Abstract

This work explores solid rocket motor grain design, leveraging additive manufacturing techniques based on slurry deposition and UV-curing. The objective is to develop an automated design procedure to identify optimal solutions that meet mission requirements, exploiting new geometries and ballistic configurations previously unattainable with the classical mix–cast–cure manufacturing process. The design procedure is based on a stochastic optimization approach coupled with surrogate modeling of the pressure–time response, considering variable geometrical and ballistic parameters. Several surrogate models were tested after the creation of suitable databases through the computation of pressure evolution for different configurations. The most appropriate surrogate model was selected and applied within optimization routines to evaluate individual designs. The optimizer identifies the most suitable configuration to obtain the desired pressure–time response and to meet motor requirements. Different design approaches have been tested to evaluate the ballistic distribution’s influence on performance and how it can be leveraged to meet requirements, even with significant modifications in grain geometry. The results show that the proposed procedure is able to effectively achieve the expressed requirements, successfully handling the novel design environment. Furthermore, they highlight the strong influence of the ballistic distribution on performance and show how it can be successfully exploited to guide grain design.

1. Introduction

Composite solid propellants are widely used in various applications [1], ranging from civilian application, for example, from gas generators for airbag devices to aerospace propulsion systems, including space launchers and missile systems. Solid rocket motors (SRMs) [2] employ composite solid propellant grains to generate hot gases and produce thrust. These propulsive systems are favored for their high thrust, high energy density, rapid ignition, and superior storage characteristics [3]. The manufacturing of composite solid propellants typically involves a mix–cast–cure process, which results in a solid cartridge that satisfies specific mechanical and geometrical properties. However, traditional manufacturing processes, currently used in this type of application, impose the use of mandrels with consequent limitations on grain dimensions and geometries. In addition, the chemical composition of the grains is generally spatially uniform. To overcome these limitations, innovative additive manufacturing approaches are under investigation. An overview of these projects applied to energetic materials is presented in [4], while some applications can be found in [5,6,7] and in NDIA proceedings [8,9] for defense applications. Among them, an innovative approach [10] for the production of composite propellants has been proposed, based on additive manufacturing techniques and UV light. This innovative method eliminates the need for a mandrel and uses photocurable polymers, which are less toxic and more suited for 3D printing. Moreover, it enables the possibility to change the composition and the infill density of the grain in a continuous manner, effectively controlling the ballistic response of the propellant. The proposed process, explored in [11,12,13,14,15,16,17,18,19,20,21], is currently under investigation to improve its Technology Readiness Level, considering the design and calibration of the deposition/printing system and new grain design approaches that can exploit the potential of the innovative process. Previous work carried out in [11,12] compared different type of UV-curable resins and selected Polybutadiene Dyacrilate (PBDA) as a suitable polymeric binder to allow for an additive manufacturing process. The compound showed similar mechanical and ballistic properties compared to classical PB-based composite propellants, and it proved sensitive to UV irradiation with a high Ammonium Nitrate (AN) solid particle loading up to 90 percent in weight. AN has been chosen as an inert surrogate for Ammonium Perchlorate (AP) since it carries similar physical properties during mechanical testing. Pot life and extrusion-curing tests have also been carried out, with the latter still need some fine tuning to account for non-Newtonian properties of the fluid during the extrusion phase. These works showed promising features for this type of compound, and its properties have been chosen for reference for material characterization during the construction of the simulation models.

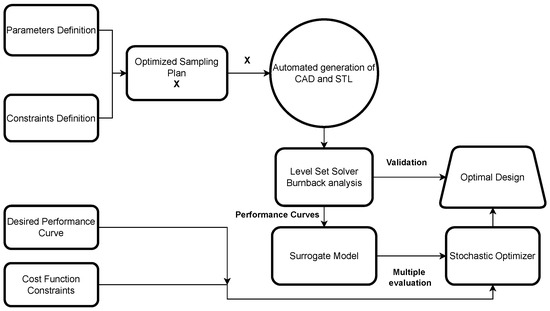

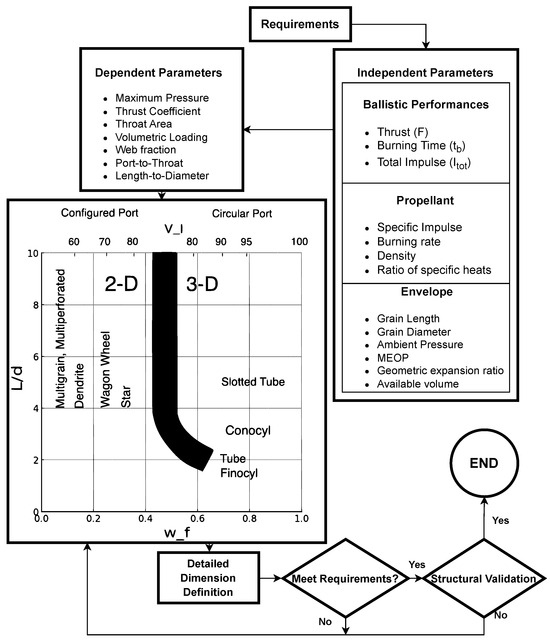

The purpose of the present work is to focus on the latter topic, with the aim of evaluating how the attractive potential of the innovative manufacturing process can be used to drive the SRM grain design to match the desired performance characteristics. Specifically, the main objective is to identify the optimal geometry and distribution of ballistic properties that can match a specified thrust-time history while minimizing a given cost functional under specified design constraints. Although this approach has previously been applied in grain design [22,23,24,25,26], it is crucial to assess how the paradigm shift in the manufacturing process can influence design choices and potentially discover novel configurations for existing mission profiles that were previously unattainable due to limitations of the classical mix–cast–cure approach. To perform this evaluation, the following design optimization process was implemented. A level set (LS) solver based on the work of Mitchell [27] was tailored to compute grain regression in order to evaluate the consequent time evolution of chamber pressure accounting for non-uniform ballistic properties [28]. A description of the physical model and an overview of the LS solver is presented in the next section. After the definition of the design space (the grain geometry and ballistic properties distribution), a sampling plan was produced using a Latin hypercube design optimized for maximum space-filling properties. The limits of the design space are driven by the design requirements of the problem. Each design in the sampling plan was evaluated using the LS solver, and the corresponding pressure–time curves were obtained; simulation parameters were computed from mission requirements. These curves formed the database used to train surrogate models through different methodologies. The use of surrogate models is mandatory when optimization is taken into account due to the numerous function evaluations required. In this work, a genetic algorithm was used to search for the configuration that better reproduces the desired pressure–time curve and that satisfies, at the same time, all the problem constraints derived from the design requirements. Once the most suitable configuration was identified, a final validation with the LS solver was performed to verify the performance of the optimal design found by the optimization routine. The overall design optimization process is outlined in Figure 1.

Figure 1.

Flow chart of design optimization procedure.

2. Physical Model and Numerical Schemes

This section describes the physical model and the numerical schemes used to integrate the equations. The methods shown here are used to compute the pressure–time response curve for a specific 3D geometry. The chamber is described by a 0D model, which allows us to compute the pressure evolution. This model requires the instantaneous gas mass flow rate generated by the combustion of the solid. This is obtained by performing an integral on the instantaneous burning area, which is computed by means of the level set method.

2.1. Chamber Model and Time Integration

Pressure evolution is computed with a 0D model, that relies on mass conservation in a combustion chamber. Pressure evolution is dependent on the balance between the mass flow of produced gas thanks to combustion processes and the mass flow expelled through nozzle . A complete description can be found in [2].

The mass flow rate produced by burning can be written as

The mass conservation equation can be written as

If an ideal gas mixture is considered, then the time derivative in Equation (2) can be rewritten as

Hence

The characteristic velocity can be evaluated according to the ideal rocket model: . The complete definition of is later reported in Equation (16). As a result, considering that , the pressure derivative can be evaluated as

This ordinary differential equation (ODE) can be integrated provided that burning area and chamber volume are available: these variables are computed through the LS integration. From Equation (5), the time derivative can be approximated implicitly as

The second term in the expansion can be expanded through a Taylor approximation, computing the Jacobian . Here geometrical features are considered frozen at previous time step k. In a similar way, pressure is considered frozen during geometry integration through the level set. The time step is the same between LS and pressure integration. With these assumptions it is possible to write

Solving for leads to

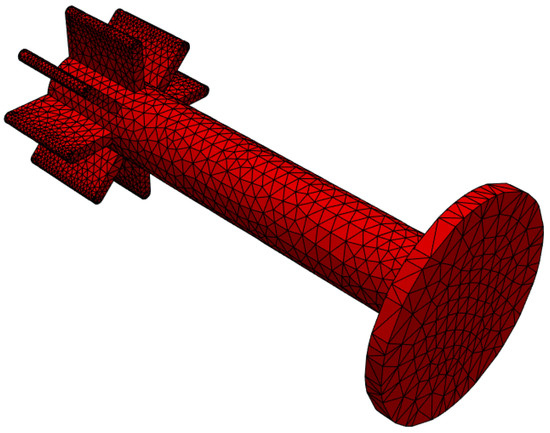

The regression rate is described by St. Robert’s law [2] where a and n are coefficients which depend on the composition of the propellant and is the chamber pressure. For the sake of simplicity, erosive burning, related to high gas speeds in the chamber, is neglected, as well as the effect of grain temperature on burning rate, mechanical stress in the grain, and nozzle erosion. The proposed model maintains a sufficient degree of fidelity, reducing computational cost in order to exploit it during the evaluation of multiple configurations. Since r can potentially vary on the surface due to the non-uniform grain properties, the computation of the burned gas mass flow rate requires integration over the burning surface . This variation is controlled through the variation in the coefficient a in the domain, while coefficient n is assumed to be constant. The zero level set, i.e., the burning surface, is reconstructed through a surface triangulation at every time step (Figure 2). Since the burning rate is defined on every point of the grid, it is possible to assign the value of the nearest point of the grid to the correspondent triangle barycenter of the surface triangulation. As a result, the burning mass flow rate is computed as

where N is the number of triangles of the isosurface and propellant density and gas pressure are assumed to be uniform. This computation allows the term R and its derivative to be evaluated with respect to pressure:

Figure 2.

