Effects of Injector Configuration on the Detonation Characteristics and Propulsion Performance of Rotating Detonation Engine (RDE)

Abstract

:1. Introduction

2. Experiment Description

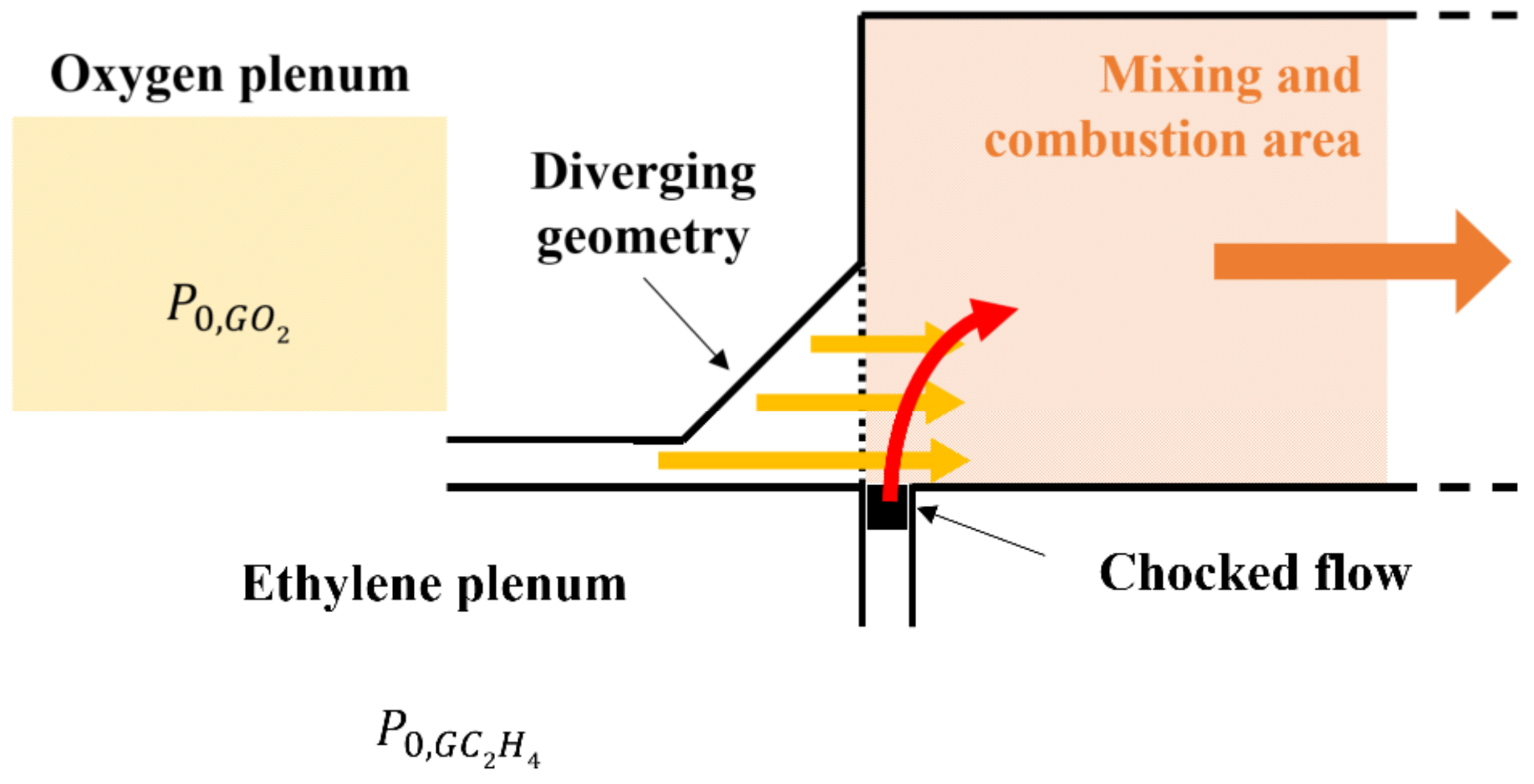

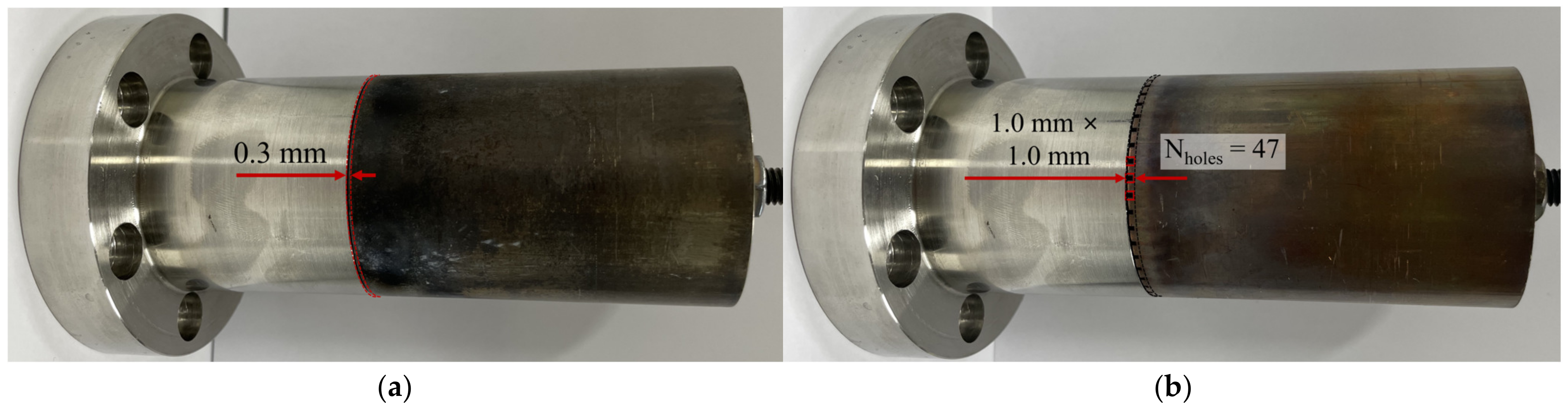

2.1. RDE Model

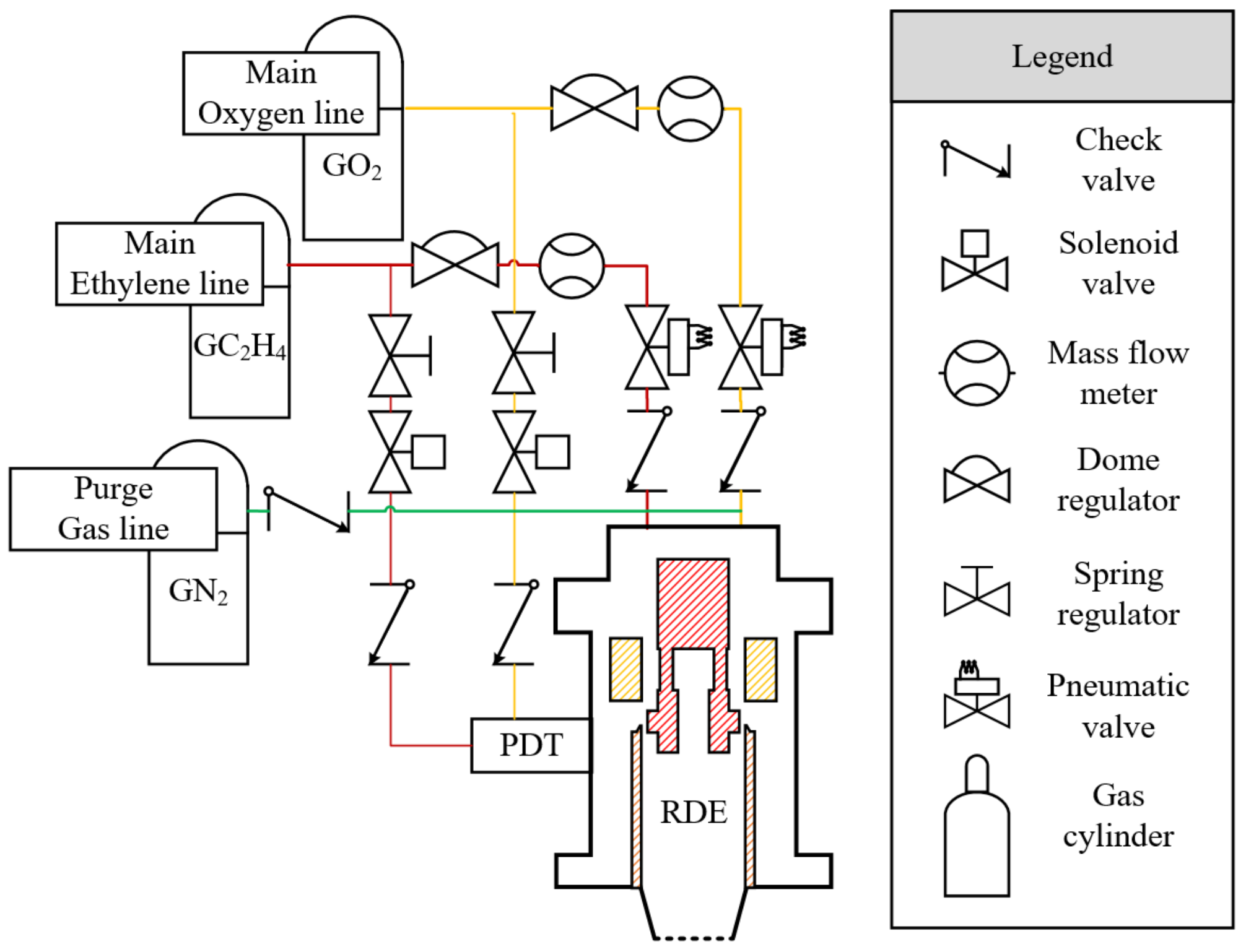

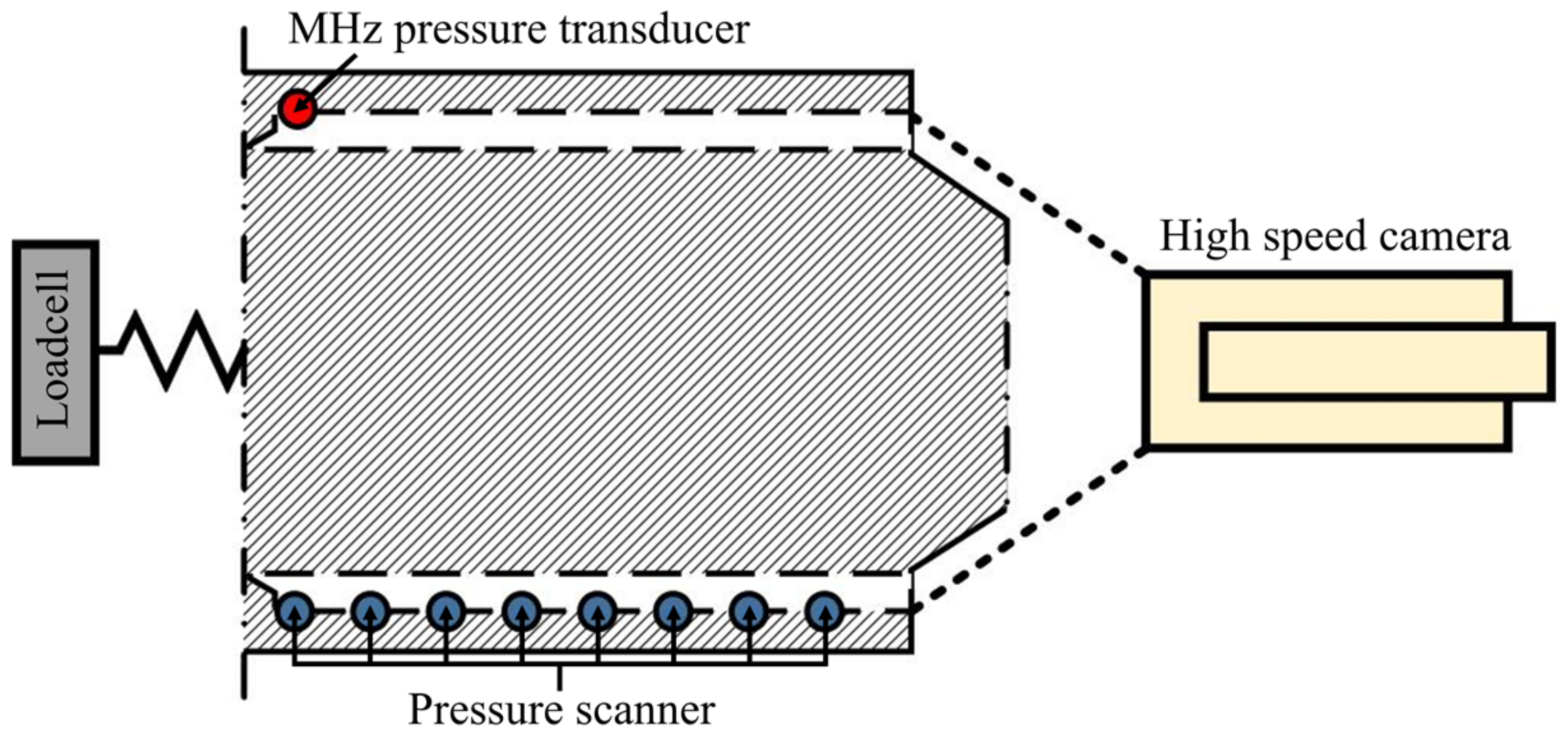

2.2. Experimental Apparatus

