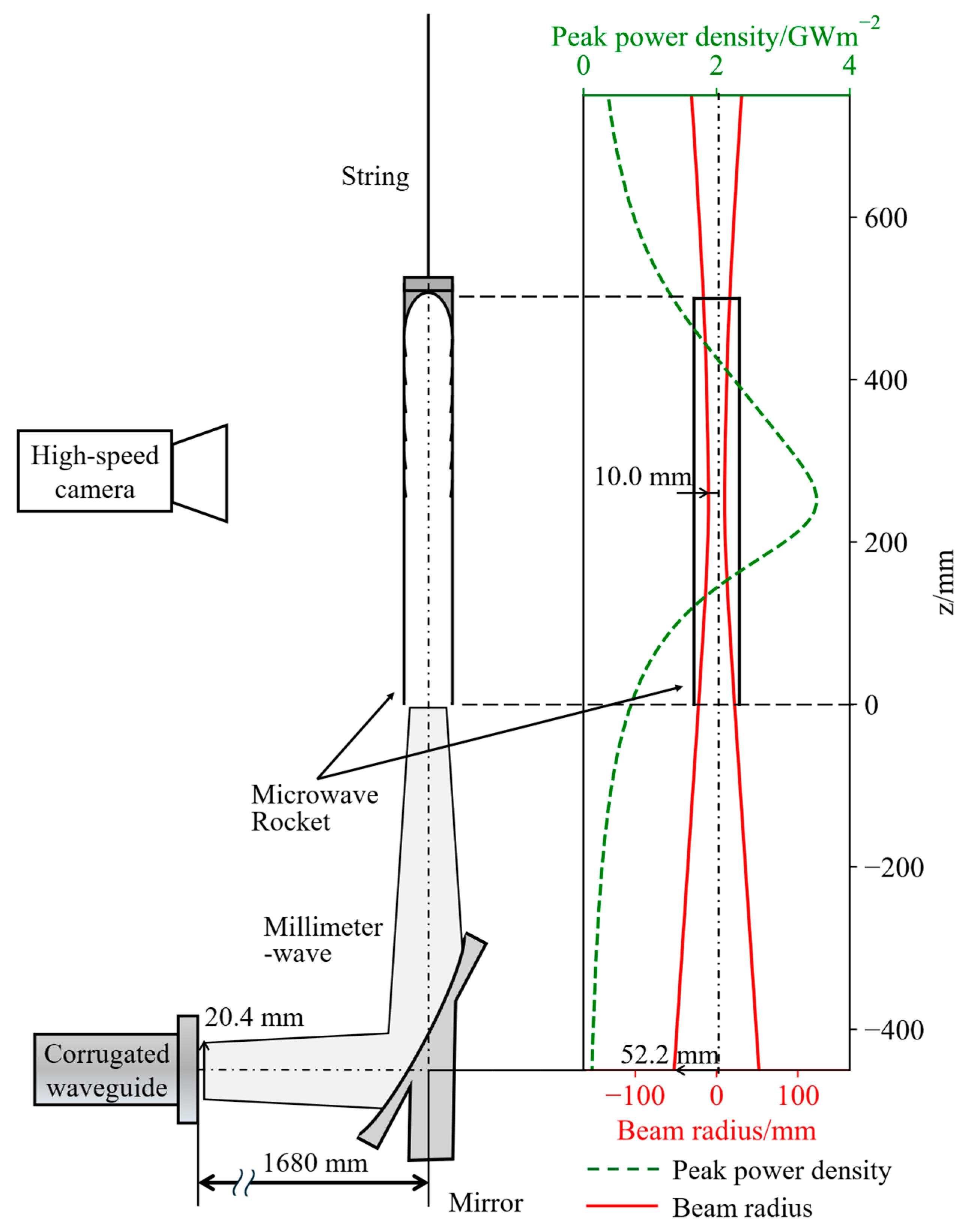

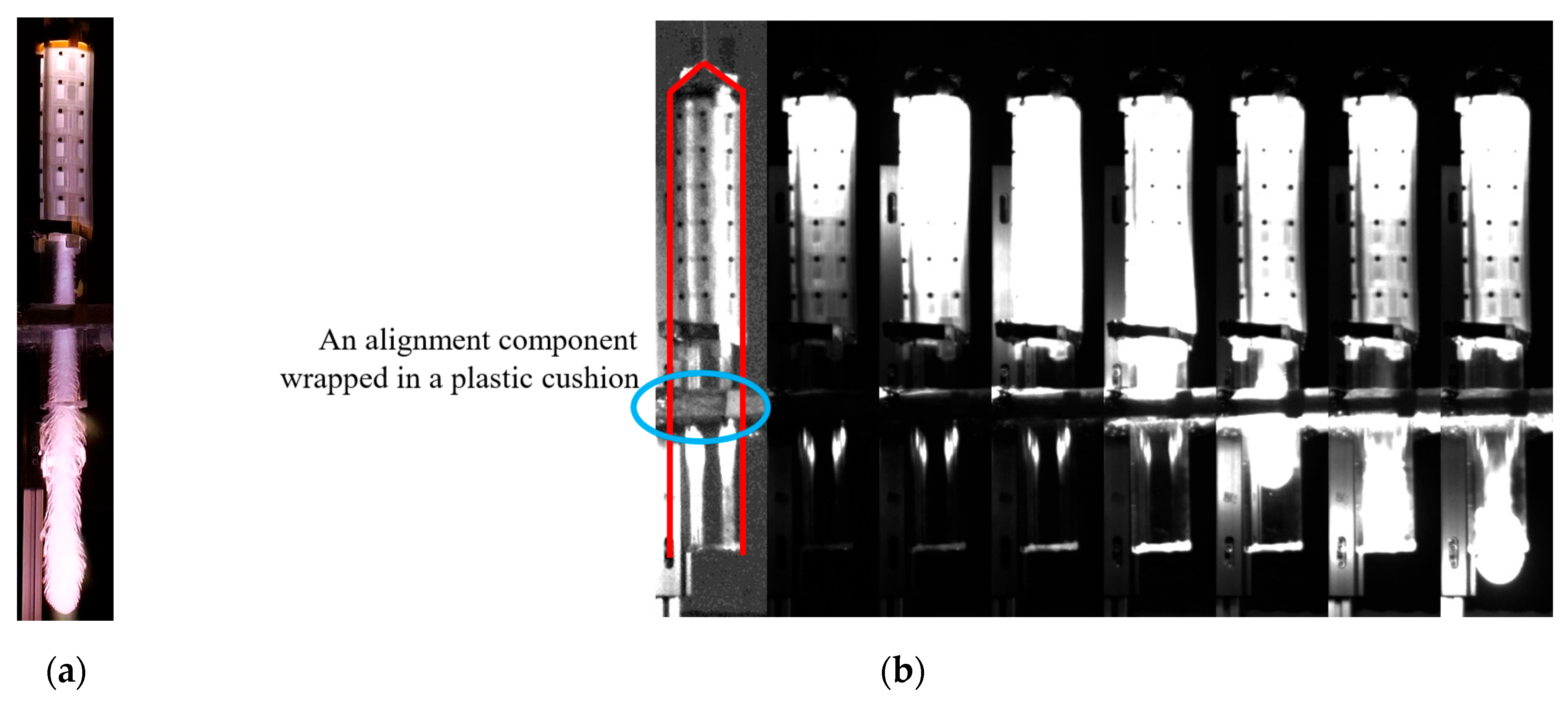

3. Setup for Launch Experiment

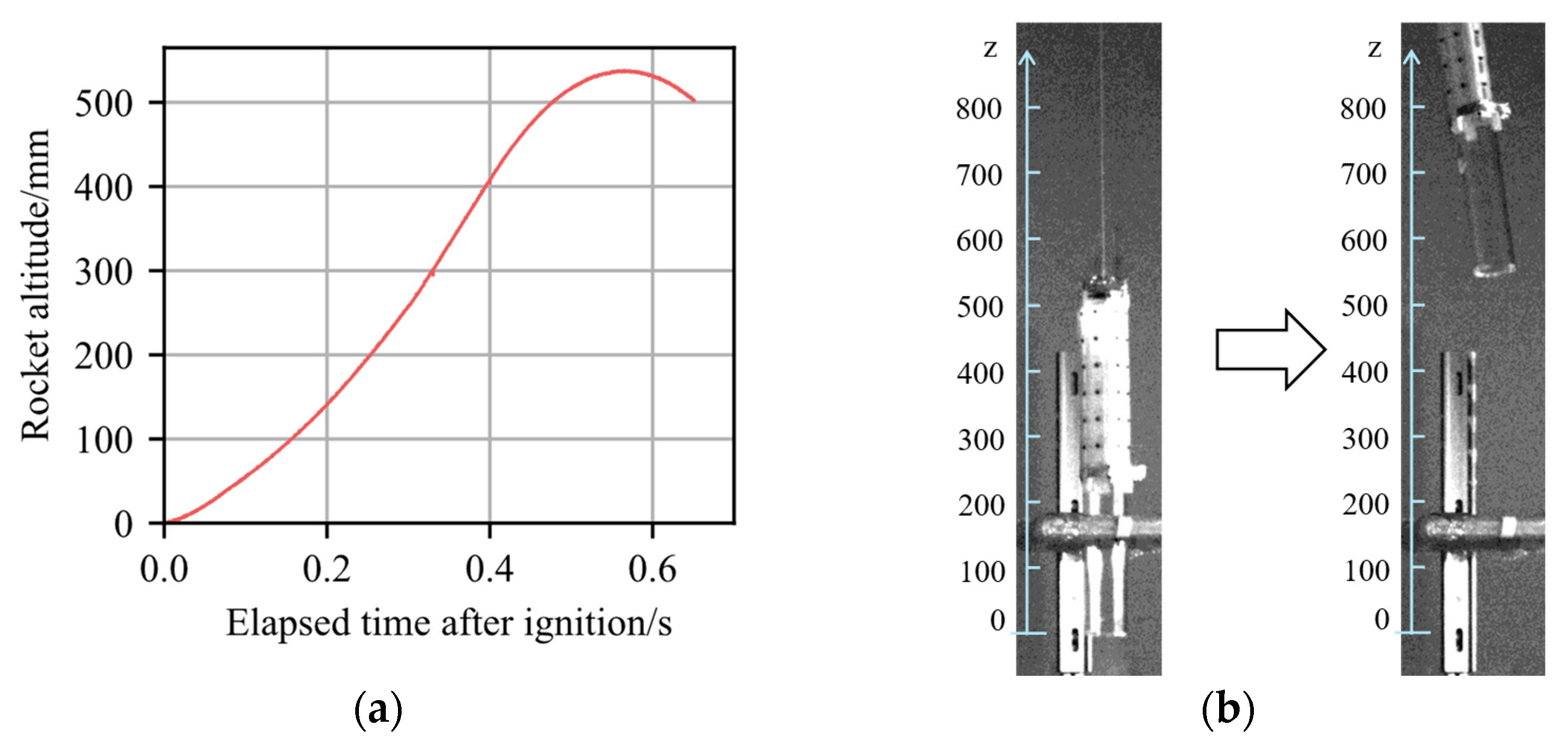

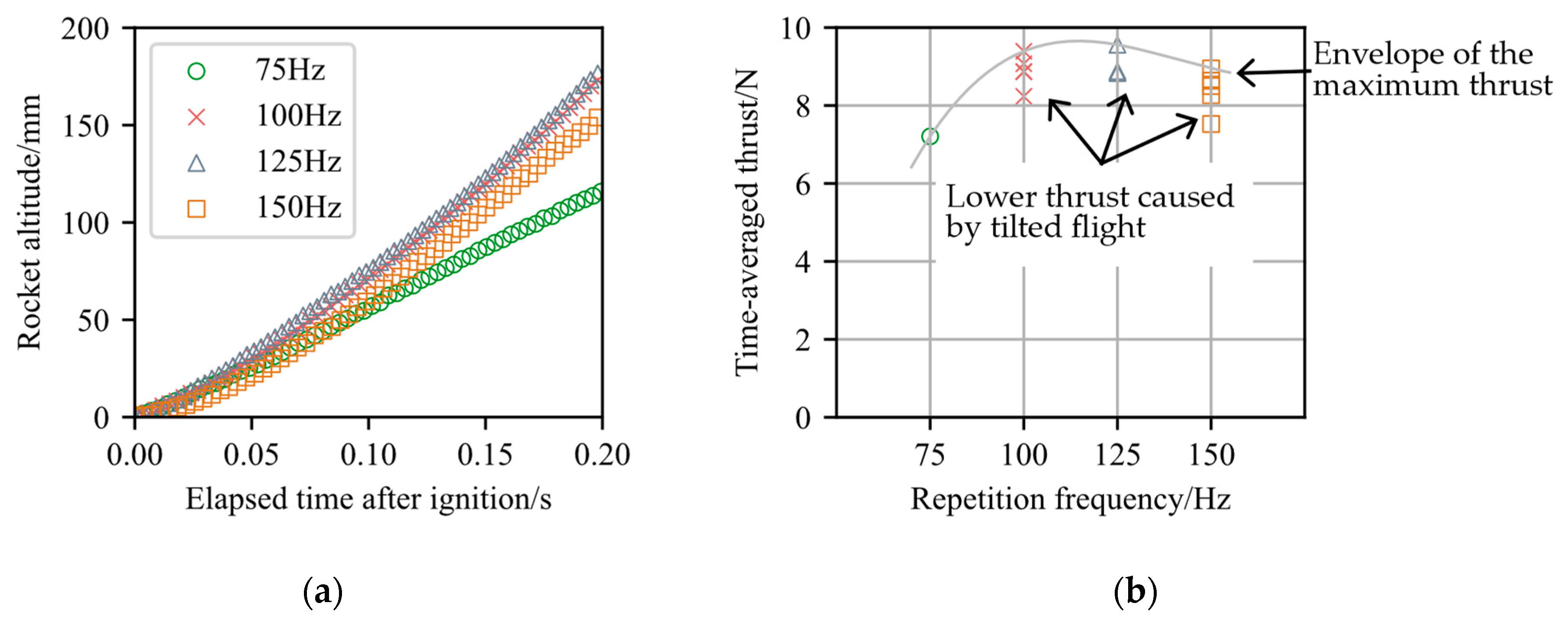

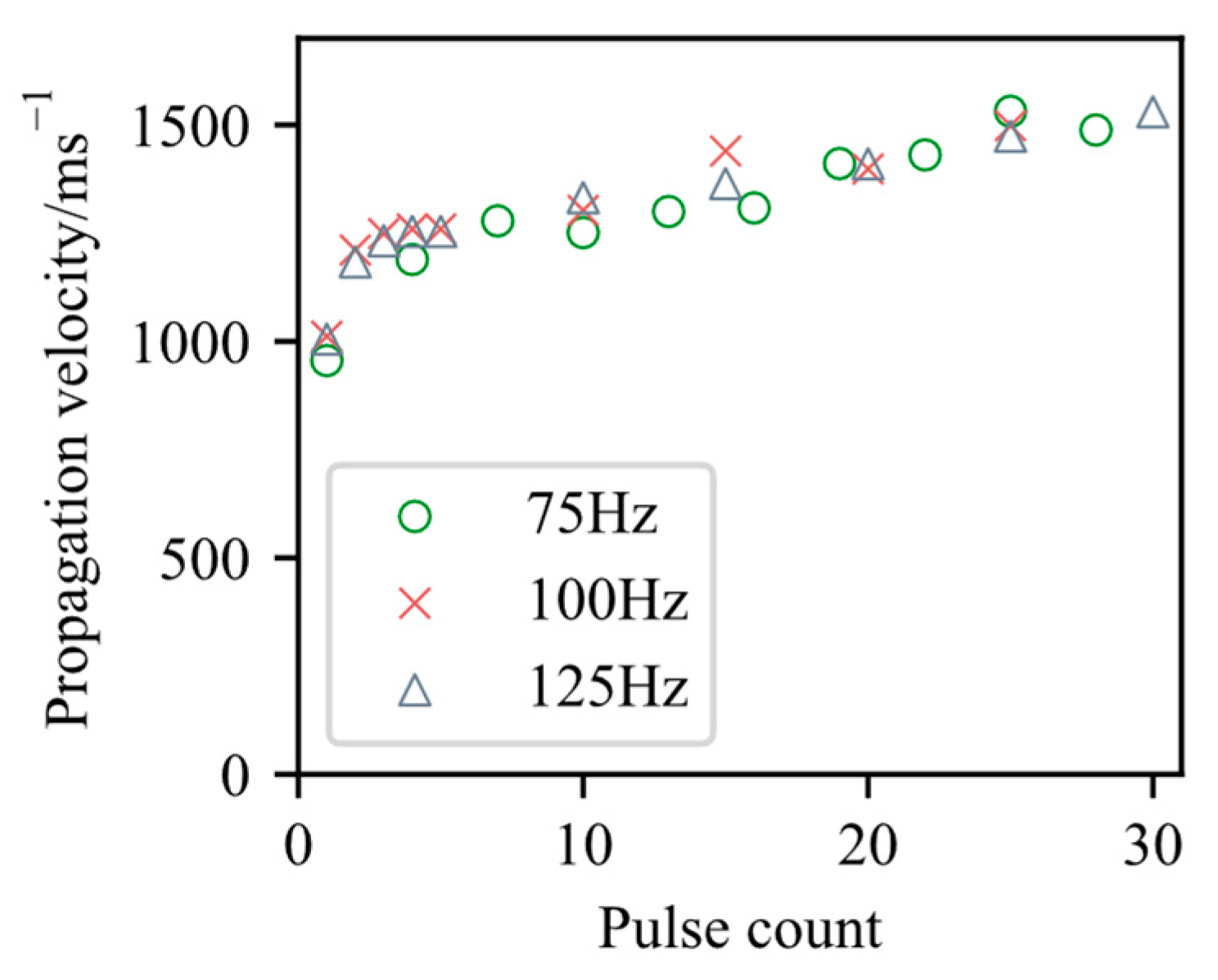

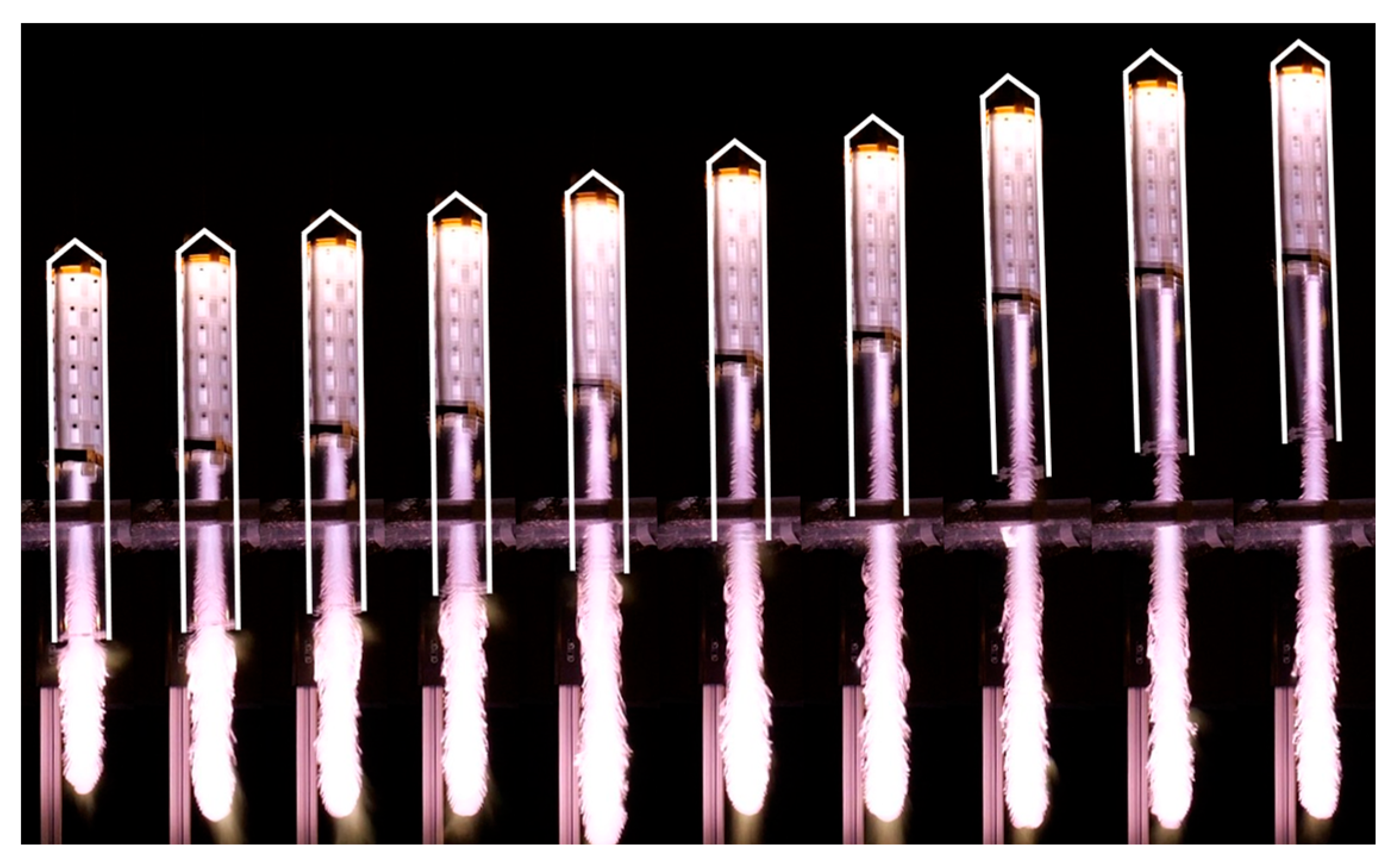

4. Results and Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Pakhomov, A.V.; Thompson, M.S.; Swift, W.; Gregory, D.A. Ablative