Abstract

This study determines the mean and fluctuating pressures for flow through a rectangular shallow cavity (ratio between the length and the depth = 2.43, 4.43, and 6.14; ratio between the length and the width = 0.5, 1.0, and 2.0) at a Mach number of 0.64 in a blowdown transonic wind tunnel. A amplitude modulation analysis is used for the post-processing of the fluctuating pressure signals. The spectral analysis (wavelet) shows the intermittent behavior of the discrete Rossiter–Heller modes. A correlation analysis determines that mode switching is more significant between the second and third modes (organized structures that are associated with shear layer vortices), particularly for two-dimensional and shallower cavities.

1. Introduction

A cavity flow is characterized by the distribution of the longitudinal surface pressure on the cavity floor [1,2,3]. The type of flowfield (open, transitional, or closed) is primarily a function of the ratio between the length, l, and the depth, h (l/h). For an open cavity flow (l/h < 6–8), an unsteady shear layer spans the cavity and impinges near the trailing edge [4,5]. There is a uniform longitudinal pressure distribution on the cavity floor. Two distinct separation regions form downstream of the front face and upstream of the rear face in a closed cavity flow (l/h > 10–15). The ratio between l and the width, w, (l/w) also characterizes a cavity flowfield [6]. The degree of three-dimensionality is associated with the value of l/w, which results in a spanwise oscillation for allocation at which there is shear layer impingement [7].

Landing gear wells or weapon bays are classified as open cavities. The incoming boundary layer separates at the leading edge, and the shear layer rolls up into vortices. The flow is subject to global instabilities (Kelvin–Helmholtz instabilities) because there is a difference in the velocity of the freestream and the velocity of the fluid inside a cavity [8]. Large-scale vortical structures are subject to convection downstream and attach near the trailing edge. Acoustic waves then propagate upstream toward the cavity’s front face and disturb the upstream shear layer to create another vortex. This is known as a feedback loop (downstream convection instabilities and upstream propagating acoustic waves), which leads to self-sustained oscillations and discrete tones [9]. The pressure fluctuations for an open cavity flow are considerably greater than those for a closed cavity flow. There is intrinsic unsteadiness in the recirculation region because of the instabilities in the shear layer and oscillations that originate in the transverse dimension of the cavity [10].

Rossiter [11] proposed a semi-empirical formula to calculate non-harmonic modal frequencies. Heller and Bliss [12] determined that the temperature in an open cavity flow affects the speed of sound. The empirical Rossiter–Heller (R–H) equation (Strouhal number, Stn) is written as Equation (1).

where n is the number of discrete modes. fn and U∞ are the discrete modal frequency and the freestrem velocity, respectively; the empirical parameters (kc and α) vary with cavity geometry and freestream Mach number, M [13], kc (=0.50–0.75) is the ratio of the perturbed convective velocity and U∞. α (=0.25 or 0.062 l/h) is the phase lag (expressed as a fraction of wavelength), which corresponds to the lag time between the passage of a vortex and the emission of an acoustic pulse [14].

The spectral characteristics of resonance in an open cavity flow are defined using a short-time Fourier transform [15,16,17]. The first R–H mode (R1) corresponds to large-scale motions in the shear layer and in the vicinity of the recirculation region. The second and third R–H modes (R2 and R3) feature organized structures that are associated with shear layer vortices [18]. However, the R–H modes do not necessarily occur simultaneously, and the dominant energy can vary with time (a process for temporally dominant energy shifts or mode switching).

Kegerisea et al. (M = 0.04–0.8) [19] used a wavelet transform to determine mode switching. The R–H modes do not exhibit strong nonlinear coupling, as verified by the study by Pandian et al. (M = 1.8) [20]. Gloerfelt et al. (M = 0.4–0.8) [21] determined that there is switching between R1 and R2 for cavity oscillations. Bacci et al. (M = 0.81) [10] showed that the energy distribution is rearranged between the R–H modes. Observations of the velocity and pressure fields showed that the ability to detect mode switching is dependent on the location within the cavity and the R–H mode number [18].

