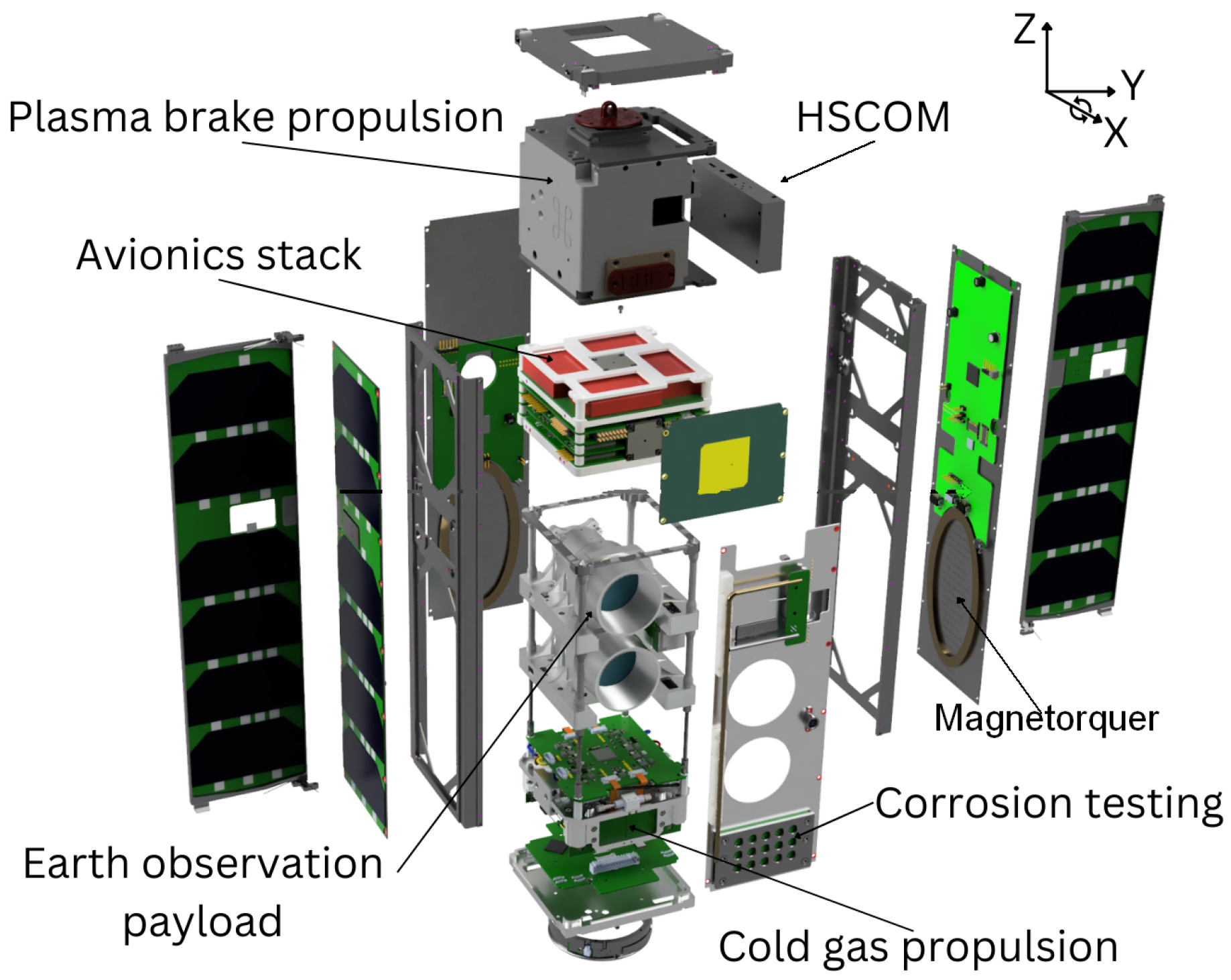

The ESTCube-2 was designed taking inspiration from the three-unit (3U) CubeSat standard but adapted to fit in a larger deployer, for example, using the “Maximum Advised Dimensions Applicable for ISIS satellite dispenser systems” for ISISpace ISIPOD and QuadPack deployers [

43]. The main design driver for the ESTCube-2 satellite was the IPB payload. To satisfy the high spin-rate deployment of the IPB tether, the satellite was developed from scratch, taking into account the lessons learned from ESTCube-1 mission [

8]. The satellite design development was split into three major parts: mechanical structure, avionics stack systems, and side panel systems. A detailed description of each structural block, the parameters of each system, and the development challenges were presented by Dalbins et al. [

18].