Surface triangulation for an example front-burning finocyl geometry.

Through this model it is possible to compute the pressure–time evolution as a consequence of grain burning.

2.2. Level Set Method

The instantaneous burning surface is described through the definition of an implicit function , whose zero-level identifies the boundary between the solid grain and the motor chamber, hence the surface that burns at a given time. The topological modification of the curve due to burning can be described through the following PDE (level set equation)

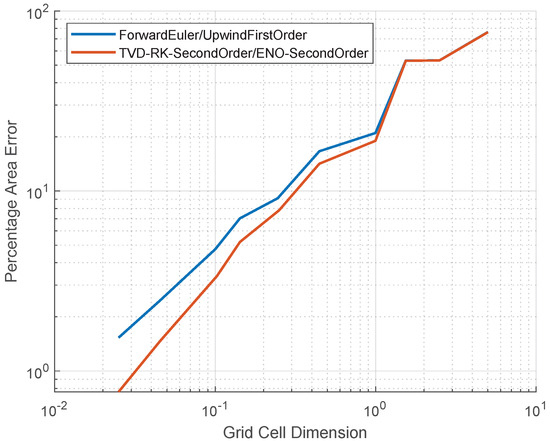

using the non-uniform burning rate field as velocity. In particular we establish that the velocity field is parallel to the local surface normal, i.e., the surface moves along the direction defined by the local normal. Since the latter can be expressed as , the LS equation becomes . Generally speaking could be an arbitrary function, but the most efficient choice is to use the Signed Distance Field (SDF), i.e., the distance of each point of the domain from the surface, with a positive or negative sign whether the point is outside or inside the surface, respectively. This choice allows the utilization of the property of the distance field, for which , to simplify resolution of Equation (11) [29]. The level set equation is discretized using a second-order accurate Essentially Non-Oscillatory (ENO) method on a orthogonal Cartesian grid and integrated in time using a second-order Total Variation Diminishing Runge–Kutta (TVD-RK) method [29]. The time step was selected through the CFL condition using the greatest surface velocity in the field. The burning area is computed through surface movement for use in the further evaluation of pressure. To evaluate the ability of the LS solver to reconstruct the surface and to evaluate the grid convergence, tests were carried out for both second- and first-order accuracy schemes. At the end of each time integration interval, the burning area was evaluated and compared against the analytical solution of a reference geometry—a star-shaped profile [30]. The maximum percentage error in the surface area was computed over the simulation time and used as a reference quantity to evaluate surface reconstruction performance. Errors were assessed for various grid resolutions (see Figure 3). To preserve SDF properties through time integration, a reinitialization step was performed at every simulation interval through the integration of reinitialization equation , in a pseudo-time variable , to retrieve the condition . This reinitialization technique is commonly found in the literature [27,29].

Figure 3.

Error estimation for different grid cell dimensions.

3. Automatic Optimizer Description

3.1. Design Space

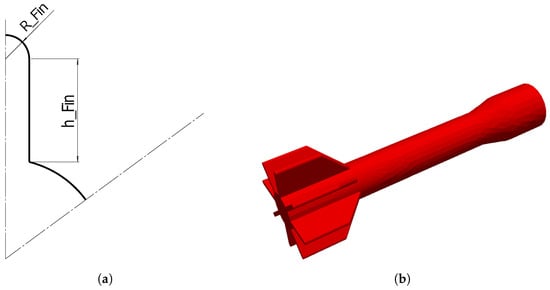

The first step of the design optimization problem concerned the definition of the parameter space. A specific finocyl geometry with non-uniform ballistic properties and a fixed number of fins was selected as a baseline configuration for optimization. This choice was motivated by the fact that this non-trivial geometry is widely used and well studied; hence, it offers a valid comparison to assess the influence of non-uniform ballistic properties of the propellant. In general, the overall optimization procedure can also be carried out on uniform grain, but in the scope of this work the importance of ballistic variability is prominent, and, consequentially, surrogate models and an optimizer were conceived to manage the non-uniform distribution. Nonetheless, a uniform distribution can be obtained from the defined distribution by altering parameters accordingly (e.g., in the polynomial distribution of Equation (12) by selecting ). The grain geometry is given by the dimensions of the main sections, e.g., diameter and length, while the fin section is described by the height and the thickness of the fin. The non-uniform ballistic properties are defined by the two coefficients of a polynomial function that describes their radial distribution,

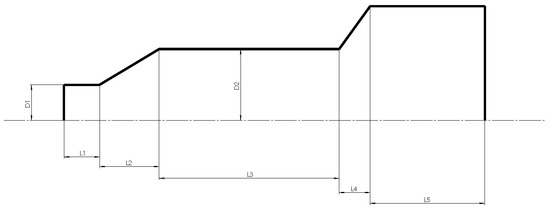

with constant [28,31]. The variation in burning rate is obtained by varying the a coefficient of St. Robert’s law, following the desired radial function. The parameter range selection ensures that the burning rate values remain within the typical range for solid propellants. Moreover, the total variation is limited to a maximum doubling of the burning rate within the grain, i.e., . This constraint is based on the fact that such a variation can be achieved with reasonable modifications to the propellant composition [32]. While further exploiting additive manufacturing through infill density variation could lead to even greater deviations in burning rate values [20], in the scope of this work, a more limited variation is considered to provide a first assessment of the influence of non-uniform ballistic properties distributions on grain design. A first approach describes the individual configuration using a total of eleven parameters, nine geometric parameters, and two ballistic distribution parameters, with no specific limitation on grain overall length, hence with a free-length approach. A second fixed-length approach was developed to enforce the maximum length requirement for the grain and to reduce the dimensionality of the problem. Fixing the overall length as well as the length percentage of each section reduces the design parameters to six, four for geometry and two for the ballistic distribution. The baseline geometry schematics are presented in Figure 4 and in Figure 5a and vary within the limits reported in Table 1 for the free-length, eleven parameter case. In addition to the design parameters, the parametric tables also contain fixed parameters that were used to run the LS simulation. These parameters were defined in the requirement definition phase (see Section 3.4) and were transferred to the LS solver before starting the evaluation of samples and the creation of dataset curves. The fixed-length case is reported in Table 2, where the lengths are related to the required length of the grain. The fin section of the grain, which contains a fixed number of eight fins, is the aft portion of the geometry, the one corresponding to L5 section in Figure 4. Figure 5b shows a 3D visualization of possible configurations. Note that the geometries presented here represent the inner cavity of the grain, whose surface moves in a direction normal to itself as the burning proceeds.

Figure 4.

General geometry and grain geometric parameters.

Figure 5.

Example configurations for testing geometry. (a) Fin parameters; (b) burning surface reconstruction at simulation start.

Table 1.

Parameters table: free length.

Table 2.

Parameters table: fixed length.

3.2. Sampling Plan and Dataset Creation

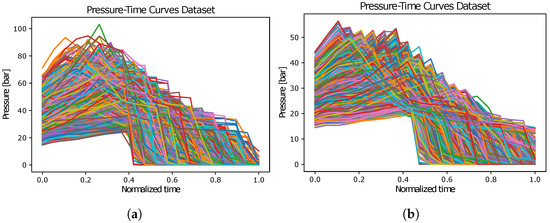

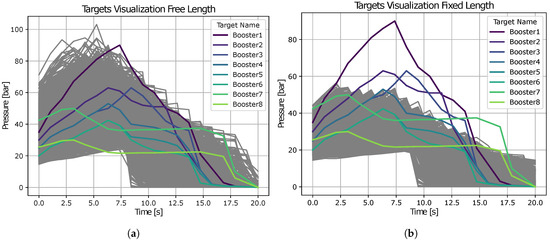

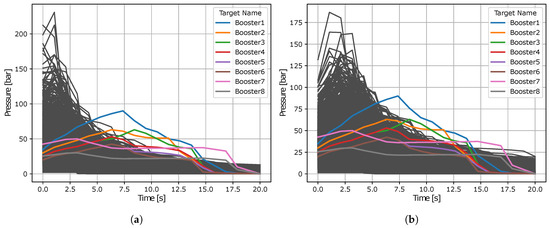

Following the definition of parameter space and its limits, a Latin Hypercube sampling plan was produced, as described in [33]. The plan was optimized to maximize its parameter-space-filling properties. Once the sample population had been defined, each grain configuration was evaluated using the LS solver. To evaluate each sample, CAD geometry and surface reconstruction via STL files are required, as described in [28]. To produce the corresponding files for every configuration defined by the sampling plan, an automated parametric routine was developed to generate the necessary files from different software tools and run all burnback simulations obtaining, for each configuration, a pressure–time curve. These curves were computed using fixed parameters chosen in the design requirements definition phase, such as and . Two different sampling plans were used. For the free-length space parameter definition, a pool of 3000 samples was produced, while the fixed-length case relied on 4096-sample evaluation to produce pressure–time curves dataset, in order to obtain a denser sampling of the parameter space. The pressure response was evaluated over a 20 s burn period. The overall simulation time was chosen to allow most of the configurations to complete the burn as a priori knowledge of the total burning time was not available. Moreover, the selected simulation time must be greater than the required burning time defined in the design phase. The burning time was then normalized with respect to the maximum burning period to allow proper rescaling for successive surrogate training. Figure 6 shows the pressure curves obtained for all samples in the free-length parameter case, as well as the fixed-length pressure–time set. Some examples extracted from database can be found in Appendix A.

Figure 6.

Curve dataset visualization. (a) Free-length dataset; (b) fixed-length dataset.

These results were then used to train the surrogate model.