Mode switching is an evolving research field for the dynamics of flow in an open cavity. However, there is very limited data on this unstable phenomenon. This study uses time-frequency analysis for the post-processing of fluctuating pressure signals that are recorded on the floor of rectangular cavities at M = 0.64. The effect of l/h and l/w (degree of three-dimensionality) on the mode amplitude over time is determined, as is the intermittent nature of the R–H modes. Mode switching is quantified using an amplitude demodulation technique and correlation coefficients. Before discussing the results, details of the experiment setup are outlined next.

2. Experimental Setup

2.1. Transonic Wind Tunnel

The experiments were conducted in a blowdown-type wind tunnel at the Aerospace Science and Technology Research Center, National Cheng Kung University (ASTRC/NCKU). The facility has two compressors, two air dryers, three storage tanks (volume = 180 m3) that allow a maximum pressure of 5.15 MPa, a hydraulic system, and a tunnel (a stilling chamber, a nozzle, and a test section). The test section within a plenum chamber is 600 mm square and 1500 mm in length. Acoustic waves in the test section are mitigated by using solid sidewalls, perforated top and bottom walls (inclined holes with 6% porosity). A rotary perforated sleeve valve controls the stagnation pressure, po, which ranges from 137.8 to 344.5 kPa. The stagnation temperature is room temperature. The operational Mach number is 0.2–1.4, and the maximum Reynolds number is per meter. The test conditions are monitored and recorded using a National Instruments system (NI PXIe-8840 RT, PXI-7846, PXI-6511, and PXI-6513; Austin, TX, USA).

2.2. Test Model

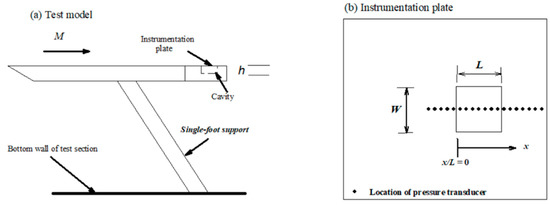

The test model was a 450-mm-long flat plate with a 4° sharp leading edge and a 180-mm instrumentation plate with an open cavity. Pressure taps were machined along the centerline of the rectangular cavities (upstream/downstream locations and cavity floor), as shown in Figure 1. The model was supported by a single foot that was fixed to the bottom wall of the test section. A turbulent boundary layer developed naturally upstream of an open cavity. The normalized boundary layer profile using a Pitot probe and a transversing device was in the 1/7 velocity power law [22].

Figure 1.

Test configuration.

Six cavity models were fabricated. The geometry for each cavity is shown in Table 1. For cavities 1–3, the value of h (=7 mm) was fixed and the value of l (=17–43 mm) was varied, which corresponds to a specific value for l/h of 2.43, 4.43, and 6.14 (open-type cavities). The value of l/w is an indication of the degree of three-dimensionality of a cavity flow [6]. The value of w was varied for the same value for l (=43 mm) and h (=9.7 mm) for cavities 4–6 (l/h = 4.43). The values for l/w were 0.5, 1.0, and 2.0. Side fences on both sides of the instrumentation plate were used to prevent crossflow.

Table 1.

Cavity dimensions.

2.3. Instrumentation and Data Acquisition System

The value of M was 0.64 ± 0.01. The stagnation pressure, p0, was 172 ± 0.5 kPa, and the stagnation temperature was room temperature. The boundary layer thickness, δ, at 475 mm from the leading edge was 7.3 0.2 mm [23], and the Reynolds number, Reδ, was 1.63 × 105.

