This section presents the MDA framework developed in the Aircraft Systems Lab at Concordia University to perform system integration studies in aircraft conceptual design.

3.1. Framework Overview

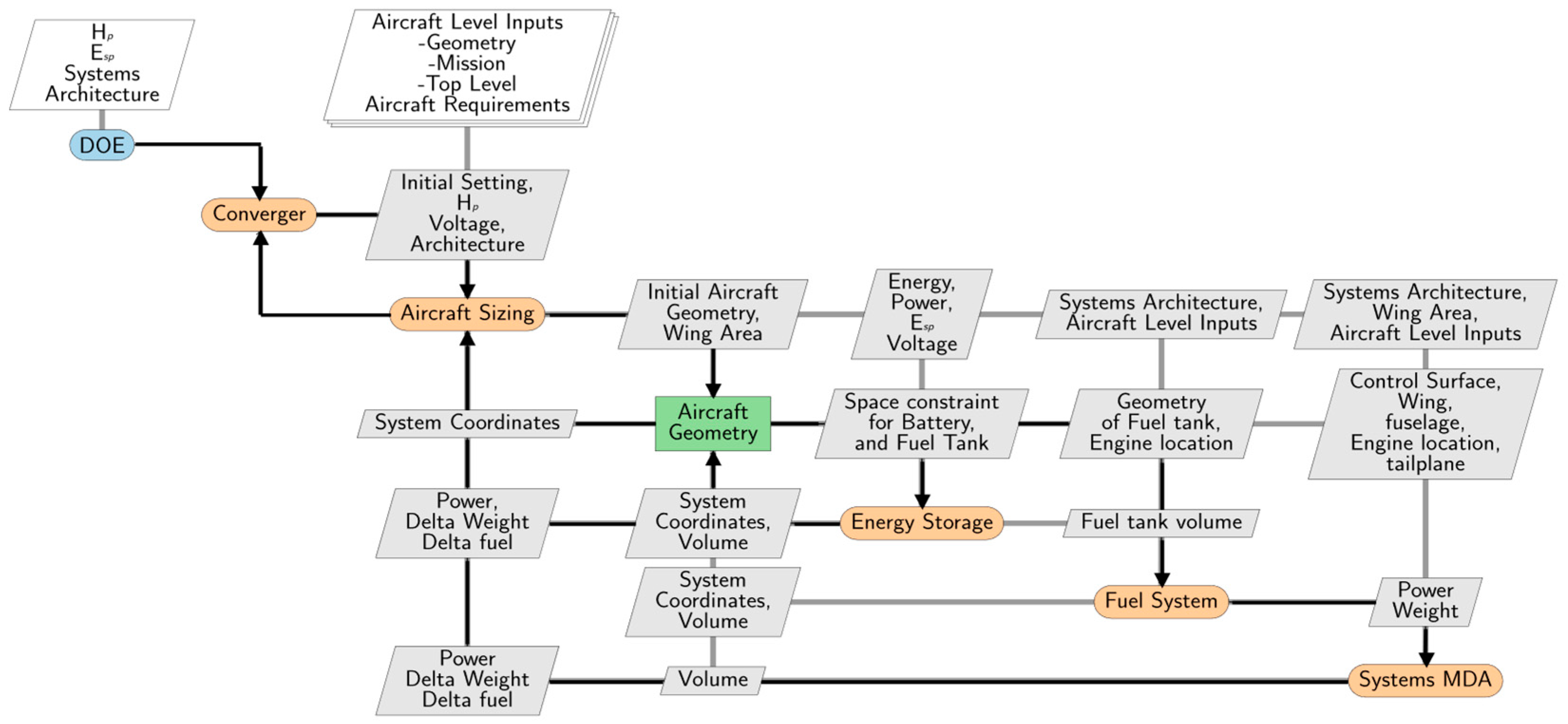

Multidisciplinary aircraft analysis consists of aircraft sizing interactions with multiple disciplines.

Figure 1 shows the eXtended Design Structure Matrix (XDSM) [

38] of the workflow introduced in this paper.

Here, the propulsion system architecture is handled within the Aircraft Sizing module, while the subsystem sizing methods are integrated within the Systems MDA module.

The Systems MDA discipline encompasses the aircraft systems and subsystems sizing and performance estimation modules. The Systems MDA allows for the evaluation of the impact of aircraft system architectures on aircraft-level parameters such as MTOW and fuel burn. Finally, the Systems MDA module drives system architecting and decision-making activities.

A key enabler for the

Systems MDA module is the system architecture descriptor. The descriptor holds information about the architecture, including subsystems, components, and the allocation of power and control to each system architecture element. Some examples of descriptors include textual descriptors [

39,

40], parametric data schema such as CPACS (Common Parametric Aircraft Configuration Schema) [

41], and the graph-based descriptor used by Jeyaraj et al. [

10].