3.3. Surrogate Modeling

Once datasets are established, they can be used to train surrogate models. The aim is to develop, from a certain number of LS evaluations, a model able to predict the pressure–time response of a certain geometric–ballistic configuration, described with a predefined set of parameters, and fast enough to compute a very high number of configurations in stochastic optimizer applications. For each configuration, the dataset is randomly split to save a certain number of sample for test purposes, in order to evaluate the performance of the model against unseen data. Training the model to estimate a pressure–time curve requires a tailored approach. In particular, the chosen approach is to train the model to estimate a specific pressure value at a specific burning time. The parameter vector is augmented with a normalized time value, and the augmented vector is coupled with a pressure label for the specific configuration from the dataset. A single curve, linked to a specific configuration, is sampled in 20 time evaluations, and for each time evaluation the correspondent pressure level is used as a data label. With this approach, models are trained to evaluate, for a single configuration, the pressure value in every time snapshot. From every pressure–time estimate, the response curve computed by the surrogate is then reconstructed. The performance of the surrogate is computed by evaluating the Root Mean Square Error (RMSE) on the validation set and global absolute error on the same set, i.e., the difference between the estimated and real value of pressure, for a specific time snapshot, for all configurations in the set. Different methodologies were applied to surrogate the response of the grain burnback, namely, a Neural Network, Adaptive Basis Functions, and Proper Orthogonal Decomposition. The three methods were compared through the aforementioned RMSE mean value over the time steps, as well as Global Residual values. The latter are the absolute difference, at each time step, between the real value and the value estimated by the model. Computing it for every sample in the test set allows the mean value of the residual to be evaluated at each time step and a mean residual line to be constructed. The closer it is to zero, the denser the evaluation of the surrogate is around the actual pressure value and the better the performance of the model.

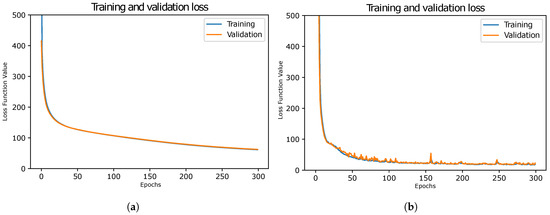

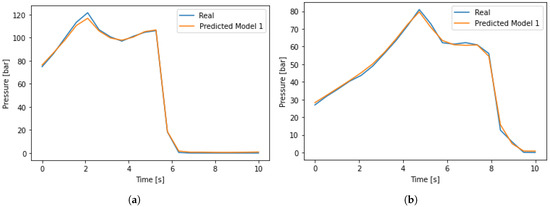

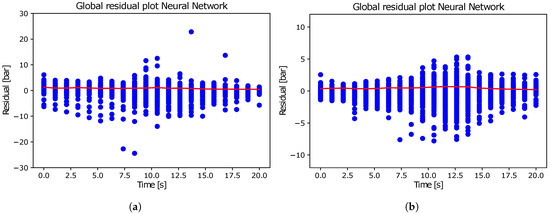

The first used methodology relies on a deep learning network, similar to the approach shown in [34]. The network was built and trained using the TensorFlow library [35]. Among all data, 10 percent was allocated for the creation of a test set to evaluate the network’s performance, while another 10 percent was used as a validation set to tune the model’s hyperparameters, such as regularization terms in every layer and adaptive parameters of the stochastic gradient descent optimizer (AdamW). The remaining configurations constitute the training set for the network. As previously described, the network was trained to predict the entire pressure–time curve by evaluating specific snapshots of the training curves, sampled from the LS solver pressure integration routine. The network’s predictions at every time step were evaluated to reconstruct the entire curve. Training performance is presented in Figure 7, where loss functions on the training and validation sets are presented. The results show that loss decreases for both sets through the epochs, and no overfitting is present. Figure 8 shows random sample prediction of the surrogate in the validation set for both the free- and fixed-length cases. The mean RMSE over the test set was computed to evaluate the model. Performance on the whole test set is reported in Figure 9, which shows a scatter plot of residuals computed on every test configuration, i.e., the pressure difference at every time snapshot, for all the curves in the test set. The mean value of the error at each step allows construction of the mean test error curve, reported over the residual scatter plot.

Figure 7.

Loss function over training epochs. (a) Free length; (b) Fixed length.

Figure 8.

Neural Network prediction on some test samples. (a) Free length; (b) Fixed length.

Figure 9.

Global residual plot for Neural Network. (a) Residual for free length; (b) residual for fixed length.

The second methodology relies on the interpolation via Adaptive Basis Function Construction (ABFC). This approach involves the approximation of a general function, in this case, the pressure value at a defined time snapshot, via a sum of polynomial functions weighted with a scalar value

The function depends on the vector of parameters and hence on geometric–ballistic properties of the examined configuration. The single polynomial basis function is computed as follows

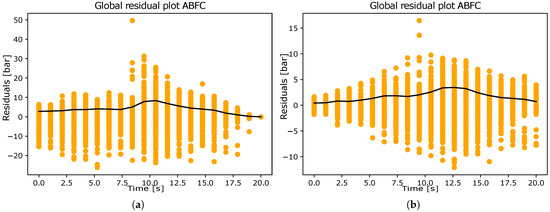

The exponent and the coefficients are defined through an iterative process to find the configuration that minimizes the mean square error between the approximate evaluation of and the known pressure value for a specific time snapshot. The number of basis functions k used to approximate the target function is a user-defined meta-parameter which can be tuned to alter the approximation, as well as the polynomial order p of the basis function (i.e., the maximum value of ). In this application, these values are fixed and not further optimized. Greater details on ABFC implementation can be found in [36]. Once the ABFC approximation was constructed for every time snapshot, the pressure–time curve was reconstructed, estimating with the surrogate model the pressure value for a certain parameter configuration at the desired time. Also, for this surrogate approach, RMSE was computed on the test set, which was created by splitting 10 percent of the overall database. Global Residual plots were obtained and are shown in Figure 10.

Figure 10.

Global residual plot for ABFC. (a) Residual for free length; (b) residual for fixed length.

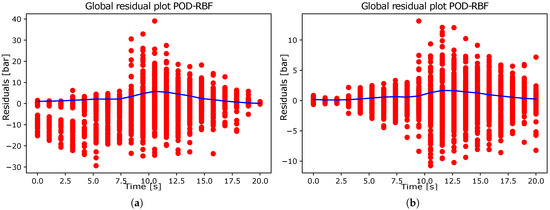

The third applied methodology relies on Reduced-Order modeling, exploiting Proper Orthogonal Decomposition (POD) to reduce problem dimensionality. Starting from the original design space, in both aforementioned cases, POD techniques were applied to reduce the parameter space. Interpolation was applied in the reduced space to create a Reduced-Order Model (ROM) and to approximate the pressure–time curve. The ROM was created using the EZyRB library [37], a flexible tool which allows ROMs to be created starting from high-level snapshots of the solution. In this study, the snapshots were the time evaluation of the pressure for each configuration. The initial database from which ROM is computed was formed by a parameter matrix, which contains all the geometric–ballistic parameters of a single configuration, and its correspondent snapshots, i.e., all the pressure evaluations for that single configuration. From this database, POD was computed by the solver using Truncated Singular Value Decomposition. The Radial Basis Function was then applied as an interpolation method to predict the modal coefficients for the new reduced set of parameters. Again, RMSE was computed on the test set. Global Residual plots were obtained and are shown in Figure 11. Comparison between sparser and denser datasets shows, as expected, a better behavior of the latter case when all other surrogate models parameters are fixed. The obtained results showed better performance for the Deep Neural Network approach, which is the selected method with the lowest RMSE value (see Table 3) and a better residual distribution in the time simulation period, with acceptable results even for sparser training datasets. On the contrary, other methods employed did not show acceptable results, and their performance is poor compared to the NN approach. For this reason, the latter was selected to support the evaluation phase in the stochastic optimization part of the design procedure. While further evaluation of additional metamodels could enhance approximation accuracy or reveal potentially better methods, such an analysis falls outside the scope of this work. In the context of this study, the selection was thus based on the most suitable tested approach for the current framework.

Figure 11.

Global residual plot for POD-RBF. (a) Residual for free length; (b) residual for fixed length.

Table 3.

Median RMSE on test dataset.

3.4. Design Problem and Optimizer

After the selection of the surrogate model, it is possible to start the design optimization phase. The global design of solid rocket motors requires a careful approach in order to define a geometrical configuration able to achieve desired performance while complying with numerous ballistic, propellant, and envelope constraints. An overall approach of SRM design is outlined in [38] and can be summarized in the flow chart in Figure 12. Starting from this approach, some modifications were made to adapt the process to non-uniform propellant grains. The main modification involves the propellant requirements, which are defined constraints in the classical design process while being considered as design parameters in the modified approach. This change affects the computation of additional dependent parameters, such as , which is a crucial parameter for burnback simulation of the grain. Moreover, the computation of geometric requirements needed to select the baseline shape of the grain from design tables is now suppressed. In the proposed approach, the baseline geometry is defined a priori, and the performance requirement matching is pursued, modifying the preselected baseline configuration and leveraging the non-uniform ballistic characteristics of the propellant. Hence, there is no need to compute these requirements in the definition phase as no geometry selection is necessary.

Figure 12.

Standard design flow for SRM.