Mean and fluctuating surface pressures were measured using flush-mounted Kulite pressure transducers (Model XCS-093-25A, B screen; Leonia, NJ, USA), which were powered by a DC power supply (GW Instek PSS-3203; Taipei, Taiwan) of 10.0 V. The nominal outer diameter of the Kulite sensors is 2.36 mm, and the sensing element is 0.97 mm in diameter. Crocos [24] showed that the sensitive area of a pressure transducer limits the temporal resolution of pressure signals. For a convection velocity of 0.8 U∞, the maximum measurable frequency for this study is approximately 63 kHz. External amplifiers (Ectron Model 753A; San Diego, CA, USA) with a gain of 20 were used to increase the signal-to-noise ratio. A National Instruments device (NI PXI-6123; Austin, TX, USA) triggered all input channels and recorded data. The sampling rate was 5 µs (200 ksamples/s).

2.4. Mean and Fluctuating Pressure Coefficients

Each measurement consisted of 131,072 data points that were divided into subsets. The mean and fluctuating pressures are determined using Equations (2) and (3):

where is the instantaneous pressure signal, and N is the number of data points.

The uncertainty is determined for flow through a flat plate. The respective values for the mean, Cp (=(pw − p∞)/q), and fluctuating pressure, (=(σp − σp,∞)/q), coefficients are 0.43% and 0.13% [23], q is the dynamic pressure, and the subscript ∞ denotes the freestream value.

2.5. Spectral Analysis

For a set of pressure signals, , that are sampled using a time step of Δt, the discrete Fourier transform is defined as:

where , (N)

The one-side power spectral density (PSD) is:

where

The PSD analysis uses 31 subsets with a 50% overlap, and a Hanning window is used to reduce leakage effects. The frequency resolution is 48.8 Hz. The ensemble PSD is determined by averaging the values for all subsets.

Wavelet analysis is a generalization of the time-frequency transform and is used to identify dynamic structures in both time and space (intermittent and non-stationary signals) [25]. It projects a signal into a set of base functions, which are wavelets. A continuous wavelet transform is defined as:

where is the wavelet function and the asterisk represents the complex conjugate. A Morlet mother wavelet is used:

where is the scale, and is the time delay. The mother wavelet is normalized by to ensure that all sets of the mother wavelet with different scales have the same energy. Torrence and Compo [26] showed that a wavelet transform can be represented by an inverse Fourier transform, as shown in Equation (8):

The term is similar to a moving Gaussian window function. The local scale, a, determines the peak amplitude and the decay rate, which are correlated with frequencies. Equation (9) shows that small scales have a higher resolution in terms of time but a lower resolution in terms of because is a constant (a constant percentage bandpass filter):

2.6. Amplitude Demodulation Technique

The joint time-frequency analysis shows that interactions can occur between the R–H modes in an open cavity flow [10,18,21], but it is difficult to quantify mode switching. However, if there is energy transfer between the R–H modes, mode switching can be quantified using amplitude demodulations. These modulations result in a transfer of energy to the sidebands of spectral peaks and contribute to a broadening of the spectrum [27].

According to Equation (1), the surface pressure fluctuating signal is a combination of the amplitude of the R–H modes and the broadband noise, z(t), as follows:

where and are the respective amplitude and the phase as a function of time. Multiplication by a complex exponential at the modal frequency of interest, fk,

Each component at a given value for fk is shifted down to frequency (fm − fk). A low-pass filter (LPF) is then used to separate the frequencies.

Equation (12) defines the relationship between the first three R–H modes [11], which is