Laser Propulsion: Specific Impulse and Thrust Derived from Force Measurements. AIAA 2002, 40, 2305–2311. [Google Scholar] [CrossRef]

- Phipps, C.; Luke, J. Diode Laser-Driven Microthrusters: A New Departure for Micropropulsion. AIAA 2002, 40, 310–318. [Google Scholar] [CrossRef]

- Kare, J.T. Laser-powered heat exchanger rocket for ground-to-orbit launch. J. Propul. Power 1995, 11, 535–543. [Google Scholar] [CrossRef]

- Eguchi, K.; Tuan, T.D.; Ymamori, H.; Mori, K. Continuous-wave Laser Propulsion Using a Porous Carbon Heat Exchanger. Aerosp. Technol. Jpn. 2018, 17, 285–288. [Google Scholar]

- Parkin, K.L.; Murakami, D.D. In 48th AIAA/ASME/SAE/ASEE Joint Propulsion Conference Exhibit; AIAA: Atlanta, GA, USA, 2012. [Google Scholar]

- Myrabo, L.N. Brief History of the Lightcraft Technology Demonstrator (LTD) Project. AIP Conf. Proc. 2003, 664, 49–60. [Google Scholar]

- Komurasaki, K.; Shimamura, K.; Fukunari, M.; Oda, Y.; Imai, T.; Takahashi, M.; Katsurayama, H.; Ohnishi, N. Microwave rocket propelled by millimeter wave. J. Plasma Fusion Res. 2017, 93, 465–466. [Google Scholar]

- Komurasaki, K.; Tabata, K. Development of a Novel Launch System Microwave Rocket Powered by Millimeter-Wave Discharge. Int. J. Aerosp. Eng. 2018, 2018, 1–9. [Google Scholar] [CrossRef]

- Batanov, G.M.; Gritsinin, S.I.; Kossyy, I.A.; Magunov, A.N.; Silakov, V.P.; Tarasova, N.M. High-pressure microwave discharges. In Subthreshold Discharge Excited by Microwave Beam in the High-Pressure GASES; Physics and Applications, Pero, Ltd.: Moscow, Russia, 2019; pp. 6–35. [Google Scholar]

- Shimamura, K.; Matsukura, M.; Ozaki, N.; Miyawaki, K.; Yokota, S.; Minami, R.; Kariya, T.; Imai, T. Wireless Power Transmission Efficiency for Microwave Rocket Using 28 GHz Gyrotron. J. Spacecr. Rocket. 2020, 57, 632–635. [Google Scholar] [CrossRef]

- Takahashi, M.; Ohnishi, N. Numerical study of discharge and thrust generation in a microwave rocket. In Proceedings of the AIAA Scitech 2019 Forum, San Diego, CA, USA, 7–11 January 2019. [Google Scholar] [CrossRef]