To start design optimization, target performance must be computed. The selected approach is to compute ballistic requirements starting from the desired pressure–time curve and computing all other requirements by adding envelope constraints. For this analysis, the propellant temperature and the sensitivity of the temperature are neglected, while the propellant density is assumed to be fixed and constant. It is important to underline that propellant density could vary if the composition or the infill density of the grain varies, but this variability is neglected since few data are available. However, this variability could be easily accounted for in burning mass integration inside LS solver fluid dynamic module, once accurate correlation between propellant composition, propellant density, and ballistic properties is available from deposition technology studies. Moreover, density variability is expected to be limited; hence, this approximation should not alter the results significantly. The very same considerations on propellant composition effects could apply for the specific heat ratio for combustion products, which is also assumed to be constant. Once the desired curve has been selected, the Maximum Expected Operating Pressure (MEOP) is evaluated as the maximum pressure level, while the required burning time is computed as the time at which the pressure level reaches 10% of the MEOP. These quantities can be directly computed from the pressure curve, while others need to be defined. In particular, maximum thrust required F at the MEOP is defined, as well as grain diameter D, grain length L, pressure expansion ratio and ambient pressure . It is necessary to add some considerations for these constraints, starting from grain length L. As mentioned in Section 3.1, for the first free-length approach, there is no direct enforcement of length constraint, so the optimum configuration length must be verified to be less than L. Alternatively, space design upper limits for length parameters can be altered to ensure that their sum is less than the maximum available length. The latter is the approach selected for the free-length case. Instead, in the second fixed-length case, L is used to define grain sections, and the optimum length is always equal to it. Regarding required thrust F, it is usually defined from mission requirements for specific SRM applications. The thrust requirement imposes a required throat area , which heavily influences pressure in the motor. It can be computed as

Throat area computation requires a thrust coefficient estimate, which can be carried out exploiting isentropic flow relations for the nozzle, given all defined parameters, as follows

While in the standard design flow, other geometrical constraints for grain configuration allow the selection of suitable geometries to meet the thrust requirement, the definition of an a priori baseline geometry and a pre-defined parametric space could limit the feasibility of a specific thrust level since burning area could grant insufficient mass flow to maintain desired pressure for values computed to obtain such thrust. The designer must be aware of this and select an adequate parameter space to include configurations which are compatible with desired pressure and thrust. It is possible that after an initial definition of parameter-space limits, a modification of the latter becomes necessary after database creation with computed . A possible approach could start with a first evaluation of a few samples to evaluate whether the design space contains a feasible configuration and, after that, continue with the creation of the entire dataset. In the context of this work, since the aim is to produce and test the overall design procedure, an initial estimate for F of 6000 N was computed using mean value of the burning area and burning rate at the reference MEOP value of 58 for some sample configurations in the parameter space. After defining the thrust requirement, the value was calculated, and this value was the one used to create training datasets. Since this value was used to create dataset curves, it was also chosen as a fixed requirement for the desired curves. This choice led to the dependence between the MEOP and F. Only maximum pressure was defined as the requirement, while the correspondent thrust was computed afterwards. In the scope of this analysis, enforcing other constraints on required maximum thrust is considered of secondary importance; hence, constraints are imposed only on total impulse and burning time. The total impulse required, , can be computed, integrating the thrust curve obtained from the pressure–time target profile. After defining all requirements from the desired curve, it is possible to define the optimization problem to find the optimal geometric–ballistic configuration to satisfy imposed constraints. The problem is defined as follows

The optimization problem aims to find the parameters vector , which minimizes RMSE between the optimum and target pressure value in the time snapshots, with the additional constraints of obtaining a total impulse and a burning time with an error lower than 10 percent of required values. To find the optimum configuration, the Pymoo optimization library [39] is employed. This library allows optimization problems to be easily set up, starting from defining the parameter space and general structure of the problem, then implementing the evaluation method for the single evaluation of individuals and finally employing the desired stochastic optimization algorithm to find the best solution. This flexibility enables easy switching between the free- and fixed-length cases, maintaining the general structure of the problem and applying the correct surrogate to evaluate individuals. Moreover, the evaluation phase includes the computation of performance parameters, following the same approach used during the requirement computation phase. This step is necessary to assess compliance with problem constraints and to evaluate additional performance metrics, such as the specific impulse for the grain, which is calculated from the total impulse evaluated from the optimum curve, and evaluated initial mass of the grain, which is computed from a volume estimate obtained using geometric parameters of the optimum vector . The optimization algorithm chosen for the problem is a Particle Swarm Optimization (PSO) algorithm, initialized with a starting population of 100 individuals and running for 15 generations, with no further termination condition. The pressure response was evaluated for each individual through the aforementioned Neural Network. Such a high number of individuals was chosen to increase the parameter-space exploration capabilities of the swarm since single individual evaluation is fast thanks to surrogate models.

4. Test Applications

Once the optimizer was defined, it was tested to assess its ability to identify the optimal configuration with respect to specific pressure–time target curves. The selection of the target curves was carried out with specific criteria: the initial targets were designed to mimic a boost-sustain mission, exhibiting a shape similar to the training curves, with a main peak occurring within the first half of the burning time (before ) and followed by an approximately constant or slightly decreasing profile after the initial boost phase. Targets named Boosters 1 to 4 were created in this manner. In a second step, these curves were slightly modified by altering the peak position and its amplitude while preserving the general trend of a pronounced maximum followed by a more or less gradual decay until burnout. Boosters 5 and 6 were selected in this fashion. Finally, as a more realistic application case, a pressure–time curve optimized for the first stage of a launcher was employed as the target for the optimization routine, following the work in [40]. Boosters 7 and 8 were obtained from the reference, with two different maximum operating pressure levels required. This approach was chosen to firstly verify the optimizer performance on familiar data and then evaluate its performance in evaluating curves outside the training dataset. The test curve set is visualized in Figure 13, while computed requirements for target curves are summarized in Table 4. Table 5 shows optimum vectors and performance of the solutions.

Figure 13.

Target curve visualization against datasets. (a) Against free-length dataset; (b) against fixed-length dataset.

Table 4.

Requirements computed for test curves.

Table 5.

Comparison of performance. Application on two configuration types for the 3000-sample and 4096-sample databases (* indicates constraints violation).

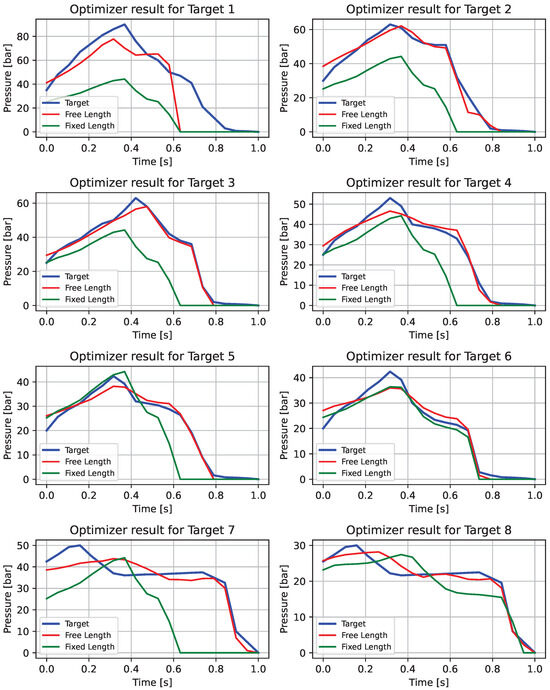

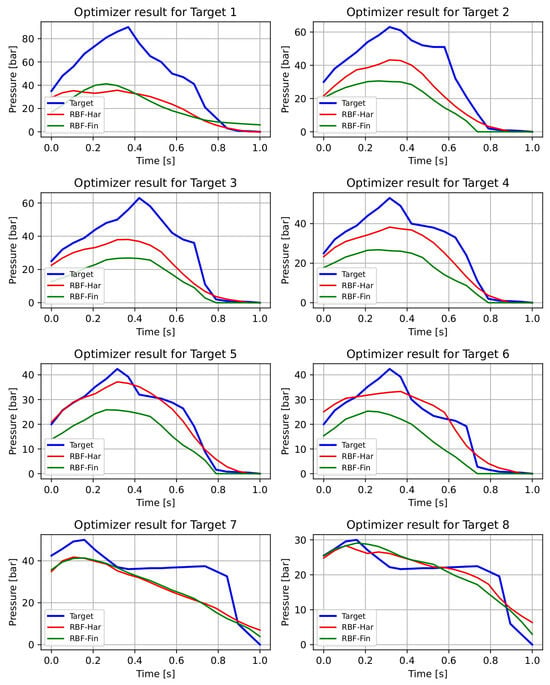

The results obtained show how, for the free-length dataset, the optimizer is well-behaved for the first group of curves, achieving optima close to the target (see Figure 14, Targets 2, 3, and 5), while the optimum is quite different from the target for curves that deviate from the dataset, possibly resulting in feasible solutions but with a poor match to the target curve (see Figure 14, Targets 4, 6, 7, and 8). On the contrary, the results for the fixed-length dataset are not equally satisfactory. These results show the ability of the optimizer routine to explore the space of the design parameters and to find a feasible configuration to meet pressure requirements, provided the target curve remains sufficiently similar to the training dataset. Conversely, when the target curves deviate substantially from the original dataset, the evaluated optima are less satisfactory, and this can be explained with some considerations. In particular, if the required curve is too dissimilar from the dataset, the optimizer cannot find an acceptable solution inside the design envelope. The main reason for this behavior should be attributed to the limitation of the design space. Since the design space is sampled for database creation including its limits, a target far from this dataset could easily be produced by a configuration which is outside the defined limits. This limitation is particularly evident for the fixed-length database, where the limited envelope of the dataset does not allow the optimizer to find an optimal solution. The attempt to search for the optimal solution for the target that vastly exceeds design envelope leads the optimizer to a common solution at the edge of the design space. The solution also violates the imposed constraints. This means that the selected target is unfeasible since it is impossible to find a solution within the design space which satisfies imposed constraints. This occurs for all the target curves outside the envelope (see Figure 14, Targets 1, 2, 3, 4, 5, and 7). As stated above, this parameter-space limitation also influences the free-length case. In this case, even if curves are inside the dataset envelope and feasible configurations are found, the overall shape of the curve is not attainable with the defined parameters, and this lack of flexibility produces slightly different pressure–time shapes for computed optima. However, even with a sparser initial dataset, the increased envelope and the greater variability in configurations make it possible to obtain better results in finding a wider class of pressure–time curves with respect to a more limited design space. Hence, to find the optimum configuration for meeting that specific target, it may be necessary to extend the parameter-space bounds to increase the variability in the pressure response. It could be possible to compensate for limited geometric flexibility by increasing the variability in ballistic properties or changing the baseline configuration entirely. Otherwise, we must accept that the evaluated optimum, although potentially far from the desired curve, represents the nearest feasible configuration within the defined design space provided that it complies, at least, with optimization constraints for and .