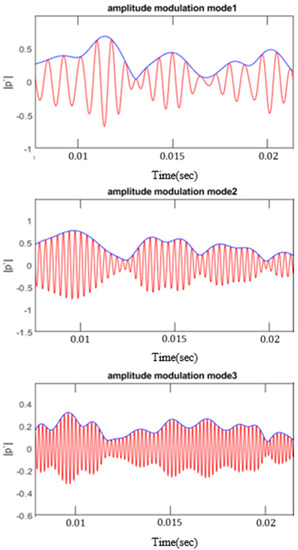

The cut-off frequency for a LPF is used to isolate the energy that is near the frequency of interest. An example of the amplitude demodulation for l/h = 6.14 is shown in Figure 2. The red lines represent fluctuations for the first three R–H modes, and the blue lines correspond to the variation in amplitude with time. There is an increase in the modal frequency for a higher mode. For upstream propagating acoustic waves, the wave length, λi, is determined as a/fi, where a is the speed of sound. The value of l is approximately 2λ1, 4λ2, or 6.7λ3. The coupling between R–H modes and acoustic waves would result in greater amplitude for the first and second modes. The standard deviation of the R–H modes, CA,Rossiter, is determined using the amplitude, Aj, for the first three R–H modes (blue lines), as shown in Equation (13).

Figure 2.

Amplitude demodulation for the R–H modes for l/h = 6.14.

Spearman’s correlation coefficient [28] is used to quantify mode switching between the R–H modes (blue lines in Figure 2). If the correlation coefficient is negative, there is a decreased monotonic trend between the R–H modes.

where is the covariance of rank variables and are the standard deviation for rank variables.

3. Results and Discussion

3.1. Mean and Fluctuating Pressure

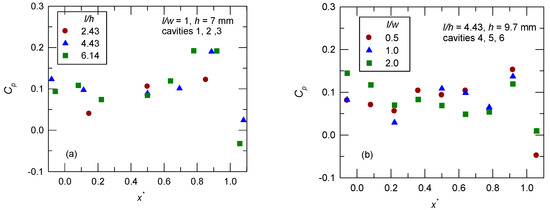

The distribution of Cp along the centerline for cavities 1–3 (l/w = 1.0) is shown in Figure 3a. The horizontal axis is the normalized streamwise location, x* (=x/l), and the origin is at the front face on the cavity floor. There is a decrease in the value of Cp downstream of the front face, particularly for l/h = 2.43, followed by an increase further downstream because the shear layer diffuses (expansion) and is deflected (compression) [29]. The value of Cp decreases near the rear face, and there is a recovery process downstream. The effect of l/w on the Cp distribution is shown in Figure 3b. For l/h = 4.43 (cavities 4–6), there is a similar effect on the distribution of Cp as l/w varies. For l/w = 2.0, an increase in the degree of three-dimensionality affects the Cp distribution. There is an increase in the value of Cp upstream of the front face and a decrease on the cavity floor. The pressure gradient is reduced near the rear face because the spanwise velocity is greater [30].

Figure 3.

Streamwise mean pressure distribution: (a) l/w = 1.0; (b) l/h = 4.43.

Figure 4a shows the distribution of for l/w = 1.0 (cavities 1–3, h = 7 mm). There is a flatter distribution of for l/h = 2.43. For l/h = 4.43 and 6.14, expansion over the leading edge causes damping downstream of the front face (a lower value in ). Self-sustained oscillations (downstream convection instabilities and upstream propagating acoustic waves) result in a peak value of , near the rear face, which corresponds to the shear layer impingement and the process for mass addition/removal. It is also noted that there is a decrease in the value of for l/h = 4.43 downstream of the rear face.

Figure 4.

Streamwise fluctuating pressure distribution: (a) l/w = 1.0; (b) l/h = 4.43.

The effect of l/w (cavities 4–6, l/h = 4.43, h = 9.7 mm) is shown in Figure 4b. The distribution of is approximately the same as that for l/w = 0.5 and 2.0. The value of is less on the cavity floor for l/w = 1.0. An increase in the three-dimensionality (l/w = 0.5) results in a greater value in . For cavities 2 and 5 (l/h = 4.43; l/w = 1.0), an increase in the value of h results in greater downstream of the rear face. This implies the effect of h/δ on the shear layer impingement and the process for mass addition/removal.