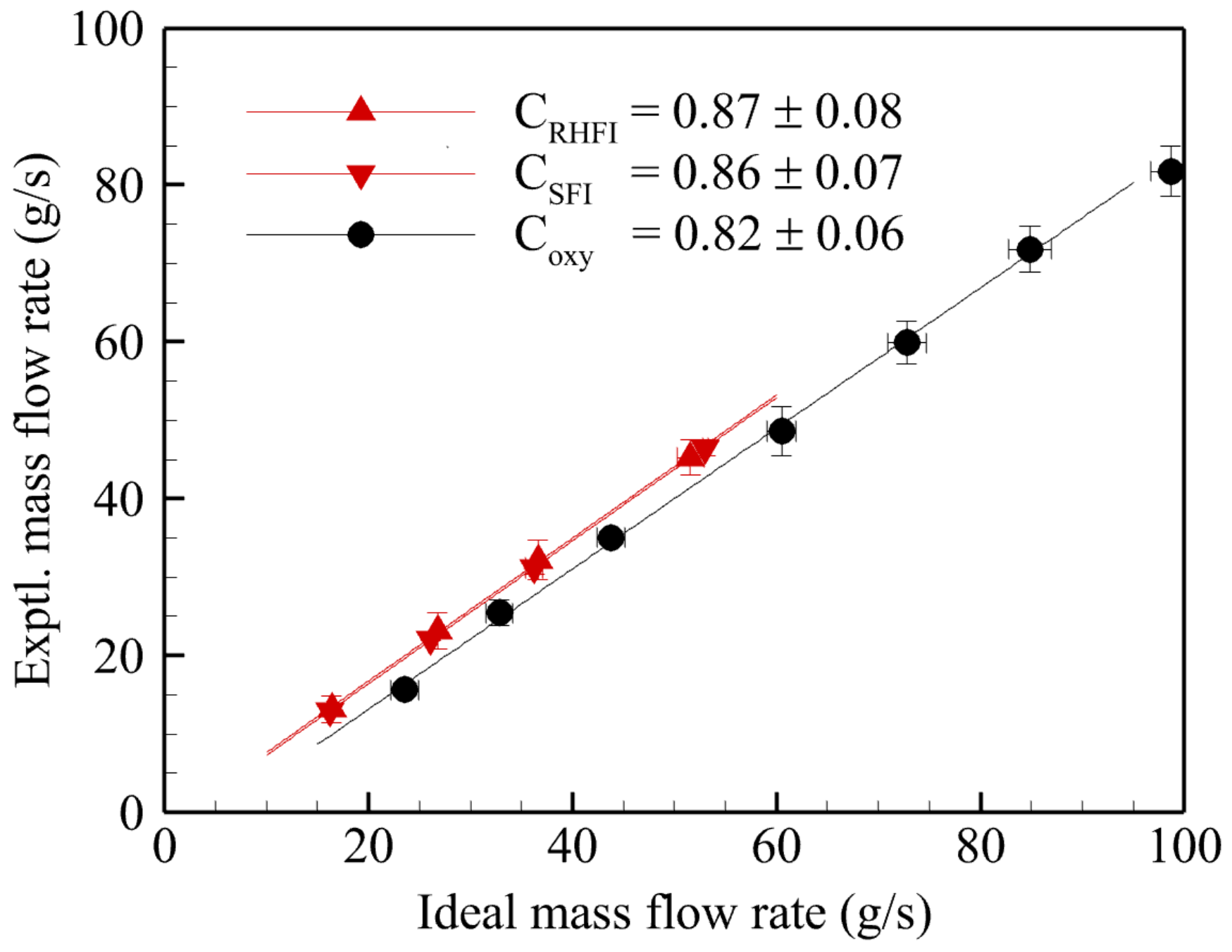

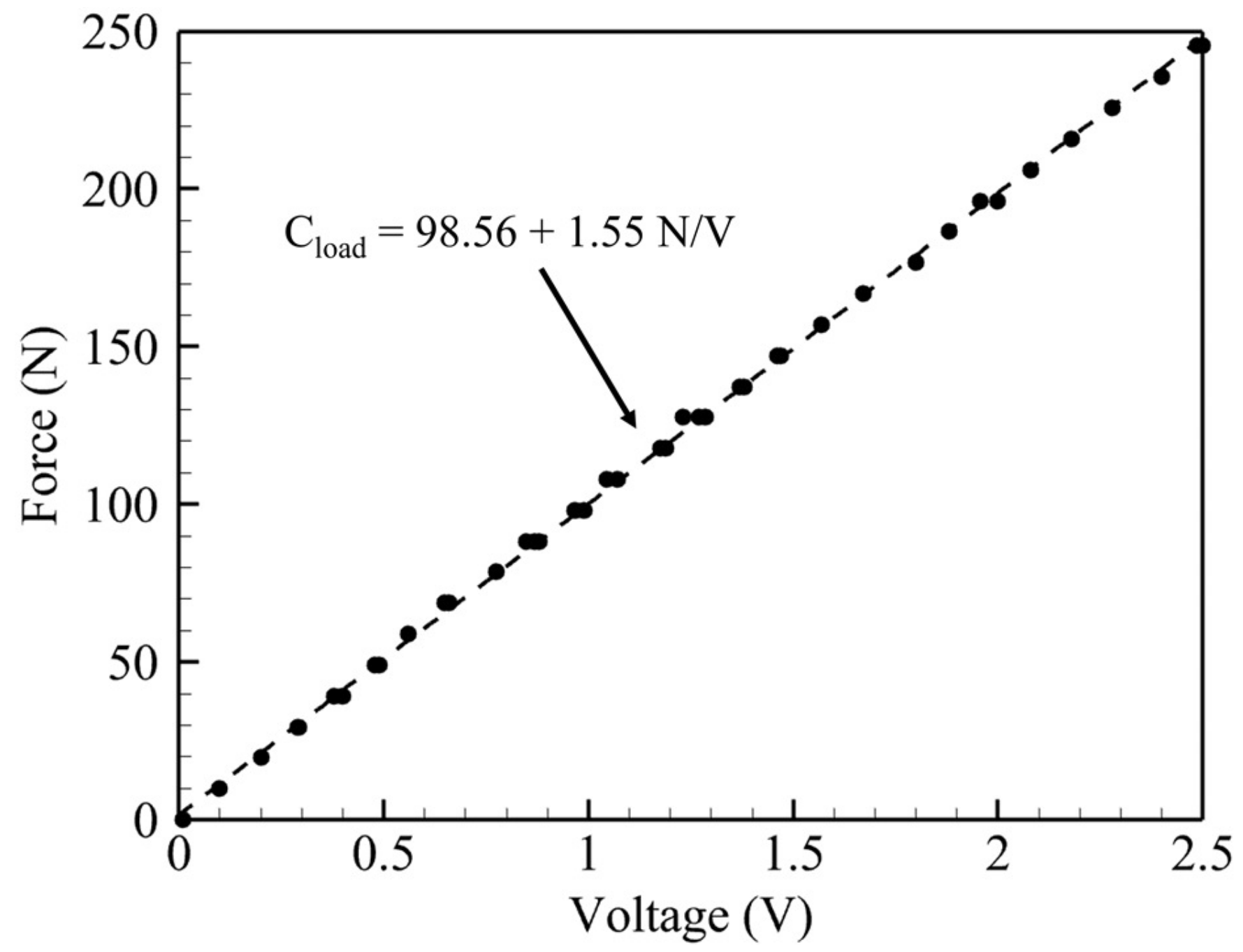

2.3. Mass Flow Rate and Loadcell Calibration

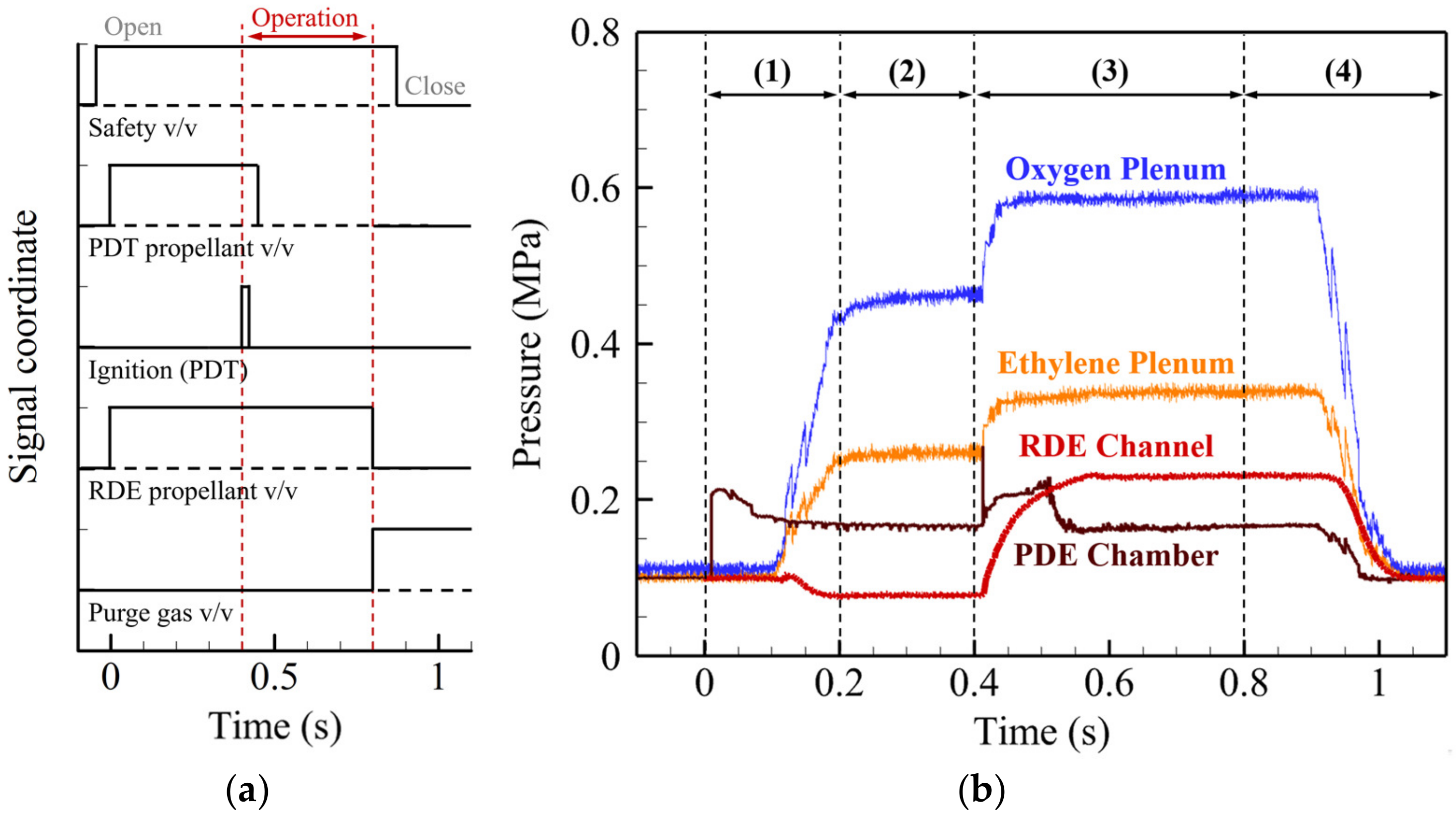

2.4. Experimental Sequence

3. Results and Discussion

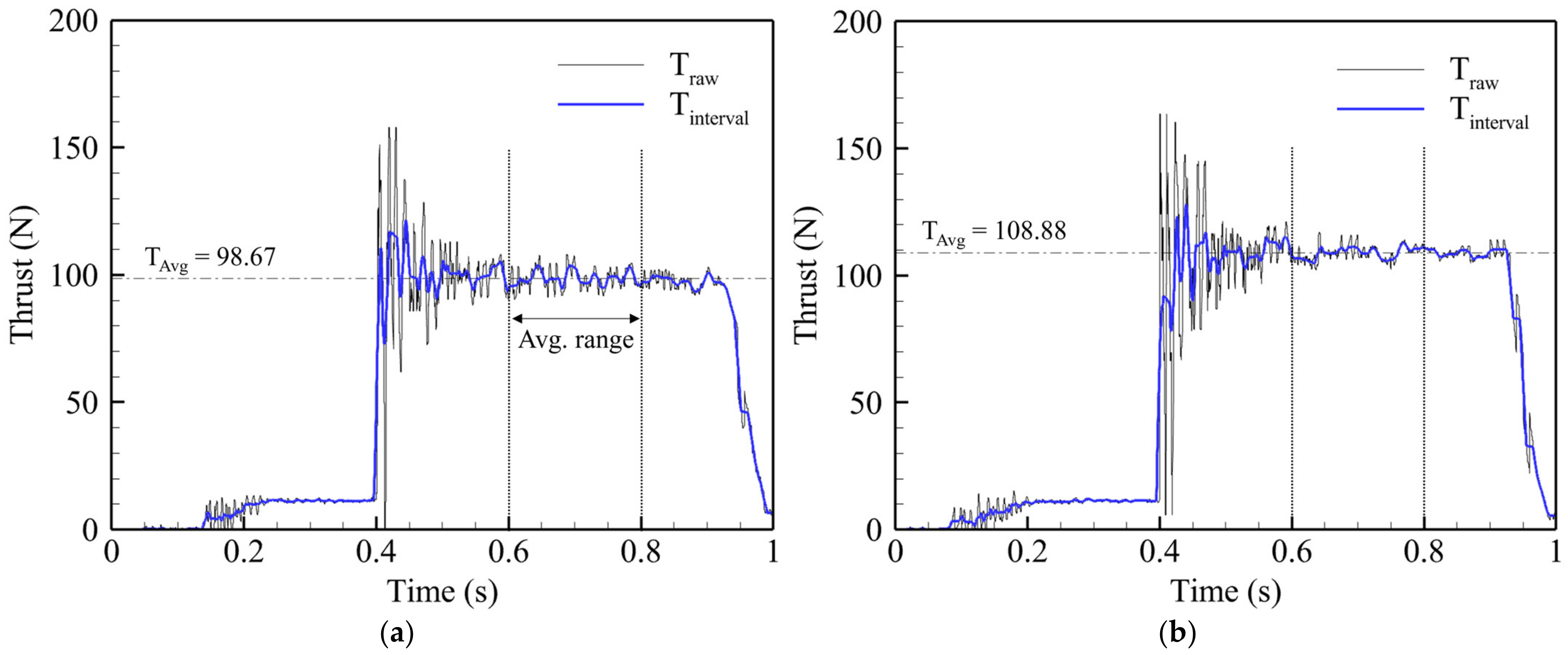

3.1. Thurst Performance

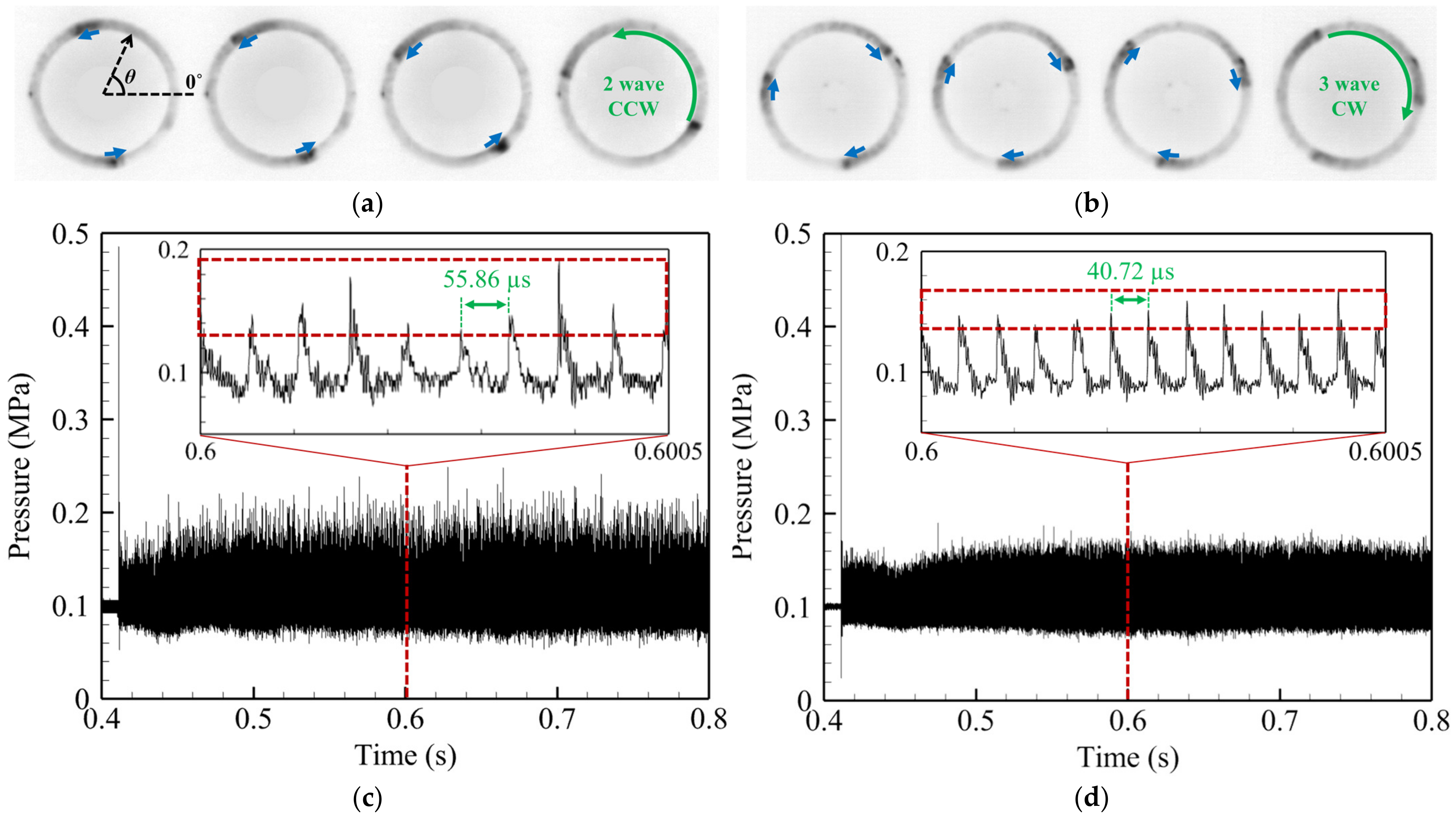

3.2. Detonation Propagation Modes

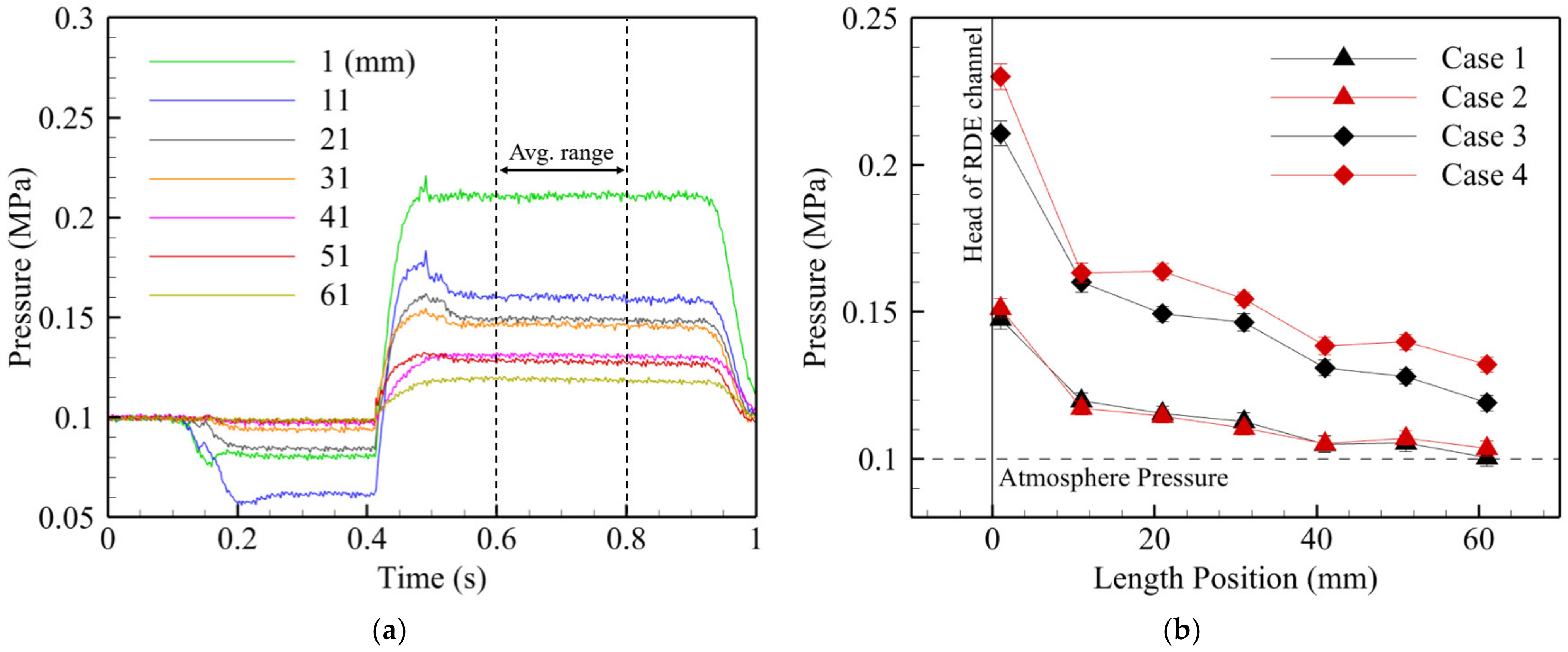

3.3. Wall Pressure

