Abstract

Launching satellites into the Earth’s orbit is a critical area of research, and very demanding satellite services increase exponentially as modern society takes shape. At the same time, the costs of developing and launching satellite missions with shorter development times increase the requirements of novel approaches in the several engineering areas required to build, test, launch, and operate satellites in the Earth’s orbit, as well as in orbits around other celestial bodies. One area with the potential to save launching costs is that of the structural integrity of satellites, particularly in the launching phase where the largest vibrations due to the rocket motion and subsequent stresses could impact the survival ability of the satellite. To address this problem, two important areas of engineering join together to provide novel, complete, and competitive solutions: topology optimisation methods and additive manufacturing. On one side, topology optimisation methods are mathematical methods that allow iteratively optimising structures (usually by decreasing mass) while improving some structural properties depending on the application (load capacity, for instance), through the maximisation or minimisation of a uni- or multi-objective function and multiple types of algorithms. This area has been widely active in general for the last 30 years and has two main core types of algorithms: continuum methods that modify continuous parameters such as density, and discrete methods that work by adding and deleting material elements in a meshing context. On the other side, additive manufacturing techniques are more recent manufacturing processes aimed at revolutionising manufacturing and supply chains. The main exponents of additive manufacturing are Selective Laser Melting (SLM) (3D printing) as well as Electron Beam Melting (EBM). Recent trends show that topology-optimised structures built with novel materials through additive manufacturing processes may provide cheaper state-of-the-art structures that are fully optimised to better perform in the outer-space environment, particularly as part of the structure subsystem of novel satellite systems. This work aims to present an extended review of the main methods of structural topology optimisation as well as additive manufacture in the aerospace field, with a particular focus on satellite structures, which may set the arena for the development of future satellite structures in the next five to ten years.

Keywords:

structural topology optimisation; continuum topology; density methods; aerospace satellite structure; additive manufacture; homogenisation; SIMP; level-set methods; evolutionary structural optimisation ESO; BESO; SBESO; topological derivative; phase-field method; metaheuristics; genetic algorithm; machine learning; review For the goal is not the last, but the best.

Aristotle

1. Introduction

As modern society evolves into a globally interconnected entity, providing high-quality real-time solutions to most human problems, the required infrastructure to support current and future trends grows exponentially in terms of both technological challenges as well as costs. The aerospace industry is no exception. Although the hunger for scientific knowledge drives human beings to explore beyond Earth into the depths of the solar system through physically visiting our cosmic neighbourhood, the rush to attend to the necessities of ever-increasing humankind with ever-demanding and reliable global services [], boosts the industry related to the design, development, test, launch, operation, and disposal of satellite technologies in Earth’s orbit.

In this sense, the satellite industry holds much pressure to evolve, providing systems which are more optimised, efficient, less expensive, and more sustainable for the planet, as our resources are limited []. In this sense, much of the current research is devoted to tackling one or more of the aforementioned aspects, and it is expected to increase exponentially in the following decades [].

A key aspect is to reduce launch costs, as nowadays, launching a satellite to Low Earth Orbit (LEO) costs between EUR 20,000 and EUR 100,000 per kilogram of mass []; such a cost increases drastically to reach the GeoStationary Orbit (GEO). Although such costs are considered affordable for large aerospace companies and large space agencies of developed countries, it is clear that they hinder the development of satellite technologies for small companies, start-ups, and educational entities, as well as for underdeveloped countries.

Although the obvious tactic to bring down such costs is in the research of cheaper and more efficient rocket designs and better fuels, a possible solution within the reach of satellite manufacturers and sponsors is the mass reduction in the satellite [].

In this sense, probably the most effective way to reduce the mass of a satellite is in the structural subsystem that makes up the satellite itself. However, such an action could have an immediate effect on the overall capability of the satellite to withstand mechanical loads present during the launch phase, which are the most critical during the life-cycle of the satellite []. Thus, structural optimisation must be wisely applied to a wide variety of situations that arise during both the launch and service life of the satellite. Thus, optimisation techniques become crucial in the aerospace sector.

According to Arora et al. [], general optimisation is a mathematical process that involves a structured approach to identifying the best possible solution among a set of alternatives, taking into account specific objectives and constraints. The process encompasses several key stages. Initially, the optimisation problem is clearly defined, specifying the objectives to be minimised or maximised, as well as any restrictions that must be honoured. Decision variables, which can be adjusted to attain optimal results, are identified, along with their allowable ranges. To do so, a mathematical objective function is formulated to quantify the system’s performance in relation to such decision variables. A starting point is established by providing initial values for decision variables. The optimisation algorithm then iterates, refining the solution through adjustments while adhering to constraints. The process continues until a stopping criterion is met, which corresponds to either a predefined number of iterations or a satisfactory level of improvement.

In particular, structural optimisation following Rotwell et al. [] entails a systematic process aimed at achieving the best configuration for a structure while adhering to specific goals and constraints. This process encompasses several key steps. First, the problem is defined by setting clear objectives and identifying constraints, such as stress limits or material properties. Mathematical modelling is then used to represent the structure’s behaviour through methods like finite element analysis (FEA), breaking it down into elements and nodes to simulate its response to external forces. Design variables, such as geometry and material properties, are determined, and an objective function is formulated to measure the structure’s performance against optimisation goals. Constraints are established to ensure the design meets specified criteria.

Structural optimisation encompasses three distinct categories: size optimisation, shape optimisation, and topology optimisation (TO) []. According to [], size optimisation focuses on finding the most suitable values for parameters such as cross-sectional dimensions, thicknesses, and other geometric attributes of structural elements. Shape optimisation, on the other hand, involves modifying the geometric arrangement, specifically the boundary conditions of the governing equations. Shape optimisation can be either non-parametric (free-form) or parametric []. In the context of non-parametric shape optimisation, the design domain encompasses the surface nodes (referred to as design nodes) within the finite element model. At each design node, displacement vectors are assigned, and the optimisation process entails adjusting scalar displacements along these vectors, which are treated as implicit parameters in this free-form optimisation approach. In contrast, parametric shape optimisation is closely related to the Computer-Aided Design (CAD) geometry of the structure, directly modifying the selected shape parameters. Lastly, TO generates concepts for material layout by either altering the quantity and properties of structural elements or changing the number of holes within a structure [].

Choosing an appropriate optimisation algorithm for satellite structural optimisation is crucial, ranging from gradient-based techniques to evolutionary algorithms. Then, the algorithm is implemented, code is written to modify design variables and evaluate the objective function, and the process iterates, refining the design while considering constraints. Convergence criteria determine when the optimisation stops. The final design’s performance is evaluated through simulations, ensuring it meets goals and constraints [].

Upon achieving a satisfactory design, it should be implemented practically, involving manufacturing components according to the optimised specifications []. Testing the physical structure validates its real-world performance, confirming that the optimised design translates effectively into practical benefits []. Throughout this process, sensitivity analysis, robustness, manufacturability, and trade-offs between objectives are taken into account.

However, structural optimisation often yields very intricate designs and patterns, which in most cases are almost impossible to manufacture with traditional manufacturing processes [,,]. This fact has hindered the physical realisation of structurally optimised components in the last three decades. However, the recent development and trends in the field of additive manufacturing (AM) have posed it as a promissory option to manufacture and test structures coming from TO processes [].

In this sense, the aerospace industry finds strong appeal in both AM and TO due to their transformative capabilities, addressing key industry challenges. AM, also known as 3D printing, interest by offering weight reduction capabilities, while critically preserving structural integrity. Its ability to fabricate intricate and complex geometries not achievable through traditional methods aligns well with aerospace’s need for aerodynamic and structurally optimised components. Moreover, AM enables cost-effective customisation, rapid prototyping for iterative design, and reduced lead times through on-demand production, promoting agility in responding to challenging changes in the industry [].

TO’s ability to generate innovative designs aligns with aerospace’s pursuit of improved strength, stiffness, and other vital parameters. Its optimisation output can be tailored to manufacturing constraints, ensuring feasibility, particularly when coupled with AM techniques. With aerospace manufacturing’s cost constraints and resource considerations, TO provides an avenue for optimising resource utilisation and achieving cost-effective, sustainable manufacturing [].

Moreover, TO methods establish technical ways in which material used to sustain a determined load within a design space can be decreased without endangering the overall capability to sustain such a mechanical load [].