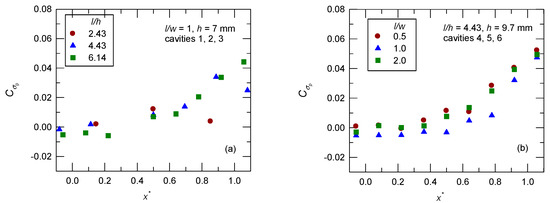

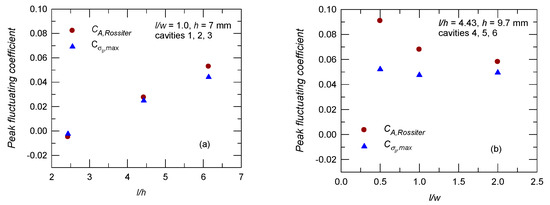

The effect of l/h on for l/w = 1.0 (cavities 1–3, h = 7 mm) is shown in Figure 5a. An increase in the value of l/h induces stronger self-sustained oscillation, so the value of CA,Rossiter increases. This shows that the first three R–H modes dominate self-sustained oscillations for an open cavity flow. For l/h = 4.43, variation in the value of l/w (cavities 4–6, h = 9.7 mm) has a minor effect on the amplitude of , as shown in Figure 5b. There is a decrease in the value of CA,Rossiter as l/w increases. This indicates that variation in depends on the value of l/h and the first three R–H modes are more dominant as the value of l/w decreases.

Figure 5.

Peak fluctuating pressure: (a) l/w = 1.0; (b) l/h = 4.43.

3.2. Spectral Analysis

The frequency of the R–H modes, which is calculated using Equation (1), is shown in Table 2a. There is a decrease in the value of the first three R–H modes (f1, f2, and f3) as l increases. The modal frequencies are also determined using fluctuating pressure signals, and the results are shown in Table 2b. This experimental data is in reasonable agreement with the R–H modes for cavities 1–3 (l/w = 1.0, h = 7 mm), and the discrepancy is less than 10%, as are f2 and f3 for cavity 5 (l/w = 1.0, h = 9.7 mm). For l/h = 4.43 (cavities 4–6), the value of f1–f3 is approximately the same for all three test cases. The discrepancy between the experimental data and R–H modes is significant (up to 30%), particularly for l/w = 0.5, which corresponds to the effect of the degree of three-dimensionality.

Table 2.

Frequency of Rossiter–Heller modes: (a) prediction; (b) experiment.

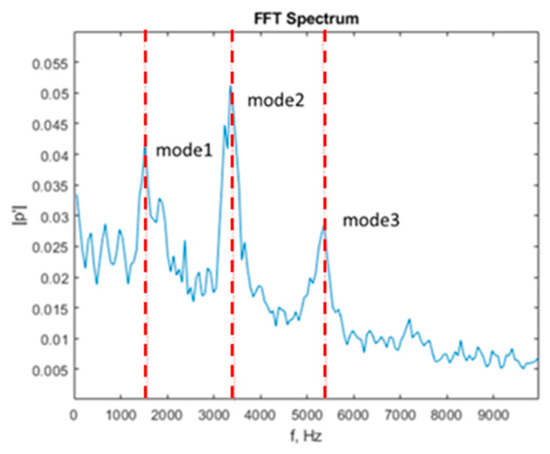

Figure 6 shows a plot of the PSD near the rear face for l/h = 6.14 and l/w = 1.0. The frequency resolution for the PSD is 48.8 Hz. There are multiple peaks at f1 = 1495 Hz, f2 = 3326 Hz, and f3 = 5310 Hz, which correspond to the first three R–H modes. The second mode is more dominant. Kegerise et al. [19] showed that nonlinear quadratic interaction can occur between the R–H modes, and other peaks (the sums and differences of f1, f2, and f3) are detected. However, this study does not demonstrate this phenomenon.

Figure 6.

PSD for l/h = 6.14.