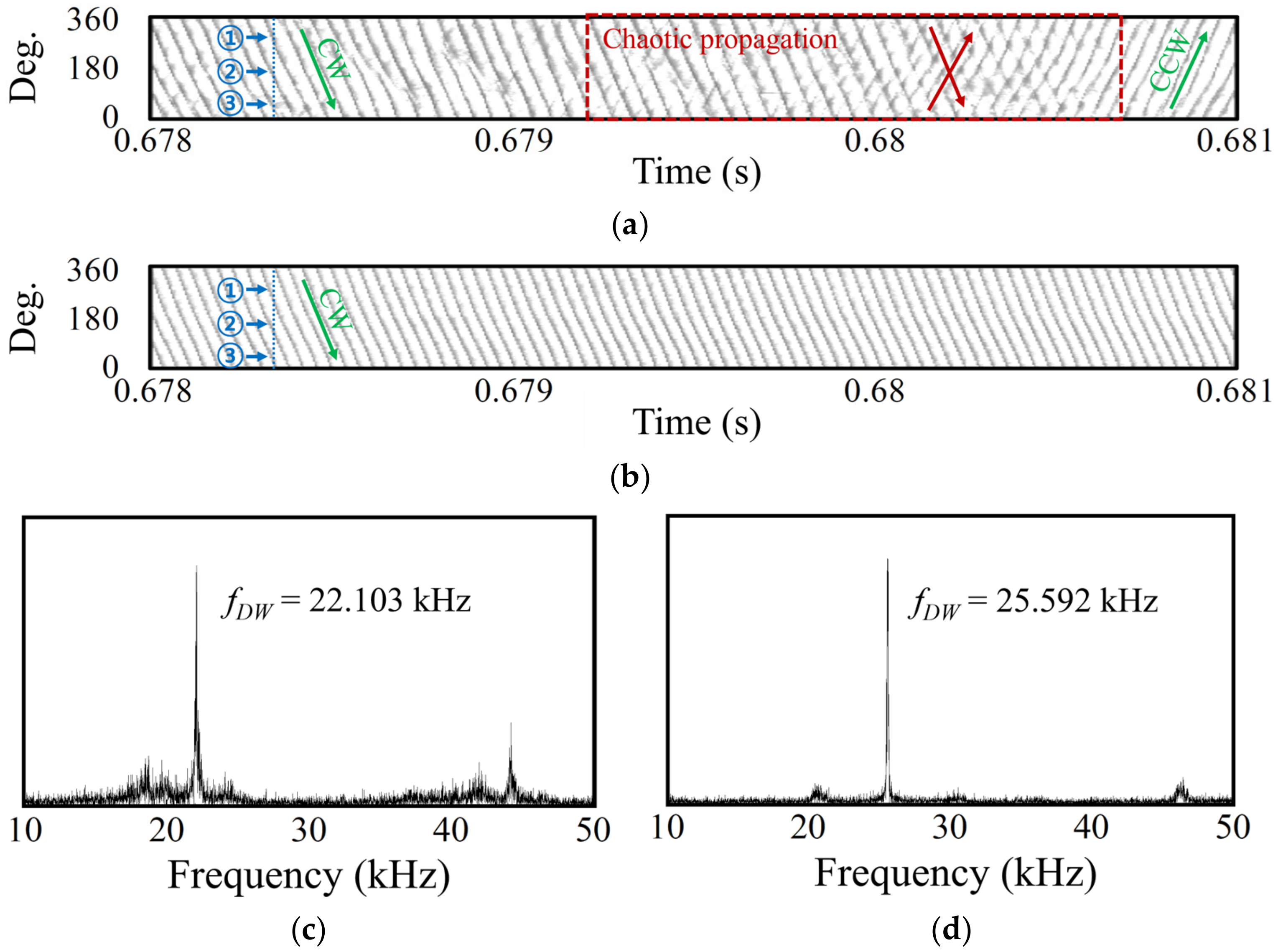

3.4. High Mass Flow Rate Condition

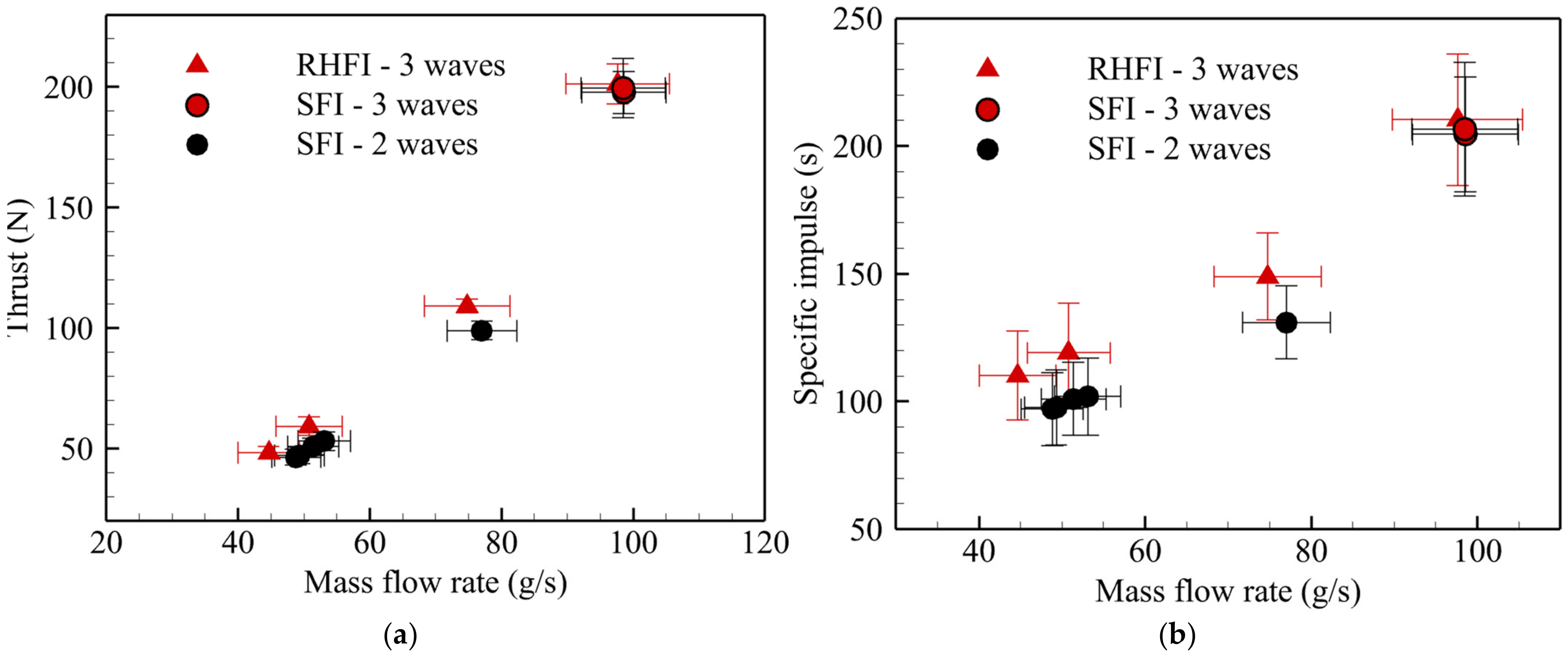

3.5. Performance

4. Conclusions

- (1)

- High-speed camera images revealed differences in detonation modes between the two kinds of fuel injectors. Additionally, MHz pressure transducer data indicated that the SFI has larger variations with respect to pressure peak values, and STFT analysis demonstrated that the RHFI maintained a consistent detonation propagation frequency, while SFI had oscillations in detonation propagation frequencies during the combustion experiment. The fuel injectors and the result of the difference in the fuel injection structure caused differences in the detonation propagation mode. Consequently, this affected the stability of the detonation propagation characteristics.

- (2)

- In high mass flow rate experiments, the post-processing of images confirmed the propagation of three detonation waves for both types of injectors. However, the SFI exhibited chaotic behavior during the transition of propagation direction, and the detonation propagation frequency was relatively lower.

- (3)

- As a result of comparing thrust and specific impulse performance, it was confirmed that RHFI has higher performances and lower deviation than SFI. These consequences are caused by differences in the combustion efficiency of fuel injectors. As an additional result, performance improvements were observed when changing from the dual-wave mode to the triple-wave mode in SFI. These results suggest that the increase in the number of waves due to an increase in mass flow rate affected the performance. These results are consistent with [27,46].