Figure 14.

Optimum visualization for target curves.

5. Further Applications

5.1. Flexibility Enhancements

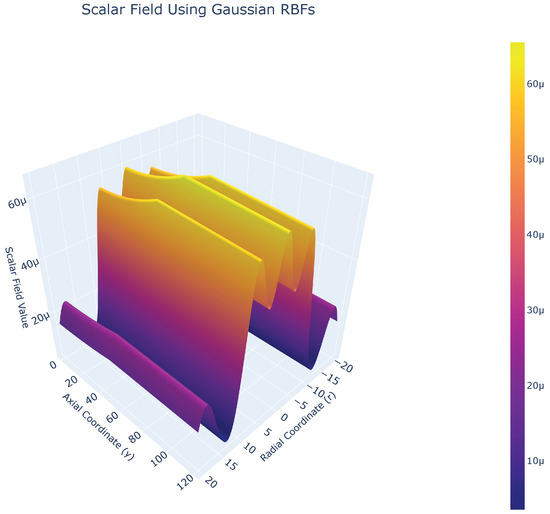

With the aim of improving the flexibility of the design tool, different strategies were implemented. First, the throat area was included in the design parameters. In addition, a new ballistic distribution was selected to enhance the variability in the burning rate inside the grain. Finally, a new geometry definition was implemented to obtain different geometries with respect to baseline finocyl geometries. The introduction of as a parameter allows for important modification in the pressure–time response since this value extensively affects chamber discharge and nozzle expansion and also guarantees a greater envelope of attainable thrust F once the MEOP is defined. The new distribution of the coefficient a is based on a Gaussian Radial Basis Function (RBF). This function allows ballistic distributions to easily be created, fixing their centers and weights and matching desired variations inside the grain. The implemented RBF is a function of the radial coordinate r and is defined as follows

where N is the number of basis functions used, is the radial coordinate of i-th center, is the i-th weight of the distribution, and is the shape parameter of the function. To implement variation along the motor axis, this distribution is multiplied by a piecewise polynomial of the axial coordinate y, defined as follows

where P is the polynomial order of the axis distribution before split, is the axial coordinate where the function shifts to a linear behavior, and m is the slope of the linear function. The final distribution allows for a greater variation and greater control of the distribution by the designer since a greater number of parameters are involved in the definition of ballistic properties, with a maximum of parameters available for design and optimization.

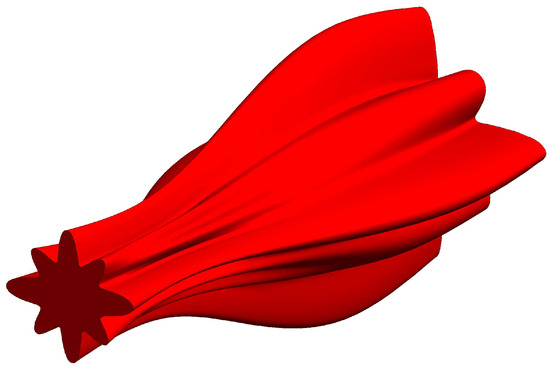

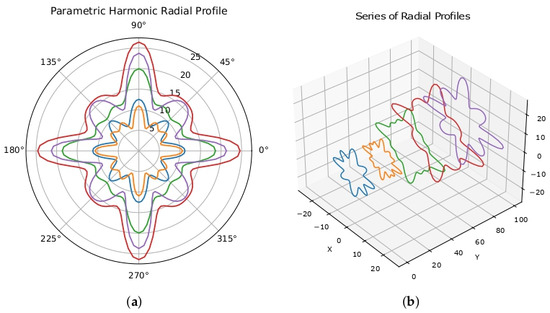

The other modification to test applications is a new geometry definition, based on the creation of the geometry of the inner cavity of the grain through the definition of port profile, for a certain number of grain sections. The profile of the port is described by an harmonic function of angular radial coordinate and is defined in the first quadrant, given the number of harmonics M, as follows

The values are then mirrored in the other quadrants to enforce the axial symmetry of the grain. The profile of the port is computed for every desired section, and the axial position is assigned to every port dividing the total length L of the grain by the desired number of ports. The 3D envelope of the grain is reconstructed by interpolating the profiles, exploiting the loft function in the CAD environment. This choice allows a wide range of geometries to be obtained, varying from a simple cylindrical bore to complex star-type shapes (see Figure 15 and Figure 16). However, it is more difficult to interpret how the choice of parameters affects the overall shape. If k is the number of ports selected to describe the geometry, this approach adds a maximum of parameters to the design space, plus the fixed length of the grain. Therefore, the total number of parameters that the designer could use in theory is , accounting for geometry and ballistic variability. The designer must define the number of parameters used by defining the values of and eventually fixing the values of additional parameters, such as . Moreover, it is also possible to fix some of the terms used in the RBF definition or port definition, without considering them as design parameters. In this work, a limited number of parameters was taken into account.

Figure 15.

CAD visualization of 3D grain example, .

Figure 16.

Example of port configuration. (a) Port visualization example, axis view; (b) port visualization example, lateral view.

Once the new design had been selected, a new application to previous test curves was run for evaluation, to the extent that a broader variation in ballistic properties was able to be exploited. In particular, the RBF configuration implemented to evaluate the design process has but, as stated before, only the first P-term was considered as a design parameter, while the other two were fixed. The same approach was used for the port definition, where of the terms of the sum, only the first was used as design parameter. Moreover, only the A term of the expansion varied between the ports, for a total of five design parameters, while the B term remained the same for all ports. With these assumptions, this type of configuration is described by 15 parameters. Table 6 shows all the design parameters and the values which define the configuration, where grain length L and casing radius are increased from the previous application to ensure sufficient burning time. Figure 17 shows an example of the Gaussian RBF obtained with the described setup. The RBF was applied to both finocyl geometry and harmonic-port geometry. For the finocyl-RBF application the geometric parameters were the same as those used for the fixed-length case (see Table 2). The finocyl geometry is described by four geometric design parameters; hence, in this case we have a total of 13 parameters to define the configuration. The same approach used previously was applied to these new configurations. New datasets, formed by 3000 individuals, were computed through LS evaluation of grain burnback and pressure computation. These datasets were used to train surrogate models to estimate the pressure response of a specific configuration. The latter was applied to evaluate individuals in the PSO algorithm. Figure 18 shows the dataset envelope and targets for the new configurations and some examples extracted from database can be found in Appendix A, while Figure 19 and Table 7 demonstrate the optimization results on the target set. Requirements on are now not enforced; however, now the desired thrust F is imposed to give an initial estimate of throat area to obtain such a level of thrust, which varies for each configuration. For this reason, the required also varies in this new application.

Table 6.

Parameters table: RBF-Port.

Figure 17.

Ballistic distribution example. Values obtained using parameters inside the RBF-Port design envelope. Scalar field refers to a parameter field.

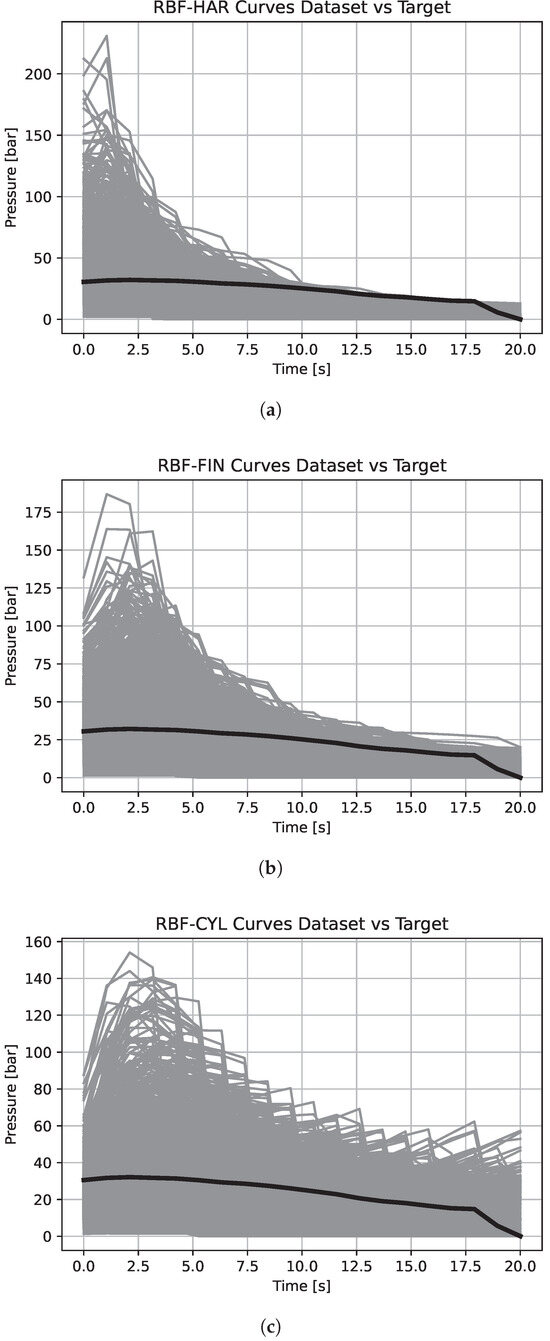

Figure 18.

New configuration design envelopes and target set. (a) Dataset for RBF-harmonic; (b) dataset for RBF-Fin.

Figure 19.

Optimum visualization for target curves RBF.

Table 7.

Comparison of performance for RBF harmonic and fin (* indicates constraints violation).

