Firing Test Campaign for a Hydrogen Peroxide Propulsion System for CubeSats in Vacuum Conditions

Abstract

1. Introduction

2. Propulsion System Design

- Maximization of the propulsive performance in terms of ∆v and total impulse capabilities;

- Minimization of the dry mass;

- Low cost;

- Simplicity.

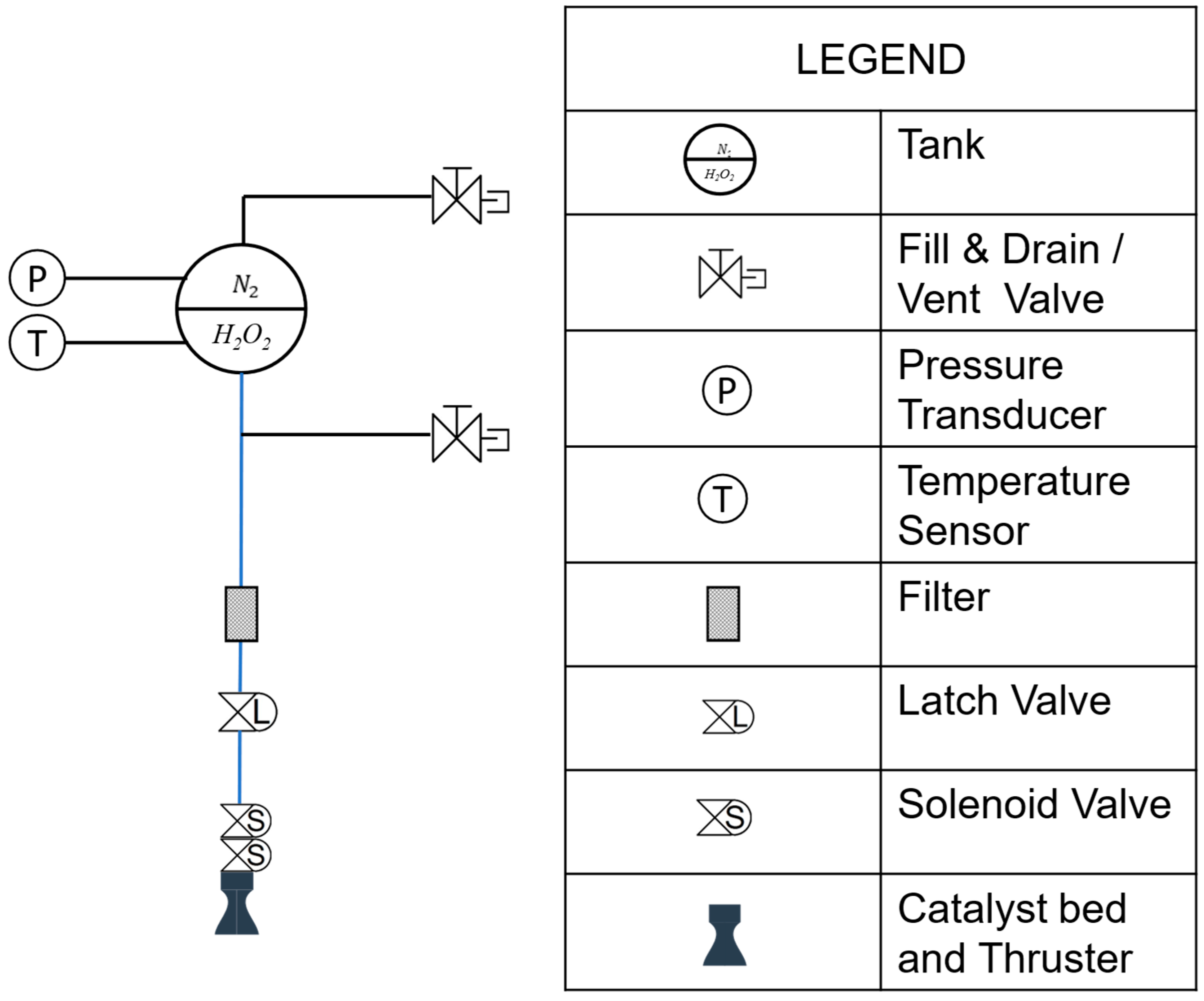

- A blowdown propellant management system contains both the propellant and a limited amount of pressurizing gas stored inside a 1U tank and separated by a bladder made of Viton, a material satisfying the HTP Grade I–II compatibility requirement. The tank shell is made of 316 stainless steels.

- Two fill-and-drain valves, one for each fluid inside the tank, constitute the flight segment of the filling and draining system; a feed-line connects the tank side storing the propellant to the thrust chamber.

- A filter and three solenoidal valves on this line guarantee the three barriers inhibit catastrophic events, as required in [17]. Valves, fittings, and tubes are all made of 316 stainless steels passivated to inhibit the HTP decomposition.

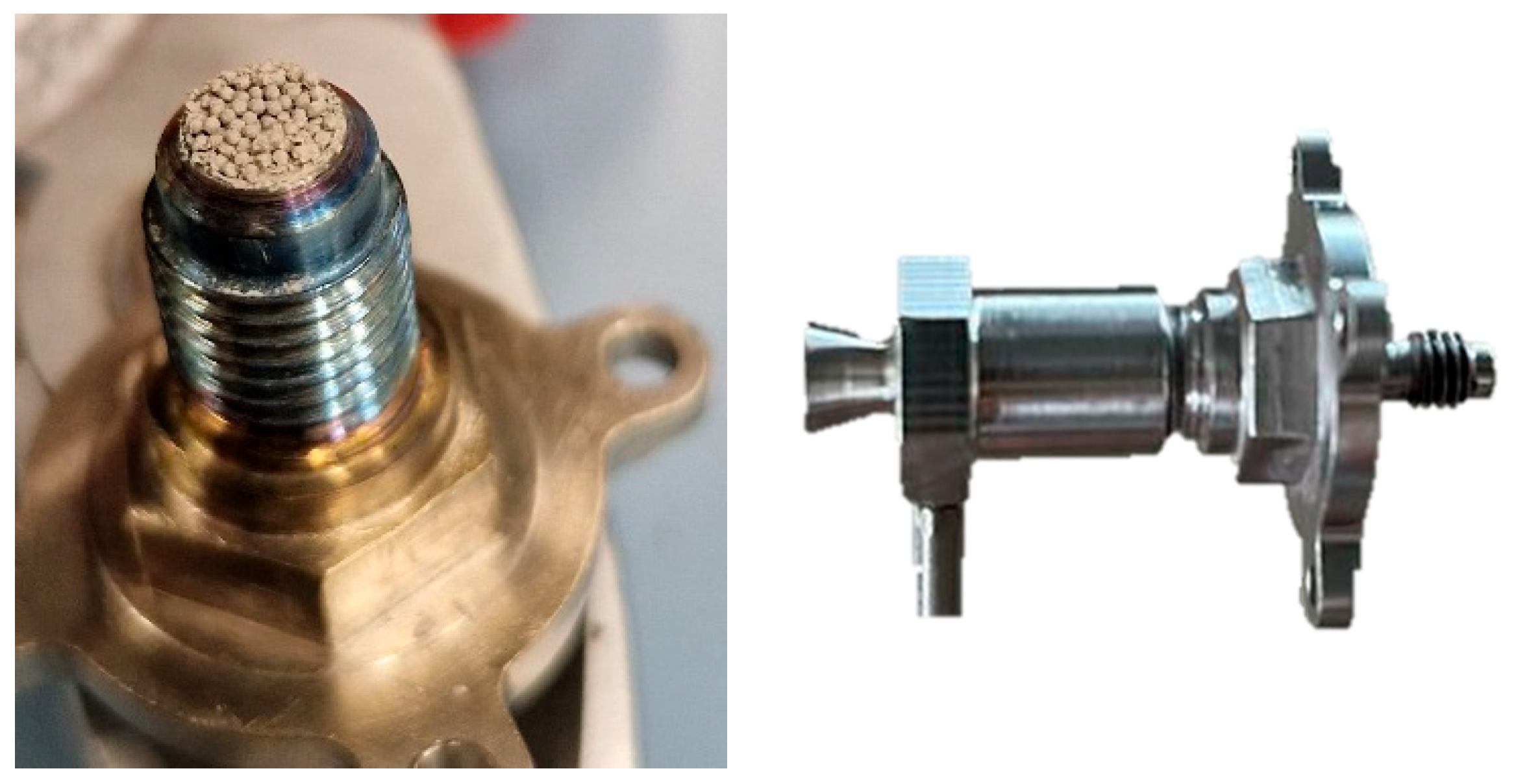

- A monopropellant thruster composed of a catalytic bed and a nozzle generates the required thrust for moving the satellites.