TO methods perform optimisation in a semi-automatic way, reducing design time and naturally reducing material waste as only the required amount of material needed is maintained in the final design. Thus, when coupled with manufacturing techniques like AM, such capabilities can be brought to the real world, where the material is scarce, valuable, and usually costly []. These two technologies enable individuals to have access to prime manufacturing capabilities without the need to invest high amounts of capital. This characteristic is highly desirable for countries that lack a highly developed aerospace industry as it fosters the beginning of serious research efforts and development with minimal spending of resources.

AM’s ability to minimise material waste, create complex multi-purpose optimised designs, and enable on-demand production makes it an environmentally friendly manufacturing method. By reducing material waste and its associated energy consumption, AM plays a role in conserving resources and contributing to a more sustainable approach to production [].

Furthermore, TO embraces multidisciplinary design considerations, a fundamental of aerospace systems. By optimising interconnected components, it contributes to system-level improvements and performance enhancements. Ultimately, the aerospace industry’s engagement with both AM and TO underscores a shared commitment to innovation, efficiency, sustainability, and the advancement of aerospace technology to meet the stringent demands of modern applications [].

This paper intends to present a comprehensive review of different TO techniques applied to satellite structures, along with a brief review of AM processes, particularly those that have been applied to manufacture satellite-optimised components. The final goal of this review is to gather in one place the state-of-the-art in TO methods and AM processes applied to satellite structural optimisation up to date. Thus, it is aimed at aiding professionals and researchers in the field as well as fostering this promissory area of knowledge in the following decade.

This work is organised as follows: Section 2 puts an emphasis on TO methods, providing a brief description of every method without disregarding their general acceptance within the scientific community. A brief overview of AM as a means to manufacture TO solutions is expressed in Section 3, including general mechanical requirements needed for taking into account the TO process for AM processes. On the other side, examples of the real applicability of TO on the topic of satellite structures and sub-structures are presented in Section 4 and Section 5, including AM processes if applicable. Finally, a discussion about the gathered information as well as brief final remarks is presented in Section 6.

2. Topology Optimisation Methods

Within the realm of structural mechanics, there exist diverse methods for optimising mechanical designs. In contrast to size optimisation and shape optimisation, TO stands apart. It does not require a nearly optimal starting design to properly work and has the capability to generate optimal solutions when conventional design strategies prove ineffective []. This might happen due to complex inter-relationships between design parameters and structural responses []. Applying TO can result in much greater savings of material than size optimisation or shape optimisation [,,,].

TO addresses the question—how can we strategically distribute a specified amount of material within a predefined design space to achieve optimal structural performance, considering defined loads and constraints?

The answer is characterised by its broad applicability, encompassing scenarios involving singular or multiple materials with isotropic or anisotropic behaviour. It extends to both two-dimensional and three-dimensional spaces and involves considerations related to weight, displacement, and stress restrictions, combined with multiple loads of diverse physical nature. Moreover, it encompasses a range of physical phenomena, including mechanical aspects such as stiffness, natural frequency, buckling, and impact, as well as thermo-mechanical and fluid interaction effects. These varied conditions have led to the emergence of a multitude of methods aiming to address as many combinations as possible. The underlying objective of these methods is to provide optimal solutions while maintaining efficiency and computational affordability.

To study the methods available, we categorise them as follows.

- Continuum approaches, which are based on the modification of continuous parameters such as mass density.

- Discrete approaches, which are based on the elimination or addition of material elements in a meshing context.

- Diverse approaches, containing TO continuum and discrete approaches that are used to solve specific problems such as multi-scale TO and multi-physics TO or that try to give a novel dimension to TO problems by integrating machine learning techniques.

The proposed classification can be observed in Table 1, where the Metaheuristic Algorithms and Metaheuristic Hybrid Algorithms have their own sub-classification, which can be found in Table 2 and Table 3, respectively.

Table 1.

Topology optimisation approaches.

Table 2.

Topology optimisation approaches—subclassification within Metaheuristic Algorithms in Table 1.

Table 3.

Topology optimisation approaches—subclassification within Metaheuristic Hybrid Algorithms in Table 1.

In what follows, we revise the most prominent exponents of each of these categories.

2.1. Topology Optimisation Continuum Approaches

2.1.1. Beginnings

The first formal paper to address the problem is probably proposed by Michell back in 1904 []. In this paper, he derived optimal criteria for the minimum weight layout of 2D truss structures.

Then, after some decades, the first general theory of TO was given by Prager and Rozvany in 1977 [] in the form of their “optimal layout theory”. In this work, the optimisation analysis is obtained analytically for grid-type structures.

Exact analytical solutions for TO problems are very difficult to obtain. Even today, there are very few papers that address the problem from such a point of view; the reader might find a thorough way to address the derivation of analytical solutions for TO problems in the recompilation of lectures given at the International Centre for Mechanical Sciences (CISM) [].

2.1.2. Homogenisation Method

The transition from truss structures to continuum structures undergoing TO began with the seminal paper of Bendsøe and Kikuchi in 1988 []. Originally, TO was perceived as a challenge involving discrete 0-1 variables, implying a binary design configuration. This particular configuration, often associated with structural compliance, is recognised as being ill-conditioned in nature [,,]. To tackle this issue, Bendsøe and Kikuchi introduced a solution. They proposed re-framing the problem by introducing intricate porous microstructures at a smaller separate scale. This is performed using the homogenisation theory, thereby transforming the problem into one that is mathematically well-defined.

The homogenisation method aims to optimise through density variables that are associated with a specific microstructure model at a separate lower scale. TO is achieved by iteratively modifying the corresponding size variables of each unit cell. It is a difficult method to implement due to mathematical complications, particularly in 3D extensions of method []. This paper meant the birth of practical (numerical) TO methods [,,,], and since their first appearance, their use has been extensive. This surge in numerical investigations coincided with revolutionary advances in computing capabilities and the progress made in numerical simulation techniques [].

The original paper of Bendsøe and Kikuchi meant the birth of practical (numerical) TO methods. Since its introduction, the concept of continuum TO has evolved in various ways, giving rise to a wide array of methods that have emerged and progressed over time.

2.1.3. Solid Isotropic Material with Penalty Method

To circumvent the mathematical complications inherent to homogenisation theory, Bendsøe [] proposed Solid Isotropic Material with Penalty (SIMP) in 1989, another density-based method with a simplified material assumption. By penalising exponentially the isotropic material density in terms of element density variables, it is possible to manipulate structural properties related to density (like structural stiffness). The design domain is discretised by using elastic linear isotropic continuum finite elements (FE), and then the finite element method (FEM) is used to obtain the structural response; analytical sensitivities are then calculated with an adjoint method (numerically solved via the Method of Moving Asymptotes (MMA) []). A filter is then applied to smooth sensitivities []. The process occurs in a loop until the required volume constraint is satisfied. The name (SIMP) was first suggested by Zhou and Rozvany in 1991 []. For its simple conceptualisation and numerical implementation, SIMP is one of the most popular and widespread TO methods [,,,].

Until today, SIMP has maintained its status and continues to develop. Recent advances include SIMP combined with phase-field method [], multi-material TO [,,,,,,,], anisotropic material behaviour [,], dynamic performance and fatigue TO [,,,,], large elastic deformation TO [], additive manufacturing (AM) constrained TO [,,,,,], subtractive manufacture (SM) constrained TO [], and casting constrained TO []. Some approaches lead to self-weight TO [], nonlinear load cases [,], stress constrained TO [], surface corrosion TO [], buckling considerations [,], non-linear heat conduction [], thermal dissipation [].

Some interesting applications include flexoelectric structures (nano-structures) [] and shape-memory alloys []. Recent approaches use Iso-Geometric Analysis (IGA) [,]. Others eliminate mesh of the design [].

2.1.4. Topology Derivative

Another approach that emerged in the 1990s is the utilisation of topology derivatives in the fields of topology and shape optimisation, pioneered by Eschenauer [] in 1994 through the introduction of the bubble-method. The fundamental concept underlying topology derivatives involves predicting the impact of introducing an infinitesimally small hole at any location within the design domain. The predictive information obtained is then employed to create holes. Topology derivative is used in conjunction with a shape optimisation method acting as the mechanism to place new holes that are then manipulated by the latter method. A more recent development is brought by Amstutz [], demonstrates that for some choices of material properties, the topology gradients used in minimising compliance correspond to the standard density gradients as used in the SIMP scheme []. Amstutz’s research highlighted that both methods yield equivalent outcomes under certain conditions (when the penalisation exponent is set to , specifically in the context of 2D elastic problems with a Poisson’s ratio of ). An additional aspect is that deriving topology derivatives demands the application of intricate mathematical concepts, as emphasised by Sokołowski and Zochowski [], a point later reiterated in []; this feature has the effect of prevent widespread of the method and practical applications, instead, one can find the topology derivative method implicit within level-set methods [,,,,,].