2.3.2. Avionics Stack Systems

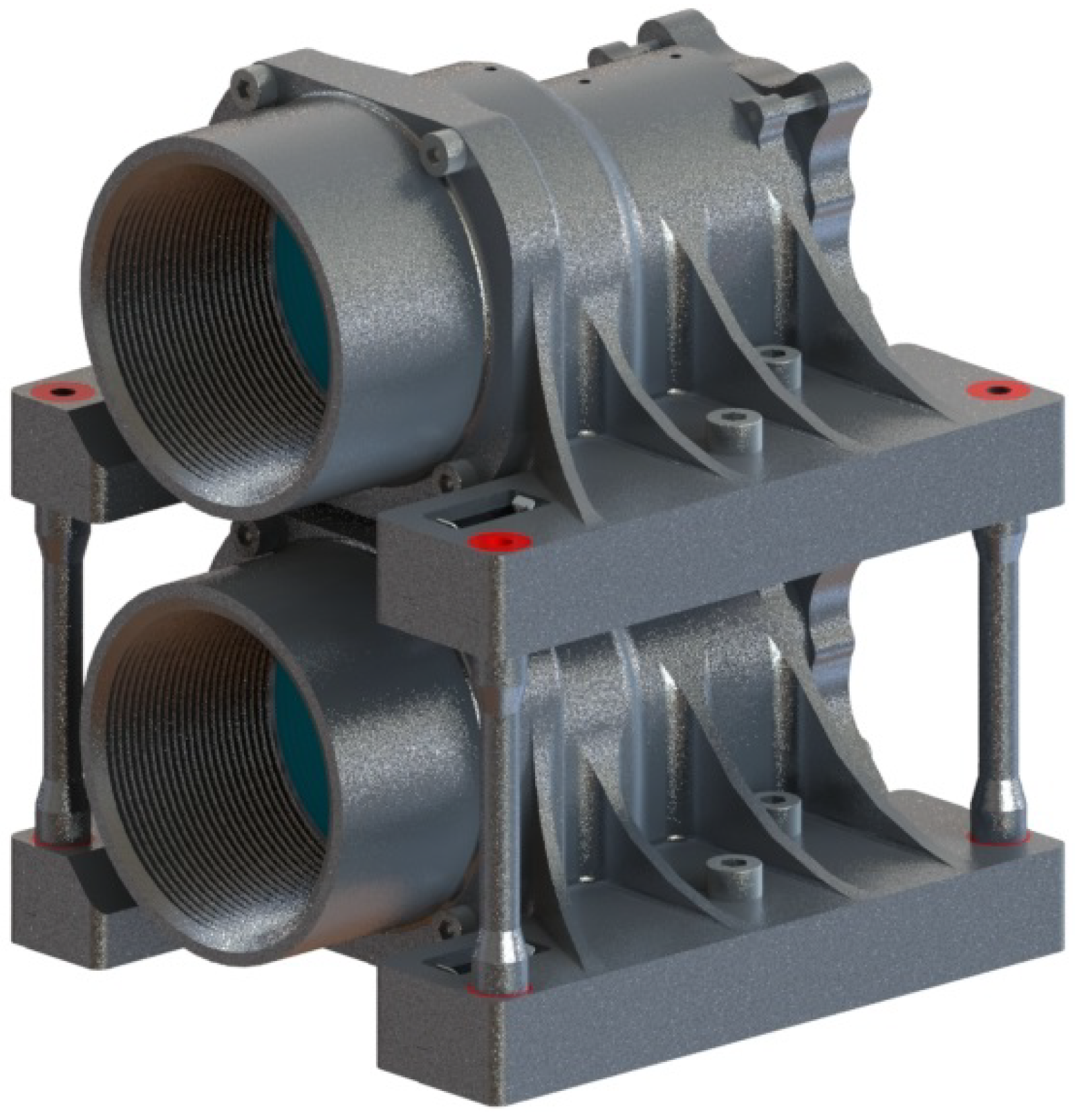

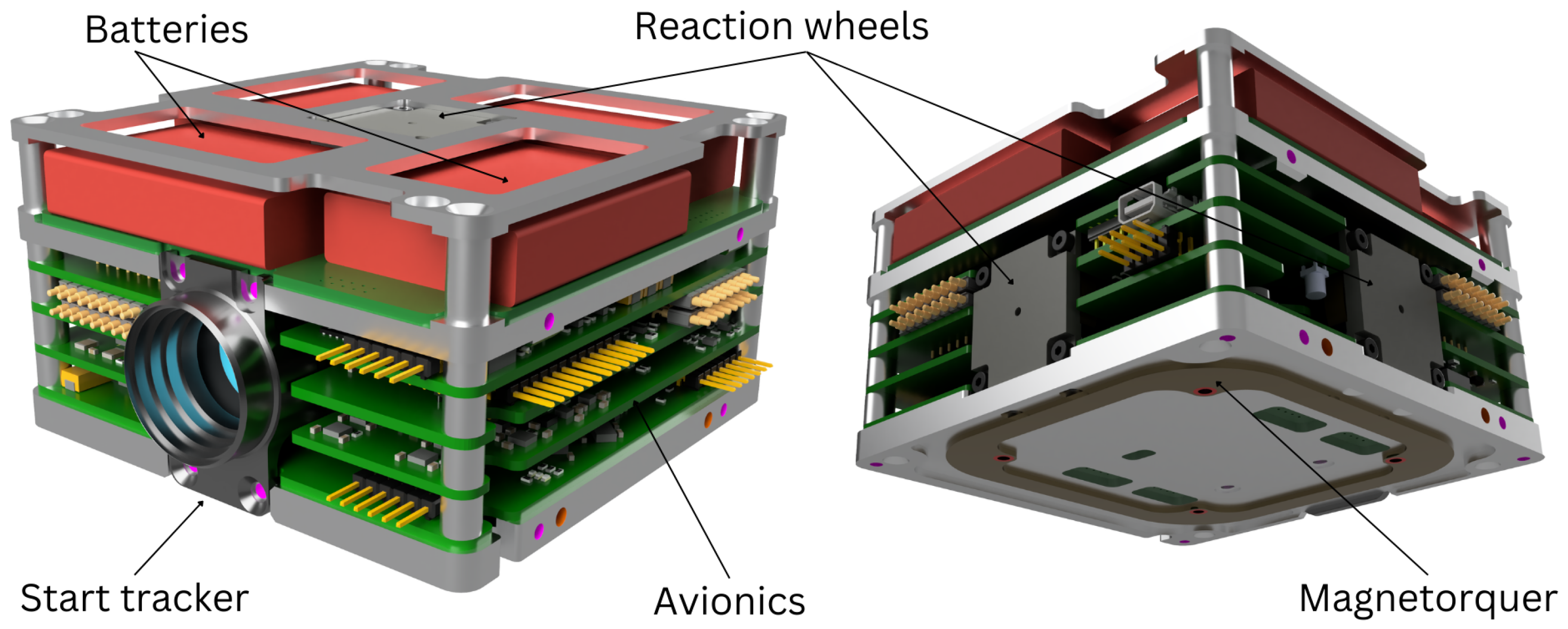

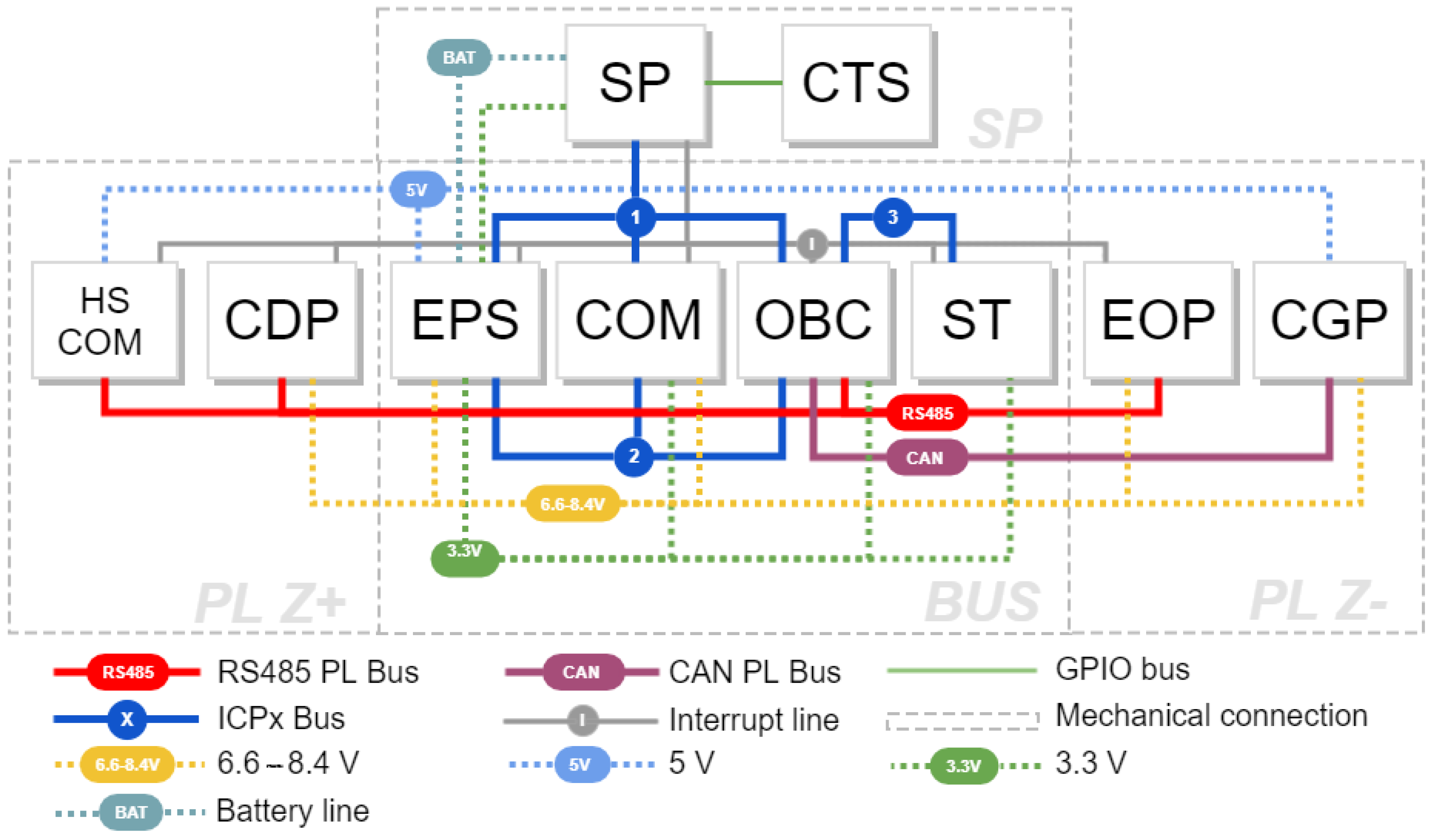

The avionics stack systems are the heart of the satellite. It consists of the onboard computer (OBC) system for task scheduling, data logging, and storage; the electrical power system (EPS) for energy storage and distribution; the communication system (COM) for telemetry and remote commands; the star tracker (ST); and the attitude and orbit control system (AOCS). The aforementioned systems are integrated into a 96 × 96 × 60 mm

volume (see

Figure 8 and

Figure 9). Each system is located on a different PCB and is implemented to use the allocated space in the satellite efficiently.

The electrical power system (EPS) is one of the most critical systems upon which the mission’s success depends greatly. The system ensures energy storage, voltage regulation, and power distribution on two boards.

The EPS battery management board controls and monitors the charging/discharging of the battery packs. The battery management PCB autonomously controls the charge and discharge currents depending on the voltage levels present. Temperature measurements of individual cells are performed to ensure the battery packs’ correct charge/discharge profile. The battery pack is configured in a 2s2p configuration and stores the energy generated by the solar arrays. Each series block of the pack consists of two commercial Panasonic 103,450 lithium-ion battery cells. Depending on the discharge state and temperature of the battery cells, this configuration ensures that the battery pack’s voltage ranges from ∼6.0 V to ∼8.4 V. Each series block is connected to the main power bus (MPB), an unregulated voltage rail supplied directly from the battery pack, and is responsible for the power path between the avionics stack and payloads.

The EPS main board is the core of the system. It incorporates hardware for an external Electrical Ground Support Equipment (EGSE) communication interface and uses a dedicated STMicroelectronics STM32L4 series microcontroller (MCU) to ensure power management functions. If required, it can override the autonomous control of the battery management board.

External analog-to-digital converters (ADCs) perform various voltage measurements for different current, voltage, and temperature level monitoring, which are stored on an external FRAM. Multiple avionics stack systems require a 3.3 V supply produced by two switching regulators. They operate in a hot-redundant configuration and convert floating MPB voltage with ∼90% conversion efficiency. A power switch for each avionics stack system provides power distribution functionality. The EPS MCU controls these switches and can sense over-current conditions that automatically trigger the off-state of the system.

Some satellite COTS systems cannot be powered from the MPB and require regulated voltage. Depending on the activity and current amplitude for a given voltage level, the MPB voltage is converted by switching or linear regulators. A switching regulator on the battery management PCB provides 5 V for the high-speed communication system (HSCOM). Two low-dropout regulators connected in parallel provide 5 V to the CGP payload.

The ESTCube-2 communication system (COM) communicates between the ground station (GS) and the satellite.