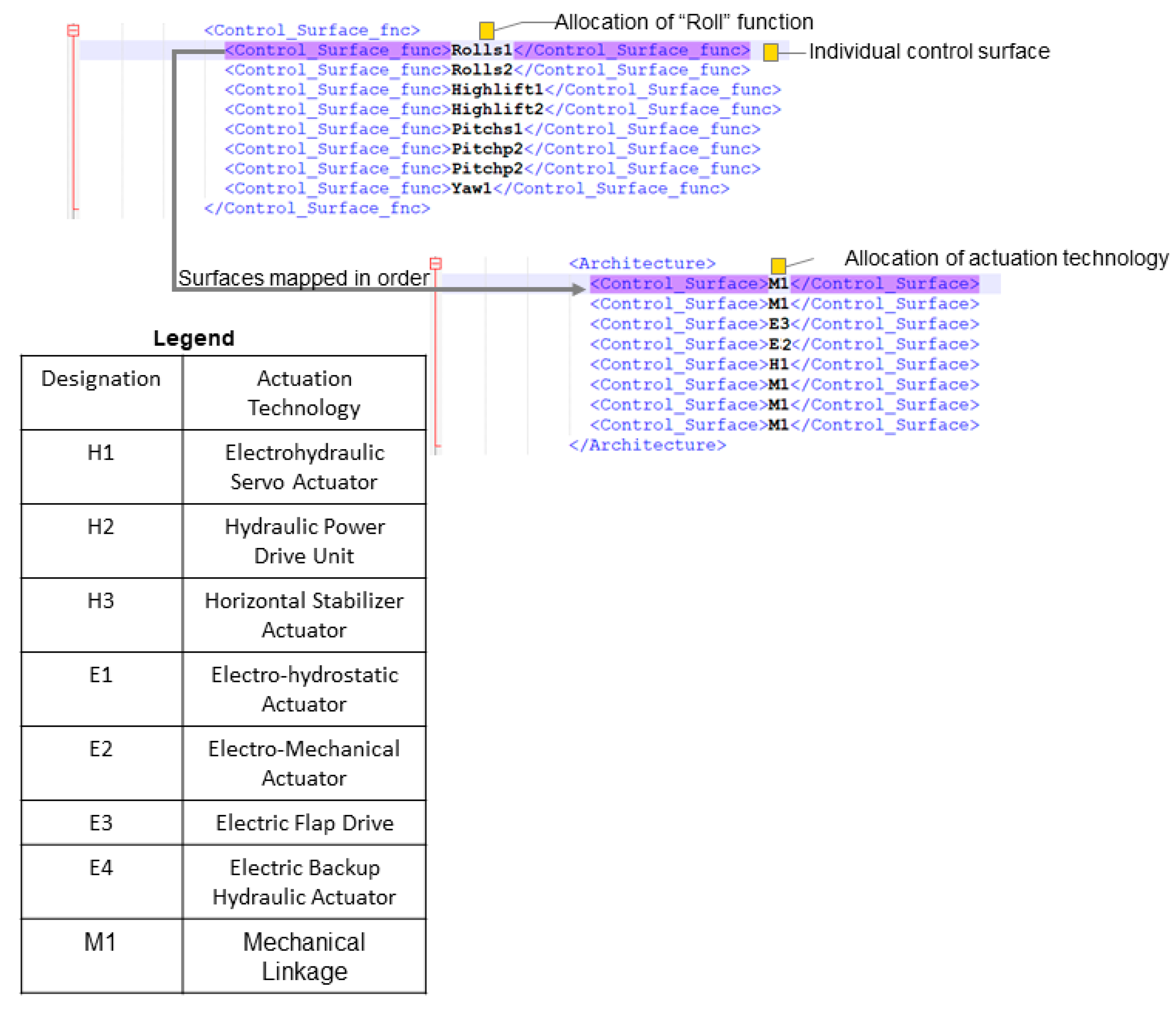

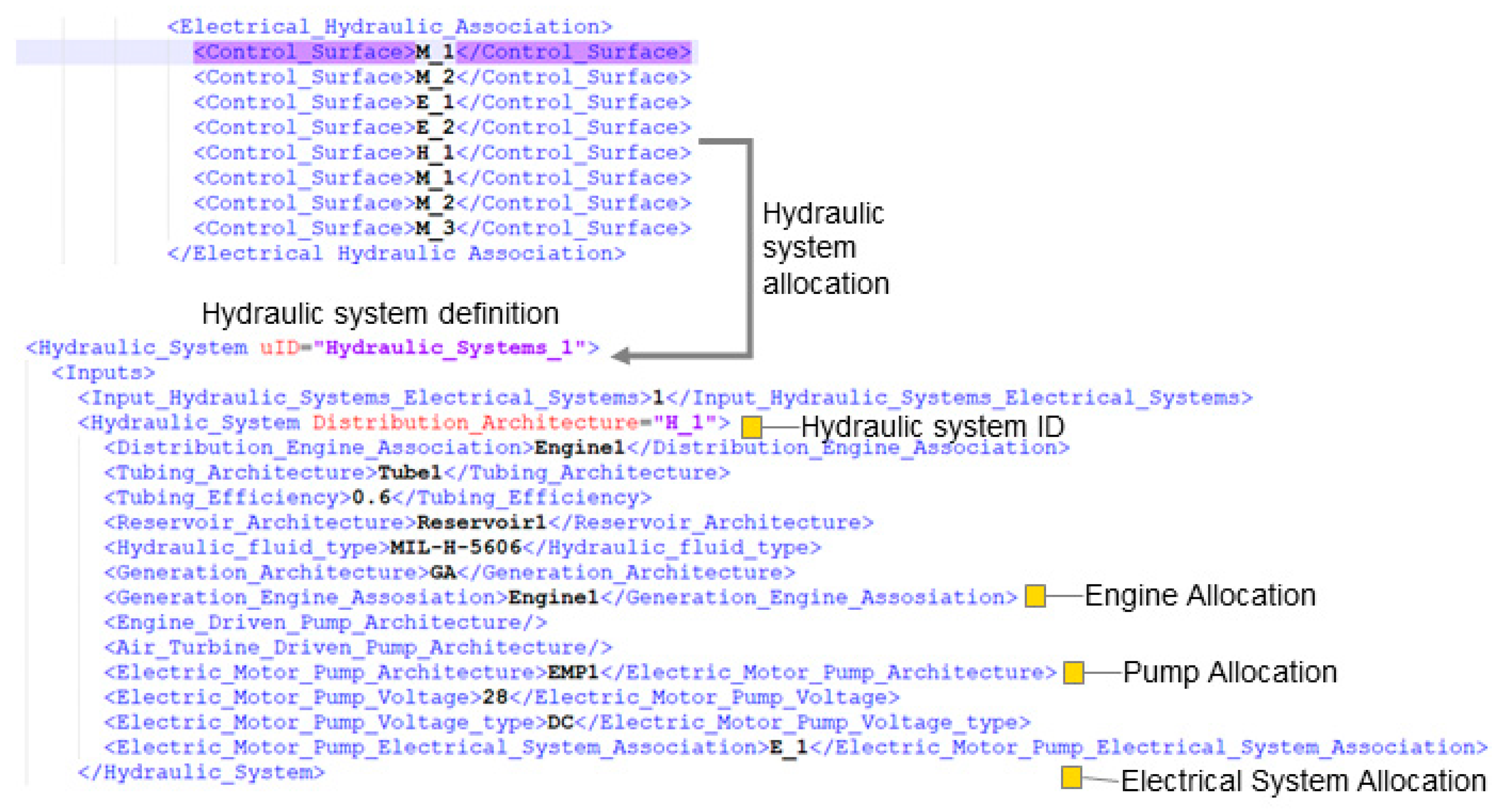

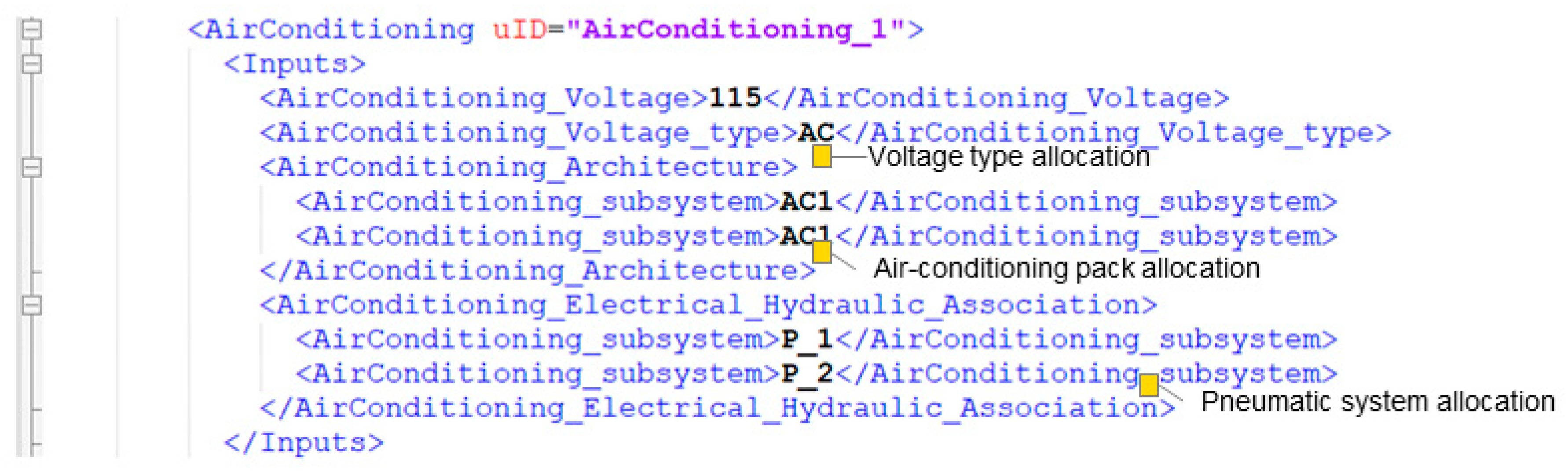

The Systems MDA module in the presented framework employs a modified CPACS-based descriptor. It stores aircraft-level parameters in a standard CPACS file, but captures system-level parameters and the systems architecture using custom tags defined within the tool-specific tag of CPACS.

The architecture descriptor in the Systems MDA can store information at multiple levels of granularity. For example, the allocation of control functions (e.g., roll) to control surfaces (e.g., aileron and spoiler) in the case of the aircraft flight control systems constitutes the high-level information that can be stored. More detailed architecture description, such as the instantiation of hydraulic and electrical power systems, encapsulates additional information, such as the allocated hydraulic pumps, electrical generators, tubing variants, and power converters. Furthermore, electrical, and hydraulic power systems can be allocated to specific consumers at the system and component levels. For example, an electrical system (further assigned to a particular power source such as an engine) can be configured to supply individual flight control actuators, environmental control system packs, and other subsystems such as landing gear braking. Electrical distribution voltage levels and power converters associated with each electrical system can also be specified using the descriptor.

Finally, the

Systems MDA descriptor is compatible with the graph-based architecture descriptor of Jeyaraj et al. (developed to allow further safety analyses), such that the information stored in the graph-based descriptor can be written directly into the

Systems MDA descriptor file. Further examples and illustrations of the

Systems MDA descriptor are shown in

Figure A1,

Figure A2,

Figure A3 and

Figure A4 in

Appendix A.