2.1.5. Level-Set Method

Methods up to now track changes in topology in an explicit way. level-set Method (LSM) is a TO method that defines boundary design implicitly. When dealing with the problem of TO, the groundwork for the LSM is initially laid out by Osher and Sethian [,]. This foundational mathematical framework subsequently found practical utility by Sethian [], Wang [,], Allaire [], and Jouve [].

LSM is originally developed to model moving boundaries. Initially, LSM is primarily employed to depict the progression of interfaces in scenarios like multi-phase flows and image segmentation. However, the application of LSM to TO commenced in the year 2000 with Sethian’s work and has advanced rapidly since then.

The core principle of the LSM involves expressing the interface (the demarcation between material and void within a design space) as the level set of a continuous function. Defining the interface enables the explicit formulation of objectives and restrictions pertaining to the interface while also facilitating the description of boundary conditions at that interface. Normally, the outcomes obtained through the utilisation of LSM are heavily reliant on the initial solution guess [,]. A notable limitation of this approach is its tendency to experience sub-optimal convergence rates, often requiring a substantial number of iterations during the optimisation process [].

A comprehensive examination of the utilisation of LSM in TO is provided by van Dijk in a detailed review [], whereas a more recent review by Gibou [] shows the capacities of this method, which has not stopped evolving.

Recent works on LSM are: LSM combined with BESO [], multi-material approaches [,], multi-component TO [], micro-architectured materials [], reliability-based TO [,,,,], dynamic TO [,], buckling [], design-dependent loads [], heat conduction TO [], AM constrained TO [,,,], SM constrained TO [], parallel LSM proposals [,,,], and Iso-Geometric Analysis (IGA) with LSM [,,].

Additionally, a level-set band approach has been introduced with the aim of enhancing the smoothness of objective and constraint functions. This method integrates the benefits of both the level-set method (LSM) and density-based techniques by introducing a single parameter, referred to as the ’level-set band’, to seamlessly merge the strengths of both methods [].

2.1.6. Phase-Field Method

The phase-field method for TO is initially developed as a means to depict the surface dynamics of phase-transition phenomena, particularly in scenarios involving transitions between solid and liquid states [,]. These methods have found application in various simulations of surface dynamics, particularly in materials science. They have been employed for tasks such as modelling diffusion, multi-phase flow, crack propagation, solidification, and phase transitions []. The phase-field method for TO is first introduced by Bourdin in 2003 [,] and then subsequently extended by Wang [].

Phase-field TO employs a penalty approach to approximate the perimeter of the interface. Through the selection of a very small positive penalty parameter, it becomes possible to achieve a penalty as a well-defined interface zone that separates solid regions from voids []. In contrast to LSM, the equations governing phase transition are solved across the entire design domain without any pre-existing knowledge regarding the whereabouts of the phase interface. However, there exist some problems; for example, the correct selection of the parameters is an important factor in ensuring the convergence behaviour of the numerical solution (affecting the number of iterations needed to obtain a solution). Unfortunately, the selection of parameters is case dependent and requires a set of tests []. Additionally, there is a high computational cost of solving the underlying fourth order Cahn–Hilliard Equation []. These are some of the reasons that have prevented the spread of the method. Despite not being a popular method, advances can be further studied in [,,,,].

2.2. Topology Optimisation Discrete Approaches

In TO discrete approaches, the treatment of individuals is twofold: one option consists of treating every finite element (FE) of a unique design as an individual of a population; then, least fit individuals of that population are removed as the optimisation process advances. This approach is common in Evolutionary Structural Optimisation methods. Specifics of formulation and implementation vary depending on each method. On the other side, the second option is to treat a design space (and its TO solution) as an individual; then, one wants to generate a large number of solutions (population) and apply some technique to generate the best individual. This approach is typical of genetic algorithms, for instance. We shall explore both approaches in what follows.

2.2.1. Evolutionary Structural Optimisation Methods

Evolutionary Structural Optimisation (ESO) is a discrete approach to the TO problem. Although in density approaches the discrete design space is relaxed, offering a continuous space design, in discrete methods, the design space is not relaxed and thus the design variable is completely discrete (0,1). The most prominent family of discrete methods is the ESO method, the first one being proposed by Xie and Steven in 1993 [,], which is grounded in the straightforward notion that a structure progresses towards an optimal state by progressively eliminating material experiencing low stress levels, while adhering to specified material volume criteria. However, achieving effective solutions can prove challenging under certain circumstances. In order to address its initial shortcomings, this method has undergone modifications throughout the years. First changes were aimed at enabling the restoration of removed elements, particularly those adjacent to heavily stressed components.

Originally, ESO could only remove low-stress elements, preventing finding optimal solutions. To improve ESO capabilities, bi-directional approaches allow previously eliminated individuals to reappear as part of the design. Early versions of the Bi-Directional ESO (BESO) method were developed by Querin [,] and Yang []. However, these methods relied heavily on heuristic concepts and lacked strong theoretical foundations. Additionally, they were susceptible to issues such as mesh dependency and the emergence of undesirable chequerboard patterns []. An improved BESO method was delivered by Huang and Xie [,], and, almost at the end of the decade a soft-kill BESO (SBESO) [] version of their method was proposed.

In SBESO, standard adjoint gradient analysis is incorporated, introducing a higher level of theoretical rigour to the approach. Additionally, filtering techniques similar to those employed in density-based methods are integrated to stabilise the algorithm and mitigate issues like chequerboard patterns. Various benchmark examples for BESO and SBESO are fully reported in the book by Huang and Xie []. For the final SBESO version, the design domain is discretised through a finite element mesh, and initial property values are assigned to construct an initial design. Subsequently, a finite element analysis is conducted and nodal sensitivity numbers are computed using an adequate compliance equation. Notably, these sensitivity numbers are directly derived from nodal values to avoid the need for elemental calculations. The implementation includes a mesh independence filter step that refines the sensitivity values by considering neighbouring nodes and employing linear weight factors within a specified radius. Furthermore, the process involves averaging the current sensitivity numbers with historical data to ensure continuity and readiness for the subsequent iteration. The determination of the target volume for upcoming iterations is based on an evolutionary volume ratio concept, wherein the structure’s volume undergoes adjustment until a predefined constraint is met. The optimisation process dynamically modifies the design configuration by introducing or removing elements according to specific conditions tied to sensitivity thresholds. Importantly, the iteration cycle, encompassing steps 2 to 6, persists until the prescribed constraint volume is attained and optimisation objectives are successfully achieved, all while maintaining convergence through a pre-established threshold.

A multitude of recent works were also found: LSM with BESO [], phase-field method with BESO [], nonlinear structures under dynamic loads [], non-linear reliability TO [], buckling TO [], fatigue considerations [], crashworthiness TO with BESO [], frequency optimisation [,], BESO with casting constraints [], and BESO with AM constraints [,,,,,]. Other interesting works are the Iso-Geometric Analysis (IGA) approach with BESO [], a meshless BESO technique [], and a parallel framework for BESO [].

2.2.2. Moving Morphable Voids Method

On 2014, Guo proposed Moving Morphable Components (MMC) []. In this method, a set of MMC are utilised as fundamental elements for TO. The process involves enhancing the arrangement, positioning, and configuration of these components to achieve an optimal structural layout; its ability to significantly decrease the quantity of design variables required in the problem definition makes this method appealing. This reduction proves advantageous in cutting down the required computational time for numerical optimisation procedures.

Based on Guo’s work, Zhang proposed Moving Morphable Voids (MMV) in 2017 [], where a set of MMV are adopted as basic building blocks for TO. This method decreases the number of design variables, the number of degrees of freedom involved in the FEA solution process, and it can also be further extended to 3D optimisation. Examples of use can be further explored in [,,,], whereas explicit use of Iso-Geometric Analysis (IGA) has also been explored [,,,].

2.2.3. Metaheuristic Topology Optimisation Methods

Although SIMP is a method exclusively centred around gradients, involving calculating derivatives of objective functions, metaheuristic algorithms prioritise sensitivity numbers by evaluating their magnitudes. As a result, this enables a more adaptable objective function and simplifies the implementation process, leading to significant advancements in the utilisation of TO within engineering disciplines []. In what follows, we shall revise some advancements in the application of metaheuristic algorithms to TO.