- Nakagawa, T.; Mihara, Y.; Komurasaki, K.; Takahashi, K.; Sakamoto, K.; Imai, T. Propulsive Impulse Measurement of a Microwave-Boosted Vehicle in the Atmosphere. J. Spacecr. Rocket. 2004, 41, 151–153. [Google Scholar] [CrossRef]

- Oda, Y.; Komurasaki, K.; Takahashi, K.; Kasugai, A.; Sakamoto, K. Plasma generation using high-power millimeter-wave beam and its application for thrust generation. J. Appl. Phys. 2006, 100, 113307. [Google Scholar] [CrossRef]

- Komatsu, R.; Ymaguchi, T.; Oda, Y.; Saito, S.; Fukunari, M.; Komurasaki, K.; Ken, K.; Takahashi, K.; Sakamoto, K. Thrust Enhancement of Microwave Rocket via High-Power, High-Duty-Cycle Operation. J. JPN. Soc. Aeronaut. Space Sci. 2012, 60, 235–237. [Google Scholar]

- Fukunari, M.; Komurasaki, K.; Nakamura, Y.; Oda, Y.; Sakamoto, K. Rocket Propulsion Powered Using a Gyrotron. J. Energy Power Eng. 2017, 11, 363–371. [Google Scholar]

- Fukunari, M.; Arnault, A.; Yamaguchi, T.; Komurasaki, K. Replacement of chemical rocket launchers by beamed energy propulsion. Appl. Opt. 2014, 53, I16–I22. [Google Scholar] [CrossRef]

- Kakinuma, K.; Fukunari, M.; Yamaguchi, T.; Nakamura, Y.; Koizumi, H.; Komurasaki, K.; Parkin, K. Two-Stage-to-Orbit Transporting System Combining Microwave Rocket and Microwave Thermal Rocket for Small Satellite Launch. Trans. Jpn. Soc. Aeronaut. Space Sci. Aerosp. Technol. Jpn. 2016, 14, Pb99–Pb103. [Google Scholar] [CrossRef][Green Version]

- Taniguchi, T.; Yabata, K.; Manabe, A.; Tamagawa, T.; Komurasaki, K.; Koizumi, H. Investigation of Transmission Frequency and Optical System Design for Cost-Effective Launch of Microwave Rockets. Space Sol. Power Syst. 2021, 6, 51–58. [Google Scholar]

- Oda, Y.; Shibata, T.; Komurasaki, K.; Takahashi, K.; Kasugai, A.; Sakamoto, K. Thrust Performance of Microwave Rocket Under Repetitive-Pulse Operation. J. Propuls. Power 2009, 25, 118–122. [Google Scholar] [CrossRef]

- Fukunari, M.; Yamaguchi, T.; Nakamura, Y.; Komurasaki, K.; Oda, Y.; Kajiwara, K.; Takahashi, K.; Sakamoto, K. Thrust generation experiments on microwave rocket with a beam concentrator for long distance wireless power feeding. Acta Astronaut. 2018, 145, 263–267. [Google Scholar] [CrossRef]

- Manabe, A.; Irie, K.; Nakatani, T.; Kinoshita, T.; Nomura, T.; Weiand, M.; Komurasaki, K.; Shinya, T.; Ikeda, R.; Ishita, K.; et al. Experimental evaluation of a reed valve air intake system for microwave rocket in ground-static tests. Acta Astronaut. 2025, 234, 410–418. [Google Scholar] [CrossRef]

- Fukunari, M.; Yamaguchi, T.; Komurasaki, K.; Oda, Y.; Ikeda, R.; Kajiwara, K.; Takahashi, K.; Sakamoto, K. Air-breathing system using reed valve for pulse detonation microwave rocket. Trans. Jpn. Soc. Aeronaut. Space Sci. Aerosp. Technol. Jpn. 2016, 14, 1–7. [Google Scholar] [CrossRef]

- Shimada, Y.; Shibata, T.; Yamaguchi, T.; Oda, Y.; Kajiwara, K.; Takahashi, K.; Kasugai, A.; Sakamoto, K.; Komurasaki, K.; Arakawa, Y.; et al. Propagating structure of a microwave driven shock wave inside a tube. AIP Conf. Proceedings. Am. Inst. Phys. 2010, 1230, 366–376. [Google Scholar]