As the framework focuses on smaller hybrid-electric aircraft, the overall workflow also integrates modules such as

Aircraft Sizing, a geometric modeler (

Aircraft Geometry),

Energy Storage,

Fuel System, and

Systems MDA. Among these subsystems,

Fuel System undergoes significant variations due to hybridization. The level of hybridization will lead to the aircraft fuel system needing less space or potentially accommodating different fuel types. Moreover, the propulsion system of the aircraft will need additional energy storage to fulfill the energy needs in the form of batteries. Therefore, separate tools have been developed for both types of systems [

42,

43]. In the workflow, it is proposed to include them independently as they drive the geometrical layout. Moreover, this implementation will enable future expansion to other technologies, such as hydrogen storage.

The framework is implemented using Python and RCE [

44], which enables integration between the different tools. The interface between the tools uses the CPACS standard, which allows for easy integration with other tools in collaborative workflows, such as those in the AGILE 4.0 project.

The systems integration process begins with the initial convergence of the aircraft design loop. Initial estimates on parameters, such as geometry and energy storage sizing, are available as outputs. The initial aircraft geometry parameters are provided as input to the aircraft design module as the current workflow focuses on redesigning an existing commuter aircraft.

The

Aircraft Sizing tool developed by Licheva and Liscouët-Hanke [

45] is used to size the hybrid-electric aircraft used in this case study. The tool covers conventional, hybrid-electric, and all-electric propulsion configurations. The conventional aircraft sizing process estimates the initial mass of the aircraft, followed by an estimation of the power plant and wing characteristics according to individual flight phases. An overall mission-level analysis is carried out to converge the aircraft’s maximum takeoff weight (MTOW). The