Thruster

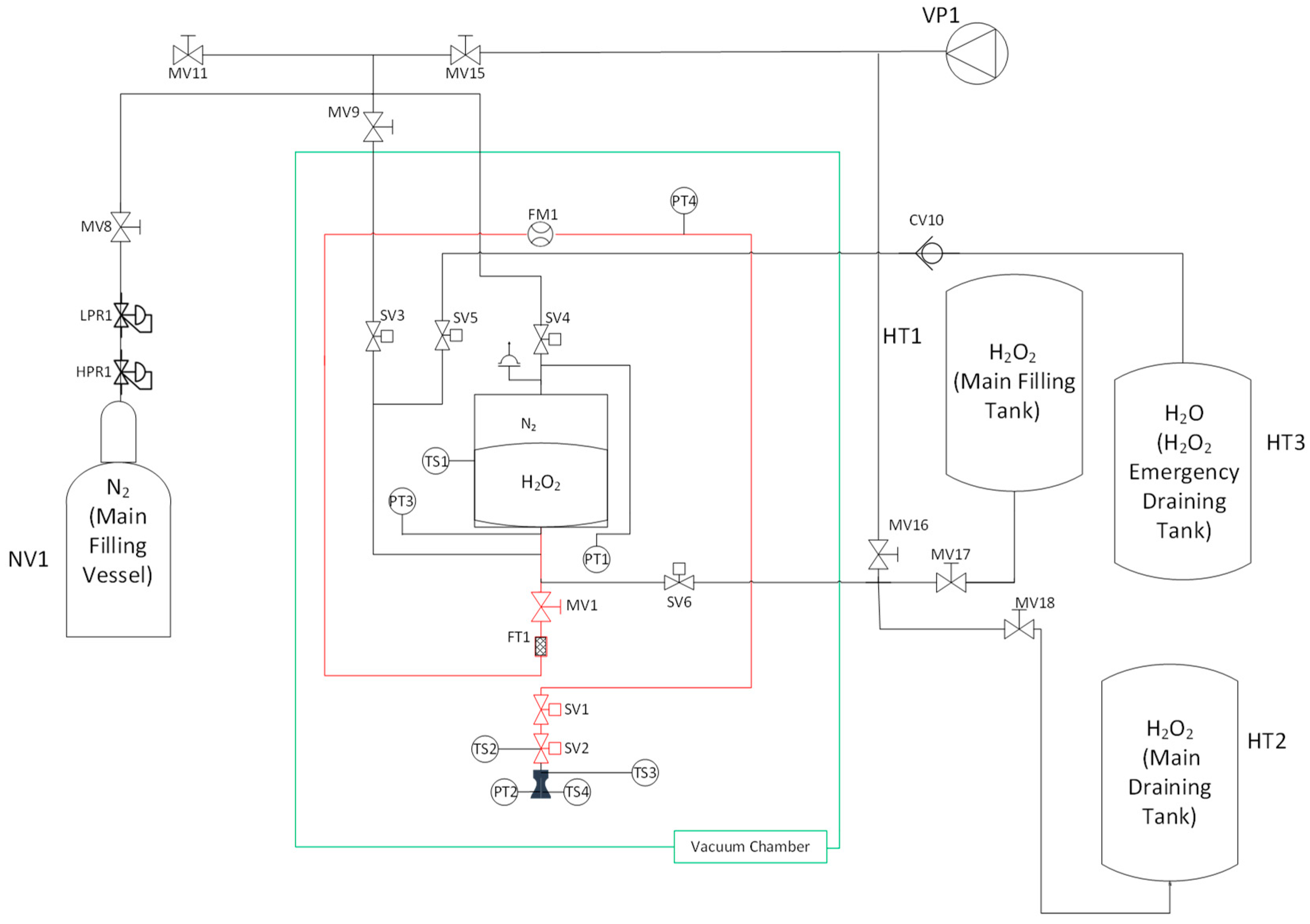

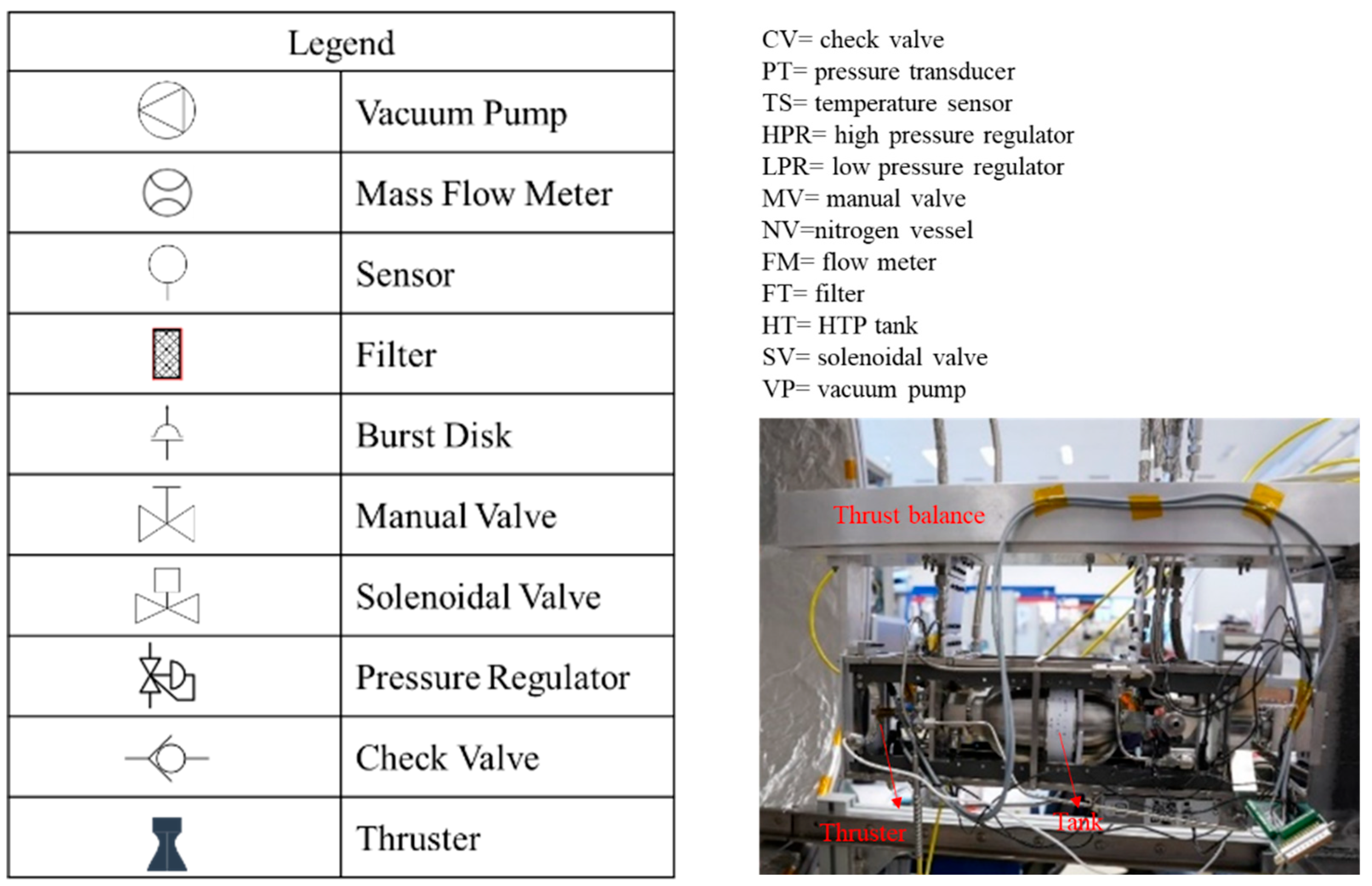

3. Test Apparatus

3.1. Diagnostic and Instrumentation

- ○

- ;

- ○

- (function of the H2O2 concentration);

- ○

- (function of the H2O2 concentration);

- ○

- (with expansion in vacuum );

- ○

- The uncertainty in the throat area is related to the manufacturing process of the nozzle and it is equal to:

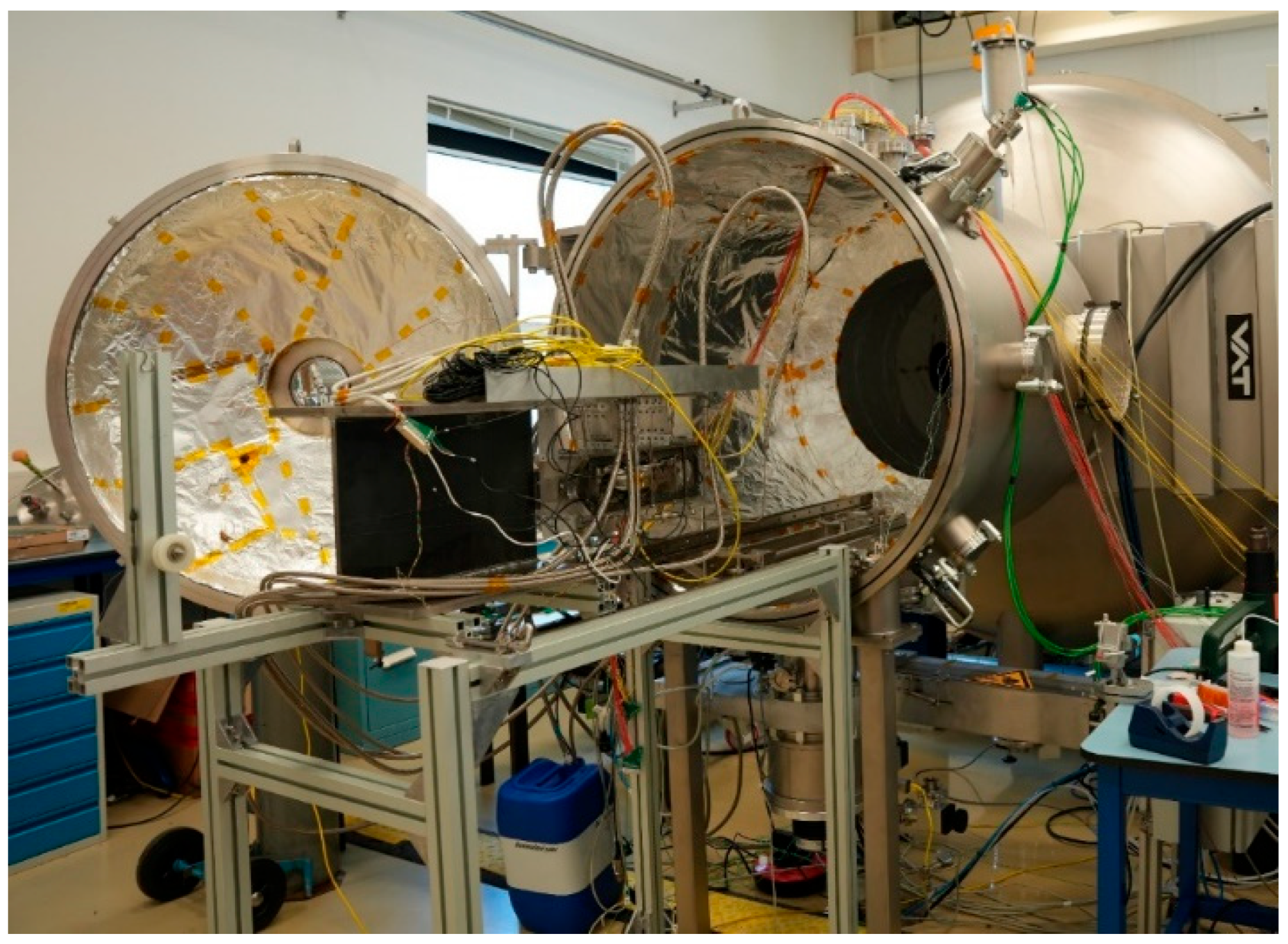

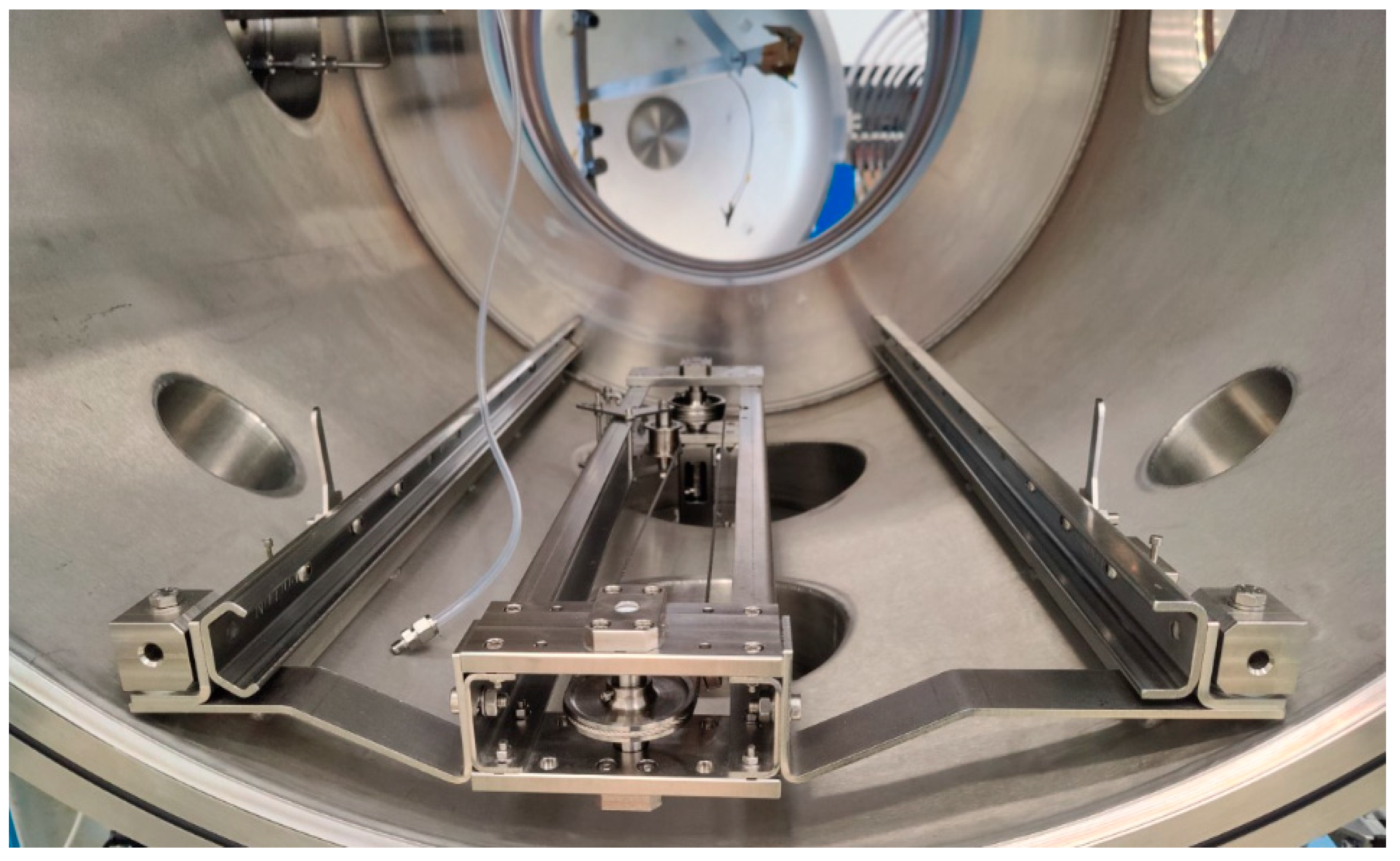

3.2. Vacuum Chamber

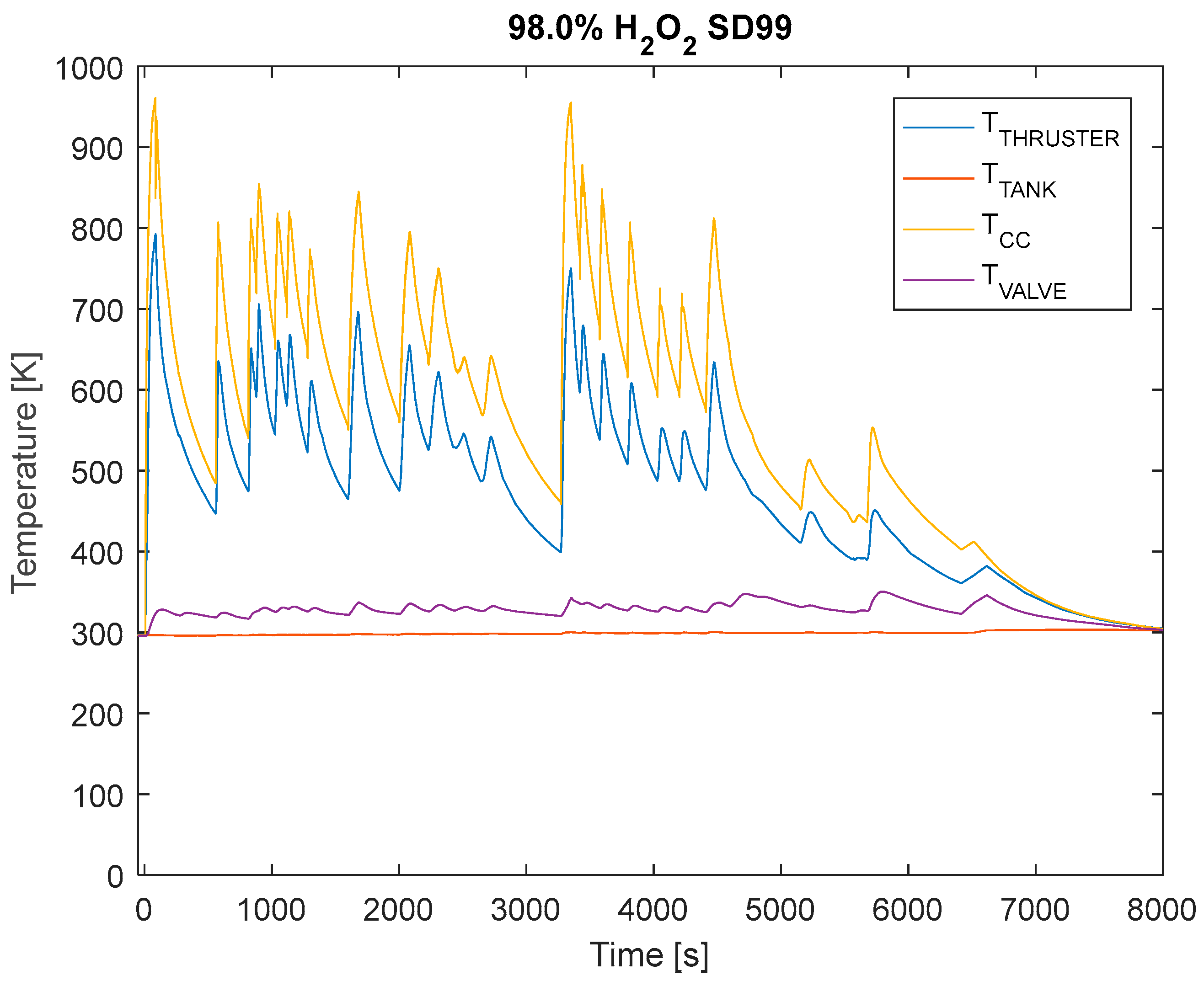

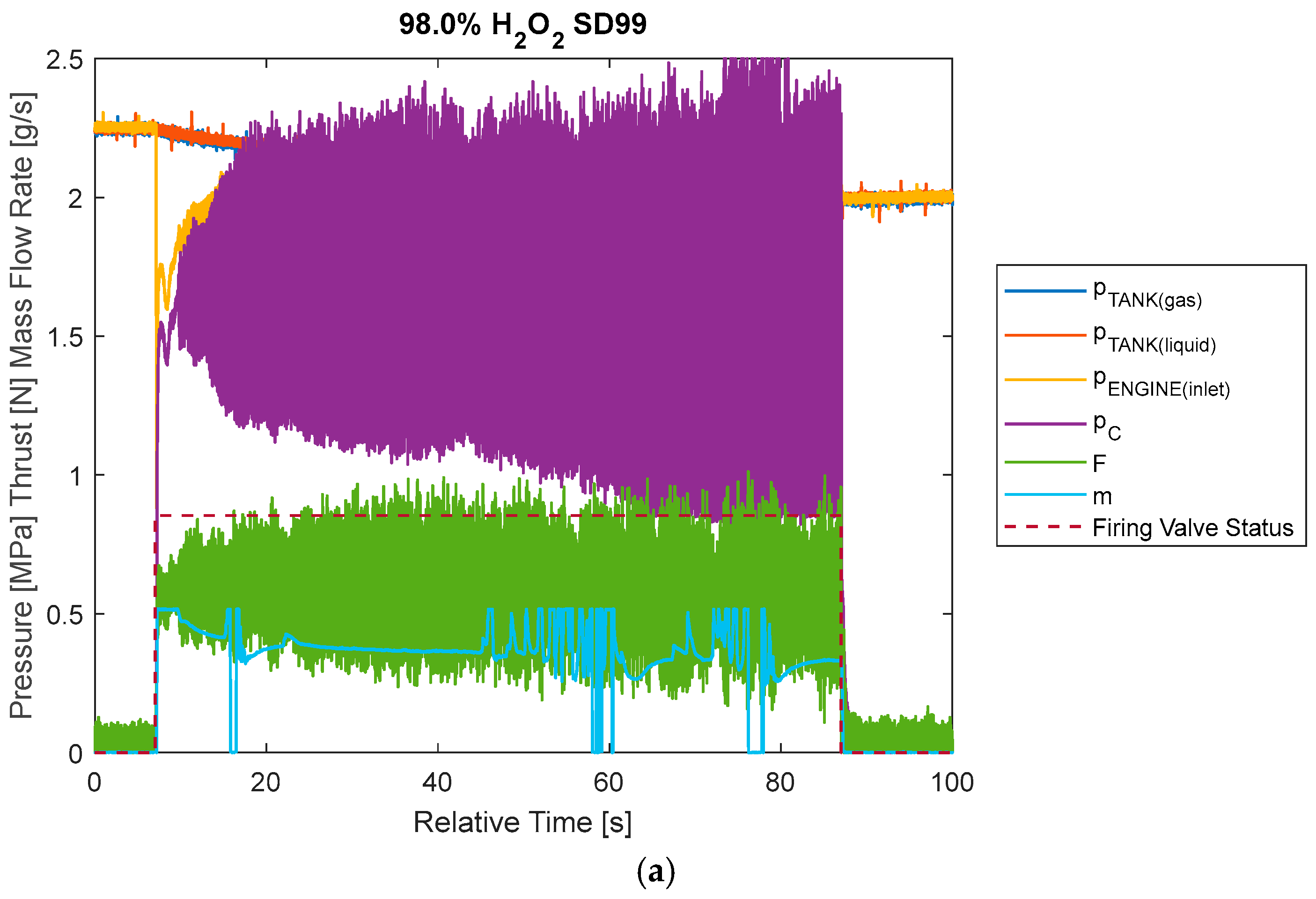

4. Experimental Results and Discussion

5. Conclusions

- ○

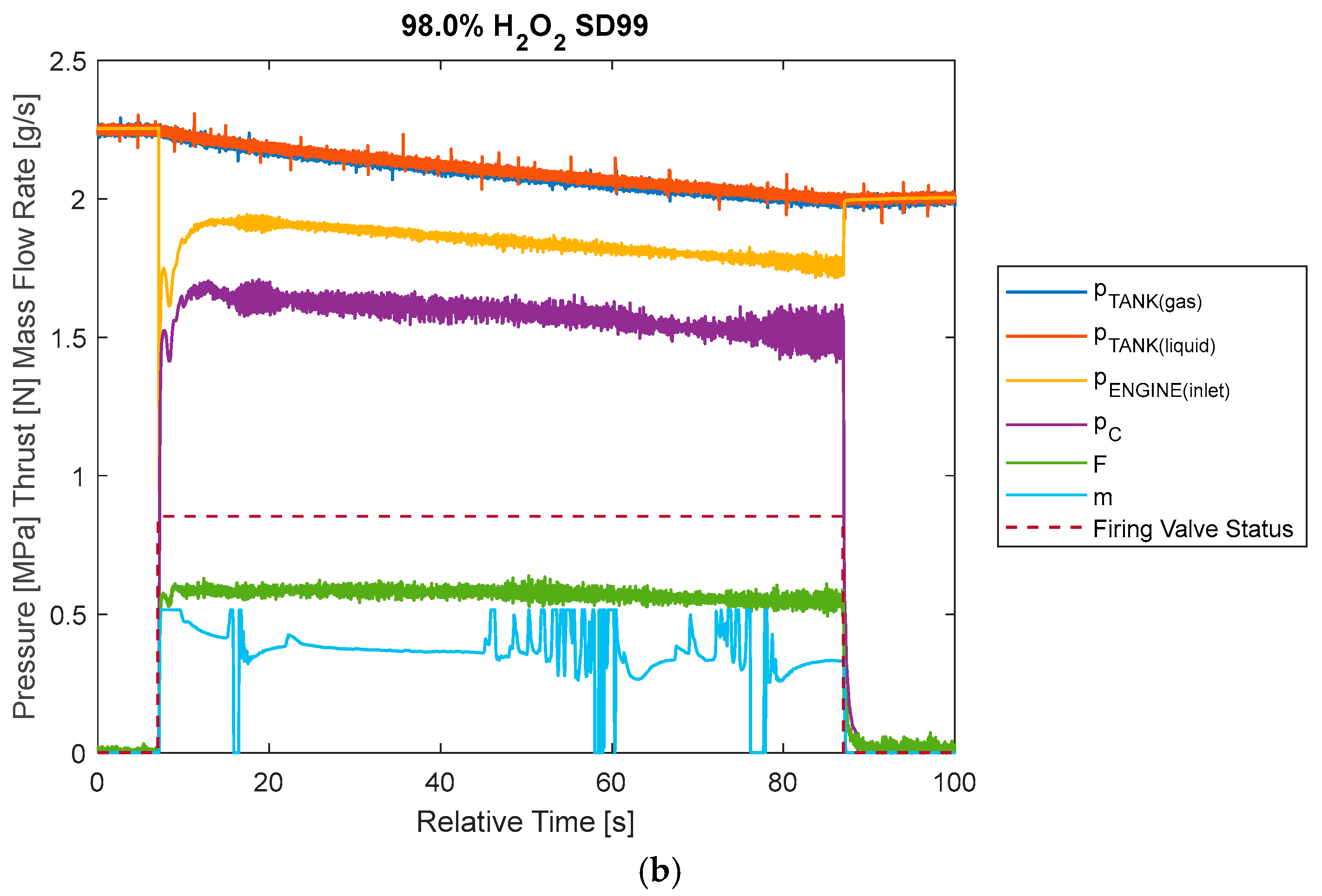