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Turns, S.R. An Introduction to Combustion, Concepts and Applications, 3rd ed.; McGraw-Hill: New York, NY, USA, 2011. [Google Scholar]

- Wolański, P. Detonative propulsion. Proc. Combust. Inst. 2013, 34, 125–158. [Google Scholar] [CrossRef]

- Wintenberger, E.; Shepherd, J.E. Thermodynamic cycle analysis for propagating detonations. J. Propuls. Power 2006, 22, 694–698. [Google Scholar] [CrossRef]

- Bussing, T.; Pappas, G. Pulse detonation engine theory and concepts. In Developments in High-Speed-Vehicle Propulsion Systems; American Institute of Aeronautics and Astronautics, Inc.: Reston, VA, USA, 1996; pp. 421–472. [Google Scholar] [CrossRef]

- Bykovskii, F.A.; Mitrofanov, V.V. Detonation combustion of a gas mixture in a cylindrical chamber. Combust. Explos. Shock Waves 1980, 16, 570–578. [Google Scholar] [CrossRef]

- Kindracki, J.; Wolański, P.; Gut, Z. Experimental research on the rotating detonation in gaseous fuels–oxygen mixtures. Shock Waves 2011, 21, 75–84. [Google Scholar] [CrossRef]

- Anand, V.; Gutmark, E. Rotating detonation combustors and their similarities to rocket instabilities. Prog. Energy Combust. Sci. 2019, 73, 182–234. [Google Scholar] [CrossRef]

- Ma, J.Z.; Luan, M.Y.; Xia, Z.J.; Wang, J.P.; Zhang, S.J.; Yao, S.B.; Wang, B. Recent progress, development trends, and consideration of continuous detonation engines. AIAA J. 2020, 58, 4976–5035. [Google Scholar] [CrossRef]

- Goto, K.; Matsuoka, K.; Matsuyama, K.; Kawasaki, A.; Watanabe, H.; Itouyama, N.; Ishihara, K.; Buyakofu, V.; Noda, T.; Kasahara, J. Space flight demonstration of rotating detonation engine using sounding rocket S-520-31. J. Spacecr. Rocket. 2023, 60, 273–285. [Google Scholar] [CrossRef]

- Kawalec, M.; Wolański, P.; Perkowski, W.; Bilar, A. Development of a Liquid-Propellant Rocket Powered by a Rotating Detonation Engine. J. Propuls. Power 2023, 39, 554–561. [Google Scholar] [CrossRef]

- Teasley, T.W.; Fedotowsky, T.M.; Gradl, P.R.; Austin, B.L.; Heister, S.D. Current State of NASA Continuously Rotating Detonation Cycle Engine Development. In Proceedings of the AIAA SciTech 2023 Forum, San Diego, CA, USA, 12–16 June 2023. [Google Scholar] [CrossRef]

- Ishihara, K.; Yoneyama, K.; Watanabe, H.; Itouyama, N.; Kawasaki, A.; Matsuoka, K.; Kasahara, J.; Matsuo, A.; Funaki, I.; Higashino, K. Thrust Performance of Converging Rotating Detonation Engine Compared with Steady Rocket Engine. J. Propuls. Power 2023, 39, 297–307. [Google Scholar] [CrossRef]

- Wu, Y.; Ma, F.; Yang, V. System performance and thermodynamic cycle analysis of airbreathing pulse detonation engines. J. Propuls. Power 2003, 19, 556–567. [Google Scholar] [CrossRef]

- Nordeen, C.A. Thermodynamics of a rotating detonation engine. Combust. Explos. Shock Waves 2014, 50, 568–577. [Google Scholar] [CrossRef]

- Zhang, S.-j.; Ma, J.Z.; Wang, J. Theoretical and numerical investigation on total pressure gain in rotating detonation engine. AIAA J. 2020, 58, 4866–4877. [Google Scholar] [CrossRef]

- Raman, V.; Prakash, S.; Gamba, M. Nonidealities in Rotating Detonation Engines. Annu. Rev. Fluid Mech. 2022, 55, 639–674. [Google Scholar] [CrossRef]

- Liu, X.Y.; Luan, M.Y.; Chen, Y.L.; Wang, J.P. Flow-field analysis and pressure gain estimation of a rotating detonation engine with banded distribution of reactants. Int. J. Hydrog. Energy 2020, 45, 19976–19988. [Google Scholar] [CrossRef]

- Goto, K.; Yokoo, R.; Kawasaki, A.; Matsuoka, K.; Kasahara, J.; Matsuo, A.; Funaki, I.; Kawashima, H. Investigation into the effective injector area of a rotating detonation engine with impact of backflow. Shock Waves 2021, 31, 753–762. [Google Scholar] [CrossRef]

- Plaehn, E.W.; Walters, I.V.; Gejji, R.M.; Slabaugh, C.D. Bifurcation in Rotating Detonation Engine Operation with Continuously Variable Fuel Injection Location. J. Propuls. Power 2023, 39, 202–216. [Google Scholar] [CrossRef]

- Matsuoka, K.; Tanaka, M.; Noda, T.; Kawasaki, A.; Kasahara, J. Experimental investigation on a rotating detonation cycle with burned gas backflow. Combust. Flame 2021, 225, 13–19. [Google Scholar] [CrossRef]

- Bennewitz, J.W.; Bigler, B.R.; Pilgram, J.J.; Hargus, W.A., Jr. Modal transitions in rotating detonation rocket engines. Int. J. Energetic Mater. Chem. Propuls. 2019, 18, 91–109. [Google Scholar] [CrossRef]

- Rankin, B.A.; Richardson, D.R.; Caswell, A.W.; Naples, A.G.; Hoke, J.L.; Schauer, F.R. Chemiluminescence imaging of an optically accessible non-premixed rotating detonation engine. Combust. Flame 2017, 176, 12–22. [Google Scholar] [CrossRef]

- Duvall, J.; Chacon, F.; Harvey, C.; Gamba, M. Study of the effects of various injection geometries on the operation of a rotating detonation engine. In Proceedings of the 2018 AIAA Aerospace Sciences Meeting, Kissimmee, FL, USA, 8–12 January 2018; p. 0631. [Google Scholar]

- Bohon, M.D.; Bluemner, R.; Paschereit, C.O.; Gutmark, E.J. High-speed imaging of wave modes in an RDC. Exp. Therm. Fluid Sci. 2019, 102, 28–37. [Google Scholar] [CrossRef]

- Zhao, M.; Zhang, H. Origin and chaotic propagation of multiple rotating detonation waves in hydrogen/air mixtures. Fuel 2020, 275, 117986. [Google Scholar] [CrossRef]

- Wang, Y.; Tian, C.; Yang, P. Effects of Ozone Addition on Multi-Wave Modes of Hydrogen–Air Rotating Detonations. Aerospace 2023, 10, 443. [Google Scholar] [CrossRef]

- Bigler, B.R.; Burr, J.R.; Bennewitz, J.W.; Danczyk, S.; Hargus, W.A. Performance effects of mode transitions in a rotating detonation rocket engine. In Proceedings of the AIAA Propulsion and Energy 2020 Forum, Online, 24–28 August 2020. [Google Scholar] [CrossRef]

- Lin, W.; Zhou, J.; Liu, S.; Lin, Z.; Zhuang, F. Experimental study on propagation mode of H2/Air continuously rotating detonation wave. Int. J. Hydrog. Energy 2015, 40, 1980–1993. [Google Scholar] [CrossRef]

- Jia, B.; Zhang, Y.; Meng, H.; Meng, F.; Pan, H.; Hong, Y. Experimental Study on the Propagation Characteristics of Rotating Detonation Wave with Liquid Hydrocarbon/High-Enthalpy Air Mixture. Aerospace 2023, 10, 682. [Google Scholar] [CrossRef]