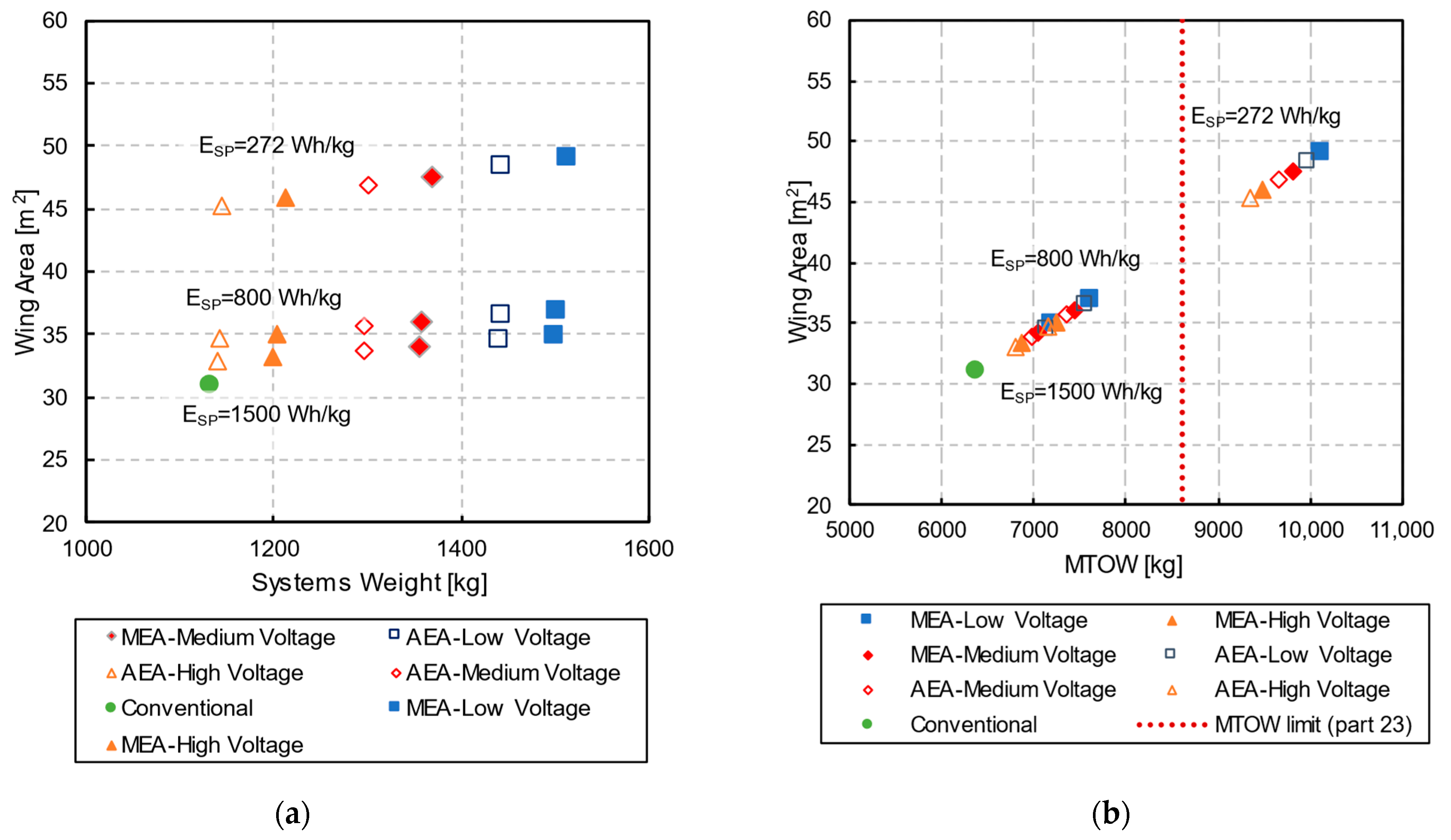

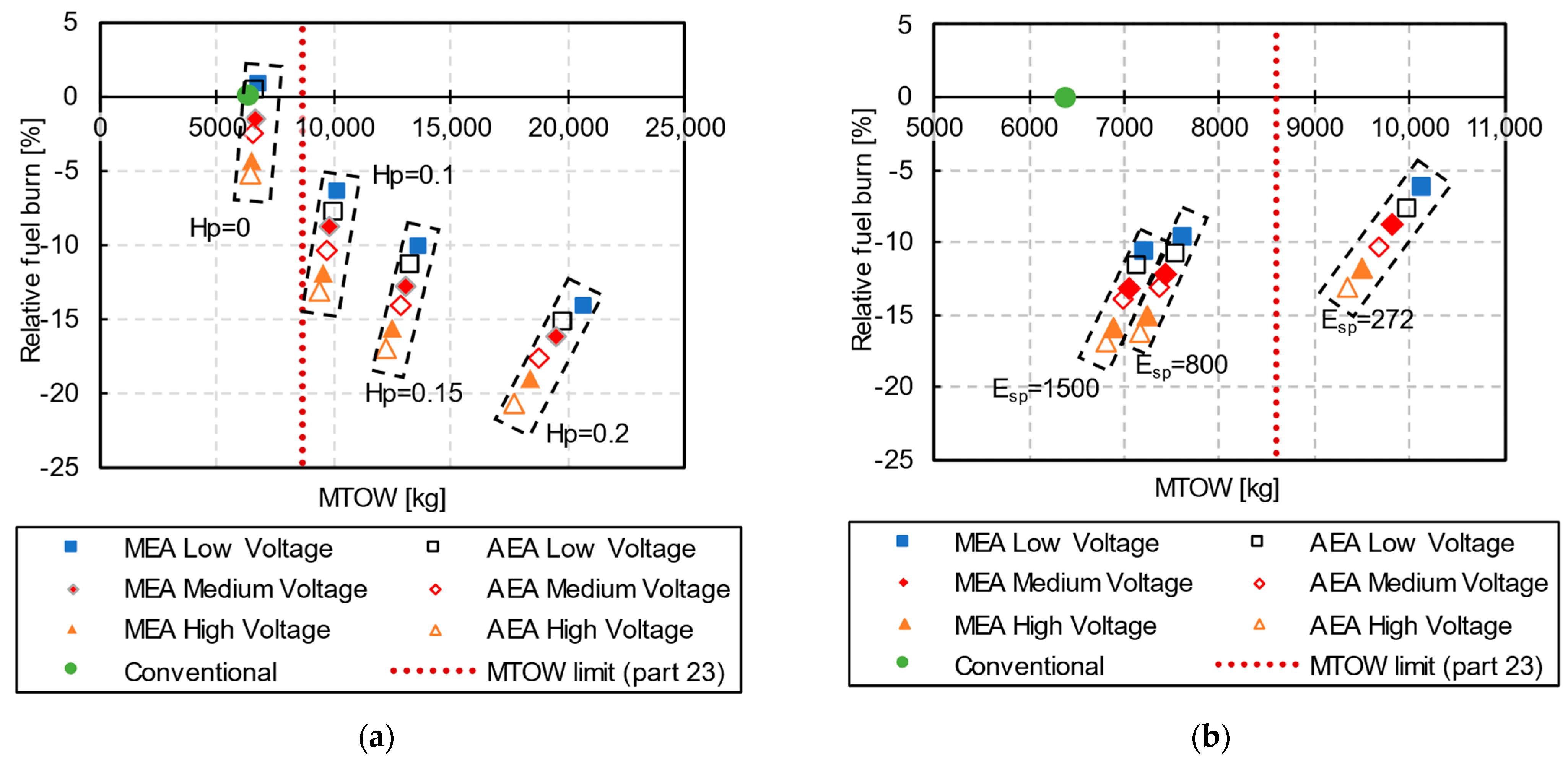

Aircraft Sizing tool uses the top-level aircraft sizing parameters and design of experiment (DOE) parameters such as hybridization of power (H

p) and specific battery energy density (E

SP) to generate initial estimates of aircraft geometry and battery weight, thereby converging the MTOW and the required wing area. Powertrain electronics are not modeled, and a simplified propulsion system model based on individual component efficiencies is employed. Additional outputs, such as space constraints and assignments for batteries and fuel tanks, are available after the analysis. An initial estimate of the system’s weight and required power is also available as an output of the

Aircraft Sizing tool. The drag penalty stemming from the systems will be integrated into a future version of the tool.

The

Energy Storage tool developed by Heit and Liscouët-Hanke [

43] is used to size the battery used in the case study. This tool uses overall energy and power requirements from the initial

Aircraft Sizing to estimate the size of the battery required to fulfill the aircraft requirement. The tool estimates the required space based on the aircraft design output parameters and the initial space assignment by the geometric modeler. The battery tool considers the conventional cuboidal packing method of cells with dimensional constraints.

Since the current workflow only supports cuboid battery shapes, we assume that the battery is placed in the center wing box for simplicity. Battery placement in wing tip locations might be interesting from a wing-loading perspective, but making assessments of this requires more capable battery layout tools to capture the physical limitations of such configurations realistically.

The output of the

Energy Storage module is fed to the

Fuel System sizing module developed by Rodriguez and Liscouët-Hanke [

42]. The

Fuel System considered within the workflow consists of all the subsystems that store and transfer the fuel required for a conventional propulsion system. The updated outputs from the aircraft geometric modeler are available as inputs to the

Fuel System. These inputs, along with top-level aircraft parameters and system architecture, are used to estimate engine feed subsystems, fuel quantity indicators, and venting subsystems. The overall integration at the system level allows us to estimate the total power and weight outputs. The finalized

Fuel System weight and the aircraft geometric outputs are inputs to the

Systems MDA module. Moreover, the

Fuel System weight and power required are merged with the outputs of the

Systems MDA module.

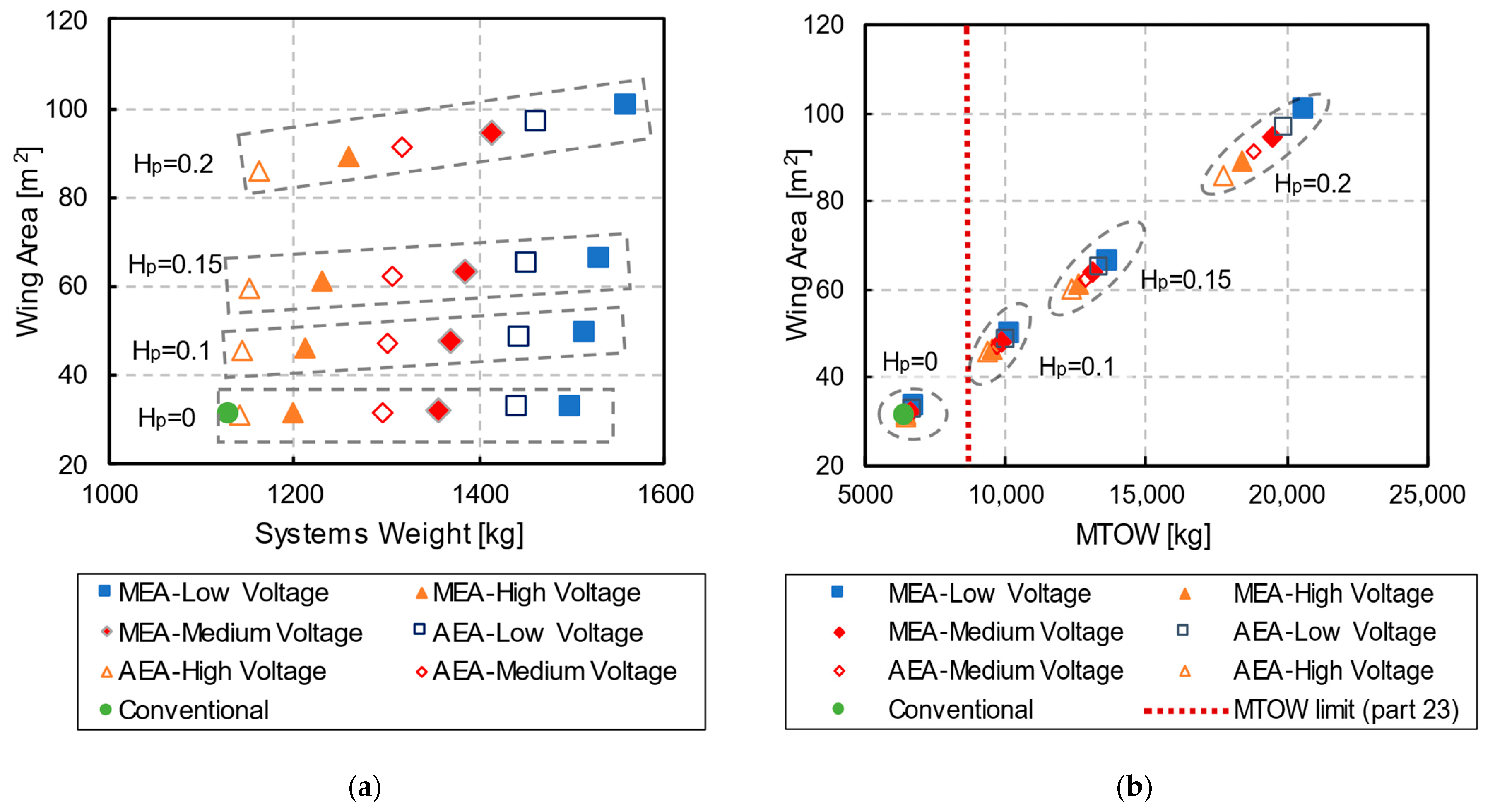

The final weight outputs from the

Energy Storage and

Systems MDA module are used to estimate overall weight change

and

. In the

Converger module, the variations from the subsystems are fed back into the

Aircraft Sizing module to update aircraft design parameters,

and

, and these updated parameters can be used to resize the aircraft. However, in the presented case study, the

Converger module only updates the wing area to compensate for the increased MTOW. This study uses a simplified resizing of the aircraft, focusing only on calculating the wing area required to carry additional weight due to the systems in order to demonstrate the capabilities of the integration framework. Additionally, the

DOE module is used for parametric analysis, as presented in the case study (

Section 4).