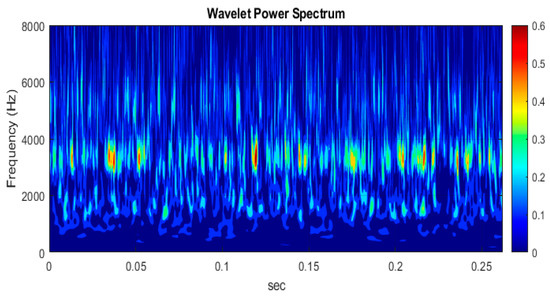

The PSD does not show that modes coexist or that mode switching occurs. The spectrum for l/h = 6.14 that is calculated using a wavelet analysis is shown in Figure 7. The time range in the plot is from 0 to 0.25 s, and the frequency range is chosen in order to cover the first three R–H modes. The amplitude varies over time, and there is intermittent behavior, which is not shown in Fourier spectra. The figure also shows that there is no evidence of a monotonic relationship between modes.

Figure 7.

Wavelet transform for l/h = 6.14.

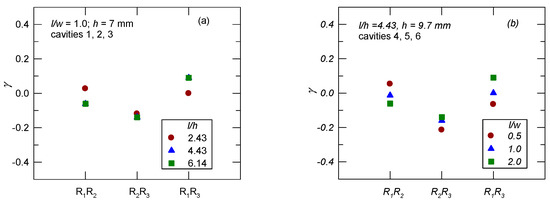

Previous studies [19,20] showed that the R–H modes do not exhibit strong nonlinear coupling. This study uses the correlation between the R–H modes, which refers to the variation of amplitude over time that is shown in Figure 2, to determine the degree of mode switching. For l/w = 1.0 (cavities 1–3), as shown in Figure 8a, the value of γ (= −0.15 to 0.09) is approximately the same for l/h = 4.43 and 6.14. Since R2 and R3 feature organized structures that are associated with shear layer vortices [18], a negative value for R2R3 denotes a decreased monotonic trend or competition for available energy for these two modes. For l/h = 2.43 (γ = −0.12 to 0.02), mode switching is less significant than that for shallower cavities (l/h = 4.43 and 6.14).

Figure 8.

Correlation between the R–H modes: (a) l/w = 1.0; (b) l/h = 4.43.

For l/h = 4.43 (cavities 4–6), the effect of l/w is shown in Figure 8b. The value of γ for R1R2 and R1R3 is −0.06–0.05, which shows that there is less mode switching. There is a slight increase in the value of γ as l/w increases, possibly because of spanwise oscillation at the location where shear layer impingement occurs for a three-dimensional rectangular cavity flow [7]. The value of l/w has an opposite effect on R1R2 and R1R3.

4. Conclusions

Self-sustained oscillations in a flow through an open cavity are associated with multiple acoustic tones with discrete frequencies (Rossiter–Heller modes), which depend on the geometry of the cavity. A wavelet analysis is used to analyze fluctuating pressure signals with discrete tones (of an intermittent nature). This study determines the effect of l/h and l/w on the strength of variations as a function of both frequency and time for six cavity models (cavities 1–3: l/w = 1.0, l/h = 2.43, 4.43, and 6.14; cavities 4–6: l/h = 4.43, l/w = 0.5, 1.0, and 2.0) at M = 0.64. Amplitude demodulation is used to trace the resonance and better describe the self-sustained oscillations. The correlation between the Rossiter–Heller modes shows that mode switching is more significant for two-dimensional and shallower cavities, particularly between the second and third modes. This implies that the energy distribution is rearranged for feature-organized structures that are associated with shear layer vortices.

Author Contributions

Conceptualization, K.-M.C.; methodology, Y.-X.H.; formal analysis, Y.-X.H.; data curation, K.-M.C. and Y.-X.H.; writing—original draft preparation, Y.-X.H.; writing—review and editing, K.-M.C.; funding acquisition, K.-M.C. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the National Science and Technology Council, Taiwan, grant number MOST 110-2221-E-006-097.

Data Availability Statement

Data is available upon request.

Acknowledgments

The authors are grateful for the technical support of the ASTRC/NCKU technical staff.