The system consists of two hot-redundant subsystems—primary communications (PCOM) and a backup subsystem called secondary communications (SCOM), housed on the same PCB. PCOM can receive and transmit signal on the radio amateur 70 cm band, and SCOM can receive on the radio amateur 2 m band and transmit on the 70 cm band, using AX.25-encapsulated data packets. SCOM serves the additional purpose of disabling the satellite’s transmission ability upon receiving an appropriate telecommand. This requirement comes from the international amateur radio union, as ESTCube-2 transmits on radio amateur frequencies [

44].

The PCOM system is tuned at the radio amateur 70 cm band with a planned frequency of 435.8 MHz and 9600 to 19,200 bit/s variable data rate. Its processing unit is an STMicroelectronics STM32L4 series MCU, and RF connectivity is achieved with a Silicon Labs Si4463 transceiver.

SCOM is primarily used as a secondary receiver subsystem and uses a radio amateur 2 m band. The data processing unit is a Silicon Labs EZR32WG330 series MCU with a built-in RF transceiver module. For transmission, the subsystem can change its carrier frequency to the 70 cm band and use PCOM’s RF path to transmit the signal as a backup transmitter.

The onboard computer (OBC) coordinates the operations of all systems and payloads and runs the AOCS algorithms using an STM32F7 series MCU. The MCU features 512 kB of static random-access memory (SRAM) and 2 MB flash memory for housekeeping and telemetry data storage.

The system can monitor the spacecraft’s overall health, mitigate identified failure scenarios, schedule telecommands for execution at a specific date and time, collect housekeeping and experiment data from payloads and other systems, perform data compression, and store the data in its onboard memory. At least two images of firmware are stored on the processor for redundancy. In addition, the system is capable of full firmware and delta updates, including an update roll-back mechanism for safety.

The OBC is central to all internal communications; the avionics stack is connected via three internal communication protocol (ICP) buses, and the payloads are connected via two CSP buses (see

Figure 9).

Although the OBC has a real-time clock (RTC), it has no uninterruptible power supply. Since the EPS is the only system that has a battery-backed RTC, the OBC synchronizes time with the EPS. The OBC provides a time synchronization service for the payload modules.

The OBC board houses two redundant sets of microelectromechanical systems (MEMS) sensors: two magnetometers (LIS3MDL), two gyroscopes (BMG160), and an accelerometer (FXOS8700CQ) in each set for attitude determination purposes.

For the ESTCube-2 mission, the star tracker (ST) is an optional attitude determination system component. It was developed as part of the deep-space platform demonstration.

It consists of STMicroelectronics STM32L4-series-based MCU to gather different analog measurements from the PCB, configure the field-programmable gate array (FPGA), and enable communication with the complementary metal–oxide–semiconductor (CMOS) sensor.

An Altera Cyclone IV-based FPGA device processes the image, extracts the star location information, compares it to a database of known stars, and extracts the valuable attitude information. A 1/2.5-inch ON Semiconductor MT9P031 5 Mp monochrome CMOS image sensor and a high-resolution imaging lens with a 16 mm focal length and F/1.2 aperture are used to obtain images of the stars. Combining the sensor and optics yields a 21.5 × 15.7 field of view.

The image sensor and FPGA require specific voltage levels. Therefore, the voltage conversion is conducted locally on the ST PCB with switching or low-dropout regulators, depending on the current levels and input/output voltage differences.