3.2. Systems MDA: Aircraft Systems Sizing Estimation Tool (ASSET) for Commuter and Regional Aircraft

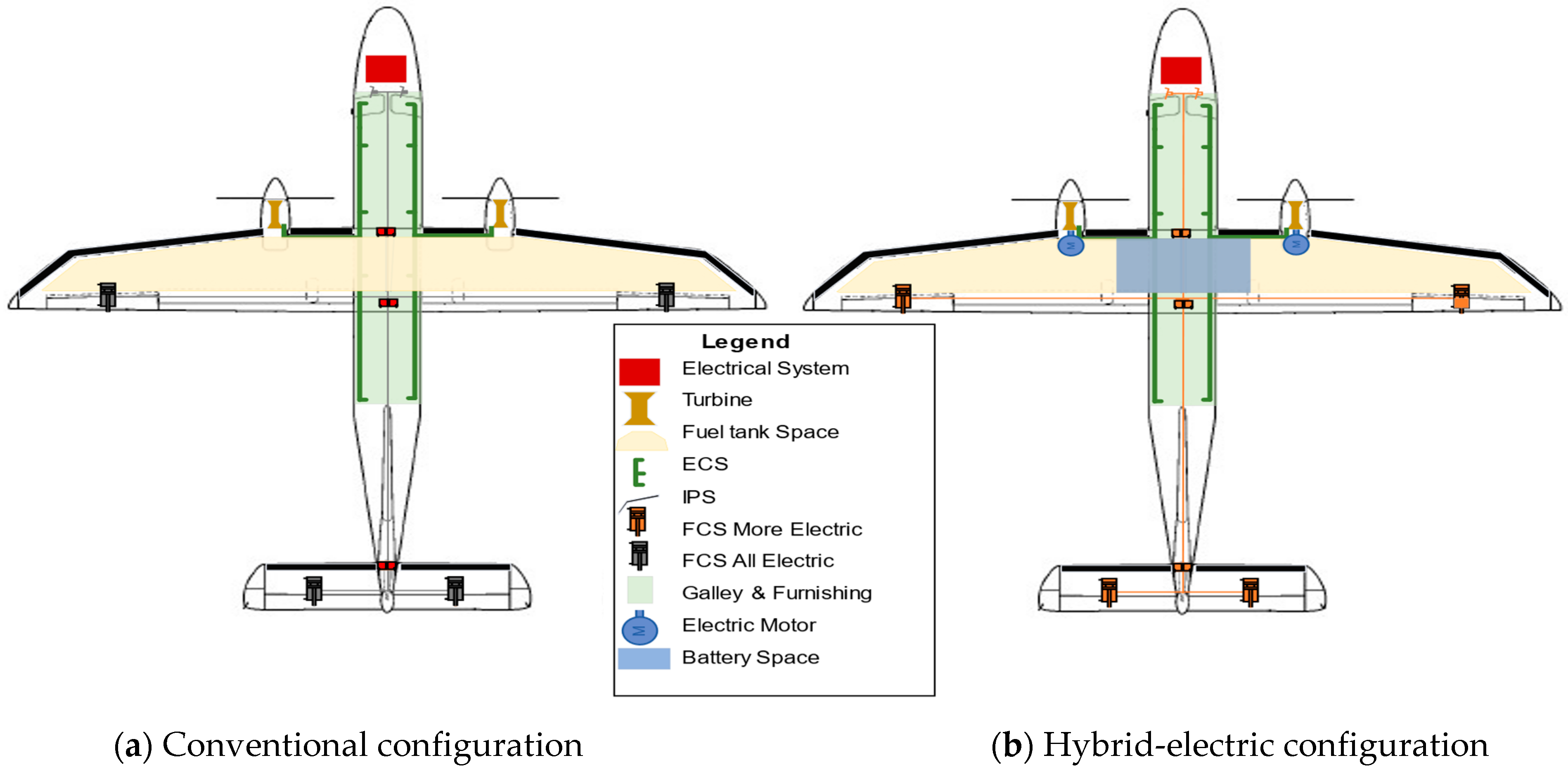

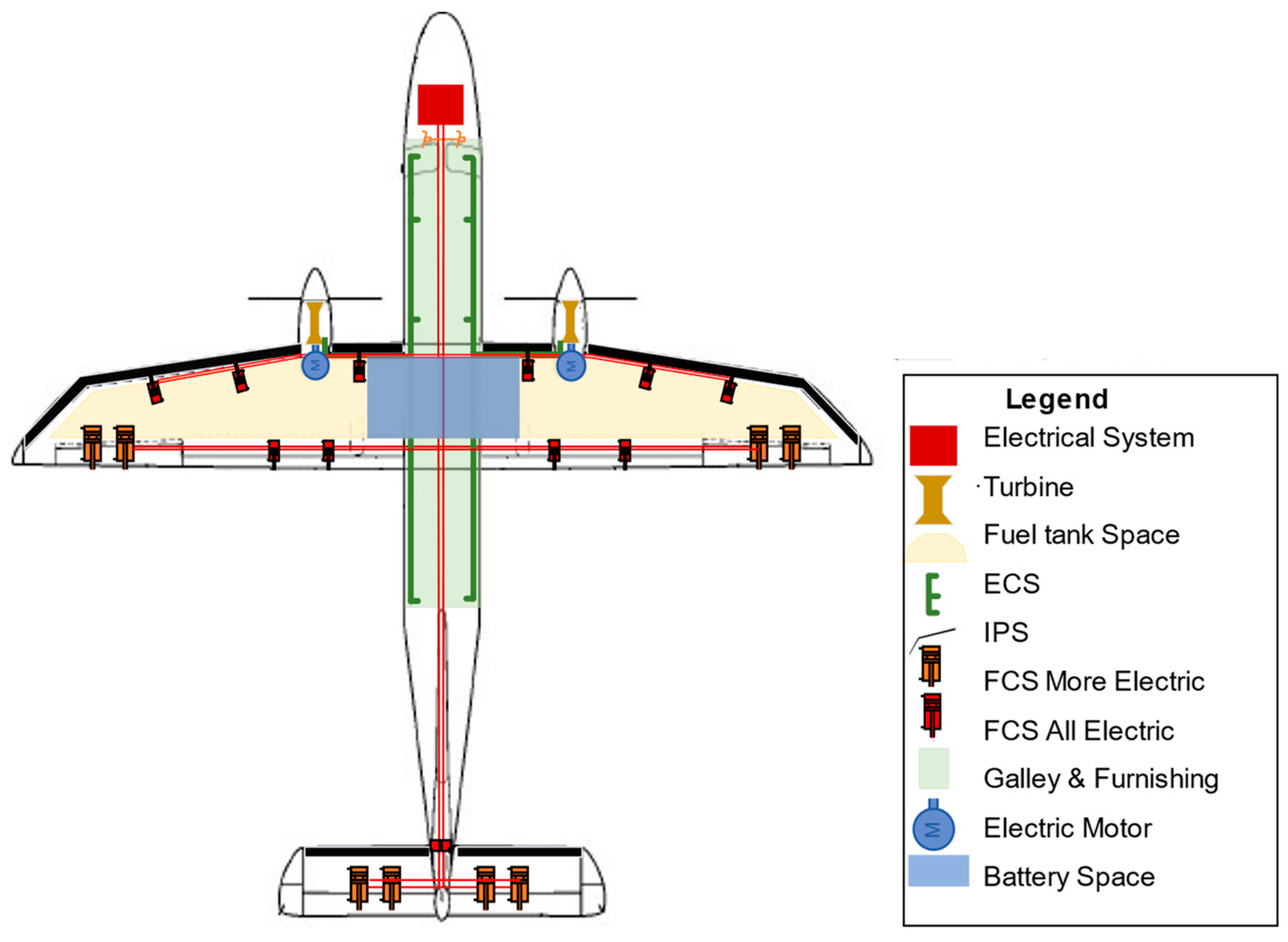

Aircraft systems sizing within the framework is structured in three types of subsystem categories, as proposed by [

17]. These are power-consuming systems, power transformation and distribution systems, and power generation systems. This categorization based on the functions and power flow patterns eases the sizing relationship between the subsystems.