Genetic Algorithms

Over the past thirty years, efforts have been devoted to applying genetic algorithms (GAs) to address challenges in structural optimisation problems [,,]. GAs function by working with a population of potential solutions, as opposed to enhancing a singular solution. Because of this characteristic, a typical structural optimisation problem tackled with GAs has to contend with a significantly larger set of design variables compared to conventional mathematical programming methods. As a result, there is a notable drawback in terms of computational burden []. Research integrating GAs into structural optimisation has focused on relatively small problem sizes. The implementation of GAs in TO has been found utilising different approaches: we can find pure GAs applied to solve the TO problem for simple compliance optimisation [,,]. In this type of approach, the entire design space is considered as a component of the chromosome of a single individual; the idea is to generate hundreds or thousands of designs which evolve towards the optimal solution. For a structure to effectively withstand a mechanical load, it must possess a strong level of connectivity.

However, ensuring adequate structural connectivity through the use of GAs is challenging due to their inherently stochastic nature. This presents a significant limitation when applying GAs to TO, and finding a viable solution to this issue proves to be exceedingly difficult. Jackiela [,] suggests altering solid elements that lack connectivity to the seed elements in order to be emptied; ref. [,] suggests enhancing connectivity by incorporating a chromosome mask to selectively filter out chromosome segments originating from disconnected positions; Wang [,] suggests the incorporation of image processing techniques. Those approaches failed to effectively reduce randomly disconnected topologies, or are excessively cumbersome. However according to Li and other scholars, GAs might have better probabilities to converge towards global solutions [,,,,,].

For some successful applications of TO using GAs, it is appropriate to review the work in [,,].

Other Metaheuristic Approaches

Other metaheuristic techniques have been applied without hybridising. Such are the cases of artificial immune algorithms [,,], ant colonies [,,,], particle swarms [,,], simulated annealing [,,,], harmony search [,,,], and differential evolution [,].

There exist a plethora of other proposals aiming to apply metaheuristic approaches with TO, but they have not experienced further development. We observed a multi-objective TO based on bacterial chemotaxis [], a joint firefly and particle swarm optimisation (PSO) algorithm [], a symbiotic organisms search algorithm [], an improved electro-search algorithm [], a plasma generation optimisation [], a binary bat algorithm [], an enhanced binary GA along with morphological reconstruction [], a semi-definite programming-based approach combined with a GA [], as well as a ground structure approach based on curved elements []. A constant in metaheuristic methods is the large quantity of iterations needed to converge which makes them difficult to extend to 3D design spaces where the computational burden increases considerably.

There is another approach in which the idea is to combine established TO algorithms with metaheuristic algorithms. Such is the case of Garcia and Silva, [] who combined SIMP with simulated annealing, or Xue [] who combined SIMP with a GA. In this sense of hybridisation, there is a tendency to combine ESO and BESO methods with other metaheuristic algorithms. This is mainly due to the discrete nature of ESO algorithms, which makes hybridisation a relatively straightforward process.

Far from the approaches used in the application of pure metaheuristics, hybrid approaches do not work over populations of individual solutions; instead, they try to assist the base algorithm to improve individual solutions. Such is the case of Liu [,]; the proposed approach treats each element within a structural domain as an individual member of a genetic algorithm (GA) population, in contrast to creating multiple entire structural designs to compose the population. In this method, the traditional ESO sensitivity number is employed as a fitness function, and a natural selection process is employed to eliminate less-fit elements, mimicking the elimination of less-fit individuals in traditional GA design problems. Cui [] presents a work following Liu’s ideas. A similar work is presented by Zuo [] to generate a genetic version of BESO. Yhunzhen [] applies Zuo’s work to architectural design optimisation. Other works hybridising BESO with GAs might be consulted [,]. In a similar way, it is possible to find works hybridising BESO with other metaheuristics; such is the case of swarm optimisation algorithm [], simulated annealing [], and harmony search [].

2.3. Diverse Approaches

Multi-scale, multi-physics, and machine learning applied to TO constitute a series of problems that may be solved by applying TO techniques that use either continuum, discrete, or combined approaches. These novel approaches have seen important development in the last 10 to 20 years, positively expanding the realm of methods and techniques available to solve a multitude of TO problems.

2.3.1. Multi-Scale Topology Optimisation Methods

Over the past three decades, TO methods have predominantly focused on the macro-scale aspects of design. However, there has been a growing interest in the development of optimisation methods that can enhance the overall performance of structures by incorporating the concept of multi-scale structural TO.

Multi-scale TO offers a novel way to optimise structures. Taking into account that the structure itself may be composed of small unit cells with a certain degree of porosity, this characteristic gives multi-scale methods the ability to obtain comparably lighter structures than using full-scale TO methods.

Features of multi-scale, such as high level of porosity, may appear when using full-scale TO methods, small details on the mesoscale (ranging from 0.1 to 10 mm) may appear if the FE mesh is fine enough to capture such details. As a result, structures that resemble grid-like patterns filling the overall macro-scale structure are obtained. Such a full-scale approach is computationally intensive as the resources needed to solve 3D problems increase with mesh density. As an option to alleviate the problem, multi-scale approaches work in two or more levels (sometimes based on homogenisation theory) of optimisation; in one level, a unit cell is proposed to fill the design volume delimited by the macro optimisation level that resembles the usual solution obtained in full-scale approaches. The main difference is that lighter structures can be obtained. Periodic patterns using TO may be imposed by subdividing the design volume and then assigning a repetitive pattern on each subdomain. Such an approach allows the obtaining of Lattice structures, and if the density (size) of unit cells is allowed to change along the design, we are then speaking of functionally graded materials.

Multi-scale structures offer the potential to attain exceptional performance characteristics, all while possessing inherent qualities of being lightweight and versatile. However, the actual advantages of these innovative multi-scale structures must be verified through numerical simulations and experimental validations as investigation research matures. Multi-scale topology approaches have been extensively reviewed by Wu et al. [].

Many full-scale TO methods can be used to obtain multi-scale lattice structures and functionally graded materials; notable examples are:

- Multi-Scale Topology Optimisation with Homogenisation [,,,,]

- Multi-Scale Topology Optimisation with SIMP [,,,,,,,,,,,,,,]

- Lattice Structure Topology Optimisation with SIMP [,,,,,]

- Multi-Scale Topology Optimisation with Level-Set Methods [,]

- Lattice Structure Topology Optimisation with Level-Set Methods [,,,]

- Functionally Graded Material Topology Optimisation with Level-Set Methods []

- Multi-scale Topology Optimisation with BESO [,,,,,,,]

- Lattice Structure Topology Optimisation with BESO [,,].

2.3.2. Multi-Physics Topology Optimisation Approaches

TO is usually applied to mechanical problems were elasticity is the most relevant phenomenon at hand. However, there are problems where the interaction of multiple physical phenomena needs to be accounted for; such problems are categorised as “multi-physics” [].

It is possible, in general, to find TO applied to problems where thermal boundary conditions impose temperature gradients, yielding thermo-mechanical stresses acting on the structure. It is possible to find in the literature implementations that are either uni-objective or multi-objective, and that provide options on how to tackle the problem at hand. Coupled thermo-mechanical TO has found application on heat dissipation structure design [,,,,].

TO has also found application in electromagnetic actuators, the work in [] considers the coupled interaction between structural and electromagnetic phenomena, whereas the research in [] considers thermal and electromagnetic interaction, both employing multi-objective TO.

Furthermore, other less-studied multi-physics TO problems include fluid–structure interaction, which is usually relevant in aeronautics for the design and optimisation of airfoils, wings, and compressor blades. Relevant applications for the purpose of this paper are found in selected works where interaction between molecular atmosphere and satellite structure is relevant to optimise orbit lifetime [,,]. As interaction occurs in the surface of the structures, only shape optimisation is needed to solve the problem.

Finally, layout optimisation deserves to be mentioned, although it does not necessarily refer to TO. Layout optimisation refers to the optimisation of the relative position of objects inside the satellite with the intention of adjusting the satellite centre of mass. Such an optimisation might be of great help to improve stability characteristics in orbit. However, its integration with structural TO might prove useful for structure redesign in the late development stages. Satellite layout optimisation can be found in [,,,,].