2.3.3. Side Panel Systems

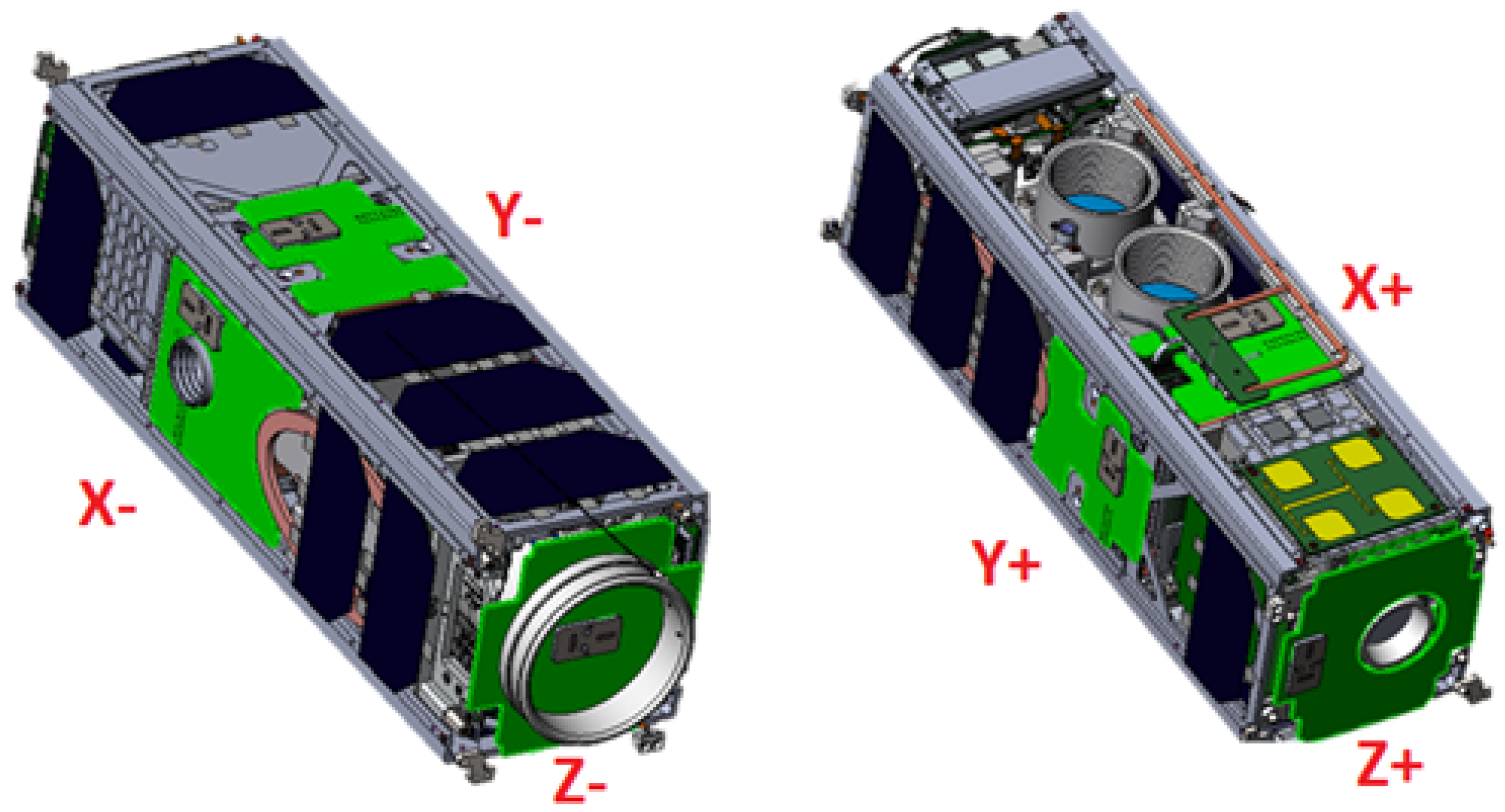

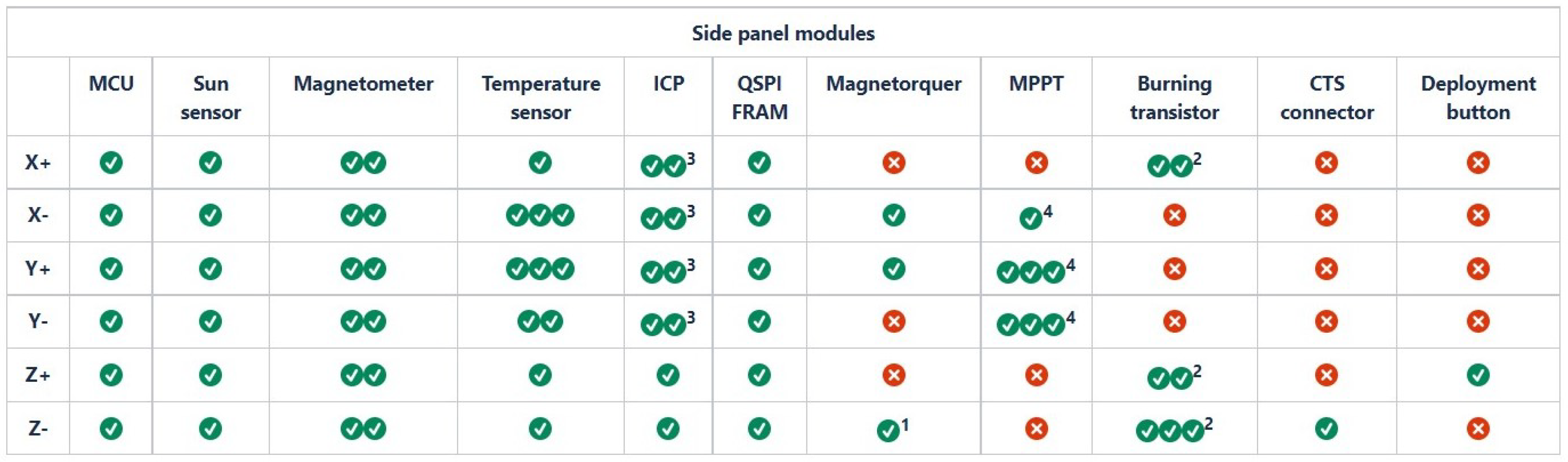

A side panel is a proxy system of the ESTCube-2 nanosatellite, and there is a different configuration on each of the six sides of the satellite (see

Figure 10). Each SP has a different functional block configuration depending on the necessary electronics hardware on each satellite’s side (see

Figure 11).