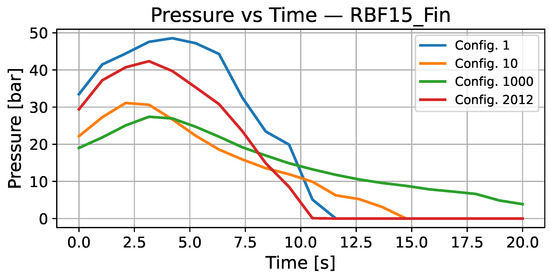

The first key consideration is the effect of the ballistic property distribution on the dataset envelope. Comparing Figure 18 and Figure 13, it is evident that the same finocyl baseline geometry produces significantly different pressure–time envelopes due to greater variation in the burning rate. The obtained results deviate considerably from the desired pressure curve, particularly for the initial targets, which were designed to replicate the behavior of previous datasets. For the last two targets, although the desired pressure curve is not fully achieved, the results show an improvement compared to the previous approach, especially in the fin configuration, due to added variability introduced by the Radial Basis Function distribution. However, this increased variability appears to reduce the optimal values for . For these targets, the two different geometries yield similar optimal solutions, highlighting the significant influence of the ballistic distribution. Further considerations must be made regarding constraint violations. Many of the optimal solutions, despite deviating from the desired pressure curve, do not violate constraints on and . This can be attributed to the use of throat area as a design parameter, which directly affects thrust computation. Since this parameter is now variable, the resulting thrust magnitude can change, allowing the delivered to meet the required value even if the pressure curve does not align with the target. In this new configuration, imposing as a constraint alone is insufficient to ensure similarity in pressure performance. Therefore, additional constraints must be introduced, such as enforcing a required thrust curve instead of a pressure curve or imposing a maximum tolerance on the root mean square error (RMSE) of the pressure curve. Although the results are not entirely satisfactory, it is crucial to emphasize the primary advantage of this new approach: the flexibility provided by the novel configuration framework. This design environment allows designers to introduce complexity simply by adjusting the number of parameters governing the geometry and RBF distribution, thereby expanding the design space. However, this increased flexibility comes at the cost of higher computational requirements and necessitates careful consideration of the applicability of surrogate modeling (see Section 6).

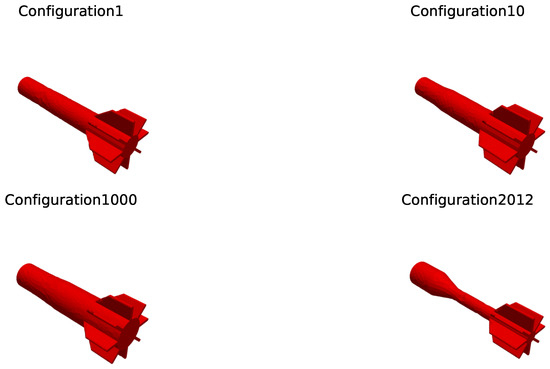

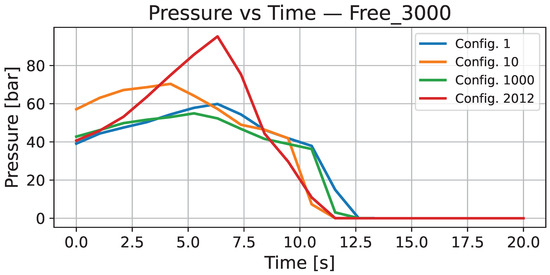

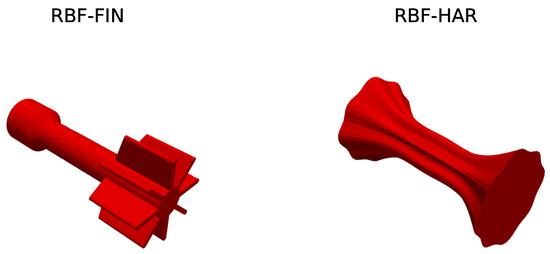

5.2. Launcher Test Case

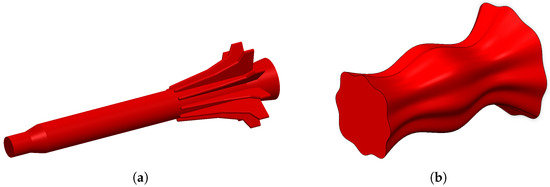

Once the RBF approach had been tested and implemented, it was applied to a space application. The Zefiro23 pressure–time curve shape was selected as the target for optimization, with the curve being sampled from reference [41] at 20 time snapshots. The reference values reported are non-dimensional and were rescaled by requiring a MEOP of 35 bar and a maximum burning time of 20 s. These values are consistent with the imposed design envelope defining the minimum and maximum allowable grain dimensions, i.e., this level of pressure is attainable for the required burning time by configurations in the training datasets. Since the objective of the optimization is to achieve a given pressure–time curve, the chosen scaling does not affect the validity of the approach. Furthermore, different maximum pressure levels or burning times can be achieved by appropriately rescaling the grain dimensions. The curve obtained with this hypotheses leads to requirements reported in Table 8. To achieve this type of curve, the Zefiro23 grain, which features a specific and relatively complex finocyl shape (as shown in Figure 20), is employed. In this part of the study, the goal was to obtain similar performance using a simplified geometry by leveraging the ballistic distribution since in the application to the target set the great extent to which the RBF can alter grain performance was evident. In particular, the finocyl-RBF and harmonic-RBF configurations were used to find optima configurations. Furthermore, a deeper level of simplification was achieved by coupling the RBF distribution with a cylindrical geometry, extending the geometric simplification in a similar manner to the dual-boost cylindrical grain evaluated in previous work [28]. The cylindrical-RBF configuration is described only by RBF values, with the same design choices made for previous cases. Here, the inner radius of the cylinder is the second center value of the distribution, while the first center is located in the motor axis, and the third is situated at the casing radius. Hence, these two values are fixed, while other design parameters are the three weights of the distribution and . Moreover, no variation is considered along the motor axis. Due to the significant geometric simplification, the number of design parameters is substantially reduced, resulting in a total of six design parameters, including the throat area . This new configuration is summarized in Table 9.

Table 8.

Requirements computed for Zefiro23 pressure curve. Note that is now a design parameter.

Figure 20.

Geometry comparison. These different geometries could have the same performance, altering the ballistic distribution. (a) Zefiro23 finocyl geometry; (b) port geometry; example obtained within selected envelope.

Table 9.

Parameters table: RBF-Cylinder.

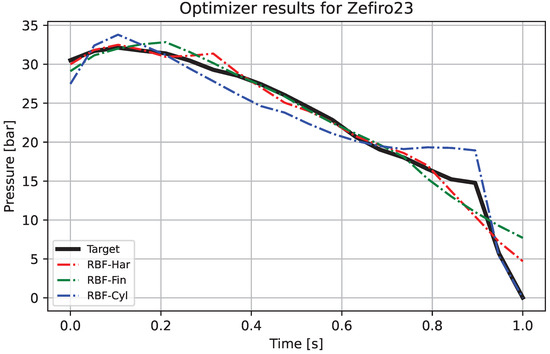

As in previous cases, a dataset of 3000 samples was generated for the RBF-Cylinder configuration and used to train the surrogate model. Figure 21 presents the selected target alongside the previously computed datasets and the new cylindrical-RBF dataset. Figure 22 illustrates the optimization results for the Zefiro23 pressure–time curve across the three design approaches, while Table 10 presents optimum vectors and computed performance. In this case, the selected target is well approximated by the optimal solutions, with minor deviations in the tail-off phase, while all three approaches satisfy the design constraints. As previously observed, specific impulse values remain lower than the typical ones. For reference, the value for Shuttle SRB, which has a similar propellant composition, is 242 s at sea level. Further investigation into the influence of the ballistic property distribution on this performance metric is necessary. The results obtained are overall satisfactory, demonstrating how the ballistic distribution can be effectively leveraged to significantly modify performance characteristics and guide the motor design process. Optimal geometries can be found in Appendix A.

Figure 21.

Zefiro23 pressure–time curve (black) against datasets. (a) RBF-HAR; (b) RBF-FIN; (c) RBF-CYL.

Figure 22.

Optima on Zefiro23 target. Exploiting ballistic distribution leads to convergent results for different geometries.

Table 10.

Comparison of performance on Zefiro23 optimization.

6. Evaluation of Surrogate Applicability

Some considerations must be accounted for regarding the opportunity to apply surrogate modeling for the optimum search. In the test carried out, datasets were built with at least 3000 LS evaluations, and then PSO was performed with a total of 1500 evaluations. With this setup it is possible to use directly level set evaluations in PSO, even for a higher number of evaluations with respect to the optimization algorithm run in the test. However, this is true in the selected setup and not in general. A critical factor to assess is the number of design parameters as it directly influences the number of sample evaluations required to adequately represent the design space. A lower-dimensional design space, such as the one used in the RBF-Cylinder configuration, can be sufficiently represented with fewer LS evaluations. If the number of LS evaluations in the offline phase is lower than the number of PSO evaluations, surrogate modeling becomes a viable alternative. Defining as the time required for an LS evaluation, as the time required for a surrogate evaluation, as the number of PSO evaluations performed, and as the number of evaluations needed for the training phase, it is possible to impose that the total computational time is equivalent for both direct and surrogate-based approaches

Since the online phase cost is negligible, and, as stated before, it is convenient to use surrogate models if < . The problem is that is difficult to estimate a priori the number of evaluations for both training and optimization routines. Moreover, it is important to define how the design tool is used. Since the surrogate cost is mostly offline and has a negligible online cost, it is configuration-specific, so it must be paid only when a new design configuration is studied. On the other end, direct computation is target-specific since it is not bonded to a specific configuration but it has to be paid for every optimized target. Defining as the number of evaluated targets, it is possible to redefine

or, alternatively, , which is the condition that ensures a lower cost when applying the surrogate model. Hence, in a scenario where multiple iterations are required across different targets, such as in an early design stage where target requirements may evolve, could be high, making surrogate training preferable. It is also true that constraints can be modified, imposing changes in design parameter limits which require a new training computation. This can decrease the benefits of using surrogate models even with a high . Moreover, instead of generating datasets through level-set (LS) evaluations, it is possible to utilize existing datasets derived from high-fidelity burnback simulations or firing tests. When such valuable data are available to designers, leveraging this knowledge completely eliminates offline computational costs. In this context, the use of surrogate models is highly advantageous. Thanks to Pymoo’s flexibility, it was possible to introduce direct evaluation in the optimization phase, and now the optimization tool can be used also without meta-modeling. Depending on the design problem and specific application, the designer can select the most suitable evaluation approach.