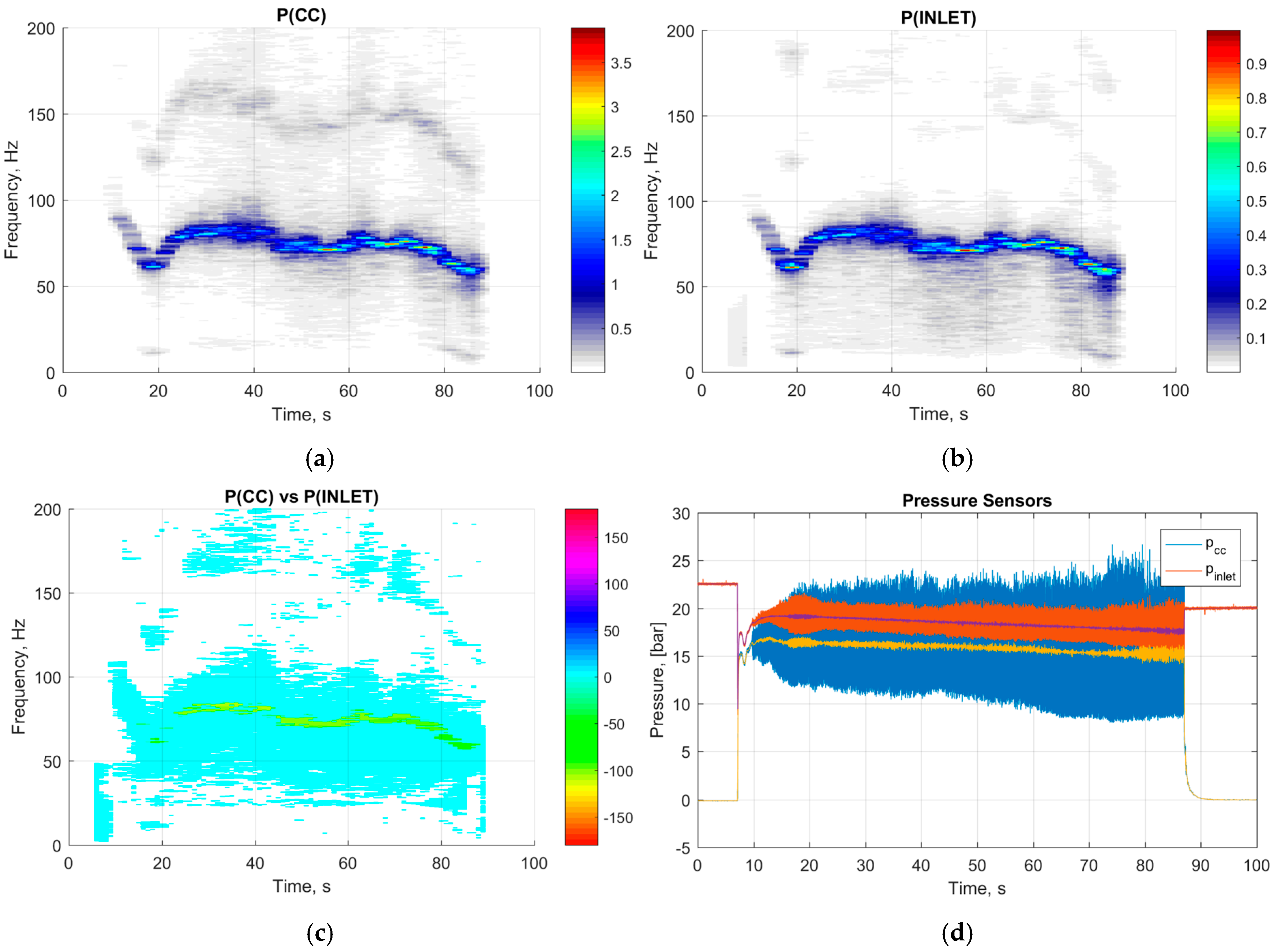

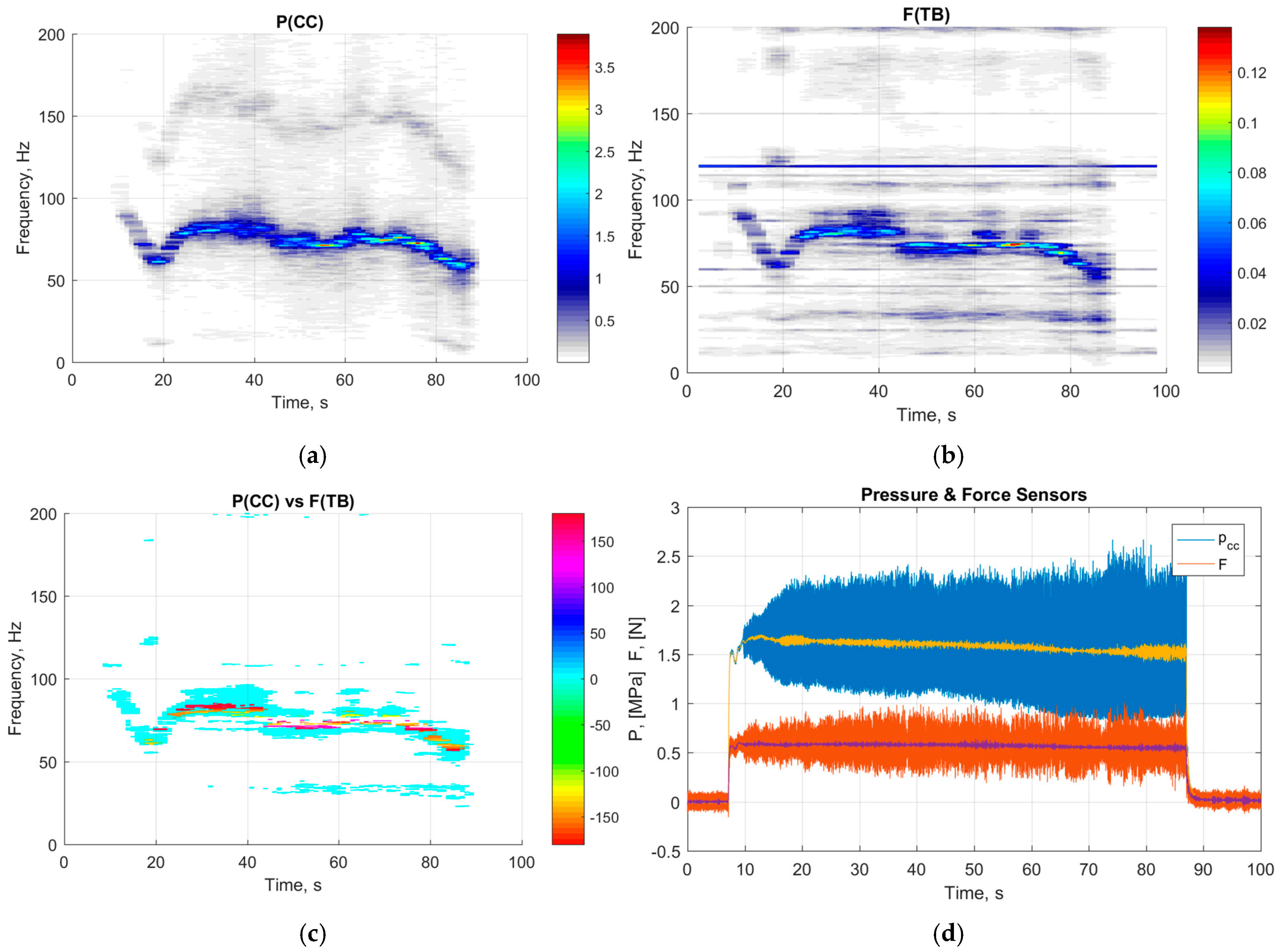

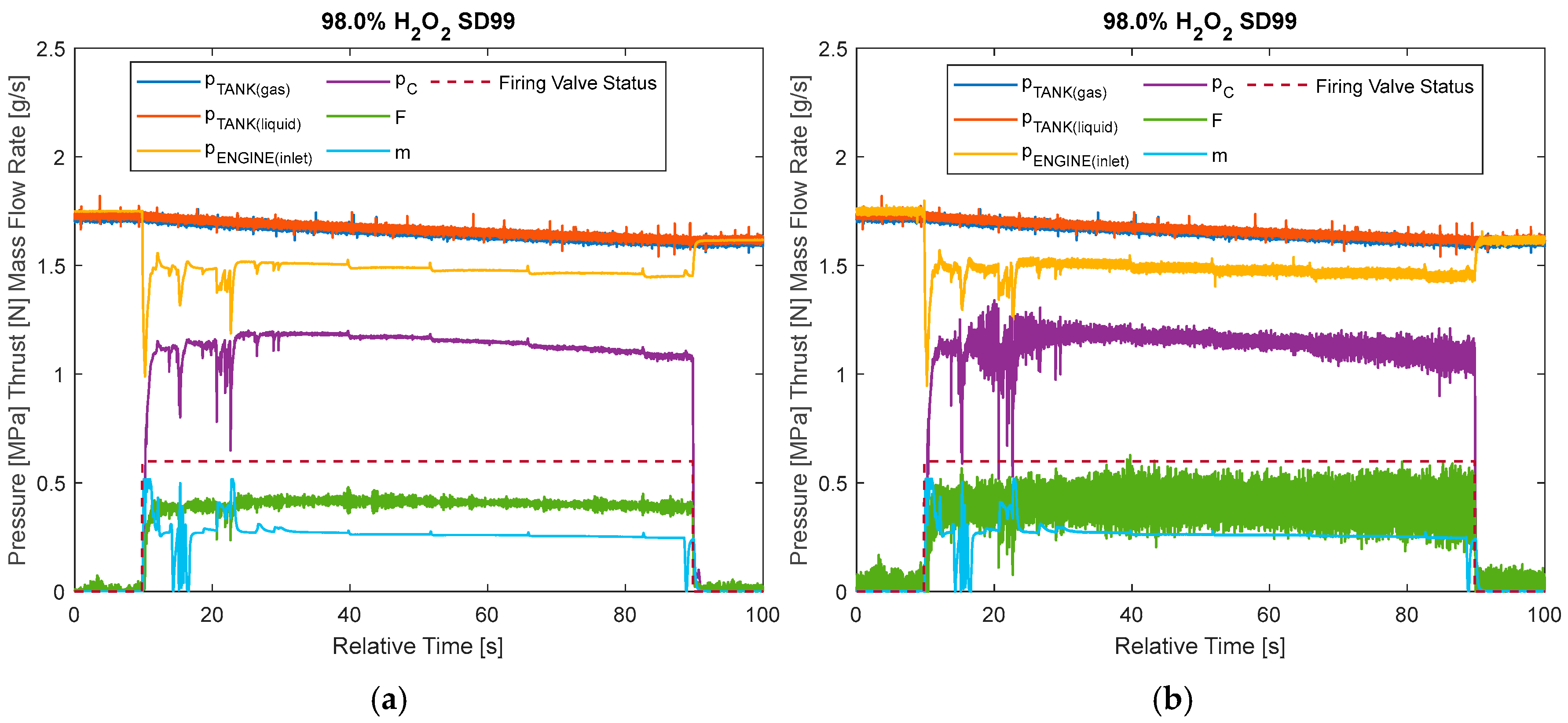

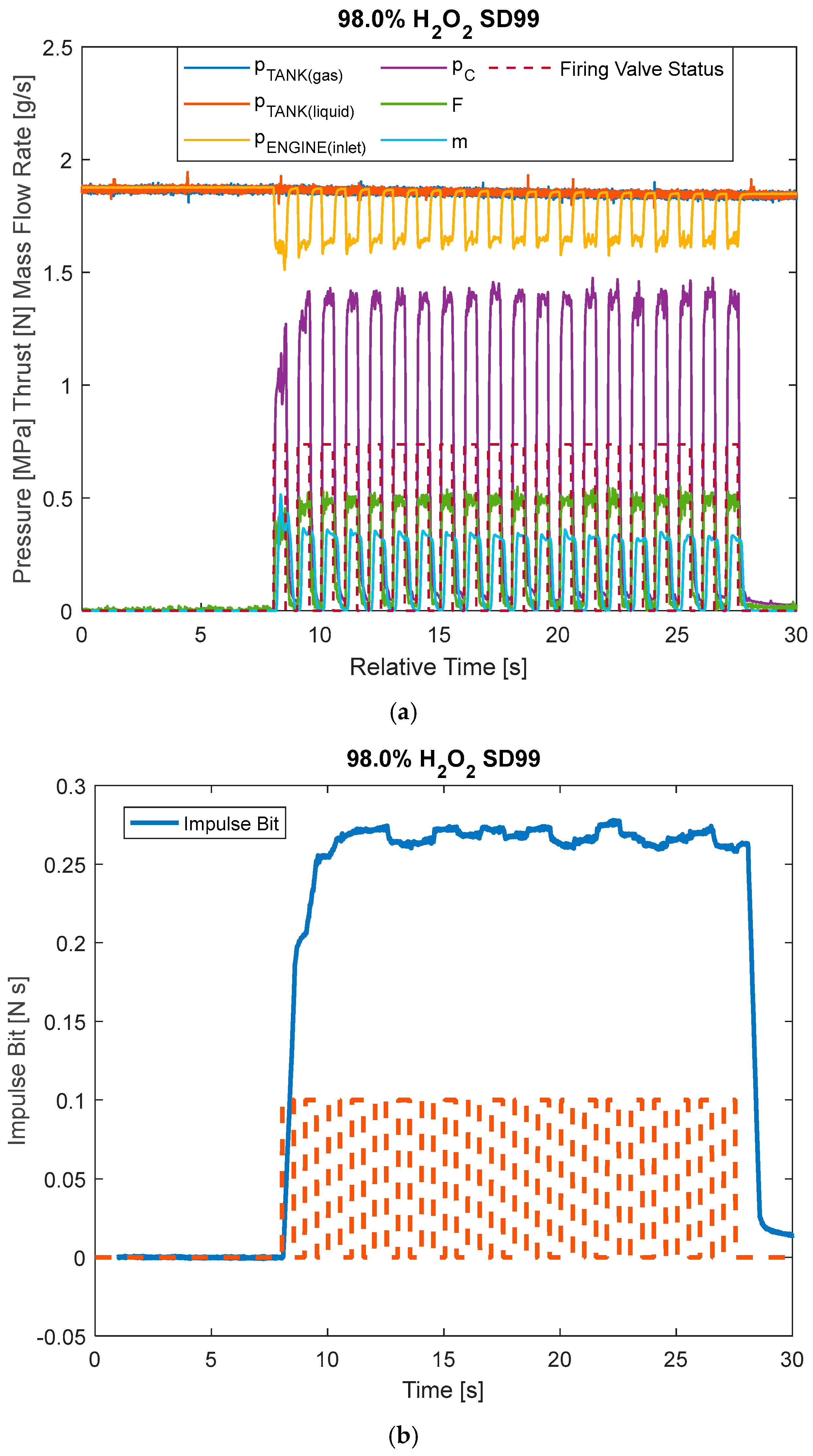

- The MEOP was set to 24 bar and during the test, it has been proven that the system is capable of firing more than once and in pulse-mode. The performances showed that the system was able to reach 90% of the steady state thrust in nominal conditions in less than 150 ms, respecting also the limit of 0.5 N for the thrust and 160 s for the SI. The c* efficiency obtained was equal to or greater than 90%.