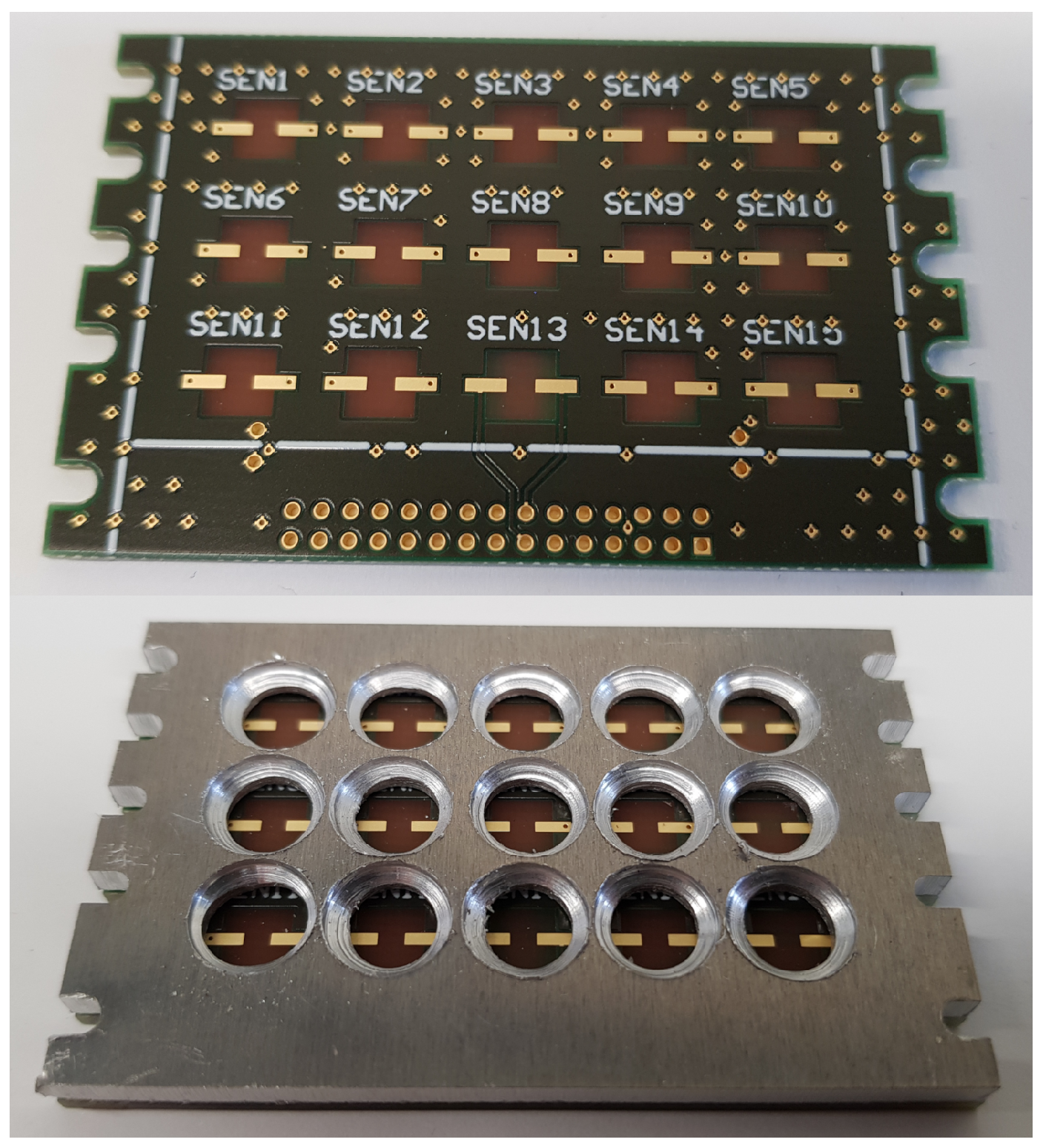

The following are located on each SP system: STMicroelectronics STM32L4 series MCU, SS, magnetometer, one or more temperature sensors, FRAM memory, and ICP electronics.

On three PCBs are custom maximum power point tracker (MPPT) solutions for energy harvesting, capable of fast power point tracking during the satellite spin-up to deploy the IPB tether.

Driver electronics for three magnetorquers are located on those SPs closest to the actuators (except the bottom Z-axis side, see footnote 1 of

Figure 11).

Approximately in the middle of every side of the satellite, there is a two-axis Sun sensor. The Sun sensors have been developed in-house and are an evolution of the similar analog sensors used on ESTCube-1 [

26].

A single magnetometer on each of the SPs is used for better characterization of the residual magnetic field of the satellite and better-averaged measurement of the external magnetic field.

2.3.4. Attitude and Orbit Control System (AOCS)

On the ESTCube-2 satellite, the AOCS is a virtual system. Its components are housed on the OBC PCB or are integrated within the SPs. The AOCS system can be separated into three different major functional blocks, which work in tandem to fulfill the set mission requirements.

Mission requirements enforced the inclusion of an ST system (described in

Section 2.3.2) and a CGP actuator (described later in this Section). These components enable attitude determination and control functionality outside the Earth’s magnetic field, thus, establishing a platform capable of successfully conducting deep-space missions. Still, for the ESTCube-2, they provide the necessary backup options for a successful LEO mission.

- 1.

Magnetometers

- 2.

Gyroscopes

- 3.

Accelerometers

- 4.

Sun sensors

- 5.

Star tracker

The available actuators for controlling the satellite are:

- 1.

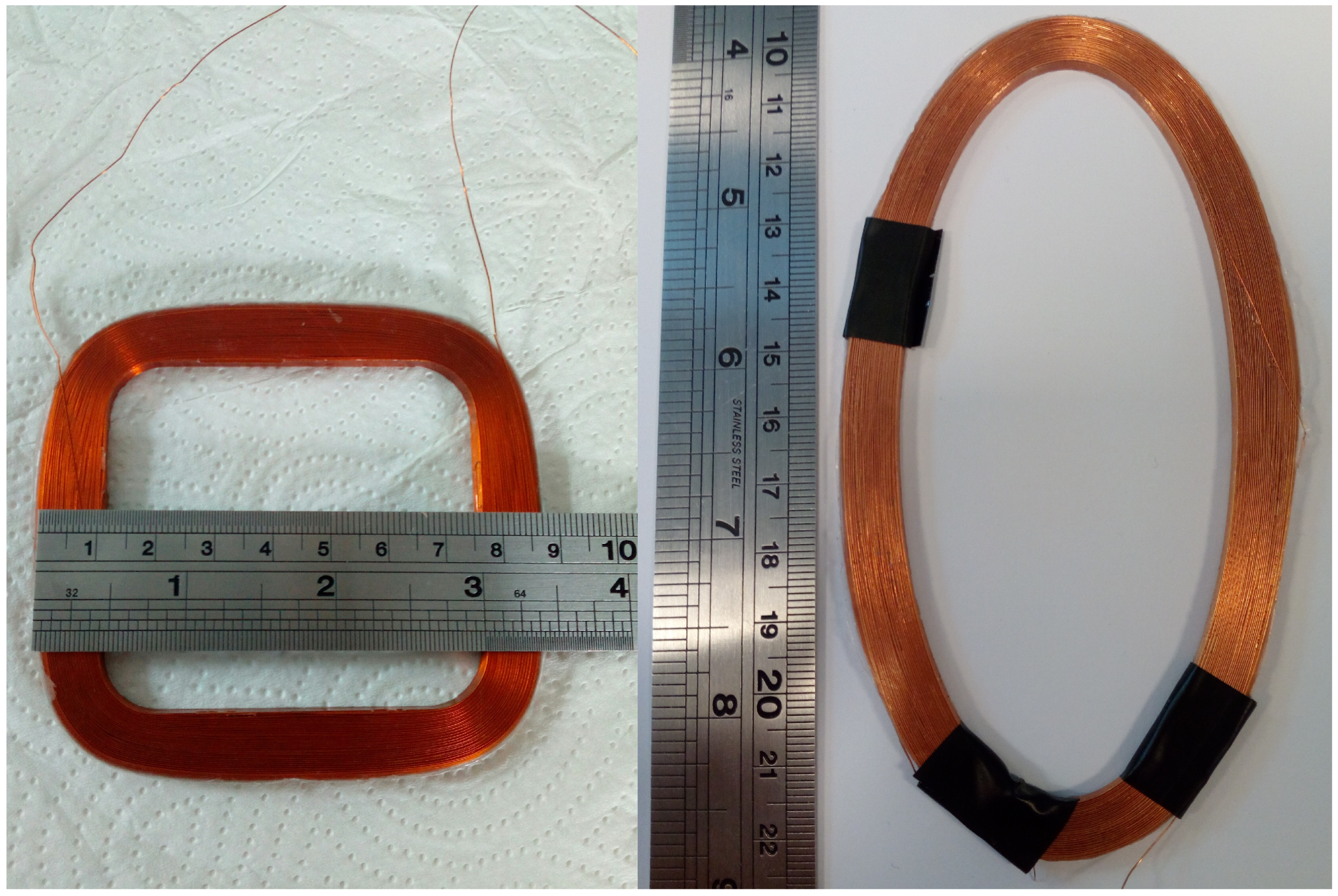

Three coreless magnetorquers with a magnetic moment of 0.45 A·m

made in-house (see

Figure 12);

- 2.