2.3.3. Machine Learning Applied to Topology Optimisation

Research in this area has focused on data-driven TO, which means using a traditional TO method to gather a database of possible solutions for a problem [,,]. Then, aiming to improve the process of obtaining optimal structures, different machine learning techniques are applied, like supervised, unsupervised, as well as reinforcement learning. These techniques serve several purposes, including speeding up the design iteration [,,,,,,].

Apart from data-driven TO, some works try to achieve non-iterative optimisation [,,,,,,,,,,,,,,,,,], or intend to replace the typical FEM process, creating meta-models [,,,,,,,,,,,,,,,,,,]. Other approaches try to reduce the dimensionality of the design space [,,].

Such approaches have effectively accelerated the optimisation process and decreased computational burden. Despite the progress in this field, there remain challenges in many studies. These include addressing the low resolution of generated designs, enhancing the performance of machine learning methods, adapting the methodologies to different design domains (three-dimensional spaces), grappling with the costs associated with gathering data and managing the high computational burden of both FEA and the machine learning approach [].

3. Additive Manufacture in the Context of Satellite Structures

Typically, topology-optimal solutions are given in disregard of standard manufacturing techniques. As a result, intricate and organic designs with notably lower weight are achieved. Thus, it is challenging or even infeasible to fabricate such designs using traditional manufacturing methods [,,]. In this sense, the following question arises: is it possible to manufacture optimal solutions given by TO methods?

TO methods can be used for components produced through additive or subtractive methods, as well as by other techniques like casting. Subtractive Manufacturing (SM) refers to processes that create objects by removing material from a solid block or billet of material [,]. The material removal process involves removing material from a workpiece, conducted manually through methods like drilling, turning, and milling, as well as using Computerised Numerical Control (CNC) automation [].

This approach ensures high-dimensional accuracy, enabling the attainment of tight tolerances and exceptional surface finishes. Particularly suited for mass production, CNC machining is adept at efficiently manufacturing large volumes of uniform components []. However, this method generates material waste in the form of machining chips, scraps, and swarf. The fundamental traditional methods include milling, which involves using rotary cutters to shape complex 3D forms; turning, a technique where a workpiece rotates and a non-rotating cutting tool is used; drilling, employing specialised drill bits to create holes; grinding, using abrasive wheels to achieve precise surface finishes; and sawing, which employs thin blades to divide workpieces into desired configurations []. Nevertheless, SM has certain factors to consider when applied to the manufacture of TO solutions, such as tool accessibility, mould removal, significant time consumption, and the need for skilled operators to create holes, shapes, cylindrical forms, and mill surfaces. These factors limit the applicability of TO methods [,,,].

On the other side, AM is defined in the standard ISO 52900:2016 as the process of joining materials to make parts from 3D model data, usually layer upon layer, as opposed to subtractive and formative manufacturing methodologies [,]. The categorisation of AM processes is highly complex due to their wide range of applications and diverse operational methods. This makes the task of defining boundaries between processes and categories extremely challenging. However, Kumar in 2021 [] presented a classification that, unlike the one provided by the American Society for Testing and Materials (ASTM) in 2012 [] and the categorisation of the standard ISO 52900:2016 [], encompasses most of the current AM processes.

- Material bed process: This category encompasses techniques where the material is first laid down in bulk to create a bed, upon which the actual fabrication process takes place layer-by-layer. Some common examples of this category include:

- Binder Jetting 3D Printing (BJ3DP) [,,,,].

- Ceramic Laser Fusion (CLF) [,,].

- Stereolithography (SLA) [,,,,].

- Electron Beam Melting (EBM) [,,,,].

- Selective Laser Melting (SLM) [,,,,,].

- High-Speed Sintering (HSS) [,].

- Selective Laser Sintering (SLS) [,,,,].

- Digital Light Processing (DLP) [,,,,].

- Material deposition process: This process involves transferring material from a feed source to a substrate in order to fabricate a part directly, as opposed to forming an intermediate bed. This category is divided into the following categories:

- Solid deposition.

- −

- Fused Filament Fabrication (FFF) [,,,,,].

- −

- Direct Metal Deposition (DMD) [,,].

- −

- Direct Energy Deposition (DED) [,,].

- −

- Wire and Arc Additive Manufacturing (WAAM) [,,,,,].

- −

- Plasma Arc Additive Manufacturing (PAM) [,].

- −

- Cold Spray [,,,,,].

- Liquid deposition.

- −

- Ink Jet Printing (IJP) [,,].

- −

- Photopolymer Jetting (PJ) [,].

- −

- Metal Jetting [,,].

- −

- Rapid Freeze Prototyping (RFP) [,,,,].

- Slurry deposition.

- −

- Thermoplastic 3D Printing (T3DP) [,,,].

- −

- 3D Gel Printing (3DGP) [,,,].

- Motionless material process: Refers to AM techniques where the material feedstock remains static and does not require active conveying or deposition to construct each layer. In processes like Two-Photon Polymerisation (2PP) and Continuous Liquid Interface Production (CLIP), the photopolymer resin is already present in a vat or container. These motionless material techniques eliminate the motion requirements of powder beds, material extrusion, or droplet jetting.

AM enables the construction of intricate TO for complex shapes that would not be feasible using subtractive techniques. Examples of design-driven AM in manufacturing are presented later in Section 3.2.

It is worth mentioning that there are other manufacturing techniques that allow TO solutions to be manufactured such as casting [,,,,,] and extrusion [,,,,,]. However, these techniques have specific requirements that require considerable changes in the topology-optimal layout resulting in a structure that is sub-optimal. AM and SM processes have been demonstrated to be less intrusive and allow the manufacture of shapes closer to the optimal TO solution at hand.

3.1. General Considerations about Additive Manufacture for Topology Optimisation-Generated Solutions

There are numerous considerations about using AM to manufacture the optimal solutions generated by TO, which become especially important in the aerospace field, where high safety levels and high reliability are expected and required.

For instance, implementing length scale limitations in TO is essential to prevent the creation of impractical geometric attributes like small openings, fragile walls, or tiny joints []. Employing density filtering is a valuable method for restricting the minimum length scale [,,]. Since AM involves a sequential layer-by-layer construction process, horizontal overhangs require the use of support structures during the building process (although these supports can be subsequently removed [,,]). Additionally, unprocessed enclosed materials in cavities lead to local high temperatures, the reason for which they have to be removed [,,].

Moreover, due to the presence of substantial thermal gradients present in various AM techniques during the progressive solidification of layers, notable residual stresses can emerge [,,]. These stresses often result in distortions such as part warping and other geometric deviations.

Additionally, formed parts generally suffer from relatively low repeatability [,]. It has been noted that parts manufactured show anisotropy [,,]. Potential solutions exist to tackle this issue. Some options include optimising AM process parameters like build orientation [,], incorporating secondary processes such as laser re-melting [], or integrating true anisotropic material models into TO []. The goal is to achieve superior performance in additively manufactured structures. These and other limitations related to AM need to be considered when designing through TO.

Despite all the mentioned considerations affecting the manufacturing process, the aerospace industry within the AM market is expected to reach USD 1.4 billion by 2027, according to reports from SmarTech Publishing [] (https://www.smartechanalysis.com accessed on 1 October 2023).

3.2. Additive Manufacture Applied to the Satellite Industry

Around 2016, the National Aeronautics and Space Administration (NASA) estimated a minimal cost of USD 10,000 to put a pound (USD 22,000 per kilogram) of payload in Low Earth Orbit (LEO) [,]. With the costs involved in launching one kilogram of mass into LEO, there is a strong focus within the space industry on reducing the weight of satellites [].

The primary goal of TO applied to the aerospace industry in the context of satellite structures is to create tools that enhance the efficiency of structural mechanical design, aiming to reduce weight while optimising mechanical capabilities [].

In the realm of TO, AM offers benefits beyond creating lightweight optimised parts. It holds the potential to enhance component functionality, increase complexity, consolidate multiple parts into a single unit for efficient use of space, and thereby reduce manufacturing and assembly efforts [], improving mechanical properties by reducing or eliminating joints. Additionally, it has the capacity to significantly reduce manufacturing waste [].

In conventional aerospace and satellite component manufacturing, the fly-to-buy ratio typically ranges from 10:1 to 25:1. However, AM has the potential to substantially reduce this ratio to as low as 1.5:1 [,,]. A lower fly-to-buy ratio directly correlates to reduced material waste [], leading to cost savings. This reduction in waste is particularly crucial given the expensive materials commonly used in the aerospace and satellite industry, such as titanium alloys.