Table 1 presents the considered subsystems and an overview of the associated modeling assumptions.

The framework is built to easily adapt and include additional subsystems (e.g., a pneumatic or fuel cell power system). However, this paper’s scope is restricted to demonstrating the integration and trade study capability of a subset of these subsystems: the flight control system, the hydraulic power system, and the electrical power systems.

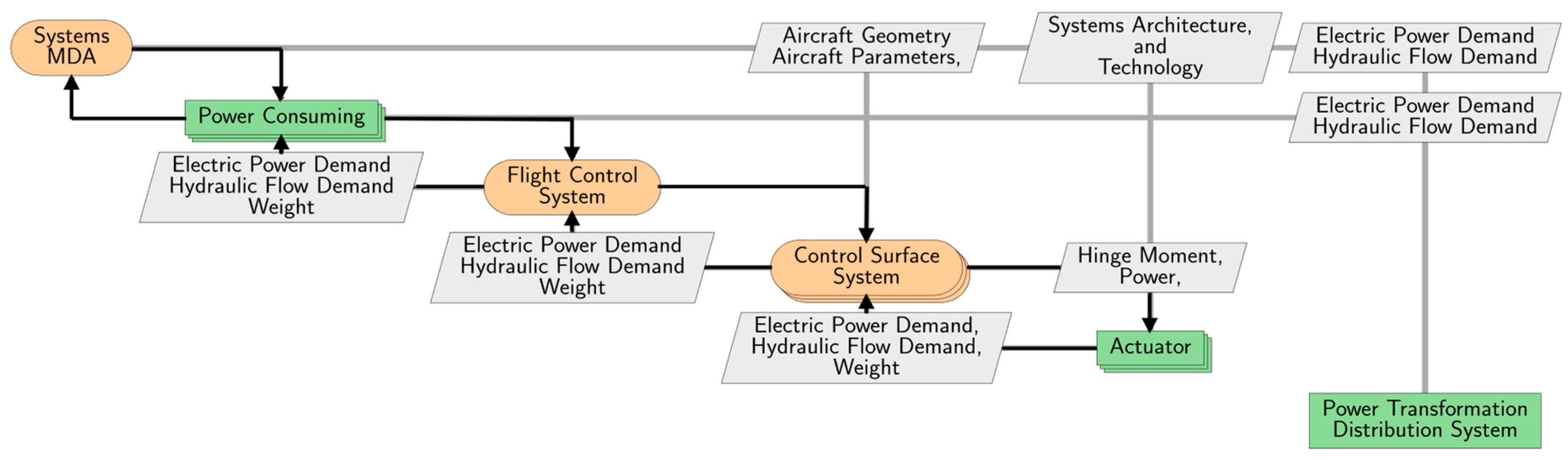

The framework implements a fully nested systems analysis in order to size the systems at each level, as depicted in

Figure 2. The aircraft level parameters, geometric parameters, and system architecture inputs are used to initialize the sizing process. The outputs of the power-consuming system module are used to size the

Power Transformation and Distribution System. The

Power Generation System and

Energy Storage module sizes the stored energy necessary to operate secondary power systems (e.g., the emergency battery in the electrical power system or the battery for starting the APU) and should not be confused with the propulsive power energy storage sizing (propulsion battery in this case). The

Systems MDA module can size the electrical power generation based on the total required power from various subsystems, including energy storage and novel power generation systems.

The following subsections explain a chosen set of subsystems and their sizing principles in more detail. We only describe the submodules that are examined in more detail in the case study.

3.2.1. Flight Control System

The flight control system (FCS) considered within the framework corresponds to all systems and subsystems responsible for the actuation of the control surface except for the flight control computer (FCC), which is responsible for signaling the actuators and is considered within avionics systems. The overview of this module is depicted in

Figure 3.

The inputs to the module are system architecture, aircraft-level parameters, and wing characteristics defined by the aircraft design. The aircraft-level parameters are the control surface descriptions and their corresponding locations. The systems architecture corresponds to the subsystem architecture as included in the architecture descriptor. The wing area characteristics correspond to the updated wing area parameter within the output of aircraft design.

The control surface parameters are used to estimate the hinge moment of the control surface. The framework evaluates the hinge moment by using two methods depending on the wing definition. The DATCOM (data compendium) method [

46] is used when the wing has a symmetrical airfoil. The method developed by Anderson et al. [

47] is used for non-symmetric or supercritical airfoils. The comparatively simpler Anderson method can easily be adapted with additional factors for application to unconventional airfoils. However, the hinge moment is an important interface parameter between the control surface and actuation sizing and requires that additional physics-based research be conducted to improve accuracy.

The FCS module is capable of analyzing several actuation technologies, such as mechanical actuation, hydro-mechanical actuation (HMA), electro-hydraulic servo-actuation (EHSA), more electric actuators, such as electro-hydrostatic actuators (EHA), and all-electric type actuation, like electro-mechanical actuators (EMA). Mechanical linkages are supported as smaller aircraft typically use this form of flight control actuation. The power drive unit (PDU) is considered for the flaps and slats. Hydraulic system pressure is used as a global parameter for hydraulic actuation. Electric actuation can be modeled with discrete AC or DC voltage levels such as 28, 115, 230, and 270 V. The limitation occurs due to the limited data availability for power transformation and distribution systems.

The power demand of the flight control system is estimated bottom-up from the individual actuators. To do so, the tool estimates the maximum power demand

from the hinge moment

and the deflection rate of the control surface

(

) using Equation (1).

Typically, only the maximum values and are available in a conceptual design. Therefore, Equation (1) includes a correction factor . In a conservative approach, the correction factor can be 1; however, if the conceptual designer has some experience, different factors can be applied to different actuators to reflect the variations better.

For simplicity, it is assumed that each actuator on the control surface can support the maximum load of the control surface. The power demand of the actuator per flight phase is then estimated as a ratio adapted based on the maximum power for each flight phase. Typical values for the case study are presented in

Table A3 in

Appendix B.

Even with a more electric and hybrid-electric architecture, smaller aircraft can potentially still completely contain mechanical surface actuation (due to low hinge moments for low-speed operation or small control surfaces). Therefore, the presented framework includes the weight estimation of a mechanical push–pull rod actuation. This is adapted from the method presented by Torenbeek [

13], which uses the MTOW as the main parameter in the empirical weight estimation. Here, the authors modified it to use the control surface area

in (

) as input. The resulting equations for the various control surfaces are presented in

Table 2.

As an additional feature, mechanical backup linkages can also be assigned to the hydraulic actuation with mechanical signaling based on information presented in SAE ARP5770 [

48]. Based on this standard, the primary flight control mechanical linkage cannot be less than 1/8 in; this allows for a reduction in linkage weight of about 12% when the application is limited to signaling. This is further applied to the Torenbeek estimation method if the mechanical linkage is assigned for signaling.

The weight estimation of conventional HMA and EHSA actuators is implemented using power-to-weight ratios (P/W) drawn from the literature, which are provided in

Table A4 of

Appendix B. The EHA and EMA actuators require additional power electronics components; their weight is accounted for using their specific P/W

As the power demand of the actuators is not constant throughout the flight, the power demand per flight phase is calculated using a factor that is multiplied by the maximum power demand calculated in Equation (1).

Hydraulic and electrical actuation is modeled based on an object-oriented approach where each subsystem corresponds to an object. Each object is identified as an electric or hydraulic subsystem based on system-level architecture inputs. This can also be assigned to a specific power transformation and distribution system. The methodology of systems allocation is similar to the methods presented in [

18]. The following sub-section will explain the subsequent sizing of the hydraulic and electric power systems.

3.2.2. Hydraulic Power System

The hydraulic system within the framework considers all the systems and subsystems responsible for generating and distributing hydraulic power within the aircraft, unless there is a localized standalone hydraulic system (as is the case with EHA implementations). The method follows the logic tree presented by Liscouët-Hanke [

17]. The framework considers distribution, conversion, and generation subsystems. The distribution consists of hydraulic fluid, tubing, and reservoir assembly. All the power-consuming systems which request hydraulic flow demand are assigned to a specific distribution system. The specific distribution system is then assigned to a specific generation system. This implementation will ease the future integration of automated safety assessment, as presented in Jeyaraj and Liscouët-Hanke [

10].