Conflicts of Interest

The authors declare no conflict of interest.

Nomenclature

| Cp | mean surface pressure coefficient |

| fluctuating pressure coefficient | |

| peak fluctuating pressure coefficient | |

| fi, f2, f3 | frequency of Rossiter–Heller (R–H) modes |

| h | cavity depth |

| l | cavity length |

| M | freestream Mach number |

| , pw | mean surface pressure |

| po | stagnation pressure |

| p∞ | freestream static pressure |

| pressure signal | |

| q | dynamic pressure |

| R1, R2, R3 | Rossiter–Heller modes |

| St | Strouhal number |

| U∞ | freestream velocity |

| w | cavity width |

| x | coordinate along the centerline of model surface |

| x* | normalized streamwise distance, x/δ |

| δ | incoming boundary-layer thickness |

| γ, γij | Spearman’s correlation coefficient |

| σp | fluctuating (rms) pressure |

References

- Stallings, R.L., Jr.; Wilcox, F.J., Jr. Experimental Cavity Pressure Distributions at Supersonic Speeds; NASA TP-2683; NASA: Washington, DC, USA, 1987. [Google Scholar]

- Mathias, M.S.; Medeiros, M.A.F. The effect of incoming boundary layer thickness and Mach number on linear and nonlinear Rossiter modes in open cavity flows. Theo. Comput. Fluid Dyn. 2021, 35, 495–513. [Google Scholar] [CrossRef]

- Doshi, P.S.; Ranjan, R.; Gaitonde, D.V. Global and local modal characteristics of supersonic open cavity flows. Phys. Fluids 2022, 34, 034104. [Google Scholar] [CrossRef]

- Kim, I.; Chokani, N. Navier-Stokes study of supersonic cavity flow field with passive control. J. Aircr. 1992, 29, 217–223. [Google Scholar] [CrossRef]

- Nair, K.M.; Sarkar, S. Large eddy simulation of self-sustained cavity oscillation for subsonic and supersonic flows. J. Fluids Eng. 2017, 139, 011102. [Google Scholar] [CrossRef]

- Chung, K.M. Three-dimensional effect on transonic rectangular cavity flows. Exp. Fluids 2001, 30, 531–536. [Google Scholar] [CrossRef]

- Turpin, A.M.; Speth, R.L.; Sherer, S.E.; Granlund, K.O. Low-frequency, spanwise oscillation in a finite-width cavity at Mach 1.5. Phys. Fluids 2021, 33, 076102. [Google Scholar] [CrossRef]

- Yamouni, S.; Sipp, D.; Jacquin, L. Interaction between feedback aeroacoustic and acoustic resonance mechanisms in a cavity flow: A global stability analysis. J. Fluid. Mech. 2013, 717, 134–165. [Google Scholar] [CrossRef]

- Maceda, G.Y.C.; Varon, E.; Lusseyran, F.; Noack, B.R. Stabilization of a multi-frequency open cavity flow with gradient-enriched machine learning control. J. Fluid Mech. 2023, 955, A20. [Google Scholar] [CrossRef]

- Bacci, D.; Saddington, A.J.; Bray, D. Identification of the formation of resonant tones in compressible cavity flows. Aerosp. Sci. Technol. 2018, 77, 320–331. [Google Scholar] [CrossRef]

- Rossiter, J. Wind Tunnel Experiments on the Flow over Rectangular Cavities at Subsonic and Transonic Speeds; Technical Report 64037; Royal Aircraft Establishment: Farnborough, UK, 1964. [Google Scholar]

- Heller, H.; Bliss, D. Aerodynamically Induced Pressure Oscillations in Cavities Physical Mechanisms and Suppression Concepts; Technical Report AFFDL-TR-74-133; Air Force Flight Dynamics Laboratory: Dayton, OH, USA, 1975. [Google Scholar]