Three Hyperion Technologies RW210 Series nanosatellite RWs. Dimensions: 25 × 25 × 15 mm3, Mass: 32 g, Momentum storage: 3.0 mNms;

- 3.

Three Wittenstein Cyber Motors CYBER2 nanosatellite RWs for redundancy. Dimensions: 20 × 20 × 20 mm3, Mass: 30 g, Momentum storage: 2.0 mNms;

- 4.

A GOMSpace NanoProp CGP3 CGP system.

Sensory data are interpreted in turn by various AOCS algorithms. The main AOCS algorithm is a type of unscented Kalman filter (UKF) capable of accounting for uncertainties arising from sensor measurements and temporal uncertainty of measurements taken.

The main requirement of the ESTCube-2 mission is to demonstrate the capability of executing each important maneuver, utilizing only the sensors and actuators available for deep-space missions.

There are four main maneuvers that the satellite must be able to execute for the mission to succeed:

Detumbling of the satellite to increase the reliability of communications between it and the ground station;

Satellite pointing for Earth observation camera operations and high-speed data downlink;

RW unloading/desaturating for continuous operations;

Satellite spin-up for IPB experiment tether deployment.

Detumbling operations will be achieved by a B-dot algorithm using magnetorquers. However, a specialized slower “predicting regulator,” which only uses the cold–gas propulsion module, will be tested for future deep-space operations.

Satellite pointing maneuvers are conducted using RWs following a PD-regulator control law. As a backup, the satellite can point itself using magnetorquers that employ a special PD-regulator.

The RW unloading is to be handled by stopping them gradually while using the detumbling controllers, but RW unloading using the CGP system is necessary for technology demonstration only. During the ESTCube-2 mission RWs will be desaturated using the magnetorquers.

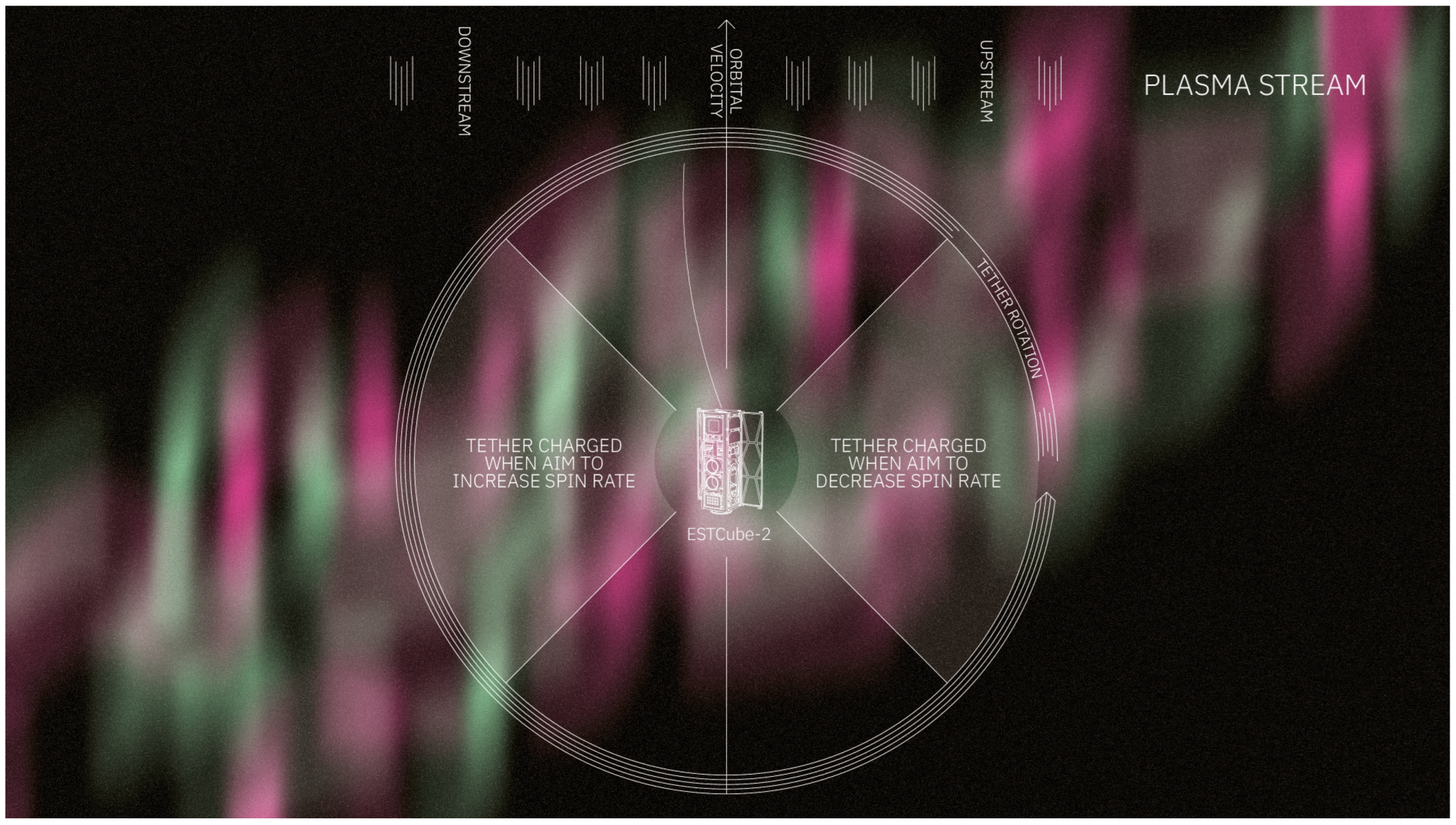

The spin-up of the satellite for the deployment of its main experiment—the ionospheric plasma brake—is handled by a double P-regulator, which uses cold–gas propulsion for technology demonstration, and magnetorquers are kept as a backup.

To increase the attitude and orbit determination precision externally, a radio satellite ranging experiment will be carried out, which aims to achieve the positioning of the satellite an order of magnitude more accurate than the two-line element set (TLE) using multiple collaborating ground stations and their respective locations.

2.3.5. Software Architecture

The software that enables the satellite to perform its scientific mission is developed alongside hardware and embedded software development.