- ○

- The system was tested in a vacuum chamber that was able to reproduce the real operational environment which is without convection and conduction with external air. The vacuum obtained inside the chamber of 10−3 mbar was enough to prevent the system from reaching flow separation conditions. Thanks to this, some components present in both the flight and engineering model were tested in their operational environment with success. Furthermore, no damage from outgassing has been detected, which is a sign that a chemical propulsion system based on HTP can be safely tested inside vacuum chambers.

- ○

- All the requirements regarding the temperature of the components have been fulfilled. The firing valve and the tank maintained their temperatures below the imposed threshold, and the stand-off configuration prevented the whole system from exceeding the 60 °C limit.

- ○

- The whole propulsion system is confirmed to occupy no more than 1.5U, with a mass that does not exceed 10 kg, satisfying the stringent mass and envelope requirements imposed by the target class of satellites.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| Ae | nozzle exit area | I.V. | Initial Value |

| Ath | nozzle throat area | MEOP | Maximum Expected Operating Pressure |

| BOL | Beginning of Life | pamb | ambient pressure |

| c* | characteristics velocity | pc | combustion chamber pressure |

| COTS | Commercial-Off-The-Shelf | pin | tank initial pressure |

| CF | Thrust Coefficient | SPF | Small Plasma Facility |

| EM | Engineering Model | Tad | adiabatic decomposition temperature |

| EOL | End of Life | ton | firing valve aperture time |

| FM | Flight Model | TRL | Technology Readiness Level |

| FS | Full Scale | U | CubeSat Unit |

| FSO | Full Scale Output | γ | gas specific heat ratio |

| g | gravity acceleration constant | ∆v | velocity change |

| HTP | High Test Peroxide | ε | error |

| IB | Impulse Bit | η | efficiency |

| Isp | Specific Impulse | σ | Standard Deviation |

References

- ESA Space Debris Mitigation Working Group. ESA Space Debris Mitigation Requirements (ESSB-ST-U-007 Issue 1); European Space Agency: Noordwijk, The Netherlands, 2023. [Google Scholar]

- Lemmer, K. Propulsion for cubesats. Acta Astronaut. 2017, 134, 231–243. [Google Scholar] [CrossRef]

- Evans, D.D.; Price, T.W. The Status of Monopropellant Hydrazine Technology; Jet Propulsion Laboratory, NASA: Pasadena, CA, USA, 1968. [Google Scholar]

- Schmidt, E.W.; Wucherer, E.J. Hydrazine (s) vs. Nontoxic Propellants—Where Do We Stand Now. In Proceedings of the 2nd Conference (International) on Green Propellants for Space Propulsion (ESA SP-557) Proceedings, Sardinia, Italy, 7–8 June 2004. [Google Scholar]

- Nosseir, A.E.; Cervone, A.; Pasini, A. Review of State-of-the-Art Green Monopropellants: For Propulsion Systems Analysts and Designers. Aerospace 2021, 8, 20. [Google Scholar] [CrossRef]

- Wucherer, E.; Christofferson, S.; Reed, B. Assessment of high performance HAN-monopropellants. In Proceedings of the 36th AIAA/ASME/SAE/ASEE Joint Propulsion Conference and Exhibit, Las Vegas, NV, USA, 24–28 July 2000; p. 3872. [Google Scholar]

- Schoyer, H.F.R.; Welland-Veltmans, W.H.M.; Louwers, J.; Korting, P.; Van der Heijden, A.; Keizers, H.L.J.; Van den Berg, R.P. Overview of the development of hydrazinium nitroformate-based propellants. J. Propuls. Power 2002, 18, 138–145. [Google Scholar] [CrossRef]

- Pasini, A.; Torre, L.; Romeo, L.; Cervone, A.; d’Agostino, L. Testing and characterization of a hydrogen peroxide monopropellant thruster. J. Propuls. Power 2008, 24, 507–515. [Google Scholar] [CrossRef]

- Pasini, A.; Pace, G.; Valentini, D. Design and Testing of a 98% H2O2 Pulsed Thruster. Presented at the Space Propulsion 2016, Rome, Italy, 2–6 May 2016. [Google Scholar]

- Constantine, M.T.; Cain, E.F. Hydrogen Peroxide Handbook; Technical Report AFRPL-TR-67-144; Chemical and Material Sciences Department Research Division Rocketdyne, a Division of North American Aviation, Inc.: Canoga Park, CA, USA, 1967; p. 488. [Google Scholar]

- Davis, D.D.; Dee, L.A.; Greene, B.; Hornung, S.D.; McClure, M.B.; Rathgeber, K.A. Fire, Explosion, Compatibility and Safety Hazards of Hydrogen Peroxide; National Aeronautics and Space Administration NASA TM-2004-213151; NASA Johnson Space Center: Houston, TX, USA, 2005. [Google Scholar]

- Torre, L.; Pasini, A.; Pace, G.; Valentini, D.; d’Agostino, L.; Siciliano, P.F.; Lecardonnel, L. PulCheR–Pulsed Chemical Rocket with Green High Performance Propellants: Project Overview. In Proceedings of the VIII International Scientific Conference: “Development Trends in Space Propulsion Systems”, Warsaw, Poland, 14–15 November 2013; pp. 18–19. [Google Scholar]

- Pasini, A.; Pace, G.; Torre, L. Propulsive performance of a 1 N 98% hydrogen peroxide thruster. In Proceedings of the 51st AIAA/SAE/ASEE Joint Propulsion Conference, Orlando, FL, USA, 27–29 July 2015; p. 4059. [Google Scholar]

- Torre, L.; Romeo, L.; Pasini, A.; Cervone, A.; d’Agostino, L. Green Propellant Research at Alta SpA. In Proceedings of the ESA Space Propulsion Conference 2010, San Sebastian, Spain, 3–6 May 2010. [Google Scholar]

- Pasini, A.; Torre, L.; Romeo, L.; Cervone, A.; d’Agostino, L. Reduced-order model for H2O2 catalytic reactor performance analysis. J. Propuls. Power 2010, 26, 446–453. [Google Scholar] [CrossRef]

- Pasini, A.; Torre, L.; Romeo, L.; Cervone, A.; d’Agostino, L.; Musker, A.J.; Saccoccia, G. Experimental characterization of a 5 N hydrogen peroxide monopropellant thruster prototype. In Proceedings of the 43rd AIAA/ASME/SAE/ASEE Joint Propulsion Conference & Exhibit, Cincinnati, OH, USA, 8–11 July 2007; p. 5465. [Google Scholar]

- Mehrparvar, A.; Pignatelli, D.; Carnahan, J.; Munakata, R.; Lan, W.; Toorian, A.; Hutputanasin, A.; Lee, S. CubeSat design specification (CDS) REV 13; CubeSat Project: San Luis Obispo, CA, USA, 2014; pp. 1–42. [Google Scholar]

- Dolci, S.; Dell’Amico, D.B.; Pasini, A.; Torre, L.; Pace, G.; Valentini, D. Platinum catalysts development for 98% hydrogen peroxide decomposition in pulsed monopropellant thrusters. J. Propuls. Power 2015, 31, 1204–1216. [Google Scholar] [CrossRef]

- Torre, L.; Romeo, L.; Pasini, A.; Cervone, A.; d’Agostino, L.; Calderazzo, F. Performance of different catalysts supported on alumina spheres for hydrogen peroxide decomposition. In Proceedings of the 43rd AIAA/ASME/SAE/ASEE Joint Propulsion Conference & Exhibit, Cincinnati, OH, USA, 8–11 July 2007; p. 5466. [Google Scholar]

- Romeo, L.; Torre, L.; Pasini, A.; d’Agostino, L.; Calderazzo, F. Development and testing of Pt/Al2O3 catalysts for hydrogen peroxide decomposition. In Proceedings of the 5th International Spacecraft Propulsion Conference and 2nd International Symposium on Propulsion for Space Transportation, Heraklion, Greece, 5–9 May 2008; pp. 5–8. [Google Scholar]

- Shaik, R.; Bellucci, L.; Labella, L.; Calatafimi, S.; Puccinelli, E.; Pasini, A. Preliminary Screening of Catalytic Beds for Hydrogen Peroxide with Thrust Level Lower Than 0.5 N. In Proceedings of the 73rd International Astronautical Congress (IAC), Paris, France, 18–22 September 2022. [Google Scholar]

- Pasini, A.; Sales, L.; Puccinelli, E.; Lin, L.; Apollonio, A.; Simi, R.; Brotini, G.; d’Agostino, L. Design of an Affordable Hydrogen Peroxide Propulsion System for CubeSats. In Proceedings of the AIAA Propulsion and Energy 2021 Forum, Online, 9–11 August 2021; p. 3690. [Google Scholar]

| Parameter | Requirement |

|---|---|

| Propellant | HTP 98% wt. |

| Specific Impulse | >150 s |

| Power Consumption | ≤5 W |

| Thrust | ≤0.5 N |

| Minimum Impulse Bit | ≤25 mN s |

| Propellant Volume | ≥0.3 dm3 |

| MEOP | ≥24 bar |

| Dry mass | ≤1.2 kg |

| Volume Envelope | ≤2U |

| Material HTP compatibility | Grade I and II |

| Lifetime | ≥3 yrs |

| Propellant Management Operation | Blow down |

| TRL | ≥3 |

| Overall Price | ≤50 k€ |

| Parameter | Requirement |

|---|---|

| Operational Temperatures | ≤1000 °C |

| MEOP | ≥18 bar |

| Thrust | ≤0.5 N |

| c* efficiency | ≥0.90 |

| Operational Mode | Continuous firing |

| Operational Mode | Pulse mode |

| Total throughput | ≥0.4 kg |

| Volume Envelope | ≤1U |

| Thrust Balance Features | Value |

|---|---|

| Calibrated Full-Scale (FS) | 4.453 N |

| Standard Deviation (σF) | 0.014 N |

| Accuracy (95.4% Confidence Level) | 0.6% FS |

| Sensor | Range | Accuracy | Place |

|---|---|---|---|

| Kulite ETL/T-500-375M-A (PT1) | 0–50 bar | ±0.25% FSO | Tank gas side |

| Kulite ETL/T-500-375M-A (PT1000) | −50–300 °C | ±0.15 °C | Tank gas side |

| Kulite ETM-500-375M-SG (PT3) | 0–70 bar | ±0.25% FSO | Tank liquid side |

| Kulite ETM-500-375M-SG (PT4) | 0–70 bar | ±0.25% FSO | Feeding line |

| Kulite XTM-190M-A (PT2) | 0–35 bar | ±1% FSO | Thrust chamber |

| TCF-A-J-3000 Tersid (TS1) | −200–1200 °C | ±2 °C | Tank surface |

| MTS-40053-K-150-3000 Tersid (TS2) | −200–1350 °C | ±1.5 °C | Firing valve surface |