- Ding, C.; Wu, Y.; Xu, G.; Xia, Y.; Li, Q.; Weng, C. Effects of the oxygen mass fraction on the wave propagation modes in a kerosene-fueled rotating detonation combustor. Acta Astronaut. 2022, 195, 204–214. [Google Scholar] [CrossRef]

- Bluemner, R.; Bohon, M.; Paschereit, C.; Gutmark, E. Counter-rotating wave mode transition dynamics in an RDC. Int. J. Hydrog. Energy 2019, 44, 7628–7641. [Google Scholar] [CrossRef]

- Han, H.-S.; Lee, E.S.; Choi, J.-Y. Experimental Investigation of Detonation Propagation Modes and Thrust Performance in a Small Rotating Detonation Engine Using C2H4/O2 Propellant. Energies 2021, 14, 1381. [Google Scholar] [CrossRef]

- Han, H.-S.; Kim, J.-M.; Oh, S.; Choi, J.-Y. An Experimental Study on Characteristics of Small-scale PDE under Low-frequency Operating Conditions. J. Korean Soc. Propuls. Eng. 2018, 22, 81–89. [Google Scholar] [CrossRef]

- Shaw, I.J.; Kildare, J.A.; Evans, M.J.; Chinnici, A.; Sparks, C.A.; Rubaiyat, S.N.; Medwell, P.R. A theoretical review of rotating detonation engines. In Direct Numerical Simulations-An Introduction and Applications; IntechOpen: London, UK, 2019. [Google Scholar]

- Rothstein, A.; Wantuck, P. A study of the normal injection of hydrogen into a heated supersonicflow using planar laser-induced fluorescence. In Proceedings of the 28th Joint Propulsion Conference and Exhibit 1992, Nashville, TN, USA, 6–8 July 1992; p. 3423. [Google Scholar]

- Gruber, M.R.; Nejad, A.S.; Chen, T.H.; Dutton, J.C. Mixing and penetration studies of sonic jets in a Mach 2 freestream. J. Propuls. Power 1995, 11, 315–323. [Google Scholar] [CrossRef]

- Won, S.H.; Jeung, I.S.; Parent, B.; Choi, J.Y. Numerical investigation of transverse hydrogen jet into supersonic crossflow using detached-eddy simulation. AIAA J. 2010, 48, 1047–1058. [Google Scholar] [CrossRef]

- Kim, K.M.; Baek, S.W.; Kim, Y.G. Effects of Aspect Ratio of a Fuel Injection Nozzle into a Supersonic Air Stream on Combustion Characteristics. J. Korean Soc. Propuls. Eng. 2004, 8, 44–53. [Google Scholar]

- Paxson, D.E.; Hoke, J.L. Time averaged pressure measurement in fundamentally unsteady pressure gain combustion systems. NASA/TM—2013-217826. In Proceedings of the 45th Combustion/33rd Airbreathing Propulsion/33rd Exhaust Plume and Signatures/27th Propulsion Hazards Joint Subcommittee Meeting 2013, Monterey, CA, USA, 3–7 December 2012. No. E-20044Jan. 2013. [Google Scholar]

- Bykovskii, F.A.; Zhdan, S.A.; Vedernikov, E.F. Continuous spin detonations. J. Propuls. Power 2006, 22, 1204–1216. [Google Scholar] [CrossRef]

- Bennewitz, J.W.; Bigler, B.R.; Ross, M.C.; Danczyk, S.A.; Hargus, W.A., Jr.; Smith, R.D. Performance of a rotating detonation rocket engine with various convergent nozzles and chamber lengths. Energies 2021, 14, 2037. [Google Scholar] [CrossRef]

- Goto, K.; Nishimura, J.; Kawasaki, A.; Matsuoka, K.; Kasahara, J.; Matsuo, A.; Higashino, K. Propulsive performance and heating environment of rotating detonation engine with various nozzles. J. Propuls. Power 2019, 35, 213–223. [Google Scholar] [CrossRef]

- Bennewitz, J.; Bigler, B.; Schumaker, S.; Hargus, W. Automated image processing method to quantify rotating detonation wave behavior. Rev. Sci. Instrum. 2019, 90, 065106. [Google Scholar] [CrossRef] [PubMed]

- Sheng, Z.; Cheng, M.; Wang, J.P. Multi-wave effects on stability and performance in rotating detonation combustors. Phys. Fluids 2023, 35, 076119. [Google Scholar] [CrossRef]

- Lee, J.H.S. The Detonation Phenomenon; Cambridge University Press: Cambridge, UK, 2008. [Google Scholar]

- Yi, T.-H.; Lou, J.; Turangan, C.; Choi, J.-Y.; Wolanski, P. Propulsive performance of a continuously rotating detonation engine. J. Propuls. Power 2011, 27, 171–181. [Google Scholar] [CrossRef]

| Injector | Material | Depth (mm) | Width (mm) | Nholes | Area (mm2) |

|---|---|---|---|---|---|

| Slit | SUS316 | 0.3 | - | - | 47.1 |

| Hole | C1020 | 1.0 | 1.0 | 47 | 47.0 |

| Case | Injector | (g/s) | Φ | T (N) | ISP (s) | NDW | fDW (kHz) |

|---|---|---|---|---|---|---|---|

| 1 | SFI | 48.82 | 1.01 | 46.46 | 97.01 | 2 | 17.848 |

| 2 | RHFI | 50.80 | 1.01 | 59.33 | 119.05 | 3 | 24.369 |

| 3 | SFI | 77.04 | 0.98 | 98.67 | 130.56 | 2 | 17.903 |

| 4 | RHFI | 74.78 | 0.98 | 108.88 | 148.42 | 3 | 24.555 |

| 5 | SFI | 98.57 | 1.00 | 197.78 | 204.54 | 3 | 22.073 |

| 6 | RHFI | 97.62 | 1.03 | 201.42 | 210.33 | 3 | 25.592 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Koo, I.-H.; Lee, K.-H.; Kim, M.-S.; Han, H.-S.; Kim, H.; Choi, J.-Y. Effects of Injector Configuration on the Detonation Characteristics and Propulsion Performance of Rotating Detonation Engine (RDE). Aerospace 2023, 10, 949. https://doi.org/10.3390/aerospace10110949

Koo I-H, Lee K-H, Kim M-S, Han H-S, Kim H, Choi J-Y. Effects of Injector Configuration on the Detonation Characteristics and Propulsion Performance of Rotating Detonation Engine (RDE). Aerospace. 2023; 10(11):949. https://doi.org/10.3390/aerospace10110949

Chicago/Turabian StyleKoo, In-Hoi, Keon-Hyeong Lee, Min-Su Kim, Hyung-Seok Han, Holak Kim, and Jeong-Yeol Choi. 2023. "Effects of Injector Configuration on the Detonation Characteristics and Propulsion Performance of Rotating Detonation Engine (RDE)" Aerospace 10, no. 11: 949. https://doi.org/10.3390/aerospace10110949

APA StyleKoo, I.-H., Lee, K.-H., Kim, M.-S., Han, H.-S., Kim, H., & Choi, J.-Y. (2023). Effects of Injector Configuration on the Detonation Characteristics and Propulsion Performance of Rotating Detonation Engine (RDE). Aerospace, 10(11), 949. https://doi.org/10.3390/aerospace10110949