During the development of ESTCube-1, it became clear that working with the STM hardware abstraction layer (HAL) created more problems than it solved, as described in [

18]. A custom HAL was created by the team called ECHAL. ECHAL supports STM32 MCUs from F7, L4, and H7 families, making the software functions above this layer portable between them. The memory footprint of ECHAL is far smaller than STM HAL, and it fits into a bootloader.

Currently, the algorithm development is ongoing. The aim is to use the bootloader to deploy the final software onto the satellite after the launch. Before the launch, the main focus is sensor validation software. It focuses on the preprocessing of the sensor data and the relevant drivers that enable taking measurements from the sensors. As the satellite’s payload requires advanced attitude determination and control, many algorithms are under development to enable a successful mission.

The main focus on algorithm development has been on a robust Unscented Kalman Filter (UKF), satellite attitude and orbit control methods, and the ST algorithms. These algorithms are developed in a simulation environment and with more computing than is available on the satellite. Although this helps validate the algorithms, porting for use with ECHAL and optimizing them for use in orbit is still necessary. This will be finalized after receiving the first measurements from space and testing the algorithms using the sensor logs.

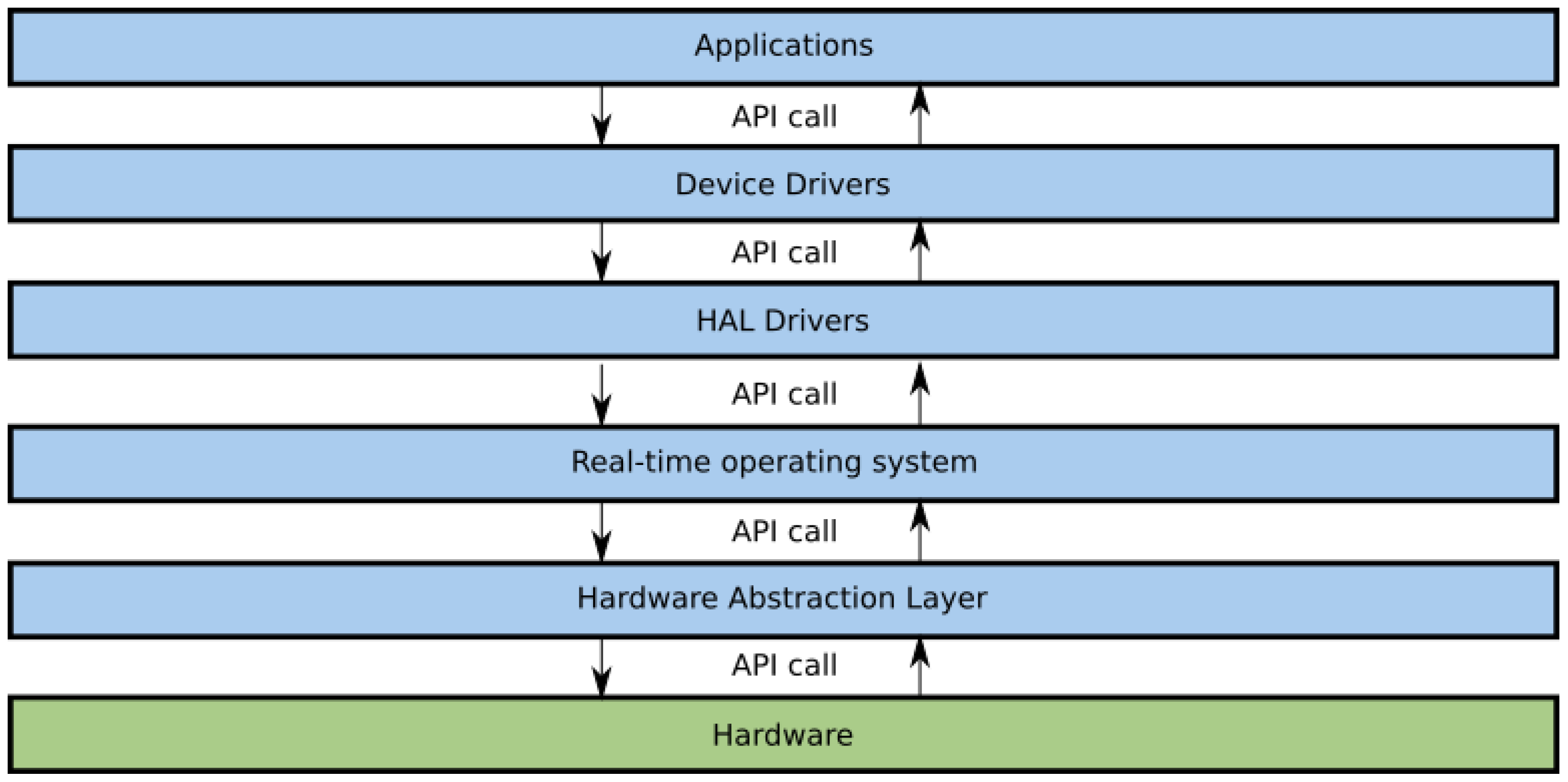

The firmware on all the satellite’s avionics stack systems is separated into logical layers, as summarized in

Figure 13.

The ICP is used for the avionics stack system’s internal communication. A detailed description of this can be found in [

18].

2.3.6. COTS Subsystems

Despite the mission requirements to create a deep-space platform in-house, two commercial systems have been acquired. They will assist in the payload experiments.