- Malone, J.; Debiasi, M.; Little, J.; Samimy, M. Analysis of the spectral relationships of cavity tones in subsonic resonant cavity flows. Phys. Fluids 2009, 21, 055103. [Google Scholar] [CrossRef]

- Heller, H.; Holmes, D.G.; Covert, E.E. Flow-induced pressure oscillations in shallow cavities. J. Sound Vib. 1971, 18, 545–546. [Google Scholar] [CrossRef]

- Rowley, C.W.; Williams, D.R. Dynamics and control of high-Reynolds-number flow over open cavities. Annu. Rev. Fluid Mech. 2006, 38, 251–276. [Google Scholar] [CrossRef]

- Li, W.; Nonomura, T.; Fujii, K. On the feedback mechanism in supersonic cavity flow. Phys. Fluids 2013, 25, 056101. [Google Scholar] [CrossRef]

- Nilsson, S.; Yao, H.-D.; Karlsson, A.; Arvidson, S. Effects of aeroelastic walls on the aeroacoustics in transonic cavity flow. Aerospace 2022, 9, 716. [Google Scholar] [CrossRef]

- Wagner, J.L.; Beresh, S.J.; Casper, K.M.; DeMauro, E.P.; Arunajatesan, S. Resonance dynamics in compressible cavity flows using time-resolved velocity and surface pressure fields. J. Fluid Mech. 2017, 830, 494–527. [Google Scholar] [CrossRef]

- Kegerisea, M.A.; Spina, E.F.; Garg, S.; Cattafesta, L.N., III. Mode-switching and nonlinear effects in compressible flow over a cavity. Phys. Fluids 2004, 16, 678–687. [Google Scholar] [CrossRef]

- Pandian, S.; Desikan, S.L.N.; Niranjan, S. Nonlinear Characteristics of a Rectangular Cavity in Supersonic Flow. AIAA J. 2020, 58, 1206–1215. [Google Scholar] [CrossRef]

- Gloerfelt, X.; Bogey, C.; Bailly, C. Numerical evidence of mode switching in the flow-induced oscillations by a cavity. Aeroacoustics 2003, 2, 193–218. [Google Scholar] [CrossRef]

- Chung, K.M. Investigation on transonic convex-corner flows. J. Aircr. 2002, 39, 1014–1018. [Google Scholar] [CrossRef]

- Chung, K.M. Unsteadiness of transonic convex-corner flows. Exp. Fluids 2004, 37, 917–922. [Google Scholar] [CrossRef]

- Corcos, G.M. Resolution of pressure in turbulence. J. Acous. Soc. Am. 1963, 35, 192–199. [Google Scholar] [CrossRef]

- Seena, A.; Sung, H.J. Wavelet spatial scaling for educing dynamic structures in turbulent open cavity flows. J. Fluids Structures 2011, 27, 962–975. [Google Scholar] [CrossRef]

- Torrence, C.; Gilbert, P.; Compo, G.P. A practical guide to wavelet analysis. Bul. Am. Meteorol. Soc. 1998, 79, 61–78. [Google Scholar] [CrossRef]

- Haji, M.R.; Miksad, R.W.; Powers, E.J. Perspective: Measurements and analyses of nonlinear wave interactions with higher-order spectral moments. J. Fluids Eng. 1998, 119, 2–13. [Google Scholar] [CrossRef]

- Liu, Y. A Short Note on Spearman Correlation: Impact of Tied Observations; SSRN Tech. Report; GRIN Verlag: Munich, Germany, 2017. [Google Scholar] [CrossRef]

- Zhang, X.; Edwards, J.A. An investigation of supersonic cavity flows driven by thick shear layers. Aero. J. 1990, 1670, 355–364. [Google Scholar] [CrossRef]

- Beresh, S.J.; Wagner, J.L.; Henfling, J.F.; Spillers, R.W.; Pruett, B.O.M. Width effects in transonic flow over a rectangular cavity. AIAA J. 2015, 53, 3831–3834. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).