7. Conclusions and Future Works

This paper summarizes the procedure proposed to simulate and design solid rocket motor grains with non-uniform ballistic properties. The initial results show the ability of the Neural Network surrogate model to predict the pressure response and confirm the suitability of the overall sampling generation and surrogate modeling approach. The selected meta-model was coupled with a design optimization routine, the latter based on the standard design process for SRM modified to account for variable propellant characteristics. The optimum design was found by exploiting the stochastic optimization algorithm. The results obtained show good behavior of the overall procedure in finding optima for curves which are sufficiently similar to the database, while its performance deteriorates for curves that are too dissimilar from the dataset. The main limitation of the design approach was the lack of variability in the design parameters. To overcome these limitations, a new type of configuration based on enhanced variability in ballistic properties was implemented. This RBF-based distribution was coupled with a varying throat area value and applied to both finocyl geometries and to new baseline harmonic geometries. Although the results on the target set of this new implementation are comparable to those of the previous case, it still offers valuable insights and potential benefits. In particular, the new paradigm allows a more complex configuration to be created by simply varying the number of parameters of the various distribution, granting huge flexibility. To further investigate the impact of ballistic properties, a representative real-world target was selected, and three distinct grain geometries were optimized to meet this objective using non-uniform burning rates. The results demonstrate the feasibility of achieving optimal solutions with highly different configurations, leveraging ballistic properties variation and highlighting their strong influence on the pressure response. This confirms their potential as a key design parameter for SRM performance optimization. Further activities will concern both the application of the optimization routine for improving the design of motors and enhance their applicability to various types of mission. Moreover, once sufficient technological maturity is reached, additional analysis on manufacturing process should be carried out to properly evaluate its competitiveness against the standard manufacturing process, as well as quality and safety standards of the overall procedure. Additionally, given that different geometries can yield comparable performance through ballistic property adjustments, further selection criteria, such as preliminary structural analysis, will be implemented to identify the most viable configurations.

Author Contributions

Conceptualization, G.P., A.F., F.M. and D.P.; Methodology, G.P., A.F., F.M. and D.P.; Software, G.P. and A.F.; Validation, G.P.; Formal analysis, G.P.; Investigation, G.P.; Data curation, G.P.; Writing—original draft, G.P.; Writing—review & editing, A.F., F.M. and D.P.; Visualization, G.P.; Supervision, A.F., F.M. and D.P.; Project administration, A.F., F.M. and D.P.; Funding acquisition, A.F., F.M. and D.P. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The original contributions presented in the study are included in the article, further inquiries can be directed to the corresponding author.

Acknowledgments

AI software (GPT-4, Claude) has been used only for text review and grammar checking to improve the readability and fluency of English text written by non-native authors.

Conflicts of Interest

The authors declare no conflicts of interest.

Nomenclature

| First coefficient for ballistic distribution | |

| Grain burning surface | |

| Nozzle throat area | |

| b | Second coefficient for ballistic distribution |

| Characteristic velocity | |

| Multiplicative factor for characteristic velocity | |

| Total impulse estimated by optimizer | |

| Total impulse required | |

| L | Required length of the grain |

| Maximum allowed length of the grain | |

| Mass flow of gas produced through solid propellant combustion | |

| Mass flow of gas expelled through nozzle | |

| n | Pressure exponent for burning rate |

| N | Total number of snapshots |

| Gas pressure in combustion chamber | |

| Pressure value estimated by optimizer at i-th time snapshot | |

| Pressure value from target curve at i-th time snapshot | |

| r | Burning rate of the propellant |

| Casing radius | |

| Radial coordinate | |

| Perfect gas constant | |

| Gas temperature in combustion chamber | |

| Burning time estimated by optimizer | |

| Burning time required | |

| Velocity field of the level set Equation | |

| Gas volume in combustion chamber | |

| Parameters vector | |

| Specific heat ratio of gas | |

| Mach function for mass flow | |

| Nozzle area expansion ratio | |

| Implicit function for level set definition | |

| Solid propellant density | |

| Gas density in combustion chamber | |

| Pseudo-time for level set reinitialization |

Appendix A

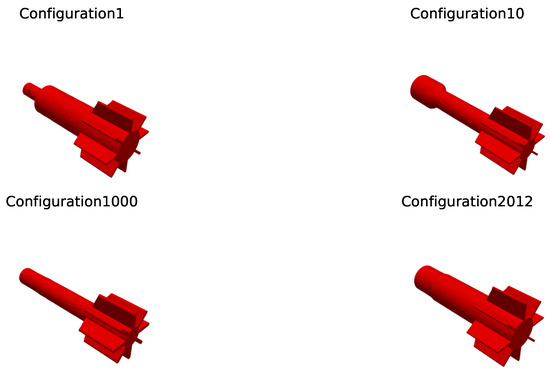

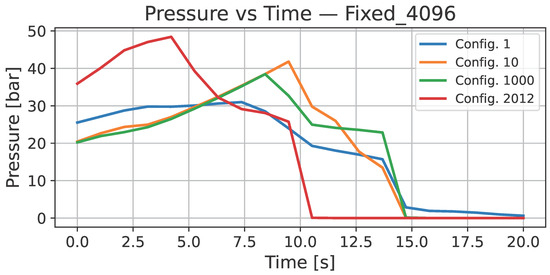

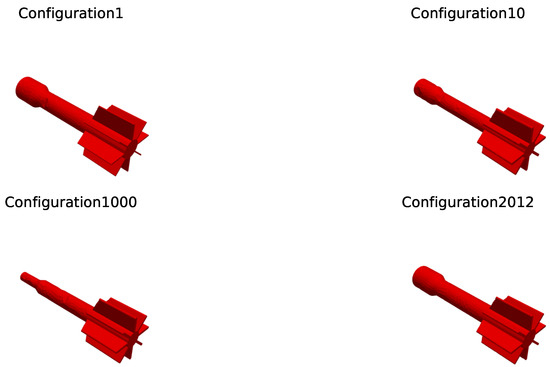

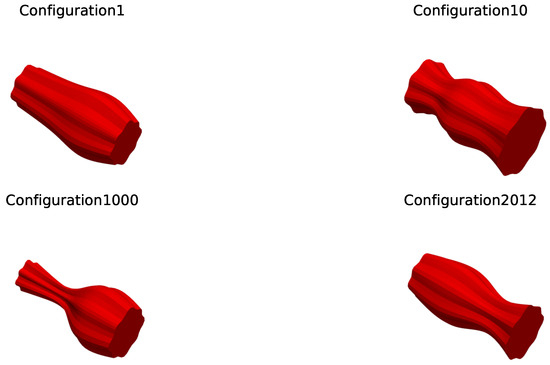

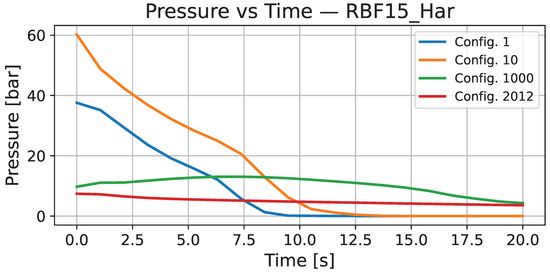

In this appendix, some visualizations of geometries and respective pressure time curves are presented to better visualize databases utilized to train surrogate models. Here four random samples extracted from the database are shown. Moreover, optimized geometries for Zefiro23 applications are presented for the finocyl and harmonic test cases to better show the difference in geometries and the influence of the ballistic properties in altering the pressure response of the grain.

Figure A1.

Visualization of finocyl geometry with polynomial ballistic distribution, free-length case: comparison for random samples.

Figure A2.

Pressure time visualization from dataset for respective finocyl configuration, free-length case.

Figure A3.

Visualization of finocyl geometry with polynomial ballistic distribution, fixed-length case: comparison for random samples.

Figure A4.

Pressure time visualization from dataset for respective finocyl configuration, fixed-length case.

Figure A5.

Visualization of finocyl geometry with polynomial ballistic distribution, RBF case: comparison for random samples.

Figure A6.

Pressure time visualization from dataset for respective finocyl configuration, RBF case.

Figure A7.

Visualization of harmonic geometry with polynomial ballistic distribution, RBF case: comparison for random samples.

Figure A8.

Pressure time visualization from dataset for respective harmonic configuration, RBF case.

Figure A9.

Geometries of optima obtained to match Zefiro23 pressure time curve, Fin, and harmonic baseline configurations.

References

- Lysien, K.; Stolarczyk, A.; Jarosz, T. Solid Propellant Formulations: A Review of Recent Progress and Utilized Components. Materials 2021, 14, 6657. [Google Scholar] [CrossRef]

- Sutton, G.P.; Biblarz, O. Rocket Propulsion Elements, 9th ed.; John Wiley & Sons: Hoboken, NJ, USA, 2016. [Google Scholar]

- Heister, S.D.; Anderson, W.E.; Pourpoint, T.L.; Cassady, R.J. Rocket Propulsion; Cambridge University Press: Cambridge, UK, 2019; Volume 47. [Google Scholar]

- Muravyev, N.V.; Monogarov, K.A.; Schaller, U.; Fomenkov, I.V.; Pivkina, A.N. Progress in additive manufacturing of energetic materials: Creating the reactive microstructures with high potential of applications. Propellants Explos. Pyrotech. 2019, 44, 941–969. [Google Scholar] [CrossRef]

- Straathof, M.H.; van Driel, C.A.; van Lingen, J.N.; Ingenhut, B.L.; ten Cate, A.T.; Maalderink, H.H. Development of propellant compositions for vat photopolymerization additive manufacturing. Propellants Explos. Pyrotech. 2020, 45, 36–52. [Google Scholar] [CrossRef]

- Zhou, X.; Mao, Y.; Zheng, D.; Zhong, L.; Wang, R.; Gao, B.; Wang, D. 3D printing of RDX-based aluminized high explosives with gradient structure, significantly altering the critical dimensions. J. Mater. Sci. 2021, 56, 9171–9182. [Google Scholar] [CrossRef]

- Kirby, L.; Udaykumar, H.; Song, X. Pressure-assisted binder jetting for additive manufacturing of mock energetic composites. Propellants Explos. Pyrotech. 2024, 49, e202300175. [Google Scholar] [CrossRef]

- Wejsa, J. ARDEC Report. Presentation at the NDIA Armament Systems Forum. Available online: https://ndia.dtic.mil/wp-content/uploads/2014/armaments/Wed16567_Wejsa.pdf (accessed on 31 October 2025).