| MTS-40053-K-150-3000 Tersid (TS3) | −200–1350 °C | ±1.5 °C | Thruster surface |

| MTS-40103-K-150-3000 Tersid (TS4) | −200–1350 °C | ±1.5 °C | Thrust chamber |

| Bronkhorst M13 Coriolis (FM1) | 30–1500 g/h | ±0.2% I.V. | Feeding line |

| Honeywell Model 13 1000 g (LD1) | 0–1000 g | ±0.7% FSO | Thrust balance |

| Quantity Formula | Accuracy Formula | Nominal Values | Accuracy |

|---|---|---|---|

| SPF Vacuum Chamber | Electric Thruster Configuration | Chemical Thruster Configuration |

|---|---|---|

| Main Chamber Dimensions (m) | 3.35 × Ø2 | 3.35 × Ø2 |

| Auxiliary Chamber Dimensions (m) | 1 × Ø1 | 1 × Ø1 |

| Pumps | 1 × roots pump (1000 m3/h) | 1 × Roots (Leybold—9800 m3/h) |

| 1 × primary pump (30 m3/h) | ||

| 1 × screw pump (250 m3/h) | ||

| 1 × turbopump (2200 L/s N2) | ||

| 4 × cryoheads (50 × 50 cm each, 29,500 L/s N2 each) | ||

| 1 × cryopump (10,000 L/s N2) | ||

| 1 × turbopump on the hatch (400 L/s N2) | ||

| 1 × scroll pump on the hatch (30 m3/h) | ||

| Lowest Achievable Pressure (mbar) | 10−7 | 10−3 |

| Beam Target | No | No |

| Bake-out System | No | No |

| Parameter | Value | Threshold Value |

|---|---|---|

| F (N) | 0.55 | ≤0.5 |

| Isp (s) | 160 | 160 |

| Rise-time (ms) | <100 | 150 |

| ηc* (c*-efficiency) | 0.9 | 0.9 |

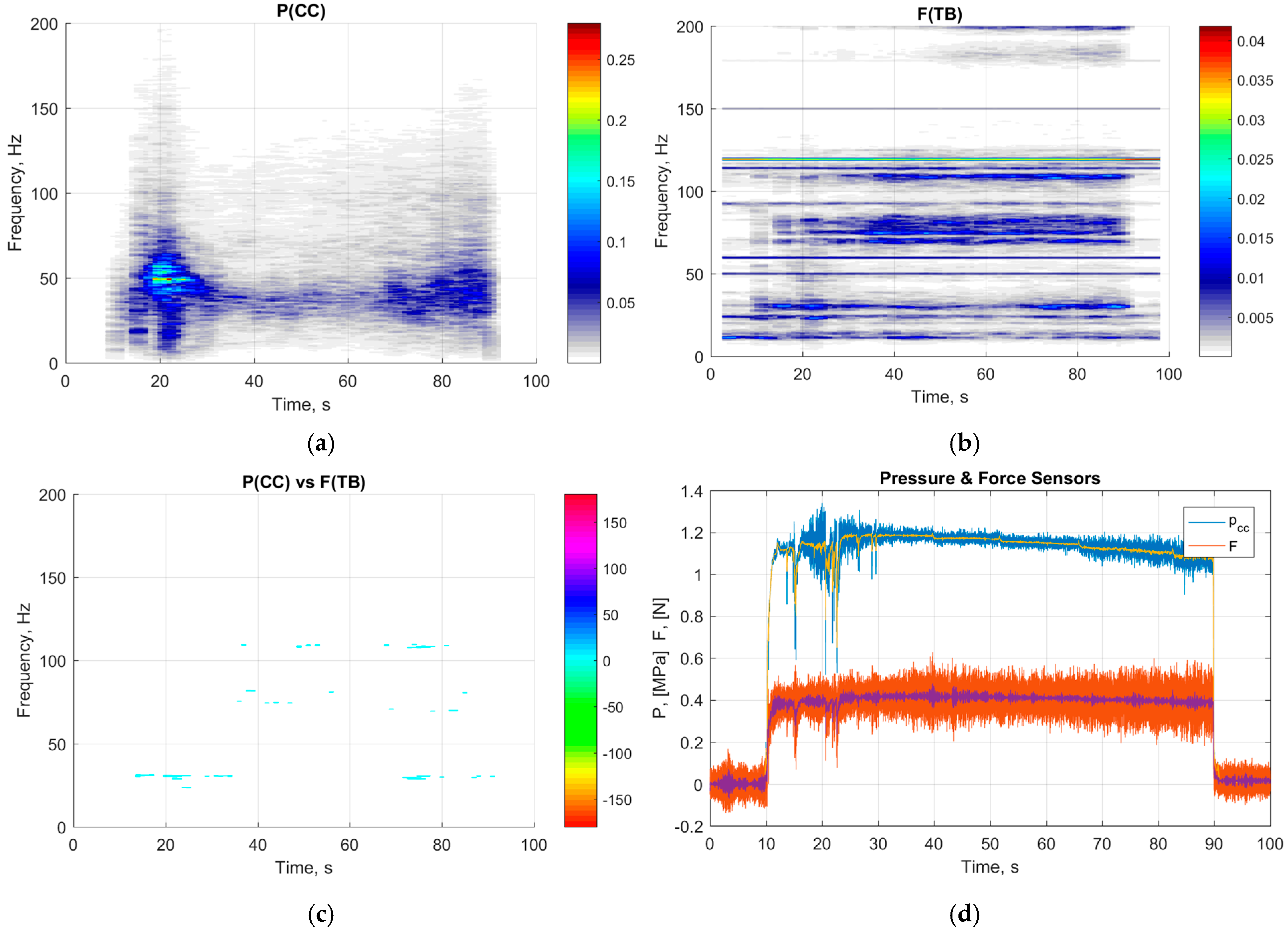

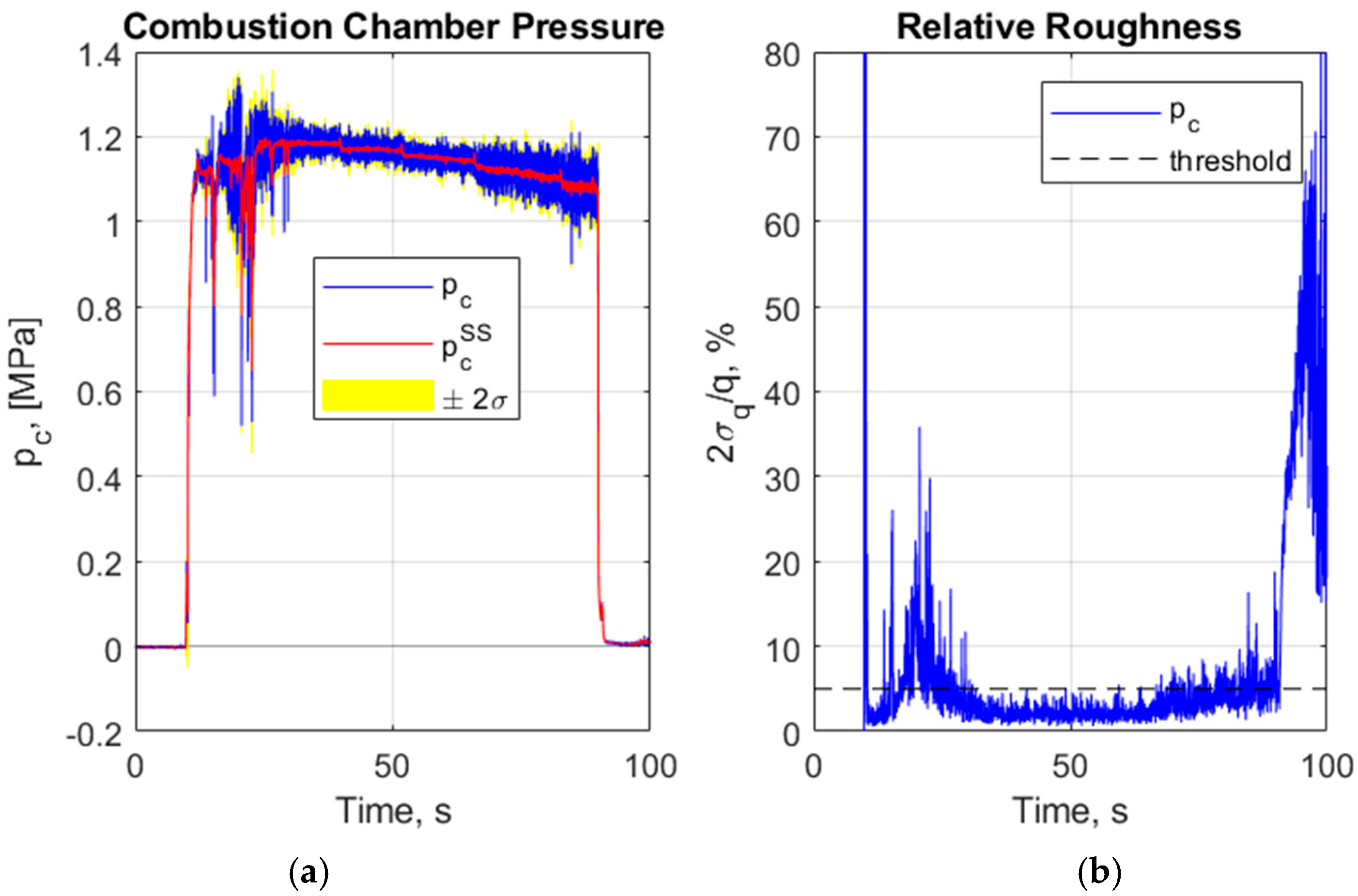

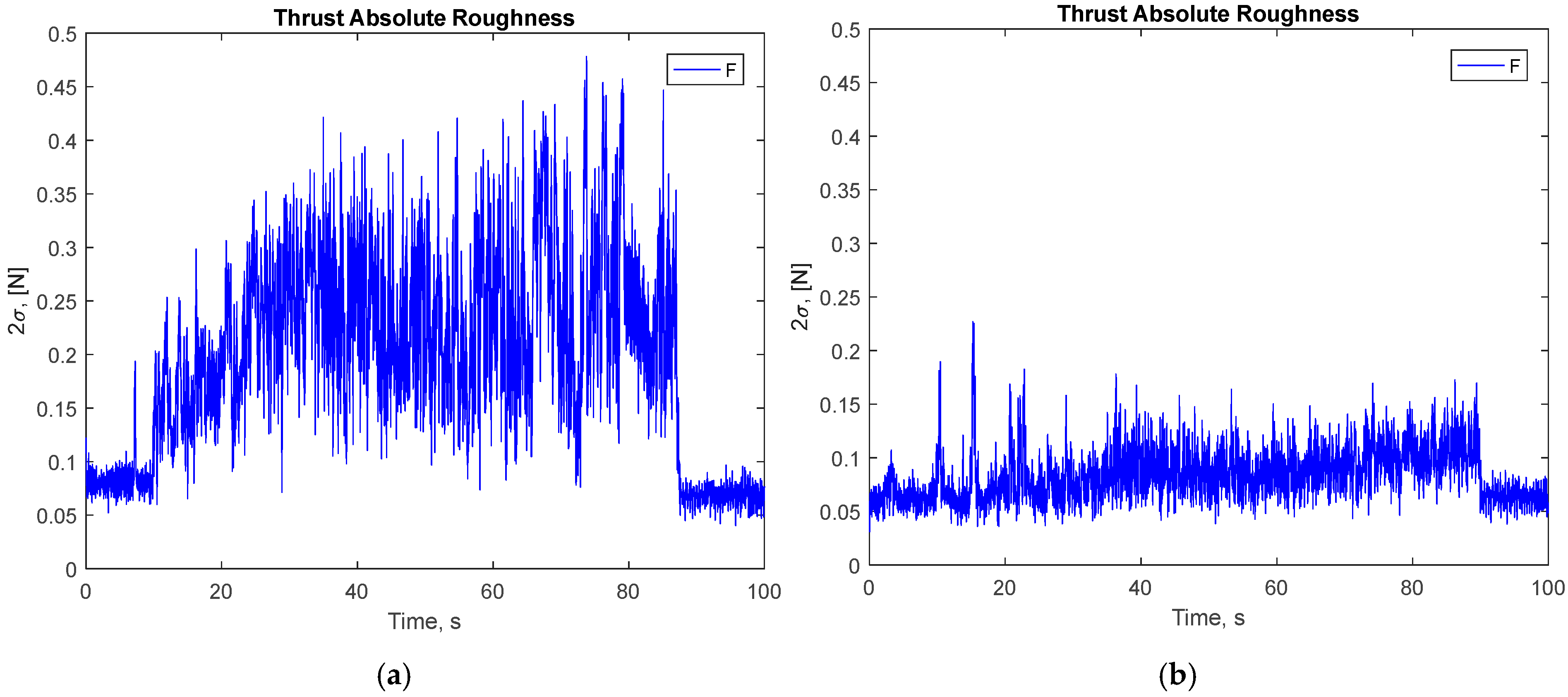

| Parameter | Value | Threshold Value |

|---|---|---|

| F (N) | 0.4 | ≤0.5 |

| Isp (s) | 160 | 160 |

| Rise-time (ms) | <100 | 150 |

| Thrust Roughness | <3% | ±5% at 2σ |

| ηc* (c*-efficiency) | 0.9 | 0.9 |

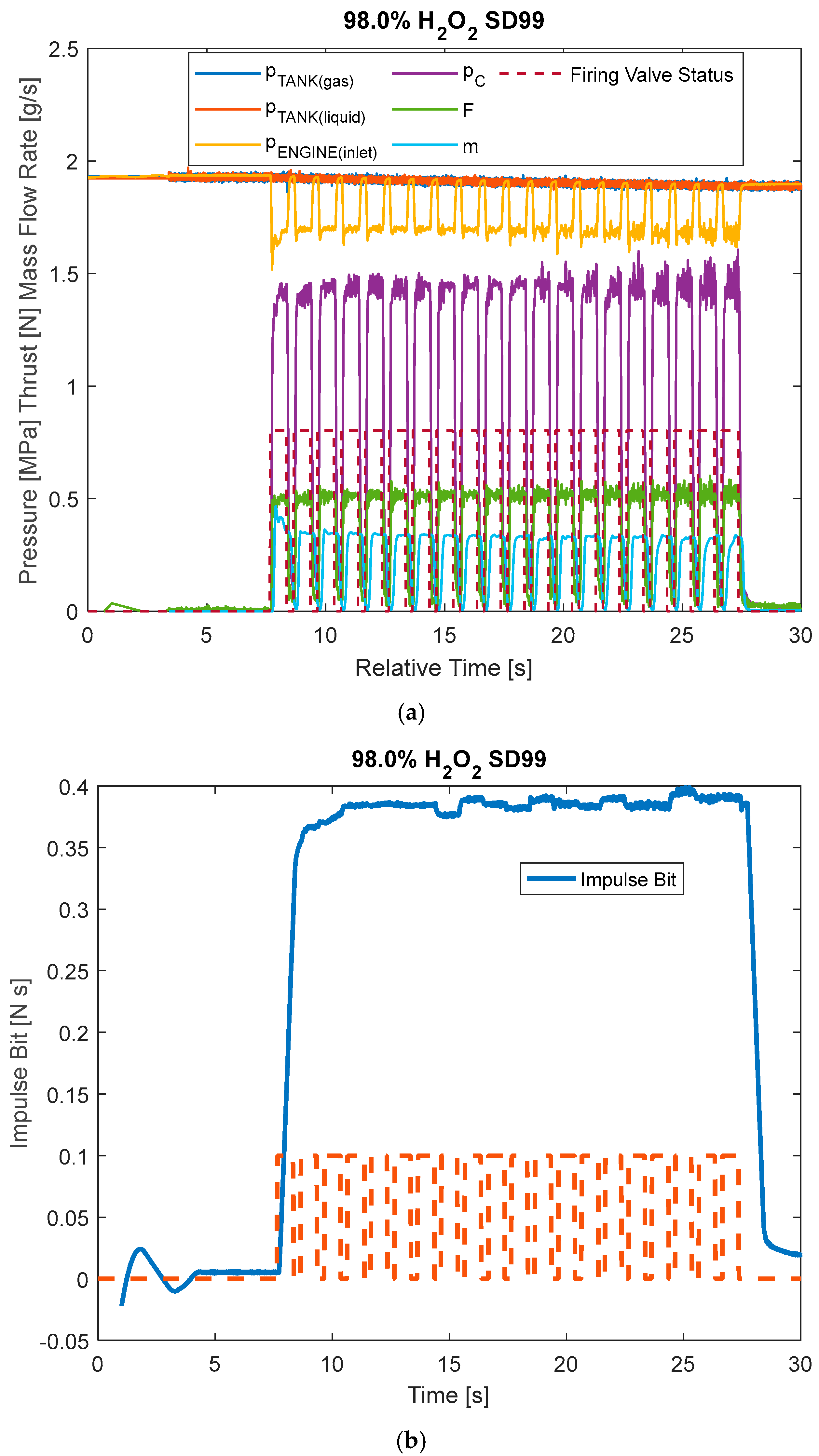

| ton (ms) | N° Pulses | pin (bar) | F (N) | Impulse Bit (Ns) |

|---|---|---|---|---|

| 900 (first series) | 20 | 17 | 0.500 | 0.480 |

| 900 (second series) | 20 | 14 | 0.400 | 0.360 |

| 800 (first series) | 20 | 17 | 0.500 | 0.430 |

| 800 (second series) | 20 | 14 | 0.350 | 0.300 |