- Oda, Y.; Komurasaki, K.; Takahashi, K.; Kasugai, A.; Sakamoto, K. Investigation of Microwave Rocket Propulsion Performance under Varying Atmospheric Pressures with a High-Power Gyrotron. J. Plasma Fusion Res. 2007, 83, 296–299. [Google Scholar]

| Parameters | Single-Pulse Operation [12] | Multi-Pulse Operation [19] |

|---|---|---|

| Model mass [g] | 19.5 | 109 |

| Model size diameter × length [mm] | ⌀66 × 177 | ⌀100 × 380 |

| RF beam power [kW] | 1000 | 600 |

| Millimeter-wave frequency [GHz] | 110 | 170 |

| Pulse duration [ms] | 0.175 | 1.25 |

| Pulse repetition frequency [Hz] | - | 100 |

| Parameters | Single-Pulse [12] | Multi-Pulse [19] |

|---|---|---|

| Altitude [m] | 1.2 | 2.0 |

| Thrust impulse [Ns] or Time-averaged thrust [N] | 0.069 | 2.32 |

| Momentum coupling coefficient [N/MW] | 395 | 30.9 |

| Parameters | Values | |

|---|---|---|

| Reed valve dimensions | Length × width [mm] | 20 × 15 |

| Thickness [mm] | 0.31 | |

| Material properties | Young’s modulus [GPa] | 17.2 |

| Density [kg/m3] | 1822 | |

| Calculated properties | Bending stiffness [GPa mm4] | 0.51 |

| Fundamental Frequency [Hz] | 384 | |

| Static tip displacement [mm] | 16.6 | |

| Circumferential occupation [%] | 30 | |

| Total reed valve window area occupation [%] | 6.80 |

| Parameters | Values |

|---|---|

| Model mass [g] | 539 |

| Model size diameter × length [mm] | ⌀56 × 500 |

| RF beam power [kW] | 550 |

| Millimeter-wave frequency [GHz] | 170 |

| Pulse duration [ms] | 1.2 |

| Pulse Repetition frequency [Hz] | 75, 100, 125, 150 |

| Duty cycle | 0.09, 0.12, 0.15, 0.18 |

| Beam waist [mm] | 10.0 |

| Peak power density [GW/m2] | 3.50 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Irie, K.; Manabe, A.; Nakatani, T.; Kinoshita, T.; Nomura, T.; Weiand, M.; Komurasaki, K.; Shinya, T.; Ikeda, R.; Ishita, K.; et al. Launch Experiment of Microwave Rocket Equipped with Six-Staged Reed Valve Air-Breathing System. Aerospace 2025, 12, 577. https://doi.org/10.3390/aerospace12070577

Irie K, Manabe A, Nakatani T, Kinoshita T, Nomura T, Weiand M, Komurasaki K, Shinya T, Ikeda R, Ishita K, et al. Launch Experiment of Microwave Rocket Equipped with Six-Staged Reed Valve Air-Breathing System. Aerospace. 2025; 12(7):577. https://doi.org/10.3390/aerospace12070577

Chicago/Turabian StyleIrie, Kosuke, Ayuto Manabe, Tomonori Nakatani, Tatsuki Kinoshita, Toshinobu Nomura, Matthias Weiand, Kimiya Komurasaki, Takahiro Shinya, Ryosuke Ikeda, Keito Ishita, and et al. 2025. "Launch Experiment of Microwave Rocket Equipped with Six-Staged Reed Valve Air-Breathing System" Aerospace 12, no. 7: 577. https://doi.org/10.3390/aerospace12070577

APA StyleIrie, K., Manabe, A., Nakatani, T., Kinoshita, T., Nomura, T., Weiand, M., Komurasaki, K., Shinya, T., Ikeda, R., Ishita, K., Nakai, T., Kajiwara, K., & Oda, Y. (2025). Launch Experiment of Microwave Rocket Equipped with Six-Staged Reed Valve Air-Breathing System. Aerospace, 12(7), 577. https://doi.org/10.3390/aerospace12070577