- Tillinghast, R.; Zunino, J. Additive Manufacturing Methods, Techniques, Procedures, and Applications. Enabling Technologies for Military Applications. Presentation at the NDIA Armament Systems Forum. Available online: https://ndia.dtic.mil/wp-content/uploads/2015/armament/wed17417_Tillinghast.pdf (accessed on 31 October 2025).

- Pastrone, D.; Sangermano, M.; Garino, S.; Maggi, F. Composite Propellant Manufacturing Process Based on Deposition and Light-Activated Polymerization for Solid Rocket Motors. WO2020212785A1, 22 October 2020. [Google Scholar]

- Garino, S.; Antonaci, P.; Pastrone, D.; Sangermano, M.; Maggi, F. Photo-Polymerization for Additive Manufacturing of Composite Solid Propellants. Acta Astronaut. 2021, 182, 58–65. [Google Scholar] [CrossRef]

- Galavotti, A.; Noè, C.; Polizzi, G.; Antonaci, P.; Maggi, F.; Masseni, F.; Pastrone, D. Solid Rocket Propellant Photo-Polymerization with an In-House LED-UV Prototype. Polymers 2023, 15, 1633. [Google Scholar] [CrossRef]

- Zumbo, A.; Stumpo, L.; Antonaci, P.; Ferrero, A.; Masseni, F.; Polizzi, G.; Tetti, G.; Pastrone, D. Rheological and Mechanical Characterization of 3D-Printable Solid Propellant Slurry. Polymers 2024, 16, 576. [Google Scholar] [CrossRef] [PubMed]

- Masseni, F.; Zumbo, A.; Stumpo, L.; Polizzi, G.; Tetti, G.; Lusetti, T.; Noé, C.; Antonaci, P.; Ferrero, A.; Pastrone, D.; et al. Advancements in Photocurable Solid Propellants for Additive Manufacturing. In Proceedings of the AIAA SCITECH 2025 Forum, Orlando, FL, USA, 6–10 January 2025; AIAA Paper 2025-2330. [Google Scholar] [CrossRef]

- McClain, M.; Gunduz, I.; Son, S. Additive Manufacturing of Ammonium Perchlorate Composite Propellant with High Solids Loadings. Proc. Combust. Inst. 2019, 37, 3135–3142. [Google Scholar] [CrossRef]

- McClain, M.; Afriat, A.; Montano, B.J.; Ray, S.; Rhoads, J.; Gunduz, I.E.; Son, S.F. Investigation of Additively Manufactured Layered Composite Solid Propellant. In Proceedings of the AIAA Scitech 2020 Forum, Orlando, FL, USA, 6–10 January 2020; AIAA Paper 2020-1427. [Google Scholar] [CrossRef]

- McClain, M.S.; Afriat, A.; Montano, B.J.; Rhoads, J.F.; Gunduz, I.E.; Son, S.F. Dynamic Combustion of Functionally Graded Additively Manufactured Composite Solid Propellant. J. Propuls. Power 2021, 37, 725–732. [Google Scholar] [CrossRef]

- Chen, N.; He, C.; Pang, S. Additive Manufacturing of Energetic Materials: Tailoring Energetic Performance via Printing. J. Mater. Sci. Technol. 2022, 127, 29–47. [Google Scholar] [CrossRef]

- Scheithauer, U.; Schwarzer, E.; Richter, H.J.; Moritz, T. Thermoplastic 3D Printing—an Additive Manufacturing Method for Producing Dense Ceramics. Int. J. Appl. Ceram. Technol. 2015, 12, 26–31. [Google Scholar] [CrossRef]

- Chandru, R.A.; Balasubramanian, N.; Oommen, C.; Raghunandan, B.N. Additive Manufacturing of Solid Rocket Propellant Grains. J. Propuls. Power 2018, 34, 1090–1093. [Google Scholar] [CrossRef]

- Li, M.; Yang, W.; Xu, M.; Hu, R.; Zheng, L. Study of Photocurable Energetic Resin Based Propellants Fabricated by 3D Printing. Mater. Des. 2021, 207, 109891. [Google Scholar] [CrossRef]

- Poppe, G.; Koch, P.; Bozic, O.; Lancelle, D. Optimization of Finocyl Grain Geometries of Solid Rocket Boosters. In Proceedings of the European Conference for Aerospace Sciences, Krakow, Poland, 29 June–3 July 2015. [Google Scholar]

- Kamran, A.; Guozhu, L. An Integrated Approach for Optimization of Solid Rocket Motor. Aerosp. Sci. Technol. 2012, 17, 50–64. [Google Scholar] [CrossRef]

- Zeping, W.; Donghui, W.; Weihua, Z.; Okolo, P.N.; Yang, F. Solid-Rocket-Motor Performance-Matching Design Framework. J. Spacecr. Rocket. 2017, 54, 698–707. [Google Scholar] [CrossRef]

- Albarado, K.; Hartfield, R.; Hurston, W.; Jenkins, R. Solid rocket motor design using hybrid optimization. Int. J. Aerosp. Eng. 2012, 2012, 987402. [Google Scholar] [CrossRef]

- Tola, C.; Nikbay, M. Solid rocket motor propellant optimization with coupled internal ballistic–structural interaction approach. J. Spacecr. Rocket. 2018, 55, 936–947. [Google Scholar] [CrossRef]

- Mitchell, I.M. The Flexible, Extensible and Efficient Toolbox of Level Set Methods. J. Sci. Comput. 2008, 35, 300–329. [Google Scholar] [CrossRef]

- Polizzi, G.; Ferrero, A.; Masseni, F.; Pastrone, D. A Numerical Method for Burnback Analysis of UV-cured Solid Rocket Propellant Grains. In Proceedings of the AIAA SCITECH 2024 Forum, Orlando, FL, USA, 8–12 January 2024; p. 0635, AIAA Paper 2024-0635. [Google Scholar] [CrossRef]

- Osher, S.; Fedkiw, R. Level Set Methods and Dynamic Implicit Surfaces; Applied Mathematical Sciences; Springer: New York, NY, USA, 2003. [Google Scholar]

- Barrère, M.; Jaumotte, A.; Fraeijs de Veubeke, B.; Vandenkerckhove, J. Rocket Propulsion; Elsevier: Amsterdam, The Netherlands, 1960. [Google Scholar] [CrossRef]

- Püskülcü, G.; Ulas, A. 3-D grain burnback analysis of solid propellant rocket motors: Part 1–ballistic motor tests. Aerosp. Sci. Technol. 2008, 12, 579–584. [Google Scholar] [CrossRef]

- Göçmez, A.; Erişken, C.; Yilmazer, Ü.; Pekel, F.; Özkar, S. Mechanical and Burning Properties of Highly Loaded Composite Propellants. J. Appl. Polym. Sci. 1998, 67, 1457–1464. [Google Scholar] [CrossRef]

- Forrester, A.; Sobester, A.; Keane, A. Engineering Design via Surrogate Modelling: A Practical Guide; John Wiley & Sons: Hoboken, NJ, USA, 2008. [Google Scholar] [CrossRef]

- Sheils, T.M. Tapered Grain Geometry and Statistical Learning for Solid Rocket Motor Simulation. Ph.D. Thesis, Auburn University, Auburn, AL, USA, 2023. [Google Scholar]

- Abadi, M.; Agarwal, A.; Barham, P.; Brevdo, E.; Chen, Z.; Citro, C.; Corrado, G.S.; Davis, A.; Dean, J.; Devin, M.; et al. TensorFlow: Large-Scale Machine Learning on Heterogeneous Systems, 2015. Available online: https://www.tensorflow.org/ (accessed on 31 October 2025).

- Jekabsons, G.; Zhang, Y. Adaptive Basis Function Construction: An Approach for Adaptive Building of Sparse Polynomial Regression Models. Mach. Learn. 2010, 1, 127–155. [Google Scholar] [CrossRef]

- Demo, N.; Tezzele, M.; Rozza, G. EZyRB: Easy Reduced Basis method. J. Open Source Softw. 2018, 3, 661. [Google Scholar] [CrossRef]

- Brooks, W.T. Solid Propellant Grain Design and Internal Ballistics; NASA Special Publication NASA-SP-8076; National Aeronautics and Space Administration: Washington, DC, USA, 1972. [Google Scholar]

- Blank, J.; Deb, K. Pymoo: Multi-Objective Optimization in Python. IEEE Access 2020, 8, 89497–89509. [Google Scholar] [CrossRef]

- Federici, L.; Zavoli, A.; Colasurdo, G.; Mancini, L.; Neri, A. Integrated Optimization of First-Stage SRM and Ascent Trajectory of Multistage Launch Vehicles. J. Spacecr. Rocket. 2021, 58, 786–797. [Google Scholar] [CrossRef]

- Cavallini, E.; Favini, B.; Di Giacinto, M.; Serraglia, F. Analysis of VEGA Solid Stages Static Firing Tests Towards the Maiden Flight. In Proceedings of the 48th AIAA/ASME/SAE/ASEE Joint Propulsion Conference & Exhibit, Atlanta, GA, USA, 30 July–1 August 2012; p. 4211, AIAA Paper 2012-4211. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).