| 700 (first series) | 20 | 17 | 0.500 | 0.370 |

| 700 (second series) | 20 | 13.5 | 0.350 | 0.270 |

| 600 (first series) | 20 | 16.5 | 0.500 | 0.320 |

| 500 (first series) | 20 | 16.5 | 0.450 | 0.260 |

| 500 (second series) | 20 | 14.5 | 0.250 | 0.100 |

| 400 (first series) | 20 | 16 | 0.450 | 0.210 |

| 400 (second series) | 20 | 14 | 0.250 | 0.130 |

| 300 (first series) | 80 | 16 | 0.400 | 0.160 |

| 300 (second series) | 80 | 14 | 0.300 | 0.130 |

| 200 (first series) | 80 | 15.5 | 0.400 | 0.110 |

| 200 (second series) | 80 | 14.5 | 0.050 | 0.005 |

| 100 (first series) | 80 | 15.5 | 0.400 | 0.065 |

| 100 (second series) | 80 | 14 | 0.050 | 0.005 |

| 50 (first series) | 80 | 16 | 0.200 | 0.020 |

| 50 (second series) | 80 | 14 | 0.070 | 0.005 |

| 25 (first series) | 80 | 16 | 0.200 | 0.020 |

| 25 (second series) | 80 | 14 | 0.050 | 0.010 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pasini, A.; Puccinelli, E.; Calatafimi, S.; Muñoz Moya, C.; Saryczew, J.; Searle, T. Firing Test Campaign for a Hydrogen Peroxide Propulsion System for CubeSats in Vacuum Conditions. Aerospace 2025, 12, 1022. https://doi.org/10.3390/aerospace12111022

Pasini A, Puccinelli E, Calatafimi S, Muñoz Moya C, Saryczew J, Searle T. Firing Test Campaign for a Hydrogen Peroxide Propulsion System for CubeSats in Vacuum Conditions. Aerospace. 2025; 12(11):1022. https://doi.org/10.3390/aerospace12111022

Chicago/Turabian StylePasini, Angelo, Elia Puccinelli, Stefano Calatafimi, Carlos Muñoz Moya, Juliusz Saryczew, and Thomas Searle. 2025. "Firing Test Campaign for a Hydrogen Peroxide Propulsion System for CubeSats in Vacuum Conditions" Aerospace 12, no. 11: 1022. https://doi.org/10.3390/aerospace12111022

APA StylePasini, A., Puccinelli, E., Calatafimi, S., Muñoz Moya, C., Saryczew, J., & Searle, T. (2025). Firing Test Campaign for a Hydrogen Peroxide Propulsion System for CubeSats in Vacuum Conditions. Aerospace, 12(11), 1022. https://doi.org/10.3390/aerospace12111022