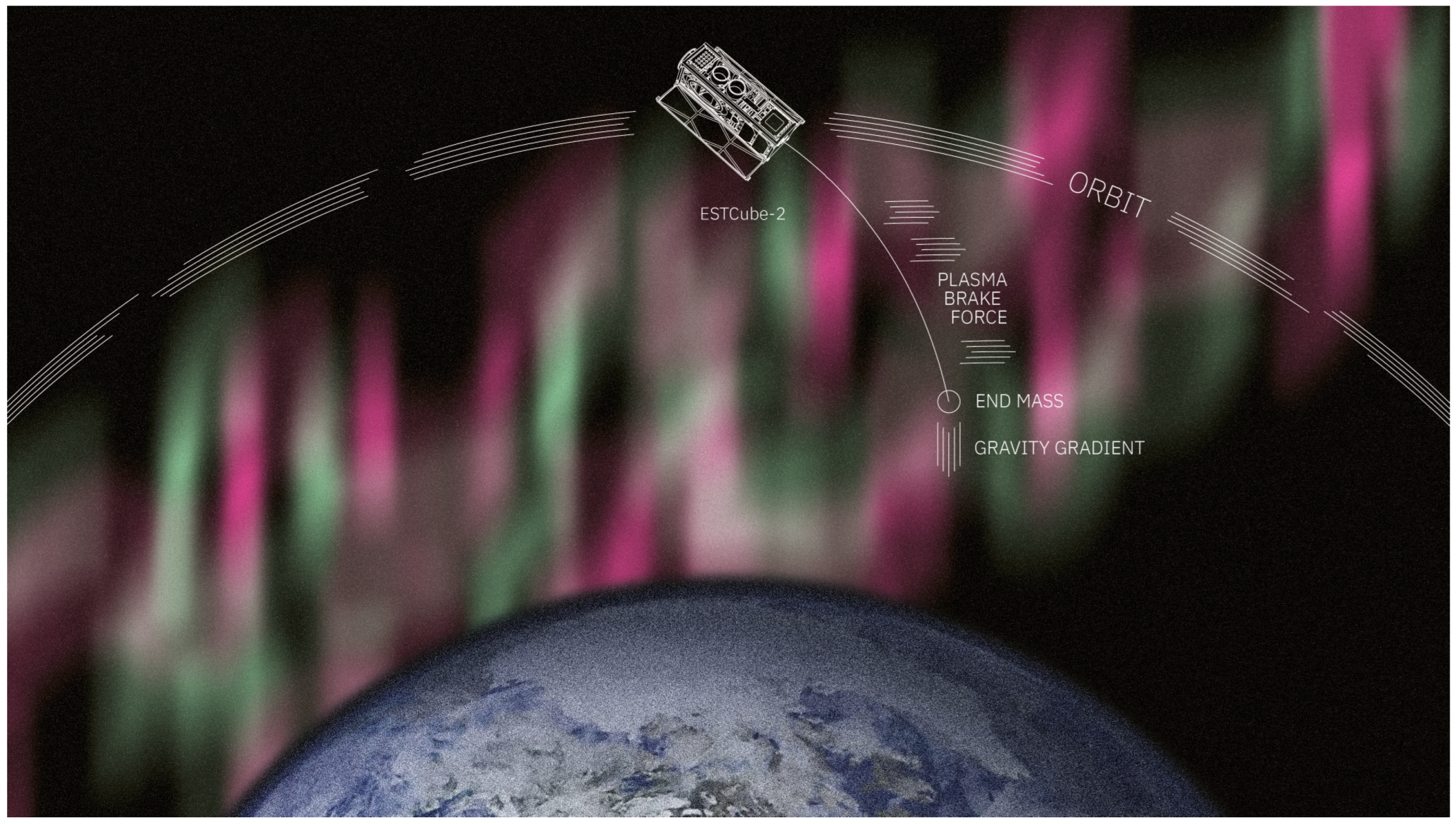

The GOMSpace NanoProp CGP3 cold–gas propulsion (CGP) system is used for the IPB tether deployment and maintenance. While it is possible to deploy the tether without additional propulsion in LEO, it will be required for E-sail deployment in deep space; therefore, for testing purposes, it will be used in LEO as well.

Compressed butane gas is used as the propellant. At operational conditions, the system would generate 1 mN thrust, and two nozzles at total capacity can run continuously for ten orbits (15 hours).

The system will be used only to desaturate the RWs, because of its suboptimal design (see

Section 3.3).

A

high-speed communications system (HSCOM) is required to download the spectral images made by the EOP. An S-band high-speed communications system HiSPiCO from IQ Spacecom is capable of up to 1 Mbps downlink speed. As our partner, who planned to use their high-speed communications system on board ESTCube-2, failed to deliver the system, our team was forced to find an alternative [

18]. The HiSPiCO module size has allowed us to integrate the system easily because its form factor is not based on the CubeSat standard, and its dimensions fit into the envelope of the planned communications system. The system’s compact dimensions have allowed it to be located near the S-band patch antenna.

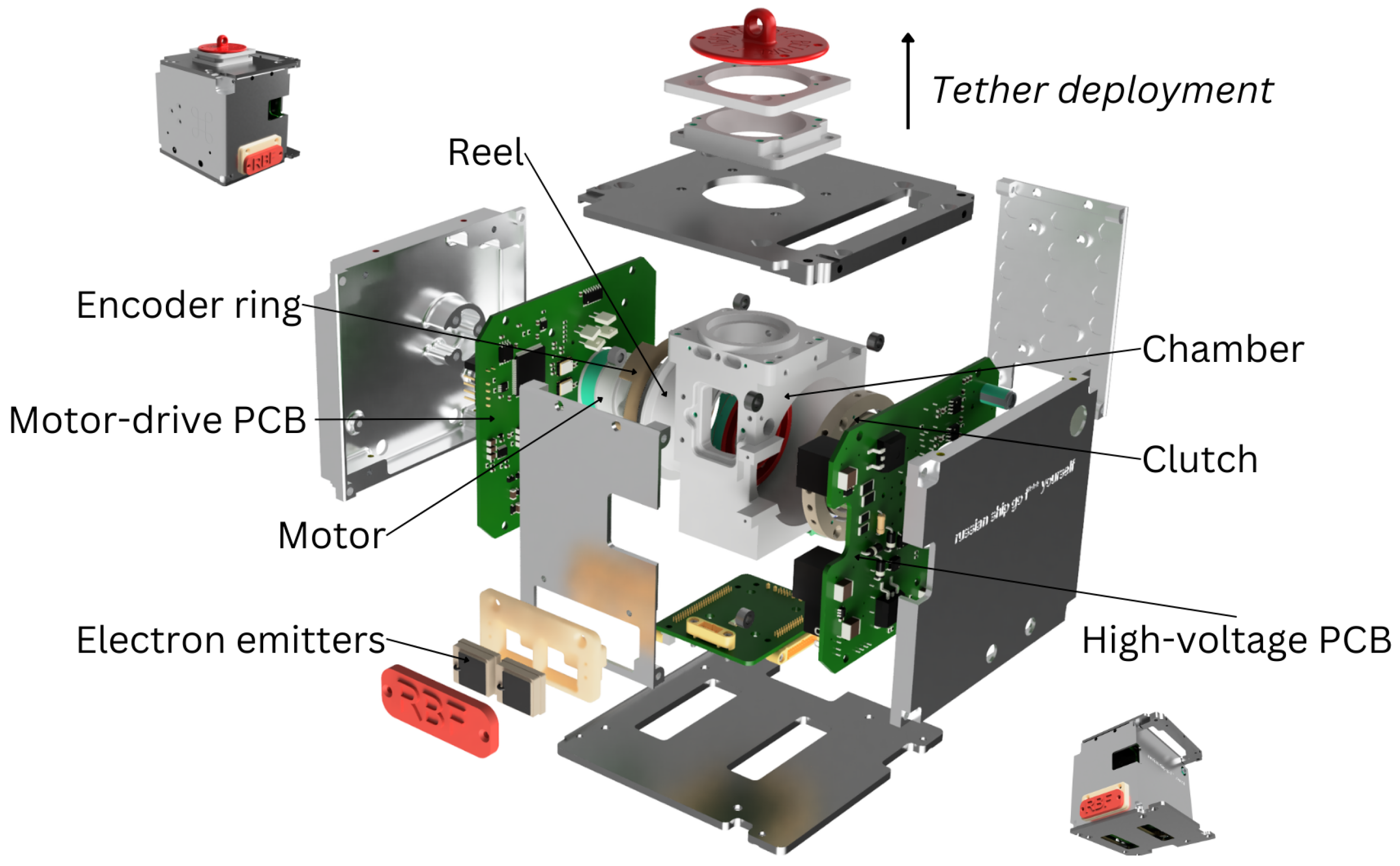

Even though most of the system is a COTS product, the S-band antenna was developed and tested in-house (see

Figure 14). The antenna’s size was limited by the dimensions of the side of the satellite and the PB electron gun opening (see

Figure 14’s RBF lid). The antenna is a circularly polarized patch-type antenna whose resonant frequency is 2.4 GHz. It has an ∼8 dBi gain, and its half-power beam width is ∼70

.