For hydraulic actuators, the power per actuator calculated in Equation (1) is translated into a hydraulic flow requirement using Equation (2)

where

is the flow demand,

is the efficiency of the actuator, and

is the pressure rating of hydraulic system (typically 3000 or 5000 psi or the associated values in SI units).

The net flow demand for a hydraulic system corresponds to the total flow demand made by the connected subsystems within power-consuming systems:

where

is the hydraulic system flow demand associated with a particular central hydraulic system

i, and

is the flow demand of the consuming systems connected to this hydraulic system

i. The system architecture descriptor performs the association between consumer systems (on the actuator level) with the different hydraulic systems. The number of hydraulic systems varies depending on the overall system architecture (typically between 0 and 3).

As a next step, the hydraulic pumps associated with the hydraulic systems are sized accordingly. The model contains the following pump types: engine-driven pumps (EDP), electric motor pumps (EMP), (rarely used) air turbine-driven pumps (ATDP), power transfer units (PTU), and emergency pumps associated with the ram air turbine (RAT).

The of the individual hydraulic system is supplied by the associated hydraulic pumps, typically one EDP and one EMP, in conventional aircraft. For more than one EDP, , where is the number of EDP available within the hydraulic system.

If the EMP if set as a backup, it only compensates the flow when the engines are at idle, according to the SAE ARP6277 [

49]; this corresponds to

0.16

. However, if the EMP is not a backup, then

is equal to

. It should be noted that the

power can be set based on the architecture of the hydraulic system.

One of the major assumptions considered within hydraulic system sizing is the type and number of pumps associated with each hydraulic system and the power split between these pumps. This implementation enables system safety assessment integration within the system architecting process. However, this paper focuses on a simple example to illustrate the sizing capability for a set of given architectures.

For example, for sizing the EDPs, Equation (4) can be used, where

is the adjusted available flowrate considering the engine operation with respect to the flight phase and

is the associated shaft speed percentage of the engine, and the EDP efficiency

:

Once the EDP is sized, the engine shaft power off-take can be estimated.

For EMPs, the required flow demand must be translated into electrical power demand, which impacts the sizing of the electrical power systems, discussed in the following subsection. All efficiency and power-to-weight ratio assumptions for the weight estimation of the pumps are provided in

Table A4 of

Appendix B.

The net shaft power requirement due to the EDP can be calculated as follows:

where

is the engine shaft power requirement and

is the gear box efficiency. For simplicity, sizing assumes

to be the maximum pressure rating of the system.

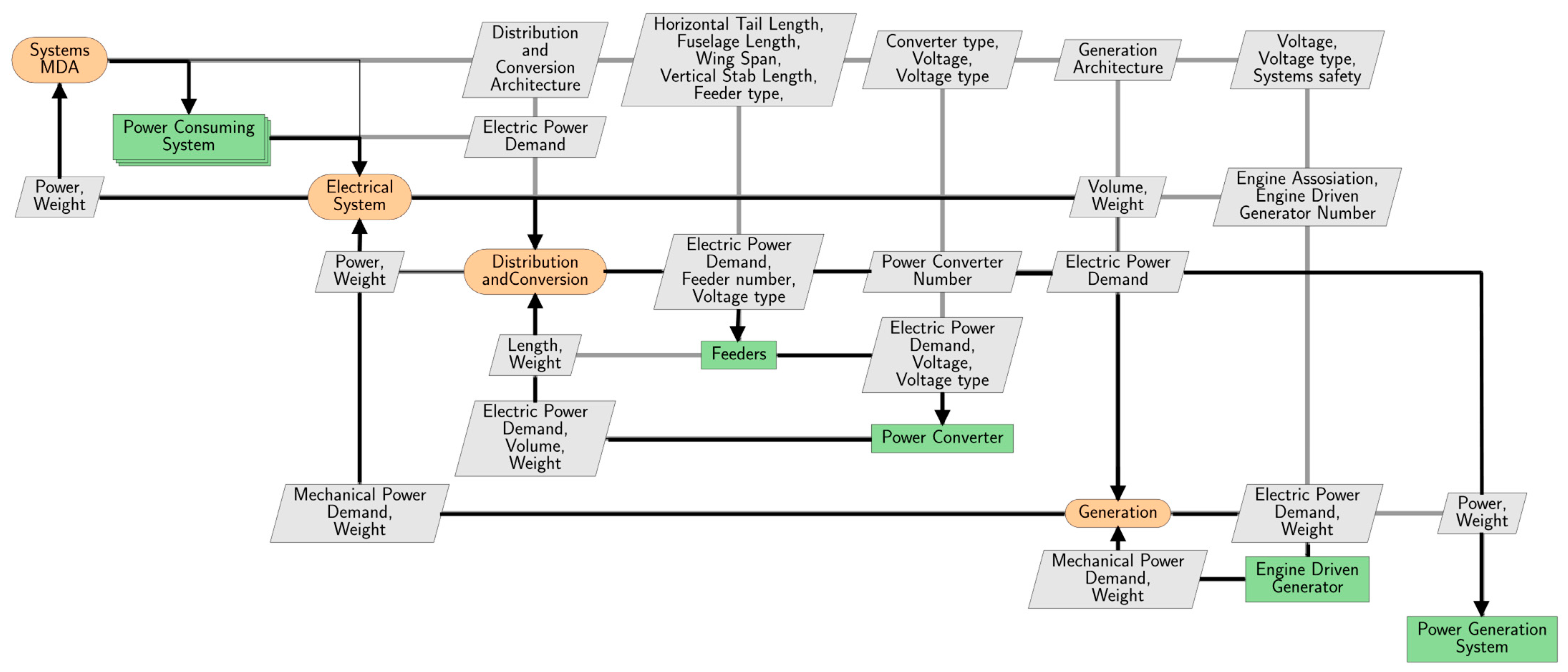

3.2.3. Electrical Power System

The electrical system within the framework corresponds to all the systems and subsystems responsible for generating, converting, and distributing electrical power supply, as shown in

Figure 4.

The overall structure of the electrical system sizing methodology is based on the approach developed by Liscouët-Hanke. However, more detail is added to the distribution and conversion system, which consists of feeders and power converters. Alternating current (AC) feeders and direct current (DC) feeders are modeled with multiple voltage assignments in order to estimate the entire load on the feeder based on consumer assignments.

Researchers have developed a more detailed wiring weight estimation method as determining wiring weight is essential, particularly for more electric aircraft. The method is based on using the SAE AIR6540 [

50] to estimate the feeder weight, giving consideration to voltage variations. Parameters such as bundle loading and altitude factors are used to account for the wiring losses. Additionally, phase lagging is considered through the power factor for AC. The SAE AS50881 [

51] is used to model different sizes of feeders. Aircraft level parameters are used to add feeder length. This is performed based on the location of the electrical power consumer. Furthermore, this approach considers the wires to have a modified PFA (Perfluoroalkoxy) insulation which is rated up to 1000 volts.

The workflow accounts for the feeders of power-consuming and generation systems. These feeders are responsible for providing power from the power generation system (such as engines or APUs) to the power transformation and distribution system (i.e., electric generators or EMPs). The basic consideration given for the length estimation is the actual location of the generator within the engine from which the wiring starts.

where

is the wiring length from the engine to the engine attachment with the wing or fuselage;

and

are the coordinates of the generator. If the location of the generator is unknown,

can be assumed to be the sum of half the diameter and half the length of the engine. This is applicable to any type of engine attachment, including blended wing body aircraft configurations with embedded engines.