AM techniques have been effectively employed in the space sector for nearly two decades. In this sense, AM techniques for the fabrication of spacecraft parts and satellite structures have been successfully used by scholars [,,,,,,] and space contractors [,]. AM technology has also been used to manufacture functional engines suitable for small spacecraft [,]. In Section 4 and Section 5 of this manuscript, a summary of formal research applying TO methods to space applications is presented.

According to Gaudenzi and Ritz [,], the space industry predominantly employs AM methods for manufacturing space components []. Two prevalent methods are SLM and EBM, both of which use lasers or electron beams to melt powders []. Another technique, known as DMD [], involves injecting powders into a molten pool. In the case of plastics, common techniques include FFF [], SLS [], and SLA [].

According to the ESA Harmonisation Roadmap on AM for Space Applications [], the technical areas within satellite platforms that exhibit the greatest interest in TO are:

- Primary structure, structural components, and mechanisms.

- Propulsion systems, valves, filters, pipes, injectors, combustion chambers, nozzles, tanks, and multi-functional integrated components.

- Thermal systems, involving advanced thermo-optical surfaces, pre-cooling channels and piping, multi-functional integrated components, re-entry thermal protection, and gradient-sized meshes for cryogenic coolers.

- Electronics encompassing waveguides, micro-batteries, structurally embedded wiring, and intricate metallic components.

The development and testing of materials have enabled the implementation of AM in the aerospace field [,]. The review [] highlights various materials used in aerospace applications, mainly alloys, superalloys, and refractory materials. The low weight, low cost, and high strength of aluminium alloys, as well as their ease of use in manufacturing processes, allow their use in aerospace applications; however, their low melting temperature and poor corrosion resistance limit their use in this field []. Titanium alloys are widely used in aircraft due to their high temperature stability and specific corrosion resistance, as well as their compatibility with carbon fibre and polymer matrix composites [,]. Nickel and iron-based superalloys find application in the production of high-pressure turbine blades and discs []. This is because of their excellent mechanical attributes, which perform effectively under extremely high temperatures and pressures, even in corrosive surroundings. Copper alloys are frequently employed in heat exchangers intended for high-heat flux conditions where both strength and thermal conductivity are essential, particularly for cooling systems in high-pressure propellant or oxidizer environments. Refractory materials like niobium, tantalum, and tungsten are utilized in aerospace applications, particularly in situations characterized by extreme temperature conditions. Table 4 shows common materials used in the aerospace field.

Table 4.

Popular commercial materials available for AM [].

3.3. General Mechanical Requirements for Satellite Structures

In general, a TO method that is able to generate optimum solutions for real space application necessities is able to handle mechanical requirements derived from the specification of the structure under study.In this sense, the following question arises: which characteristics should a TO algorithm have to enable satellite TO? According to ECSS standard [], general mechanical requirements are as follows.

Artificial satellites must operate in an environment completely different from the terrestrial environment. Outer space is fundamentally empty (material outgas concerns arise). It must also be considered that the launch environment of a spacecraft is characterised by the imposition of high loads of a mechanical nature.

It is expected that every structure mounted on the launcher complies with minimal mechanical requirements, including both satellites and their payloads:

- Strength: the structure must endure the designated maximum loads without failure; it is imperative that any permanent deformations that might compromise the mission’s objectives are strictly controlled.

- Local yielding: in cases of metal structures or components, localised yielding may occur, as long as it does not induce overall permanent deformation, instability, or fatigue-related structural failure.

- Buckling: the stability (i.e., no buckling) of the structure must be verified under the prescribed design loads.

- Stiffness: stiffness requirements under specified loads and boundary conditions must be identified (stiffness is often quantified in terms of a minimum natural frequency requirement), thus preventing deformations that breach specified thresholds, gaps at joints, and dynamic interaction with other subsystems.

- Dynamic behaviour: the natural frequencies of the structure must fall within designated ranges to prevent dynamic resonance with significant excitation frequencies (e.g., fundamental frequencies of launch vehicles). Avoiding mechanical resonance is a must when TO is applied to satellite structures.

General mechanical requirements in the context of TO for satellites implies that the algorithm selected is fundamentally able to find a new material disposition, effectively reducing structure mass at the same time that stiffness is maximised (allowing enough safety factor to withstand launch-induced loads without experiencing permanent deformation). These optimisation objectives may be assessed either in a uni-objective or multi-objective sense.

All TO methods presented in Section 2 have been demonstrated to solve these problems at least in a uni-objective sense.

4. Cases of Study on Satellite Structures by Topology Optimisation Continuum Approaches

The scientific literature does not feature all the methods presented in Section 2 as effectively applied to obtain optimal solutions in the context of satellite structures. Thus, in this section, we only report an overview of study cases of different TO methods available for this purpose. Whenever the research includes the implementation of some AM technique to further create physical prototypes of optimised components, it is also covered.

Methods that lack any practical application in satellite structures TO are not listed in what follows.

4.1. Homogenisation Method

As discussed earlier, the homogenisation method has seen limited adoption for TO. This limitation is reflected in the minimal examples found in the literature documenting the use of homogenisation for the TO of satellite structures or components, whereas the fundamentals of the method remain strong, overcoming mathematical and computational barrier is vital for applying homogenisation more broadly in satellite TO. With the popularisation of multi-scale methods, we hope to see a surge in homogenisation practical applications. In this section, we present a case of study where the homogenisation method is applied to satellite development.

Small Satellite Structural Optimisation Using Genetic Algorithm Approach

A sandwich structure consists of two facesheets bonded to a lightweight core. This structure is commonly used in a variety of applications but in recent years it has been used in aerospace research and applications [,,,,,,]. Composite skin efficiently carries bending and membrane loads while the core transfers shear, also bringing support to the skin, aiding against buckling.

The challenge in the design of a honeycomb lies in modelling the mechanical behaviour of sandwich structures to enable optimisation. It is a complex task because composite materials are anisotropic and heterogeneous. An efficient modelling is needed to strike a balance between accuracy and computational feasibility. The proposed methodology for the implementation of optimisation is as follows:

- An unspecified mathematical homogenisation technique is presented to derive equivalent properties for the sandwich structure.

- There are derived relationships between the sandwich geometries and equivalent elastic module, shear rigidity, and plate rigidity.

- The equivalences enabled feasible analysis of the sandwich properties and optimisation of its design.

The model provides sandwich panel tension and compression stiffness as a function of facing the sheet module, Poisson’s ratio, and geometry. The equations offer useful approximations of the stiffness behaviours providing good initial estimates before costly 3D simulations. Further work is identified to capture additional failure mechanisms and improve upon the accuracy relative to 3D FEA. It is worth mentioning that this work is the closest found in the literature, along with method [], regarding the application of the homogenisation.

4.2. Solid Isotropic Material Interpolation Method

In what follows, we present cases of study where the SIMP method is applied to satellite development.

The work in [] presents a combination of TO and AM to design, analyse, manufacture, and qualify a lightweight satellite bracket. Lightweight aerospace structures can significantly improve performance and reduce emission but their design optimisation and manufacturing is challenging.

4.2.1. Design Optimisation and Validation for Additive Manufacturing: A Satellite Bracket Application

The goal of the paper is to reduce the mass of an existing satellite bracket subjected to mechanical and thermal loads during launch while maintaining structural integrity. Manufacturing constraints like printability, surface finish, overhang angles, and assembly interfaces need consideration in the design process. The methodology applied is as follows:

- Stress and size constraints involving a minimum member size were performed using the SIMP method through the software Altair OptiStruct® to obtain an initial optimised bracket configuration minimising compliance.

- SIMP expressed material properties as a power law function of density to interpolate between solid and void.

- The design is subjected to progressive FEA simulations under different loads to virtually validate its performance.

- The AlSi10Mg alloy is used in SLM to fabricate the final design.

Hence, TO is performed using the SIMP approach, taking into account minimum member size and stress constraints. This leads to a 25% reduction in mass, equivalent to 1.2 kg, compared to the initial bracket design intended for CNC manufacturing. Consequently, this reduction results in a decrease in launch costs, including fuel expenses, amounting to USD 15,600. Additionally, the lowered fuel demand contributes to a reduction in the environmental footprint of the launch process.

4.2.2. Topology Design of a Nanosatellite Structure with Optimal Frequency Responses Filled by Non-Uniform Lattices

A nanosatellite main structure filled with non-uniform lattices to improve stiffness and reduce mass is proposed in []. Nanosatellite structures require high stiffness and low weight. Lattice filling enables lightweight designs but controlling spatial lattice distribution for optimal performance.

The goal is to reduce nanosatellite box mass while retaining and improving stiffness to meet frequency requirements. Factors such as load paths, local weak points, vibration modes, and interfaces are considered in the lattice design. The steps followed by [] are:

- A nanosatellite box with uniform lattice panels is vibration tested to obtain target frequency response data in three orthogonal axes.

- An equivalent FE model of the box is created and density-based TO is performed using the SIMP method to maximise frequency under mass constraints.

- TO result is interpreted to design variable density lattices tailored to the load paths.

As a general result, the mass of the optimised design is reduced by 50.32% compared to the initial design, whereas the fundamental frequency increased by 1.19% with the new tailored lattice design.

4.2.3. Topology Optimisation and Modal Analysis of Nanosatellite Structure

Designing nanosatellite structures requires balancing strength, low mass, accessibility, and dynamic performance. Ref. [] presents the structural design, analysis, and optimisation of a nanosatellite structure.

The structure must withstand inertia, vibration, thermal, and mechanical loads during launch while being lightweight. The fundamental frequency needed to be sufficiently high to avoid resonance and dynamic issues. Additionally, the mass of the design is constrained to 800 g, which is 8% of the total satellite mass. Considerations made by [] are:

- A vertical partitioned conceptual nanosatellite structure is designed based on requirements.

- FE modelling and analysis are performed to evaluate strength under accelerations of 11 g’s longitudinal and 6 g’s lateral launch loads.

- TO is applied through ANSYS® to reduce mass while restricting maximum displacement and stress as constraints.

- Modal analysis determined the natural frequencies and mode shapes of the optimised structure.

This study yielded that TO obtains a 12% reduction in mass from 912 g to 800 g, whereas the total deformation is reduced from 0.262 mm before optimisation to 0.045 mm after optimisation.

4.2.4. Optimisation Design of the Spaceborne Connecting Structure for a Lightweight Space Camera

An optimisation method for the spaceborne connecting structure considering the camera line of sight (LOS) drift is presented in [], where a variable density TO method is utilised. The objective of the article is to optimise the optomechanical structure of the camera so that it achieves a high lightweight ratio considering the camera drift. The following key steps are taken in []:

- A FE model of the chamber and the initial structure is established using Hypermesh® software.

- The elastic modulus of each element is introduced using the SIMP method, whereas the optimisation model is solved by MMA.

- Parametric models were created and solved to ensure that the overall shape and dimensions of the topology remained consistent.

- A sensitivity analysis is conducted by employing a design of experiment approach to assess how size parameters impact the performance of the camera.

- Engineering analysis (static and dynamic) and performance comparison are realised.

The outcome is that the relative linear displacements and angular displacements between mirrors are within 10 µm and 10”, respectively, and the lightweight ratio of the connecting structures reached 54%. The optimised connecting structures have a higher lightweight ratio. Moreover, the relative linear displacement along the X-axis and the relative angular displacement in the Y direction for the optimised spaceborne connecting structure are 35% and 42% smaller compared with the traditional structure.

4.2.5. Optimum Design of the Support Structure of the CMG Based on CAE

A Control Moment Gyroscope (CMG) generates a torque for attitude control of manned satellites, a flywheel that rotates at a constant speed, supporting connecting rods and motors. that drive the cardan shafts. A rotating flywheel has angular momentum with a vector, of which the direction is changed by the movement of the gimbal and generates a torque due to the gyroscopic effect. Authors of the article [] propose the design of the support structure for a CMG, as well as a TO, frequency calculations and vibration tests.

The objective for this TO is to maximise the support stiffness. The authors’ methodology consists of:

- Study of facets of the support structure of the CMG with the ANSYS® FEM software package.

- The 3D models of the CMG are established based on the optimisation.

- Vibration tests to validate the optimised design.

In the vibration test, the peak response to the centre of the high-speed flywheel linked with the gimbal is shown in Table 5.

Table 5.

Peak results in evaluated point [].

4.2.6. Multi-Scale Design and Optimisation for Solid-Lattice Hybrid Structures and Their Application to Aerospace Vehicle Components

In the article [], authors propose a two-step structural optimisation method that integrates the SIMP topology method and lattice-based optimisation, then carrying out the optimisation of two aerospace structures, one of which is a satellite launch support.

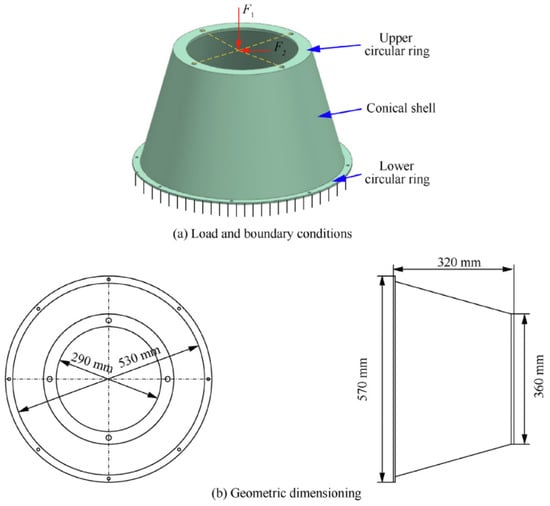

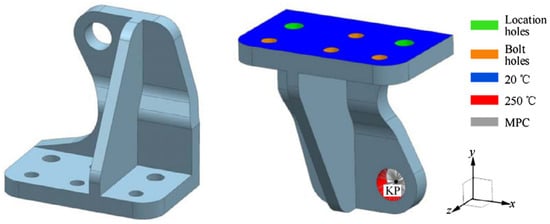

The main objective of the method is to obtain manufacturable solid-lattice hybrid structures with better performance while meeting all design requirements. A two-step procedure is realised to design and optimise solid-lattice hybrid structures by the combination of TO and lattice-based optimisation. In this review, we focus on the optimisation process of a payload adaptor structure designed for satellite (see Figure 1).

Figure 1.

A payload adaptor structure with load and boundary conditions [].

The authors propose a general methodology for applying the optimisation method as follows:

- Create a solid model and define design domain.

- Establish finite mesh model and impose boundary conditions.

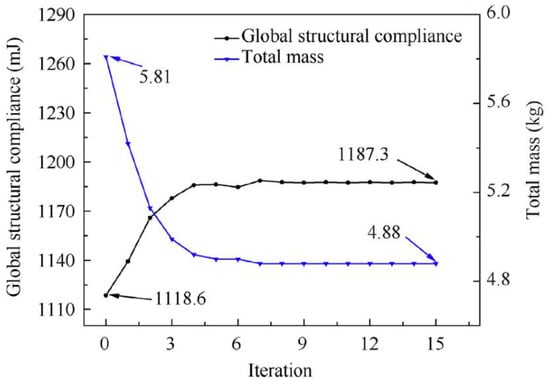

Figure 2. Iteration curves of objective function and mass constraint [].

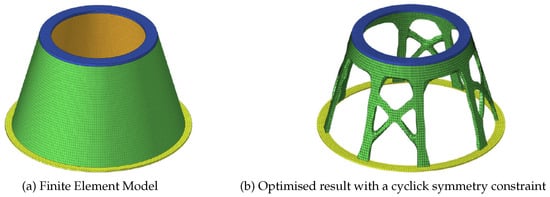

Figure 2. Iteration curves of objective function and mass constraint []. Figure 3. TO of the payload adaptor structure [].

Figure 3. TO of the payload adaptor structure [].- Reconstruct and lattice infill.

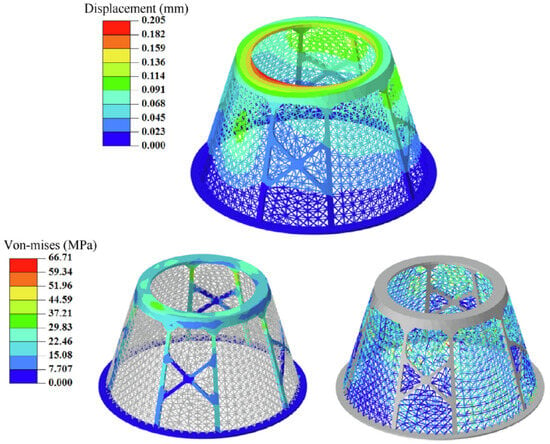

- Perform size optimisation and verify its convergence.