To represent the wiring length from the generation to the distribution conversion

, the subsystem location factor

is introduced, which is the ratio of the distance between generation and conversion to the fuselage length. The wiring length can be calculated according to Equation (7) as a function of the fuselage length

:

For subsystems such as APU, which is traditionally placed at the aft fuselage, .9 can be used. For fuselage, mounted engine 0.8 can be used for simplicity. If the battery is placed near the power conversion system, a value of 0 is used to eliminate the length. The maximum value of 1 is applicable to a tail-mounted engine configuration with an electrical subsystem placed in the front fuselage. For a wing-mounted engine configuration, a value of 0.5 can be used for simplicity. Additionally, the subsystems placed within the wing need to consider the length of wiring in the wing.

For low-wing configurations, the length of wiring is:

where

is the distance of the engine from the aircraft center axis along the

y axis, and

is the wing sweep angle,

For high-wing configurations, one needs to account for additional wiring in the fuselage, considering the fuselage diameter

:

For the consumer wiring, it is assumed that the feeders power several subsystems along the fuselage, leading to the accumulation of the power demand, which is fulfilled by the power conversion system. Hence, except for the flight control system, the wiring is assumed to run across the fuselage. The critical parameters for the flight control system are the electric subsystem in the wings and tail section, which triggers the wiring length extension to the subsystem location. Equation (7) can be adapted to estimate the length of consumer wiring. However, the parameter will need to consider the maximum distance between connected subsystems. For the consumer system within the wing, Equations (8) and (9) can be adapted to replace with connected to the feeder within the wing.

The aircraft can use AC and DC types of generation systems. The DC system consists of a two-wire setup, and the three-phase AC uses a three-wire setup. The DC system benefits from using the airframe as a ground return carried by one of the wires. This kind of architecture is modeled by halving the length of the wires. The high voltage return line considerations must meet the certification requirements due to electromagnetic interference and safety hazards. Additionally, composite structures pose a high resistance to the return line, requiring detailed study to enable ground return capability. These cases must consider a dedicated return line for the aircraft systems wiring.

where

is the wiring length when the ground return is possible, typically in a ‘DC’ system measured in

.

The net electric power demand on the distribution system is estimated by considering the voltage drop across the length of the wiring.

where

is the effective voltage estimated in

,

is the voltage drop across the wiring length in

,

is the bundle loading factor, and

is the altitude derating factor. The

and

as functions of wire resistance across the length are estimated based on [

50]. A wire resistance correction factor is applied for AC feeders to account for skin effects due to high frequency. The SAE method for AC wires is valid until 1 kHz. Additionally, frequency is also used to estimate AC inductance, which is then used to update the voltage drop. The current case study assumes a 400 Hz frequency for AC wiring. For simplicity, the bundle loading is considered to be 100%, and the single wire resistance is considered to be 62 ohms/1000 ft as per recommendations from [

50]. With the known effective current

, one can use the lookup table provided in SAE AS50881 [

51] to shortlist the required wire size. The lookup table consists of a wire gauge (AWG) and the specific weight. The power on the feeders can be estimated as follows:

The power converter options in the model consist of AC/AC, AC/DC, DC/AC, and DC/DC converter types, with voltage levels of 28, 115, 270, and 230 V. The values are limited due to the data availability of power converters for aerospace applications. The sizing of the power converters is based on overall power consumption. The power converter weight variations for electric aircraft can be found in [

52,

53]. The AC/AC type of power converter is one of the heaviest subsystems since it consists of several components, adding to the P/W ratio [

54,

55]. The DC/DC converter consists of fewer components and is lighter. The power converter improvement in power density of over 5 kW is considered using the consumer load on the power converters. The generation and distribution systems are linked with power converters within the electrical system framework. This means that all the feeders must be interfaced with power converters.

The electrical power generation system consists of AC or DC generators (according to the overall electrical system architecture) and can contain additional elements, such as a hydraulic motor generator with voltage levels similar to those of power converters. The sizing of the generation system is based on the minimal safety considerations as given in [

17], considering three scenarios: normal operation, single-engine failure, and a combined failure (conditions of the single-engine being off and opposite generator being off). Additionally, safety conditions will be considered upon integration with the ASSESS tool developed by Jeyaraj et al. [

13]. The sizing considers the power demand of all associated consumers (implemented in a dedicated model in the framework) per flight phase and for normal and degraded operation, selecting the maximum power as the generator sizing point. The generators’ power extraction can be translated into the mechanical power demand from the engine.

The net power demand by the electrical generators is translated into the engine’s secondary power shaft in terms of mechanical power demand.

where

is the shaft power demand of electrical generators,

is the secondary power gearbox efficiency, and

is the power demand of the electrical generator.

3.2.4. Electrical Power Consumer Systems

The electrical power consumers consist of subsystems that depend on electrical power for their functionality. These include galley, entertainment, furnishing, lights, avionics, instruments, electrically driven hydraulic pumps, air-conditioning fans, and fuel pumps. In a more-electric aircraft, additional and significantly higher electrical loads consist of the air-conditioning system, ice protection system, and any electrical actuation (e.g., landing gear and flight controls).

Categorizing AC and DC power consumers depends on specific requests by the subsystems. Voltage and voltage type-based decomposition is also generated to assign feeders to the subsystem and the electrical generation. As discussed earlier, the voltage levels are limited by the data availability of power converters.

Table A1 in

Appendix B presents a summary of the electrical power consumers’ equations.

In conventional aircraft, the galley, entertainment, and furnishing are the most significant power consumers within the aircraft systems. These are operated as per the aircraft configuration and passenger demands. However, these loads can be shed during emergency conditions when considered non-essential (this might differ for business aircraft operations). The electric power demand estimation of the galley, entertainment, and furnishing subsystems in this paper is adapted from the methodology established by Esdras and Liscouët-Hanke [

56]. The nominal electric power demand for these systems

is defined in Equation (15) as a function of the fuselage length

, fuselage width

, and the number of engines

.

The nominal power demand,

must be multiplied by the empirical usage factors provided in

Appendix B,

Table A7, to obtain the power demand per flight phase.

The galley, entertainment, and furnishing contribute significantly towards the aircraft’s overall weight. The method used by Anderson et al. [

47] has applications specifically to larger aircraft and overpredicts the weight of these systems for smaller commuter aircraft. This paper considers the weight build-up of the subsystems based on the number of passengers, the number of crew, and cabin volume. Smaller aircraft, such as Dash 6 or Cessna aircraft, typically have front and aft baggage compartments and different cabin layouts are enabled by trading passenger seats with baggage area. Therefore, the method presented here considers the front and aft baggage volume along with the cabin volume in order to estimate the net weight of the galley, entertainment, and furnishing subsystems. The weight of the galley, entertainment, and furnishing subsystem

(

) can be estimated using Equation (14), with

as the number of crew members,

as the number of passengers, and

as the cabin volume in

and the factor

:

where

depends on the size of the aircraft:

for commercial aircraft with

for business jet and commuter aircraft

for smaller aircraft

Although the above equations can also be used to estimate for commercial aircraft, the current study focuses more on smaller aircraft; therefore, detailed validation was only performed for aircraft up to the size of an Airbus A320. It has to be noted that, depending on the equipment level for the various flight operations, larger variations can occur for galley weight. However, the presented method is suitable for comparing different power system architectures for the same baseline aircraft.

The net shaft power demand can be estimated from Equations (5) and (14) as follows:

where

is the net engine shaft power.

Systems MDA estimates net mission fuel consumption due to systems as per SAE AIR1168/8 [

57,

58]. The total fuel consumption is due to the fixed systems weight component itself, shaft power demand, bleed air component, ram air component and variable weight penalty, which corresponds to expandable material.

Scholz [

59] provides a methodology with which to estimate the specific fuel consumption due to systems (SFC

p). According to Scholz, a shaft power factor (k

p) translates SFC into SFC

p. As per the turboprop engine used on the DO-228, and data availability [

59], a k

p value of 0.00404 is assumed in the current workflow for the fuel weight estimation. The Federal Aviation Regulation (FAR) Part 23.831 and Part 25.831 set the bleed air requirement as 0.55 lb/min/pax. This is translated into the bleed air requirement for conventional configurations. MEA and AEA configurations without engine bleed off-takes have dedicated ram air inlets, and the bleed air requirements are translated into ram air requirements.