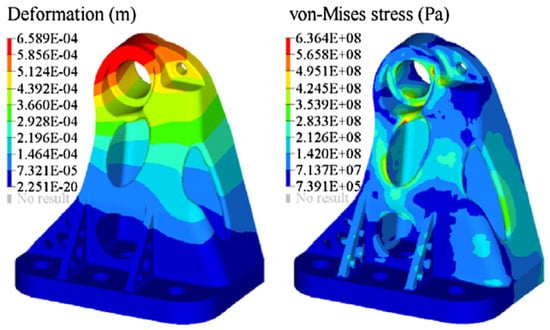

This study yields that the maximum deformation is 20.3% lower than the solid design and 55.5% lower than the lattice design as Figure 4 shows, whereas the solid-lattice hybrid design has the highest first-order modal frequency 14.8% and 49.8% higher to the solid design and lattice design, respectively.

Figure 4.

Global deformation and von Mises stress distribution of optimised solid-lattice hybrid payload adaptor structure [].

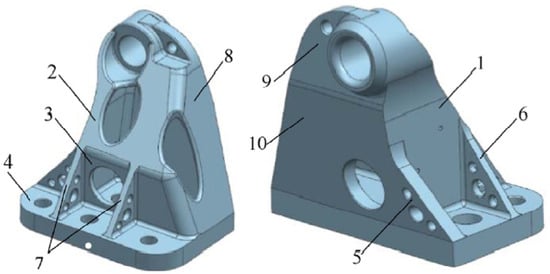

4.2.7. An Aerospace Bracket Designed by Thermo-Elastic Topology Optimisation and Manufactured by Additive Manufacturing

The lightweight and high-performance structures are critical for aerospace applications. The paper [] presents a combination of TO and SLM to design and manufacture a lightweight aerospace bracket. The goal of this work is to minimise the mass of an aerospace bracket subjected to mechanical loads and thermal stresses while maintaining its structural integrity (see Figure 5). The phases of the methodology followed by the authors are:

Figure 5.

Original design of the aerospace bracket [].

- A thermo-elastic TO formulation is proposed to minimise compliance under displacement, volume, and thermal load constraints.

- The Rational Approximation of Material Properties (RAMP) scheme is used for material interpolation. RAMP expressed the Young’s modulus, thermal stress coefficient, and thermal conductivity of the density variables.

- Sensitivity analysis is derived for the coupled thermo-elastic response and RAMP material properties.

Table 6. Parameters in Figure 6.

Table 6. Parameters in Figure 6. Figure 6. Reconstructed aerospace bracket []. Number parts can be consulted in Table 6.

Figure 6. Reconstructed aerospace bracket []. Number parts can be consulted in Table 6.

The results of this work can be summarised as follows:

- An 18.3% reduction in bracket mass is achieved while satisfying all stiffness, strength, and displacement constraints.

- Mechanical testing validates the performance of the additively manufactured bracket under extreme loads (see Figure 7).

Figure 7. Final analysis [].

Figure 7. Final analysis []. - The paper demonstrates an effective integrated approach combining TO (RAMP method) and AM for aerospace applications.

4.3. Level-Set Methods

LSM are interesting for their ability to provide crisp boundaries, while also aiding in reducing the need for applying shape optimisation to TO solutions. However, as previously mentioned, the initial guess solution continues to be a problem; also, users need a fairly competent knowledge of the method and the problem at hand to perform TO effectively. These limitations are reflected in the minimal examples found in the literature documenting the use of LSM for the TO of satellite structures or components. In this section, we present a case study where LSM is applied to satellite development.

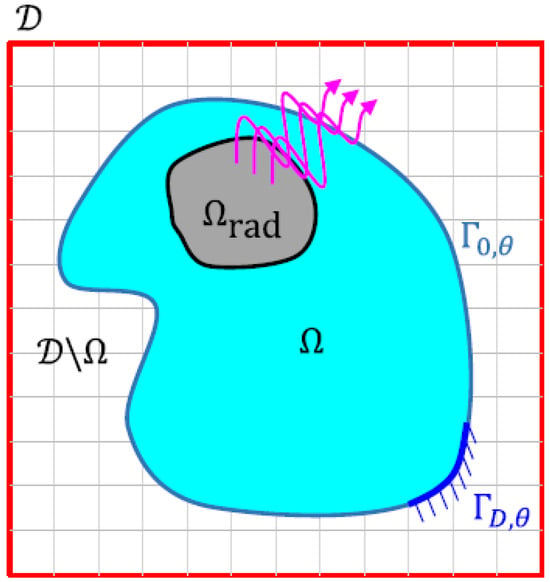

A Level- Set-Based Topology Optimisation Approach for Thermally Radiating Structures

Ref. [] presents a level-set-based TO approach for maximising the heat power radiated by a structure. The goal in this paper is to design thermally efficient radiating components, subject to a volume fraction constraint.

The authors consider a 2D problem of optimising a thin plate (see Figure 8) to maximise heat power radiated from a fixed radiating surface on one edge. An edge segment on the structural boundary is subjected to a Dirichlet boundary condition, whereas the radiating surface is defined as a fixed subdomain. Their general methodology is as follows:

Figure 8.

Domains and boundaries for the thermal radiation problem in a 2D structural context [].

- To define the level-set function to implicitly represent structural boundaries.

- To construct augmented Lagrangian with volume constraint.

- To derive shape sensitivity Lagrangian using adjoint method.

- To solve state equations for and adjoint state q*.

- To construct velocity field from the shape sensitivity analysis.

- To solve the Hamilton–Jacobi equation to evolve the level set based on .

- To re-initialise periodically as signed distance function.

- To iterate steps (iii) to (vii) until convergence.

- To extract final structure shape .

- To validate the approach on a 2D aluminium plate with dimensions of 100 cm × 100 cm × 1 cm.

The main outcome converges locally optimal solutions (see Figure 9) for the 2D plate problem. The solution improves heat power radiated compared to baseline designs, showing that maximal thermal compliance is insufficient for this problem.

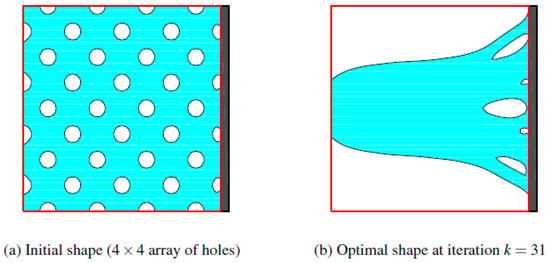

Figure 9.

The initial and optimal shapes for the optimisation problem with an initial configuration consisting of a 4 × 4 array of holes [].

4.4. Other Topology Optimisation Applications on Satellite Secondary Structures

It is possible to find published papers that feature the utilisation of optimisation tools integrated within finite element analysis (FEA) software to execute the optimisation process. Although this approach simplifies the optimisation procedure, it can also hinder objective comparisons due to the lack of transparency regarding algorithm specifics, parameters, and code implementation; although this practice streamlines optimisation, it often falls short of providing comprehensive insights necessary for detailed evaluation and comparative analysis. However, they are briefly mentioned in what follows.

Other applications of the SIMP method in the aerospace field within satellite structures can be found in.

In [], a mounting for a telescope is optimised using TO techniques to minimise mass while meeting constraints related to space environment like temperature, thermal conduction, and vibration resistance.

Article [] applied lattice TO to the main structure of a CubeSat, obtaining a structure that is 50% lighter, 20% stiffer, and consolidating 125 parts into only 25, while using Inconel 718 and 3D metal printing technology. Reportedly, the lighter assembly translated to USD 8000 to USD 10,000 in launch cost savings.

In [], authors describe the process of designing an optical bench for integrating instruments like mid-wavelength infrared (MWIR) imagers. The optical bench’s design process involves TO to ensure mechanical stability and thermal performance. The optimised version increases the net power emission by 36.5%. Verification methods, including vibration testing, confirm the suitability of AM-produced structures for spacecraft use.

The authors of [] apply TO to redesign and reduce the weight of a satellite’s secondary structure. A launcher connector is a mechanical device that supports the satellite inside the rocket fairing, and the authors accomplish TO without compromising mechanical performance. The optimised design is built via laser beam melting. Authors achieve a weight reduction of 57%, satisfying the first and second modal requirements; this is performed using specialised software that allows TO.